engine JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1692 of 1784

(4) Connect the heater hoses to the heater core.

(5) Fill the cooling system.

HEATER CORE HOUSING REPLACEMENT

(1) Remove the evaporator/blower housing.

(2) Remove the heater core.

(3) Remove the defroster duct.

(4) Disconnect the vacuum hoses from the heater

core housing vacuum motors.

(5) Remove the heater housing retaining nuts in

the engine compartment. Remove the heater core

housing.

(6) Transfer the vacuum motors, etc. to the re-

placement housing.

To install the heater core housing, reverse the re-

moval procedure.

DEFROSTER DUCT REPLACEMENT

REMOVAL

(1) Disconnect negative cable from battery.

(2) If equipped with center console remove the con-

sole as follows:

(a) MANUAL TRANSMISSIONÐRemove shift

knob, boot and bezel.

(b) AUTOMATIC TRANSMISSIONÐRemove

shift handle by pulling up. Remove the shift bezel.

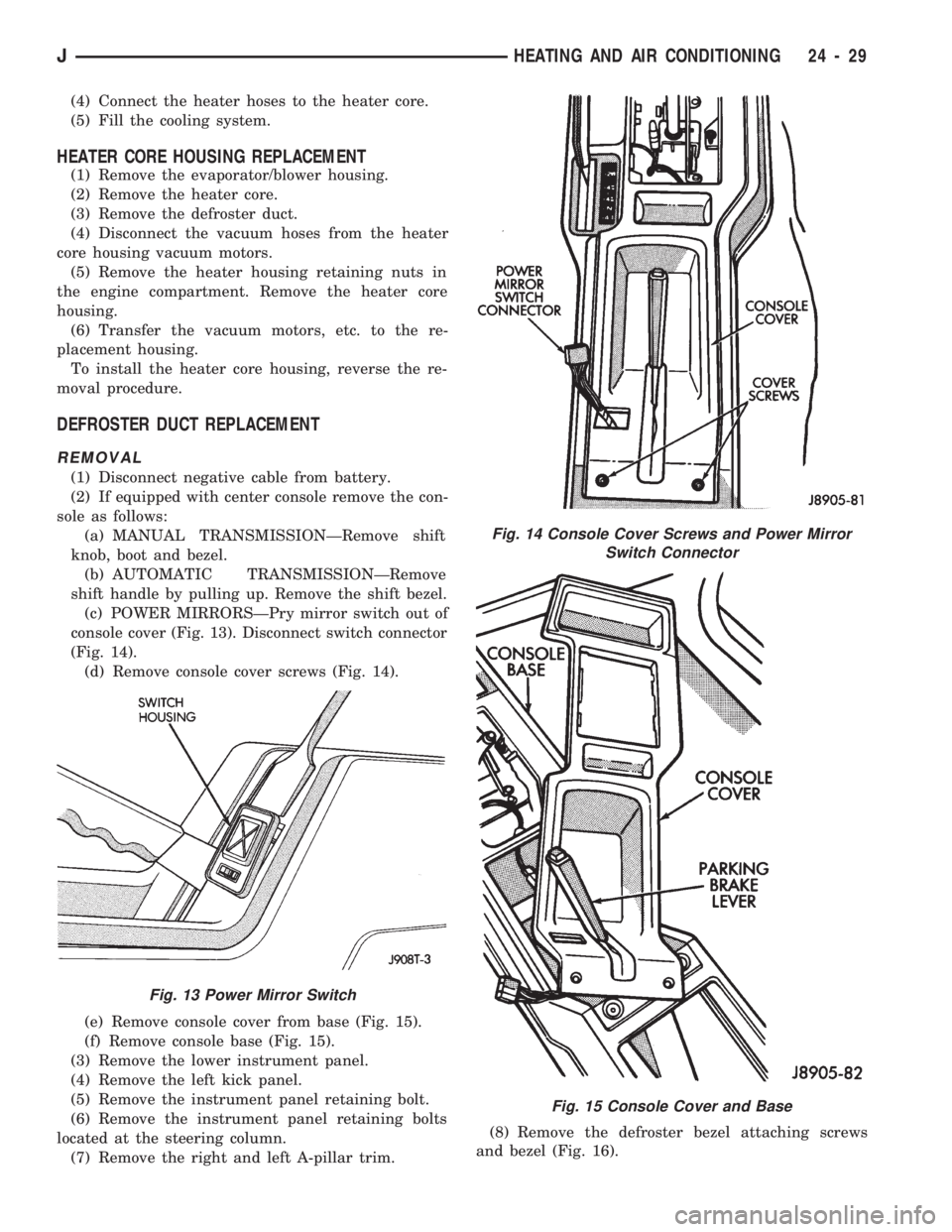

(c) POWER MIRRORSÐPry mirror switch out of

console cover (Fig. 13). Disconnect switch connector

(Fig. 14).

(d) Remove console cover screws (Fig. 14).

(e) Remove console cover from base (Fig. 15).

(f) Remove console base (Fig. 15).

(3) Remove the lower instrument panel.

(4) Remove the left kick panel.

(5) Remove the instrument panel retaining bolt.

(6) Remove the instrument panel retaining bolts

located at the steering column.

(7) Remove the right and left A-pillar trim.(8) Remove the defroster bezel attaching screws

and bezel (Fig. 16).

Fig. 13 Power Mirror Switch

Fig. 14 Console Cover Screws and Power Mirror

Switch Connector

Fig. 15 Console Cover and Base

JHEATING AND AIR CONDITIONING 24 - 29

Page 1694 of 1784

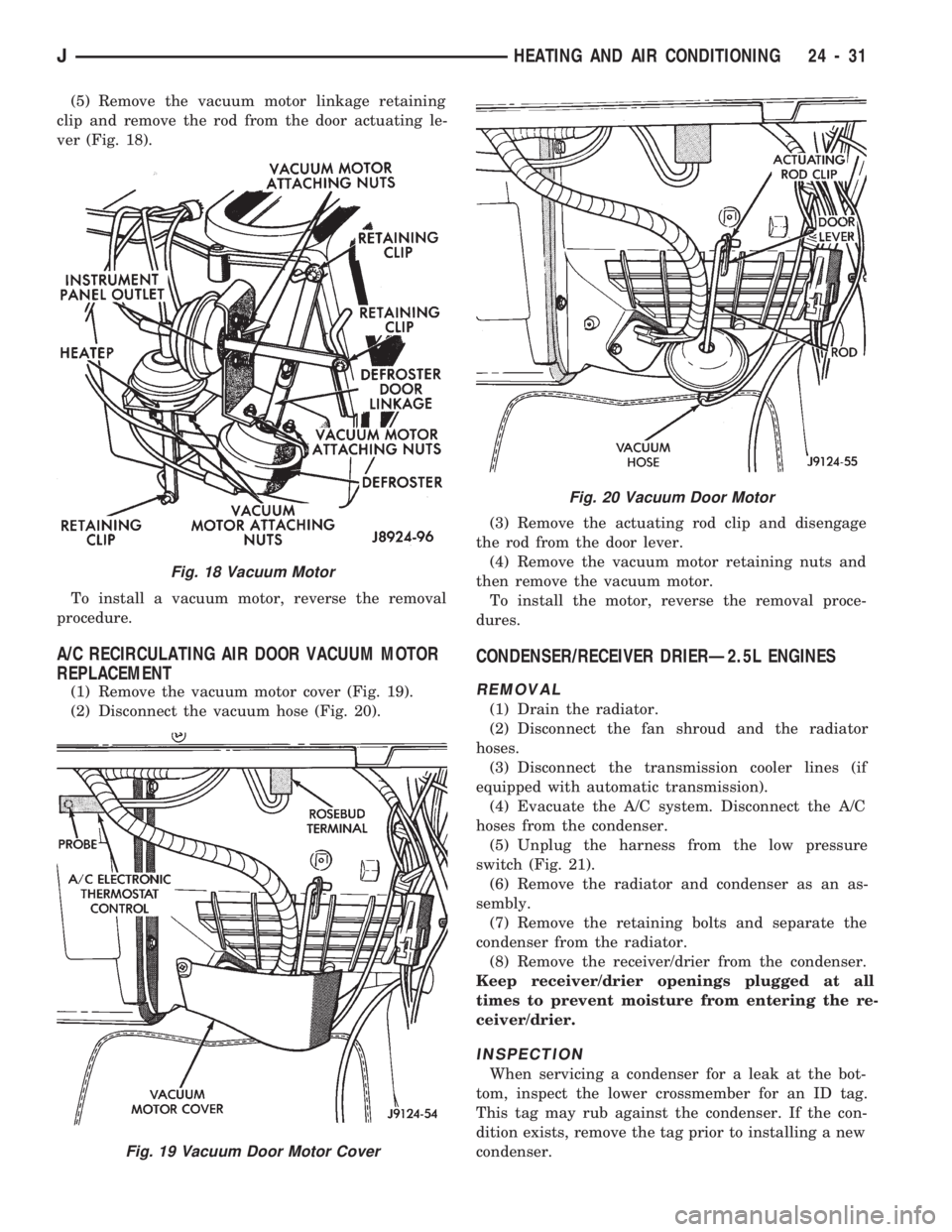

(5) Remove the vacuum motor linkage retaining

clip and remove the rod from the door actuating le-

ver (Fig. 18).

To install a vacuum motor, reverse the removal

procedure.

A/C RECIRCULATING AIR DOOR VACUUM MOTOR

REPLACEMENT

(1) Remove the vacuum motor cover (Fig. 19).

(2) Disconnect the vacuum hose (Fig. 20).(3) Remove the actuating rod clip and disengage

the rod from the door lever.

(4) Remove the vacuum motor retaining nuts and

then remove the vacuum motor.

To install the motor, reverse the removal proce-

dures.

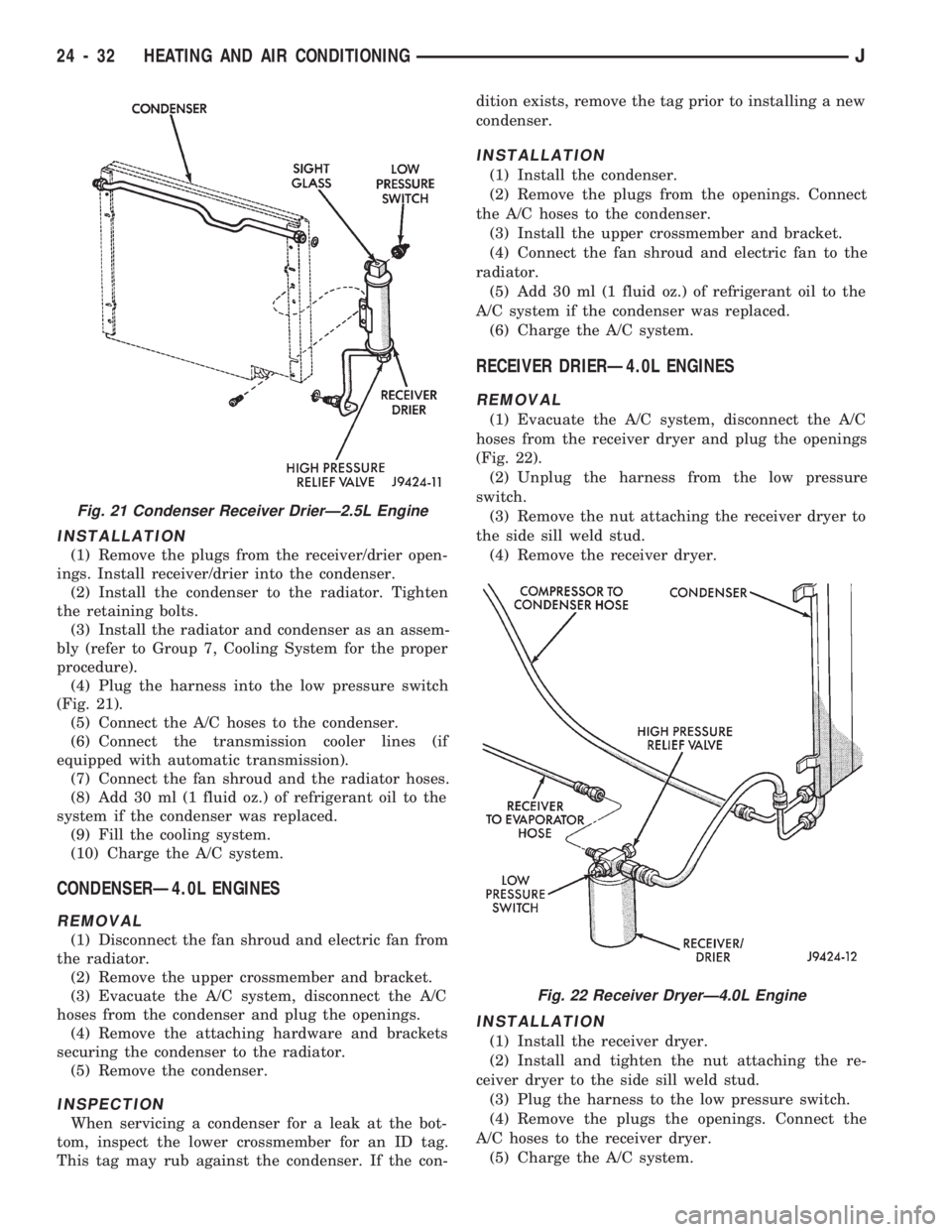

CONDENSER/RECEIVER DRIERÐ2.5L ENGINES

REMOVAL

(1) Drain the radiator.

(2) Disconnect the fan shroud and the radiator

hoses.

(3) Disconnect the transmission cooler lines (if

equipped with automatic transmission).

(4) Evacuate the A/C system. Disconnect the A/C

hoses from the condenser.

(5) Unplug the harness from the low pressure

switch (Fig. 21).

(6) Remove the radiator and condenser as an as-

sembly.

(7) Remove the retaining bolts and separate the

condenser from the radiator.

(8) Remove the receiver/drier from the condenser.

Keep receiver/drier openings plugged at all

times to prevent moisture from entering the re-

ceiver/drier.

INSPECTION

When servicing a condenser for a leak at the bot-

tom, inspect the lower crossmember for an ID tag.

This tag may rub against the condenser. If the con-

dition exists, remove the tag prior to installing a new

condenser.

Fig. 18 Vacuum Motor

Fig. 19 Vacuum Door Motor Cover

Fig. 20 Vacuum Door Motor

JHEATING AND AIR CONDITIONING 24 - 31

Page 1695 of 1784

INSTALLATION

(1) Remove the plugs from the receiver/drier open-

ings. Install receiver/drier into the condenser.

(2) Install the condenser to the radiator. Tighten

the retaining bolts.

(3) Install the radiator and condenser as an assem-

bly (refer to Group 7, Cooling System for the proper

procedure).

(4) Plug the harness into the low pressure switch

(Fig. 21).

(5) Connect the A/C hoses to the condenser.

(6) Connect the transmission cooler lines (if

equipped with automatic transmission).

(7) Connect the fan shroud and the radiator hoses.

(8) Add 30 ml (1 fluid oz.) of refrigerant oil to the

system if the condenser was replaced.

(9) Fill the cooling system.

(10) Charge the A/C system.

CONDENSERÐ4.0L ENGINES

REMOVAL

(1) Disconnect the fan shroud and electric fan from

the radiator.

(2) Remove the upper crossmember and bracket.

(3) Evacuate the A/C system, disconnect the A/C

hoses from the condenser and plug the openings.

(4) Remove the attaching hardware and brackets

securing the condenser to the radiator.

(5) Remove the condenser.

INSPECTION

When servicing a condenser for a leak at the bot-

tom, inspect the lower crossmember for an ID tag.

This tag may rub against the condenser. If the con-dition exists, remove the tag prior to installing a new

condenser.

INSTALLATION

(1) Install the condenser.

(2) Remove the plugs from the openings. Connect

the A/C hoses to the condenser.

(3) Install the upper crossmember and bracket.

(4) Connect the fan shroud and electric fan to the

radiator.

(5) Add 30 ml (1 fluid oz.) of refrigerant oil to the

A/C system if the condenser was replaced.

(6) Charge the A/C system.

RECEIVER DRIERÐ4.0L ENGINES

REMOVAL

(1) Evacuate the A/C system, disconnect the A/C

hoses from the receiver dryer and plug the openings

(Fig. 22).

(2) Unplug the harness from the low pressure

switch.

(3) Remove the nut attaching the receiver dryer to

the side sill weld stud.

(4) Remove the receiver dryer.

INSTALLATION

(1) Install the receiver dryer.

(2) Install and tighten the nut attaching the re-

ceiver dryer to the side sill weld stud.

(3) Plug the harness to the low pressure switch.

(4) Remove the plugs the openings. Connect the

A/C hoses to the receiver dryer.

(5) Charge the A/C system.

Fig. 21 Condenser Receiver DrierÐ2.5L Engine

Fig. 22 Receiver DryerÐ4.0L Engine

24 - 32 HEATING AND AIR CONDITIONINGJ

Page 1696 of 1784

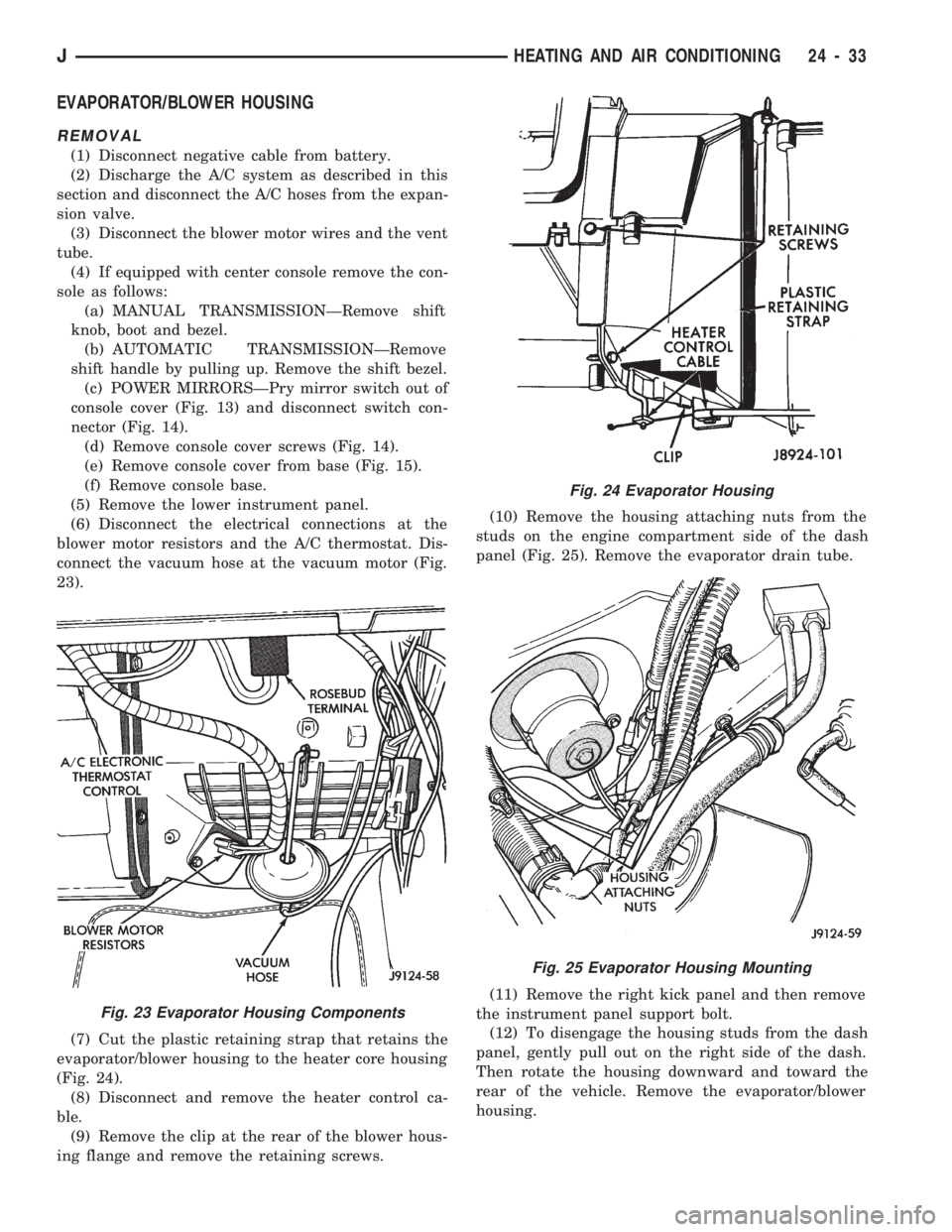

EVAPORATOR/BLOWER HOUSING

REMOVAL

(1) Disconnect negative cable from battery.

(2) Discharge the A/C system as described in this

section and disconnect the A/C hoses from the expan-

sion valve.

(3) Disconnect the blower motor wires and the vent

tube.

(4) If equipped with center console remove the con-

sole as follows:

(a) MANUAL TRANSMISSIONÐRemove shift

knob, boot and bezel.

(b) AUTOMATIC TRANSMISSIONÐRemove

shift handle by pulling up. Remove the shift bezel.

(c) POWER MIRRORSÐPry mirror switch out of

console cover (Fig. 13) and disconnect switch con-

nector (Fig. 14).

(d) Remove console cover screws (Fig. 14).

(e) Remove console cover from base (Fig. 15).

(f) Remove console base.

(5) Remove the lower instrument panel.

(6) Disconnect the electrical connections at the

blower motor resistors and the A/C thermostat. Dis-

connect the vacuum hose at the vacuum motor (Fig.

23).

(7) Cut the plastic retaining strap that retains the

evaporator/blower housing to the heater core housing

(Fig. 24).

(8) Disconnect and remove the heater control ca-

ble.

(9) Remove the clip at the rear of the blower hous-

ing flange and remove the retaining screws.(10) Remove the housing attaching nuts from the

studs on the engine compartment side of the dash

panel (Fig. 25). Remove the evaporator drain tube.

(11) Remove the right kick panel and then remove

the instrument panel support bolt.

(12) To disengage the housing studs from the dash

panel, gently pull out on the right side of the dash.

Then rotate the housing downward and toward the

rear of the vehicle. Remove the evaporator/blower

housing.

Fig. 23 Evaporator Housing Components

Fig. 24 Evaporator Housing

Fig. 25 Evaporator Housing Mounting

JHEATING AND AIR CONDITIONING 24 - 33

Page 1700 of 1784

CLIMATE CONTROL SYSTEMÐYJ VEHICLES

INDEX

page page

A/C Blower Motor........................ 43

A/C Condenser.......................... 42

A/C Control Panel........................ 41

Blower Motor (Heating).................... 40

Blower Motor/Air Door Motor Switch Replacement . 39

Defroster Nozzle and Duct................. 40

Description (Air Conditioning)................ 41

Description (Heating)...................... 37

Evaporator and Housing................... 42

Expansion (H) Valve...................... 43Fresh Air Door Vacuum Motor............... 41

Fresh Air Intake Duct..................... 41

Fresh Air Ventilation...................... 39

Heater Control Panel Replacement........... 39

Heater Core and Housing.................. 40

Heater/Defroster Operation................. 37

Receiver-Drier Replacement................ 42

Sight Glass............................. 41

Vent Door Control Cables.................. 39

DESCRIPTION (HEATING)

A blend-air heating system is used in YJ vehicles.

The blend-air system provides a constant flow of en-

gine coolant through the heater core.

The temperature of heated air entering the passen-

ger compartment is controlled by regulating the

quantity of air flow through the heater core. This is

accomplished by blending a controlled amount of un-

heated air from outside the vehicle with heated air

from the heater core.

HEATER/DEFROSTER OPERATION

The heater core is connected to the engine cooling

system. It operates on the circulation of heated en-

gine coolant through the core and a supply of fresh

air drawn in through the intake grille on the cowl.

Engine coolant flows through the heater core at all

times.

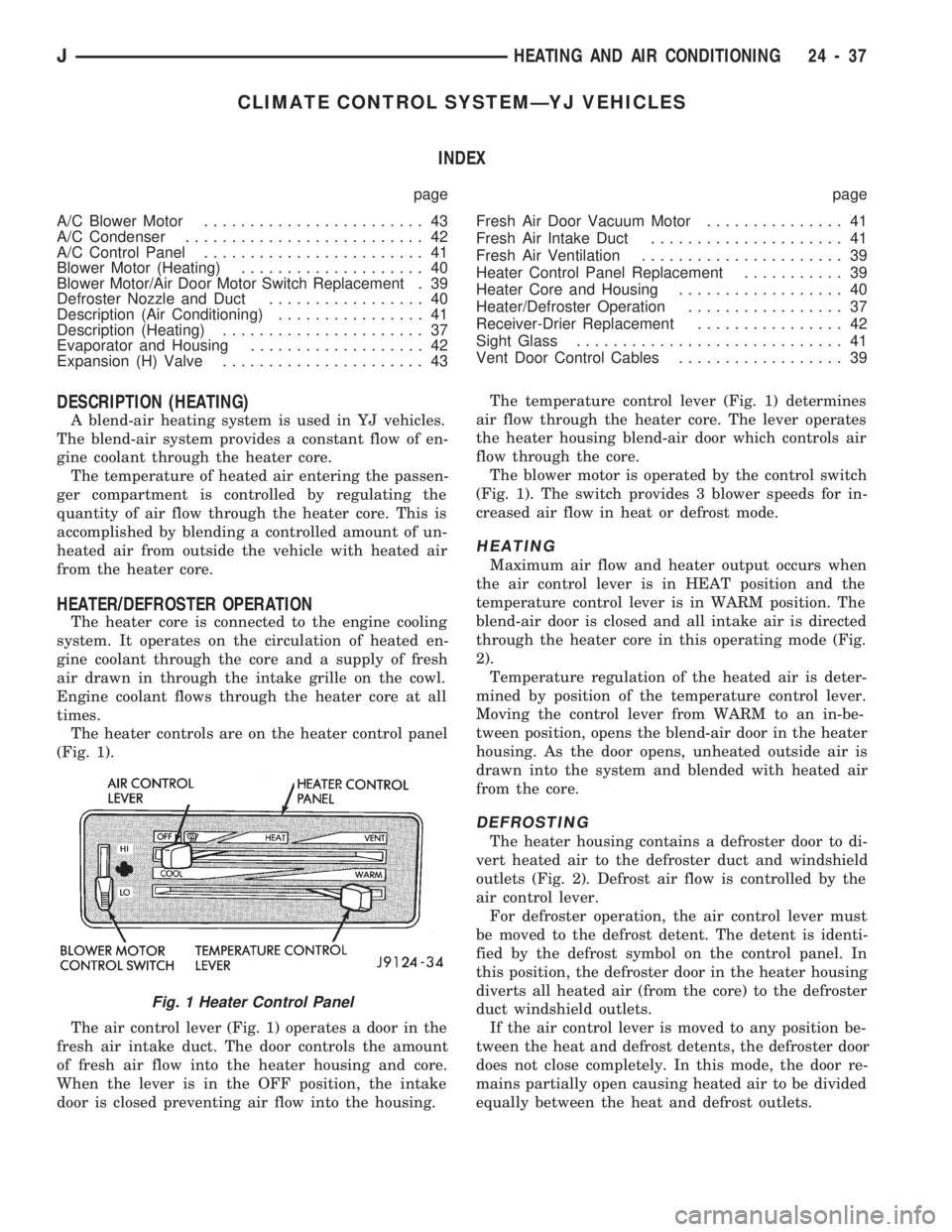

The heater controls are on the heater control panel

(Fig. 1).

The air control lever (Fig. 1) operates a door in the

fresh air intake duct. The door controls the amount

of fresh air flow into the heater housing and core.

When the lever is in the OFF position, the intake

door is closed preventing air flow into the housing.The temperature control lever (Fig. 1) determines

air flow through the heater core. The lever operates

the heater housing blend-air door which controls air

flow through the core.

The blower motor is operated by the control switch

(Fig. 1). The switch provides 3 blower speeds for in-

creased air flow in heat or defrost mode.

HEATING

Maximum air flow and heater output occurs when

the air control lever is in HEAT position and the

temperature control lever is in WARM position. The

blend-air door is closed and all intake air is directed

through the heater core in this operating mode (Fig.

2).

Temperature regulation of the heated air is deter-

mined by position of the temperature control lever.

Moving the control lever from WARM to an in-be-

tween position, opens the blend-air door in the heater

housing. As the door opens, unheated outside air is

drawn into the system and blended with heated air

from the core.

DEFROSTING

The heater housing contains a defroster door to di-

vert heated air to the defroster duct and windshield

outlets (Fig. 2). Defrost air flow is controlled by the

air control lever.

For defroster operation, the air control lever must

be moved to the defrost detent. The detent is identi-

fied by the defrost symbol on the control panel. In

this position, the defroster door in the heater housing

diverts all heated air (from the core) to the defroster

duct windshield outlets.

If the air control lever is moved to any position be-

tween the heat and defrost detents, the defroster door

does not close completely. In this mode, the door re-

mains partially open causing heated air to be divided

equally between the heat and defrost outlets.

Fig. 1 Heater Control Panel

JHEATING AND AIR CONDITIONING 24 - 37

Page 1703 of 1784

HEATER CORE AND HOUSING

REMOVAL

WARNING: HOT ENGINE COOLANT CAN CAUSE

SEVERE BURNS. DO NOT OPEN THE RADIATOR

DRAIN COCK WHEN THE COOLING SYSTEM IS

HOT AND PRESSURIZED. ALLOW THE COOLANT

TO DECREASE TO ROOM TEMPERATURE BEFORE

STARTING REPAIR OPERATIONS.

(1) Drain approximately 1.9 liters (2 qts) of coolant

from the radiator. Drain the coolant into a clean con-

tainer.

(2) Disconnect the heater hoses.

(3) Disconnect the vent door cables.

(4) Disconnect the blower motor wire.

(5) Disconnect the defroster duct.

(6) Remove the nuts that attach the heater hous-

ing studs to the engine compartment side of the dash

panel.

(7) Remove the heater housing assembly by tilting

it downward, to disengage it from the defroster duct.

Pull it rearward and out from under the instrument

panel.

(8) Remove the heater hosing cover from the hous-

ing.

(9) Remove the heater core from the housing.

INSTALLATION

(1) Install the heater core in the housing and in-

stall the cover on the housing.

(2) Position the heater housing on the dash panel.

Be sure the housing studs all extend through the

dash panel.

(3) Install the seals on the heater core outlet and

inlet tubes and over the blower motor housing.

(4) Install the attaching nuts on the housing studs.

CAUTION: DO NOT over tighten the attaching nuts.

The housing could become distorted causing air

leaks and improper heater door operation. Tighten

the nuts alternately and evenly until 2 stud threads

are visible beyond each nut.

(5) Connect the defroster duct to the housing.

(6) Connect the blower motor wire.

(7) Connect the vent door control cables.

(8) Connect the heater hoses.

(9) Fill and bleed the cooling system.

(10) Check system operation.

BLOWER MOTOR (HEATING)

REMOVAL

(1) Remove the heater housing.

(2) Remove the blower motor-to-heater housing at-

taching screws/nuts.

(3) Remove the blower motor from the housing.

INSTALLATION

(1) Position the blower motor into the housing.

(2) Install and tighten the blower motor-to-heater

housing attaching screws/nuts.

(3) Install the heater housing.

(4) Check blower motor and heater operation.

DEFROSTER NOZZLE AND DUCT

REMOVAL

WARNING: HOT ENGINE COOLANT CAN CAUSE

SEVERE BURNS. DO NOT OPEN THE RADIATOR

DRAIN COCK WHEN THE COOLING SYSTEM IS

HOT AND PRESSURIZED. ALLOW THE COOLANT

TO DECREASE TO ROOM TEMPERATURE BEFORE

STARTING REPAIR OPERATIONS.

(1) Drain approximately 1.9 liters (2 qts) of coolant

from the radiator. Drain the coolant into a clean con-

tainer.

(2) Disconnect the heater hoses.

(3) Remove the nuts attaching the heater housing

studs to the engine compartment side of the dash

panel.

(4) Disconnect the speedometer cable.

(5) Remove the glove box.

(6) Tilt the heater housing back and pull it rear-

ward and out from under the instrument panel.

(7) Disconnect the vent control cables.

(8) Remove the fresh air intake grille from the

cowl.

(9) Remove the fresh air intake duct.

(10) Lower the windshield.

(11) Remove the defroster nozzle attaching screws

and remove the nozzle and duct.

INSTALLATION

(1) Install the defroster nozzle and duct.

(2) Raise and secure the windshield.

(3) Install the fresh air intake duct.

(4) Install the fresh air intake grille on the cowl.

(5) Install the vent cables.

(6) Position the heater housing on the dash panel.

Be sure all the housing studs extend through the

dash panel.

(7) Install the seals on the blower motor and the

heater core inlet and outlet tubes.

(8) Install the attaching nuts on the housing studs.

CAUTION: DO NOT over tighten the attaching nuts.

The housing could become distorted causing air

leaks and improper heater door operation. Tighten

the nuts alternately and evenly until 2 stud threads

are visible beyond each nut.

(9) Install the glove box.

(10) Connect the speedometer cable.

(11) Connect the heater hoses.

24 - 40 HEATING AND AIR CONDITIONINGJ

Page 1704 of 1784

(12) Fill and bleed the cooling system.

FRESH AIR DOOR VACUUM MOTOR

REMOVAL

(1) Remove the glove box and assist handle.

(2) Disconnect the vacuum hose from the motor.

(3) Remove the motor lever retaining clip.

(4) Remove the motor attaching nuts and remove

the motor from the fresh air duct.

INSTALLATION

(1) Position the motor on the fresh air duct and in-

stall the motor attaching nuts.

(2) Align the motor lever with the air door lever

and install the lever retaining clip.

(3) Connect the vacuum hose to the motor.

(4) Install the glove box and assist handle.

FRESH AIR INTAKE DUCT

REMOVAL

WARNING: HOT ENGINE COOLANT CAN CAUSE

SEVERE BURNS. DO NOT OPEN THE RADIATOR

DRAIN COCK WHEN THE COOLING SYSTEM IS

HOT AND PRESSURIZED. ALLOW THE COOLANT

TO DECREASE TO ROOM TEMPERATURE BEFORE

STARTING REPAIR OPERATIONS.

(1) Drain approximately 1.9 liters (2 qts) of coolant

from the radiator. Drain the coolant into a clean con-

tainer.

(2) Disconnect the heater hoses.

(3) Remove the nuts attaching the heater housing

studs to the dash panel from inside the engine com-

partment.

(4) Disconnect the speedometer cable.

(5) Remove the glove box and assist handle.

(6) Tilt the heater housing back and pull it rear-

ward and out from under the instrument panel.

(7) Disconnect the vent cables.

(8) Remove the fresh air intake grille from the

cowl.

(9) Remove the fresh air intake duct.

INSTALLATION

(1) Install the fresh air intake duct.

(2) Install the defroster nozzle and duct.

(3) Raise and secure the windshield.

(4) Install the fresh air grille on the cowl.

(5) Install the vent cables.

(6) Position the heater housing on the dash panel.

Be sure all the housing studs extend through the

dash panel.

(7) Install the seals on the blower motor and

heater core inlet and outlet tubes.

(8) Install the attaching nuts on the heater hous-

ing studs.CAUTION: DO NOT over tighten the attaching nuts.

The housing could become distorted causing air

leaks and improper heater door operation. Tighten

the nuts alternately and evenly until 2 stud threads

are visible beyond each nut.

(9) Install the glove box and assist handle.

(10) Connect the speedometer cable.

(11) Connect the heater hoses.

(12) Fill and bleed the cooling system.

DESCRIPTION (AIR CONDITIONING)

The evaporator, blower fan and motor, thermostat,

expansion valve, capillary tube, air outlets and sys-

tem controls are located in the evaporator housing.

The evaporator housing is mounted under the instru-

ment panel. The compressor, condenser, receiver-

dryer and refrigerant lines are located in the engine

compartment.

A rotary-type compressor with magnetic clutch op-

erated drive pulley is used for all vehicles equipped

with air conditioning.

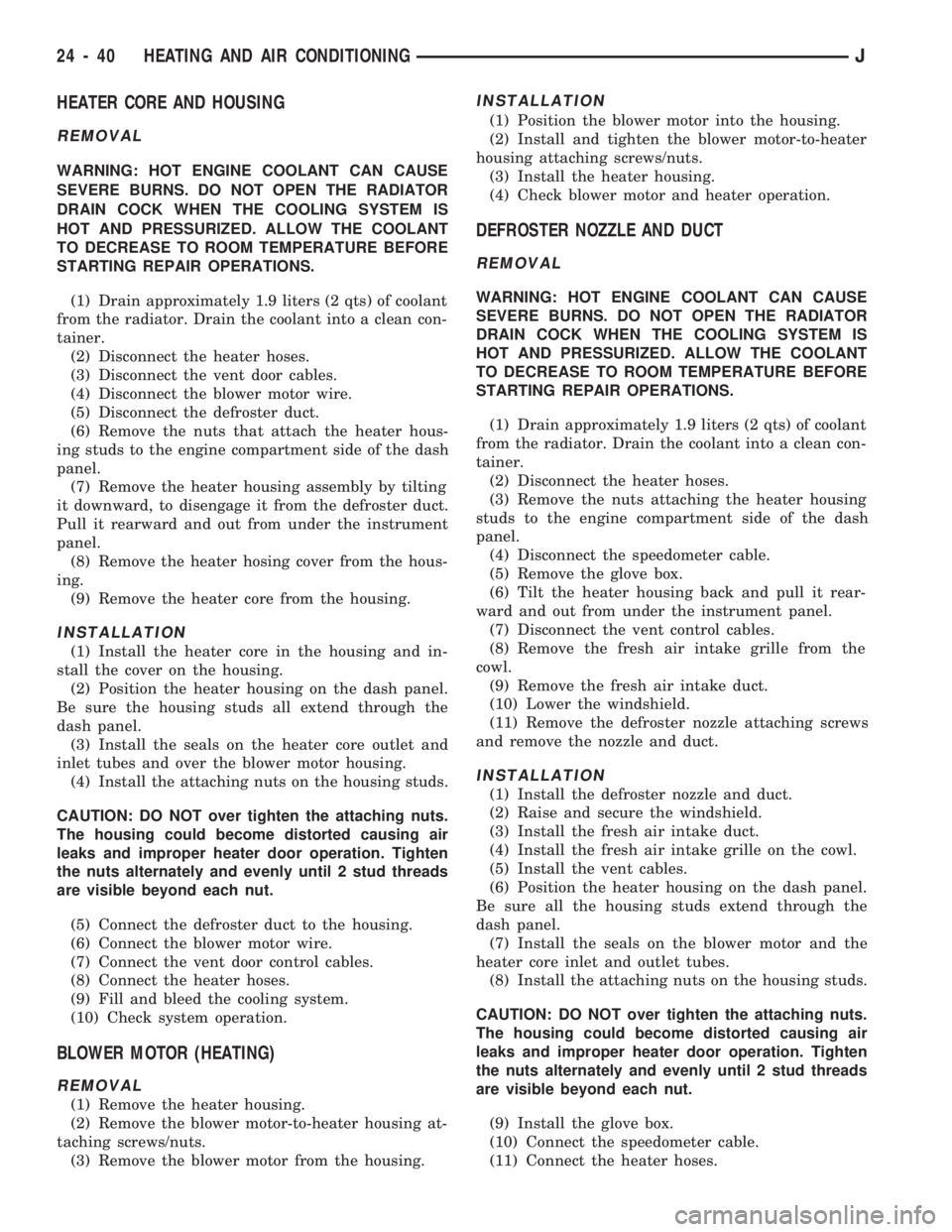

SIGHT GLASS

A sight glass is located on the top of the receiver-

drier (Fig. 6). The sight glass provides a visual check

of system refrigerant level. A continuous stream of

bubbles will appear in the sight glass when system

charge is low. Bubbles will not appear when the sys-

tem is fully charged.

A/C CONTROL PANEL

FAN SWITCH

The fan switch may be serviced by removing the

access plate located on the lower evaporator core

housing.

TEMPERATURE CONTROL THERMOSTAT

REMOVAL

(1) Lower the evaporator housing.

(2) Remove the attaching screws holding the top

and bottom housings together.

(3) Separate the housings.

(4) Remove the thermostat.

Fig. 6 Sight Glass (Typical)

JHEATING AND AIR CONDITIONING 24 - 41

Page 1705 of 1784

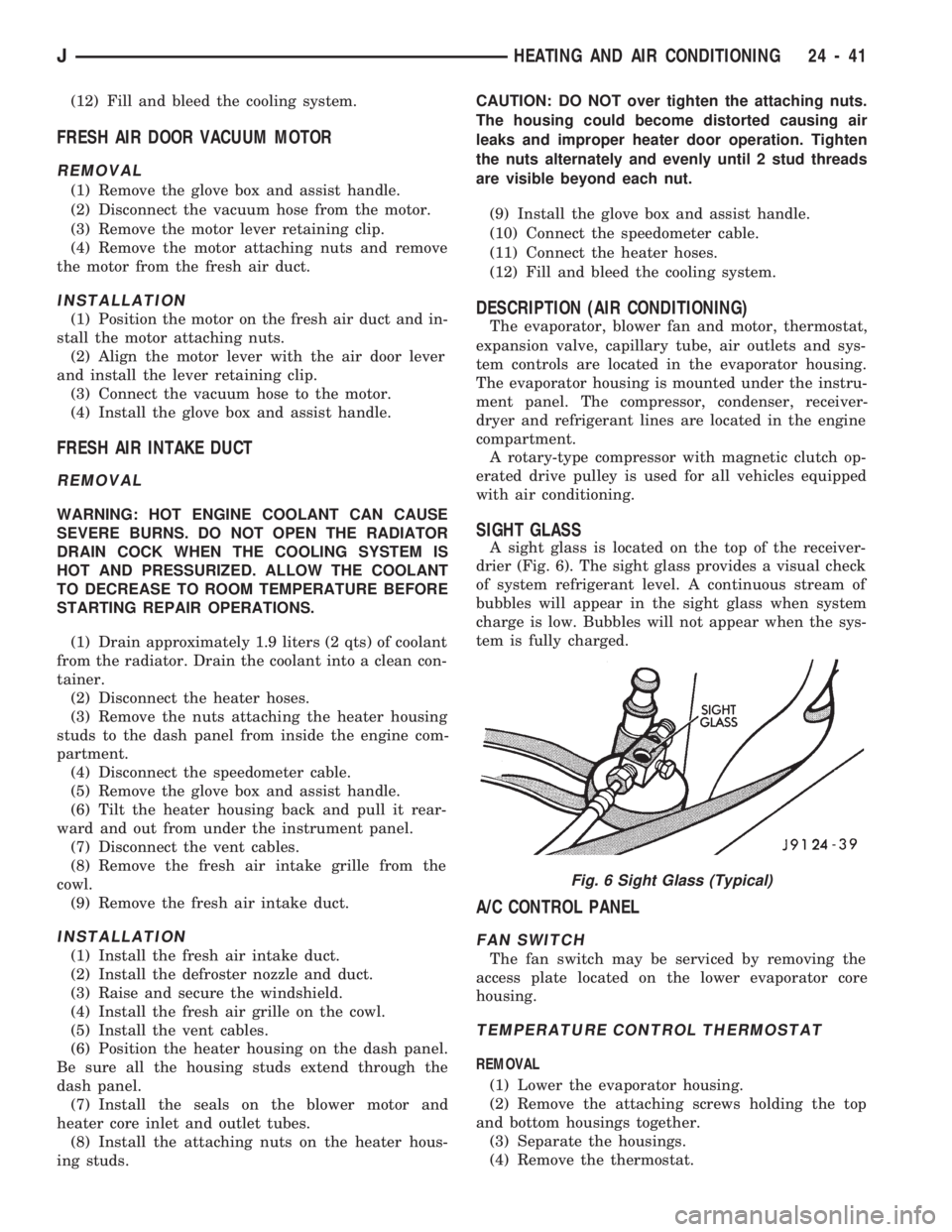

INSTALLATION

(1) When installing a replacement temperature

control thermostat, insert the capillary tube into the

evaporator coil a minimum of 50 mm (2 inch) (Fig.

7).

CAUTION: Handle the tube with care to avoid bends

or kinks that could cause the thermostat to mal-

function.

(2) Assemble the housing and install the attaching

screws. DO NOT over tighten the attaching screws.

(3) Install the evaporator housing.

A/C CONDENSER

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAIN COCK WHEN THE COOLING SYSTEM IS

HOT AND PRESSURIZED. HOT COOLANT CAN

CAUSE SERIOUS BURNS.

(1) Discharge the system slowly to prevent loss of

compressor oil.

(2) Drain the radiator. Drain the coolant into a

clean container.

(3) Remove the fan shroud and radiator.

(4) Disconnect the pressure pipe fitting from the

condenser.

(5) Remove the condenser attaching screws and tilt

the bottom of the condenser toward the engine.Plug

all the condenser openings to prevent entry of

dirt or moisture.

(6) Working from under the vehicle, disconnect the

receiver-drier to-evaporator hose fitting from the re-

ceiver-drier.

(7) Remove the condenser and receiver-drier as an

assembly.

(8) Remove the receiver-drier from the condenser,

if necessary.

INSTALLATION

(1) If the condenser is replaced, add 30 ml (1 fluid

oz.) of refrigerant oil to the system.(2) Attach the receiver-drier to the condenser.

(3) Place the condenser in position and connect the

hose fitting to the receiver-drier.

(4) Install the condenser attaching screws.

(5) Connect the condenser pressure pipe fitting.

(6) Install the radiator and fan shroud.

(7) Fill the cooling system.

(8) Evacuate, charge and leak test the air condi-

tioning system.

RECEIVER-DRIER REPLACEMENT

REMOVAL

(1) Discharge the system slowly to prevent loss of

compressor oil.

(2) Disconnect the evaporator and condenser hose

fittings from the receiver-drier.

(3) Remove the receiver-drier attaching screws. Re-

move the receiver-drier.

INSTALLATION

(1) Position the receiver-drier in place. Install and

tighten the receiver-drier attaching screws.

(2) Connect the evaporator and condenser hose fit-

tings to the receiver-drier.

(3) Charge the system.

(4) Preform the leak test on the system.

EVAPORATOR AND HOUSING

REMOVAL

(1) Discharge the system.Discharge the system

slowly to prevent loss of compressor oil.

(2) Disconnect the inlet (suction) hose.

(3) Disconnect the receiver-drier-to-evaporator

hoses.

(4) Remove the hose clamps and dash grommet re-

taining screws.

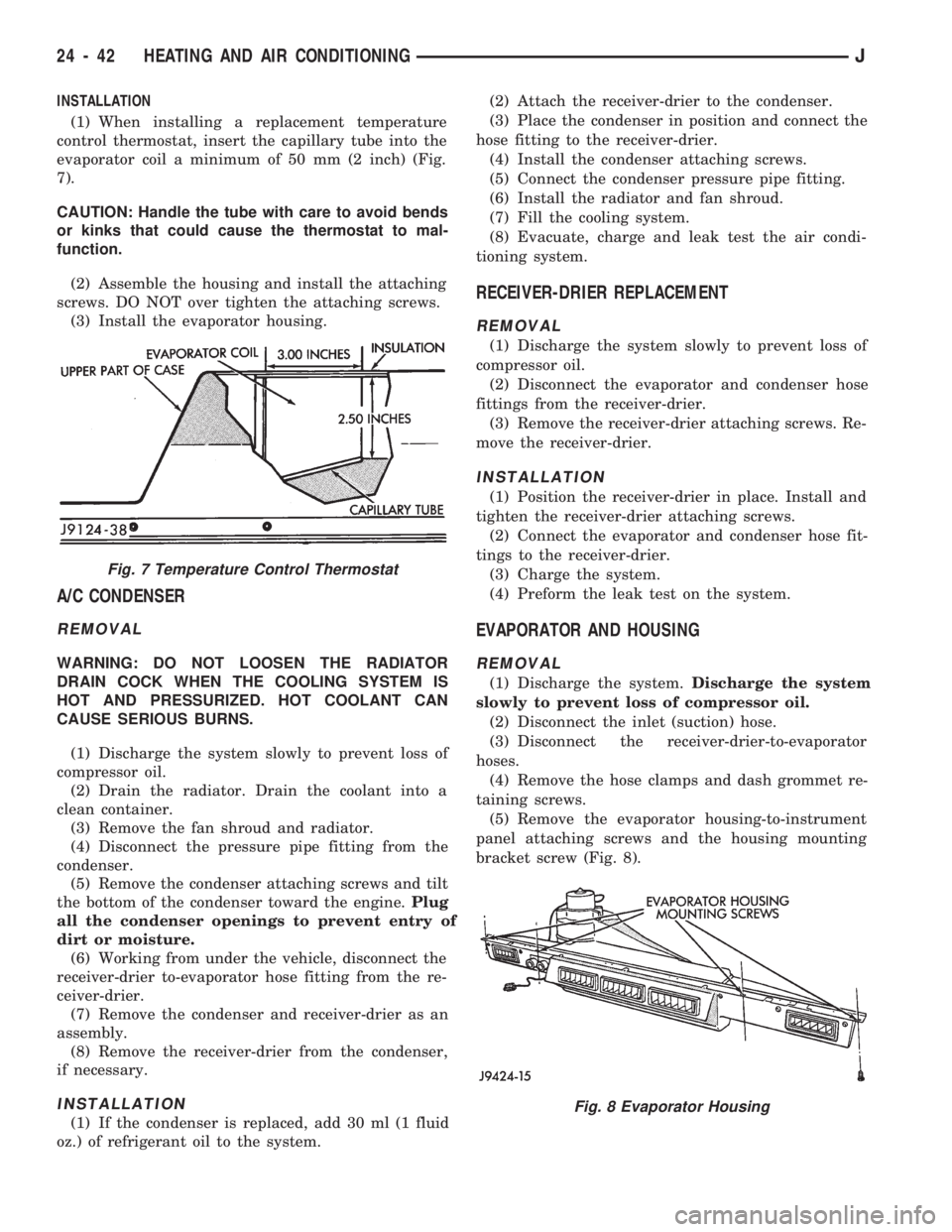

(5) Remove the evaporator housing-to-instrument

panel attaching screws and the housing mounting

bracket screw (Fig. 8).

Fig. 7 Temperature Control Thermostat

Fig. 8 Evaporator Housing

24 - 42 HEATING AND AIR CONDITIONINGJ

Page 1706 of 1784

(6) Lower the evaporator housing and pull the

hoses and hose grommet through the dash opening.

The blower motor, blower motor housing, evapora-

tor core, control switches and expansion valve can all

be serviced after removing the evaporator housing

(Fig. 9).

INSTALLATION

(1) If the evaporator is replaced, add 30 ml (1 fluid

oz.) of refrigerant oil to the system.

(2) Push the hoses through the grommet openings

and install the hose grommet by pushing it toward

the engine compartment.

(3) Install the hose grommet attaching screws.

(4) Raise the evaporator housing. Install the evap-

orator housing-to- instrument panel attaching screws

and the evaporator housing mounting bracket screw.

(5) Install the hose clamps.

(6) Connect the receiver-drier hoses.

(7) Connect the inlet (suction) hose.

(8) Evacuate, charge and leak test the system.

EXPANSION (H) VALVE

REMOVAL

(1) Discharge the system slowly to prevent loss of

compressor oil.

(2) Remove the evaporator housing.

(3) Remove the insulation wrapped around the suc-

tion hose fitting, expansion valve and evaporator

tubing.(4) Mark the capillary tube location on the evapo-

rator tubing.

(5) Disconnect the inlet and outlet hose fittings,

and remove the capillary tube clamp.

(6) Disconnect and remove the expansion valve.

INSTALLATION

(1) Clean the evaporator tubing to provide a posi-

tive metal-to-metal contact for the replacement ex-

pansion valve capillary tube.

(2) Install the replacement expansion valve.

(3) Clamp the capillary tube at the marked loca-

tion on the evaporator tubing.

(4) Connect the inlet and outlet hose fittings.The

capillary tube must be securely clamped and

have positive metal-to-metal contact with the

evaporator tubing.

(5) Wrap the expansion valve, inlet hose fitting

and capillary tube with insulation.

(6) Install the evaporator housing.

(7) Evacuate, charge and leak test the system.

A/C BLOWER MOTOR

It is not necessary to discharge the system to ser-

vice the blower motor. The evaporator housing need

only be lowered for access to the blower motor at-

taching screws.

JHEATING AND AIR CONDITIONING 24 - 43

Page 1710 of 1784

AIR CONDITIONING

CONTENTS

page page

AIR CONDITIONING EQUIPMENT........... 4

AIR CONDITIONING PERFORMANCE TESTS . . 5

GENERAL INFORMATION.................. 1

REFRIGERANT LEAK TESTING, DISCHARGING,

EVACUATING AND CHARGING............ 8REFRIGERANT OIL....................... 9

SERVICE PRECAUTIONS.................. 3

WARNINGS AND CAUTIONS FOR R134A

SYSTEM.............................. 3

GENERAL INFORMATION

A/C COMPONENTS

COMPRESSORÐThe SD-709 Compressor is used

on all models. The compressor compresses the low-

pressure refrigerant vapor from the evaporator into a

high pressure, high temperature vapor. The compres-

sor is serviced as an assembly only.

CLUTCH PULLEY AND COILÐThey are

mounted on the compressor and providing a way to

drive the compressor. The compressor clutch and coil

are the only serviced parts on the SD-709 compres-

sor. When the compressor is not in operation, the

pulley free wheels on the clutch hub bearing. When

the coil is energized the clutch plate is magnetically

engaged with the pulley and turns the compressor

shaft.

CONDENSERÐThe condenser is located in front

of the engine radiator. Its function is to cool the hot

high pressure refrigerant gas. This causes it to con-

dense into high pressure liquid refrigerant.

FILTER-DRIERÐThe drier is used to remove con-

taminates and traces of moisture from the refriger-

ant system.

SIGHT-GLASSÐThe sight glass is located on top

of the filter drier. It is used as a diagnostic tool to ob-

serve refrigerant flow.

LOW-PRESSURE HIGH-PRESSURE CUT-OFF

SWITCHÐThe switch is located on the filter drier

and is wired in series with compressor clutch. When

the pressure drops down to 193 kPa (28 psi) the

switch interrupts the power to the compressor clutch.

When the pressure increases above 3100 to 3375 kPa

(450 to 490 psi) the switch interrupts the power to

the compressor clutch.

HIGH PRESSURE RELIEF VALVEÐThe valve

is located on the filter drier. The valve is used to pre-

vent excessive pressure up build of 3445 to 4135

kPag (500 to 600 psi) and above. This will prevent

damage to the compressor and other system compo-

nents.EXPANSION VALVEÐThe expansion valve is lo-

cated in the engine compartment on XJ vehicles. On

YJ vehicles it is located behind the A/C housing. Its

function is to meter refrigerant into the evaporator in

accordance with cooling requirements.

EVAPORATOR COILÐThe coil is located in the

A/C housing. Its function is to remove heat and de-

humidify the air before it enters the vehicle.

FIN SENSING CYCLING CLUTCH SWITCHÐ

The switch is attached to the evaporator coil. This

switch prevents condensate water on the evaporator

coil from freezing. It does this by cycling the com-

pressor clutch on and off. This switch is used onXJ

only

THERMOSTATÐThe thermostat is located in the

evaporator housing. Its function is to cycle the com-

pressor clutch to control temperature. The thermo-

stat is used on theYJonly.

REFRIGERANT LINESÐThe lines are used to

carry the refrigerant between the various system

components.

SERVICE PORTSÐThe high pressure service

port is located on the discharge line near the com-

pressor. The low pressure service port is located on

the suction line near the compressor. The compressor

no longer uses service valves.

After servicing the refrigerant system, always in-

stall service port caps.

REFRIGERANT

The vehicles use a new type of refrigerant called

R-134a. It is a non-toxic, non-flammable, clear color-

less liquified gas.

R-134a refrigerant is not compatible with R-12 re-

frigerant in an air conditioning system. A small

amount of R-12 in a R-134a system will cause com-

pressor failure, refrigerant oil sludge or poor A/C per-

formance.

JAIR CONDITIONING1