cooling JEEP CHEROKEE 1994 Service Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 266 of 1784

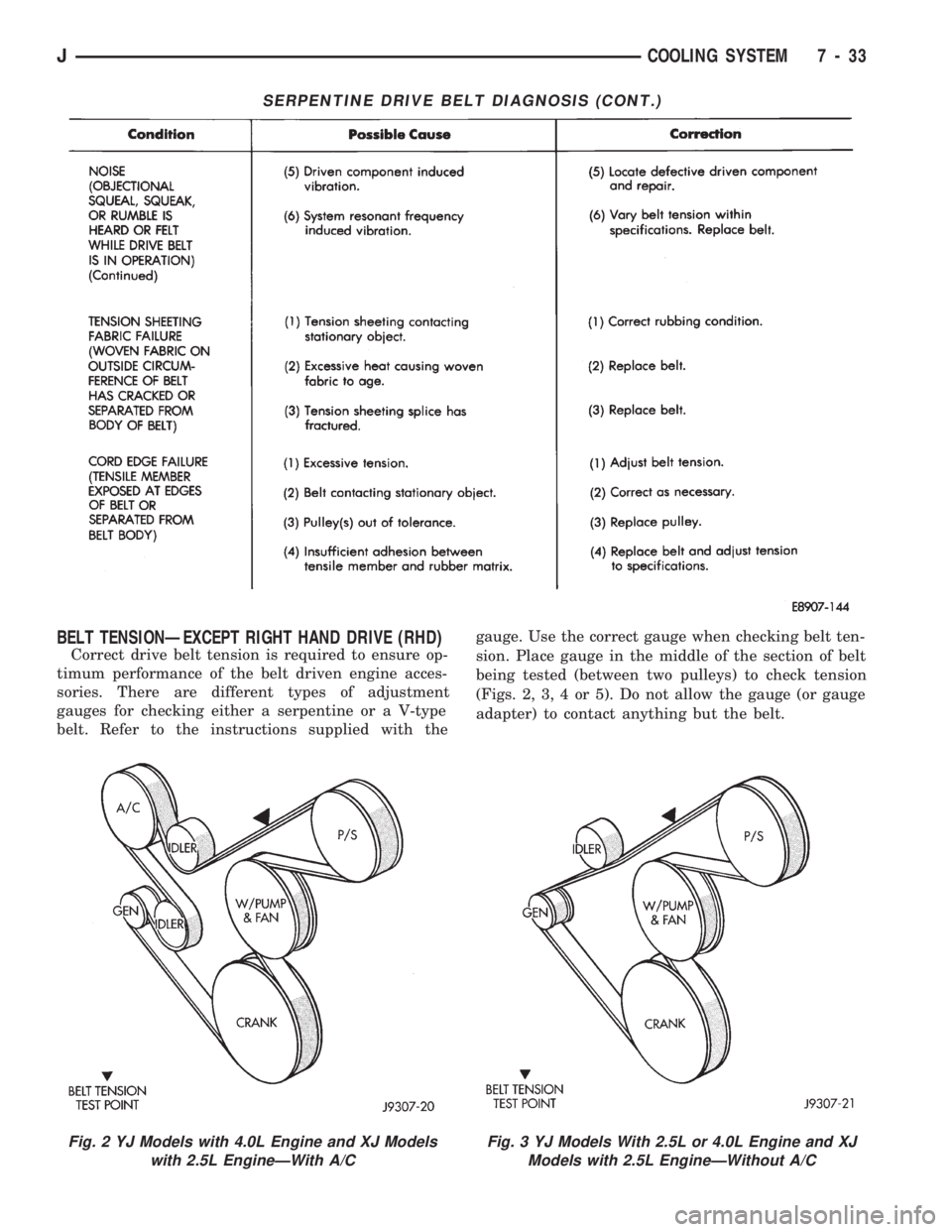

BELT TENSIONÐEXCEPT RIGHT HAND DRIVE (RHD)

Correct drive belt tension is required to ensure op-

timum performance of the belt driven engine acces-

sories. There are different types of adjustment

gauges for checking either a serpentine or a V-type

belt. Refer to the instructions supplied with thegauge. Use the correct gauge when checking belt ten-

sion. Place gauge in the middle of the section of belt

being tested (between two pulleys) to check tension

(Figs. 2, 3, 4 or 5). Do not allow the gauge (or gauge

adapter) to contact anything but the belt.

SERPENTINE DRIVE BELT DIAGNOSIS (CONT.)

Fig. 2 YJ Models with 4.0L Engine and XJ Models

with 2.5L EngineÐWith A/CFig. 3 YJ Models With 2.5L or 4.0L Engine and XJ

Models with 2.5L EngineÐWithout A/C

JCOOLING SYSTEM 7 - 33

Page 267 of 1784

BELT TENSIONÐRIGHT HAND DRIVE (RHD)

XJ MODELS WITH 4.0L ENGINE

It is not necessary to adjust belt tension on RHD

vehicles if equipped with a 4.0L engine. The engine

is equipped with an automatic belt tensioner (Fig. 7).

The tensioner maintains correct belt tension at all

times.Due to the use of this belt tensioner, DO

NOT attempt to use a belt tension gauge on this

engine.

BELT TENSION SPECIFICATIONS

Refer to the Specifications section at the end of this

group.

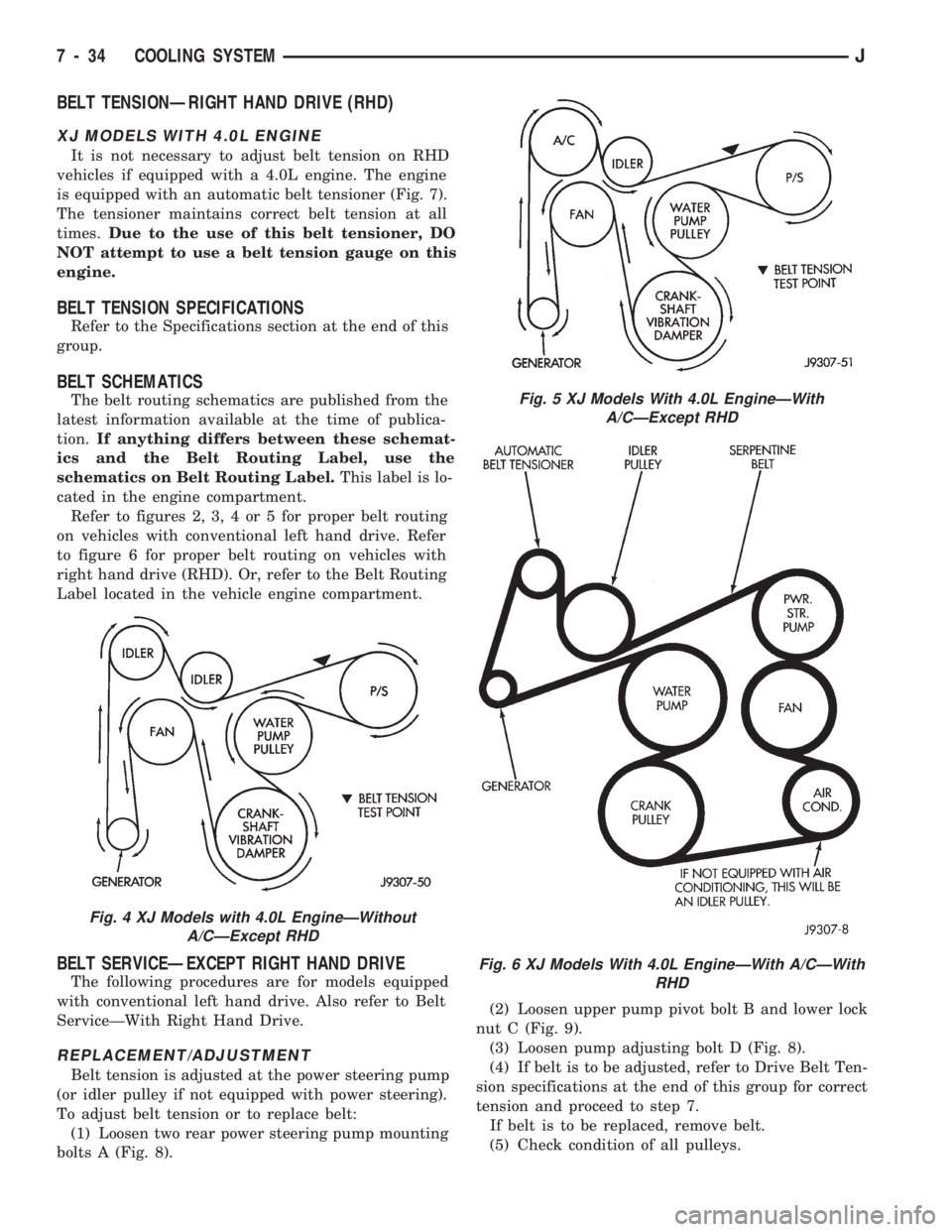

BELT SCHEMATICS

The belt routing schematics are published from the

latest information available at the time of publica-

tion.If anything differs between these schemat-

ics and the Belt Routing Label, use the

schematics on Belt Routing Label.This label is lo-

cated in the engine compartment.

Refer to figures 2, 3, 4 or 5 for proper belt routing

on vehicles with conventional left hand drive. Refer

to figure 6 for proper belt routing on vehicles with

right hand drive (RHD). Or, refer to the Belt Routing

Label located in the vehicle engine compartment.

BELT SERVICEÐEXCEPT RIGHT HAND DRIVE

The following procedures are for models equipped

with conventional left hand drive. Also refer to Belt

ServiceÐWith Right Hand Drive.

REPLACEMENT/ADJUSTMENT

Belt tension is adjusted at the power steering pump

(or idler pulley if not equipped with power steering).

To adjust belt tension or to replace belt:

(1) Loosen two rear power steering pump mounting

bolts A (Fig. 8).(2) Loosen upper pump pivot bolt B and lower lock

nut C (Fig. 9).

(3) Loosen pump adjusting bolt D (Fig. 8).

(4) If belt is to be adjusted, refer to Drive Belt Ten-

sion specifications at the end of this group for correct

tension and proceed to step 7.

If belt is to be replaced, remove belt.

(5) Check condition of all pulleys.

Fig. 4 XJ Models with 4.0L EngineÐWithout

A/CÐExcept RHD

Fig. 5 XJ Models With 4.0L EngineÐWith

A/CÐExcept RHD

Fig. 6 XJ Models With 4.0L EngineÐWith A/CÐWith

RHD

7 - 34 COOLING SYSTEMJ

Page 268 of 1784

CAUTION: When installing the serpentine accessory

drive belt, the belt MUST be routed correctly. If not,

the engine may overheat due to the water pump ro-

tating in the wrong direction. Refer to (Figs. 2, 3, 4

or 5) for correct belt routing.

(6) Install new belt. Refer to the end of this group

for Drive Belt Tension specifications.

(7) Tighten pump adjusting bolt D (Fig. 8) to at-

tain proper belt tension.(8) Tighten rear pump mounting bolts, pivot bolt

and lock nut to 27 Nzm (20 ft. lbs.) torque.

(9) After power steering pump has been tightened

into position, recheck belt tension. Adjust if neces-

sary.

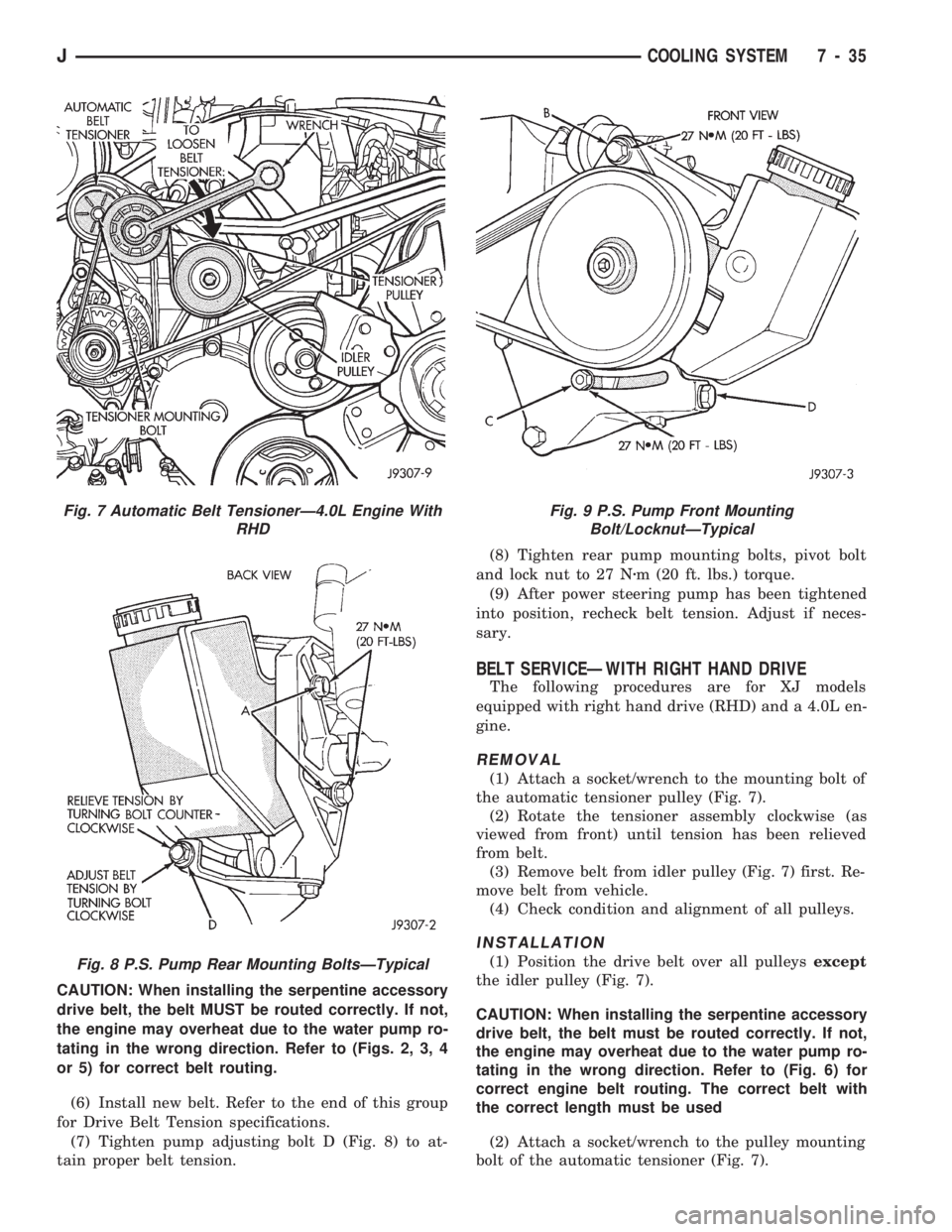

BELT SERVICEÐWITH RIGHT HAND DRIVE

The following procedures are for XJ models

equipped with right hand drive (RHD) and a 4.0L en-

gine.

REMOVAL

(1) Attach a socket/wrench to the mounting bolt of

the automatic tensioner pulley (Fig. 7).

(2) Rotate the tensioner assembly clockwise (as

viewed from front) until tension has been relieved

from belt.

(3) Remove belt from idler pulley (Fig. 7) first. Re-

move belt from vehicle.

(4) Check condition and alignment of all pulleys.

INSTALLATION

(1) Position the drive belt over all pulleysexcept

the idler pulley (Fig. 7).

CAUTION: When installing the serpentine accessory

drive belt, the belt must be routed correctly. If not,

the engine may overheat due to the water pump ro-

tating in the wrong direction. Refer to (Fig. 6) for

correct engine belt routing. The correct belt with

the correct length must be used

(2) Attach a socket/wrench to the pulley mounting

bolt of the automatic tensioner (Fig. 7).

Fig. 7 Automatic Belt TensionerÐ4.0L Engine With

RHD

Fig. 8 P.S. Pump Rear Mounting BoltsÐTypical

Fig. 9 P.S. Pump Front Mounting

Bolt/LocknutÐTypical

JCOOLING SYSTEM 7 - 35

Page 269 of 1784

(3) Rotate the socket/wrench clockwise (Fig. 7).

Place the belt over the idler pulley. Let tensioner ro-

tate back into place. Remove wrench. Be sure belt is

properly seated in the grooves of all pulleys.

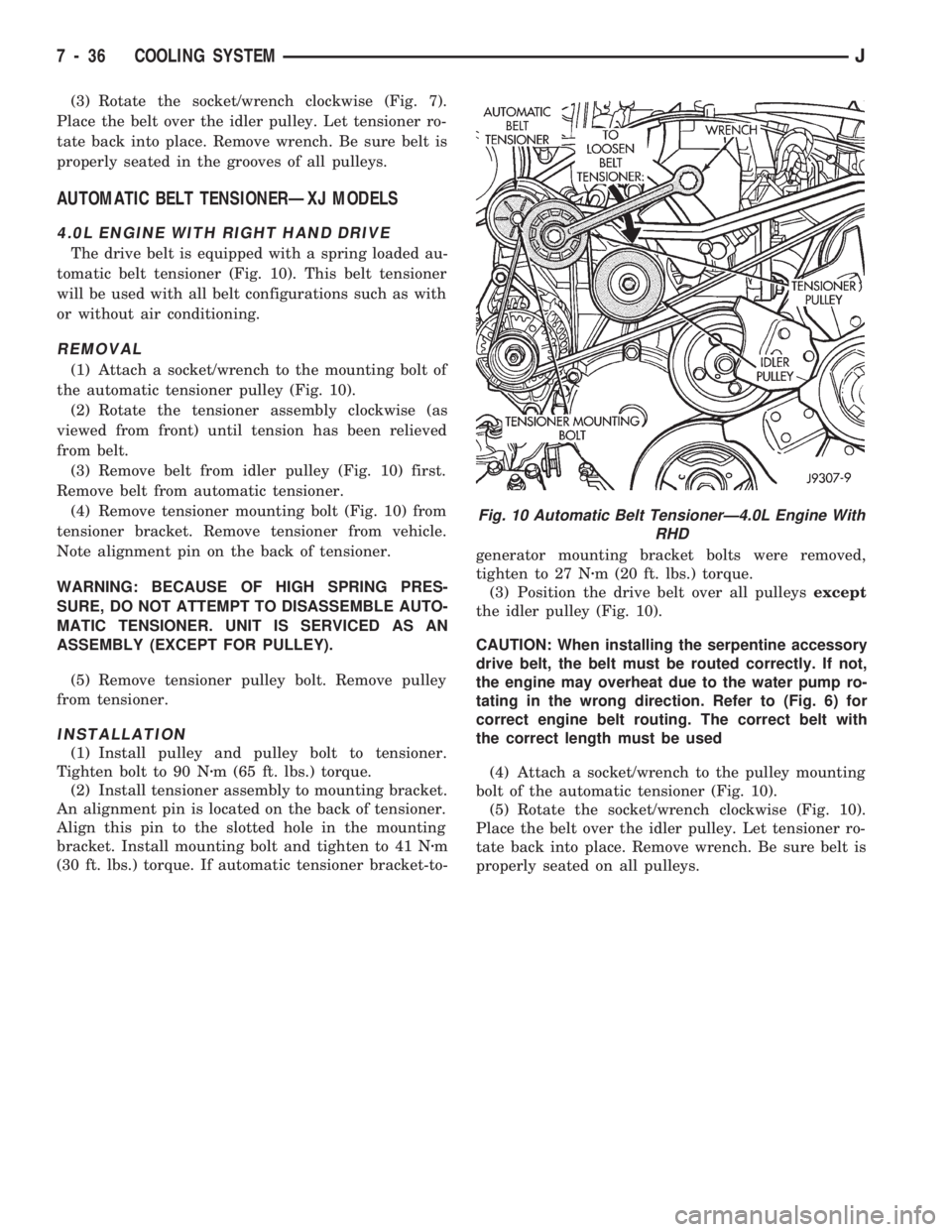

AUTOMATIC BELT TENSIONERÐXJ MODELS

4.0L ENGINE WITH RIGHT HAND DRIVE

The drive belt is equipped with a spring loaded au-

tomatic belt tensioner (Fig. 10). This belt tensioner

will be used with all belt configurations such as with

or without air conditioning.

REMOVAL

(1) Attach a socket/wrench to the mounting bolt of

the automatic tensioner pulley (Fig. 10).

(2) Rotate the tensioner assembly clockwise (as

viewed from front) until tension has been relieved

from belt.

(3) Remove belt from idler pulley (Fig. 10) first.

Remove belt from automatic tensioner.

(4) Remove tensioner mounting bolt (Fig. 10) from

tensioner bracket. Remove tensioner from vehicle.

Note alignment pin on the back of tensioner.

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY (EXCEPT FOR PULLEY).

(5) Remove tensioner pulley bolt. Remove pulley

from tensioner.

INSTALLATION

(1) Install pulley and pulley bolt to tensioner.

Tighten bolt to 90 Nzm (65 ft. lbs.) torque.

(2) Install tensioner assembly to mounting bracket.

An alignment pin is located on the back of tensioner.

Align this pin to the slotted hole in the mounting

bracket. Install mounting bolt and tighten to 41 Nzm

(30 ft. lbs.) torque. If automatic tensioner bracket-to-generator mounting bracket bolts were removed,

tighten to 27 Nzm (20 ft. lbs.) torque.

(3) Position the drive belt over all pulleysexcept

the idler pulley (Fig. 10).

CAUTION: When installing the serpentine accessory

drive belt, the belt must be routed correctly. If not,

the engine may overheat due to the water pump ro-

tating in the wrong direction. Refer to (Fig. 6) for

correct engine belt routing. The correct belt with

the correct length must be used

(4) Attach a socket/wrench to the pulley mounting

bolt of the automatic tensioner (Fig. 10).

(5) Rotate the socket/wrench clockwise (Fig. 10).

Place the belt over the idler pulley. Let tensioner ro-

tate back into place. Remove wrench. Be sure belt is

properly seated on all pulleys.

Fig. 10 Automatic Belt TensionerÐ4.0L Engine With

RHD

7 - 36 COOLING SYSTEMJ

Page 270 of 1784

ENGINE BLOCK HEATER

GENERAL INFORMATION

DESCRIPTION AND OPERATION

An optional engine block heater is available for all

models. The heater is equipped with a power cord.

The cord is attached to an engine compartment com-

ponent with tie-straps. The heater warms the engine

providing easier engine starting and faster warm-up

in low temperatures. The heater is mounted in a core

hole of the engine cylinder block (in place of a freeze

plug) with the heating element immersed in engine

coolant. Connect the power cord to a grounded 110-

120 volt AC electrical outlet with a grounded, three-

wire extension cord.

WARNING: DO NOT OPERATE ENGINE UNLESS

BLOCK HEATER CORD HAS BEEN DISCONNECTED

FROM POWER SOURCE AND SECURED IN PLACE.

BLOCK HEATER SPECIFICATIONS

²2.5L Engine: 115 Volts 400 Watts

²4.0L Engine: 120 Volts 600 Watts

REMOVAL

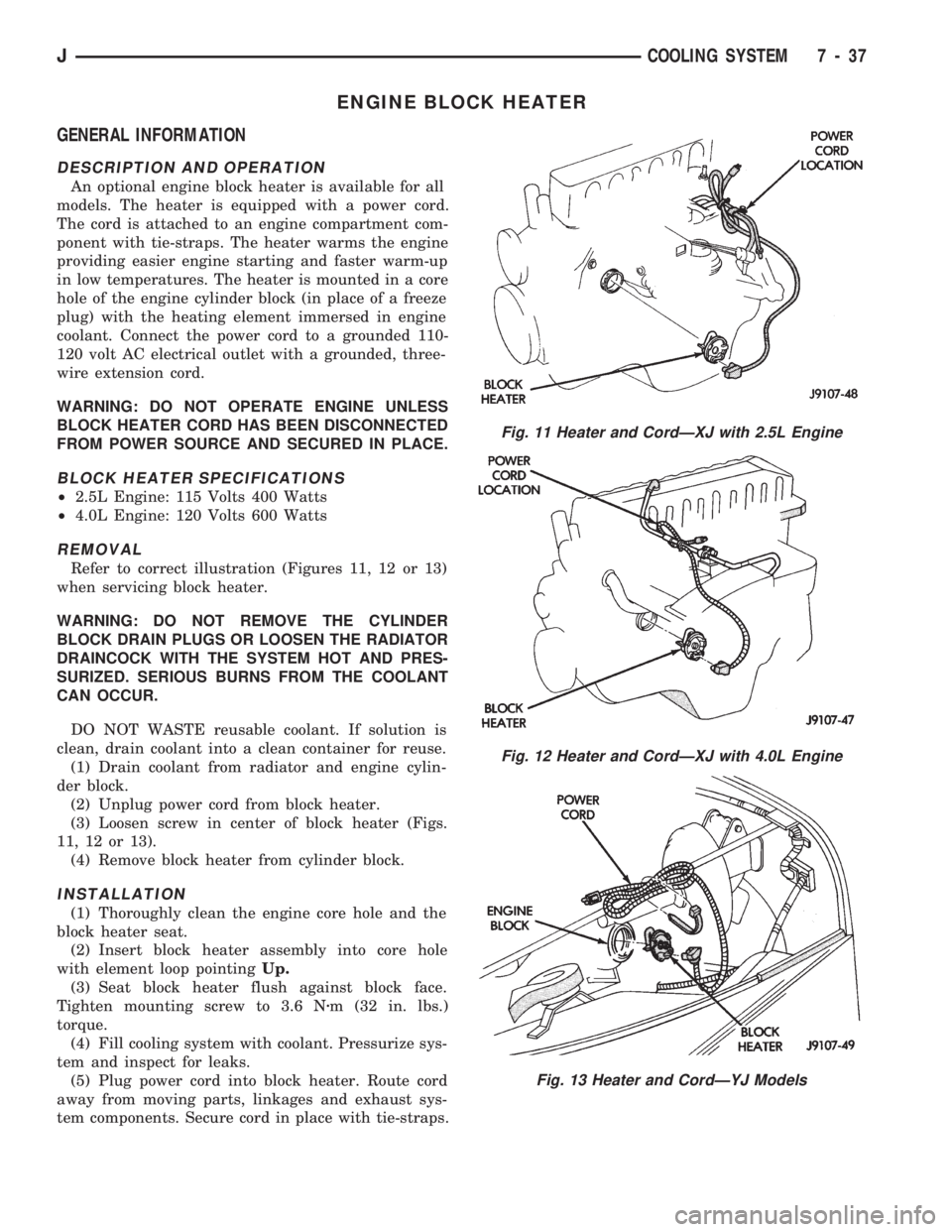

Refer to correct illustration (Figures 11, 12 or 13)

when servicing block heater.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND PRES-

SURIZED. SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

(1) Drain coolant from radiator and engine cylin-

der block.

(2) Unplug power cord from block heater.

(3) Loosen screw in center of block heater (Figs.

11, 12 or 13).

(4) Remove block heater from cylinder block.

INSTALLATION

(1) Thoroughly clean the engine core hole and the

block heater seat.

(2) Insert block heater assembly into core hole

with element loop pointingUp.

(3) Seat block heater flush against block face.

Tighten mounting screw to 3.6 Nzm (32 in. lbs.)

torque.

(4) Fill cooling system with coolant. Pressurize sys-

tem and inspect for leaks.

(5) Plug power cord into block heater. Route cord

away from moving parts, linkages and exhaust sys-

tem components. Secure cord in place with tie-straps.

Fig. 11 Heater and CordÐXJ with 2.5L Engine

Fig. 12 Heater and CordÐXJ with 4.0L Engine

Fig. 13 Heater and CordÐYJ Models

JCOOLING SYSTEM 7 - 37

Page 271 of 1784

SPECIFICATIONS

GENERAL INFORMATION

The following specifications are published from the

latest information available at the time of publica-

tion.If anything differs between the specifica-

tions found on the Vehicle Emission Control

Information (VECI) label and the following

specifications, use specifications on VECI label.

The VECI label is located in the engine compart-

ment.

DRIVE BELT TENSION

Belt tension can be adjusted only on models

equipped with conventional left hand drive. Refer to

the following Belt TensionÐExcept RHD Models

chart for specifications.

It is not necessary to adjust belt tension on right

hand drive (RHD) vehicles if equipped with a 4.0L

engine. The engine is equipped with an automatic

belt tensioner. The tensioner maintains correct belt

tension at all times.Due to the use of this belt

tensioner, DO NOT attempt to use a belt ten-

sion gauge on this engine.Refer to Automatic Belt

Tensioner for additional information.

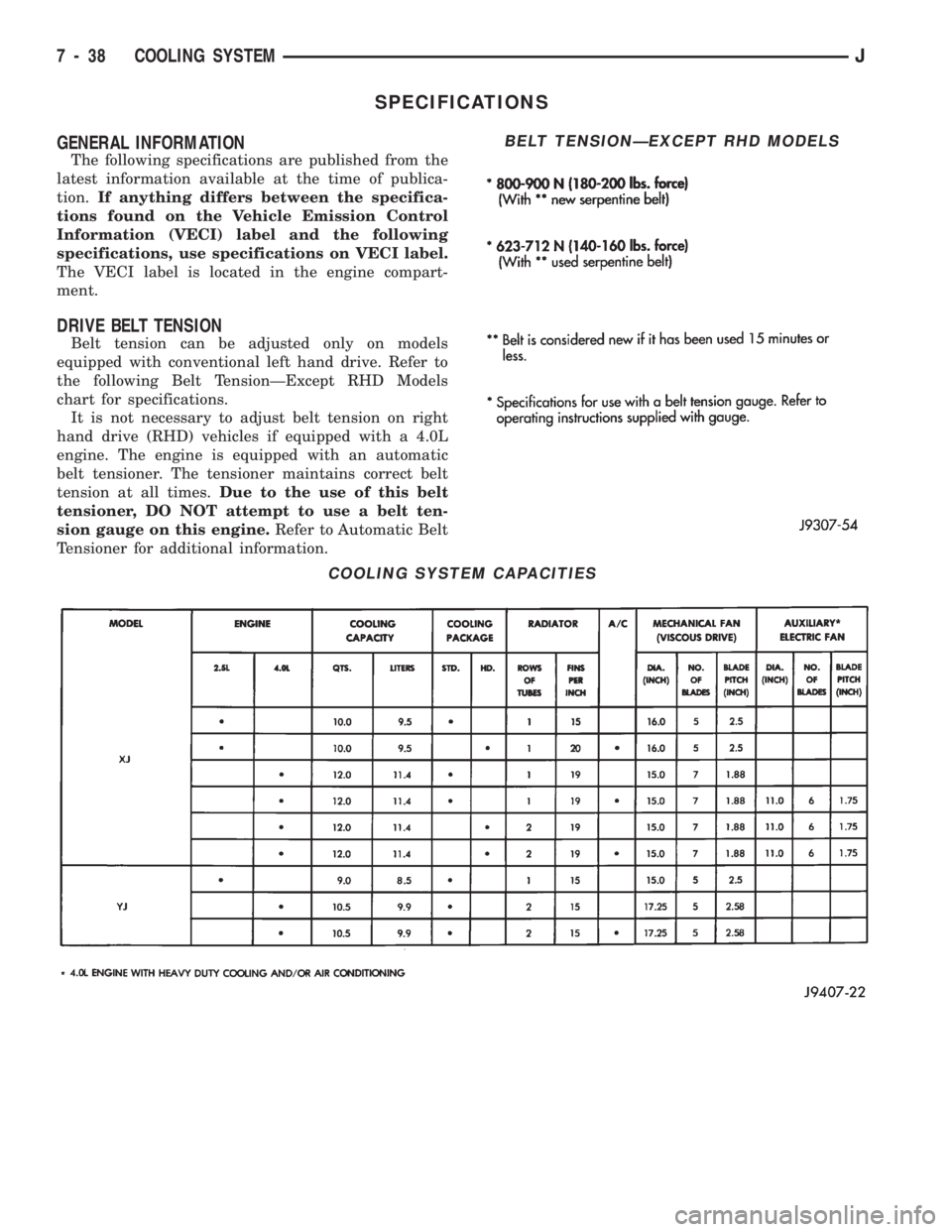

COOLING SYSTEM CAPACITIES

BELT TENSIONÐEXCEPT RHD MODELS

7 - 38 COOLING SYSTEMJ

Page 272 of 1784

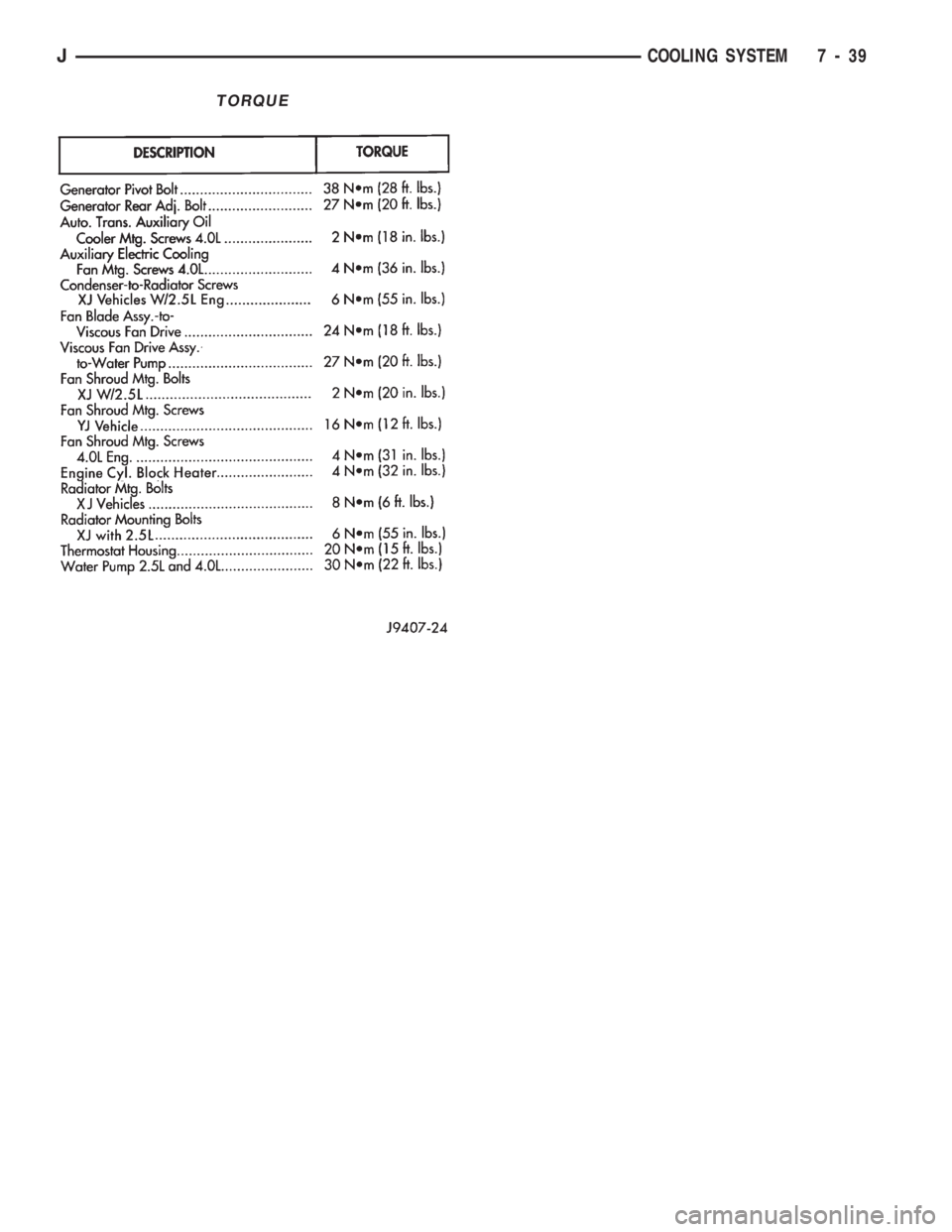

TORQUE

JCOOLING SYSTEM 7 - 39

Page 302 of 1784

CAUTION: Never force a belt over a pulley rim us-

ing a screwdriver as the synthetic fiber may be

damaged.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

engine may overheat because the water pump will

be rotating in the wrong direction if the belt is in-

stalled incorrectly. Refer to the belt routing label in

engine compartment, or see Group 7 - Belt Sche-

matics.

(10) Place serpentine belt over pulley.

(11) Belt tension adjustment is made at power

steering pump (Fig. 6).

(12) Turn adjusting bolt until belt has correct ten-

sion. See Belt Tension in Specifications.

(13) Tighten rear mounting bolts, pivot bolt, and

lock nut to 27 Nzm (20 ft. lbs.) torque.

(14) Remove support and lower vehicle.

(15) Connect negative cable to battery.

GENERATOR REPLACEMENTÐRIGHT HAND DRIVE

The generator used on the right hand drive is the

same as used on left hand drive. However, the

mounting and accessory drive belt installation are

different.

WARNING: FAILURE TO DISCONNECT NEGATIVE

CABLE FROM BATTERY BEFORE DISCONNECTING

RED (OUTPUT) WIRE CONNECTOR FROM GENER-

ATOR CAN RESULT IN INJURY.

(1) Remove negative cable from battery.

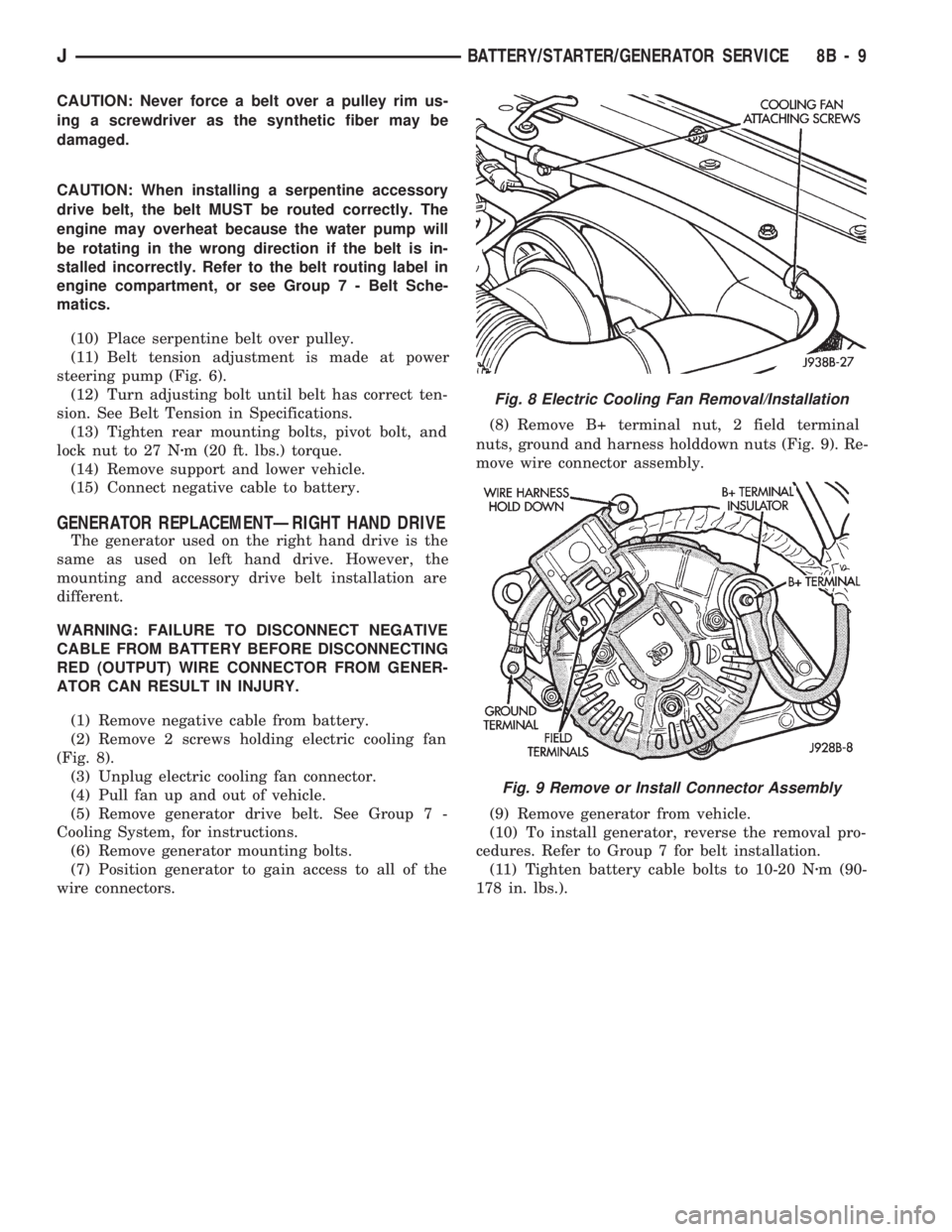

(2) Remove 2 screws holding electric cooling fan

(Fig. 8).

(3) Unplug electric cooling fan connector.

(4) Pull fan up and out of vehicle.

(5) Remove generator drive belt. See Group 7 -

Cooling System, for instructions.

(6) Remove generator mounting bolts.

(7) Position generator to gain access to all of the

wire connectors.(8) Remove B+ terminal nut, 2 field terminal

nuts, ground and harness holddown nuts (Fig. 9). Re-

move wire connector assembly.

(9) Remove generator from vehicle.

(10) To install generator, reverse the removal pro-

cedures. Refer to Group 7 for belt installation.

(11) Tighten battery cable bolts to 10-20 Nzm (90-

178 in. lbs.).

Fig. 8 Electric Cooling Fan Removal/Installation

Fig. 9 Remove or Install Connector Assembly

JBATTERY/STARTER/GENERATOR SERVICE 8B - 9

Page 330 of 1784

plugs with scavenger deposits can be considered nor-

mal in condition and can be cleaned using standard

procedures.

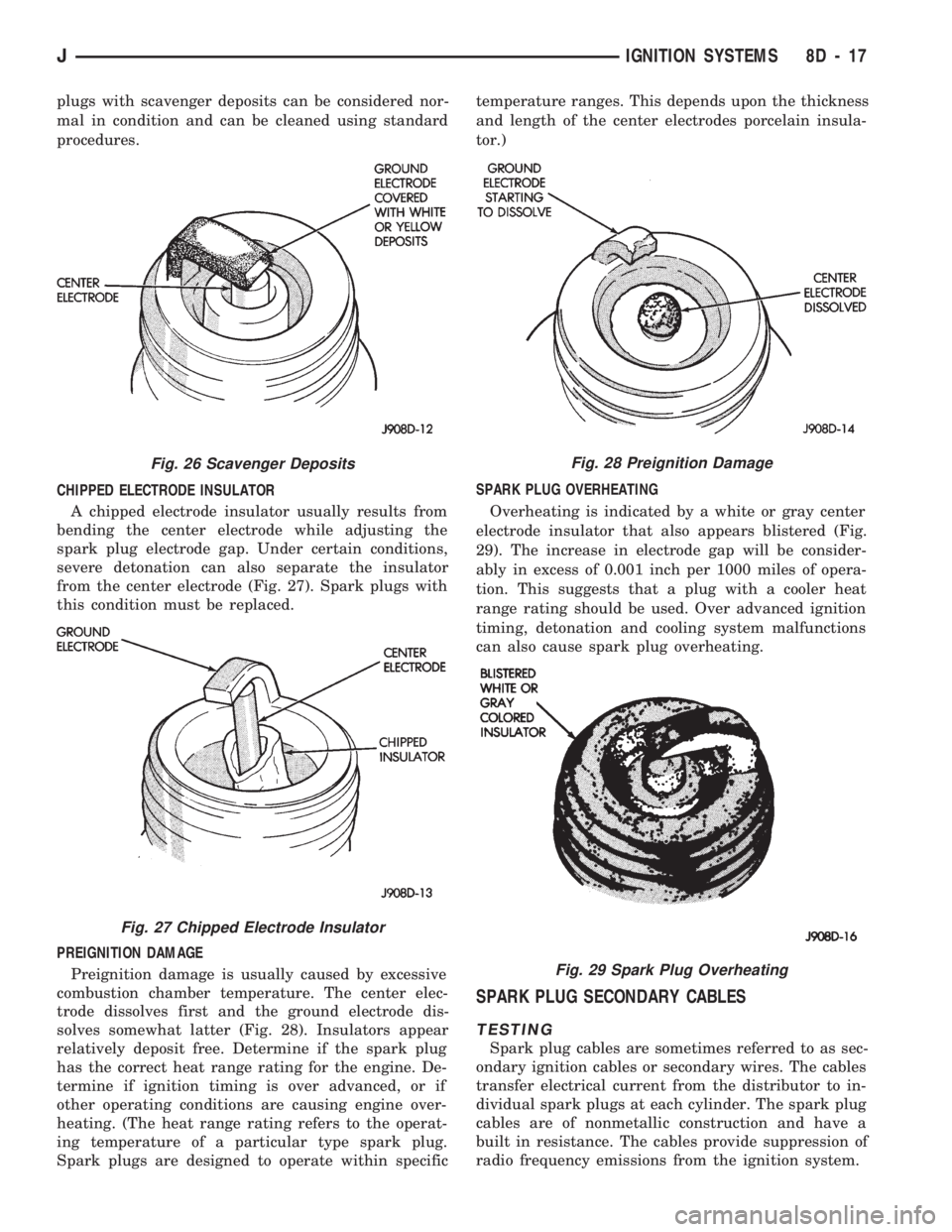

CHIPPED ELECTRODE INSULATOR

A chipped electrode insulator usually results from

bending the center electrode while adjusting the

spark plug electrode gap. Under certain conditions,

severe detonation can also separate the insulator

from the center electrode (Fig. 27). Spark plugs with

this condition must be replaced.

PREIGNITION DAMAGE

Preignition damage is usually caused by excessive

combustion chamber temperature. The center elec-

trode dissolves first and the ground electrode dis-

solves somewhat latter (Fig. 28). Insulators appear

relatively deposit free. Determine if the spark plug

has the correct heat range rating for the engine. De-

termine if ignition timing is over advanced, or if

other operating conditions are causing engine over-

heating. (The heat range rating refers to the operat-

ing temperature of a particular type spark plug.

Spark plugs are designed to operate within specifictemperature ranges. This depends upon the thickness

and length of the center electrodes porcelain insula-

tor.)

SPARK PLUG OVERHEATING

Overheating is indicated by a white or gray center

electrode insulator that also appears blistered (Fig.

29). The increase in electrode gap will be consider-

ably in excess of 0.001 inch per 1000 miles of opera-

tion. This suggests that a plug with a cooler heat

range rating should be used. Over advanced ignition

timing, detonation and cooling system malfunctions

can also cause spark plug overheating.

SPARK PLUG SECONDARY CABLES

TESTING

Spark plug cables are sometimes referred to as sec-

ondary ignition cables or secondary wires. The cables

transfer electrical current from the distributor to in-

dividual spark plugs at each cylinder. The spark plug

cables are of nonmetallic construction and have a

built in resistance. The cables provide suppression of

radio frequency emissions from the ignition system.

Fig. 26 Scavenger Deposits

Fig. 27 Chipped Electrode Insulator

Fig. 28 Preignition Damage

Fig. 29 Spark Plug Overheating

JIGNITION SYSTEMS 8D - 17

Page 335 of 1784

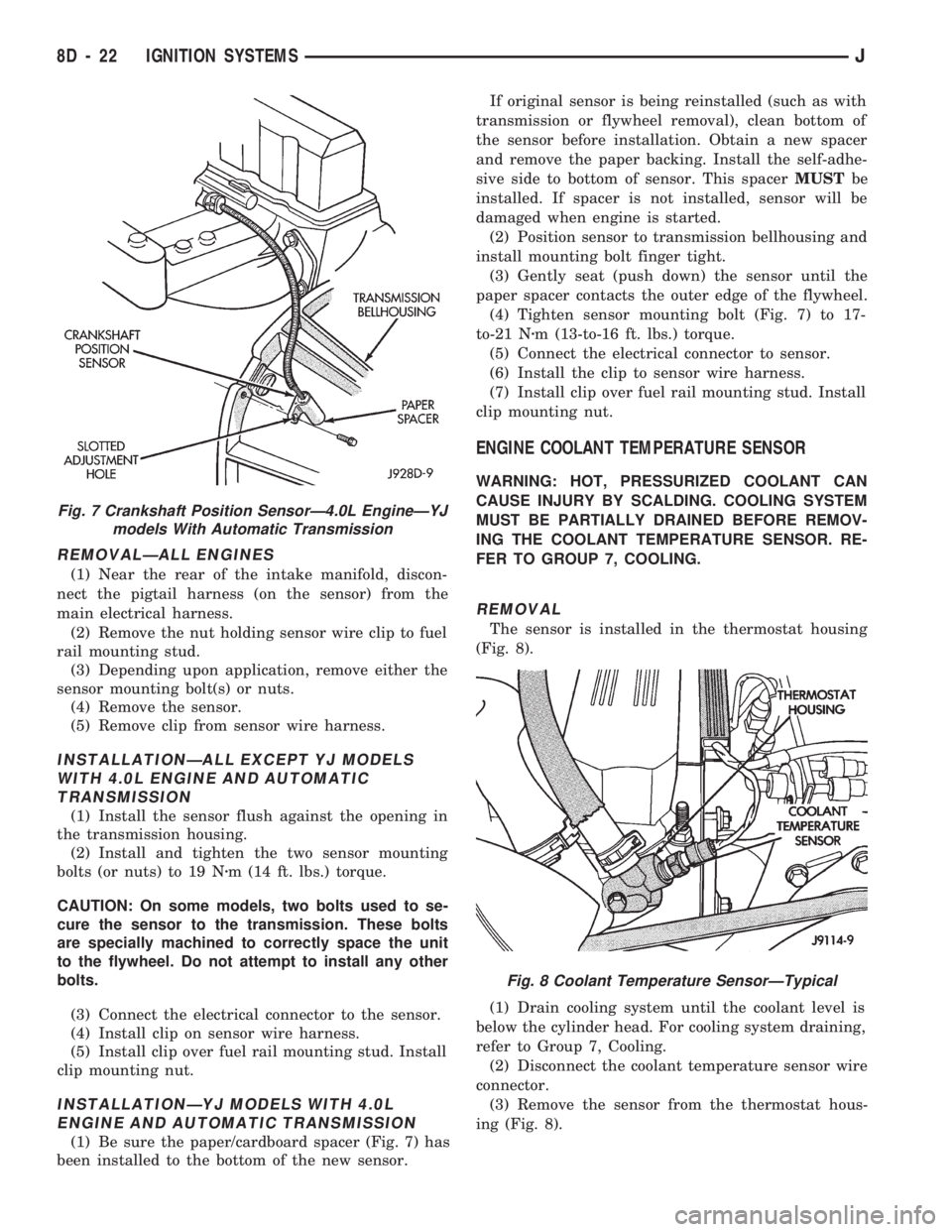

REMOVALÐALL ENGINES

(1) Near the rear of the intake manifold, discon-

nect the pigtail harness (on the sensor) from the

main electrical harness.

(2) Remove the nut holding sensor wire clip to fuel

rail mounting stud.

(3) Depending upon application, remove either the

sensor mounting bolt(s) or nuts.

(4) Remove the sensor.

(5) Remove clip from sensor wire harness.

INSTALLATIONÐALL EXCEPT YJ MODELS

WITH 4.0L ENGINE AND AUTOMATIC

TRANSMISSION

(1) Install the sensor flush against the opening in

the transmission housing.

(2) Install and tighten the two sensor mounting

bolts (or nuts) to 19 Nzm (14 ft. lbs.) torque.

CAUTION: On some models, two bolts used to se-

cure the sensor to the transmission. These bolts

are specially machined to correctly space the unit

to the flywheel. Do not attempt to install any other

bolts.

(3) Connect the electrical connector to the sensor.

(4) Install clip on sensor wire harness.

(5) Install clip over fuel rail mounting stud. Install

clip mounting nut.

INSTALLATIONÐYJ MODELS WITH 4.0L

ENGINE AND AUTOMATIC TRANSMISSION

(1) Be sure the paper/cardboard spacer (Fig. 7) has

been installed to the bottom of the new sensor.If original sensor is being reinstalled (such as with

transmission or flywheel removal), clean bottom of

the sensor before installation. Obtain a new spacer

and remove the paper backing. Install the self-adhe-

sive side to bottom of sensor. This spacerMUSTbe

installed. If spacer is not installed, sensor will be

damaged when engine is started.

(2) Position sensor to transmission bellhousing and

install mounting bolt finger tight.

(3) Gently seat (push down) the sensor until the

paper spacer contacts the outer edge of the flywheel.

(4) Tighten sensor mounting bolt (Fig. 7) to 17-

to-21 Nzm (13-to-16 ft. lbs.) torque.

(5) Connect the electrical connector to sensor.

(6) Install the clip to sensor wire harness.

(7) Install clip over fuel rail mounting stud. Install

clip mounting nut.

ENGINE COOLANT TEMPERATURE SENSOR

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE COOLANT TEMPERATURE SENSOR. RE-

FER TO GROUP 7, COOLING.

REMOVAL

The sensor is installed in the thermostat housing

(Fig. 8).

(1) Drain cooling system until the coolant level is

below the cylinder head. For cooling system draining,

refer to Group 7, Cooling.

(2) Disconnect the coolant temperature sensor wire

connector.

(3) Remove the sensor from the thermostat hous-

ing (Fig. 8).

Fig. 7 Crankshaft Position SensorÐ4.0L EngineÐYJ

models With Automatic Transmission

Fig. 8 Coolant Temperature SensorÐTypical

8D - 22 IGNITION SYSTEMSJ