sensor JEEP CHEROKEE 1994 Service Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 196 of 1784

Clean the reservoir and caps thoroughly before

checking level or adding fluid. Cap open lines and

hoses during service to prevent dirt entry.

Dirt or foreign material entering the ABS hydrau-

lic system through the reservoir opening will circu-

late within the system. The result will be poor brake

performance and possible component failure. Use

clean, fresh fluid only to top off, or refill the system.

WHEEL SENSOR AIR GAP ADJUSTMENT

Only rear sensor air gap is adjustable. The front

sensors are fixed and cannot be adjusted.

A rear sensor air gap adjustment is only

needed when reinstalling an original sensor. Re-

placement sensors have an air gap spacer at-

tached to the sensor pickup face. The spacer

establishes correct air gap when pressed against

the tone ring during installation. As the tone

ring rotates, it peels the spacer off the sensor to

create the required air gap.

Preferred rear sensor air gap is 1.1 mm (0.043 in.).

Acceptable air gap range is 0.92 to 1.275 mm (0.036

to 0.050 in.).

Front sensor air gap is not adjustable. The front

sensors are fixed in position and cannot be adjusted.

Front sensor air gap can only be checked. Air gap

should be 0.040 to 1.3 mm (0.0157 to 0.051 in.). If

front sensor air gap is incorrect, the sensor is either

loose, or damaged.

FRONT WHEEL SENSOR REMOVAL

(1) Raise vehicle and turn wheel outward for eas-

ier access to sensor.

(2) Remove sensor wire from mounting brackets.

(3) Clean sensor and surrounding area before removal.

(4) Remove bolt attaching sensor to steering

knuckle and remove sensor.

(5) Unseat grommet retaining sensor wire in wheel

house panel.

(6) In engine compartment, disconnect sensor wire con-

nector at harness plug. Then remove sensor and wire.

FRONT WHEEL SENSOR INSTALLATION

(1) Apply Mopar Lock N' Seal or Loctite 242 to

bolt that attaches sensor to steering knuckle. Use

new sensor bolt if original bolt is worn or damaged.

(2) Position sensor on steering knuckle. Seat sen-

sor locating tab in hole in knuckle and install sensor

attaching bolt finger tight.

(3) Tighten sensor bolt to 14 NIm (11 ft. lbs.) torque.

(4) Attach sensor wire to steering knuckle bracket

with grommets on sensor wire.

(5) Route sensor wire forward and behind shock

absorber. Then attach sensor wire to spring seat

bracket with grommets on sensor wire.

(6) Route sensor wire to outer sill bracket. Remove

all twists or kinks from wire.(7) Attach sensor wire to sill bracket with grom-

met. Be sure wire is free of twists and kinks.

(8) Verify sensor wire routing. Wire should loop

forward and above sill bracket. Loose end of wire

should be below sill bracket and towards brake hose.

(9) Seat sensor wire grommet in body panel and

clip wire to brake line at grommet location.

(10) Connect sensor wire to harness in engine com-

partment.

REAR WHEEL SENSOR REMOVAL

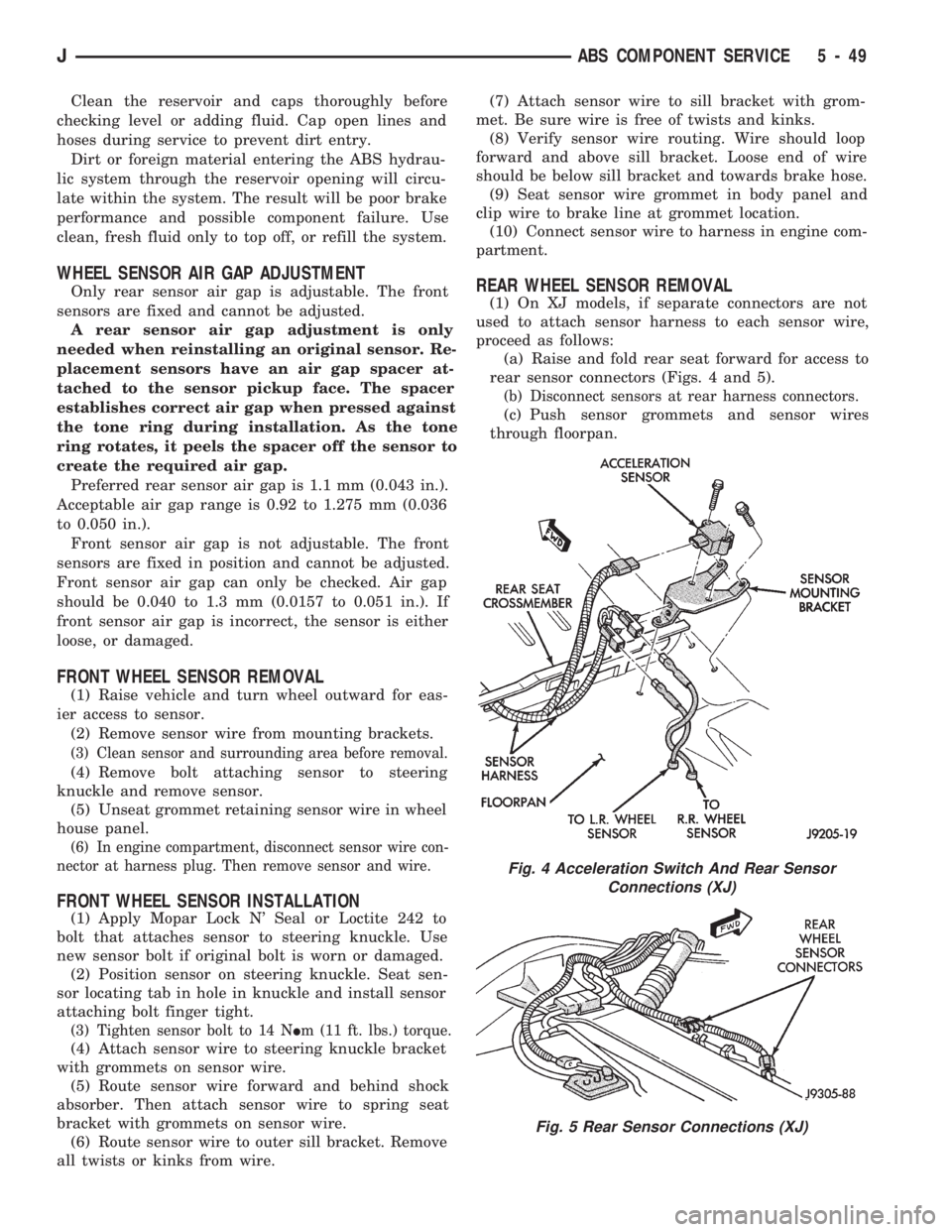

(1) On XJ models, if separate connectors are not

used to attach sensor harness to each sensor wire,

proceed as follows:

(a) Raise and fold rear seat forward for access to

rear sensor connectors (Figs. 4 and 5).

(b) Disconnect sensors at rear harness connectors.

(c) Push sensor grommets and sensor wires

through floorpan.

Fig. 4 Acceleration Switch And Rear Sensor

Connections (XJ)

Fig. 5 Rear Sensor Connections (XJ)

JABS COMPONENT SERVICE 5 - 49

Page 197 of 1784

(2) Raise vehicle.

(3) Disconnect sensor wires at rear axle connectors.

(4) Remove wheel and tire assembly.

(5) Remove brake drum.

(6) Remove clips securing sensor wires to brake

lines or rear axle and rear brake hose.

(7) Unseat sensor support plate grommet.

(8) Remove bolt attaching sensor to bracket and

remove sensor.

REAR WHEEL SENSOR INSTALLATION

(1) Insert sensor wire through support plate hole

and seat sensor grommet in support plate.

(2) Apply Mopar Lock N' Seal or Loctite 242 to

original sensor bolt. Use new bolt if original is worn

or damaged.

(3) Install sensor bolt finger tight only at this

time.

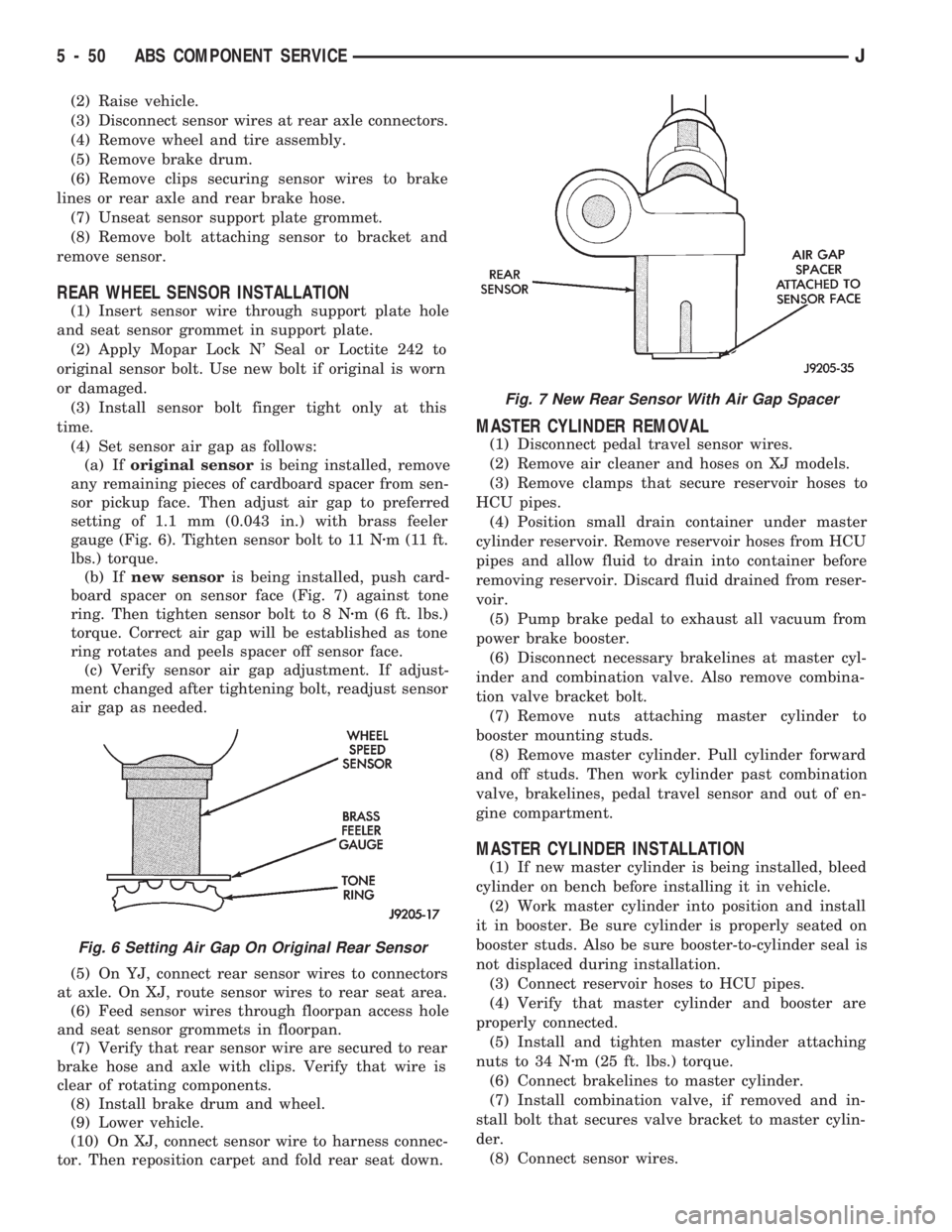

(4) Set sensor air gap as follows:

(a) Iforiginal sensoris being installed, remove

any remaining pieces of cardboard spacer from sen-

sor pickup face. Then adjust air gap to preferred

setting of 1.1 mm (0.043 in.) with brass feeler

gauge (Fig. 6). Tighten sensor bolt to 11 Nzm (11 ft.

lbs.) torque.

(b) Ifnew sensoris being installed, push card-

board spacer on sensor face (Fig. 7) against tone

ring. Then tighten sensor bolt to 8 Nzm (6 ft. lbs.)

torque. Correct air gap will be established as tone

ring rotates and peels spacer off sensor face.

(c) Verify sensor air gap adjustment. If adjust-

ment changed after tightening bolt, readjust sensor

air gap as needed.

(5) On YJ, connect rear sensor wires to connectors

at axle. On XJ, route sensor wires to rear seat area.

(6) Feed sensor wires through floorpan access hole

and seat sensor grommets in floorpan.

(7) Verify that rear sensor wire are secured to rear

brake hose and axle with clips. Verify that wire is

clear of rotating components.

(8) Install brake drum and wheel.

(9) Lower vehicle.

(10) On XJ, connect sensor wire to harness connec-

tor. Then reposition carpet and fold rear seat down.

MASTER CYLINDER REMOVAL

(1) Disconnect pedal travel sensor wires.

(2) Remove air cleaner and hoses on XJ models.

(3) Remove clamps that secure reservoir hoses to

HCU pipes.

(4) Position small drain container under master

cylinder reservoir. Remove reservoir hoses from HCU

pipes and allow fluid to drain into container before

removing reservoir. Discard fluid drained from reser-

voir.

(5) Pump brake pedal to exhaust all vacuum from

power brake booster.

(6) Disconnect necessary brakelines at master cyl-

inder and combination valve. Also remove combina-

tion valve bracket bolt.

(7) Remove nuts attaching master cylinder to

booster mounting studs.

(8) Remove master cylinder. Pull cylinder forward

and off studs. Then work cylinder past combination

valve, brakelines, pedal travel sensor and out of en-

gine compartment.

MASTER CYLINDER INSTALLATION

(1) If new master cylinder is being installed, bleed

cylinder on bench before installing it in vehicle.

(2) Work master cylinder into position and install

it in booster. Be sure cylinder is properly seated on

booster studs. Also be sure booster-to-cylinder seal is

not displaced during installation.

(3) Connect reservoir hoses to HCU pipes.

(4) Verify that master cylinder and booster are

properly connected.

(5) Install and tighten master cylinder attaching

nuts to 34 Nzm (25 ft. lbs.) torque.

(6) Connect brakelines to master cylinder.

(7) Install combination valve, if removed and in-

stall bolt that secures valve bracket to master cylin-

der.

(8) Connect sensor wires.

Fig. 6 Setting Air Gap On Original Rear Sensor

Fig. 7 New Rear Sensor With Air Gap Spacer

5 - 50 ABS COMPONENT SERVICEJ

Page 198 of 1784

(9) Fill reservoir and bleed brakes. Refer to proce-

dure in this section.

(10) Install air cleaner and hoses.

PEDAL TRAVEL SENSOR SERVICE

CAUTION: The pedal travel sensor and booster

must form a matched set. The cap on the sensor

plunger and booster shell are color coded for iden-

tification, and to ensure they are used as matched

sets. Be sure the color of the sensor cap and the

color dot on the booster shell are the same before

installation. Refer to the Sensor Replacement infor-

mation before installing a new or original sensor.

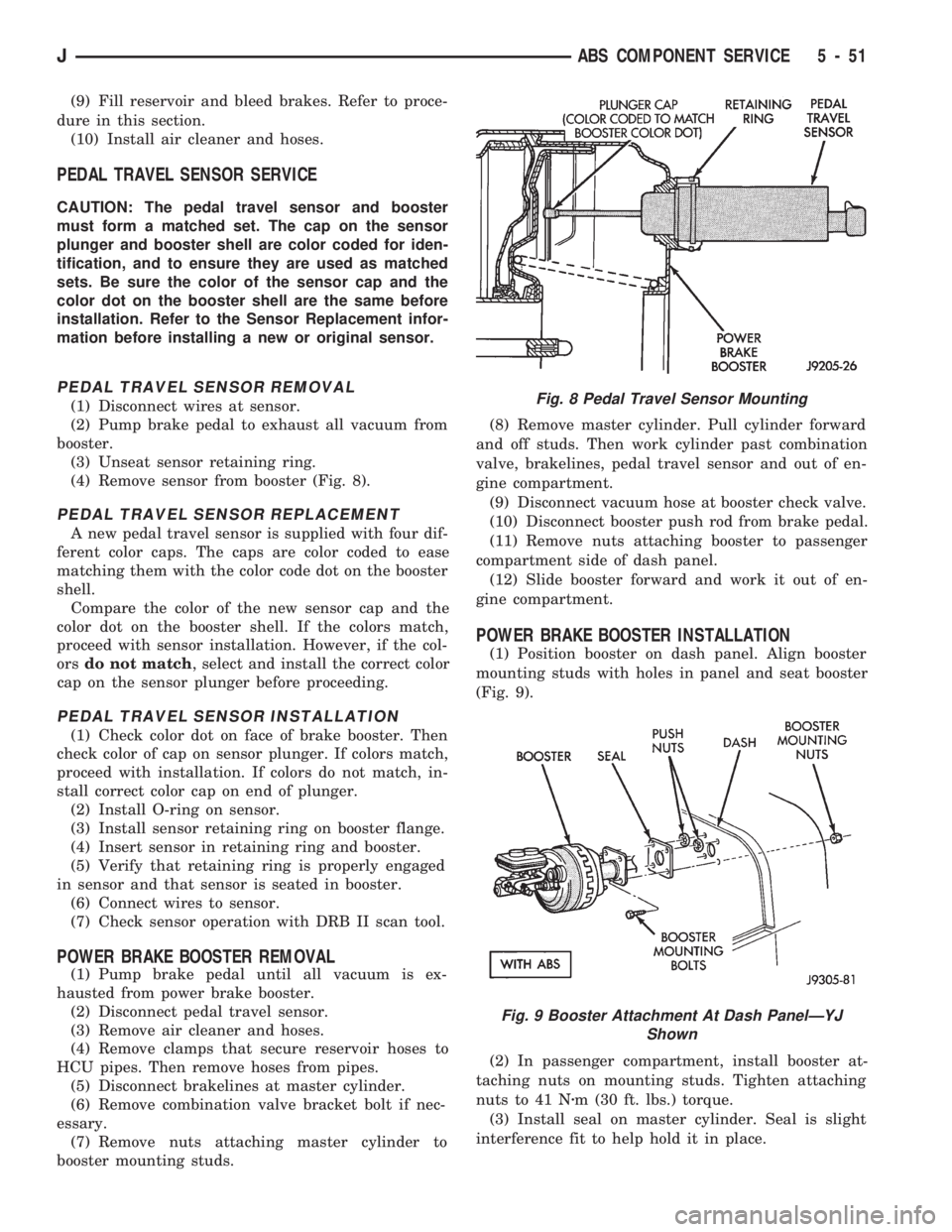

PEDAL TRAVEL SENSOR REMOVAL

(1) Disconnect wires at sensor.

(2) Pump brake pedal to exhaust all vacuum from

booster.

(3) Unseat sensor retaining ring.

(4) Remove sensor from booster (Fig. 8).

PEDAL TRAVEL SENSOR REPLACEMENT

A new pedal travel sensor is supplied with four dif-

ferent color caps. The caps are color coded to ease

matching them with the color code dot on the booster

shell.

Compare the color of the new sensor cap and the

color dot on the booster shell. If the colors match,

proceed with sensor installation. However, if the col-

orsdo not match, select and install the correct color

cap on the sensor plunger before proceeding.

PEDAL TRAVEL SENSOR INSTALLATION

(1) Check color dot on face of brake booster. Then

check color of cap on sensor plunger. If colors match,

proceed with installation. If colors do not match, in-

stall correct color cap on end of plunger.

(2) Install O-ring on sensor.

(3) Install sensor retaining ring on booster flange.

(4) Insert sensor in retaining ring and booster.

(5) Verify that retaining ring is properly engaged

in sensor and that sensor is seated in booster.

(6) Connect wires to sensor.

(7) Check sensor operation with DRB II scan tool.

POWER BRAKE BOOSTER REMOVAL

(1) Pump brake pedal until all vacuum is ex-

hausted from power brake booster.

(2) Disconnect pedal travel sensor.

(3) Remove air cleaner and hoses.

(4) Remove clamps that secure reservoir hoses to

HCU pipes. Then remove hoses from pipes.

(5) Disconnect brakelines at master cylinder.

(6) Remove combination valve bracket bolt if nec-

essary.

(7) Remove nuts attaching master cylinder to

booster mounting studs.(8) Remove master cylinder. Pull cylinder forward

and off studs. Then work cylinder past combination

valve, brakelines, pedal travel sensor and out of en-

gine compartment.

(9) Disconnect vacuum hose at booster check valve.

(10) Disconnect booster push rod from brake pedal.

(11) Remove nuts attaching booster to passenger

compartment side of dash panel.

(12) Slide booster forward and work it out of en-

gine compartment.

POWER BRAKE BOOSTER INSTALLATION

(1) Position booster on dash panel. Align booster

mounting studs with holes in panel and seat booster

(Fig. 9).

(2) In passenger compartment, install booster at-

taching nuts on mounting studs. Tighten attaching

nuts to 41 Nzm (30 ft. lbs.) torque.

(3) Install seal on master cylinder. Seal is slight

interference fit to help hold it in place.

Fig. 8 Pedal Travel Sensor Mounting

Fig. 9 Booster Attachment At Dash PanelÐYJ

Shown

JABS COMPONENT SERVICE 5 - 51

Page 199 of 1784

CAUTION: The pedal travel sensor and booster

must form a matched set. The cap on the sensor

plunger and the color dot on the booster shell are

color coded for identification, and to ensure they

are used as matched sets. Be sure the color on the

sensor cap and booster shell are the same before

installation. Refer to the Sensor Replacement infor-

mation before installing a new or original sensor.

(4) If new pedal travel sensor is being installed in

original booster, compare color dot on booster shell with

color of cap on sensor (Fig. 10). If both are same color,

proceed with installation. However, if colorsdo not

match, select correct color cap from kit supplied with

new sensor and install it on end of sensor plunger.

(5) Install O-ring on pedal travel sensor.

(6) Install sensor retaining ring on booster flange.

Be sure retaining ring is firmly seated.

(7) Insert sensor into booster. Be sure sensor is

fully seated and engaged in retaining ring.

(8) Connect booster push rod to brake pedal.

(9) Attach vacuum hose to booster check valve.

(10) Install master cylinder on booster. Tighten

cylinder attaching nuts to 25-30 Nzm (220-267 in.

lbs.) torque.

(11) Connect brakelines to master cylinder.

(12) Install combination valve bracket bolt if re-

moved.

(13) Connect reservoir hoses to HCU pipes.

(14) Connect sensor wires.

(15) Bleed brakes. Refer to procedure in this section.

(16) Install air cleaner and hoses.

ACCELERATION SENSOR REMOVAL

(1) On XJ models, tilt rear seat assembly forward

for access to sensor (Fig. 11).

(2) On YJ models, move driver seat forward or

rearward for access to sensor and mounting bracket

(Fig. 11).

(3) Disconnect sensor harness (Fig. 10).

(4) On XJ models, remove screws attaching sensor

to bracket. Then remove sensor.

(5) On YJ models, remove screws attaching sensor

bracket to floorpan. Then remove sensor from bracket.

ACCELERATION SENSOR INSTALLATION

(1) Note position of locating arrow on sensor. Sen-

sor must be positioned so arrow faces forward.

CAUTION: The sensor mercury switch will not func-

tion properly if the sensor is mispositioned. Verify

that the sensor locating arrow is pointing to the

front of the vehicle.

(2) Position sensor in mounting bracket (Fig. 10).

(3) Install and tighten sensor attaching screws to

2-4 Nzm (17-32 in. lbs.) torque.

(4) Connect harness to sensor. Be sure harness

connecter is firmly seated.

(5) Move seat back to normal position.

Fig. 10 Booster Push Rod And Pedal Travel Sensor

Fig. 11 Acceleration Sensor Mounting

5 - 52 ABS COMPONENT SERVICEJ

Page 201 of 1784

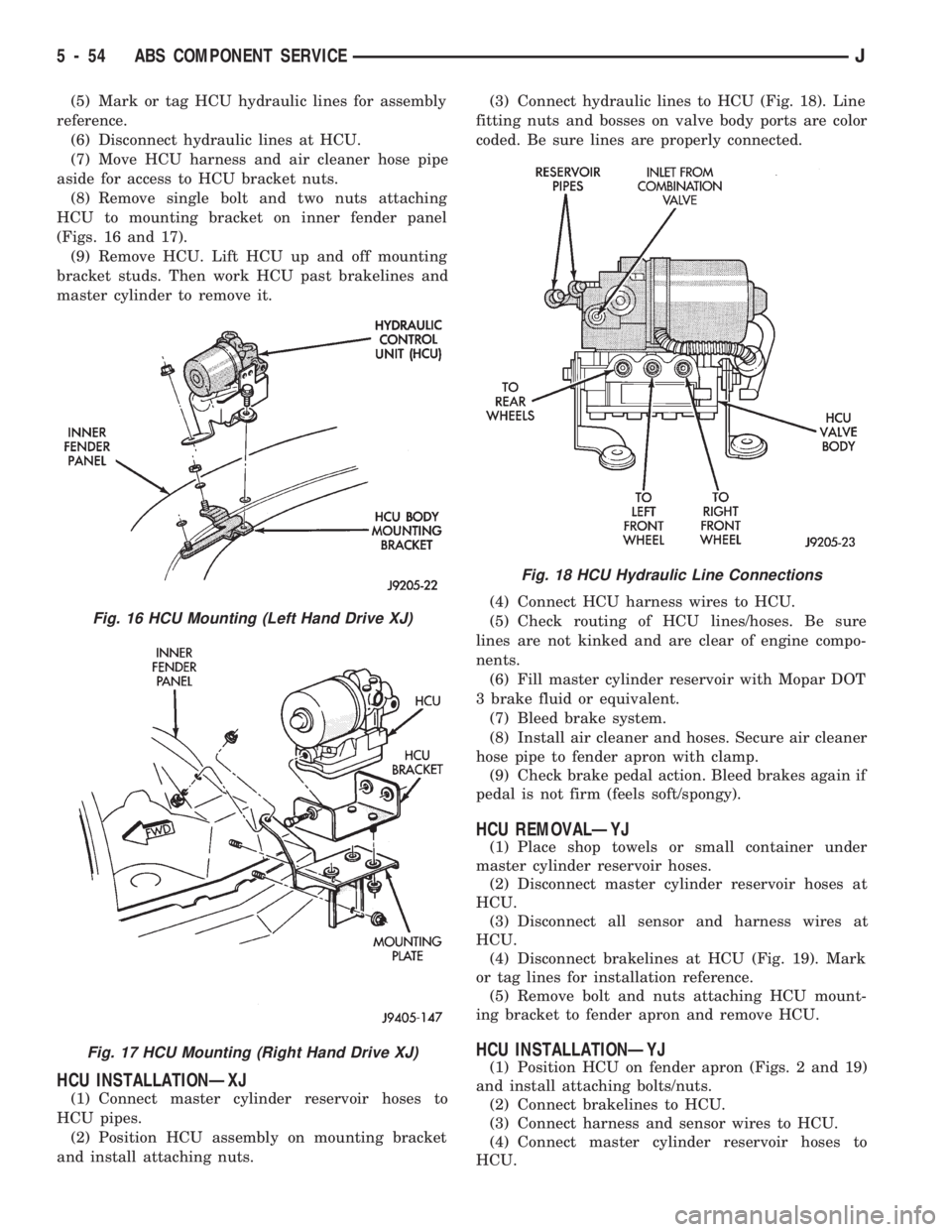

(5) Mark or tag HCU hydraulic lines for assembly

reference.

(6) Disconnect hydraulic lines at HCU.

(7) Move HCU harness and air cleaner hose pipe

aside for access to HCU bracket nuts.

(8) Remove single bolt and two nuts attaching

HCU to mounting bracket on inner fender panel

(Figs. 16 and 17).

(9) Remove HCU. Lift HCU up and off mounting

bracket studs. Then work HCU past brakelines and

master cylinder to remove it.

HCU INSTALLATIONÐXJ

(1) Connect master cylinder reservoir hoses to

HCU pipes.

(2) Position HCU assembly on mounting bracket

and install attaching nuts.(3) Connect hydraulic lines to HCU (Fig. 18). Line

fitting nuts and bosses on valve body ports are color

coded. Be sure lines are properly connected.

(4) Connect HCU harness wires to HCU.

(5) Check routing of HCU lines/hoses. Be sure

lines are not kinked and are clear of engine compo-

nents.

(6) Fill master cylinder reservoir with Mopar DOT

3 brake fluid or equivalent.

(7) Bleed brake system.

(8) Install air cleaner and hoses. Secure air cleaner

hose pipe to fender apron with clamp.

(9) Check brake pedal action. Bleed brakes again if

pedal is not firm (feels soft/spongy).

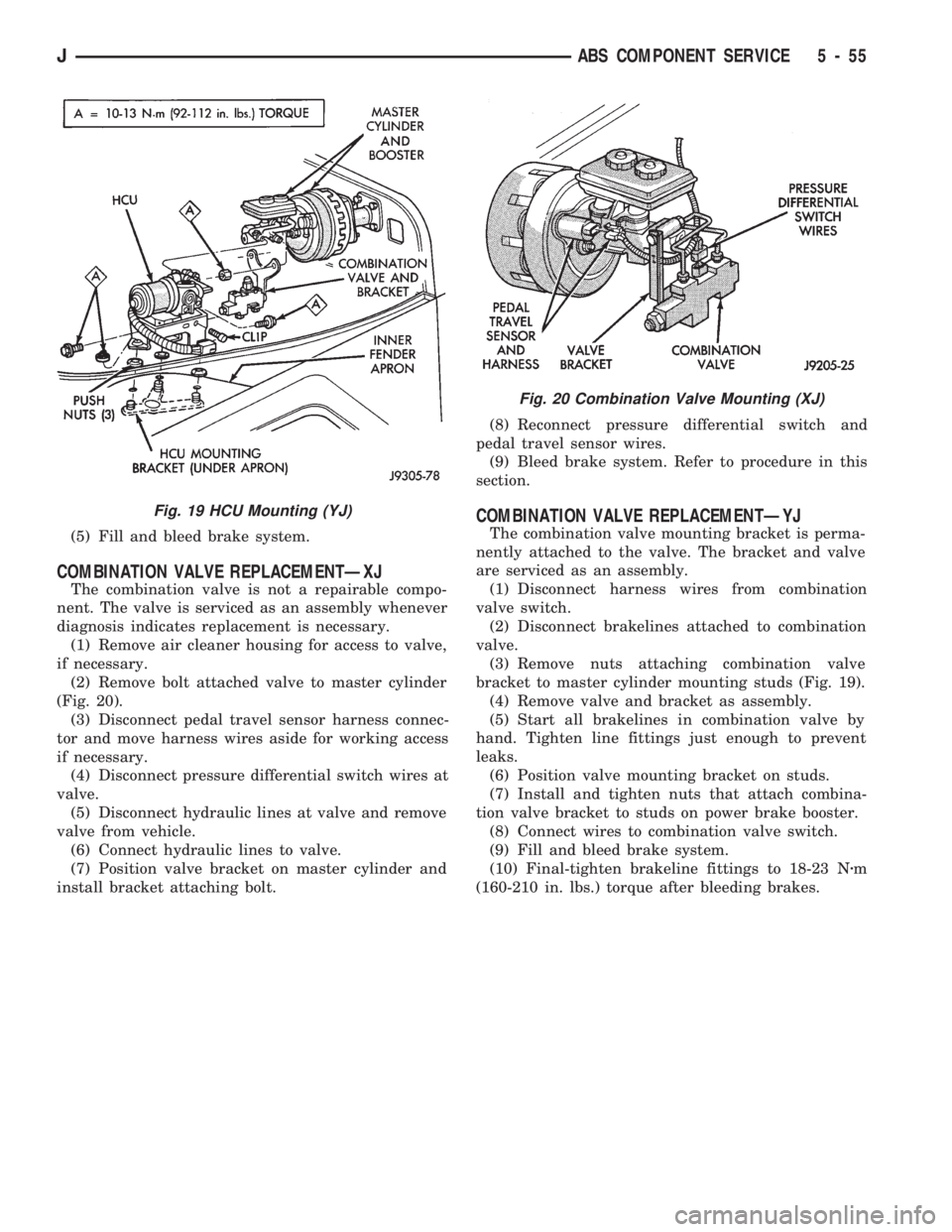

HCU REMOVALÐYJ

(1) Place shop towels or small container under

master cylinder reservoir hoses.

(2) Disconnect master cylinder reservoir hoses at

HCU.

(3) Disconnect all sensor and harness wires at

HCU.

(4) Disconnect brakelines at HCU (Fig. 19). Mark

or tag lines for installation reference.

(5) Remove bolt and nuts attaching HCU mount-

ing bracket to fender apron and remove HCU.

HCU INSTALLATIONÐYJ

(1) Position HCU on fender apron (Figs. 2 and 19)

and install attaching bolts/nuts.

(2) Connect brakelines to HCU.

(3) Connect harness and sensor wires to HCU.

(4) Connect master cylinder reservoir hoses to

HCU.

Fig. 16 HCU Mounting (Left Hand Drive XJ)

Fig. 17 HCU Mounting (Right Hand Drive XJ)

Fig. 18 HCU Hydraulic Line Connections

5 - 54 ABS COMPONENT SERVICEJ

Page 202 of 1784

(5) Fill and bleed brake system.

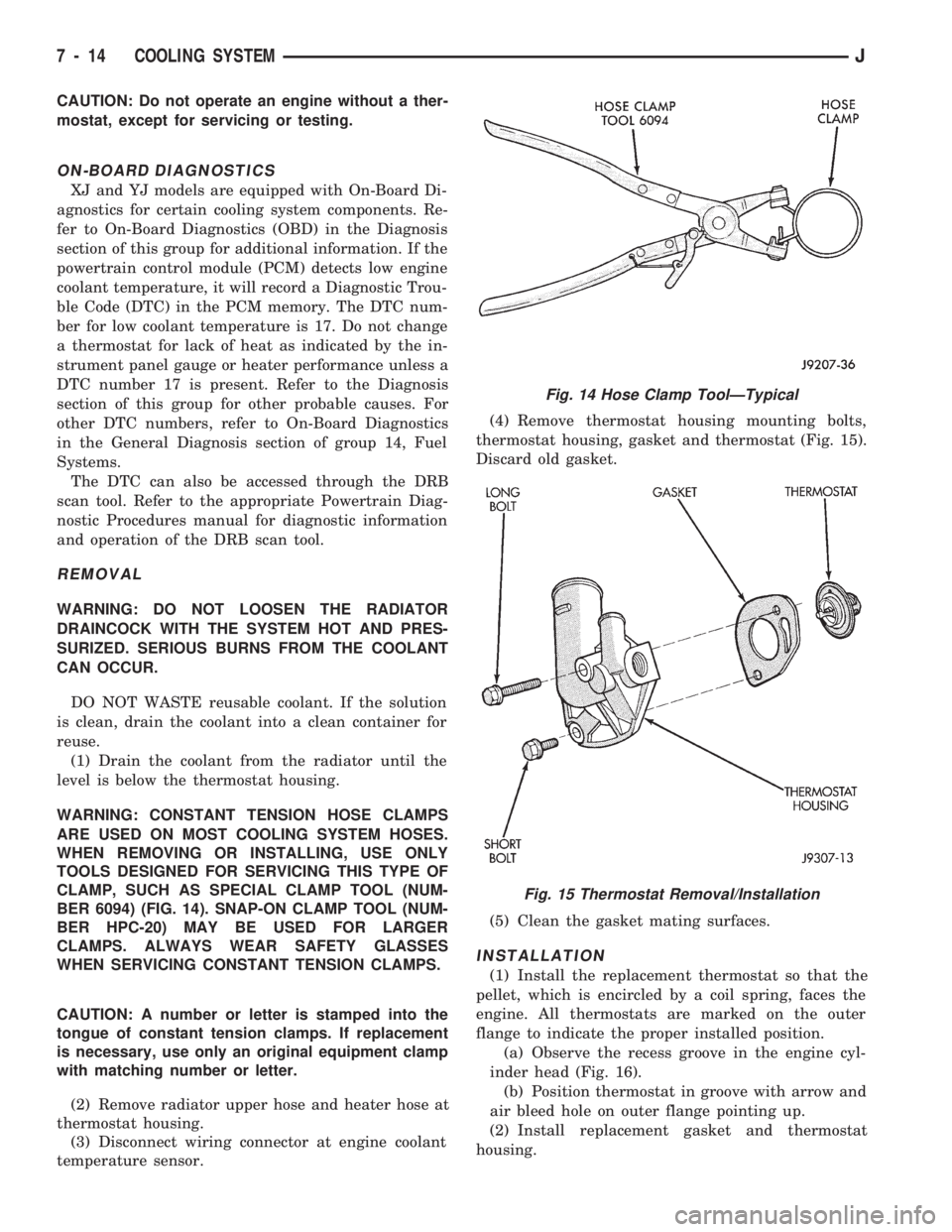

COMBINATION VALVE REPLACEMENTÐXJ

The combination valve is not a repairable compo-

nent. The valve is serviced as an assembly whenever

diagnosis indicates replacement is necessary.

(1) Remove air cleaner housing for access to valve,

if necessary.

(2) Remove bolt attached valve to master cylinder

(Fig. 20).

(3) Disconnect pedal travel sensor harness connec-

tor and move harness wires aside for working access

if necessary.

(4) Disconnect pressure differential switch wires at

valve.

(5) Disconnect hydraulic lines at valve and remove

valve from vehicle.

(6) Connect hydraulic lines to valve.

(7) Position valve bracket on master cylinder and

install bracket attaching bolt.(8) Reconnect pressure differential switch and

pedal travel sensor wires.

(9) Bleed brake system. Refer to procedure in this

section.

COMBINATION VALVE REPLACEMENTÐYJ

The combination valve mounting bracket is perma-

nently attached to the valve. The bracket and valve

are serviced as an assembly.

(1) Disconnect harness wires from combination

valve switch.

(2) Disconnect brakelines attached to combination

valve.

(3) Remove nuts attaching combination valve

bracket to master cylinder mounting studs (Fig. 19).

(4) Remove valve and bracket as assembly.

(5) Start all brakelines in combination valve by

hand. Tighten line fittings just enough to prevent

leaks.

(6) Position valve mounting bracket on studs.

(7) Install and tighten nuts that attach combina-

tion valve bracket to studs on power brake booster.

(8) Connect wires to combination valve switch.

(9) Fill and bleed brake system.

(10) Final-tighten brakeline fittings to 18-23 Nzm

(160-210 in. lbs.) torque after bleeding brakes.

Fig. 19 HCU Mounting (YJ)

Fig. 20 Combination Valve Mounting (XJ)

JABS COMPONENT SERVICE 5 - 55

Page 247 of 1784

CAUTION: Do not operate an engine without a ther-

mostat, except for servicing or testing.

ON-BOARD DIAGNOSTICS

XJ and YJ models are equipped with On-Board Di-

agnostics for certain cooling system components. Re-

fer to On-Board Diagnostics (OBD) in the Diagnosis

section of this group for additional information. If the

powertrain control module (PCM) detects low engine

coolant temperature, it will record a Diagnostic Trou-

ble Code (DTC) in the PCM memory. The DTC num-

ber for low coolant temperature is 17. Do not change

a thermostat for lack of heat as indicated by the in-

strument panel gauge or heater performance unless a

DTC number 17 is present. Refer to the Diagnosis

section of this group for other probable causes. For

other DTC numbers, refer to On-Board Diagnostics

in the General Diagnosis section of group 14, Fuel

Systems.

The DTC can also be accessed through the DRB

scan tool. Refer to the appropriate Powertrain Diag-

nostic Procedures manual for diagnostic information

and operation of the DRB scan tool.

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND PRES-

SURIZED. SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

(1) Drain the coolant from the radiator until the

level is below the thermostat housing.

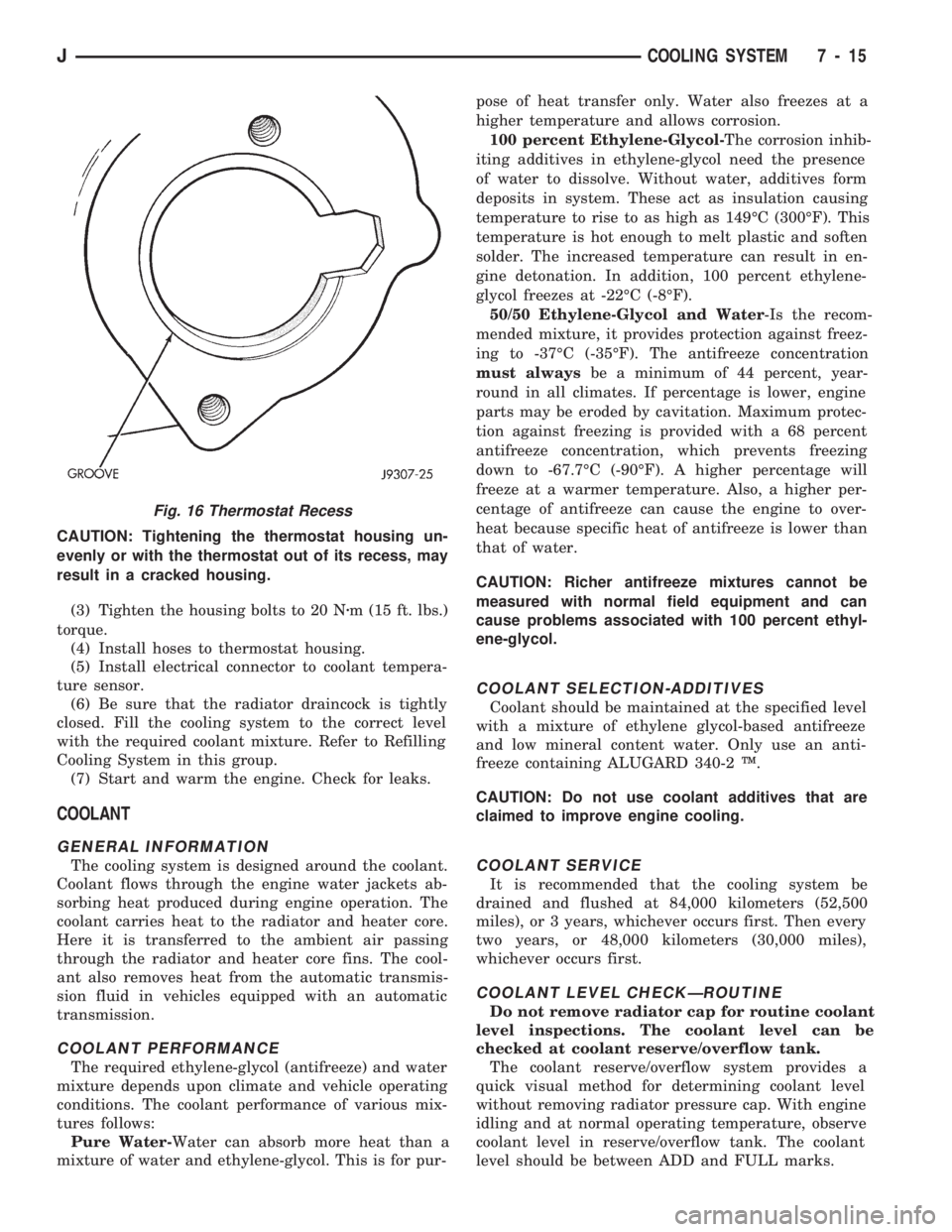

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUM-

BER 6094) (FIG. 14). SNAP-ON CLAMP TOOL (NUM-

BER HPC-20) MAY BE USED FOR LARGER

CLAMPS. ALWAYS WEAR SAFETY GLASSES

WHEN SERVICING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with matching number or letter.

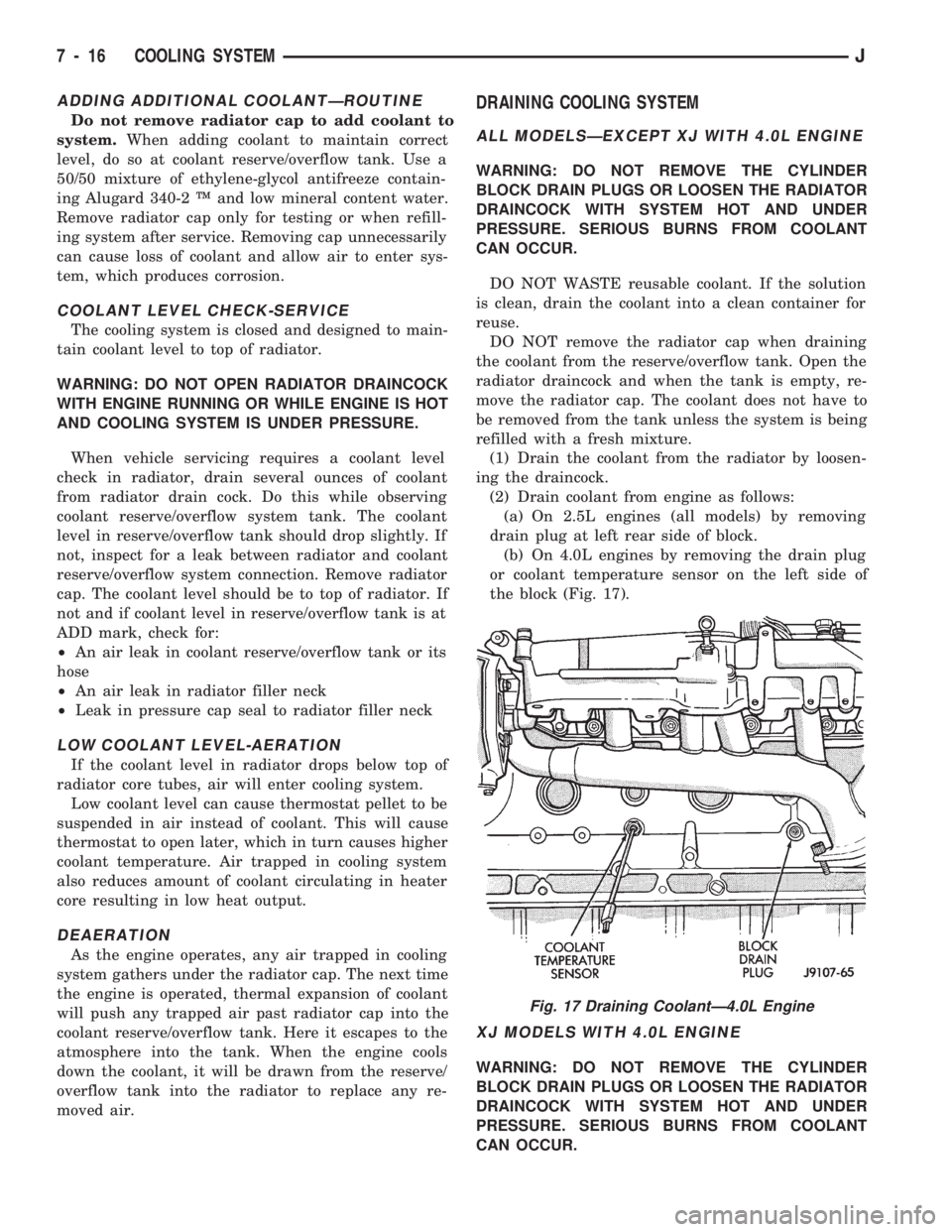

(2) Remove radiator upper hose and heater hose at

thermostat housing.

(3) Disconnect wiring connector at engine coolant

temperature sensor.(4) Remove thermostat housing mounting bolts,

thermostat housing, gasket and thermostat (Fig. 15).

Discard old gasket.

(5) Clean the gasket mating surfaces.

INSTALLATION

(1) Install the replacement thermostat so that the

pellet, which is encircled by a coil spring, faces the

engine. All thermostats are marked on the outer

flange to indicate the proper installed position.

(a) Observe the recess groove in the engine cyl-

inder head (Fig. 16).

(b) Position thermostat in groove with arrow and

air bleed hole on outer flange pointing up.

(2) Install replacement gasket and thermostat

housing.

Fig. 14 Hose Clamp ToolÐTypical

Fig. 15 Thermostat Removal/Installation

7 - 14 COOLING SYSTEMJ

Page 248 of 1784

CAUTION: Tightening the thermostat housing un-

evenly or with the thermostat out of its recess, may

result in a cracked housing.

(3) Tighten the housing bolts to 20 Nzm (15 ft. lbs.)

torque.

(4) Install hoses to thermostat housing.

(5) Install electrical connector to coolant tempera-

ture sensor.

(6) Be sure that the radiator draincock is tightly

closed. Fill the cooling system to the correct level

with the required coolant mixture. Refer to Refilling

Cooling System in this group.

(7) Start and warm the engine. Check for leaks.

COOLANT

GENERAL INFORMATION

The cooling system is designed around the coolant.

Coolant flows through the engine water jackets ab-

sorbing heat produced during engine operation. The

coolant carries heat to the radiator and heater core.

Here it is transferred to the ambient air passing

through the radiator and heater core fins. The cool-

ant also removes heat from the automatic transmis-

sion fluid in vehicles equipped with an automatic

transmission.

COOLANT PERFORMANCE

The required ethylene-glycol (antifreeze) and water

mixture depends upon climate and vehicle operating

conditions. The coolant performance of various mix-

tures follows:

Pure Water-Water can absorb more heat than a

mixture of water and ethylene-glycol. This is for pur-pose of heat transfer only. Water also freezes at a

higher temperature and allows corrosion.

100 percent Ethylene-Glycol-The corrosion inhib-

iting additives in ethylene-glycol need the presence

of water to dissolve. Without water, additives form

deposits in system. These act as insulation causing

temperature to rise to as high as 149ÉC (300ÉF). This

temperature is hot enough to melt plastic and soften

solder. The increased temperature can result in en-

gine detonation. In addition, 100 percent ethylene-

glycol freezes at -22ÉC (-8ÉF).

50/50 Ethylene-Glycol and Water-Is the recom-

mended mixture, it provides protection against freez-

ing to -37ÉC (-35ÉF). The antifreeze concentration

must alwaysbe a minimum of 44 percent, year-

round in all climates. If percentage is lower, engine

parts may be eroded by cavitation. Maximum protec-

tion against freezing is provided with a 68 percent

antifreeze concentration, which prevents freezing

down to -67.7ÉC (-90ÉF). A higher percentage will

freeze at a warmer temperature. Also, a higher per-

centage of antifreeze can cause the engine to over-

heat because specific heat of antifreeze is lower than

that of water.

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

COOLANT SELECTION-ADDITIVES

Coolant should be maintained at the specified level

with a mixture of ethylene glycol-based antifreeze

and low mineral content water. Only use an anti-

freeze containing ALUGARD 340-2 Ÿ.

CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

COOLANT SERVICE

It is recommended that the cooling system be

drained and flushed at 84,000 kilometers (52,500

miles), or 3 years, whichever occurs first. Then every

two years, or 48,000 kilometers (30,000 miles),

whichever occurs first.

COOLANT LEVEL CHECKÐROUTINE

Do not remove radiator cap for routine coolant

level inspections. The coolant level can be

checked at coolant reserve/overflow tank.

The coolant reserve/overflow system provides a

quick visual method for determining coolant level

without removing radiator pressure cap. With engine

idling and at normal operating temperature, observe

coolant level in reserve/overflow tank. The coolant

level should be between ADD and FULL marks.

Fig. 16 Thermostat Recess

JCOOLING SYSTEM 7 - 15

Page 249 of 1784

ADDING ADDITIONAL COOLANTÐROUTINE

Do not remove radiator cap to add coolant to

system.When adding coolant to maintain correct

level, do so at coolant reserve/overflow tank. Use a

50/50 mixture of ethylene-glycol antifreeze contain-

ing Alugard 340-2 Ÿ and low mineral content water.

Remove radiator cap only for testing or when refill-

ing system after service. Removing cap unnecessarily

can cause loss of coolant and allow air to enter sys-

tem, which produces corrosion.

COOLANT LEVEL CHECK-SERVICE

The cooling system is closed and designed to main-

tain coolant level to top of radiator.

WARNING: DO NOT OPEN RADIATOR DRAINCOCK

WITH ENGINE RUNNING OR WHILE ENGINE IS HOT

AND COOLING SYSTEM IS UNDER PRESSURE.

When vehicle servicing requires a coolant level

check in radiator, drain several ounces of coolant

from radiator drain cock. Do this while observing

coolant reserve/overflow system tank. The coolant

level in reserve/overflow tank should drop slightly. If

not, inspect for a leak between radiator and coolant

reserve/overflow system connection. Remove radiator

cap. The coolant level should be to top of radiator. If

not and if coolant level in reserve/overflow tank is at

ADD mark, check for:

²An air leak in coolant reserve/overflow tank or its

hose

²An air leak in radiator filler neck

²Leak in pressure cap seal to radiator filler neck

LOW COOLANT LEVEL-AERATION

If the coolant level in radiator drops below top of

radiator core tubes, air will enter cooling system.

Low coolant level can cause thermostat pellet to be

suspended in air instead of coolant. This will cause

thermostat to open later, which in turn causes higher

coolant temperature. Air trapped in cooling system

also reduces amount of coolant circulating in heater

core resulting in low heat output.

DEAERATION

As the engine operates, any air trapped in cooling

system gathers under the radiator cap. The next time

the engine is operated, thermal expansion of coolant

will push any trapped air past radiator cap into the

coolant reserve/overflow tank. Here it escapes to the

atmosphere into the tank. When the engine cools

down the coolant, it will be drawn from the reserve/

overflow tank into the radiator to replace any re-

moved air.

DRAINING COOLING SYSTEM

ALL MODELSÐEXCEPT XJ WITH 4.0L ENGINE

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

DO NOT remove the radiator cap when draining

the coolant from the reserve/overflow tank. Open the

radiator draincock and when the tank is empty, re-

move the radiator cap. The coolant does not have to

be removed from the tank unless the system is being

refilled with a fresh mixture.

(1) Drain the coolant from the radiator by loosen-

ing the draincock.

(2) Drain coolant from engine as follows:

(a) On 2.5L engines (all models) by removing

drain plug at left rear side of block.

(b) On 4.0L engines by removing the drain plug

or coolant temperature sensor on the left side of

the block (Fig. 17).

XJ MODELS WITH 4.0L ENGINE

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

Fig. 17 Draining CoolantÐ4.0L Engine

7 - 16 COOLING SYSTEMJ

Page 250 of 1784

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

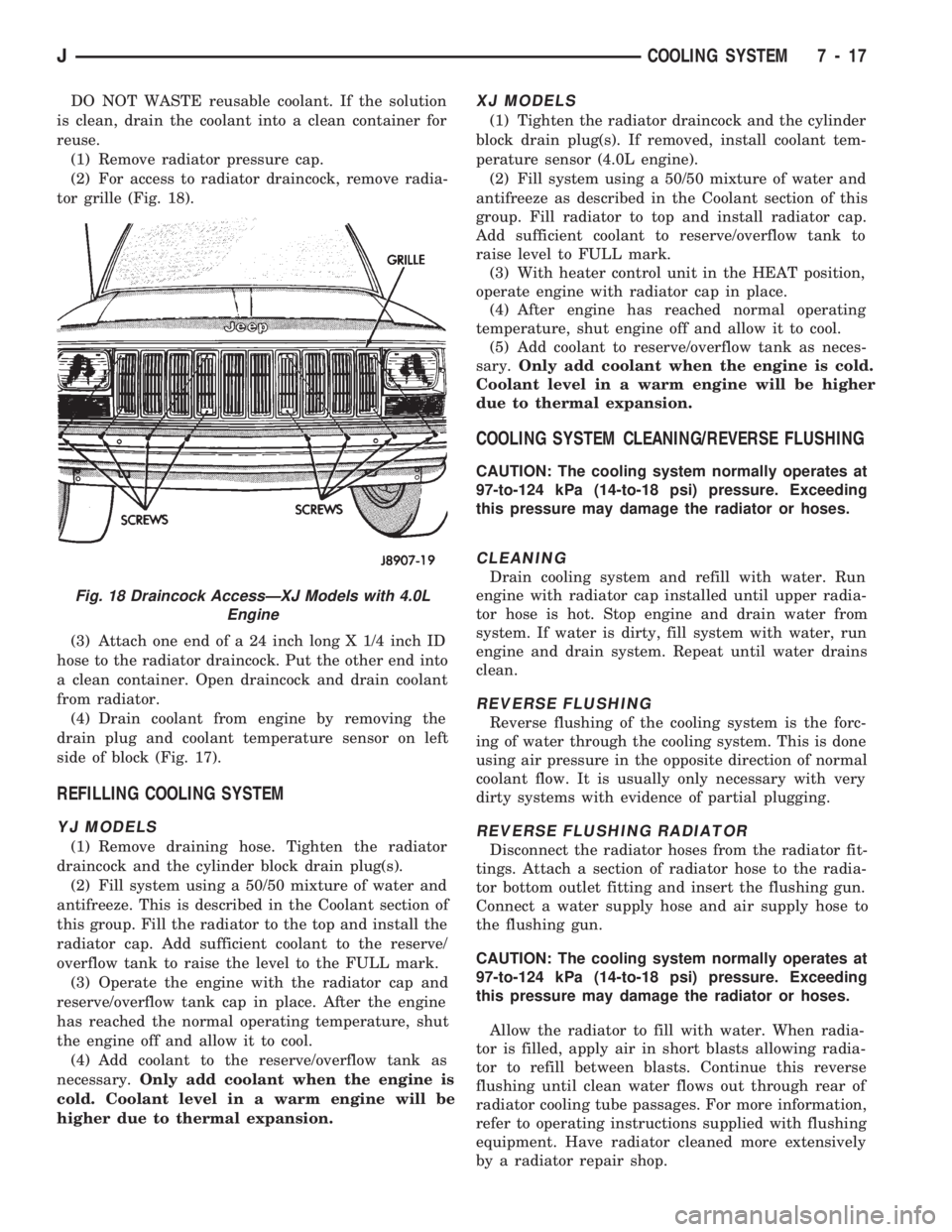

(1) Remove radiator pressure cap.

(2) For access to radiator draincock, remove radia-

tor grille (Fig. 18).

(3) Attach one end of a 24 inch long X 1/4 inch ID

hose to the radiator draincock. Put the other end into

a clean container. Open draincock and drain coolant

from radiator.

(4) Drain coolant from engine by removing the

drain plug and coolant temperature sensor on left

side of block (Fig. 17).

REFILLING COOLING SYSTEM

YJ MODELS

(1) Remove draining hose. Tighten the radiator

draincock and the cylinder block drain plug(s).

(2) Fill system using a 50/50 mixture of water and

antifreeze. This is described in the Coolant section of

this group. Fill the radiator to the top and install the

radiator cap. Add sufficient coolant to the reserve/

overflow tank to raise the level to the FULL mark.

(3) Operate the engine with the radiator cap and

reserve/overflow tank cap in place. After the engine

has reached the normal operating temperature, shut

the engine off and allow it to cool.

(4) Add coolant to the reserve/overflow tank as

necessary.Only add coolant when the engine is

cold. Coolant level in a warm engine will be

higher due to thermal expansion.

XJ MODELS

(1) Tighten the radiator draincock and the cylinder

block drain plug(s). If removed, install coolant tem-

perature sensor (4.0L engine).

(2) Fill system using a 50/50 mixture of water and

antifreeze as described in the Coolant section of this

group. Fill radiator to top and install radiator cap.

Add sufficient coolant to reserve/overflow tank to

raise level to FULL mark.

(3) With heater control unit in the HEAT position,

operate engine with radiator cap in place.

(4) After engine has reached normal operating

temperature, shut engine off and allow it to cool.

(5) Add coolant to reserve/overflow tank as neces-

sary.Only add coolant when the engine is cold.

Coolant level in a warm engine will be higher

due to thermal expansion.

COOLING SYSTEM CLEANING/REVERSE FLUSHING

CAUTION: The cooling system normally operates at

97-to-124 kPa (14-to-18 psi) pressure. Exceeding

this pressure may damage the radiator or hoses.

CLEANING

Drain cooling system and refill with water. Run

engine with radiator cap installed until upper radia-

tor hose is hot. Stop engine and drain water from

system. If water is dirty, fill system with water, run

engine and drain system. Repeat until water drains

clean.

REVERSE FLUSHING

Reverse flushing of the cooling system is the forc-

ing of water through the cooling system. This is done

using air pressure in the opposite direction of normal

coolant flow. It is usually only necessary with very

dirty systems with evidence of partial plugging.

REVERSE FLUSHING RADIATOR

Disconnect the radiator hoses from the radiator fit-

tings. Attach a section of radiator hose to the radia-

tor bottom outlet fitting and insert the flushing gun.

Connect a water supply hose and air supply hose to

the flushing gun.

CAUTION: The cooling system normally operates at

97-to-124 kPa (14-to-18 psi) pressure. Exceeding

this pressure may damage the radiator or hoses.

Allow the radiator to fill with water. When radia-

tor is filled, apply air in short blasts allowing radia-

tor to refill between blasts. Continue this reverse

flushing until clean water flows out through rear of

radiator cooling tube passages. For more information,

refer to operating instructions supplied with flushing

equipment. Have radiator cleaned more extensively

by a radiator repair shop.

Fig. 18 Draincock AccessÐXJ Models with 4.0L

Engine

JCOOLING SYSTEM 7 - 17