Front axle JEEP CHEROKEE 1994 Service Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 768 of 1784

Wiring Diagram Name Sheet Number

Turn/Hazard Flasher Switch....................24

Vehicle Speed Control Switch...................53

Washer Switch............................33

Washer Fluid Level Switch.....................33

Wiper/Washer Switch........................33

Telltale Connector..........................38, 68

Telltale Printed Circuit Board.....................38

Throttle Position (Sensor).......................11

Transfer Case Lamp...........................26

Transmission Control Magnetic Trigger Wheel..........17

Transmission Control Module..................17, 18

Transmission Control Module Connector..............72

Transmission Control System...............16, 17, 18

Back-Up Lamp Switch........................16

Front Axle Switch...........................16

Reed Switch..............................18

Transmission Data Link Connector.................17Wiring Diagram Name Sheet Number

Transmission Range Lamp......................26

Transmission Range Switch......................17

Trigger Wheel...............................18

Vehicle Speed Sensor (VSS).....................16

Turn Signal Flasher...........................23

Underhood Lamp............................28

Upshift Indicator Lamp......................39, 40

Vanity Lamps...............................31

Vehicle Speed Control Servo.....................53

Vehicle Speed Control Switch.....................53

Vehicle Speed Control System....................53

Vehicle Speed Sensor (VSS).....................16

Wall Plug, Engine Block Heater...................58

Washer Fluid Level Switch......................33

Windshield Wiper Circuit Breaker................2,33

Wiper/Washer Switch..........................33

Windshield Wiper System (Intermittent)...........33, 34

JWIRING DIAGRAMS 8W - 275

Page 937 of 1784

red. Remove the exhaust tailpipe/muffler clamp and

twist the exhaust tailpipe out of the muffler.

INSTALLATION

(1) Install the muffler onto the catalytic converter.

Install the clamp and tighten the nuts finger tight.

(2) Install the exhaust tailpipe into the rear of the

muffler.

(3) Install the exhaust tailpipe/muffler assembly

on the rear exhaust tailpipe hanger. Make sure that

the exhaust tailpipe has sufficient clearance from the

floor pan.

(4) Install the remaining clamps and the front ex-

haust tailpipe hanger.

(5) Tighten the nuts on the muffler-to-catalytic

converter clamp to 61 Nzm (45 ft. lbs.) torque (Fig.

6). Tighten the nuts on the rear exhaust tailpipe

clamp to 14 Nzm (10 ft. lbs.) torque (Fig. 7).

(6) Lower the vehicle.

(7) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

MUFFLER AND EXHAUST TAILPIPEÐYJ VEHICLES

All original equipment exhaust systems are manu-

factured with the exhaust tailpipe welded to the muf-

fler. Service replacement mufflers and exhaust

tailpipes are clamped together.

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

REMOVAL

(1) Raise the vehicle and support the rear of the

vehicle by the side rails and allow the axle to hang

free.

(2) Remove the front muffler clamp from the cata-

lytic converter and muffler connection (Fig. 6).

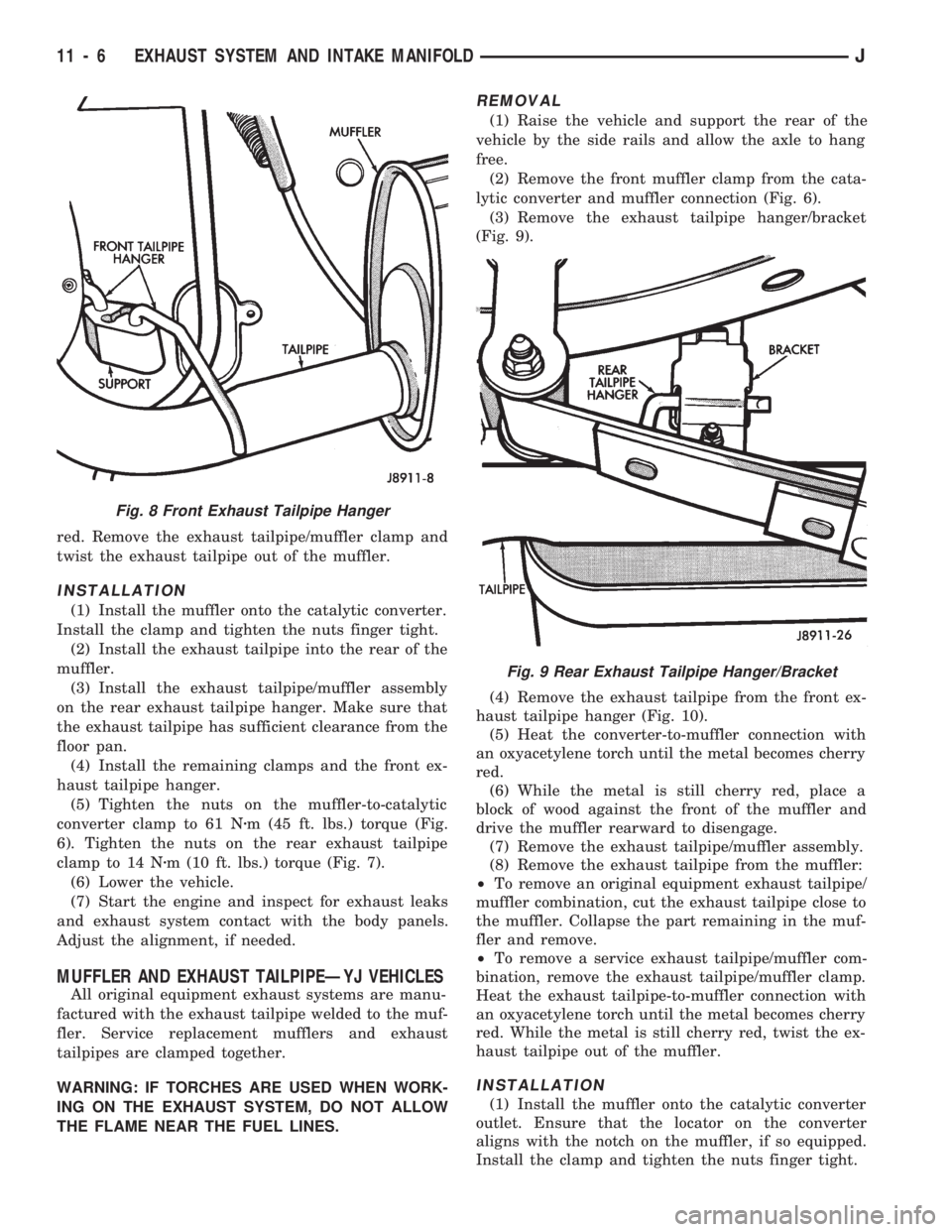

(3) Remove the exhaust tailpipe hanger/bracket

(Fig. 9).

(4) Remove the exhaust tailpipe from the front ex-

haust tailpipe hanger (Fig. 10).

(5) Heat the converter-to-muffler connection with

an oxyacetylene torch until the metal becomes cherry

red.

(6) While the metal is still cherry red, place a

block of wood against the front of the muffler and

drive the muffler rearward to disengage.

(7) Remove the exhaust tailpipe/muffler assembly.

(8) Remove the exhaust tailpipe from the muffler:

²To remove an original equipment exhaust tailpipe/

muffler combination, cut the exhaust tailpipe close to

the muffler. Collapse the part remaining in the muf-

fler and remove.

²To remove a service exhaust tailpipe/muffler com-

bination, remove the exhaust tailpipe/muffler clamp.

Heat the exhaust tailpipe-to-muffler connection with

an oxyacetylene torch until the metal becomes cherry

red. While the metal is still cherry red, twist the ex-

haust tailpipe out of the muffler.

INSTALLATION

(1) Install the muffler onto the catalytic converter

outlet. Ensure that the locator on the converter

aligns with the notch on the muffler, if so equipped.

Install the clamp and tighten the nuts finger tight.

Fig. 8 Front Exhaust Tailpipe Hanger

Fig. 9 Rear Exhaust Tailpipe Hanger/Bracket

11 - 6 EXHAUST SYSTEM AND INTAKE MANIFOLDJ

Page 951 of 1784

CONSTRUCTION

The frame is constructed of high-strength channel

steel siderails and crossmembers. The crossmembers

join the siderails and retain them in alignment in re-

lation to each other. This provides resistance to

frame twists and strains.

FRAME ALIGNMENT

INCORRECT ALIGNMENT

Incorrect frame alignment is usually a result of:

²collision impact, or

²the vehicle being operated with excessive loads, or

²loads not positioned in a properly distributed man-

ner on the vehicle.

A mis-aligned frame will affect front axle and/or

rear axle alignment. It can cause excessive wear and

mechanical failures in the powertrain. Window glass

cracks and door opening/closing problems. Vehicle

performance can also be impaired.

RE-ALIGNMENT

With collision damage, it is important that the ex-

istence of any frame alignment damage be deter-

mined. If necessary, the frame should be correctly re-

aligned. Refer to the reference dimensions listed on

frame alignment dimension chart (Fig. 4).

FRAME INSPECTION/MEASUREMENTS

INSPECTION

Before proceeding with measurements, inspect all

components for visible damage and other metal dam-

age. Also, inspect all connections for loose and miss-

ing hardware.

All damaged areas must be repaired and/or the

components replaced, as necessary.

MEASUREMENTS

Measure the frame for mis-alignment with the

body attached to the frame. Figure 4 provides the

alignment reference dimensions. The following infor-

mation applies to all measurements.

(1) Place the vehicle on a level surface.

(2) If the vehicle is loaded, ensure that the vehicle

weight plus the payload does not exceed the gross ve-

hicle weight rating. Also, ensure that the load is dis-

tributed in the vehicle as evenly as possible.

(3) Measure the tire inflation pressures and adjust

the pressure, if necessary.

HORIZONTAL OR DIAGONAL FRAME MEASUREMENTS

Determine the frame horizontal non-square devia-

tion(s) according to the following procedure.

(1) Select several reference points along one frame

siderail, preferably at the crossmember junctions.(2) Transfer these reference points to the surface/

floor with a plumb bob. Paper sheets can be attached

to the surface below the reference points for better

measurement accuracy.

(3) Locate the reference points on the other frame

siderail and transfer them to the surface/floor with

the same procedure as above.

(4) Move the vehicle away and measure between

all the reference points diagonally from and parallel

to the siderails (Fig. 5). The measurements should

not differ by more than 6 mm (1/4 in).

(5) Measure the distance between the two front

reference points and the distance between the two

rear reference points. Divide each distance in half

and indicate the two half-way points on the surface/

floor. Designate the front point as ``1'' and the rear

point as ``2'' (Fig. 5).

(6) Place a chalk-line between points 1 and 2 and

``snap'' the string.

(7) Determine how close the center line is to the

diagonal intersection points A, B, C, D, E, and F in

Figure 5.

(8) The reference marks on the surface/floor will

provide an illustrated indication of the degree of

frame misalignment.

(9) A reference point transferred from one frame

siderail may be 3 mm (1/8 in) ahead or behind the

reference point from the opposite siderail.

(10) Frame bow to the side should not exceed 3

mm per 2,540 mm (1/8 inch per 100 inches) in

length.

(11) The overall width of the frame should not

vary more than 3 mm (1/8 in) from reference point-

to-reference point.

(12) Repeat steps (1) through (11) after straighten-

ing the frame to evaluate the effectiveness.

TWIST AND PARALLEL FRAME MEASUREMENTS

Determine the amount of frame twist and siderail

deviation according to the following procedure.

(1) Mark the vertical measurement reference

points under the frame siderails at 305-mm (12-in)

intervals starting at the rear frame crossmember.

(2) Measure the vertical distance up from a level

surface to each reference point located under the left

and right frame siderails.

(3) The distance to a reference point under one

frame siderail should be 3 mm (1/8 in) greater or less

than the point under the opposite siderail.

(4) Plot the measured vertical distances to scale on

a sheet of graph paper. Plot the distances so that the

frame siderails are located adjacent to each other.

Join the vertical distance points.

13 - 10 FRAME AND BUMPERSJ

Page 1028 of 1784

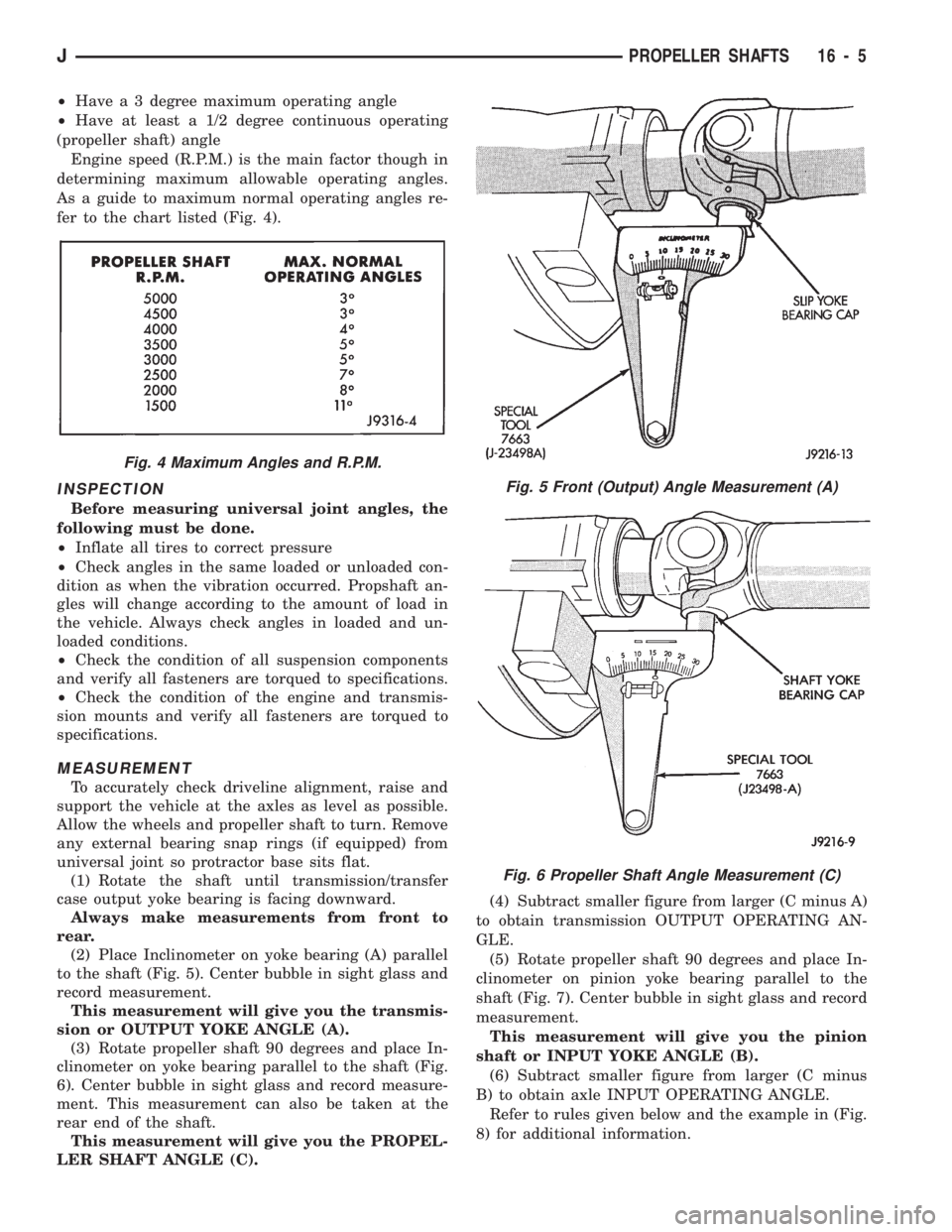

²Have a 3 degree maximum operating angle

²Have at least a 1/2 degree continuous operating

(propeller shaft) angle

Engine speed (R.P.M.) is the main factor though in

determining maximum allowable operating angles.

As a guide to maximum normal operating angles re-

fer to the chart listed (Fig. 4).

INSPECTION

Before measuring universal joint angles, the

following must be done.

²Inflate all tires to correct pressure

²Check angles in the same loaded or unloaded con-

dition as when the vibration occurred. Propshaft an-

gles will change according to the amount of load in

the vehicle. Always check angles in loaded and un-

loaded conditions.

²Check the condition of all suspension components

and verify all fasteners are torqued to specifications.

²Check the condition of the engine and transmis-

sion mounts and verify all fasteners are torqued to

specifications.

MEASUREMENT

To accurately check driveline alignment, raise and

support the vehicle at the axles as level as possible.

Allow the wheels and propeller shaft to turn. Remove

any external bearing snap rings (if equipped) from

universal joint so protractor base sits flat.

(1) Rotate the shaft until transmission/transfer

case output yoke bearing is facing downward.

Always make measurements from front to

rear.

(2) Place Inclinometer on yoke bearing (A) parallel

to the shaft (Fig. 5). Center bubble in sight glass and

record measurement.

This measurement will give you the transmis-

sion or OUTPUT YOKE ANGLE (A).

(3) Rotate propeller shaft 90 degrees and place In-

clinometer on yoke bearing parallel to the shaft (Fig.

6). Center bubble in sight glass and record measure-

ment. This measurement can also be taken at the

rear end of the shaft.

This measurement will give you the PROPEL-

LER SHAFT ANGLE (C).(4) Subtract smaller figure from larger (C minus A)

to obtain transmission OUTPUT OPERATING AN-

GLE.

(5) Rotate propeller shaft 90 degrees and place In-

clinometer on pinion yoke bearing parallel to the

shaft (Fig. 7). Center bubble in sight glass and record

measurement.

This measurement will give you the pinion

shaft or INPUT YOKE ANGLE (B).

(6) Subtract smaller figure from larger (C minus

B) to obtain axle INPUT OPERATING ANGLE.

Refer to rules given below and the example in (Fig.

8) for additional information.

Fig. 4 Maximum Angles and R.P.M.

Fig. 5 Front (Output) Angle Measurement (A)

Fig. 6 Propeller Shaft Angle Measurement (C)

JPROPELLER SHAFTS 16 - 5

Page 1030 of 1784

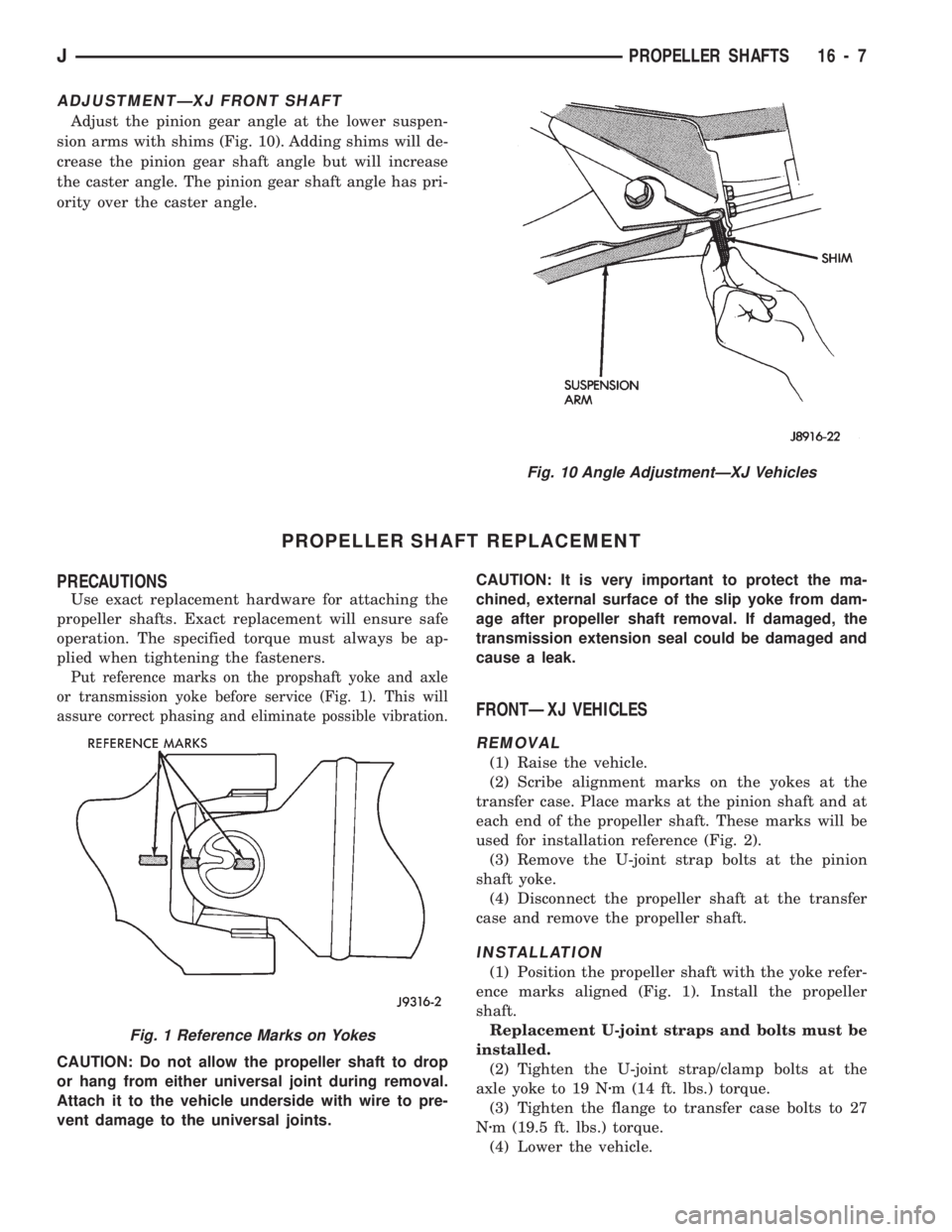

ADJUSTMENTÐXJ FRONT SHAFT

Adjust the pinion gear angle at the lower suspen-

sion arms with shims (Fig. 10). Adding shims will de-

crease the pinion gear shaft angle but will increase

the caster angle. The pinion gear shaft angle has pri-

ority over the caster angle.

PROPELLER SHAFT REPLACEMENT

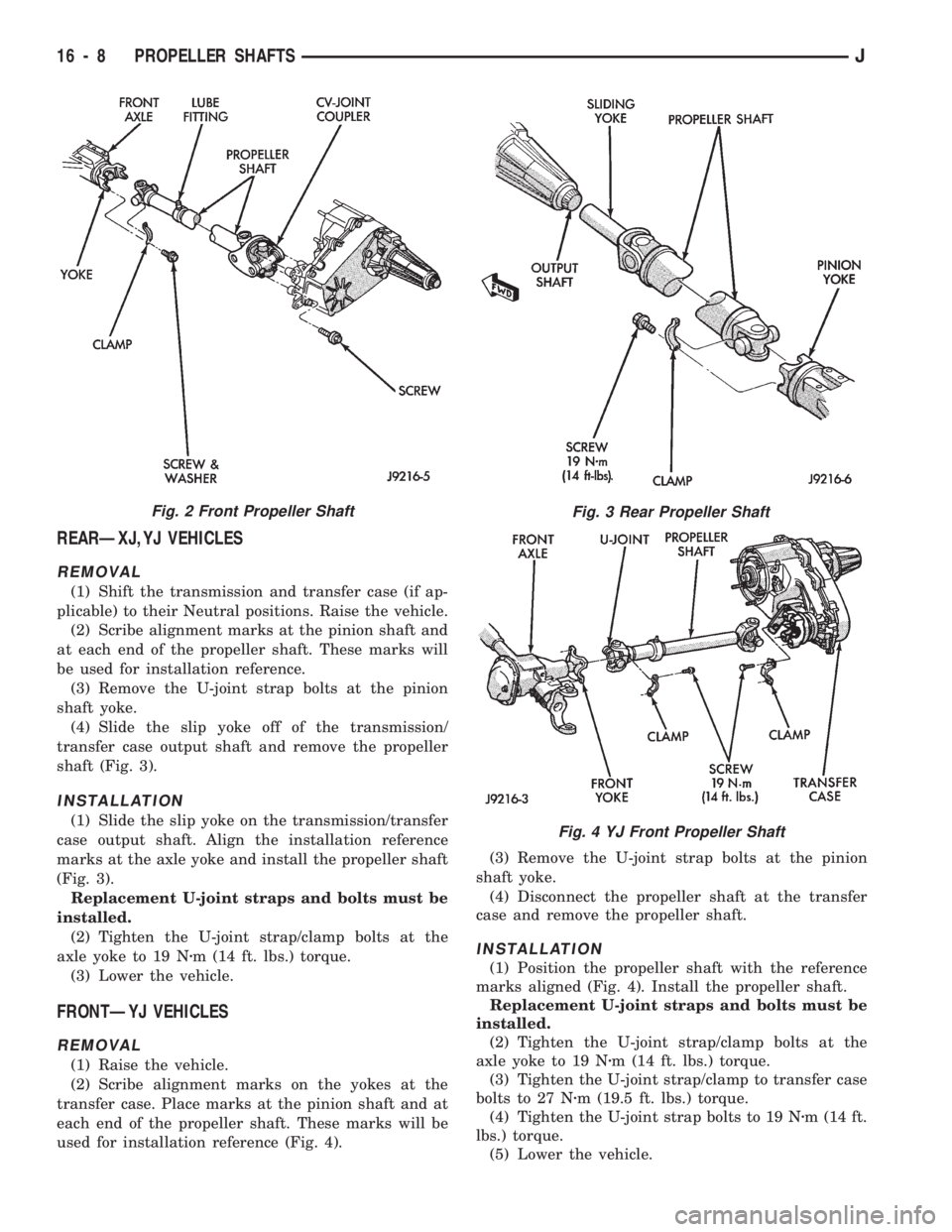

PRECAUTIONS

Use exact replacement hardware for attaching the

propeller shafts. Exact replacement will ensure safe

operation. The specified torque must always be ap-

plied when tightening the fasteners.

Put reference marks on the propshaft yoke and axle

or transmission yoke before service (Fig. 1). This will

assure correct phasing and eliminate possible vibration.

CAUTION: Do not allow the propeller shaft to drop

or hang from either universal joint during removal.

Attach it to the vehicle underside with wire to pre-

vent damage to the universal joints.CAUTION: It is very important to protect the ma-

chined, external surface of the slip yoke from dam-

age after propeller shaft removal. If damaged, the

transmission extension seal could be damaged and

cause a leak.

FRONTÐXJ VEHICLES

REMOVAL

(1) Raise the vehicle.

(2) Scribe alignment marks on the yokes at the

transfer case. Place marks at the pinion shaft and at

each end of the propeller shaft. These marks will be

used for installation reference (Fig. 2).

(3) Remove the U-joint strap bolts at the pinion

shaft yoke.

(4) Disconnect the propeller shaft at the transfer

case and remove the propeller shaft.

INSTALLATION

(1) Position the propeller shaft with the yoke refer-

ence marks aligned (Fig. 1). Install the propeller

shaft.

Replacement U-joint straps and bolts must be

installed.

(2) Tighten the U-joint strap/clamp bolts at the

axle yoke to 19 Nzm (14 ft. lbs.) torque.

(3) Tighten the flange to transfer case bolts to 27

Nzm (19.5 ft. lbs.) torque.

(4) Lower the vehicle.

Fig. 10 Angle AdjustmentÐXJ Vehicles

Fig. 1 Reference Marks on Yokes

JPROPELLER SHAFTS 16 - 7

Page 1031 of 1784

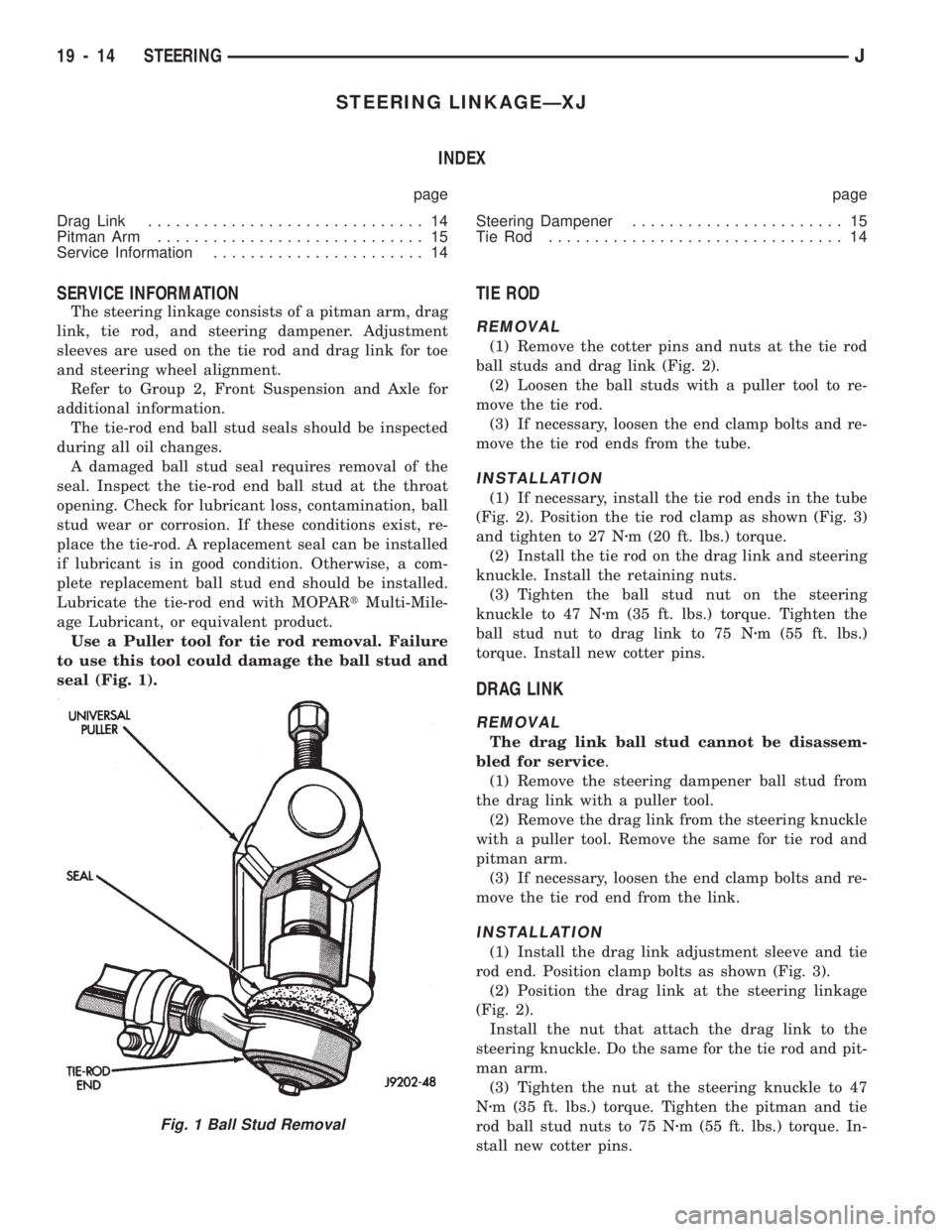

REARÐXJ,YJ VEHICLES

REMOVAL

(1) Shift the transmission and transfer case (if ap-

plicable) to their Neutral positions. Raise the vehicle.

(2) Scribe alignment marks at the pinion shaft and

at each end of the propeller shaft. These marks will

be used for installation reference.

(3) Remove the U-joint strap bolts at the pinion

shaft yoke.

(4) Slide the slip yoke off of the transmission/

transfer case output shaft and remove the propeller

shaft (Fig. 3).

INSTALLATION

(1) Slide the slip yoke on the transmission/transfer

case output shaft. Align the installation reference

marks at the axle yoke and install the propeller shaft

(Fig. 3).

Replacement U-joint straps and bolts must be

installed.

(2) Tighten the U-joint strap/clamp bolts at the

axle yoke to 19 Nzm (14 ft. lbs.) torque.

(3) Lower the vehicle.

FRONTÐYJ VEHICLES

REMOVAL

(1) Raise the vehicle.

(2) Scribe alignment marks on the yokes at the

transfer case. Place marks at the pinion shaft and at

each end of the propeller shaft. These marks will be

used for installation reference (Fig. 4).(3) Remove the U-joint strap bolts at the pinion

shaft yoke.

(4) Disconnect the propeller shaft at the transfer

case and remove the propeller shaft.

INSTALLATION

(1) Position the propeller shaft with the reference

marks aligned (Fig. 4). Install the propeller shaft.

Replacement U-joint straps and bolts must be

installed.

(2) Tighten the U-joint strap/clamp bolts at the

axle yoke to 19 Nzm (14 ft. lbs.) torque.

(3) Tighten the U-joint strap/clamp to transfer case

bolts to 27 Nzm (19.5 ft. lbs.) torque.

(4) Tighten the U-joint strap bolts to 19 Nzm (14 ft.

lbs.) torque.

(5) Lower the vehicle.

Fig. 3 Rear Propeller Shaft

Fig. 4 YJ Front Propeller Shaft

Fig. 2 Front Propeller Shaft

16 - 8 PROPELLER SHAFTSJ

Page 1051 of 1784

STEERING LINKAGEÐXJ

INDEX

page page

Drag Link.............................. 14

Pitman Arm............................. 15

Service Information....................... 14Steering Dampener....................... 15

Tie Rod ................................ 14

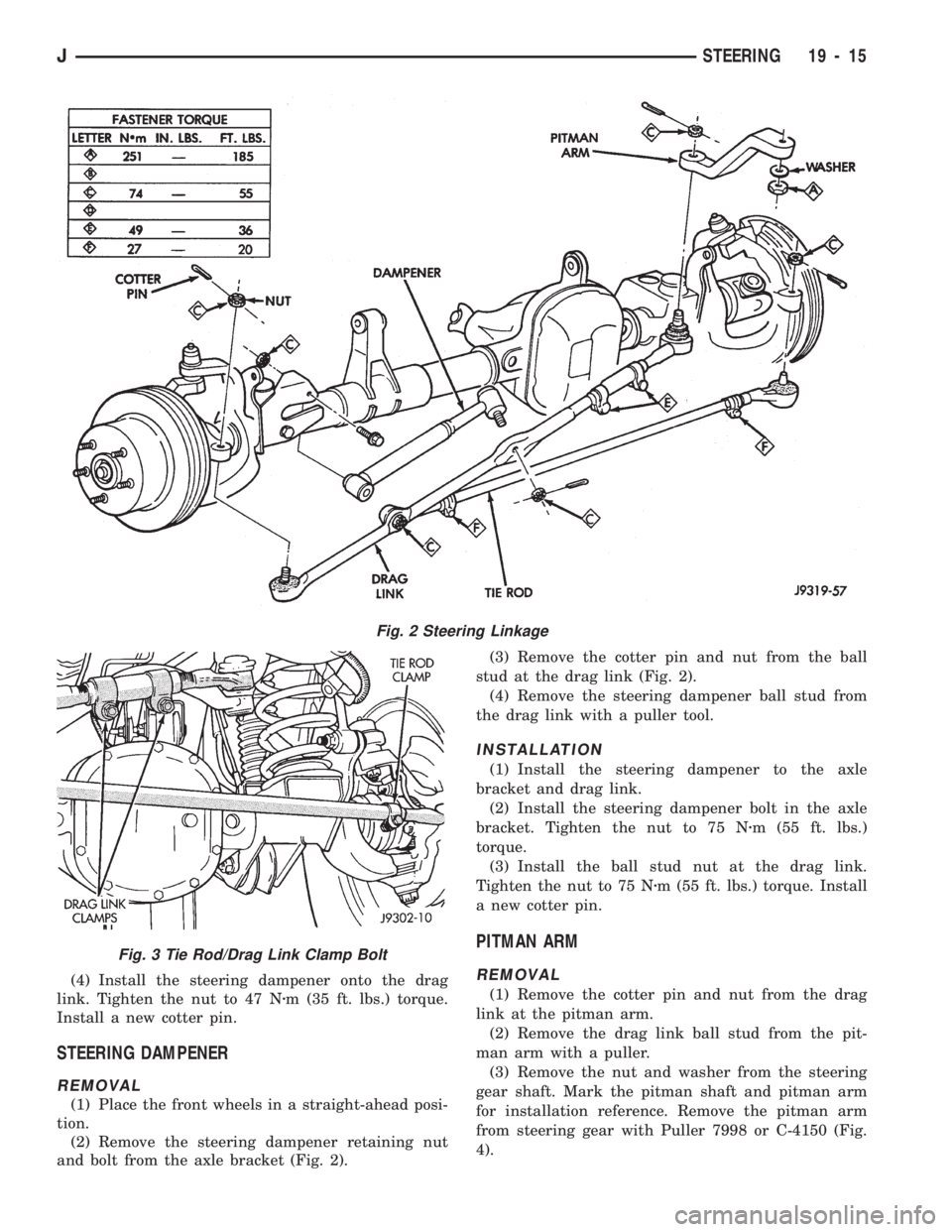

SERVICE INFORMATION

The steering linkage consists of a pitman arm, drag

link, tie rod, and steering dampener. Adjustment

sleeves are used on the tie rod and drag link for toe

and steering wheel alignment.

Refer to Group 2, Front Suspension and Axle for

additional information.

The tie-rod end ball stud seals should be inspected

during all oil changes.

A damaged ball stud seal requires removal of the

seal. Inspect the tie-rod end ball stud at the throat

opening. Check for lubricant loss, contamination, ball

stud wear or corrosion. If these conditions exist, re-

place the tie-rod. A replacement seal can be installed

if lubricant is in good condition. Otherwise, a com-

plete replacement ball stud end should be installed.

Lubricate the tie-rod end with MOPARtMulti-Mile-

age Lubricant, or equivalent product.

Use a Puller tool for tie rod removal. Failure

to use this tool could damage the ball stud and

seal (Fig. 1).

TIE ROD

REMOVAL

(1) Remove the cotter pins and nuts at the tie rod

ball studs and drag link (Fig. 2).

(2) Loosen the ball studs with a puller tool to re-

move the tie rod.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod ends from the tube.

INSTALLATION

(1) If necessary, install the tie rod ends in the tube

(Fig. 2). Position the tie rod clamp as shown (Fig. 3)

and tighten to 27 Nzm (20 ft. lbs.) torque.

(2) Install the tie rod on the drag link and steering

knuckle. Install the retaining nuts.

(3) Tighten the ball stud nut on the steering

knuckle to 47 Nzm (35 ft. lbs.) torque. Tighten the

ball stud nut to drag link to 75 Nzm (55 ft. lbs.)

torque. Install new cotter pins.

DRAG LINK

REMOVAL

The drag link ball stud cannot be disassem-

bled for service.

(1) Remove the steering dampener ball stud from

the drag link with a puller tool.

(2) Remove the drag link from the steering knuckle

with a puller tool. Remove the same for tie rod and

pitman arm.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod end from the link.

INSTALLATION

(1) Install the drag link adjustment sleeve and tie

rod end. Position clamp bolts as shown (Fig. 3).

(2) Position the drag link at the steering linkage

(Fig. 2).

Install the nut that attach the drag link to the

steering knuckle. Do the same for the tie rod and pit-

man arm.

(3) Tighten the nut at the steering knuckle to 47

Nzm (35 ft. lbs.) torque. Tighten the pitman and tie

rod ball stud nuts to 75 Nzm (55 ft. lbs.) torque. In-

stall new cotter pins.

Fig. 1 Ball Stud Removal

19 - 14 STEERINGJ

Page 1052 of 1784

(4) Install the steering dampener onto the drag

link. Tighten the nut to 47 Nzm (35 ft. lbs.) torque.

Install a new cotter pin.

STEERING DAMPENER

REMOVAL

(1) Place the front wheels in a straight-ahead posi-

tion.

(2) Remove the steering dampener retaining nut

and bolt from the axle bracket (Fig. 2).(3) Remove the cotter pin and nut from the ball

stud at the drag link (Fig. 2).

(4) Remove the steering dampener ball stud from

the drag link with a puller tool.

INSTALLATION

(1) Install the steering dampener to the axle

bracket and drag link.

(2) Install the steering dampener bolt in the axle

bracket. Tighten the nut to 75 Nzm (55 ft. lbs.)

torque.

(3) Install the ball stud nut at the drag link.

Tighten the nut to 75 Nzm (55 ft. lbs.) torque. Install

a new cotter pin.

PITMAN ARM

REMOVAL

(1) Remove the cotter pin and nut from the drag

link at the pitman arm.

(2) Remove the drag link ball stud from the pit-

man arm with a puller.

(3) Remove the nut and washer from the steering

gear shaft. Mark the pitman shaft and pitman arm

for installation reference. Remove the pitman arm

from steering gear with Puller 7998 or C-4150 (Fig.

4).

Fig. 2 Steering Linkage

Fig. 3 Tie Rod/Drag Link Clamp Bolt

JSTEERING 19 - 15

Page 1054 of 1784

STEERING LINKAGEÐYJ

INDEX

page page

Drag Link.............................. 17

Pitman Arm............................. 18

Service Information....................... 17Steering Dampener....................... 18

Tie Rod ................................ 17

SERVICE INFORMATION

The steering linkage consists of a pitman arm, drag

link, tie rod, and steering dampener. Adjustment

sleeves are used on the tie rod and drag link for toe

and steering wheel alignment.

Refer to Group 2, Front Suspension and Axle for

additional information.

The tie-rod end ball stud seals should be inspected

during all oil changes.

A damaged ball stud seal requires removal of the

seal. Inspect the tie-rod end ball stud at the throat

opening. Check for lubricant loss, contamination, ball

stud wear or corrosion. If these conditions exist, re-

place the tie-rod. A replacement seal can be installed

if lubricant is in good condition. Otherwise, a com-

plete replacement ball stud end should be installed.

Lubricate the tie-rod end with MOPARtMulti-Mile-

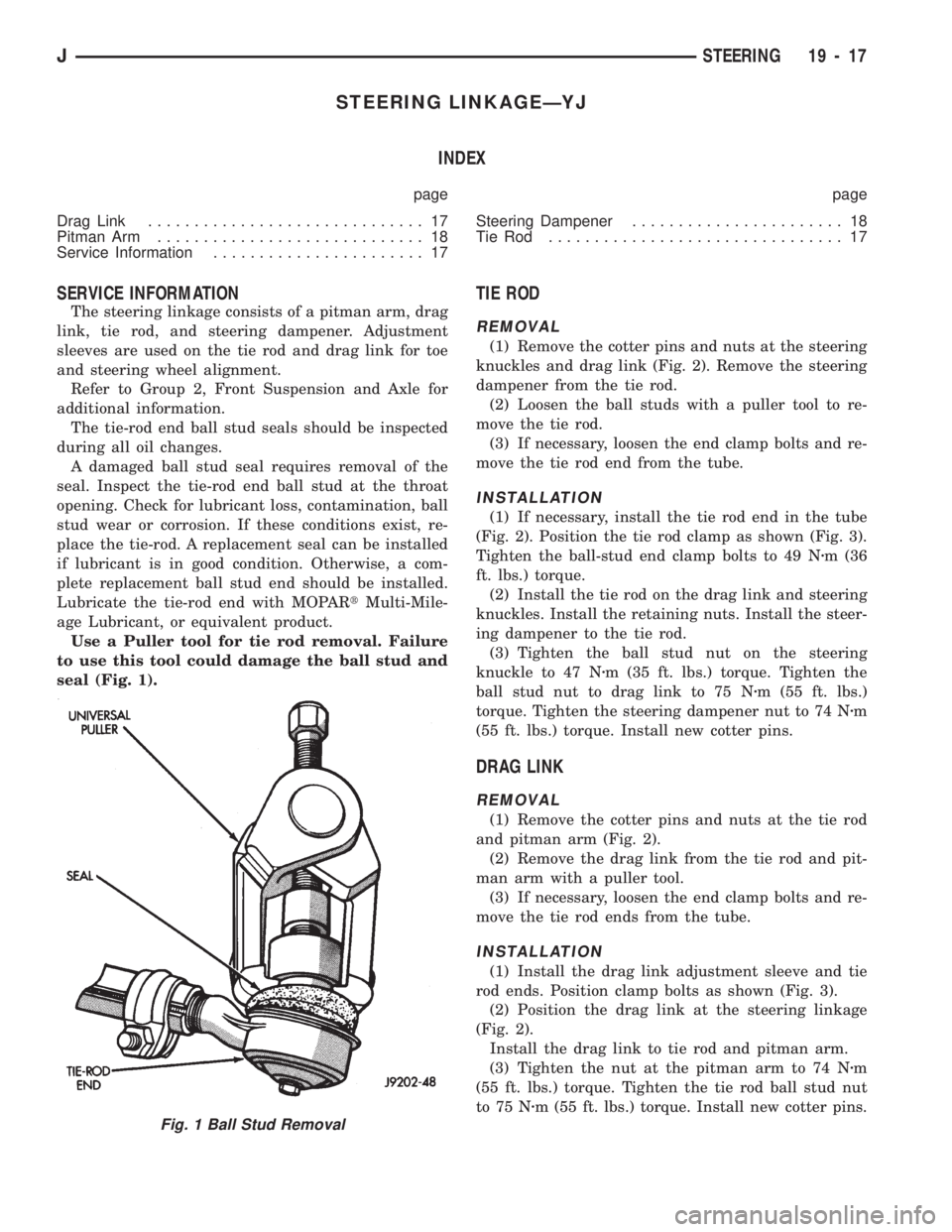

age Lubricant, or equivalent product.

Use a Puller tool for tie rod removal. Failure

to use this tool could damage the ball stud and

seal (Fig. 1).

TIE ROD

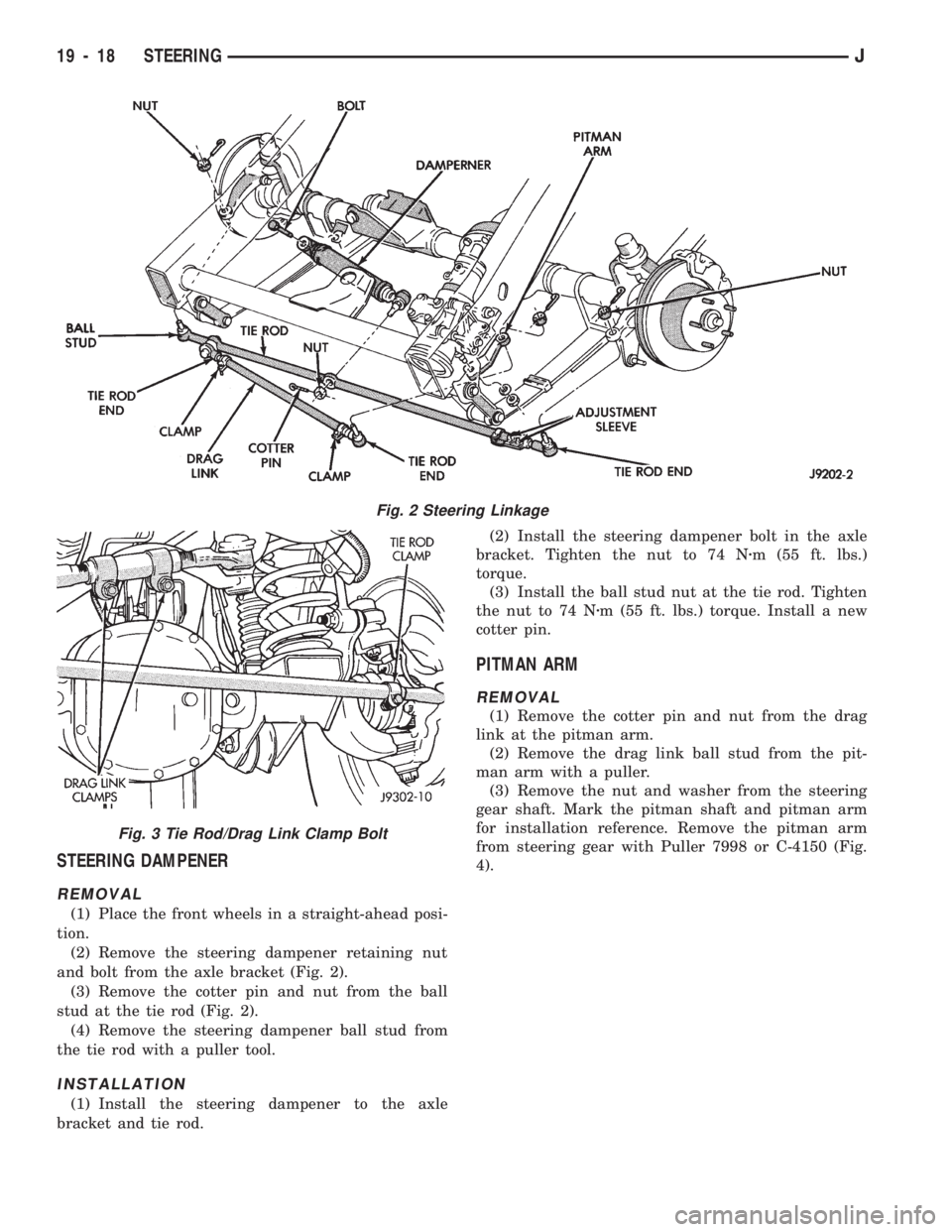

REMOVAL

(1) Remove the cotter pins and nuts at the steering

knuckles and drag link (Fig. 2). Remove the steering

dampener from the tie rod.

(2) Loosen the ball studs with a puller tool to re-

move the tie rod.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod end from the tube.

INSTALLATION

(1) If necessary, install the tie rod end in the tube

(Fig. 2). Position the tie rod clamp as shown (Fig. 3).

Tighten the ball-stud end clamp bolts to 49 Nzm (36

ft. lbs.) torque.

(2) Install the tie rod on the drag link and steering

knuckles. Install the retaining nuts. Install the steer-

ing dampener to the tie rod.

(3) Tighten the ball stud nut on the steering

knuckle to 47 Nzm (35 ft. lbs.) torque. Tighten the

ball stud nut to drag link to 75 Nzm (55 ft. lbs.)

torque. Tighten the steering dampener nut to 74 Nzm

(55 ft. lbs.) torque. Install new cotter pins.

DRAG LINK

REMOVAL

(1) Remove the cotter pins and nuts at the tie rod

and pitman arm (Fig. 2).

(2) Remove the drag link from the tie rod and pit-

man arm with a puller tool.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod ends from the tube.

INSTALLATION

(1) Install the drag link adjustment sleeve and tie

rod ends. Position clamp bolts as shown (Fig. 3).

(2) Position the drag link at the steering linkage

(Fig. 2).

Install the drag link to tie rod and pitman arm.

(3) Tighten the nut at the pitman arm to 74 Nzm

(55 ft. lbs.) torque. Tighten the tie rod ball stud nut

to 75 Nzm (55 ft. lbs.) torque. Install new cotter pins.

Fig. 1 Ball Stud Removal

JSTEERING 19 - 17

Page 1055 of 1784

STEERING DAMPENER

REMOVAL

(1) Place the front wheels in a straight-ahead posi-

tion.

(2) Remove the steering dampener retaining nut

and bolt from the axle bracket (Fig. 2).

(3) Remove the cotter pin and nut from the ball

stud at the tie rod (Fig. 2).

(4) Remove the steering dampener ball stud from

the tie rod with a puller tool.

INSTALLATION

(1) Install the steering dampener to the axle

bracket and tie rod.(2) Install the steering dampener bolt in the axle

bracket. Tighten the nut to 74 Nzm (55 ft. lbs.)

torque.

(3) Install the ball stud nut at the tie rod. Tighten

the nut to 74 Nzm (55 ft. lbs.) torque. Install a new

cotter pin.

PITMAN ARM

REMOVAL

(1) Remove the cotter pin and nut from the drag

link at the pitman arm.

(2) Remove the drag link ball stud from the pit-

man arm with a puller.

(3) Remove the nut and washer from the steering

gear shaft. Mark the pitman shaft and pitman arm

for installation reference. Remove the pitman arm

from steering gear with Puller 7998 or C-4150 (Fig.

4).

Fig. 2 Steering Linkage

Fig. 3 Tie Rod/Drag Link Clamp Bolt

19 - 18 STEERINGJ