Change filter JEEP CHEROKEE 1995 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 178 of 2198

(2) Align and attach harness connector to ECU.

Slide connector into engagement with tangs on ECU.

Then tilt connector downward and into engagement

with ECU pin terminals. Exercise care as pin termi-

nals can be damaged if connector is forced into place.

(3) Connect harness to security alarm module, if

equipped.

(4) Position ECU bracket under instrument panel.

(5) Install and tighten ECU mounting bracket

bolts/nuts to 8-14 Nzm (75- 125 in. lbs.) torque.

(6) Install trim panel on instrument panel, if re-

moved.

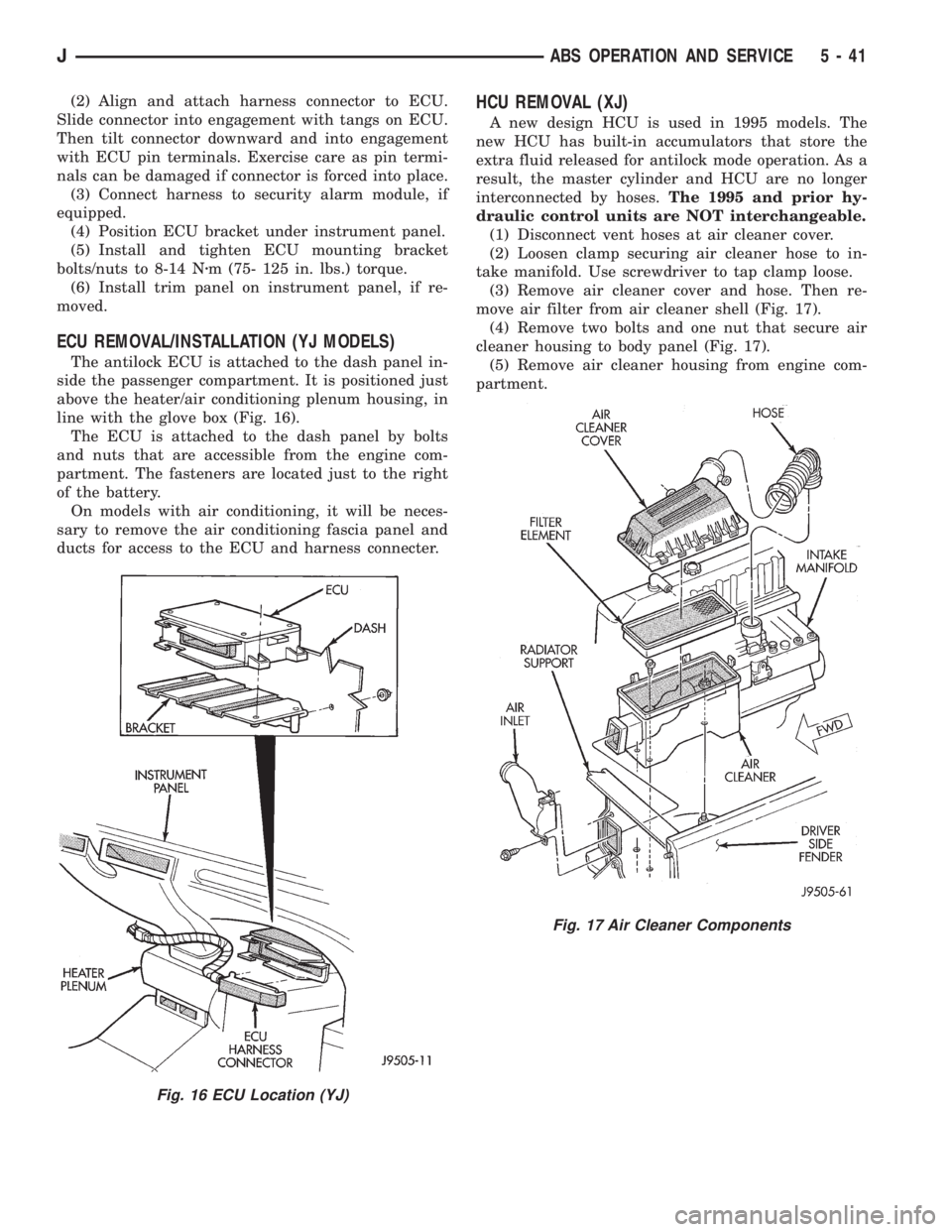

ECU REMOVAL/INSTALLATION (YJ MODELS)

The antilock ECU is attached to the dash panel in-

side the passenger compartment. It is positioned just

above the heater/air conditioning plenum housing, in

line with the glove box (Fig. 16).

The ECU is attached to the dash panel by bolts

and nuts that are accessible from the engine com-

partment. The fasteners are located just to the right

of the battery.

On models with air conditioning, it will be neces-

sary to remove the air conditioning fascia panel and

ducts for access to the ECU and harness connecter.

HCU REMOVAL (XJ)

A new design HCU is used in 1995 models. The

new HCU has built-in accumulators that store the

extra fluid released for antilock mode operation. As a

result, the master cylinder and HCU are no longer

interconnected by hoses.The 1995 and prior hy-

draulic control units are NOT interchangeable.

(1) Disconnect vent hoses at air cleaner cover.

(2) Loosen clamp securing air cleaner hose to in-

take manifold. Use screwdriver to tap clamp loose.

(3) Remove air cleaner cover and hose. Then re-

move air filter from air cleaner shell (Fig. 17).

(4) Remove two bolts and one nut that secure air

cleaner housing to body panel (Fig. 17).

(5) Remove air cleaner housing from engine com-

partment.

Fig. 16 ECU Location (YJ)

Fig. 17 Air Cleaner Components

JABS OPERATION AND SERVICE 5 - 41

Page 1476 of 2198

30RH/32RH IN-VEHICLE SERVICE

INDEX

page page

Converter Drainback Check Valve Service...... 113

Fluid and Filter Replacement................. 99

Fluid Level Check......................... 99

Front Band Adjustment.................... 102

Governor and Park Gear Service............. 105

Oil Filter Replacement..................... 103

Park Interlock Cable Adjustment (XJ).......... 101

Park Lock Component Replacement.......... 108

Park/Neutral Position Switch Service.......... 109

Rear Band Adjustment.................... 103

Recommended Fluid....................... 99Refilling After Overhaul or Fluid/Filter Change . . . 100

Shift Cable Adjustment (XJ)................. 100

Shift Linkage Adjustment (YJ)............... 100

Speedometer Service..................... 109

Throttle Valve Cable Adjustment (XJ/YJ)....... 101

Transmission Cooler Flow Testing............ 113

Transmission Cooler Line and Fitting Service.... 111

Transmission Cooler Reverse Flushing......... 114

Valve Body Installation.................... 104

Valve Body Removal...................... 104

Valve Body Service....................... 104

RECOMMENDED FLUID

Recommended (and preferred) fluid for 30RH/32RH

transmissions is Mopar ATF Plus, type 7176.

Dexron II is not really recommended and should

only be used when ATF Plus is not available.

FLUID LEVEL CHECK

Transmission fluid level should be checked monthly

under normal operation. If the vehicle is used for

trailer towing or similar heavy load hauling, check

fluid level and condition weekly.

Fluid level is checked with the engine running at

curb idle speed, the transmission in Neutral and the

transmission fluid at normal operating temperature.

FLUID LEVEL CHECK PROCEDURE

(1) Transmission fluid must be at normal operating

temperature for accurate fluid level check. Drive ve-

hicle if necessary to bring fluid temperature up to

normal hot operating temperature of 82ÉC (180ÉF).

(2) Position vehicle on level surface. This is ex-

tremely important for accurate fluid level check.

(3) Start and run engine at curb idle speed.

(4) Apply parking brakes.

(5) Shift transmission momentarily into all gear

ranges. Then shift transmission back to Neutral.

(6) Clean top of filler tube and dipstick to keep dirt

from entering tube.

(7) Remove dipstick and check fluid level as fol-

lows:

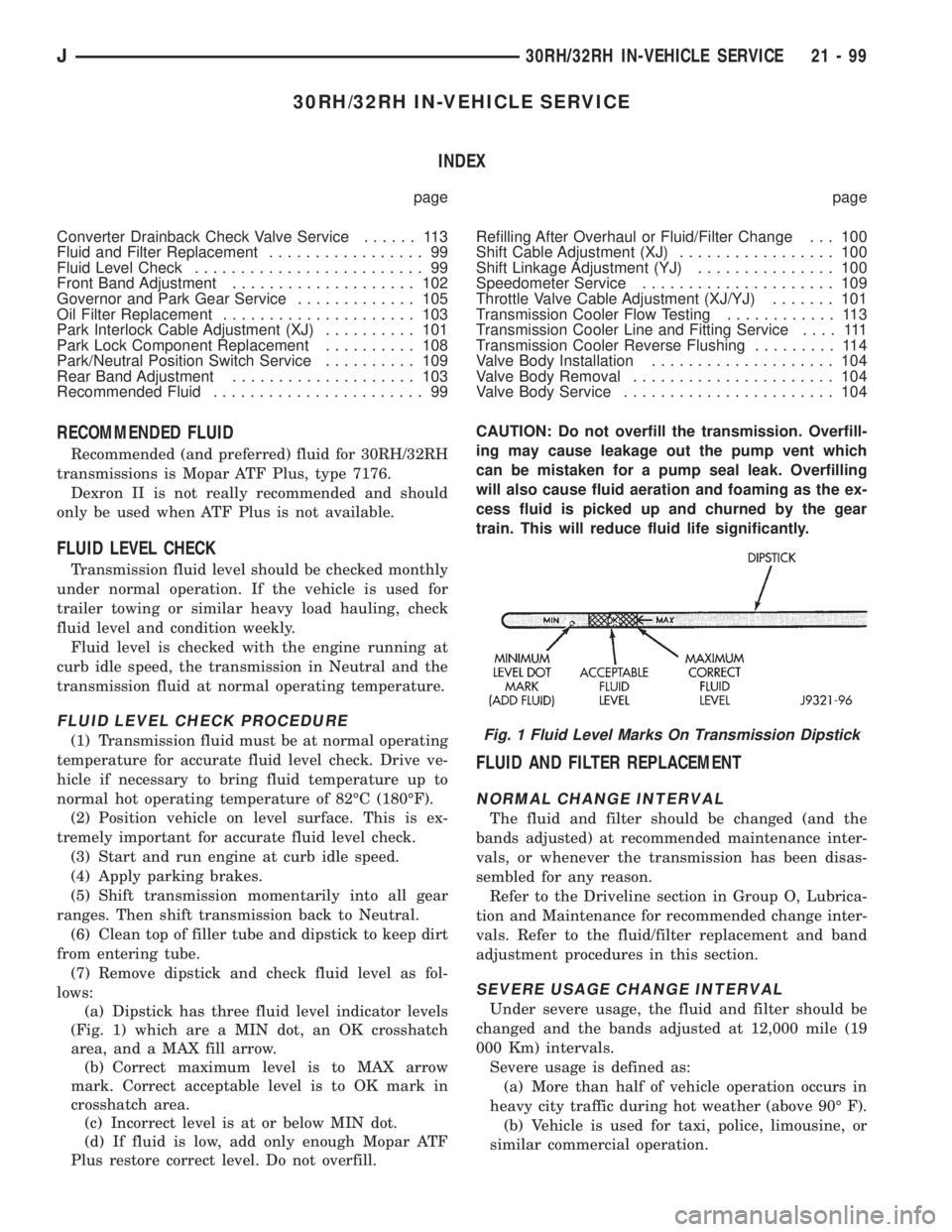

(a) Dipstick has three fluid level indicator levels

(Fig. 1) which are a MIN dot, an OK crosshatch

area, and a MAX fill arrow.

(b) Correct maximum level is to MAX arrow

mark. Correct acceptable level is to OK mark in

crosshatch area.

(c) Incorrect level is at or below MIN dot.

(d) If fluid is low, add only enough Mopar ATF

Plus restore correct level. Do not overfill.CAUTION: Do not overfill the transmission. Overfill-

ing may cause leakage out the pump vent which

can be mistaken for a pump seal leak. Overfilling

will also cause fluid aeration and foaming as the ex-

cess fluid is picked up and churned by the gear

train. This will reduce fluid life significantly.

FLUID AND FILTER REPLACEMENT

NORMAL CHANGE INTERVAL

The fluid and filter should be changed (and the

bands adjusted) at recommended maintenance inter-

vals, or whenever the transmission has been disas-

sembled for any reason.

Refer to the Driveline section in Group O, Lubrica-

tion and Maintenance for recommended change inter-

vals. Refer to the fluid/filter replacement and band

adjustment procedures in this section.

SEVERE USAGE CHANGE INTERVAL

Under severe usage, the fluid and filter should be

changed and the bands adjusted at 12,000 mile (19

000 Km) intervals.

Severe usage is defined as:

(a) More than half of vehicle operation occurs in

heavy city traffic during hot weather (above 90É F).

(b) Vehicle is used for taxi, police, limousine, or

similar commercial operation.

Fig. 1 Fluid Level Marks On Transmission Dipstick

J30RH/32RH IN-VEHICLE SERVICE 21 - 99

Page 1477 of 2198

(c) Vehicle is used for trailer towing or heavy

load hauling.

FLUID/FILTER REPLACEMENT PROCEDURE

(1) Raise vehicle.

(2) Remove oil pan and drain fluid.

(3) Clean oil pan and pan magnet. Then clean re-

maining gasket material from gasket surface of

transmission case.

(4) Remove fluid filter screws and remove filter.

(5) Position new filter on valve body and install fil-

ter screws. Tighten screws to 4 Nzm (35 in. lbs.)

torque.

(6) Adjust rear band at this time if required.

(7) Position new gasket on oil pan and install pan

on transmission. Tighten pan bolts to 150 in. lbs. (17

Nzm) torque.

(8) Adjust front band at this time if required.

(9) Lower vehicle and refill transmission with Mo-

par ATF Plus, type 7176 fluid.

REFILLING AFTER OVERHAUL OR FLUID/FILTER

CHANGE

The most effective way to avoid overfilling after a

fluid change or overhaul is as follows:

(1) Remove dipstick and insert clean funnel in

transmission fill tube.

(2) Add following initial quantity of Mopar ATF

Plus to transmission:

(a) If only fluid and filter were changed, add3

pints (1-1/2 quarts)of ATF Plus to transmission.

(b) If transmission was completely overhauled

and torque converter was replaced or drained, add

10 pints (5 quarts)of ATF Plus to transmission.

(3) Apply parking brakes.

(4) Start and run engine at normal curb idle speed.

(5) Apply service brakes, shift transmission

through all gear ranges then back to Neutral, and

leave engine running at curb idle speed.

(6) Remove funnel, insert dipstick and check fluid

level. Add only enough fluid to bring level toMIN

dot mark on dipstick.

(7) Drive vehicle until transmission fluid is at nor-

mal operating temperature. Then recheck fluid level

as described in next step.

(8) Leave engine running at curb idle speed, shift

into Neutral, and check fluid level again. This time,

add just enough fluid to bring level up toMAX ar-

row mark but do not overfill.

(9) When fluid level is correct, shut engine off, re-

lease park brake, remove funnel, and reseat dipstick

in fill tube.

SHIFT LINKAGE ADJUSTMENT (YJ)

(1) Check linkage adjustment by starting engine in

Park and Neutral.(2) Adjustment is OK if engine starts only in park

and Neutral. Adjustment is incorrect if engine starts

in one but not both positions.

(3) If engine starts in any position other than Park

or Neutral, or if engine will not start at all, park/

neutral position switch may be faulty.

(4) Shift transmission into Park.

(5) Raise vehicle.

(6) Check condition of shift rods, bellcrank,

bellcrank brackets and linkage bushings/grommets

(Fig. 2). Tighten, repair, replace worn, damaged

parts. Do not attempt adjustment if linkage compo-

nents are worn or damaged.

(7) Loosen shift rod trunnion lock bolt or nut. Be

sure upper shift rod slides freely in trunnion (Fig. 2).

Also be sure shift rods and bellcrank rotate freely

and do not bind at any point.

(8) Verify that manual lever is in Park detent (Fig.

2). Move lever all the way rearward to be sure it is in

Park.

(9) Check for positive engagement of park lock by

attempting to rotate propeller shaft. Shaft will not

turn when park pawl is engaged.

(10) Adjust shift rod trunnion to a obtain free pin

fit in bellcrank arm and tighten trunnion lock bolt or

nut. Prevent shift rod from turning while tightening

bolt or nut. Gearshift linkage lash must be elimi-

nated to obtain proper adjustment. Eliminate lash by

pulling downward on shift rod and pressing upward

on bellcrank.

(11) Confirm proper adjustment by starting engine

in Park and Neutral. Engine should start in these

positions only.If engine starts in any position

other than Park or Neutral, adjustment is in-

correct or neutral switch is faulty.

(12) Lower vehicle and verify that steering lock op-

erates correctly.

SHIFT CABLE ADJUSTMENT (XJ)

(1) Shift transmission into Park.

(2) Raise vehicle.

(3) Release cable adjuster clamp to unlock cable

(Figs. 3 and 4). Clamp is at transmission end of ca-

ble.

(4) Unsnap cable from transmission cable bracket.

(5) Move transmission shift lever fully rearward to

Park detent. Lever is on manual valve shaft at driver

side of case.

(6) Verify positive engagement of park lock by at-

tempting to rotate propeller shaft. Shaft will not ro-

tate when park lock is engaged.

(7) Snap cable into cable bracket.

(8) Lock shift cable by pressing cable adjuster

clamp down until it snaps into place.

(9) Check engine starting. Engine should start only

in Park and Neutral.

(10) Lower vehicle.

21 - 100 30RH/32RH IN-VEHICLE SERVICEJ

Page 1540 of 2198

(3) Move input shaft in and out and record read-

ing. End play should be 0.56 - 2.31 mm (0.022 - 0.091

in.).

(4) If end play is incorrect, transmission is incor-

rectly assembled, or output shaft thrust washer

and/or thrust plate are worn and need to be changed.

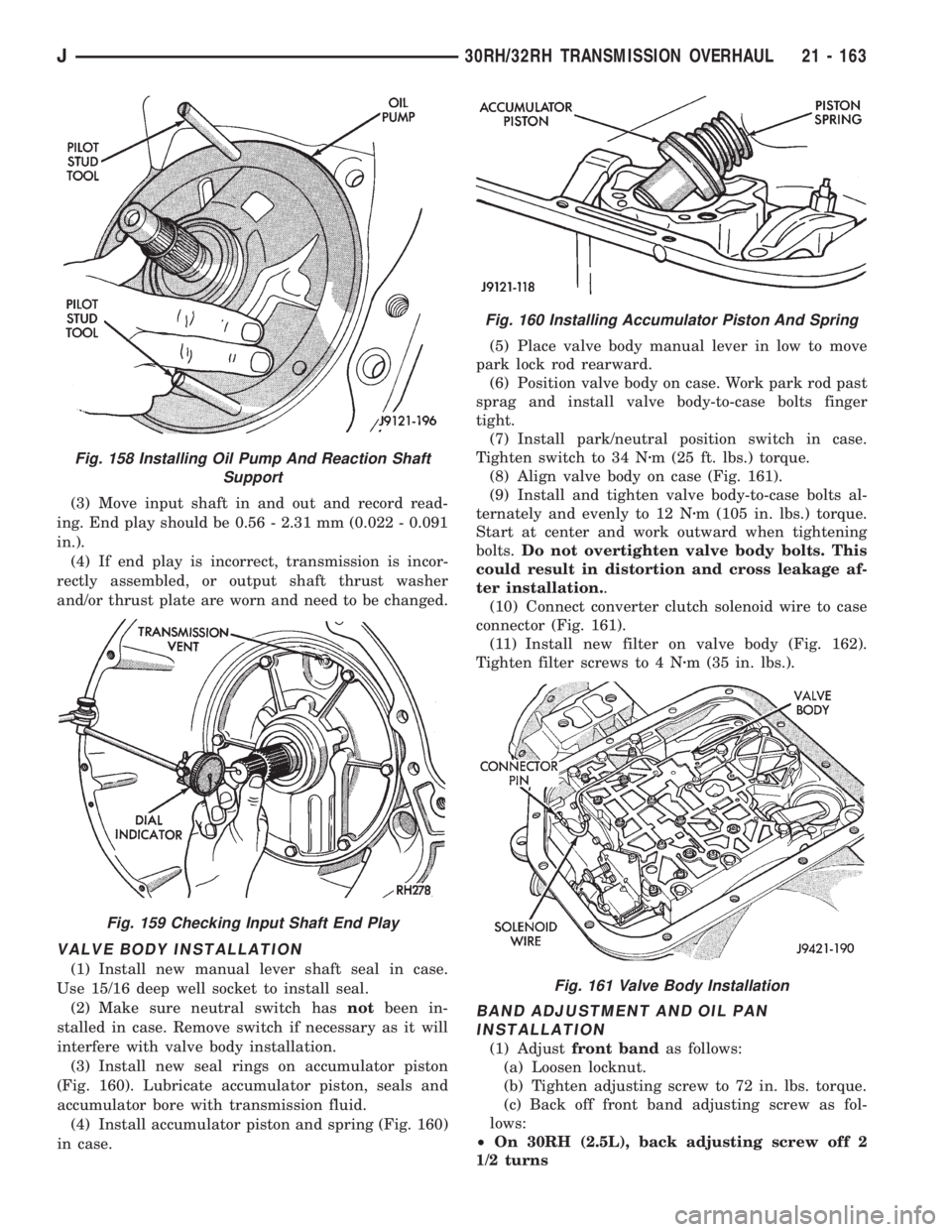

VALVE BODY INSTALLATION

(1) Install new manual lever shaft seal in case.

Use 15/16 deep well socket to install seal.

(2) Make sure neutral switch hasnotbeen in-

stalled in case. Remove switch if necessary as it will

interfere with valve body installation.

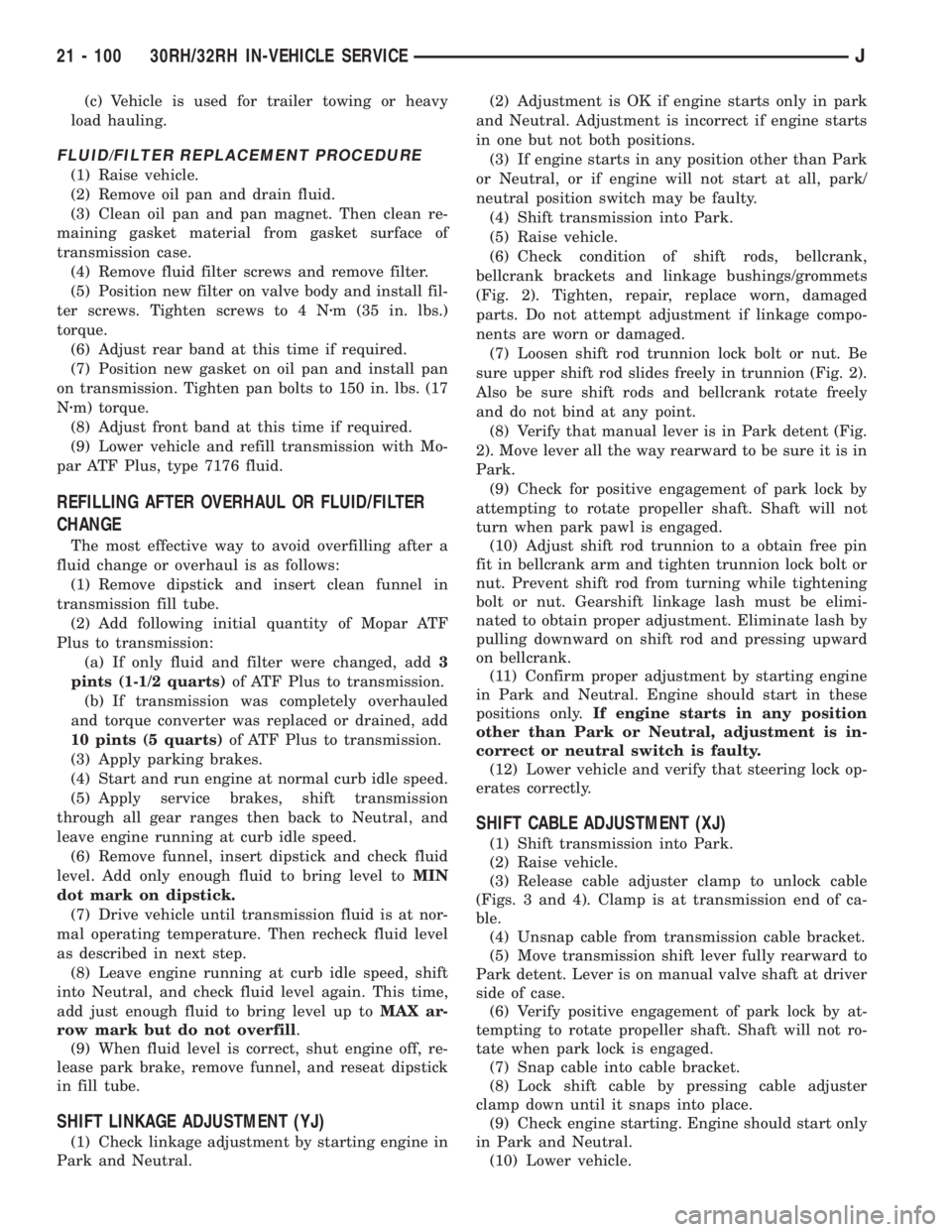

(3) Install new seal rings on accumulator piston

(Fig. 160). Lubricate accumulator piston, seals and

accumulator bore with transmission fluid.

(4) Install accumulator piston and spring (Fig. 160)

in case.(5) Place valve body manual lever in low to move

park lock rod rearward.

(6) Position valve body on case. Work park rod past

sprag and install valve body-to-case bolts finger

tight.

(7) Install park/neutral position switch in case.

Tighten switch to 34 Nzm (25 ft. lbs.) torque.

(8) Align valve body on case (Fig. 161).

(9) Install and tighten valve body-to-case bolts al-

ternately and evenly to 12 Nzm (105 in. lbs.) torque.

Start at center and work outward when tightening

bolts.Do not overtighten valve body bolts. This

could result in distortion and cross leakage af-

ter installation..

(10) Connect converter clutch solenoid wire to case

connector (Fig. 161).

(11) Install new filter on valve body (Fig. 162).

Tighten filter screws to 4 Nzm (35 in. lbs.).

BAND ADJUSTMENT AND OIL PAN

INSTALLATION

(1) Adjustfront bandas follows:

(a) Loosen locknut.

(b) Tighten adjusting screw to 72 in. lbs. torque.

(c) Back off front band adjusting screw as fol-

lows:

²On 30RH (2.5L), back adjusting screw off 2

1/2 turns

Fig. 158 Installing Oil Pump And Reaction Shaft

Support

Fig. 159 Checking Input Shaft End Play

Fig. 160 Installing Accumulator Piston And Spring

Fig. 161 Valve Body Installation

J30RH/32RH TRANSMISSION OVERHAUL 21 - 163

Page 1559 of 2198

AW-4 IN-VEHICLE SERVICE

INDEX

page page

Accumulator Pistons and Springs............. 189

Adapter Housing Seal Replacement........... 191

Checking Fluid Level and Condition........... 182

Manual Valve Shaft Seal Replacement......... 187

Park Interlock Cable Adjustment............. 195

Park Rod and Pawl Service................. 190

Park/Neutral Position Switch................ 183

Refilling After Overhaul or Fluid/Filter Change . . . 182

Second Coast Brake Servo................. 190

Shift Cable Adjustment.................... 195

Speed Sensor........................... 192Speed Sensor RotorÐSpeedometer Drive Gear . . 193

Throttle Position Sensor (TPS) Service........ 193

Transmission Control Module (TCM) Service.... 183

Transmission Cooler Line Fittings............ 197

Transmission Cooler Service................ 196

Transmission Throttle Cable Adjustment........ 194

Transmission Throttle Cable Replacement...... 193

Transmission Valve Body Installation.......... 187

Transmission Valve Body Removal........... 186

Transmission Valve Body Solenoids........... 184

CHECKING FLUID LEVEL AND CONDITION

Recommended fluid for AW-4 transmissions is Mo-

par Dexron IIE/Mercon.

Mopar Dexron II can also be used but only when

Mercon fluid is not available.

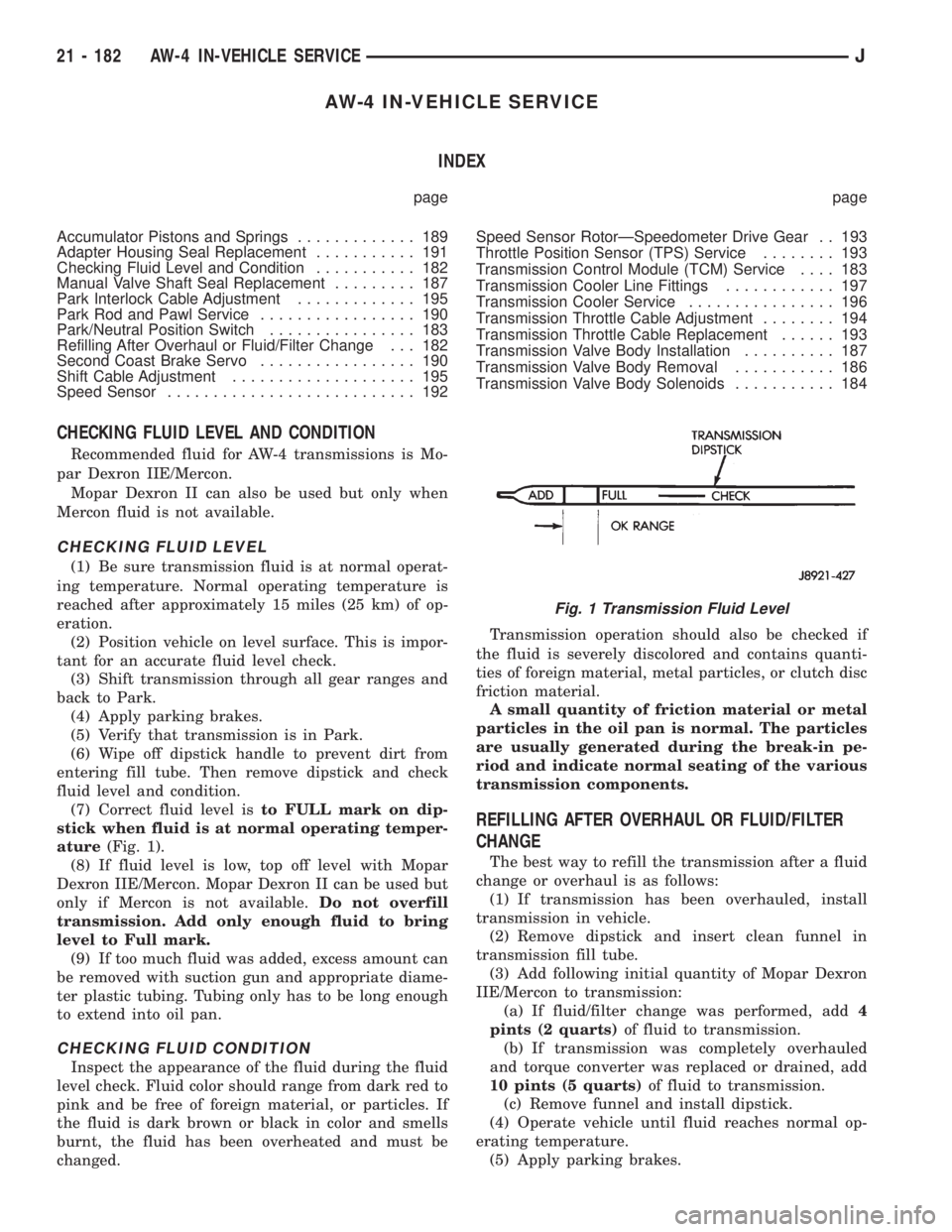

CHECKING FLUID LEVEL

(1) Be sure transmission fluid is at normal operat-

ing temperature. Normal operating temperature is

reached after approximately 15 miles (25 km) of op-

eration.

(2) Position vehicle on level surface. This is impor-

tant for an accurate fluid level check.

(3) Shift transmission through all gear ranges and

back to Park.

(4) Apply parking brakes.

(5) Verify that transmission is in Park.

(6) Wipe off dipstick handle to prevent dirt from

entering fill tube. Then remove dipstick and check

fluid level and condition.

(7) Correct fluid level isto FULL mark on dip-

stick when fluid is at normal operating temper-

ature(Fig. 1).

(8) If fluid level is low, top off level with Mopar

Dexron IIE/Mercon. Mopar Dexron II can be used but

only if Mercon is not available.Do not overfill

transmission. Add only enough fluid to bring

level to Full mark.

(9) If too much fluid was added, excess amount can

be removed with suction gun and appropriate diame-

ter plastic tubing. Tubing only has to be long enough

to extend into oil pan.

CHECKING FLUID CONDITION

Inspect the appearance of the fluid during the fluid

level check. Fluid color should range from dark red to

pink and be free of foreign material, or particles. If

the fluid is dark brown or black in color and smells

burnt, the fluid has been overheated and must be

changed.Transmission operation should also be checked if

the fluid is severely discolored and contains quanti-

ties of foreign material, metal particles, or clutch disc

friction material.

A small quantity of friction material or metal

particles in the oil pan is normal. The particles

are usually generated during the break-in pe-

riod and indicate normal seating of the various

transmission components.

REFILLING AFTER OVERHAUL OR FLUID/FILTER

CHANGE

The best way to refill the transmission after a fluid

change or overhaul is as follows:

(1) If transmission has been overhauled, install

transmission in vehicle.

(2) Remove dipstick and insert clean funnel in

transmission fill tube.

(3) Add following initial quantity of Mopar Dexron

IIE/Mercon to transmission:

(a) If fluid/filter change was performed, add4

pints (2 quarts)of fluid to transmission.

(b) If transmission was completely overhauled

and torque converter was replaced or drained, add

10 pints (5 quarts)of fluid to transmission.

(c) Remove funnel and install dipstick.

(4) Operate vehicle until fluid reaches normal op-

erating temperature.

(5) Apply parking brakes.

Fig. 1 Transmission Fluid Level

21 - 182 AW-4 IN-VEHICLE SERVICEJ

Page 1965 of 2198

BUMPERÐXJ, LIFTGATE LICENSE PLATE

SCREW ANCHOR.....................23-65

BUMPERÐXJ, REAR SEATBACK LATCH

STRIKER...........................23-84

BUMPERS......................13-16,13-5

BUS, CCD; FUEL/IGNITION (XJ).......8W-30-5

BUSHING AND PISTON CLEARANCE,

AW-4 .............................21-339

BUSHING REPLACEMENT, AXLE......2-12,2-34

BUSHING REPLACEMENT, LEAF SPRING

EYE; FRONT SUSPENSION AND AXLE.....2-17

BUSHING REPLACEMENT, LEAF SPRING

EYE; REAR SUSPENSION AND AXLES . . . 3-5,3-7

BUSHINGS, CLUTCH AND BRAKE PEDAL . . . 0-22

BUZZER, COMBINATION; INTERIOR

LIGHTING (YJ)....................8W-44-1

BUZZER MODULE.................8U-1,8U-2

BUZZER MODULE SCHEMATIC - YJ.......8U-4

CABLE, ACCELERATOR PEDAL AND

THROTTLE.....................14-17,14-58

CABLE ADJUSTMENT, PARK INTERLOCK . 21-195

CABLE ADJUSTMENT, SHIFT...........21-195

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE.........................21-194

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE VALVE....................21-71

CABLE ADJUSTMENT (XJ), PARK

INTERLOCK........................21-101

CABLE ADJUSTMENT (XJ), SHIFT.......21-100

CABLE ADJUSTMENT (XJ/YJ), THROTTLE

VALVE..............................21-101

CABLE REMOVE/INSTALL, SERVO.......8H-10

CABLE REPLACEMENT, TRANSMISSION

THROTTLE.........................21-193

CABLE REPLACEMENT (XJ), PARKING

BRAKE REAR.........................5-67

CABLE REPLACEMENT (YJ), PARKING

BRAKE FRONT........................5-67

CABLE REPLACEMENT (YJ), PARKING

BRAKE REAR.........................5-68

CABLE REPLACEMENTÐXJ, LATCH

RELEASE...........................23-11

CABLE RESISTANCE, SPARK PLUG......8D-14

CABLE, SERVO.......................8H-1

CABLE, SPEEDOMETER.................0-33

CABLE TENSIONER ADJUSTMENT

(XJ/YJ), PARKING BRAKE...............5-69

CABLE TENSIONER REPLACEMENT (XJ),

PARKING BRAKE......................5-66

CABLE, THROTTLE...................14-17

CABLE/LINKAGE ADJUSTMENT,

GEARSHIFT.........................21-71

CABLES, DISTRIBUTOR CAP AND

ROTOR, IGNITION.....................0-20

CABLES, SPARK PLUG SECONDARY.....8D-14,

8D-24

CABLES, VENT DOOR CONTROL.........24-32

CALIBRATION, COMPASS...............8C-5

CALIPER ASSEMBLY...................5-50

CALIPER CLEANING AND INSPECTION.....5-50

CALIPER DISASSEMBLY................5-48

CALIPER INSTALLATION................5-51

CALIPER OPERATION AND WEAR

COMPENSATION......................5-45

CALIPER REMOVAL....................5-48

CAMSHAFT......................9-32,9-74

CAMSHAFT PIN REPLACEMENT......9-34,9-75

CAMSHAFT POSITION SENSOR; FUEL

SYSTEM............................14-60

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (XJ)................8W-30-3

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (YJ)................8W-30-3

CAMSHAFT POSITION SENSOR;

IGNITION SYSTEMS..............8D-17,8D-2

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (XJ-RHD)............8W-30-3

CAMSHAFT POSITION SENSOR TEST;

FUEL SYSTEM.......................14-46

CAMSHAFT POSITION SENSOR TEST;

IGNITION SYSTEMS

...................8D-6

CAMSHAFT POSITION SENSORÐPCM

INPUT

.............................14-22

(CANADA ONLY)ÐXJ, DAYTIME

RUNNING LIGHTS

....................8L-15

(CANADA ONLY)ÐYJ, DAYTIME

RUNNING LIGHTS

....................8L-30

CANISTER, EVAP

..................25-4,25-7CAP AND ROTOR, IGNITION CABLES,

DISTRIBUTOR........................0-20

CAP, DISTRIBUTOR....................8D-7

CAP, FUEL TANK FILLER TUBE;

EMISSION CONTROL SYSTEMS......25-4,25-7

CAP, FUEL TANK FILLER TUBE; FUEL

SYSTEM............................14-13

CAP, RADIATOR PRESSURE.............7-25

CAPACITIES, COOLING SYSTEM..........7-45

CAPACITIES, FLUID.....................0-3

CAPACITIES, FUEL TANK..........14-13,14-67

CAPACITY TEST, FUEL PUMP............14-7

CAR REPLACEMENT, PITMAN SHAFT

SEALSÐIN.........................19-23

CARDAN (CV), DOUBLE................16-11

CARDAN, SINGLE....................16-10

CARGO BARRIERÐXJ................23-101

CARGO LAMP AND DOME LAMP;

INTERIOR LIGHTING (XJ-RHD)........8W-44-1

CARGO LAMP, COURTESY LAMPS AND

DOME LAMP; INTERIOR LIGHTING (XJ) . 8W-44-1

CARGO LAMPÐXJ...................23-94

CARPET/MATÐXJ, FRONT.............23-99

CARPET/MATÐXJ, REAR.............23-100

CARPETÐYJ.......................23-156

CARPETS AND FLOOR MATSÐXJ.......23-99

CARRIERÐYJ, EXTERNAL SPARE/

WHEEL TIRE.......................23-133

CASE (4WD VEHICLES), TRANSFER........0-24

CASE ASSEMBLY, TRANSFER....21-294,21-319

CASE CHANGES, TRANSFER...........21-307

CASE CLEANING AND INSPECTION,

TRANSMISSION.....................21-125

CASE COVER OIL SEAL REPLACEMENT,

TIMING.........................9-30,9-73

CASE COVER, TIMING..............9-31,9-72

CASE DISASSEMBLY AND OVERHAUL,

TRANSFER...................21-289,21-310

CASE IDENTIFICATION, TRANSFER.....21-284,

21-307

CASE INSTALLATION, TRANSFER . 21-288,21-309

CASE LUBRICANT AND FILL LEVEL,

TRANSFER.........................21-284

CASE, NP231 TRANSFER.......21-283,21-305

CASE, NP242 TRANSFER.......21-307,21-331

CASE OVERHAUL, FIRST-REVERSE

BRAKE PISTON AND TRANSMISSION....21-247

CASE REMOVAL, TRANSFER.....21-287,21-309

CASE SKID PLATE, TRANSFER......13-15,13-3

CASE SPECIFICATIONS, TRANSMISSION/

TRANSFER.........................21-333

CATALYTIC CONVERTER............11-1,11-4

CATALYTIC CONVERTOR................25-1

CAUTIONS, AND WARNINGS, NOTES;

WIRING DIAGRAMSÐGENERAL

INFORMATION (XJ)...................8W-1

CCD BUS; FUEL/IGNITION (XJ)........8W-30-5

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐXJ.......................8L-12

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐYJ.......................8L-28

CERTIFICATION LABEL, VEHICLE SAFETY . Intro.-4

CHAIN AND SPROCKETS, TIMING....9-31,9-73

CHANGE AND FILTER REPLACEMENT,

ENGINE OIL

..........................0-16

CHANGE, LUBRICANT; FRONT

SUSPENSION AND AXLE

................2-23

CHANGE, LUBRICANT; REAR

SUSPENSION AND AXLES

...........3-13,3-31

CHANGE, REFILLING AFTER OVERHAUL

OR FLUID/FILTER

..............21-100,21-182

CHANGES AND PARTS

INTERCHANGEABILITY, TRANSMISSION

. . . 21-67

CHANGES, TRANSFER CASE

...........21-307

CHANNEL REPLACEMENTÐYJ, DOOR

FRAME GLASS

......................23-142

CHARGING, BATTERY

..................8A-7

CHARGING REFRIGERANT SYSTEM

......24-11

CHARGING SYSTEM; BATTERY/

STARTING/CHARGING SYSTEMS

DIAGNOSTICS

.......................8A-17

CHARGING SYSTEM; CHARGING

SYSTEM (XJ)

.....................8W-20-1

CHARGING SYSTEM; CHARGING

SYSTEM (XJ-RHD)

.................8W-20-1

CHARGING SYSTEM; CHARGING

SYSTEM (YJ)

.....................8W-20-1CHARGING SYSTEM INDICATOR LAMP;

INSTRUMENT CLUSTER (XJ).........8W-40-3

CHARGING SYSTEM SPECIFICATIONS....8A-23

CHARGING TIME TABLE, BATTERY........8A-8

CHART, MAIN BEARING FITTING......9-48,9-90

CHART, XJ PERFORMANCE

TEMPERATURE AND PRESSURE.........24-13

CHART, YJ PERFORMANCE

TEMPERATURE AND PRESSURE.........24-13

CHARTÐAX 15 MANUAL

TRANSMISSION, SELECTIVE SNAP

RING.............................21-334

CHARTS, BRAKELINE..................5-12

CHARTS, DIAGNOSIS GUIDES...........21-77

CHARTS, GEARTRAIN OPERATION AND

APPLICATION.......................21-169

CHARTS, INSPECTION AND DIAGNOSIS.....6-4

CHASSIS AND BODY COMPONENTS.......0-28

CHASSIS COMPONENT AND WHEEL

BEARING LUBRICANTS.................0-28

CHECK VALVE TEST, POWER BOOSTER.....5-9

CHECKING FLUID LEVEL AND

CONDITION........................21-182

CHECKS, PRELIMINARY.................7-5

CHIME/BUZZER MODULE; INTERIOR

LIGHTING (XJ)....................8W-44-2

CHIME/BUZZER MODULE; INTERIOR

LIGHTING (XJ-RHD)................8W-44-2

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (XJ)....................8W-51-1

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (XJ-RHD)................8W-51-1

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (YJ)....................8W-51-1

(CHMSL)ÐXJ, CENTER HIGH MOUNTED

STOP LAMP.........................8L-12

(CHMSL)ÐYJ, CENTER HIGH MOUNTED

STOP LAMP.........................8L-28

CIGAR LIGHTER; HORN/CIGAR LIGHTER . . . 8E-1

CIGAR LIGHTER; HORN/CIGAR LIGHTER

(YJ).............................8W-41-1

CIGAR LIGHTER; INSTRUMENT CLUSTER

(XJ).............................8W-40-1

CIRCUIT IDENTIFICATION; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-1

CIRCUIT REMOVE/INSTALL, PRINTED....8E-19,

8E-40

CIRCUIT SENSEÐPCM INPUT, IGNITION . . 14-23

CIRCUIT VOLTAGE, OPEN...............8A-6

CLAMPS, FUEL TUBES/LINES/HOSES . 14-62,14-9

CLASSIFICATION OF LUBRICANTS.........0-2

CLASSIFICATIONS AND RATINGS,

BATTERY...........................8A-23

CLEANER, AIR.......................14-29

CLEANER ELEMENT, AIR; EMISSION

CONTROL SYSTEMS...................25-7

CLEANER ELEMENT, AIR; FUEL SYSTEM . . 14-59

CLEANER ELEMENT, AIR; LUBRICATION

AND MAINTENANCE...................0-18

CLEANER HOUSING, AIR...............14-58

CLEANING AND INSPECTION, CALIPER....5-50

CLEANING AND INSPECTION, GEAR......19-42

CLEANING AND INSPECTION,

TRANSMISSION CASE................21-125

CLEANING OF TIRES...................22-2

CLEANING/INSPECTION; FRONT

SUSPENSION AND AXLE

................2-37

CLEANING/INSPECTION; REAR

SUSPENSION AND AXLES

...............3-20

CLEANING/REVERSE FLUSHING,

COOLING SYSTEM

....................7-22

CLEARANCE AND RAMP ANGLE,

GROUND

............................0-11

CLEARANCE, AW-4 BUSHING AND

PISTON

...........................21-339

CLOCKSPRING

.......................19-51

CLUSTER AND GAUGE HOUSINGSÐYJ,

INSTRUMENT

......................23-151

CLUSTER ASSEMBLY REMOVE/INSTALL

. . 8E-17,

8E-35

CLUSTER BEZELÐXJ, INSTRUMENT

.....23-80

CLUSTER BEZELÐYJ, INSTRUMENT

....23-151

CLUSTER CONNECTORS (RHD)

.........8E-11

CLUSTER, GAUGE PACKAGE

.......8E-31,8E-43

CLUSTER GROUND; INSTRUMENT

CLUSTER (XJ)

.....................8W-40-3

4 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 1970 of 2198

DOOR REMOVAL/INSTALLATIONÐXJ.....23-35

DOOR RESTRAINT REPLACEMENTÐXJ . . . 23-41

DOOR SERVICEÐYJ, FULL-METAL......23-142

DOOR SPACER BLOCKSÐTWO-DOOR

VEHICLES, FRONT....................23-53

DOOR STATIONARY WINDOW

GLASSÐXJ, REAR...................23-46

DOOR TRIM PANELÐXJ...............23-31

DOOR TRIM PANELÐYJ, FULL-METAL . . . 23-137

DOOR VACUUM MOTOR, FRESH AIR.....24-34

DOOR VACUUM MOTOR REPLACEMENT,

A/C RECIRCULATING..................24-27

DOOR VENT WINDOW GLASSÐYJ,

FULL-METAL.......................23-137

DOOR WATERDAMÐYJ, FULL-METAL . . . 23-137

DOOR WEATHERSTRIP SEAL

REPLACEMENTÐYJ.................23-142

DOOR WEATHERSTRIP SEALSÐYJ,

FULL-METAL.......................23-141

DOOR WINDOW EXTERIOR

MOLDINGSÐXJ.....................23-54

DOOR WINDOW GLASS AND DOOR

OPENING WEATHERSTRIP SEALSÐXJ....23-55

DOOR WINDOW GLASS REGULATOR

HANDLEÐYJ, FULL-METAL............23-136

DOOR WINDOW GLASS REGULATORÐ

XJ, FRONT..........................23-42

DOOR WINDOW GLASS REGULATORÐ

XJ, REAR...........................23-44

DOOR WINDOW GLASS REGULATORÐ

YJ, FULL-METAL....................23-138

DOOR WINDOW GLASSÐXJ, FRONT.....23-43

DOOR WINDOW GLASSÐXJ, REAR......23-45

DOOR WINDOW GLASSÐYJ, FULL-

METAL............................23-139

DOORÐYJ, HALF-METAL SOFT TOP.....23-134

DOUBLE CARDAN (CV)................16-11

DRAG LINK....................19-16,19-20

DRAINING COOLING SYSTEM............7-21

DRAW FUSE, IGNITION-OFF.............8F-1

DRAW, IGNITION-OFF.................8A-10

DRB SCAN TOOL; BRAKES...............5-3

DRB SCAN TOOL; COOLING SYSTEM.......7-5

DRB SCAN TOOL; EMISSION CONTROL

SYSTEMS...........................25-2

DRB SCAN TOOL; FUEL SYSTEM........14-54

DRB SCAN TOOL; IGNITION SYSTEMS....8D-8

DRIERÐ2.5L ENGINES, CONDENSER

FILTER.............................24-27

DRIERÐ4.0L ENGINES, FILTER.........24-28

DRIP RAIL MOLDINGÐXJ.............23-25

DRIVE (4WD) SWITCH, FOUR-WHEEL;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

DRIVE (4WD) SWITCH, FOUR-WHEEL;

TRANSMISSION CONTROLS (XJ-RHD) . . 8W-31-1

DRIVE, AUTOMATIC BELT TENSIONERÐ

XJ MODELS WITH RIGHT HAND..........7-42

DRIVE AXLE ASSEMBLY

REPLACEMENTÐXJ VEHICLES; FRONT

SUSPENSION AND AXLE................2-23

DRIVE AXLE ASSEMBLY

REPLACEMENTÐXJ VEHICLES; REAR

SUSPENSION AND AXLES...........3-14,3-31

DRIVE AXLE ASSEMBLY

REPLACEMENTÐYJ VEHICLES; FRONT

SUSPENSION AND AXLE................2-24

DRIVE AXLE ASSEMBLY

REPLACEMENTÐYJ VEHICLES; REAR

SUSPENSION AND AXLES

...............3-14

DRIVE AXLE, FRONT

....................2-3

DRIVE BELT, ACCESSORY

...............0-21

DRIVE BELT DIAGNOSIS (CONT.),

SERPENTINE

.........................7-40

DRIVE BELT DIAGNOSIS, SERPENTINE

.....7-39

DRIVE, BELT SERVICEÐEXCEPT RIGHT

HAND

...............................7-40

DRIVE, BELT SERVICEÐXJ MODELS

WITH RIGHT HAND

....................7-42

DRIVE BELT TENSION

..................7-45

DRIVE BELTS, ENGINE ACCESSORY

.......7-38

DRIVE GEAR, SPEED SENSOR

ROTORÐSPEEDOMETER

.............21-193

DRIVE, GENERATOR REMOVE/INSTALLÐ

LEFT-HAND

..........................8B-6

DRIVE, GENERATOR REMOVE/INSTALLÐ

RIGHT-HAND

.........................8B-7

DRIVE PULLEY REPLACEMENT

..........19-13DRIVE (RHD), BELT TENSIONÐEXCEPT

RIGHT HAND.........................7-38

DRIVE (RHD), BELT TENSIONÐRIGHT

HAND...............................7-38

DRIVE (RHD) MODELS, BELT TENSIONÐ

EXCEPT RIGHT HAND..................7-45

DRIVE SHAFTS.......................0-26

DRIVE VEHICLES, RIGHT HAND..........23-1

DRIVE, VISCOUS FAN..................7-34

DRIVELINE SNAP; FRONT SUSPENSION

AND AXLE...........................2-19

DRIVELINE SNAP; REAR SUSPENSION

AND AXLES..........................3-10

DRIVELINE VIBRATION.................16-3

DRIVER'S DOOR JAMB SWITCH.....8U-1,8U-2

DRIVER'S POWER LOCK SWITCHÐ2-

DOOR (LHD).........................8P-3

DRIVER'S POWER LOCK SWITCHÐ2-

DOOR (RHD).........................8P-4

DRIVER'S POWER LOCK SWITCHÐ4-

DOOR..............................8P-5

DRIVER'S POWER WINDOW SWITCHÐ

2-DOOR (LHD).......................8S-4

DRIVER'S POWER WINDOW SWITCHÐ

2-DOOR (RHD).......................8S-5

DRIVER'S POWER WINDOW SWITCHÐ

4-DOOR.............................8S-3

DRIVER'S SEAT BELT SWITCH.......8U-1,8U-3

DRIVETRAIN.........................0-22

DRL MODULE REPLACEMENTÐXJ.......8L-15

DRL MODULE REPLACEMENTÐYJ........8L-30

DRUM BRAKE ADJUSTMENT............5-57

DRUM BRAKES.......................5-55

DRUM BRAKESHOE INSTALLATION.......5-55

DRUM BRAKESHOE REMOVAL...........5-55

DRUM REFINISHING, BRAKE............5-58

DRUMÐREAR SUPPORT OVERHAUL,

OVERRUNNING CLUTCHÐLOW-

REVERSE..........................21-125

DUCT, DEFROSTER NOZZLE............24-33

DUCT, FRESH AIR INTAKE..............24-34

ECU AND HCU DIAGNOSIS, ANTILOCK......5-3

ECU INSTALLATION (XJ MODELS)........5-40

ECU OPERATION......................5-37

ECU REMOVAL (XJ MODELS)............5-40

ECU REMOVAL/INSTALLATION (YJ

MODELS)............................5-41

EDGE GUARD/EDGE PROTECTOR

STRIPÐXJ, DOOR....................23-54

EFFECTS OF INCORRECT FLUID LEVEL....21-71

EFFORT, HARD PEDAL OR HIGH PEDAL.....5-6

ELECTRIC COOLING FANÐXJ MODELS

WITH 4.0L 6-CYLINDER ENGINE,

AUXILIARY..........................7-35

ELECTRICAL CONTROL, FUEL PUMP......14-5

ELECTRONIC CONTROL UNIT (ECU).......5-34

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-2

ELEMENT, AIR CLEANER; EMISSION

CONTROL SYSTEMS...................25-7

ELEMENT, AIR CLEANER; FUEL SYSTEM . . 14-59

ELEMENT, AIR CLEANER; LUBRICATION

AND MAINTENANCE...................0-18

ELEMENT TEST, OXYGEN SENSOR (O2S)

HEATING...........................14-48

ELEMENTS, HEATER; POWER MIRRORS

(XJ-RHD).........................8W-62-1

EMISSION CONTROL INFORMATION

(VECI) LABEL, VEHICLE.................25-1

EMISSION CONTROL SYSTEM...........0-20

EMISSION CONTROL SYSTEM

MAINTENANCE........................0-4

EMISSION CONTROLS..................25-4

EMR LAMPÐPCM OUTPUT............14-27

ENGINE ACCESSORY DRIVE BELTS.......7-38

ENGINE AND TRANSMISSION/TRANSFER

CASE IDENTIFICATION...............Intro.-5

ENGINE ASSEMBLY (SHORT BLOCK),

SERVICE.............................9-4

ENGINE ASSEMBLYÐXJ VEHICLES

. . . 9-18,9-59

ENGINE ASSEMBLYÐYJ VEHICLES

. . . 9-20,9-62

ENGINE, AUXILIARY ELECTRIC COOLING

FANÐXJ MODELS WITH 4.0L

6-CYLINDER

.........................7-35

ENGINE BLOCK HEATER

................7-44

ENGINE BREAK-IN

.....................0-15ENGINE COOLANT TEMPERATURE

GAUGE; INSTRUMENT CLUSTER (XJ) . . 8W-40-1

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL SYSTEM...............14-60

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL/IGNITION (XJ)........8W-30-3

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL/IGNITION (YJ)........8W-30-3

ENGINE COOLANT TEMPERATURE

SENSOR; IGNITION SYSTEMS......8D-19,8D-5

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL/IGNITION (XJ-RHD)....8W-30-3

ENGINE COOLANT TEMPERATURE

SENSOR TEST; FUEL SYSTEM..........14-46

ENGINE COOLANT TEMPERATURE

SENSOR TEST; IGNITION SYSTEMS.......8D-9

ENGINE COOLANT TEMPERATURE

SENSORÐPCM INPUT................14-23

ENGINE COOLANT TEMPERATURE

WARNING LAMP; INSTRUMENT

CLUSTER (XJ).....................8W-40-1

ENGINE COOLANT TEMPERATURE

WARNING LAMP; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-1

ENGINE COOLING SYSTEM..............0-18

ENGINE CYLINDER HEAD...........9-25,9-67

ENGINE CYLINDER HEAD COVER.....9-22,9-64

ENGINE CYLINDER HEAD GASKET

FAILURE DIAGNOSIS....................9-5

ENGINE DAMPER.....................9-17

ENGINE DIAGNOSIS....................9-5

ENGINE, DIAGRAM INDEXÐ2.5L;

FUEL/IGNITION (XJ)..................8W-30-6

ENGINE, DIAGRAM INDEXÐ4.0L;

FUEL/IGNITION (XJ)................8W-30-6

ENGINE, ENGINE EXHAUST MANIFOLDÐ

2.5L................................11-7

ENGINE, ENGINE EXHAUST MANIFOLDÐ

4.0L................................11-7

ENGINE, ENGINE FIRING ORDERÐ2.5L

4-CYLINDER........................8D-32

ENGINE, ENGINE FIRING ORDERÐ4.0L

6-CYLINDER........................8D-32

ENGINE EXHAUST MANIFOLDÐ2.5L

ENGINE.............................11-7

ENGINE EXHAUST MANIFOLDÐ4.0L

ENGINE.............................11-7

ENGINE FIRING ORDERÐ2.5L

4-CYLINDER ENGINE.................8D-32

ENGINE FIRING ORDERÐ4.0L

6-CYLINDER ENGINE.................8D-32

ENGINE, INTAKE MANIFOLDÐ2.5L........11-7

ENGINE, INTAKE MANIFOLDÐ4.0L........11-8

ENGINE MAINTENANCE.................0-15

ENGINE MOUNTÐREAR............9-16,9-57

ENGINE MOUNTSÐFRONT..........9-14,9-56

ENGINE OIL..........................0-15

ENGINE OIL CHANGE AND FILTER

REPLACEMENT.......................0-16

ENGINE OIL FILTER....................0-17

ENGINE OIL PRESSURE.................9-7

ENGINE ONLY, POWER STEERING

PRESSURE SWITCHÐ2.5L.............14-63

ENGINE ONLY, TORQUE CONVERTER

CLUTCH (TCC) SOLENOID AND

RELAYÐ2.5L; TRANSMISSION

CONTROLS (XJ)...................8W-31-1

ENGINE ONLY, TRANSMISSION

CONTROL MODULEÐ4.0L;

TRANSMISSION CONTROLS (XJ)......8W-31-1

ENGINE PERFORMANCE.................9-2

ENGINE SERVICE PROCEDURES, 2.5L.....9-13

ENGINE SERVICE PROCEDURES, 4.0L.....9-55

ENGINE SPECIFICATIONS...........9-52,9-93

ENGINE, VACUUM ROUTING

SCHEMATICÐ2.5L 4 CYLINDER..........25-3

ENGINE, VACUUM ROUTING

SCHEMATICÐ4.0L 6 CYLINDER..........25-3

ENGINES, CONDENSER FILTER

DRIERÐ2.5L........................24-27

ENGINES, CONDENSERÐ4.0L..........24-28

ENGINES, FILTER DRIERÐ4.0L

.........24-28

ENGINES, FUEL USAGE STATEMENTÐ

GAS

................................0-19

ENGLISH/SAE CONVERSION, METRIC

. . Intro.-11

ENTRY MODULE, KEYLESS

.........8P-1,8P-7

ENTRY MODULE, REMOTE KEYLESS;

POWER DOOR LOCKS (XJ)

...........8W-61-1

JINDEX 9

Description Group-Page Description Group-Page Description Group-Page

Page 1971 of 2198

ENTRY MODULE REMOVE/INSTALL,

KEYLESS...........................8P-10

ENTRY RECEIVER, KEYLESS.............8C-1

ENTRY RECEIVERÐXJ, KEYLESS........23-93

ENTRY TRANSMITTER, KEYLESS . 8P-1,8P-7,8P-8

EQUIPMENT, REFRIGERANT.............24-7

EQUIVALENT VALUES, CONVERSION

FORMULAS.......................Intro.-11

EVACUATING REFRIGERANT SYSTEM.....24-11

EVAP CANISTER..................25-4,25-7

EVAP (EVAPORATION) CONTROL

SYSTEM............................25-4

EVAPORATIVE HOUSING

COMPONENTSÐYJ....................24-6

EVAPORATOR AND HOUSING...........24-35

EVAPORATOR COIL...................24-30

EVAPORATOR/BLOWER HOUSING........24-29

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM............................25-1

EXHAUST GRILLEÐXJ, AIR............23-25

EXHAUST HEAT SHIELDS...............11-1

EXHAUST MANIFOLDÐ2.5L ENGINE,

ENGINE.............................11-7

EXHAUST MANIFOLDÐ4.0L ENGINE,

ENGINE.............................11-7

EXHAUST PIPEÐXJ VEHICLES...........11-3

EXHAUST PIPEÐYJ VEHICLES...........11-4

EXHAUST SYSTEM; EXHAUST SYSTEM

AND INTAKE MANIFOLD................11-1

EXHAUST SYSTEM; LUBRICATION AND

MAINTENANCE.......................0-21

EXHAUST SYSTEM DIAGNOSIS..........11-2

EXHAUST TAILPIPEÐXJ VEHICLES,

MUFFLER............................11-5

EXHAUST TAILPIPEÐYJ VEHICLES,

MUFFLER............................11-6

EXPANSION VALVE..............24-31,24-35

EXTENDED IDLE SWITCH; FUEL/

IGNITION (XJ).....................8W-30-5

EXTENDED IDLE SWITCH TEST..........14-48

EXTENDED IDLE SWITCHÐPCM INPUT . . . 14-23

EXTENSIONÐXJ, QUARTER TRIM PANEL . 23-87

EXTERIOR COMPONENTS.........23-104,23-3

EXTERIOR LAMPSÐXJ................8L-18

EXTERIOR LAMPSÐYJ................8L-32

EXTERIOR MOLDINGSÐXJ, DOOR

WINDOW...........................23-54

EXTERIOR NAMEPLATES (ADHESIVE-

BACKED)ÐYJ......................23-120

EXTERIOR NAMEPLATESÐXJ...........23-26

EXTERNAL HANDLEÐXJ, DOOR.........23-48

EXTERNAL MIRRORSÐXJ.............23-27

EXTERNAL RELEASE HANDLEÐYJ,

FULL-METAL DOOR LATCH............23-140

EXTERNAL SPARE/WHEEL TIRE

CARRIERÐYJ......................23-133

(EXTERNAL)ÐYJ, HALF METAL DOOR

MIRROR..........................23-121

EYE BUSHING REPLACEMENT, LEAF

SPRING; FRONT SUSPENSION AND

AXLE...............................2-17

EYE BUSHING REPLACEMENT, LEAF

SPRING; REAR SUSPENSION AND

AXLES............................3-5,3-7

FAN RELAY AND MOTOR, RADIATOR;

AIR CONDITIONING/HEATER (XJ)......8W-42-2

FAN RELAY AND MOTOR, RADIATOR;

AIR CONDITIONING/HEATER (XJ-RHD) . . 8W-42-2

FAN RELAYÐPCM OUTPUT, RADIATOR . . . 14-28

FANÐXJ MODELS WITH 4.0L

6-CYLINDER ENGINE, AUXILIARY

ELECTRIC COOLING...................7-35

FANS, COOLING SYSTEM...............7-32

FEED, BATTERY; FUEL/IGNITION (XJ) . . . 8W-30-1

FEED, BATTERY; FUEL/IGNITION (YJ) . . . 8W-30-2

FEED, BATTERY; FUEL/IGNITION

(XJ-RHD).........................8W-30-1

FEED, IGNITION; FUEL/IGNITION

(XJ-RHD).........................8W-30-1

FENDER FLAREÐYJ.................23-114

FENDER INNER SPLASH SHIELDSÐYJ . . 23-116

FENDER SPLASH APRONSÐYJ........23-115

FENDERÐXJ, FRONT

.................23-14

FENDERSÐYJ

......................23-110

FIELDÐPCM OUTPUT, GENERATOR

......14-27

FILL LEVEL, TRANSFER CASE

LUBRICANT

........................21-284

FILLER DOOR BUMPERSÐXJ, FUEL

.....23-27FILLER HOSE SPLASH SHIELDÐXJ

VEHICLES, FUEL......................13-4

FILLER NOZZLE/TUBEÐXJ, FUEL........23-26

FILLER PROTECTOR/NOZZLEÐYJ, FUEL . 23-121

FILLER TUBE CAP, FUEL TANK;

EMISSION CONTROL SYSTEMS......25-4,25-7

FILLER TUBE CAP, FUEL TANK; FUEL

SYSTEM............................14-13

FILLER TUBE, NO-LEAD FUEL TANK......14-13

FILTER DRIERÐ2.5L ENGINES,

CONDENSER........................24-27

FILTER DRIERÐ4.0L ENGINES..........24-28

FILTER, ENGINE OIL...................0-17

FILTER, FUEL; FUEL SYSTEM.......14-60,14-9

FILTER, FUEL; LUBRICATION AND

MAINTENANCE.......................0-19

FILTER REPLACEMENT, ENGINE OIL

CHANGE............................0-16

FILTER REPLACEMENT, FLUID..........21-99

FILTER REPLACEMENT, OIL............21-103

FIN SENSING CYCLING CLUTCH SWITCH . 24-15,

24-31

FINAL ASSEMBLY; FRONT SUSPENSION

AND AXLE...........................2-46

FINAL ASSEMBLY; REAR SUSPENSION

AND AXLES..........................3-29

FIRING ORDERÐ2.5L 4-CYLINDER

ENGINE, ENGINE.....................8D-32

FIRING ORDERÐ4.0L 6-CYLINDER

ENGINE, ENGINE.....................8D-32

FIRST-REVERSE BRAKE PISTON AND

TRANSMISSION CASE OVERHAUL......21-247

FIRST/SECOND/THIRD/REVERSE

COMPONENTS......................21-168

FITTING CHART, CONNECTING ROD

BEARING........................9-41,9-83

FITTING CHART, MAIN BEARING......9-48,9-90

FITTING O-RING SEAL, FLOW CONTROL

VALVE .............................19-14

FITTING SERVICE, TRANSMISSION

COOLER LINE......................21-111

FITTINGS, TRANSMISSION COOLER LINE . 21-197

FLAREÐYJ, FENDER.................23-114

FLARES AND LINERSÐXJ, REAR

WHEELHOUSE.......................23-19

FLASHER, COMBINATION; TURN

SIGNALS (XJ).....................8W-52-1

FLASHERS, HAZARD; TURN SIGNALS

(XJ).............................8W-52-1

FLASHERS, HAZARD; TURN SIGNALS

(XJ-RHD).........................8W-52-1

FLASHERS, HAZARD; TURN SIGNALS

(YJ).............................8W-52-1

FLOOR BRACKETSÐXJ, SPARE

TIRE/WHEEL HOLDDOWN..............23-98

FLOOR CONSOLEÐXJ, FULL...........23-95

FLOOR CONSOLESÐYJ...............23-155

FLOOR MATSÐXJ, CARPETS...........23-99

FLOOR SHIFTÐXJ, MINI-CONSOLE WITH . 23-94

FLOW CONTROL VALVE FITTING O-RING

SEAL..............................19-14

FLOW TESTING, TRANSMISSION

COOLER...........................21-113

FLUID AND FILTER REPLACEMENT.......21-99

FLUID CAPACITIES.....................0-3

FLUID, CLUTCH LINKAGE................6-1

FLUID CONTAMINATION, BRAKE.......5-10,5-7

FLUID LEVEL AND CONDITION,

CHECKING.........................21-182

FLUID LEVEL, BRAKE..................5-10

FLUID LEVEL CHECK.............21-70,21-99

FLUID LEVEL, CLUTCH.................6-14

FLUID, RECOMMENDED BRAKE..........5-10

FLUID WARNING LAMP, LOW WASHER;

INSTRUMENT CLUSTER (XJ).........8W-40-2

FLUID WARNING LAMP, LOW WASHER;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

FLUID/FILTER CHANGE, REFILLING

AFTER OVERHAUL OR..........21-100,21-182

FLUID/LUBRICANTS/CLEANING

SOLVENTS, BRAKE

.....................5-2

FLUIDÐBRAKE BLEEDINGÐ

BRAKELINES AND HOSES, BRAKE

........5-10

FLUSHING, COOLING SYSTEM

CLEANING/REVERSE

...................7-22

FLUSHING, TRANSMISSION COOLER

REVERSE

..........................21-114

FLYWHEEL RUNOUT

....................6-3FLYWHEEL SERVICE...................6-16

FOG LAMP DIAGNOSIS............8L-21,8L-3

FOG LAMP REPLACEMENTÐXJ..........8L-9

FOG LAMP REPLACEMENTÐYJ.........8L-25

FOG LAMP SWITCH REPLACEMENTÐXJ . . 8L-10

FOG LAMP SWITCH REPLACEMENTÐYJ . . 8L-26

FOG LAMPS; FRONT LIGHTING (XJ) . . . 8W-50-1

FOG LAMPS; FRONT LIGHTING (XJ-RHD) . 8W-50-2

FOG LAMPS; FRONT LIGHTING (YJ) . . . 8W-50-1

FOG LAMPSÐXJ......................8L-7

FOG LAMPSÐYJ.....................8L-23

FORM-IN-PLACE GASKETS...............9-1

FORMULAS AND EQUIVALENT VALUES,

CONVERSION.....................Intro.-11

FORWARD CLUTCH OVERHAUL........21-232

FOURTH GEAR OVERDRIVE

COMPONENTS......................21-167

FOUR-WHEEL DRIVE (4WD) SWITCH;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

FOUR-WHEEL DRIVE (4WD) SWITCH;

TRANSMISSION CONTROLS (XJ-RHD) . . 8W-31-1

FOUR-WHEEL-DRIVE VEHICLE TOWING....0-12

FRAME.........................13-10,13-1

FRAME CROSSMEMBER COVER.........13-16

FRAME DIMENSIONS.............13-13,13-1

FRAME GLASS CHANNEL

REPLACEMENTÐYJ, DOOR...........23-142

FRAME REPAIRS......................13-13

FRAME STRAIGHTENING...............13-13

FRAME WEATHERSTRIP SEALÐYJ,

WINDSHIELD.......................23-146

FRAMEÐXJ, BUCKET SEATBACK COVER . . 23-81

FRAMEÐYJ, WINDSHIELD............23-145

FREQUENCY INTERFERENCE, RADIO......8F-5

FRESH AIR DOOR VACUUM MOTOR......24-34

FRESH AIR INTAKE DUCT..............24-34

FRONT AND REAR AXLES...............0-24

FRONT AXLE, MODEL 30...............2-49

FRONT BUCKET SEATSÐXJ............23-81

FRONT BUMPER.................13-16,13-5

FRONT CABLE REPLACEMENT (YJ),

PARKING BRAKE......................5-67

FRONT CARPET/MATÐXJ..............23-99

FRONT CLUTCH OVERHAUL...........21-134

FRONT DOOR SPACER BLOCKSÐTWO-

DOOR VEHICLES.....................23-53

FRONT DOOR WINDOW GLASS

REGULATORÐXJ....................23-42

FRONT DOOR WINDOW GLASSÐXJ.....23-43

FRONT DRIVE AXLE....................2-3

FRONT FENDERÐXJ..................23-14

FRONT INNER SCUFF PLATE/COWL SIDE

TRIM PANELÐXJ....................23-86

FRONT PARK/TURN SIGNAL LAMP BULB

REPLACEMENTÐXJ...................8L-9

FRONT PARK/TURN SIGNAL LAMP BULB

REPLACEMENTÐYJ..................8L-25

FRONT PLANETARY GEAR OVERHAUL . . . 21-237

FRONT SERVO AND BAND OVERHAUL . . . 21-146

FRONT SHOULDER BELT/BUCKLEÐXJ....23-90

FRONT SHOULDER BELTSÐYJ.........23-154

FRONT SKID PLATE

....................13-1

FRONT SUSPENSION

...................2-1

FRONT SUSPENSION COMPONENTS, XJ

. . . 2-49

FRONT SUSPENSION COMPONENTS, YJ

. . . 2-49

FRONT SUSPENSION, XJ

...............2-11

FRONT SUSPENSION, YJ

...............2-15

FRONT TOW HOOKS

...................13-7

FRONT WHEEL ALIGNMENT

..............2-5

FRONT WHEEL BEARINGS

..............0-28

FRONT WHEEL SENSOR INSTALLATION

....5-38

FRONT WHEEL SENSOR REMOVAL

.......5-38

FUEL DELIVERY SYSTEM

...............14-3

FUEL FILLER DOOR BUMPERSÐXJ

......23-27

FUEL FILLER HOSE SPLASH SHIELDÐXJ

VEHICLES

...........................13-4

FUEL FILLER NOZZLE/TUBEÐXJ

........23-26

FUEL FILLER PROTECTOR/NOZZLEÐYJ

. . 23-121

FUEL FILTER; FUEL SYSTEM

........14-60,14-9

FUEL FILTER; LUBRICATION AND

MAINTENANCE

.......................0-19

FUEL GAUGE; INSTRUMENT CLUSTER

(XJ)

.............................8W-40-1

FUEL GAUGE; INSTRUMENT CLUSTER

(XJ-RHD)

.........................8W-40-1

FUEL GAUGE SENDING UNIT

...........14-16

10 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 1980 of 2198

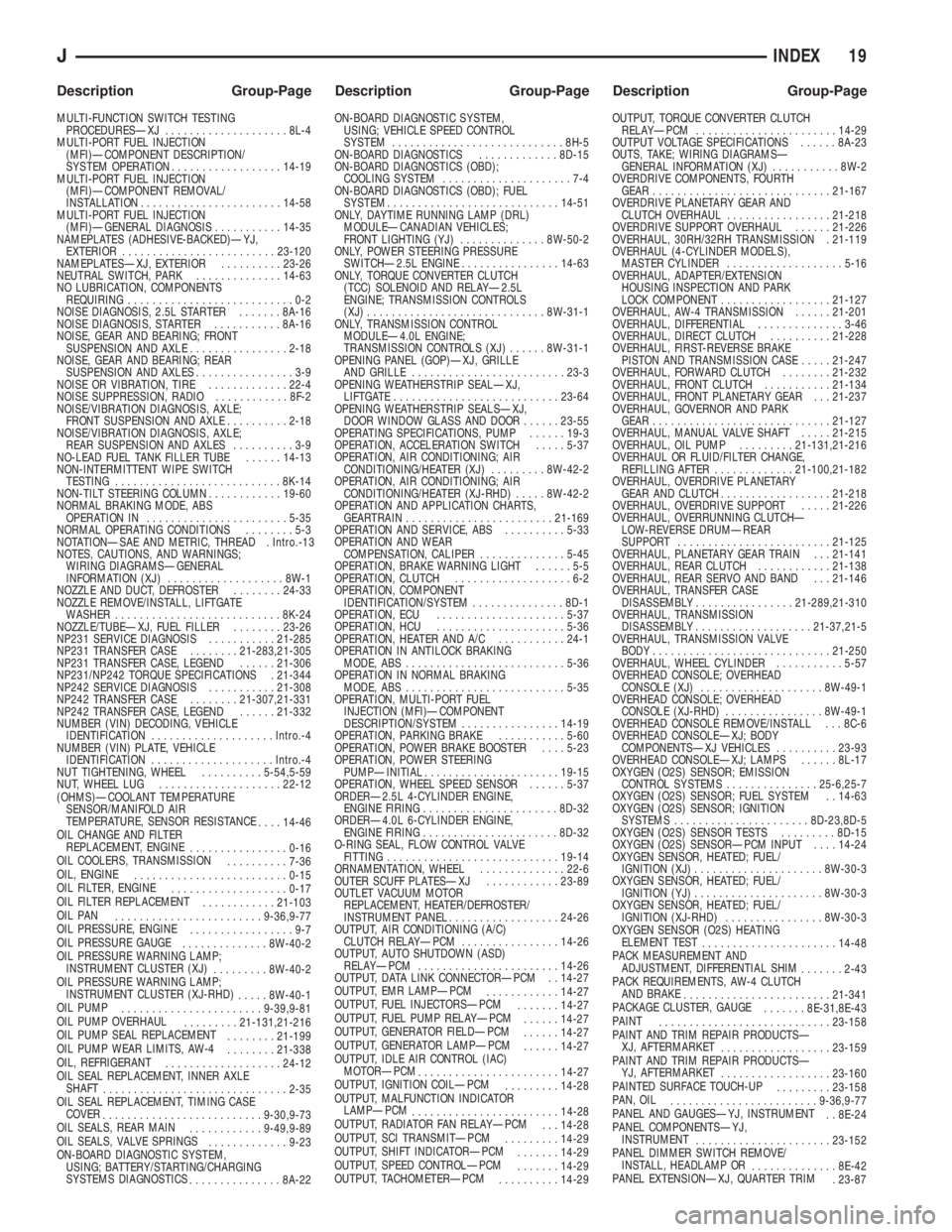

MULTI-FUNCTION SWITCH TESTING

PROCEDURESÐXJ....................8L-4

MULTI-PORT FUEL INJECTION

(MFI)ÐCOMPONENT DESCRIPTION/

SYSTEM OPERATION..................14-19

MULTI-PORT FUEL INJECTION

(MFI)ÐCOMPONENT REMOVAL/

INSTALLATION.......................14-58

MULTI-PORT FUEL INJECTION

(MFI)ÐGENERAL DIAGNOSIS...........14-35

NAMEPLATES (ADHESIVE-BACKED)ÐYJ,

EXTERIOR.........................23-120

NAMEPLATESÐXJ, EXTERIOR..........23-26

NEUTRAL SWITCH, PARK..............14-63

NO LUBRICATION, COMPONENTS

REQUIRING...........................0-2

NOISE DIAGNOSIS, 2.5L STARTER.......8A-16

NOISE DIAGNOSIS, STARTER...........8A-16

NOISE, GEAR AND BEARING; FRONT

SUSPENSION AND AXLE................2-18

NOISE, GEAR AND BEARING; REAR

SUSPENSION AND AXLES................3-9

NOISE OR VIBRATION, TIRE.............22-4

NOISE SUPPRESSION, RADIO............8F-2

NOISE/VIBRATION DIAGNOSIS, AXLE;

FRONT SUSPENSION AND AXLE..........2-18

NOISE/VIBRATION DIAGNOSIS, AXLE;

REAR SUSPENSION AND AXLES..........3-9

NO-LEAD FUEL TANK FILLER TUBE......14-13

NON-INTERMITTENT WIPE SWITCH

TESTING...........................8K-14

NON-TILT STEERING COLUMN............19-60

NORMAL BRAKING MODE, ABS

OPERATION IN.......................5-35

NORMAL OPERATING CONDITIONS........5-3

NOTATIONÐSAE AND METRIC, THREAD . Intro.-13

NOTES, CAUTIONS, AND WARNINGS;

WIRING DIAGRAMSÐGENERAL

INFORMATION (XJ)...................8W-1

NOZZLE AND DUCT, DEFROSTER........24-33

NOZZLE REMOVE/INSTALL, LIFTGATE

WASHER...........................8K-24

NOZZLE/TUBEÐXJ, FUEL FILLER........23-26

NP231 SERVICE DIAGNOSIS...........21-285

NP231 TRANSFER CASE........21-283,21-305

NP231 TRANSFER CASE, LEGEND......21-306

NP231/NP242 TORQUE SPECIFICATIONS . 21-344

NP242 SERVICE DIAGNOSIS...........21-308

NP242 TRANSFER CASE........21-307,21-331

NP242 TRANSFER CASE, LEGEND......21-332

NUMBER (VIN) DECODING, VEHICLE

IDENTIFICATION....................Intro.-4

NUMBER (VIN) PLATE, VEHICLE

IDENTIFICATION....................Intro.-4

NUT TIGHTENING, WHEEL..........5-54,5-59

NUT, WHEEL LUG....................22-12

(OHMS)ÐCOOLANT TEMPERATURE

SENSOR/MANIFOLD AIR

TEMPERATURE, SENSOR RESISTANCE

....14-46

OIL CHANGE AND FILTER

REPLACEMENT, ENGINE

................0-16

OIL COOLERS, TRANSMISSION

..........7-36

OIL, ENGINE

.........................0-15

OIL FILTER, ENGINE

...................0-17

OIL FILTER REPLACEMENT

............21-103

OIL PAN

........................9-36,9-77

OIL PRESSURE, ENGINE

.................9-7

OIL PRESSURE GAUGE

..............8W-40-2

OIL PRESSURE WARNING LAMP;

INSTRUMENT CLUSTER (XJ)

.........8W-40-2

OIL PRESSURE WARNING LAMP;

INSTRUMENT CLUSTER (XJ-RHD)

.....8W-40-1

OIL PUMP

.......................9-39,9-81

OIL PUMP OVERHAUL

.........21-131,21-216

OIL PUMP SEAL REPLACEMENT

........21-199

OIL PUMP WEAR LIMITS, AW-4

........21-338

OIL, REFRIGERANT

...................24-12

OIL SEAL REPLACEMENT, INNER AXLE

SHAFT

..............................2-35

OIL SEAL REPLACEMENT, TIMING CASE

COVER

..........................9-30,9-73

OIL SEALS, REAR MAIN

............9-49,9-89

OIL SEALS, VALVE SPRINGS

.............9-23

ON-BOARD DIAGNOSTIC SYSTEM,

USING; BATTERY/STARTING/CHARGING

SYSTEMS DIAGNOSTICS

...............8A-22ON-BOARD DIAGNOSTIC SYSTEM,

USING; VEHICLE SPEED CONTROL

SYSTEM............................8H-5

ON-BOARD DIAGNOSTICS.............8D-15

ON-BOARD DIAGNOSTICS (OBD);

COOLING SYSTEM.....................7-4

ON-BOARD DIAGNOSTICS (OBD); FUEL

SYSTEM............................14-51

ONLY, DAYTIME RUNNING LAMP (DRL)

MODULEÐCANADIAN VEHICLES;

FRONT LIGHTING (YJ)..............8W-50-2

ONLY, POWER STEERING PRESSURE

SWITCHÐ2.5L ENGINE................14-63

ONLY, TORQUE CONVERTER CLUTCH

(TCC) SOLENOID AND RELAYÐ2.5L

ENGINE; TRANSMISSION CONTROLS

(XJ).............................8W-31-1

ONLY, TRANSMISSION CONTROL

MODULEÐ4.0L ENGINE;

TRANSMISSION CONTROLS (XJ)......8W-31-1

OPENING PANEL (GOP)ÐXJ, GRILLE

AND GRILLE.........................23-3

OPENING WEATHERSTRIP SEALÐXJ,

LIFTGATE...........................23-64

OPENING WEATHERSTRIP SEALSÐXJ,

DOOR WINDOW GLASS AND DOOR......23-55

OPERATING SPECIFICATIONS, PUMP......19-3

OPERATION, ACCELERATION SWITCH.....5-37

OPERATION, AIR CONDITIONING; AIR

CONDITIONING/HEATER (XJ).........8W-42-2

OPERATION, AIR CONDITIONING; AIR

CONDITIONING/HEATER (XJ-RHD).....8W-42-2

OPERATION AND APPLICATION CHARTS,

GEARTRAIN........................21-169

OPERATION AND SERVICE, ABS..........5-33

OPERATION AND WEAR

COMPENSATION, CALIPER..............5-45

OPERATION, BRAKE WARNING LIGHT......5-5

OPERATION, CLUTCH...................6-2

OPERATION, COMPONENT

IDENTIFICATION/SYSTEM...............8D-1

OPERATION, ECU.....................5-37

OPERATION, HCU.....................5-36

OPERATION, HEATER AND A/C...........24-1

OPERATION IN ANTILOCK BRAKING

MODE, ABS..........................5-36

OPERATION IN NORMAL BRAKING

MODE, ABS..........................5-35

OPERATION, MULTI-PORT FUEL

INJECTION (MFI)ÐCOMPONENT

DESCRIPTION/SYSTEM................14-19

OPERATION, PARKING BRAKE...........5-60

OPERATION, POWER BRAKE BOOSTER....5-23

OPERATION, POWER STEERING

PUMPÐINITIAL......................19-15

OPERATION, WHEEL SPEED SENSOR......5-37

ORDERÐ2.5L 4-CYLINDER ENGINE,

ENGINE FIRING......................8D-32

ORDERÐ4.0L 6-CYLINDER ENGINE,

ENGINE FIRING......................8D-32

O-RING SEAL, FLOW CONTROL VALVE

FITTING............................19-14

ORNAMENTATION, WHEEL..............22-6

OUTER SCUFF PLATESÐXJ............23-89

OUTLET VACUUM MOTOR

REPLACEMENT, HEATER/DEFROSTER/

INSTRUMENT PANEL..................24-26

OUTPUT, AIR CONDITIONING (A/C)

CLUTCH RELAYÐPCM................14-26

OUTPUT, AUTO SHUTDOWN (ASD)

RELAYÐPCM.......................14-26

OUTPUT, DATA LINK CONNECTORÐPCM . . 14-27

OUTPUT, EMR LAMPÐPCM

............14-27

OUTPUT, FUEL INJECTORSÐPCM

.......14-27

OUTPUT, FUEL PUMP RELAYÐPCM

......14-27

OUTPUT, GENERATOR FIELDÐPCM

......14-27

OUTPUT, GENERATOR LAMPÐPCM

......14-27

OUTPUT, IDLE AIR CONTROL (IAC)

MOTORÐPCM

.......................14-27

OUTPUT, IGNITION COILÐPCM

.........14-28

OUTPUT, MALFUNCTION INDICATOR

LAMPÐPCM

........................14-28

OUTPUT, RADIATOR FAN RELAYÐPCM

. . . 14-28

OUTPUT, SCI TRANSMITÐPCM

.........14-29

OUTPUT, SHIFT INDICATORÐPCM

.......14-29

OUTPUT, SPEED CONTROLÐPCM

.......14-29

OUTPUT, TACHOMETERÐPCM

..........14-29OUTPUT, TORQUE CONVERTER CLUTCH

RELAYÐPCM.......................14-29

OUTPUT VOLTAGE SPECIFICATIONS......8A-23

OUTS, TAKE; WIRING DIAGRAMSÐ

GENERAL INFORMATION (XJ)...........8W-2

OVERDRIVE COMPONENTS, FOURTH

GEAR.............................21-167

OVERDRIVE PLANETARY GEAR AND

CLUTCH OVERHAUL.................21-218

OVERDRIVE SUPPORT OVERHAUL......21-226

OVERHAUL, 30RH/32RH TRANSMISSION . 21-119

OVERHAUL (4-CYLINDER MODELS),

MASTER CYLINDER...................5-16

OVERHAUL, ADAPTER/EXTENSION

HOUSING INSPECTION AND PARK

LOCK COMPONENT..................21-127

OVERHAUL, AW-4 TRANSMISSION......21-201

OVERHAUL, DIFFERENTIAL..............3-46

OVERHAUL, DIRECT CLUTCH..........21-228

OVERHAUL, FIRST-REVERSE BRAKE

PISTON AND TRANSMISSION CASE.....21-247

OVERHAUL, FORWARD CLUTCH........21-232

OVERHAUL, FRONT CLUTCH...........21-134

OVERHAUL, FRONT PLANETARY GEAR . . . 21-237

OVERHAUL, GOVERNOR AND PARK

GEAR.............................21-127

OVERHAUL, MANUAL VALVE SHAFT.....21-215

OVERHAUL, OIL PUMP.........21-131,21-216

OVERHAUL OR FLUID/FILTER CHANGE,

REFILLING AFTER.............21-100,21-182

OVERHAUL, OVERDRIVE PLANETARY

GEAR AND CLUTCH..................21-218

OVERHAUL, OVERDRIVE SUPPORT.....21-226

OVERHAUL, OVERRUNNING CLUTCHÐ

LOW-REVERSE DRUMÐREAR

SUPPORT.........................21-125

OVERHAUL, PLANETARY GEAR TRAIN . . . 21-141

OVERHAUL, REAR CLUTCH............21-138

OVERHAUL, REAR SERVO AND BAND . . . 21-146

OVERHAUL, TRANSFER CASE

DISASSEMBLY................21-289,21-310

OVERHAUL, TRANSMISSION

DISASSEMBLY...................21-37,21-5

OVERHAUL, TRANSMISSION VALVE

BODY.............................21-250

OVERHAUL, WHEEL CYLINDER...........5-57

OVERHEAD CONSOLE; OVERHEAD

CONSOLE (XJ)....................8W-49-1

OVERHEAD CONSOLE; OVERHEAD

CONSOLE (XJ-RHD)................8W-49-1

OVERHEAD CONSOLE REMOVE/INSTALL . . . 8C-6

OVERHEAD CONSOLEÐXJ; BODY

COMPONENTSÐXJ VEHICLES..........23-93

OVERHEAD CONSOLEÐXJ; LAMPS......8L-17

OXYGEN (O2S) SENSOR; EMISSION

CONTROL SYSTEMS...............25-6,25-7

OXYGEN (O2S) SENSOR; FUEL SYSTEM . . 14-63

OXYGEN (O2S) SENSOR; IGNITION

SYSTEMS......................8D-23,8D-5

OXYGEN (O2S) SENSOR TESTS.........8D-15

OXYGEN (O2S) SENSORÐPCM INPUT....14-24

OXYGEN SENSOR, HEATED; FUEL/

IGNITION (XJ).....................8W-30-3

OXYGEN SENSOR, HEATED; FUEL/

IGNITION (YJ).....................8W-30-3

OXYGEN SENSOR, HEATED; FUEL/

IGNITION (XJ-RHD)................8W-30-3

OXYGEN SENSOR (O2S) HEATING

ELEMENT TEST

......................14-48

PACK MEASUREMENT AND

ADJUSTMENT, DIFFERENTIAL SHIM

.......2-43

PACK REQUIREMENTS, AW-4 CLUTCH

AND BRAKE

........................21-341

PACKAGE CLUSTER, GAUGE

.......8E-31,8E-43

PAINT

............................23-158

PAINT AND TRIM REPAIR PRODUCTSÐ

XJ, AFTERMARKET

..................23-159

PAINT AND TRIM REPAIR PRODUCTSÐ

YJ, AFTERMARKET

..................23-160

PAINTED SURFACE TOUCH-UP

.........23-158

PAN, OIL

........................9-36,9-77

PANEL AND GAUGESÐYJ, INSTRUMENT

. . 8E-24

PANEL COMPONENTSÐYJ,

INSTRUMENT

......................23-152

PANEL DIMMER SWITCH REMOVE/

INSTALL, HEADLAMP OR

..............8E-42

PANEL EXTENSIONÐXJ, QUARTER TRIM

. 23-87

JINDEX 19

Description Group-Page Description Group-Page Description Group-Page