battery replacement JEEP CHEROKEE 1995 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 512 of 2198

POWER MIRRORS

CONTENTS

page page

DIAGNOSIS............................. 1

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 4

GENERAL INFORMATION

Power outside rear view mirrors are an available

option on XJ (Cherokee) models. Following are gen-

eral descriptions of the major components in the

power mirror system. Refer to Group 8W - Wiring Di-

agrams for complete circuit descriptions and dia-

grams.

POWER MIRROR

The power mirrors are connected to battery feed at

all times. Each mirror head contains two electric mo-

tors, two drive mechanisms and the mirror glass.

One motor and drive controls mirror up-and-down

movement, and the other controls right-and-left

movement.

The mirror glass is the only serviced replacement

part for the power mirror assembly. If any other com-ponent of the mirror unit is faulty or damaged, the

entire assembly must be replaced.

POWER MIRROR SWITCH

Both the right and left mirror are controlled by a

multi-function switch located on the front of the cen-

ter console storage compartment, directly below the

armrest. The selector switch is moved right (right

mirror control), left (left mirror control), or center to

turn power mirrors off. Then one of four directional

control buttons is depressed to control movement of

the selected mirror up, down, right, or left. The

power mirror switch is serviced only as a complete

unit.

DIAGNOSIS

POWER MIRROR SYSTEM

(1) Check fuse 16 in Power Distribution Center

(PDC) and fuse 9 in fuseblock module. If OK, go to

next step. If not OK, replace fuse.

(2) Check for battery voltage at fuse 9 in fuseblock

module. If OK, go to next step. If not OK, repair cir-

cuit to fuse 16 in PDC.

(3) Remove power mirror switch from the center

console. See Power Mirror Switch Remove/Install.

(4) Disconnect wiring harness connector from

switch. Check for battery voltage at pink wire. If OK,

go to next step. If not OK, repair circuit to fuse 9 in

fuseblock module.

(5) Check for continuity between black wire in

switch harness connector and a good ground. There

should be continuity. If OK, go to next step. If not

OK, repair circuit to ground.

(6) Check switch continuity as shown in the Mirror

Switch Continuity charts. If OK, go to next step. If

not OK, replace switch.(7) See Power Mirror Switch illustration. Connect

a jumper wire from mirror switch connector cavity

for pin E to cavity for pin F. Now connect a second

jumper from connector cavity for pin G to each of the

following pin cavities: A, B, C, then D. In each case,

the selected mirror head should move. If OK, replace

switch. If not OK, go to next step.

(8) Remove door trim panel and unplug power mir-

ror connector inside door. Connect one jumper wire to

a good ground and a second jumper wire to a battery

feed. Connect other ends of jumpers to the mirror

side of connector in door (refer to Group 8W - Wiring

Diagrams for connector cavity identification). Mirror

head should move in each of the four directions. If

OK, repair wiring between mirror switch and door

connectors. If not OK, replace mirror.

JPOWER MIRRORS 8T - 1

Page 518 of 2198

CHIME/BUZZER WARNING SYSTEMS

CONTENTS

page page

DIAGNOSIS............................. 2

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 4

GENERAL INFORMATION

This group covers the buzzer warning system,

which is standard equipment on XJ (Cherokee)/YJ

(Wrangler) models. The system provides an audible

warning to the driver when it monitors the following

conditions:

²key is in ignition switch with the driver's door

open

²head or park lamps are on with driver's door open

(XJ only)

²driver's seat belt is not buckled with ignition

switch in ON position.

Following are general descriptions of the major

components in the buzzer warning system. Refer to

Group 8W - Wiring Diagrams for complete circuit de-

scriptions and diagrams.

BUZZER MODULE

The buzzer module is located in the fuseblock mod-

ule under the left end of the instrument panel. It re-

ceives battery voltage at all times from (fuse 15 - XJ,

fuse 3 - YJ) the fuseblock module. It also receives a

second battery feed (fuse 17 - XJ, fuse 9 - YJ) when

the ignition switch is in the ON or START position.

Other inputs to the module include the driver's door

jamb switch, the driver's seat belt switch, the ignition

key-in switch, and the headlamp switch (XJ only). The

only output of the module is a timed 4 to 8 second feed

to the seat belt reminder lamp in the message center of

the instrument cluster. The timer function begins after

the ignition switch is turned to the ON position.

The buzzer module can not be repaired. If faulty, it

must be replaced.

DRIVER'S DOOR JAMB SWITCH

The driver's door jamb switch is mounted to the

driver's door hinge pillar. The switch closes a path to

ground for the buzzer module through the key-in

switch or headlamp switch (XJ only) when the driv-

er's door is opened, and opens when the driver's door

is closed. This switch can not be repaired. If faulty, it

must be replaced.

IGNITION KEY-IN SWITCH

XJ MODELS

The key-in switch is integral to the ignition switch,

which is mounted on the right side of the steering col-

umn. It closes a path to ground for the buzzer module

when the ignition key is inserted in the ignition lock cyl-

inder and the driver's door jamb switch is closed (door

open). The switch opens when the key is removed from

the ignition lock cylinder. This switch can not be re-

paired. If faulty, the entire ignition switch must be re-

placed. Refer to Group 8D - Ignition Systems for service

procedures.

YJ MODELS

The key-in switch is mounted within the steering col-

umn in the lock cylinder housing. It closes a path to

ground for the buzzer module when the ignition key is

inserted in the ignition lock cylinder and the driver's

door jamb switch is closed (door open). The switch opens

when the key is removed from the ignition lock cylinder.

This switch is available for service replacement. Refer

to Group 19 - Steering for service procedures.

HEADLAMP SWITCH (XJ ONLY)

The headlamp switch is located in the instrument

panel. It closes a path to ground for the buzzer module

when the park or headlamps are on and the driver's

door jamb switch is closed (door open). The switch opens

the ground path when the park and headlamps are

turned off. The headlamp switch can not be repaired. If

faulty, it must be replaced. Refer to Group 8E - Instru-

ment Panel and Gauges for service procedures.

DRIVER'S SEAT BELT SWITCH

The driver's seat belt switch is integral to the driv-

er's seat belt buckle-half assembly. The switch is nor-

mally closed, providing a ground path to the buzzer

module. When the tip-half of the seat belt is inserted

into the seat belt buckle, the switch opens the buzzer

module ground path. The seat belt switch can not be

repaired. If faulty, the entire driver's seat belt buck-

le-half must be replaced. Refer to Group 23 - Body

Components for service procedures.

JCHIME/BUZZER WARNING SYSTEMS 8U - 1

Page 522 of 2198

WIRING DIAGRAMSÐGENERAL INFORMATION

INDEX

page page

Circuit Identification......................... 1

Connector and Terminal Replacement........... 7

Connector Replacement..................... 6

Connectors............................... 2

Diode Replacement........................ 8

Electrostatic Discharge (ESC) Sensitive Devices . . . 2

General Information......................... 1

Intermittent and Poor Connections.............. 4

Notes, Cautions, and Warnings................ 1Symbols................................. 2

Take Outs................................ 2

Terminal Replacement....................... 8

Terminal/Connector RepairÐMolex Connectors.... 6

Troubleshooting Tests....................... 4

Troubleshooting Tools....................... 4

Troubleshooting Wiring Problems.............. 5

Wire Code Identification..................... 1

Wiring Repair............................. 6

GENERAL INFORMATION

This Group is divided into three stand alone sec-

tions; XJ, YJ, and XJ Right Hand Drive (XJ-RHD).

Separate circuit descriptions and wiring diagrams are

provided for each vehicle. Each section contains a

Contents list for the wiring diagrams and circuit de-

scriptions for that vehicle.

The complete XJ circuit descriptions and diagrams

are printed first, followed by those for the YJ and

then the XJ-RHD. The heading at the top of each

page identifies the vehicle covered in the section.

NOTES, CAUTIONS, and WARNINGS

Throughout this group additional important infor-

mation is presented in three ways; Notes, Cautions,

and Warnings.

NOTESare used to help describe how switches or

components operate to complete a particular circuit.

They are also used to indicate different conditions

that may appear on the vehicle. For example, an

up-to and after condition.

CAUTIONSare used to indicate information that

could prevent making an error that may damage the

vehicle.

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

ALWAYS WEAR SAFETY GLASSES FOR EYE PRO-

TECTION.

USE SAFETY STANDS ANYTIME A PROCEDURE RE-

QUIRES BEING UNDER A VEHICLE.

BE SURE THAT THE IGNITION SWITCH ALWAYS IS

IN THE OFF POSITION, UNLESS THE PROCEDURE

REQUIRES IT TO BE ON.SET THE PARKING BRAKE WHEN WORKING ON

ANY VEHICLE. AN AUTOMATIC TRANSMISSION

SHOULD BE IN PARK. A MANUAL TRANSMISSION

SHOULD BE IN NEUTRAL.

OPERATE THE ENGINE ONLY IN A WELL-VENTI-

LATED AREA.

KEEP AWAY FROM MOVING PARTS WHEN THE EN-

GINE IS RUNNING, ESPECIALLY THE FAN AND BELTS.

TO PREVENT SERIOUS BURNS, AVOID CONTACT

WITH HOT PARTS SUCH AS THE RADIATOR, EX-

HAUST MANIFOLD(S), TAIL PIPE, CATALYTIC CON-

VERTER, AND MUFFLER.

DO NOT ALLOW FLAME OR SPARKS NEAR THE

BATTERY. GASES ARE ALWAYS PRESENT IN AND

AROUND THE BATTERY.

ALWAYS REMOVE RINGS, WATCHES, LOOSE

HANGING JEWELRY, AND LOOSE CLOTHING.

WIRE CODE IDENTIFICATION

Each wire shown in the diagrams contains a code

(Fig. 1) which identifies the main circuit, part of the

main circuit, gauge of wire, and color. The color is

shown as a two letter code which can be identified by

referring to the Wire Color Code Chart (Fig. 2).

CIRCUIT IDENTIFICATION

All circuits in the diagrams use an alpha/numeric

code to identify the wire and its function (Fig. 3). To

identify which circuit code applies to a system, refer

to the Circuit Identification Code Chart. This chart

shows the main circuits only and does not show the

secondary codes that may apply to some models.

JWIRING DIAGRAMSÐGENERAL INFORMATION 8W - 1

Page 527 of 2198

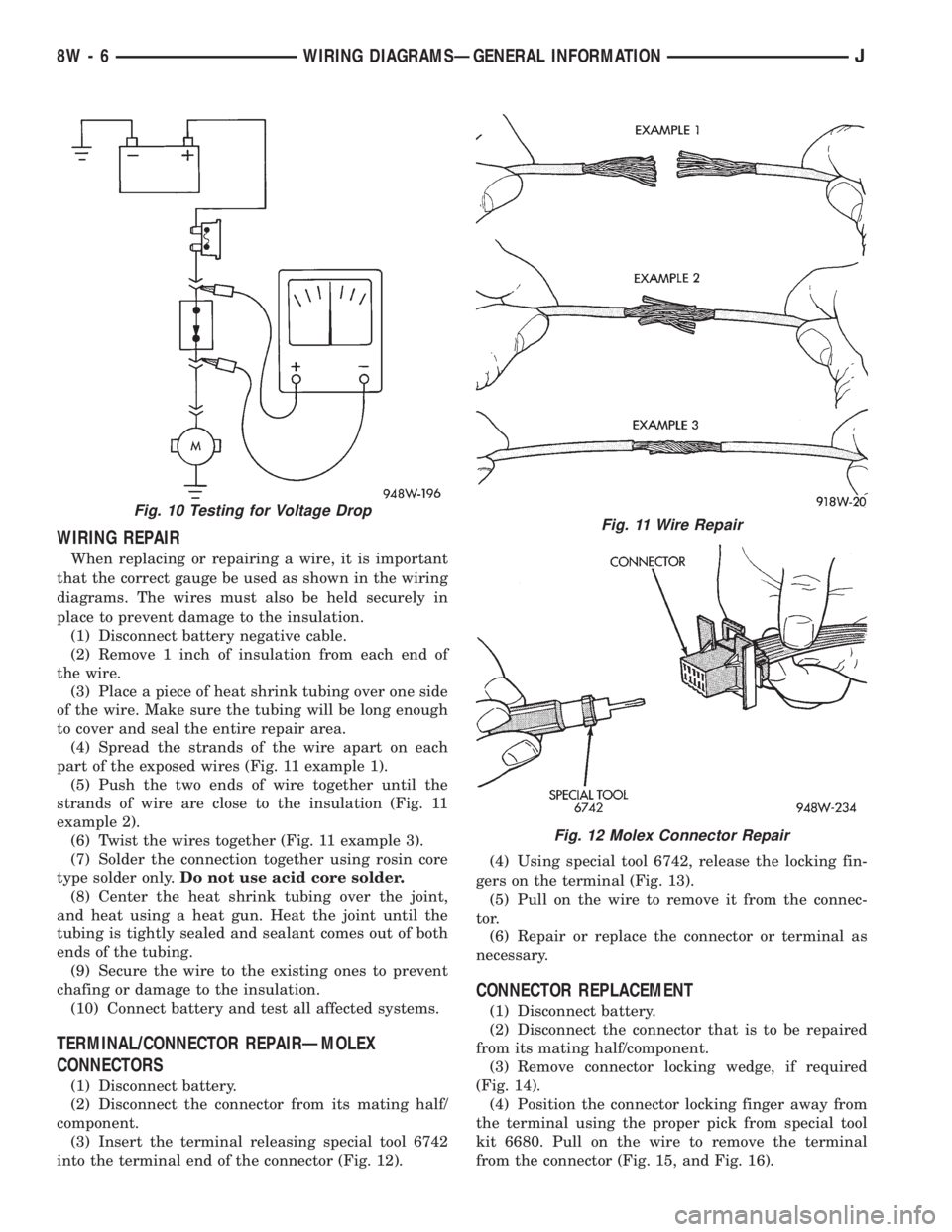

WIRING REPAIR

When replacing or repairing a wire, it is important

that the correct gauge be used as shown in the wiring

diagrams. The wires must also be held securely in

place to prevent damage to the insulation.

(1) Disconnect battery negative cable.

(2) Remove 1 inch of insulation from each end of

the wire.

(3) Place a piece of heat shrink tubing over one side

of the wire. Make sure the tubing will be long enough

to cover and seal the entire repair area.

(4) Spread the strands of the wire apart on each

part of the exposed wires (Fig. 11 example 1).

(5) Push the two ends of wire together until the

strands of wire are close to the insulation (Fig. 11

example 2).

(6) Twist the wires together (Fig. 11 example 3).

(7) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(8) Center the heat shrink tubing over the joint,

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(9) Secure the wire to the existing ones to prevent

chafing or damage to the insulation.

(10) Connect battery and test all affected systems.

TERMINAL/CONNECTOR REPAIRÐMOLEX

CONNECTORS

(1) Disconnect battery.

(2) Disconnect the connector from its mating half/

component.

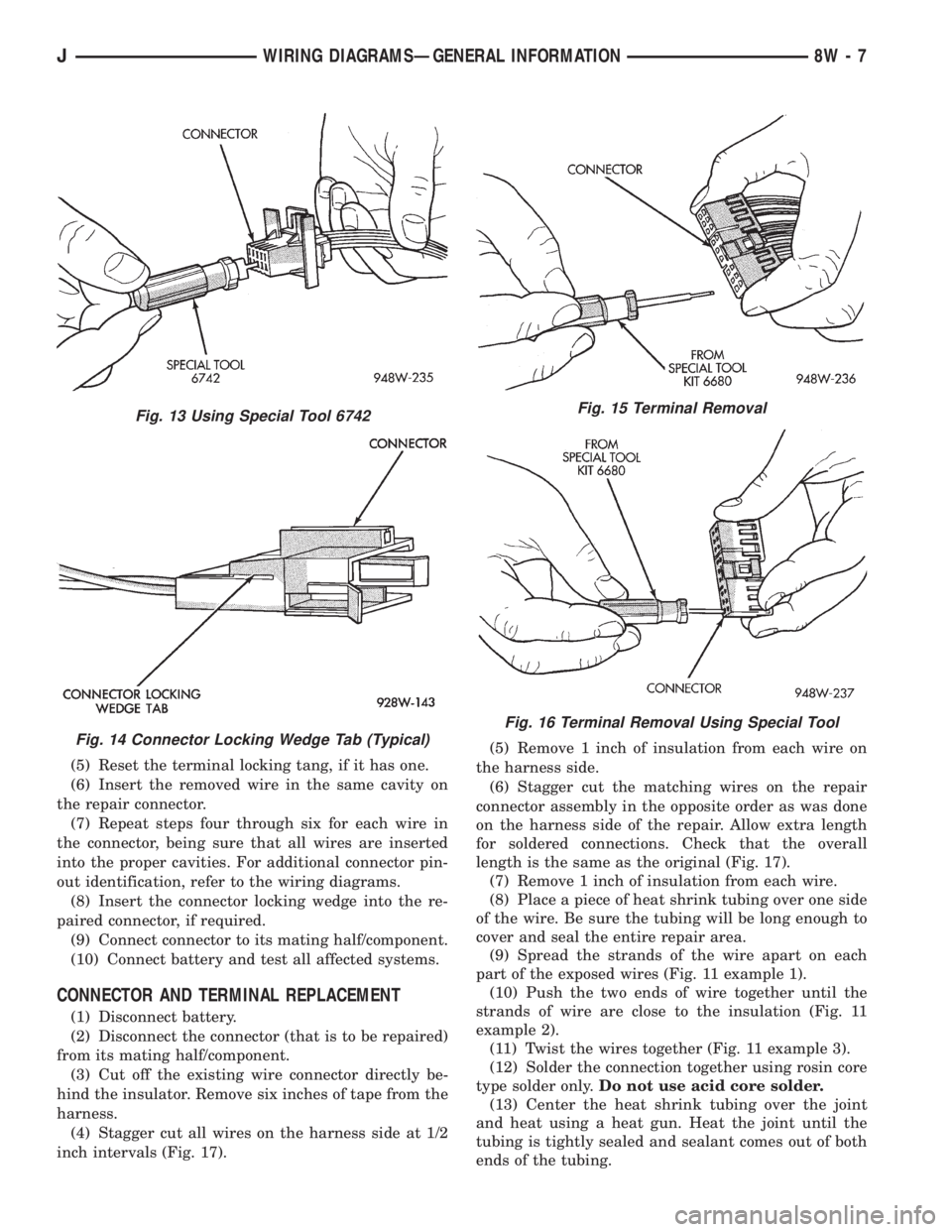

(3) Insert the terminal releasing special tool 6742

into the terminal end of the connector (Fig. 12).(4) Using special tool 6742, release the locking fin-

gers on the terminal (Fig. 13).

(5) Pull on the wire to remove it from the connec-

tor.

(6) Repair or replace the connector or terminal as

necessary.

CONNECTOR REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector that is to be repaired

from its mating half/component.

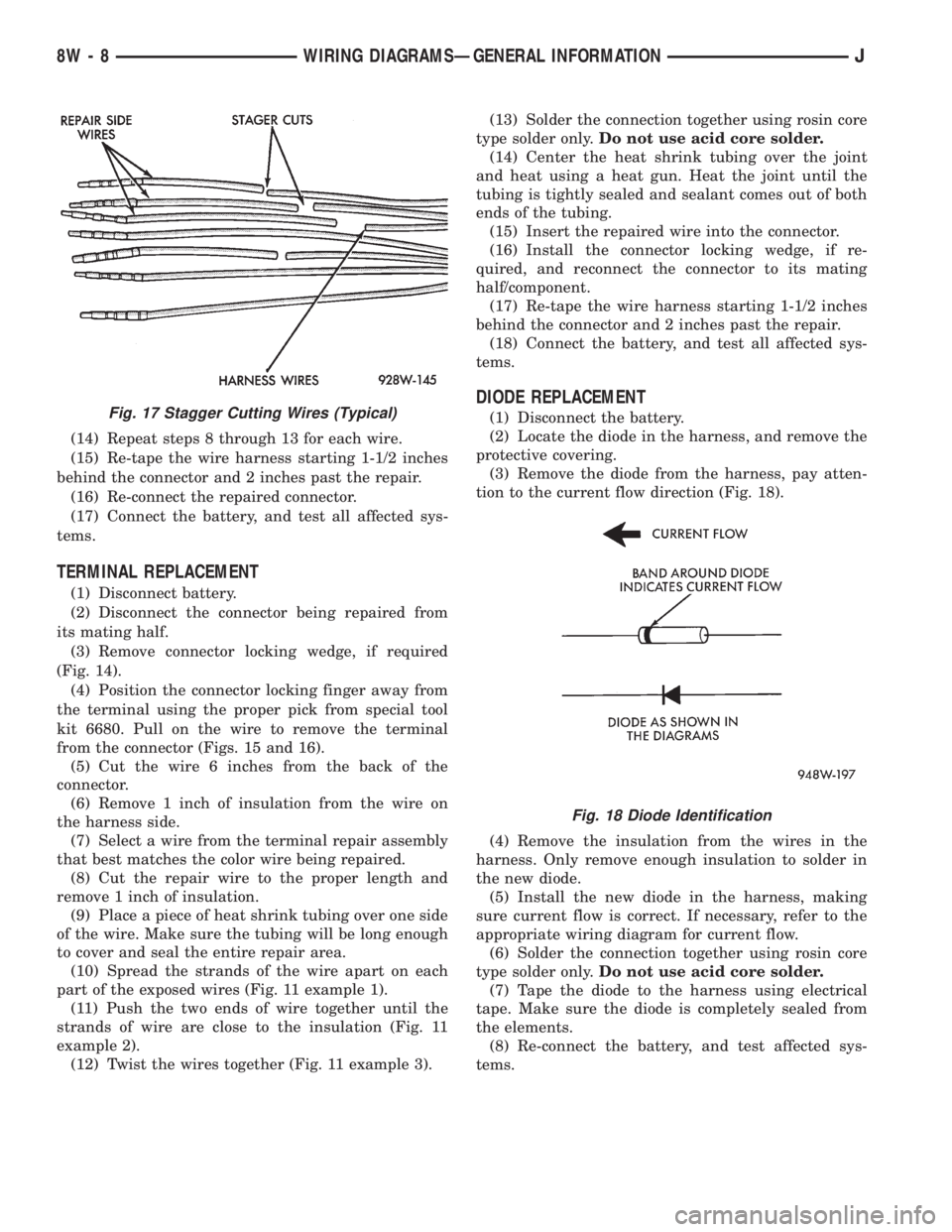

(3) Remove connector locking wedge, if required

(Fig. 14).

(4) Position the connector locking finger away from

the terminal using the proper pick from special tool

kit 6680. Pull on the wire to remove the terminal

from the connector (Fig. 15, and Fig. 16).

Fig. 10 Testing for Voltage DropFig. 11 Wire Repair

Fig. 12 Molex Connector Repair

8W - 6 WIRING DIAGRAMSÐGENERAL INFORMATIONJ

Page 528 of 2198

(5) Reset the terminal locking tang, if it has one.

(6) Insert the removed wire in the same cavity on

the repair connector.

(7) Repeat steps four through six for each wire in

the connector, being sure that all wires are inserted

into the proper cavities. For additional connector pin-

out identification, refer to the wiring diagrams.

(8) Insert the connector locking wedge into the re-

paired connector, if required.

(9) Connect connector to its mating half/component.

(10) Connect battery and test all affected systems.

CONNECTOR AND TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector (that is to be repaired)

from its mating half/component.

(3) Cut off the existing wire connector directly be-

hind the insulator. Remove six inches of tape from the

harness.

(4) Stagger cut all wires on the harness side at 1/2

inch intervals (Fig. 17).(5) Remove 1 inch of insulation from each wire on

the harness side.

(6) Stagger cut the matching wires on the repair

connector assembly in the opposite order as was done

on the harness side of the repair. Allow extra length

for soldered connections. Check that the overall

length is the same as the original (Fig. 17).

(7) Remove 1 inch of insulation from each wire.

(8) Place a piece of heat shrink tubing over one side

of the wire. Be sure the tubing will be long enough to

cover and seal the entire repair area.

(9) Spread the strands of the wire apart on each

part of the exposed wires (Fig. 11 example 1).

(10) Push the two ends of wire together until the

strands of wire are close to the insulation (Fig. 11

example 2).

(11) Twist the wires together (Fig. 11 example 3).

(12) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(13) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

Fig. 13 Using Special Tool 6742

Fig. 14 Connector Locking Wedge Tab (Typical)

Fig. 15 Terminal Removal

Fig. 16 Terminal Removal Using Special Tool

JWIRING DIAGRAMSÐGENERAL INFORMATION 8W - 7

Page 529 of 2198

(14) Repeat steps 8 through 13 for each wire.

(15) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.

(16) Re-connect the repaired connector.

(17) Connect the battery, and test all affected sys-

tems.

TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector being repaired from

its mating half.

(3) Remove connector locking wedge, if required

(Fig. 14).

(4) Position the connector locking finger away from

the terminal using the proper pick from special tool

kit 6680. Pull on the wire to remove the terminal

from the connector (Figs. 15 and 16).

(5) Cut the wire 6 inches from the back of the

connector.

(6) Remove 1 inch of insulation from the wire on

the harness side.

(7) Select a wire from the terminal repair assembly

that best matches the color wire being repaired.

(8) Cut the repair wire to the proper length and

remove 1 inch of insulation.

(9) Place a piece of heat shrink tubing over one side

of the wire. Make sure the tubing will be long enough

to cover and seal the entire repair area.

(10) Spread the strands of the wire apart on each

part of the exposed wires (Fig. 11 example 1).

(11) Push the two ends of wire together until the

strands of wire are close to the insulation (Fig. 11

example 2).

(12) Twist the wires together (Fig. 11 example 3).(13) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(14) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(15) Insert the repaired wire into the connector.

(16) Install the connector locking wedge, if re-

quired, and reconnect the connector to its mating

half/component.

(17) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.

(18) Connect the battery, and test all affected sys-

tems.

DIODE REPLACEMENT

(1) Disconnect the battery.

(2) Locate the diode in the harness, and remove the

protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 18).

(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary, refer to the

appropriate wiring diagram for current flow.

(6) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape. Make sure the diode is completely sealed from

the elements.

(8) Re-connect the battery, and test affected sys-

tems.Fig. 17 Stagger Cutting Wires (Typical)

Fig. 18 Diode Identification

8W - 8 WIRING DIAGRAMSÐGENERAL INFORMATIONJ

Page 1095 of 2198

CONNECTING ROD BEARING CLEARANCE

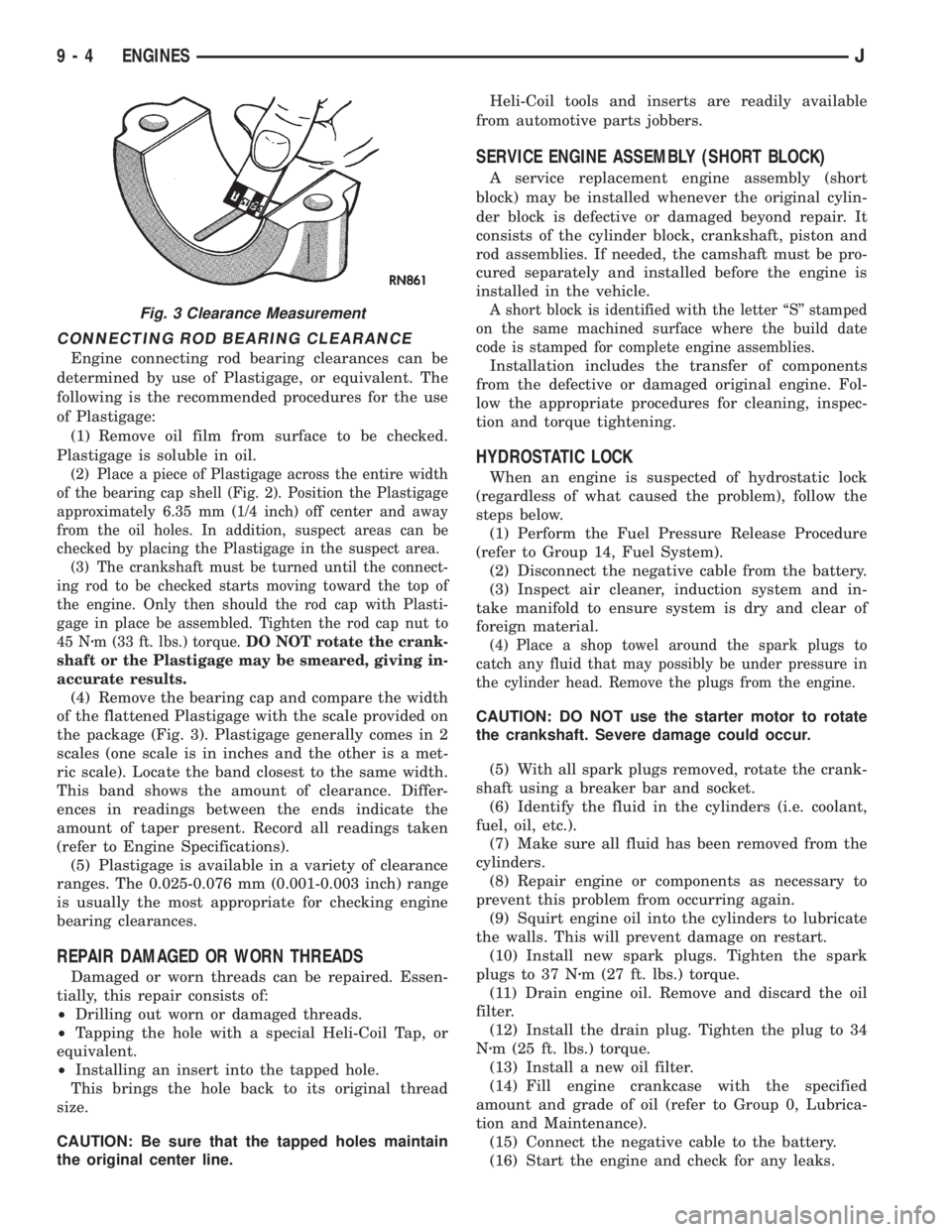

Engine connecting rod bearing clearances can be

determined by use of Plastigage, or equivalent. The

following is the recommended procedures for the use

of Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire width

of the bearing cap shell (Fig. 2). Position the Plastigage

approximately 6.35 mm (1/4 inch) off center and away

from the oil holes. In addition, suspect areas can be

checked by placing the Plastigage in the suspect area.

(3) The crankshaft must be turned until the connect-

ing rod to be checked starts moving toward the top of

the engine. Only then should the rod cap with Plasti-

gage in place be assembled. Tighten the rod cap nut to

45 Nzm (33 ft. lbs.) torque.DO NOT rotate the crank-

shaft or the Plastigage may be smeared, giving in-

accurate results.

(4) Remove the bearing cap and compare the width

of the flattened Plastigage with the scale provided on

the package (Fig. 3). Plastigage generally comes in 2

scales (one scale is in inches and the other is a met-

ric scale). Locate the band closest to the same width.

This band shows the amount of clearance. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken

(refer to Engine Specifications).

(5) Plastigage is available in a variety of clearance

ranges. The 0.025-0.076 mm (0.001-0.003 inch) range

is usually the most appropriate for checking engine

bearing clearances.

REPAIR DAMAGED OR WORN THREADS

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole.

This brings the hole back to its original thread

size.

CAUTION: Be sure that the tapped holes maintain

the original center line.Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

SERVICE ENGINE ASSEMBLY (SHORT BLOCK)

A service replacement engine assembly (short

block) may be installed whenever the original cylin-

der block is defective or damaged beyond repair. It

consists of the cylinder block, crankshaft, piston and

rod assemblies. If needed, the camshaft must be pro-

cured separately and installed before the engine is

installed in the vehicle.

A short block is identified with the letter ``S'' stamped

on the same machined surface where the build date

code is stamped for complete engine assemblies.

Installation includes the transfer of components

from the defective or damaged original engine. Fol-

low the appropriate procedures for cleaning, inspec-

tion and torque tightening.

HYDROSTATIC LOCK

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(refer to Group 14, Fuel System).

(2) Disconnect the negative cable from the battery.

(3) Inspect air cleaner, induction system and in-

take manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure in

the cylinder head. Remove the plugs from the engine.

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (i.e. coolant,

fuel, oil, etc.).

(7) Make sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt engine oil into the cylinders to lubricate

the walls. This will prevent damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 37 Nzm (27 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

Nzm (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil (refer to Group 0, Lubrica-

tion and Maintenance).

(15) Connect the negative cable to the battery.

(16) Start the engine and check for any leaks.

Fig. 3 Clearance Measurement

9 - 4 ENGINESJ

Page 1113 of 2198

(14) Install the remaining flywheel housing bolts.

Tighten the bolts to 38 Nzm (28 ft. lbs.) torque.

(15) Install the starter motor and connect the ca-

ble. Tighten the bolts to 45 Nzm (33 ft. lbs.) torque.

(16) Install the oil filter.

(17) Lower the vehicle.

(18) Connect the coolant hoses and tighten the

clamps.

(19) If equipped with power steering:

(a) Remove the protective caps

(b) Connect the hoses to the fittings at the steer-

ing gear. Tighten the nut to 52 Nzm (38 ft. lbs.)

torque.

(c) Fill the pump reservoir with fluid.

(20) Remove the pulley-to-water pump flange

alignment capscrew and install the fan and spacer or

Tempatrol fan assembly.

(21) Tighten the serpentine drive belt according to

the specifications listed in Group 7, Cooling System.

(22) Install the fan shroud and radiator.

(23) Connect the radiator hoses.

(24) Connect the heater hoses.

(25) Connect the throttle valve rod and retainer.

(26) Connect the throttle cable and install the rod.

(27) Install the throttle valve rod spring.

(28) Connect the speed control cable, if equipped.

(29) Connect the oxygen sensor wire connector.

(30) Install the vacuum hose and check valve on

the brake booster.

(31) Connect the coolant temperature sensor wire

connector.

(32) Connect the idle speed actuator wire connec-

tor.

(33) Connect the fuel inlet and return hoses at the

fuel rail. Verify that the quick-connect fitting assem-

bly fits securely over the fuel lines by giving the fuel

lines a firm tug.

(34) Install the fuel line bracket to the intake man-

ifold.

(35) Connect all fuel injection wire connections.

(36) Install the engine ground strap.

(37) Connect the ignition coil wire connector.

(38) Remove the coolant temperature sending unit

to permit air to escape from the block. Fill the cool-

ing system with coolant. Install the coolant tempera-

ture sending unit when the system is filled.

(39) Install the battery and connect the battery ca-

bles.

(40) Install the air cleaner bonnet to the throttle

body.

(41) Install the air cleaner.

(42) Lower the hood and secure in place.

(43) Start the engine and inspect for leaks.

(44) Stop the engine and check the fluid levels.

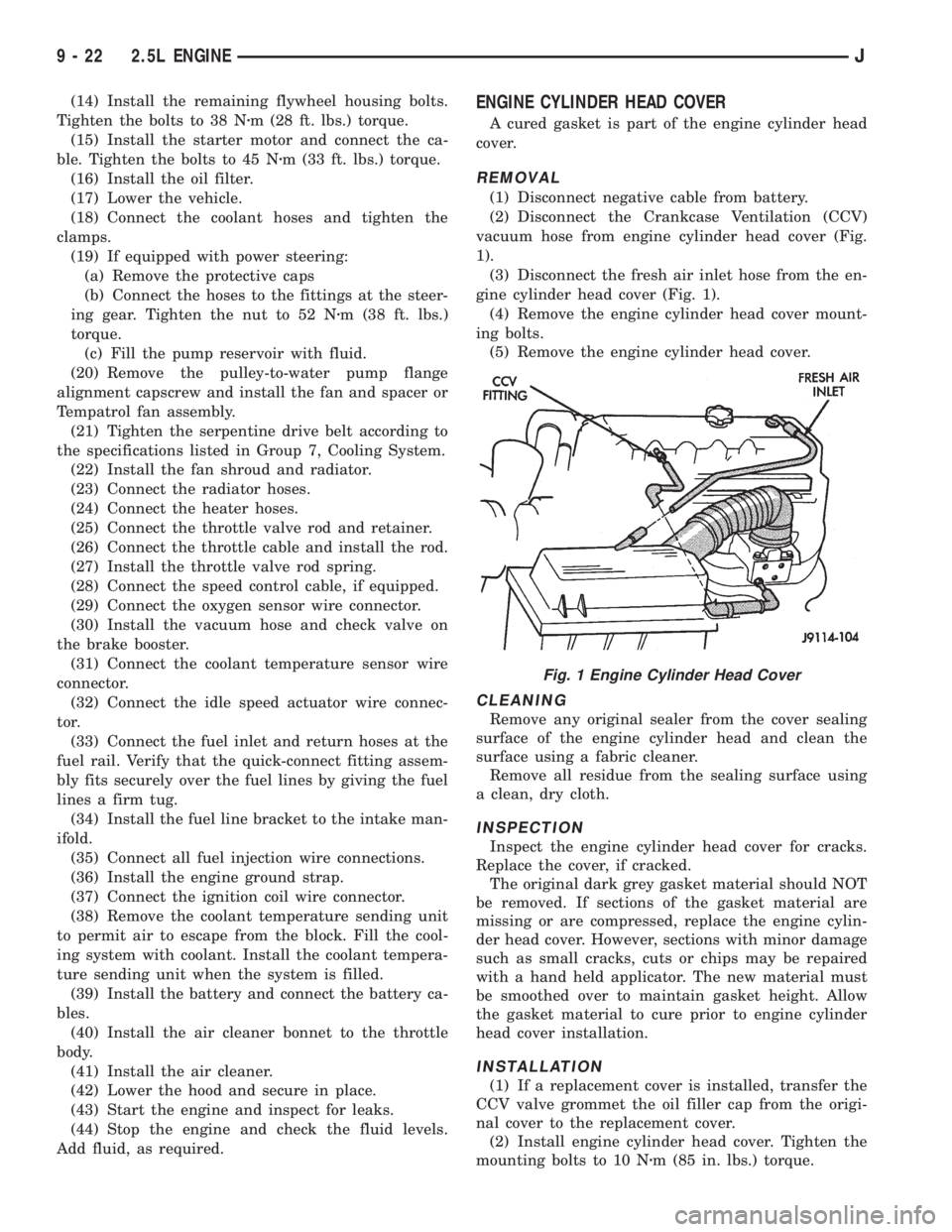

Add fluid, as required.ENGINE CYLINDER HEAD COVER

A cured gasket is part of the engine cylinder head

cover.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Disconnect the Crankcase Ventilation (CCV)

vacuum hose from engine cylinder head cover (Fig.

1).

(3) Disconnect the fresh air inlet hose from the en-

gine cylinder head cover (Fig. 1).

(4) Remove the engine cylinder head cover mount-

ing bolts.

(5) Remove the engine cylinder head cover.

CLEANING

Remove any original sealer from the cover sealing

surface of the engine cylinder head and clean the

surface using a fabric cleaner.

Remove all residue from the sealing surface using

a clean, dry cloth.

INSPECTION

Inspect the engine cylinder head cover for cracks.

Replace the cover, if cracked.

The original dark grey gasket material should NOT

be removed. If sections of the gasket material are

missing or are compressed, replace the engine cylin-

der head cover. However, sections with minor damage

such as small cracks, cuts or chips may be repaired

with a hand held applicator. The new material must

be smoothed over to maintain gasket height. Allow

the gasket material to cure prior to engine cylinder

head cover installation.

INSTALLATION

(1) If a replacement cover is installed, transfer the

CCV valve grommet the oil filler cap from the origi-

nal cover to the replacement cover.

(2) Install engine cylinder head cover. Tighten the

mounting bolts to 10 Nzm (85 in. lbs.) torque.

Fig. 1 Engine Cylinder Head Cover

9 - 22 2.5L ENGINEJ

Page 1121 of 2198

at the engine cylinder head. Also tap the top of the

retainer to seat the valve locks.

(8) Install the engine cylinder head.

VALVE TIMING

Disconnect the spark plug wires and remove the

spark plugs.

Remove the engine cylinder head cover.

Remove the capscrews, bridge and pivot assembly,

and rocker arms from above the No.1 cylinder.

Alternately loosen each capscrew, one turn at a

time, to avoid damaging the bridge.

Rotate the crankshaft until the No.4 piston is at

top dead center (TDC) on the compression stroke.

Rotate the crankshaft counterclockwise (viewed

from the front of the engine) 90É.

Install a dial indicator on the end of the No.1 cyl-

inder intake valve push rod. Use rubber tubing to se-

cure the indicator stem on the push rod.

Set the dial indicator pointer at zero.

Rotate the crankshaft clockwise (viewed from the

front of the engine) until the dial indicator pointer

indicates 0.305 mm (0.012 inch) travel distance (lift).

The timing notch index on the vibration damper

should be aligned with the TDC mark on the timing

degree scale.

If the timing notch is more than 13 mm (1/2 inch)

away from the TDC mark in either direction, the

valve timing is incorrect.

If the valve timing is incorrect, the cause may be a

broken camshaft pin. It is not necessary to replace

the camshaft because of pin failure. A spring pin is

available for service replacement.

VIBRATION DAMPER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the serpentine drive belt and fan

shroud.

(3) Remove the vibration damper retaining bolt

and washer.

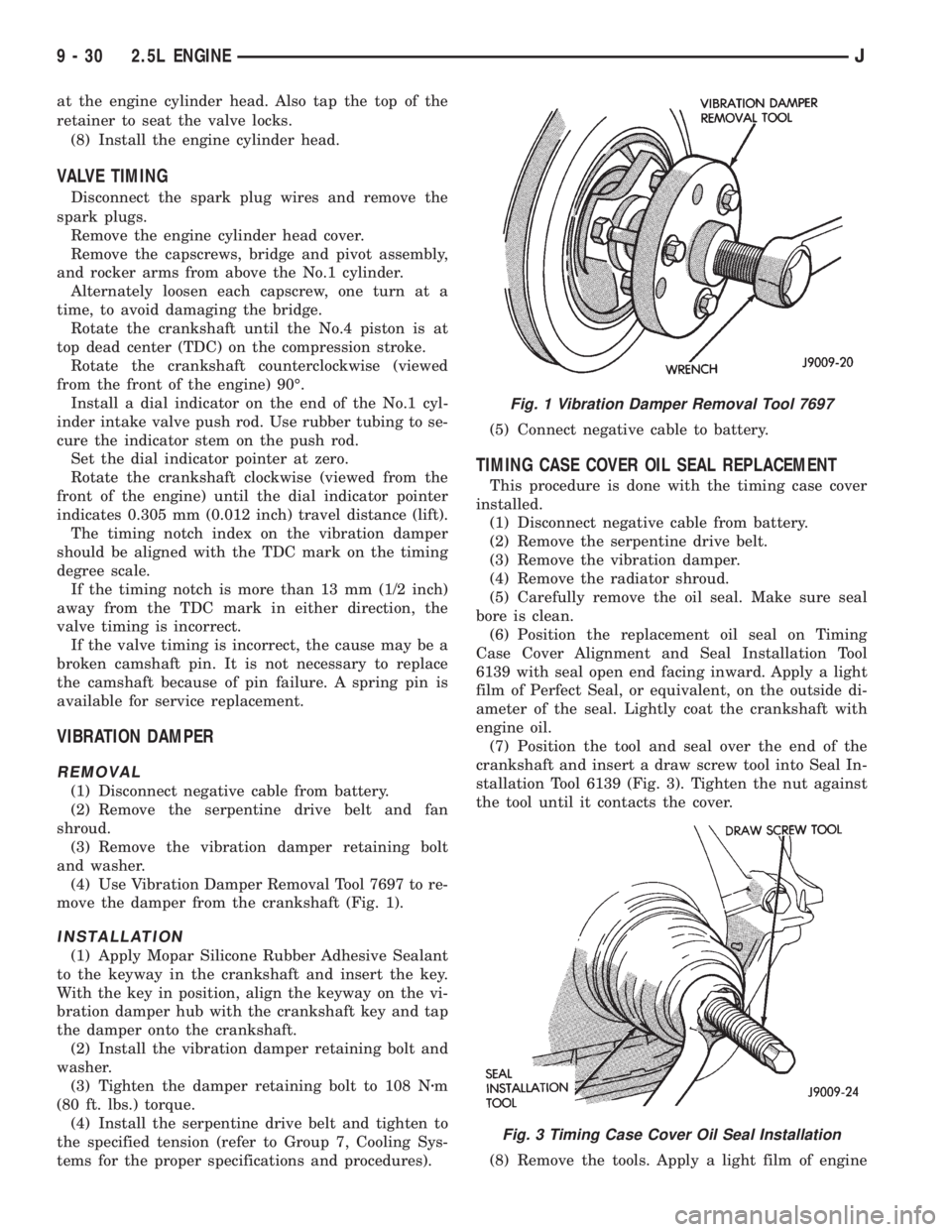

(4) Use Vibration Damper Removal Tool 7697 to re-

move the damper from the crankshaft (Fig. 1).

INSTALLATION

(1) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key in position, align the keyway on the vi-

bration damper hub with the crankshaft key and tap

the damper onto the crankshaft.

(2) Install the vibration damper retaining bolt and

washer.

(3) Tighten the damper retaining bolt to 108 Nzm

(80 ft. lbs.) torque.

(4) Install the serpentine drive belt and tighten to

the specified tension (refer to Group 7, Cooling Sys-

tems for the proper specifications and procedures).(5) Connect negative cable to battery.

TIMING CASE COVER OIL SEAL REPLACEMENT

This procedure is done with the timing case cover

installed.

(1) Disconnect negative cable from battery.

(2) Remove the serpentine drive belt.

(3) Remove the vibration damper.

(4) Remove the radiator shroud.

(5) Carefully remove the oil seal. Make sure seal

bore is clean.

(6) Position the replacement oil seal on Timing

Case Cover Alignment and Seal Installation Tool

6139 with seal open end facing inward. Apply a light

film of Perfect Seal, or equivalent, on the outside di-

ameter of the seal. Lightly coat the crankshaft with

engine oil.

(7) Position the tool and seal over the end of the

crankshaft and insert a draw screw tool into Seal In-

stallation Tool 6139 (Fig. 3). Tighten the nut against

the tool until it contacts the cover.

(8) Remove the tools. Apply a light film of engine

Fig. 1 Vibration Damper Removal Tool 7697

Fig. 3 Timing Case Cover Oil Seal Installation

9 - 30 2.5L ENGINEJ

Page 1125 of 2198

tor in the Component Removal/Installation section of

Group 8D, Ignition Systems.

(14) Install the distributor and ignition wires. Re-

fer to Distributor in the Component Removal/Instal-

lation section of Group 8D, Ignition Systems.

(15) Install the radiator or radiator and condenser,

if equipped with A/C.

(16) Fill the cooling system.

(17) Connect negative cable to battery.

CAMSHAFT PIN REPLACEMENT

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM COOL-

ANT CAN OCCUR.

(1) Disconnect negative cable from battery.

(2) Drain the radiator. DO NOT waste reusable

coolant. Drain the coolant into a clean container.

(3) Remove the fan and shroud.

(4) Disconnect the radiator overflow tube, radiator

hoses, automatic transmission fluid cooler pipes (if

equipped).

(5) Remove the radiator.

(6) If equipped with air conditioning:

CAUTION: DO NOT loosen or disconnect any air

conditioner system fittings. Move the condenser

and receiver/drier aside as a complete assembly.

(a) Remove the A/C compressor serpentine drive

belt idler pulley.

(b) Disconnect and remove the generator.

(c) Remove the A/C condenser attaching bolts

and move the condenser and receiver/drier assem-

bly up and out of the way.

(7) Remove the serpentine drive belt.

(8) Remove the crankshaft vibration damper.

(9) Remove the timing case cover. Clean the gasket

material from the cover.

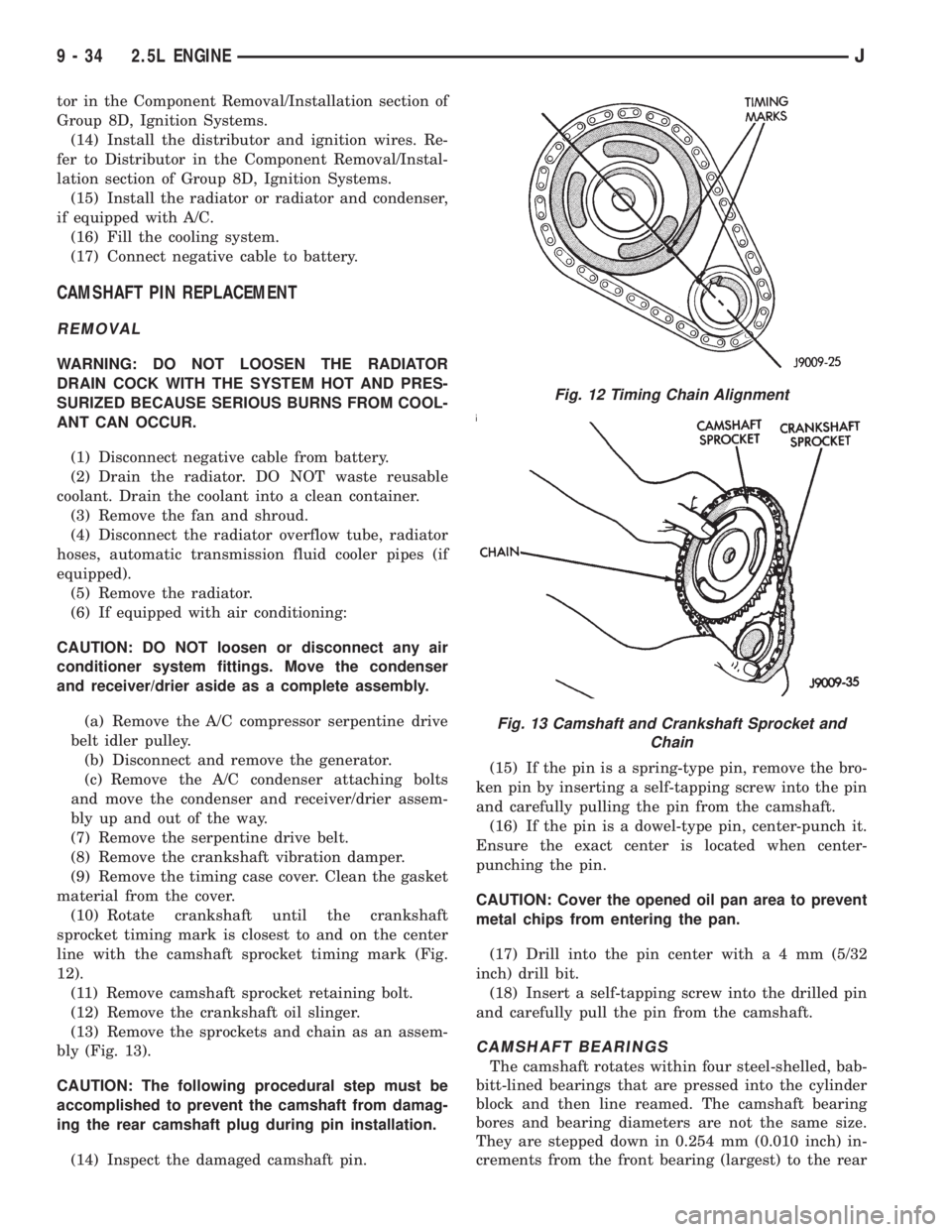

(10) Rotate crankshaft until the crankshaft

sprocket timing mark is closest to and on the center

line with the camshaft sprocket timing mark (Fig.

12).

(11) Remove camshaft sprocket retaining bolt.

(12) Remove the crankshaft oil slinger.

(13) Remove the sprockets and chain as an assem-

bly (Fig. 13).

CAUTION: The following procedural step must be

accomplished to prevent the camshaft from damag-

ing the rear camshaft plug during pin installation.

(14) Inspect the damaged camshaft pin.(15) If the pin is a spring-type pin, remove the bro-

ken pin by inserting a self-tapping screw into the pin

and carefully pulling the pin from the camshaft.

(16) If the pin is a dowel-type pin, center-punch it.

Ensure the exact center is located when center-

punching the pin.

CAUTION: Cover the opened oil pan area to prevent

metal chips from entering the pan.

(17) Drill into the pin center witha4mm(5/32

inch) drill bit.

(18) Insert a self-tapping screw into the drilled pin

and carefully pull the pin from the camshaft.

CAMSHAFT BEARINGS

The camshaft rotates within four steel-shelled, bab-

bitt-lined bearings that are pressed into the cylinder

block and then line reamed. The camshaft bearing

bores and bearing diameters are not the same size.

They are stepped down in 0.254 mm (0.010 inch) in-

crements from the front bearing (largest) to the rear

Fig. 12 Timing Chain Alignment

Fig. 13 Camshaft and Crankshaft Sprocket and

Chain

9 - 34 2.5L ENGINEJ