hinge JEEP CHEROKEE 1995 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1743 of 2198

(6) Attach the latch release cable to the clips.

(7) Connect the latches to the latch rod and posi-

tion them on the hood.

(8) Install the screws to attach the latches to the

hood.

Tighten the screws to 9 Nzm (77 in-lbs) torque.

(9) Position the safety latch on the hood and install

the attaching nuts. Tighten the screws to 13 Nzm

(115 in-lbs) torque.

(10) Test latch release cable and latches for proper

operation.

(11) Connect the underhood lamp wire harness

connector.

(12) Inspect the hood for proper alignment and ad-

just as necessary.

HOOD ADJUSTMENTÐXJ

The hood bolt holes are elongated for fore and aft

and side-to-side adjustment.

(1) If hood is low to the cowl panel, insert shims

between the hinge and hood at the rear hinge bolts.

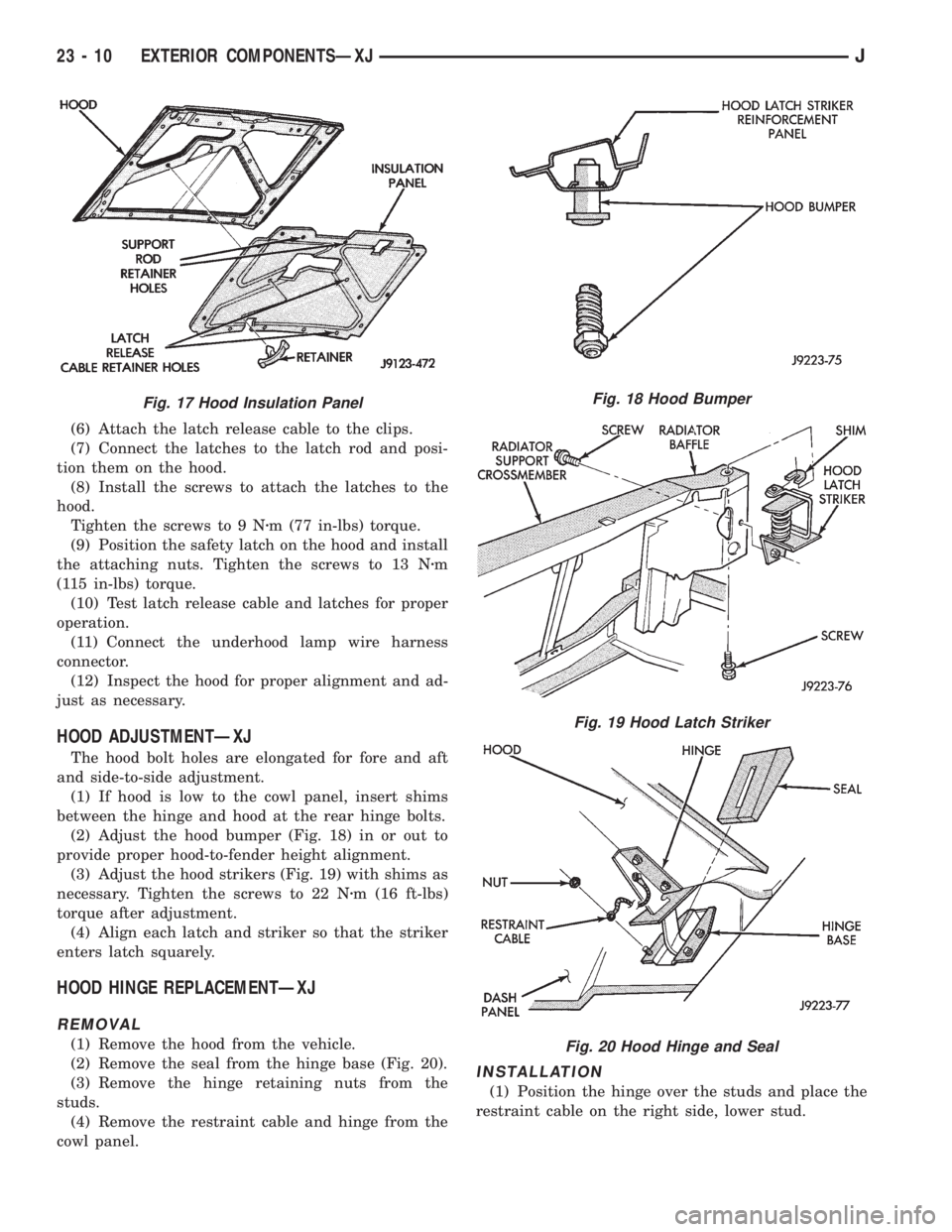

(2) Adjust the hood bumper (Fig. 18) in or out to

provide proper hood-to-fender height alignment.

(3) Adjust the hood strikers (Fig. 19) with shims as

necessary. Tighten the screws to 22 Nzm (16 ft-lbs)

torque after adjustment.

(4) Align each latch and striker so that the striker

enters latch squarely.

HOOD HINGE REPLACEMENTÐXJ

REMOVAL

(1) Remove the hood from the vehicle.

(2) Remove the seal from the hinge base (Fig. 20).

(3) Remove the hinge retaining nuts from the

studs.

(4) Remove the restraint cable and hinge from the

cowl panel.

INSTALLATION

(1) Position the hinge over the studs and place the

restraint cable on the right side, lower stud.

Fig. 17 Hood Insulation PanelFig. 18 Hood Bumper

Fig. 19 Hood Latch Striker

Fig. 20 Hood Hinge and Seal

23 - 10 EXTERIOR COMPONENTSÐXJJ

Page 1744 of 2198

(2) Install the hinge nuts on the studs. Tighten the

restraint cable nut to 4 Nzm (38 in-lbs) torque.

Tighten the remaining nuts to 9 Nzm (77 in-lbs)

torque.

If a replacement hinge seal is being installed,

position it around the hinge arm, force it

against the hinge base.

(3) Position the hinge seal around the hinge arm

and on hinge base.

(4) Install the hood.

(5) Adjust the hood as necessary.

HOOD LATCH REPLACEMENTÐXJ

REMOVAL

(1) Remove the screw that attaches the latch to the

hood inner panel (Fig. 15).

(2) Disconnect the latch from the hood and latch

connecting rod. Remove the latch from the hood.

INSTALLATION

(1) Connect the latch to the latch connecting rod

and position it on the hood inner panel.

(2) Install the screw that attaches the latch to the

hood inner panel.

(3) Tighten the screw to 9 Nzm (77 in-lbs) torque.

(4) Test the operation of the latch release cable and

latch.

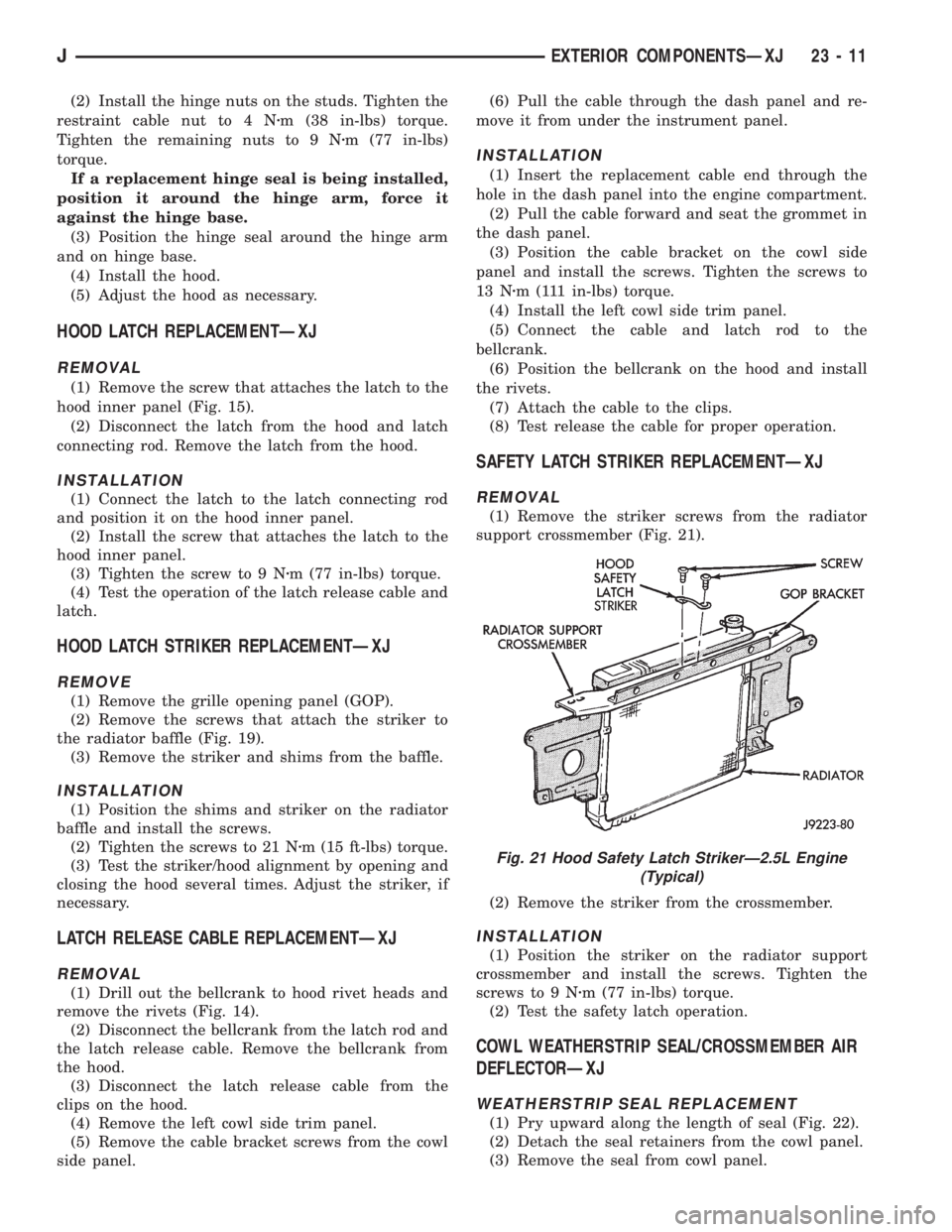

HOOD LATCH STRIKER REPLACEMENTÐXJ

REMOVE

(1) Remove the grille opening panel (GOP).

(2) Remove the screws that attach the striker to

the radiator baffle (Fig. 19).

(3) Remove the striker and shims from the baffle.

INSTALLATION

(1) Position the shims and striker on the radiator

baffle and install the screws.

(2) Tighten the screws to 21 Nzm (15 ft-lbs) torque.

(3) Test the striker/hood alignment by opening and

closing the hood several times. Adjust the striker, if

necessary.

LATCH RELEASE CABLE REPLACEMENTÐXJ

REMOVAL

(1) Drill out the bellcrank to hood rivet heads and

remove the rivets (Fig. 14).

(2) Disconnect the bellcrank from the latch rod and

the latch release cable. Remove the bellcrank from

the hood.

(3) Disconnect the latch release cable from the

clips on the hood.

(4) Remove the left cowl side trim panel.

(5) Remove the cable bracket screws from the cowl

side panel.(6) Pull the cable through the dash panel and re-

move it from under the instrument panel.

INSTALLATION

(1) Insert the replacement cable end through the

hole in the dash panel into the engine compartment.

(2) Pull the cable forward and seat the grommet in

the dash panel.

(3) Position the cable bracket on the cowl side

panel and install the screws. Tighten the screws to

13 Nzm (111 in-lbs) torque.

(4) Install the left cowl side trim panel.

(5) Connect the cable and latch rod to the

bellcrank.

(6) Position the bellcrank on the hood and install

the rivets.

(7) Attach the cable to the clips.

(8) Test release the cable for proper operation.

SAFETY LATCH STRIKER REPLACEMENTÐXJ

REMOVAL

(1) Remove the striker screws from the radiator

support crossmember (Fig. 21).

(2) Remove the striker from the crossmember.

INSTALLATION

(1) Position the striker on the radiator support

crossmember and install the screws. Tighten the

screws to 9 Nzm (77 in-lbs) torque.

(2) Test the safety latch operation.

COWL WEATHERSTRIP SEAL/CROSSMEMBER AIR

DEFLECTORÐXJ

WEATHERSTRIP SEAL REPLACEMENT

(1) Pry upward along the length of seal (Fig. 22).

(2) Detach the seal retainers from the cowl panel.

(3) Remove the seal from cowl panel.

Fig. 21 Hood Safety Latch StrikerÐ2.5L Engine

(Typical)

JEXTERIOR COMPONENTSÐXJ 23 - 11

Page 1755 of 2198

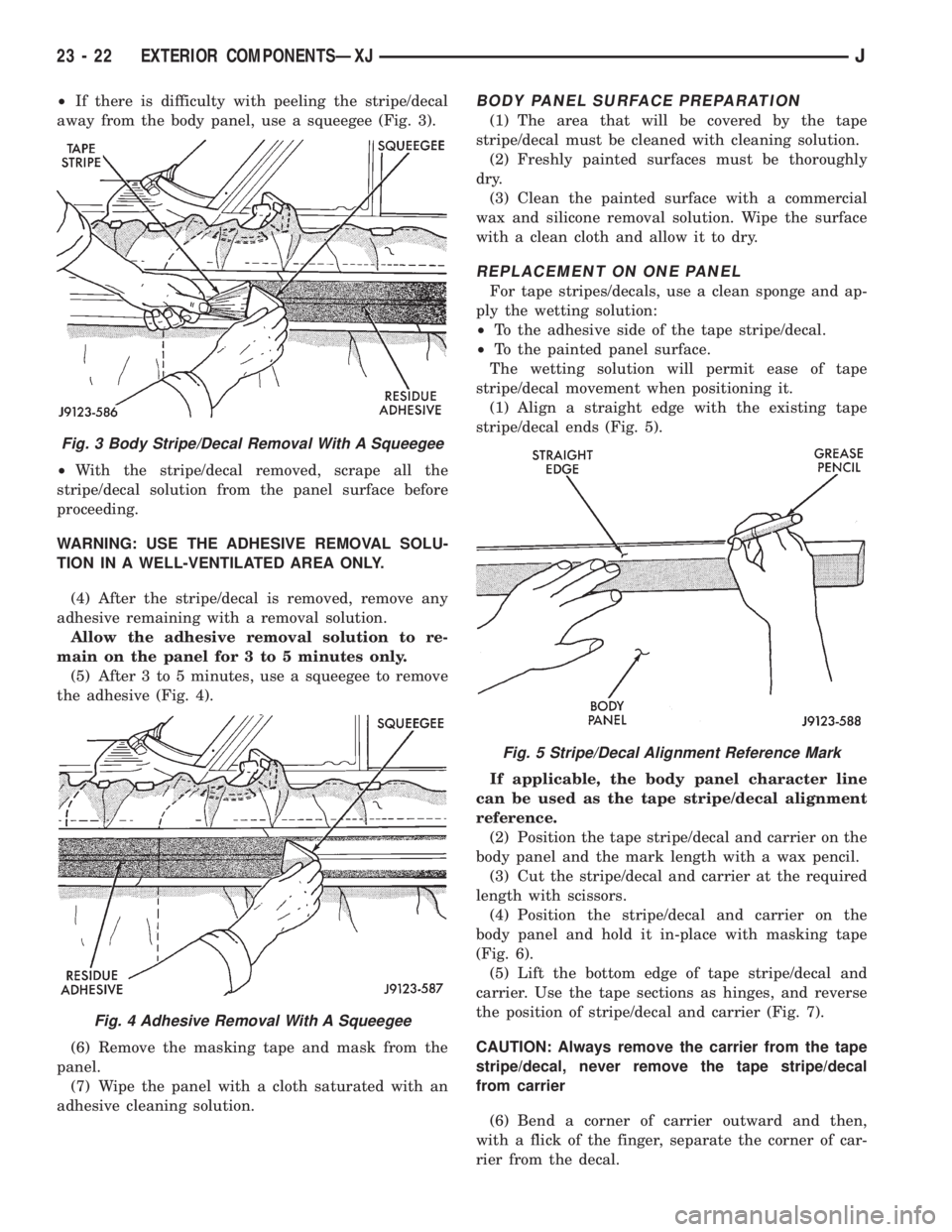

²If there is difficulty with peeling the stripe/decal

away from the body panel, use a squeegee (Fig. 3).

²With the stripe/decal removed, scrape all the

stripe/decal solution from the panel surface before

proceeding.

WARNING: USE THE ADHESIVE REMOVAL SOLU-

TION IN A WELL-VENTILATED AREA ONLY.

(4) After the stripe/decal is removed, remove any

adhesive remaining with a removal solution.

Allow the adhesive removal solution to re-

main on the panel for 3 to 5 minutes only.

(5) After 3 to 5 minutes, use a squeegee to remove

the adhesive (Fig. 4).

(6) Remove the masking tape and mask from the

panel.

(7) Wipe the panel with a cloth saturated with an

adhesive cleaning solution.BODY PANEL SURFACE PREPARATION

(1) The area that will be covered by the tape

stripe/decal must be cleaned with cleaning solution.

(2) Freshly painted surfaces must be thoroughly

dry.

(3) Clean the painted surface with a commercial

wax and silicone removal solution. Wipe the surface

with a clean cloth and allow it to dry.

REPLACEMENT ON ONE PANEL

For tape stripes/decals, use a clean sponge and ap-

ply the wetting solution:

²To the adhesive side of the tape stripe/decal.

²To the painted panel surface.

The wetting solution will permit ease of tape

stripe/decal movement when positioning it.

(1) Align a straight edge with the existing tape

stripe/decal ends (Fig. 5).

If applicable, the body panel character line

can be used as the tape stripe/decal alignment

reference.

(2) Position the tape stripe/decal and carrier on the

body panel and the mark length with a wax pencil.

(3) Cut the stripe/decal and carrier at the required

length with scissors.

(4) Position the stripe/decal and carrier on the

body panel and hold it in-place with masking tape

(Fig. 6).

(5) Lift the bottom edge of tape stripe/decal and

carrier. Use the tape sections as hinges, and reverse

the position of stripe/decal and carrier (Fig. 7).

CAUTION: Always remove the carrier from the tape

stripe/decal, never remove the tape stripe/decal

from carrier

(6) Bend a corner of carrier outward and then,

with a flick of the finger, separate the corner of car-

rier from the decal.

Fig. 3 Body Stripe/Decal Removal With A Squeegee

Fig. 4 Adhesive Removal With A Squeegee

Fig. 5 Stripe/Decal Alignment Reference Mark

23 - 22 EXTERIOR COMPONENTSÐXJJ

Page 1763 of 2198

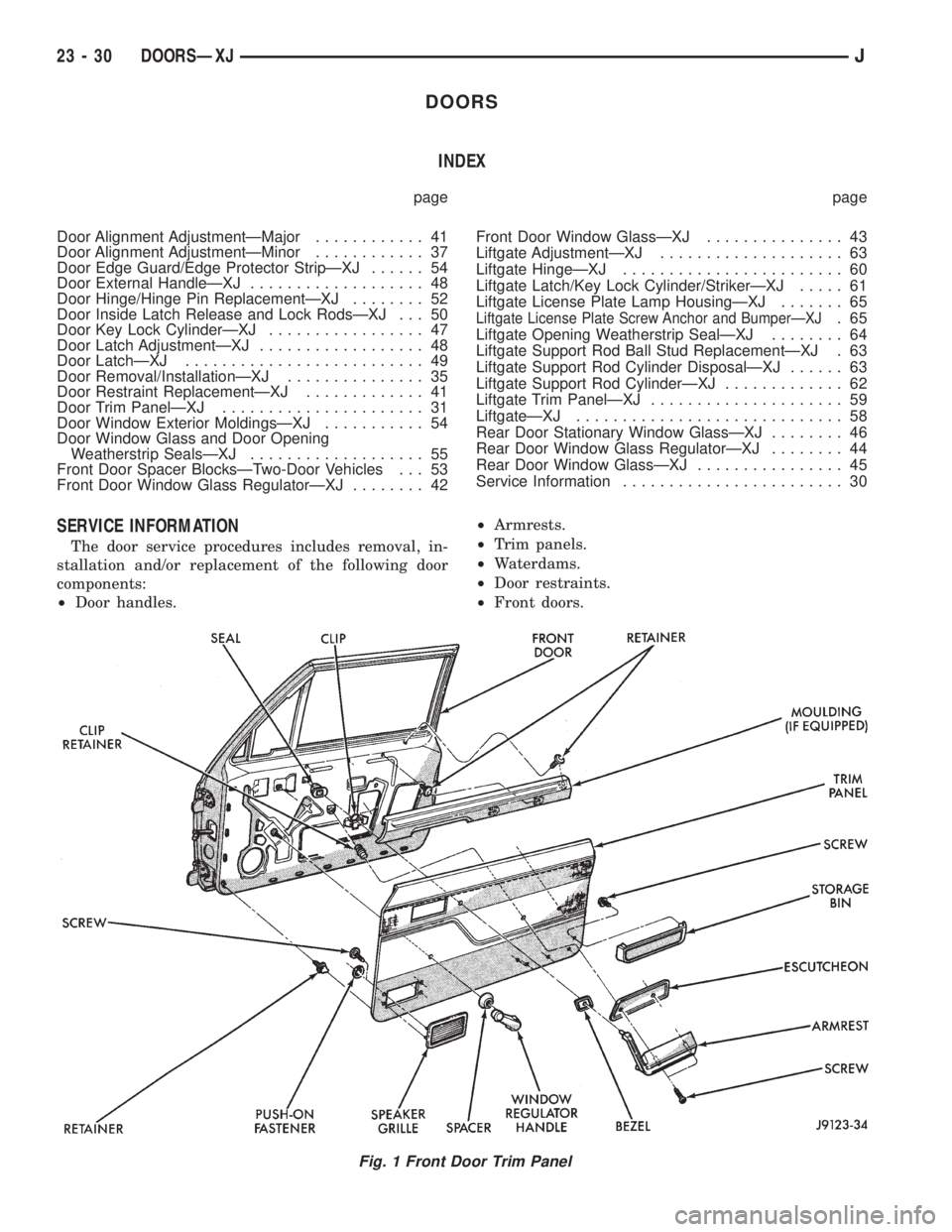

DOORS

INDEX

page page

Door Alignment AdjustmentÐMajor............ 41

Door Alignment AdjustmentÐMinor............ 37

Door Edge Guard/Edge Protector StripÐXJ...... 54

Door External HandleÐXJ................... 48

Door Hinge/Hinge Pin ReplacementÐXJ........ 52

Door Inside Latch Release and Lock RodsÐXJ . . . 50

Door Key Lock CylinderÐXJ................. 47

Door Latch AdjustmentÐXJ.................. 48

Door LatchÐXJ.......................... 49

Door Removal/InstallationÐXJ............... 35

Door Restraint ReplacementÐXJ............. 41

Door Trim PanelÐXJ...................... 31

Door Window Exterior MoldingsÐXJ........... 54

Door Window Glass and Door Opening

Weatherstrip SealsÐXJ................... 55

Front Door Spacer BlocksÐTwo-Door Vehicles . . . 53

Front Door Window Glass RegulatorÐXJ........ 42Front Door Window GlassÐXJ............... 43

Liftgate AdjustmentÐXJ.................... 63

Liftgate HingeÐXJ........................ 60

Liftgate Latch/Key Lock Cylinder/StrikerÐXJ..... 61

Liftgate License Plate Lamp HousingÐXJ....... 65

Liftgate License Plate Screw Anchor and BumperÐXJ.65

Liftgate Opening Weatherstrip SealÐXJ........ 64

Liftgate Support Rod Ball Stud ReplacementÐXJ . 63

Liftgate Support Rod Cylinder DisposalÐXJ...... 63

Liftgate Support Rod CylinderÐXJ............. 62

Liftgate Trim PanelÐXJ..................... 59

LiftgateÐXJ............................. 58

Rear Door Stationary Window GlassÐXJ........ 46

Rear Door Window Glass RegulatorÐXJ........ 44

Rear Door Window GlassÐXJ................ 45

Service Information........................ 30

SERVICE INFORMATION

The door service procedures includes removal, in-

stallation and/or replacement of the following door

components:

²Door handles.²Armrests.

²Trim panels.

²Waterdams.

²Door restraints.

²Front doors.

Fig. 1 Front Door Trim Panel

23 - 30 DOORSÐXJJ

Page 1764 of 2198

²Rear doors.

²Window glass regulators.

²Key lock cylinders.

²Door half-hinges.

²Liftgate.

²Liftgate hinges.

²Liftgate gas support rod cylinders.

²Rocker panel seals.

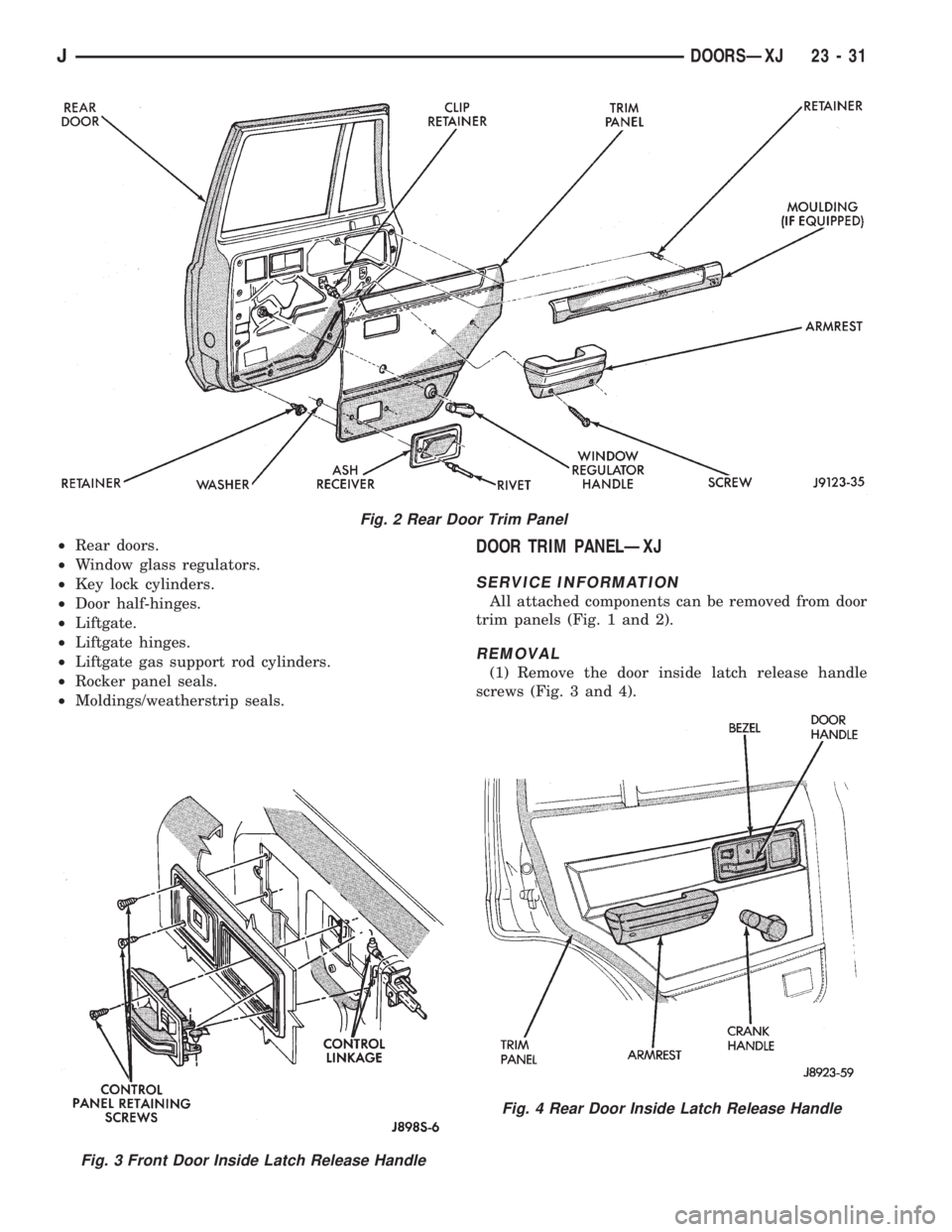

²Moldings/weatherstrip seals.DOOR TRIM PANELÐXJ

SERVICE INFORMATION

All attached components can be removed from door

trim panels (Fig. 1 and 2).

REMOVAL

(1) Remove the door inside latch release handle

screws (Fig. 3 and 4).

Fig. 2 Rear Door Trim Panel

Fig. 3 Front Door Inside Latch Release Handle

Fig. 4 Rear Door Inside Latch Release Handle

JDOORSÐXJ 23 - 31

Page 1770 of 2198

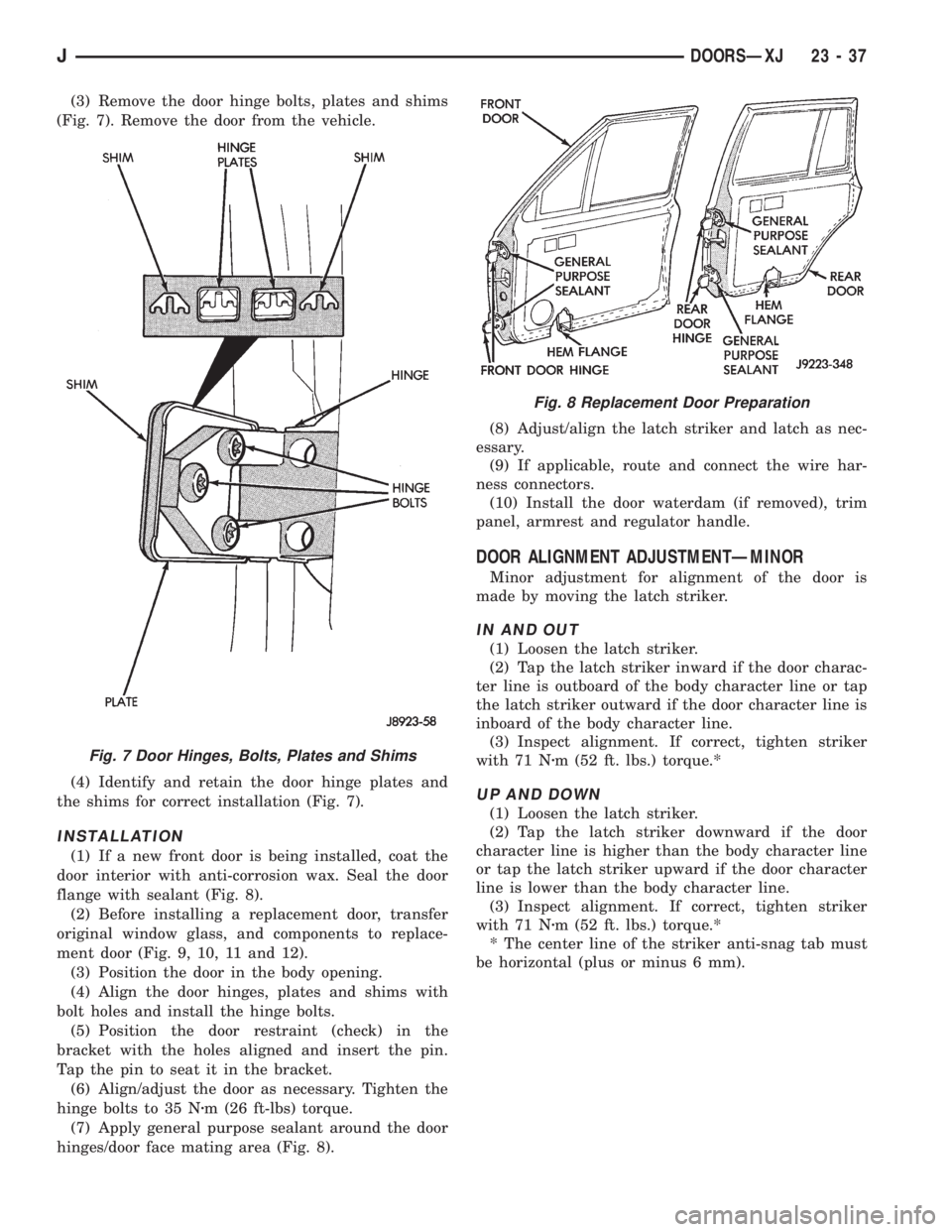

(3) Remove the door hinge bolts, plates and shims

(Fig. 7). Remove the door from the vehicle.

(4) Identify and retain the door hinge plates and

the shims for correct installation (Fig. 7).

INSTALLATION

(1) If a new front door is being installed, coat the

door interior with anti-corrosion wax. Seal the door

flange with sealant (Fig. 8).

(2) Before installing a replacement door, transfer

original window glass, and components to replace-

ment door (Fig. 9, 10, 11 and 12).

(3) Position the door in the body opening.

(4) Align the door hinges, plates and shims with

bolt holes and install the hinge bolts.

(5) Position the door restraint (check) in the

bracket with the holes aligned and insert the pin.

Tap the pin to seat it in the bracket.

(6) Align/adjust the door as necessary. Tighten the

hinge bolts to 35 Nzm (26 ft-lbs) torque.

(7) Apply general purpose sealant around the door

hinges/door face mating area (Fig. 8).(8) Adjust/align the latch striker and latch as nec-

essary.

(9) If applicable, route and connect the wire har-

ness connectors.

(10) Install the door waterdam (if removed), trim

panel, armrest and regulator handle.

DOOR ALIGNMENT ADJUSTMENTÐMINOR

Minor adjustment for alignment of the door is

made by moving the latch striker.

IN AND OUT

(1) Loosen the latch striker.

(2) Tap the latch striker inward if the door charac-

ter line is outboard of the body character line or tap

the latch striker outward if the door character line is

inboard of the body character line.

(3) Inspect alignment. If correct, tighten striker

with 71 Nzm (52 ft. lbs.) torque.*

UP AND DOWN

(1) Loosen the latch striker.

(2) Tap the latch striker downward if the door

character line is higher than the body character line

or tap the latch striker upward if the door character

line is lower than the body character line.

(3) Inspect alignment. If correct, tighten striker

with 71 Nzm (52 ft. lbs.) torque.*

* The center line of the striker anti-snag tab must

be horizontal (plus or minus 6 mm).

Fig. 7 Door Hinges, Bolts, Plates and Shims

Fig. 8 Replacement Door Preparation

JDOORSÐXJ 23 - 37

Page 1774 of 2198

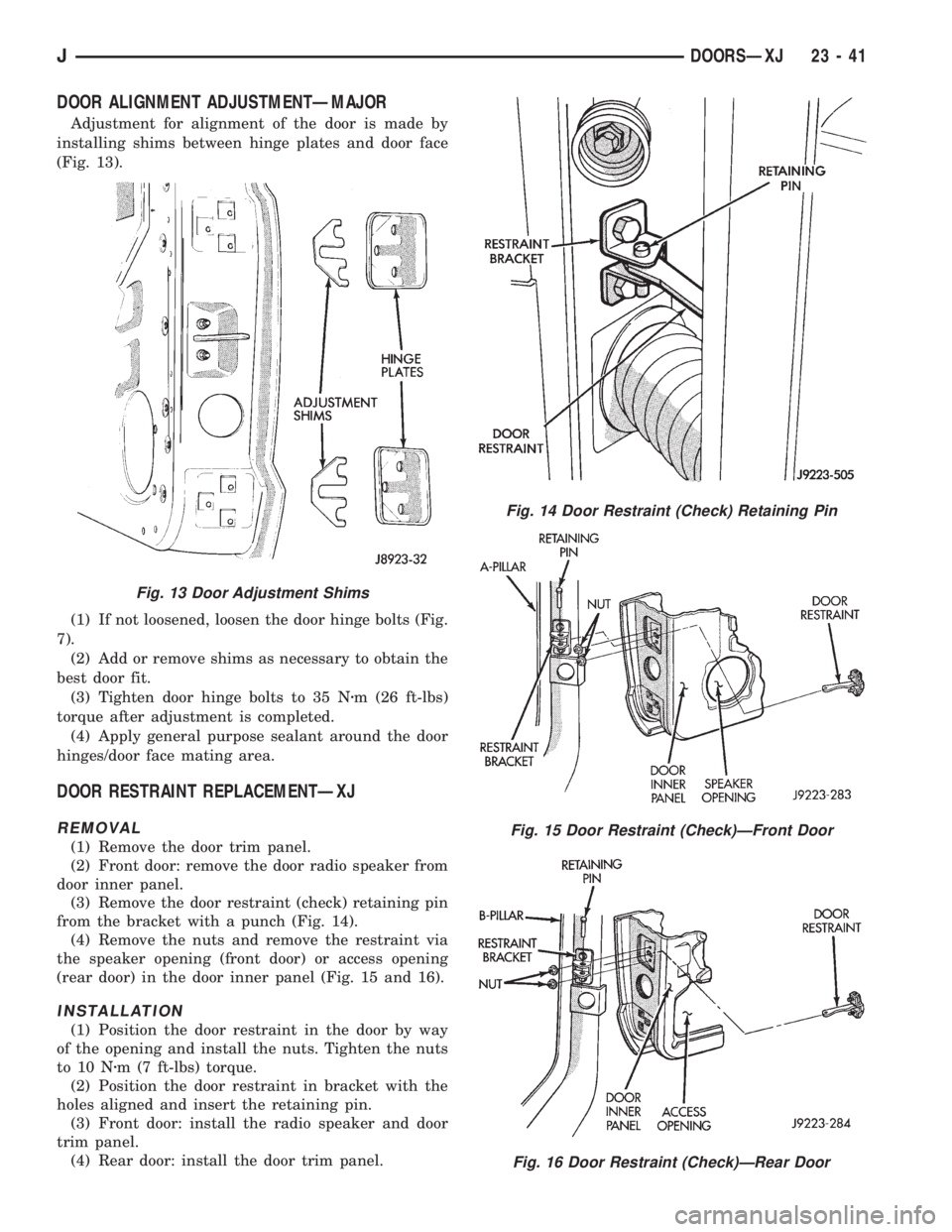

DOOR ALIGNMENT ADJUSTMENTÐMAJOR

Adjustment for alignment of the door is made by

installing shims between hinge plates and door face

(Fig. 13).

(1) If not loosened, loosen the door hinge bolts (Fig.

7).

(2) Add or remove shims as necessary to obtain the

best door fit.

(3) Tighten door hinge bolts to 35 Nzm (26 ft-lbs)

torque after adjustment is completed.

(4) Apply general purpose sealant around the door

hinges/door face mating area.

DOOR RESTRAINT REPLACEMENTÐXJ

REMOVAL

(1) Remove the door trim panel.

(2) Front door: remove the door radio speaker from

door inner panel.

(3) Remove the door restraint (check) retaining pin

from the bracket with a punch (Fig. 14).

(4) Remove the nuts and remove the restraint via

the speaker opening (front door) or access opening

(rear door) in the door inner panel (Fig. 15 and 16).

INSTALLATION

(1) Position the door restraint in the door by way

of the opening and install the nuts. Tighten the nuts

to 10 Nzm (7 ft-lbs) torque.

(2) Position the door restraint in bracket with the

holes aligned and insert the retaining pin.

(3) Front door: install the radio speaker and door

trim panel.

(4) Rear door: install the door trim panel.

Fig. 14 Door Restraint (Check) Retaining Pin

Fig. 15 Door Restraint (Check)ÐFront Door

Fig. 16 Door Restraint (Check)ÐRear Door

Fig. 13 Door Adjustment Shims

JDOORSÐXJ 23 - 41

Page 1785 of 2198

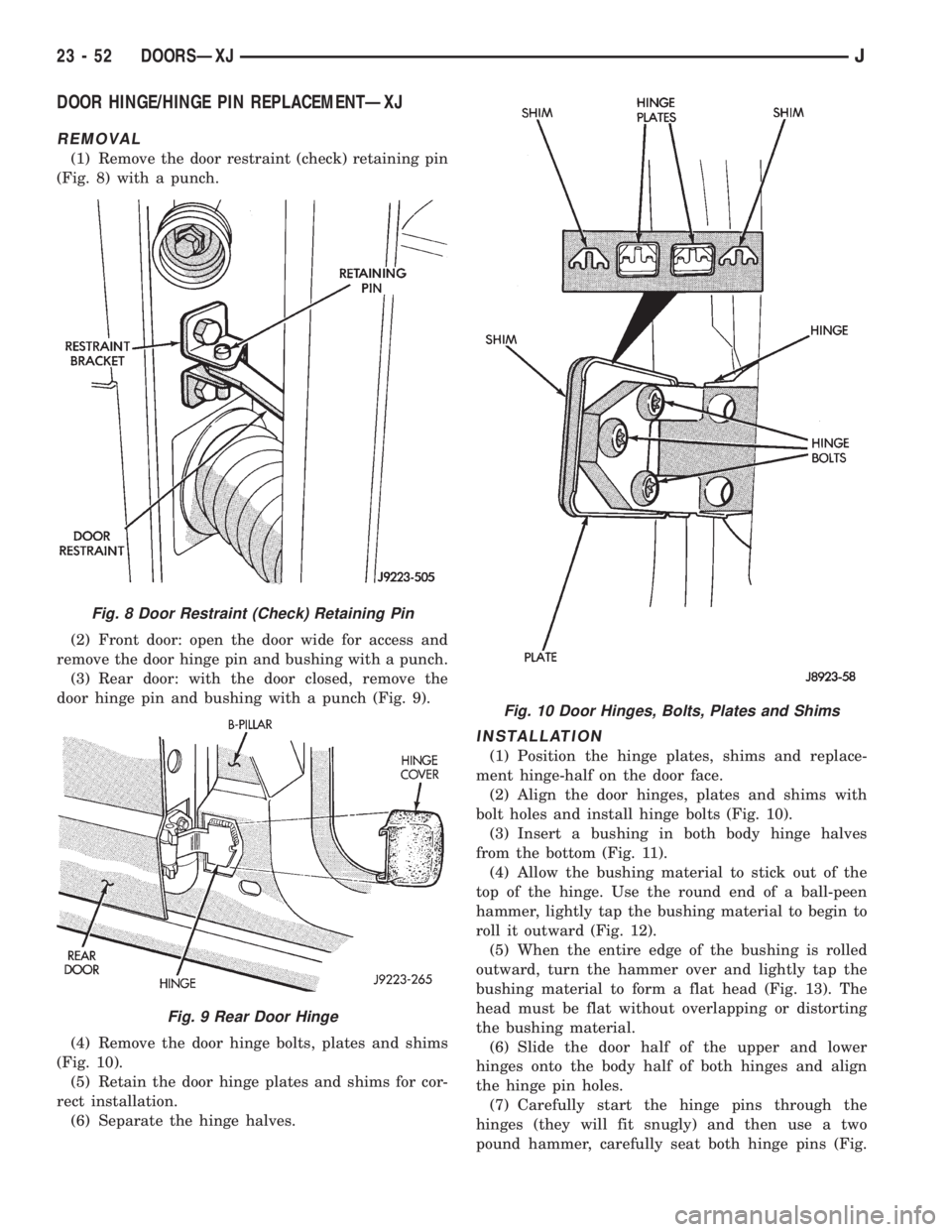

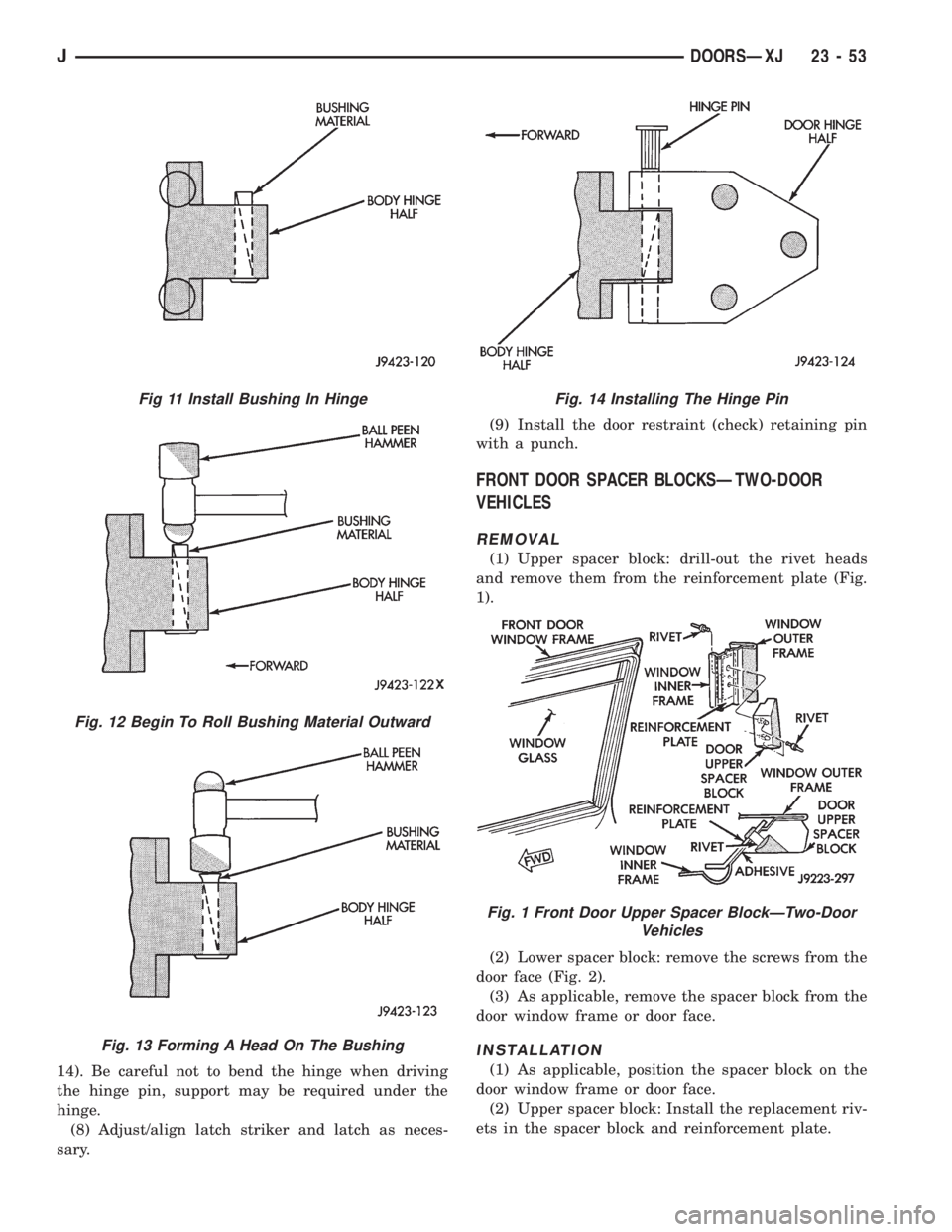

DOOR HINGE/HINGE PIN REPLACEMENTÐXJ

REMOVAL

(1) Remove the door restraint (check) retaining pin

(Fig. 8) with a punch.

(2) Front door: open the door wide for access and

remove the door hinge pin and bushing with a punch.

(3) Rear door: with the door closed, remove the

door hinge pin and bushing with a punch (Fig. 9).

(4) Remove the door hinge bolts, plates and shims

(Fig. 10).

(5) Retain the door hinge plates and shims for cor-

rect installation.

(6) Separate the hinge halves.

INSTALLATION

(1) Position the hinge plates, shims and replace-

ment hinge-half on the door face.

(2) Align the door hinges, plates and shims with

bolt holes and install hinge bolts (Fig. 10).

(3) Insert a bushing in both body hinge halves

from the bottom (Fig. 11).

(4) Allow the bushing material to stick out of the

top of the hinge. Use the round end of a ball-peen

hammer, lightly tap the bushing material to begin to

roll it outward (Fig. 12).

(5) When the entire edge of the bushing is rolled

outward, turn the hammer over and lightly tap the

bushing material to form a flat head (Fig. 13). The

head must be flat without overlapping or distorting

the bushing material.

(6) Slide the door half of the upper and lower

hinges onto the body half of both hinges and align

the hinge pin holes.

(7) Carefully start the hinge pins through the

hinges (they will fit snugly) and then use a two

pound hammer, carefully seat both hinge pins (Fig.

Fig. 8 Door Restraint (Check) Retaining Pin

Fig. 9 Rear Door Hinge

Fig. 10 Door Hinges, Bolts, Plates and Shims

23 - 52 DOORSÐXJJ

Page 1786 of 2198

14). Be careful not to bend the hinge when driving

the hinge pin, support may be required under the

hinge.

(8) Adjust/align latch striker and latch as neces-

sary.(9) Install the door restraint (check) retaining pin

with a punch.

FRONT DOOR SPACER BLOCKSÐTWO-DOOR

VEHICLES

REMOVAL

(1) Upper spacer block: drill-out the rivet heads

and remove them from the reinforcement plate (Fig.

1).

(2) Lower spacer block: remove the screws from the

door face (Fig. 2).

(3) As applicable, remove the spacer block from the

door window frame or door face.

INSTALLATION

(1) As applicable, position the spacer block on the

door window frame or door face.

(2) Upper spacer block: Install the replacement riv-

ets in the spacer block and reinforcement plate.

Fig 11 Install Bushing In Hinge

Fig. 12 Begin To Roll Bushing Material Outward

Fig. 13 Forming A Head On The Bushing

Fig. 14 Installing The Hinge Pin

Fig. 1 Front Door Upper Spacer BlockÐTwo-Door

Vehicles

JDOORSÐXJ 23 - 53

Page 1792 of 2198

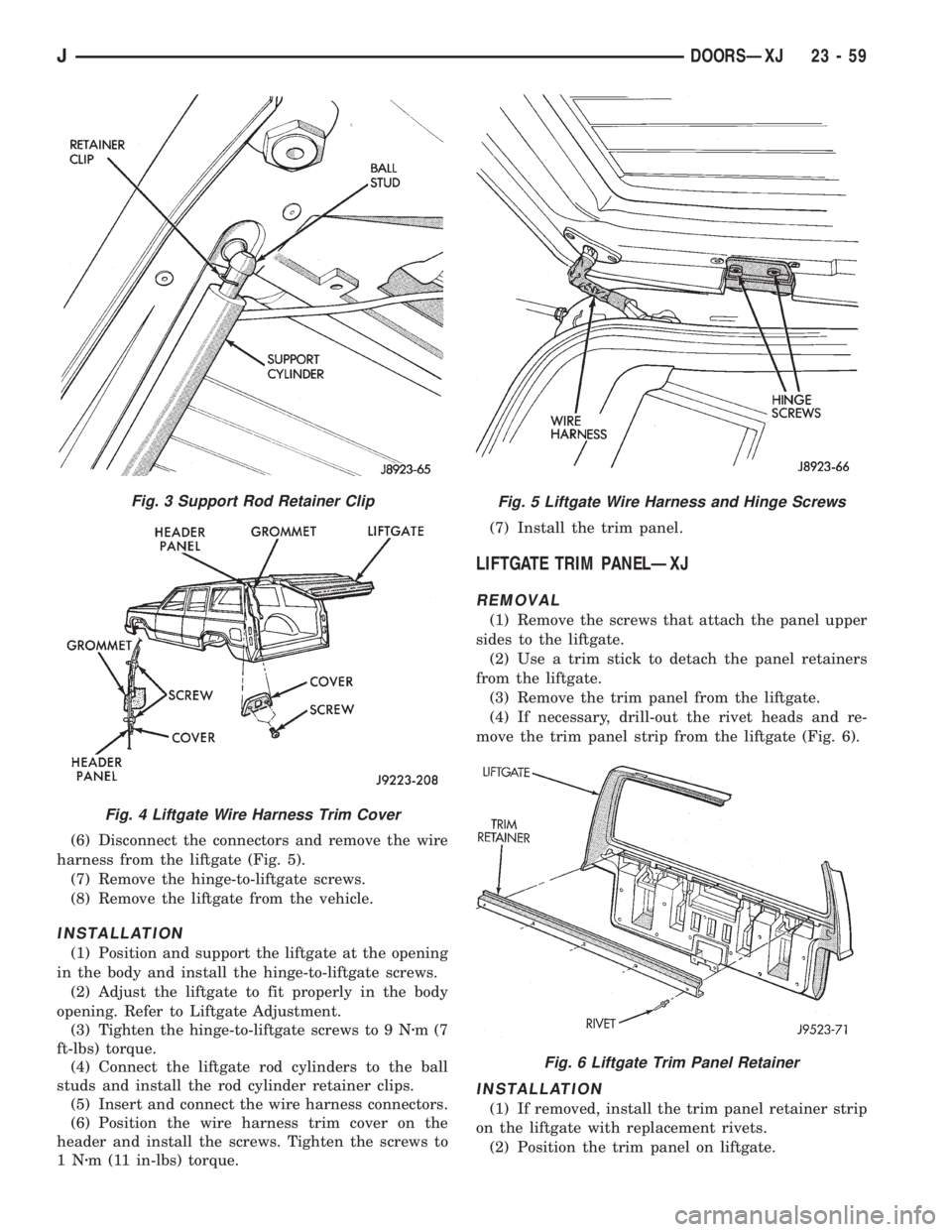

(6) Disconnect the connectors and remove the wire

harness from the liftgate (Fig. 5).

(7) Remove the hinge-to-liftgate screws.

(8) Remove the liftgate from the vehicle.

INSTALLATION

(1) Position and support the liftgate at the opening

in the body and install the hinge-to-liftgate screws.

(2) Adjust the liftgate to fit properly in the body

opening. Refer to Liftgate Adjustment.

(3) Tighten the hinge-to-liftgate screws to 9 Nzm(7

ft-lbs) torque.

(4) Connect the liftgate rod cylinders to the ball

studs and install the rod cylinder retainer clips.

(5) Insert and connect the wire harness connectors.

(6) Position the wire harness trim cover on the

header and install the screws. Tighten the screws to

1Nzm (11 in-lbs) torque.(7) Install the trim panel.

LIFTGATE TRIM PANELÐXJ

REMOVAL

(1) Remove the screws that attach the panel upper

sides to the liftgate.

(2) Use a trim stick to detach the panel retainers

from the liftgate.

(3) Remove the trim panel from the liftgate.

(4) If necessary, drill-out the rivet heads and re-

move the trim panel strip from the liftgate (Fig. 6).

INSTALLATION

(1) If removed, install the trim panel retainer strip

on the liftgate with replacement rivets.

(2) Position the trim panel on liftgate.

Fig. 3 Support Rod Retainer Clip

Fig. 4 Liftgate Wire Harness Trim Cover

Fig. 5 Liftgate Wire Harness and Hinge Screws

Fig. 6 Liftgate Trim Panel Retainer

JDOORSÐXJ 23 - 59