Interior fuse panel JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 359 of 2198

CLUSTER ILLUMINATION LAMPS

(1) Check fuse 19 (fuse 25 - RHD) in fuseblock

module. If OK, go to next step. If not OK, replace

fuse.

(2) Turn park lamps on at headlamp switch. Rotate

headlamp switch knob counterclockwise to just before

interior lamps detent. Check for battery voltage at

fuse 19 (fuse 25 - RHD) in fuseblock module. Rotate

headlamp switch clockwise while observing test volt-

meter. Reading should go from battery voltage to zero

volts. If OK, go to next step. If not OK, repair open

circuit to headlamp switch or refer to Group 8L -

Lamps to diagnose headlamp switch.

(3) Disconnect battery negative cable. Remove in-

strument cluster bezel and cluster assembly. Unplug

cluster connector A. Connect battery negative cable.Turn park lamps on at headlamp switch. Rotate

headlamp switch knob counterclockwise to just before

interior lamps detent. Check for battery voltage at

cavity A7 (cavity A6 - RHD) of cluster connector A. If

OK, go to next step. If not OK, repair open circuit to

fuse as required.

(4) Turn park lamps off. Disconnect battery nega-

tive cable. Remove fuse 19 (fuse 25 - RHD) from fuse-

block module. Probe cavity A7 (cavity A6 - RHD) of

cluster connector A. Check for continuity to a good

ground. There should be no continuity. If OK, go to

next step. If not OK, repair short circuit as required.

(5) Probe cavity A3 of cluster connector A. Check

for continuity to ground. There should be continuity.

If not OK, repair open circuit as required.

8E - 16 INSTRUMENT PANEL AND GAUGESÐXJJ

Page 377 of 2198

TURN SIGNAL INDICATOR LAMPS

(1) Disconnect battery negative cable. Remove left

instrument cluster bezel and main cluster assembly.

Probe cavity 20 of cluster connector. Check for conti-

nuity to a good ground. There should be continuity. If

OK, go to next step. If not OK, repair open circuit to

ground.

(2) Connect battery negative cable. Install a

jumper wire from cavity 18 (left indicator) or cavity 7

(right indicator) of cluster connector to a 12-volt bat-

tery feed. Lamp should light. If OK, continue to next

step. If not OK, replace bulb.

(3) Disconnect battery negative cable. Check for

continuity between cavity 18 (left indicator) or cavity

7 (right indicator) of cluster connector and cavity H

(left front turn signal) or cavity J (right front turn

signal) of steering column wiring connector. There

should be continuity. If OK, refer to Group 8J - Turn

Signal and Hazard Warning Systems for further di-

agnosis. If not OK, repair open circuit as required.

UPSHIFT INDICATOR LAMP

(1) Disconnect battery negative cable. Unplug PCM

connector. Connect battery negative cable. Turn igni-

tion switch to ON. Install a jumper wire from cavity

54 of PCM connector (Fig. 5) to a good ground. Lamp

should light. Remove jumper from ground. Lamp

should go off. If OK, refer to Powertrain Diagnostic

Procedures manual to diagnose PCM. If not OK, turn

ignition switch to OFF and go to next step.

(2) Disconnect battery negative cable. Remove left

instrument cluster bezel and main cluster assembly.

Install a jumper wire from cavity 5 of cluster connec-

tor to a good ground. Connect battery negative cable.

Turn ignition switch to ON. Lamp should light. If

OK, go to next step. If not OK, replace bulb.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Unplug cluster connector. Check for

continuity between cavity 5 of cluster connector and

a good ground. There should be no continuity. If OK,

go to next step. If not OK, repair short circuit as re-

quired.(4) Check for continuity between cavity 5 of cluster

connector and cavity 54 of PCM connector. There

should be continuity. If not OK, repair open circuit as

required.

CLUSTER ILLUMINATION LAMPS

(1) Check fuse 10 in fuseblock module. If OK, go to

next step. If not OK, replace fuse.

(2) Turn park lamps on at headlamp switch. Rotate

panel dimmer switch thumb-wheel to HI position,

just before interior lamps detent. Check for battery

voltage at fuse 10 in fuseblock module. Rotate panel

dimmer thumb-wheel towards LO position while ob-

serving test voltmeter. Reading should go from bat-

tery voltage to zero volts. If OK, go to next step. If

not OK, repair open circuit to headlamp switch or re-

fer to Group 8L - Lamps to diagnose headlamp

switch.

(3) Disconnect battery negative cable. Remove left

or center instrument cluster bezel and main or gauge

package cluster assembly. Unplug cluster connector.

Connect battery negative cable. Turn park lamps on

at headlamp switch. Rotate panel dimmer thumb-

wheel to HI position, just before interior lamps de-

tent. Check for battery voltage at cavity 21 of main

cluster connector, or cavity 7 of gauge package clus-

ter connector. If OK, go to next step. If not OK, re-

pair open circuit to fuse as required.

(4) Turn park lamps off. Disconnect battery nega-

tive cable. Remove fuse 10 from fuseblock module.

Probe cavity 21 of main cluster connector, or cavity 7

of gauge package cluster connector. Check for conti-

nuity to a good ground. There should be no continu-

ity. If OK, go to next step. If not OK, repair short

circuit as required.

(5) Probe cavity 20 of main cluster connector, or

cavities 1 and 13 of gauge package cluster connector.

Check for continuity to ground. There should be con-

tinuity. If not OK, repair open circuit as required.

8E - 34 INSTRUMENT PANEL AND GAUGESÐYJJ

Page 431 of 2198

GENERAL INFORMATION - YJ

Following are general descriptions of the major

components in the YJ (Wrangler) wiper and washer

systems. Refer to Group 8W - Wiring Diagrams for

complete circuit descriptions and diagrams.

WINDSHIELD WIPER SYSTEM

A two-speed wiper system is standard equipment

on all YJ models. An optional intermittent wipe sys-

tem is available. The standard system allows the

driver to select from two wiper speeds. The optional

intermittent wipe system allows the driver to select

from two wiper speeds or an intermittent wipe fea-

ture that allows a delay between wipes of 2 to 15 sec-

onds. Refer to the owner's manual for more

information on wiper system controls and operation.

The wipers will operate only when the ignition

switch is in the ACCESSORY or ON position. A cir-

cuit breaker in the fuseblock module protects the cir-

cuitry of the wiper system.

WINDSHIELD WASHER SYSTEM

A electrically-operated windshield washer system is

standard equipment on all YJ models. The washers

will operate only when the ignition switch is in the

ACCESSORY or ON position. A circuit breaker in the

fuseblock module protects the circuitry of the washer

system. Refer to the owner's manual for more infor-

mation on washer system controls and operation.

LIFTGATE WIPER/WASHER SYSTEM

A liftgate wiper/washer system is an available op-

tion on YJ models equipped with the optional hard-

top. The liftgate wiper is a fixed cycle wipe system. A

single switch on the instrument panel controls both

the liftgate wiper and washer functions. These sys-

tems will operate only when the ignition switch is in

the ON position. Fuse 1 in the fuseblock module pro-

tects the circuitry of both the liftgate wiper and

washer. Refer to the owner's manual for more infor-

mation on liftgate wiper/washer system controls and

operation.

WIPER ARMS, BLADES, AND ELEMENTS

All YJ models have two 12-inch windshield wiper

blades with replaceable rubber elements (squeegees).

Models with the liftgate wiper option use a single 16-

inch wiper blade with a replaceable rubber element

(squeegee).

Caution should be exercised to protect the rubber

squeegees from any petroleum-based cleaners or con-

taminants, which will rapidly deteriorate the squee-

gee rubber. If squeegees are damaged, worn or

contaminated they must be replaced.

Wiper squeegees exposed to the weather for a long

time tend to lose their wiping effectiveness. Periodiccleaning of the squeegees is suggested to remove de-

posits of salt and road film. The wiper blades, arms

and windshield or liftgate glass should be cleaned

with a sponge or cloth and a mild detergent or non-

abrasive cleaner. If the squeegees continue to streak

or smear, they should be replaced.

The blades are mounted to spring-loaded wiper

arms. Spring tension of the wiper arms controls the

pressure applied to the blades on the glass. The

windshield wiper arms are attached by an integral

latch to the two wiper pivots on the windshield frame

at the base of the windshield. The liftgate wiper arm

is attached by an integral latch directly to the lift-

gate wiper motor output shaft on the liftgate glass.

The wiper arms and blades can not be adjusted or re-

paired. If faulty, they must be replaced.

WIPER LINKAGE AND PIVOTS

The wiper pivots are fastened to the windshield

frame with nuts. The pivots and linkage are serviced

through access holes in the interior side of the lower

windshield frame. The two pivots and their connect-

ing link are serviced as a unit. The drive link, which

connects the motor crank arm to the left pivot, is ser-

viced separately.

WINDSHIELD WIPER MOTOR

The two-speed permanent magnet wiper motor has

an integral transmission and park switch. The motor

is mounted to a cover plate on the interior side of the

lower windshield frame. The wiper motor output

shaft passes through a gasket and the cover plate

into the space between the inner and outer lower

windshield frame, where the crank arm attached to

the output shaft drives the wiper drive link.

Wiper speed is controlled by current flow to the ap-

propriate set of brushes. The wiper motor completes

its wipe cycle when the switch is turned OFF, and

parks the blades in the lowest portion of the wipe

pattern. The wiper motor assembly can not be re-

paired. If faulty, the entire motor assembly must be

replaced. The cover plate, gasket and drive link to

crank arm retaining ring are available for service.

LIFTGATE WIPER MOTOR

The liftgate wiper motor operates in three modes:

²constant wipe that operates when the liftgate

wiper/washer switch is placed in the Wipe position

²constant wipe that operates when the liftgate

washers are operated

²a park mode that runs the motor until the wiper

blade reaches the park position after the liftgate

wiper switch or ignition switch is turned OFF.

8K - 10 WIPER AND WASHER SYSTEMS - YJJ

Page 478 of 2198

INTERIOR LAMPS

INDEX

page page

Dome/Courtesy Lamp Service InformationÐYJ . . . 31

Dome/Courtesy Lamp Trouble DiagnosisÐYJ.... 31Hardtop Dome/Cargo Lamp Bulb ReplacementÐYJ

Vehicles............................... 31

DOME/COURTESY LAMP SERVICE

INFORMATIONÐYJ

The dome/cargo and underpanel courtesy lamps are

controlled via ON/OFF switches. The ON/OFF

switches are in the lamp ground circuits. Voltage via

the dome/courtesy lamp fuse is applied directly to the

lamp bulbs. When either door is opened, the door pil-

lar switch contacts close and provide a direct path to

vehicle body ground.

The dome/cargo and underpanel courtesy lamps

can also be turned on via the interior lamp illumina-

tion rheostat.

DOME/COURTESY LAMP TROUBLE DIAGNOSISÐ

YJ

ALL LAMPS INOPERATIVE FROM INTERIOR

LAMP ILLUMINATION RHEOSTAT

(1) Rotate the interior lamp illumination rheostat

in an upward direction. The lamps should light. If

not OK, remove, inspect and test the dome lamp

fuse. Replace if bad.

(2) If the fuse is OK, repair the open circuit in the

wire harness to vehicle body ground.

(3) If lamp still does not light, replace the switch.

ONE LAMP INOPERATIVE

(1) Measure the resistance across the bulb holder

terminals. The ohmmeter should indicate zero ohms.

If not, replace the bulb.

(2) Measure the voltage between the voltage side

of the bulb holder and vehicle body ground. The volt-

meter should indicate battery voltage. If not, repair

the open circuit in the wire harness to the splice.

LAMPS INOPERATIVE WITH ONE OR MORE

DOORS OPENED

(1) Remove the inoperative switch from the door

pillar and connect the switch wire directly to ground.

The lamp should light.(2) If not, check for an open circuit in black

(ground) wire. Repair as necessary. If lamps still do

not light, replace the switch.

HARDTOP DOME/CARGO LAMP BULB

REPLACEMENTÐYJ VEHICLES

REMOVAL

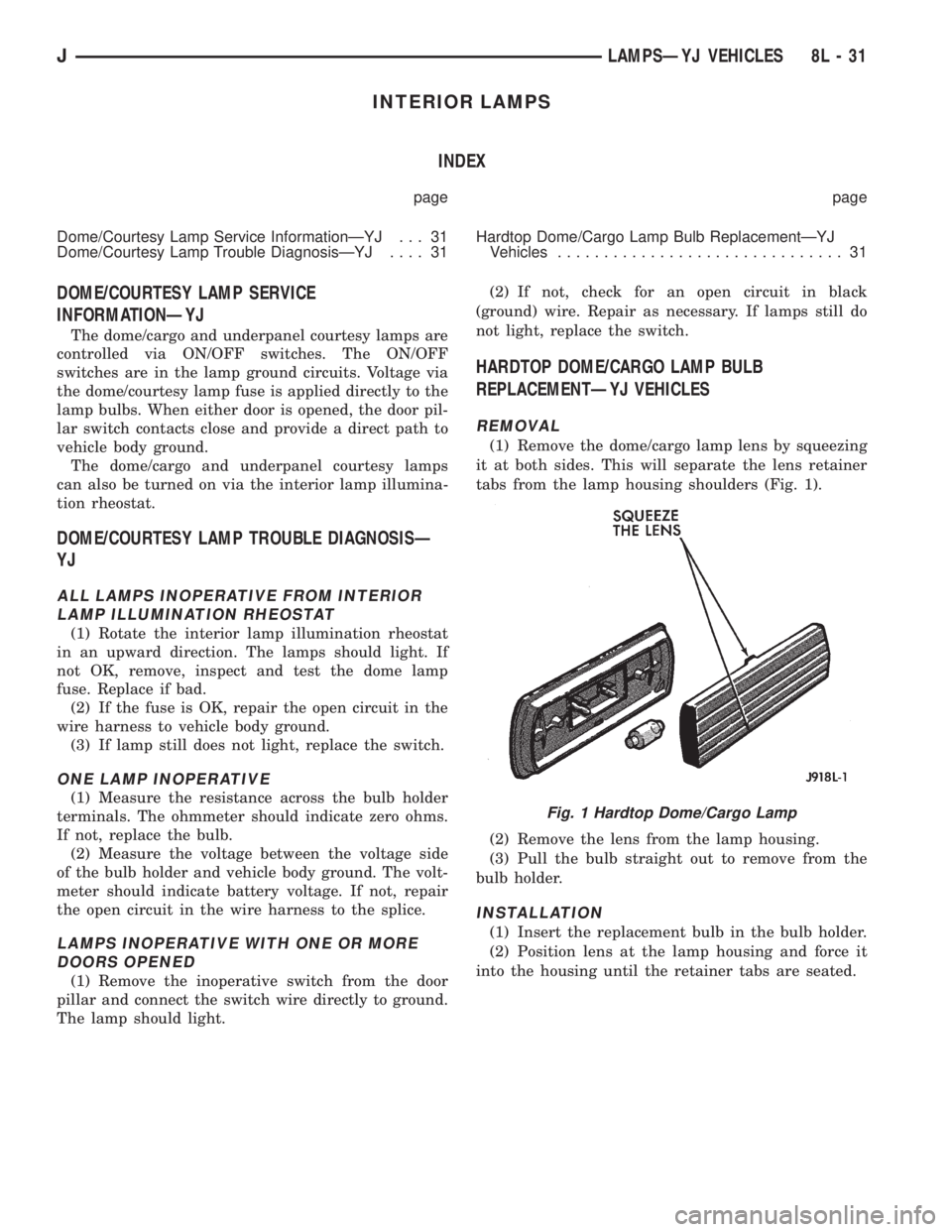

(1) Remove the dome/cargo lamp lens by squeezing

it at both sides. This will separate the lens retainer

tabs from the lamp housing shoulders (Fig. 1).

(2) Remove the lens from the lamp housing.

(3) Pull the bulb straight out to remove from the

bulb holder.

INSTALLATION

(1) Insert the replacement bulb in the bulb holder.

(2) Position lens at the lamp housing and force it

into the housing until the retainer tabs are seated.

Fig. 1 Hardtop Dome/Cargo Lamp

JLAMPSÐYJ VEHICLES 8L - 31

Page 632 of 2198

INTERIOR LIGHTING

INDEX

page page

Cargo Lamp, Courtesy Lamps and Dome Lamp.... 1

Chime/Buzzer Module....................... 2

Diagram Index............................ 2

General Information........................ 1

Glove Box Lamp........................... 1

Ignition Switch Lamp........................ 1Instrument Panel Illumination Lamps............ 1

Reading Lamps........................... 2

Time Delay Relay.......................... 1

Underhood Lamp.......................... 2

Visor Vanity Mirror Lamps.................... 2

GENERAL INFORMATION

Circuit M1 supplies power to the glove box lamp,

left courtesy lamp, right courtesy lamp, dome lamp,

and cargo lamp. The M1 circuit also connects to the

remote keyless entry module. Circuit M1 is protected

by the ignition off draw (IOD) fuse (fuse 9) in the fuse

block.

Circuit E2 supplies power for the instrument panel

illumination lamps.

INSTRUMENT PANEL ILLUMINATION LAMPS

Circuit E2 from the headlamp switch splices to

supply power to the following illumination lamps:

²Ash receiver lamp

²Cigar lighter lamp

²Transmission range indicator lamp

²Transfer case range indicator lamp

²A/C-Heater switch lamp

²Heated rear window lamp

²Rear wiper switch lamp

²Fog lamp switch lamp

Fuse 19 in the fuse block protects circuit E2. Circuit

Z1 provides ground for all of the illumination lamps

except for the cigar lighter lamp. The cigar lighter

lamp is case grounded.

HELPFUL INFORMATION

Circuit E2 also supplies power to the radio, LCD

relay and the illumination lamps in the instrument

cluster.

IGNITION SWITCH LAMP

The time delay relay is used to allow a time-ON

function for the ignition switch lamp and the courtesy

lamp. Power for the relay is received on the M1

circuit from the IOD fuse (fuse F9) in the fuse block.

Circuit M2 provides ground for the time delay relay

through the right and left door ajar switches and the

headlamp switch. When a door is opened, or the

headlamp switch is moved to the dome lamp position,a ground path is provided for the relay on circuit M2.

This energizes the relay, causing the contacts to close.

When the relay contacts close, power is provided

through the relay to circuit M50. The M50 circuit

supplies current to the ignition switch lamp. Circuit

Z1 provides ground for the lamp.

GLOVE BOX LAMP

Circuit M1 from the IOD fuse (fuse F9) in the fuse

block powers the glove box lamp. A case grounded

switch, in series after the lamp, closes when the glove

box door is opened. The switch completes a path to

ground on circuit Z1.

CARGO LAMP, COURTESY LAMPS AND DOME

LAMP

Circuit M1 from the IOD fuse (fuse F9) in the fuse

block supplies power to the cargo, courtesy lamps and

dome lamp. This circuit is HOT at all times. The

ground path for the lamp is provided in three differ-

ent ways.

One way is through the door jamb switches. Circuit

M2 connects to the door jamb switches from the cour-

tesy and dome lamps. The switches are connected to

ground circuit Z1. When a door is opened, the plunger

in the switch closes, completing a path to ground.

The second way is through the liftgate switch. Cir-

cuit M2 connects to circuit M4 at the cargo lamp.

Circuit M4 connects to the liftgate switch. The lift-

gate switch connects to ground circuit Z1. When the

lift gate opens, the plunger in the switch closes, com-

pleting a path to ground.

The third ground path is through the headlamp

switch. Circuit M2 is spliced in with the headlamp

switch. When the operator turns the headlamp switch

to the dome lamp ON position, a ground path is

provided through the switch.

J8W-44 INTERIOR LIGHTINGÐXJ VEHICLES 8W - 44 - 1

Page 633 of 2198

READING LAMPS

Circuit M1 from the IOD fuse (fuse F9) in the fuse

block supplies power to the reading lamps. Circuit

M1 is HOT at all times. When the operator depresses

the reading lamp, the reading lamp switch closes and

supplies ground on circuit Z1.

VISOR VANITY MIRROR LAMPS

Circuit M1 from the IOD fuse (fuse F9) in the fuse

block supplies power to the vanity lamps. Circuit M1

is HOT at all times. When the vanity lamps switch

closes, voltage flows to vanity mirror lamps. The van-

ity mirror is case grounded.

UNDERHOOD LAMP

Circuit A6 from fuse 16 in the Power Distribution

Center (PDC) supplies battery voltage for the under-

hood lamp. A mercury switch, in series after the

lamp, connects the lamp to ground on circuit Z1.

When the hood is raised, mercury inside the switch

moves to a position where it connects circuit M1 to

ground circuit Z1, illuminating the lamp.

CHIME/BUZZER MODULE

The buzzer or optional chime module sounds an au-

dible warning tone. The tone sounds for seat belt

warning and when the ignition key is in the ignition

switch while the drivers door is open. The tone also

sounds when the ignition key is in the ON position

while the drivers side seat belt is not buckled. Lastly,

the tone sounds when the headlamps are ON when

the ignition is OFF. Refer to Group 8U for system op-

eration.

When the ignition switch is in the RUN or START

position, circuit F87 from fuse 17 in the fuse block

supplies power to the chime/buzzer module. Circuit

A21 from the ignition switch supplies power to fuse

17.

Circuit L7 from fuse 15 in the fuse block also sup-

plies power to the chime/buzzer module. Circuit A3

from fuse 5 in the Power Distribution Center (PDC)

powers fuse 15.

When the parking lamps or headlamps are ON, the

headlamp switch connects circuit G26 with the driv-

ers side door jamb switch. Circuit G26 also connects

to the key-in switch. Circuit M11 connects the key-in

switch to the chime/buzzer module and the headlamp

switch.

If the headlamps are ON, and the drivers door

opens, ground for the chime/buzzer is on circuit C26

from the headlamp switch through the door jamb

switch to circuit Z1.

If the headlamps are OFF with the key in the ig-

nition while the drivers side door is open, ground forthe chime/buzzer is supplied through the key-in

switch. The ground path is over circuit M11, through

the closed key-in switch to circuit C26. From circuit

C26, the ground path continues through the drivers

door jamb switch to circuit Z1.

Circuit G11 from the buzzer powers the seat belt

warning lamp in the instrument cluster. Circuit Z1

at the instrument cluster provides ground for the

lamp.

Circuit G10 from the buzzer connects to the seat

belt switch. When the seat belt switch closes a path

to ground is completed on circuit Z1 and the tone

sounds momentarily.

Circuit Z1 also grounds the chime\buzzer module.

HELPFUL INFORMATION

Circuit F87 also powers the instrument cluster and

the headlamp delay module.

DIAGRAM INDEX

Component Page

Cargo Lamp............................8W-44-6

Chime/Buzzer Module......................8W-44-3

Courtesy Lamps.........................8W-44-5

Dome Lamp............................8W-44-7

Door Jamb Switches.....................8W-44-10

Fuse 3 (PDC).........................8W-44-4, 6

Fuse 5 (PDC).........................8W-44-3, 8

Fuse 6 (PDC)...........................8W-44-3

Fuse 9 (Fuse Block).....................8W-44-4, 6

Fuse 15 (Fuse Block)....................8W-44-3, 8

Fuse 16 (PDC)........................8W-44-4, 6

Fuse 17 (Fuse Block)......................8W-44-3

Fuse 19 (Fuse Block)......................8W-44-8

Glove Box Lamp and Switch.................8W-44-5

Headlamp Switch...................8W-44-3, 4, 5, 8

Headlamp Delay Module....................8W-44-4

Headlamp Delay Relay.....................8W-44-3

Ignition Switch..........................8W-44-3

Instrument Cluster........................8W-44-3

Instrument Panel Illumination Lamps..........8W-44-8, 9

Intermittent Wiper Control Module.............8W-44-4

Key-In Switch...........................8W-44-4

Liftgate Switch..........................8W-44-6

Reading Lamps..........................8W-44-7

Remote Keyless Entry Module................8W-44-7

Seat Belt Switch.........................8W-44-3

Telltale Connector (Instrument Cluster)...........8W-44-3

Time Delay Relay........................8W-44-4

Underhood Lamp.........................8W-44-4

Vanity Lamps...........................8W-44-7

8W - 44 - 2 8W-44 INTERIOR LIGHTINGÐXJ VEHICLESJ

Page 908 of 2198

INTERIOR LIGHTING

INDEX

page page

Cargo Lamp and Dome Lamp................. 1

Chime/Buzzer Module....................... 2

Diagram Index............................ 2

General Information........................ 1

Glove Box Lamp........................... 1Ignition Switch Lamp........................ 1

Instrument Panel Illumination Lamps............ 1

Reading Lamps........................... 1

Underhood Lamp.......................... 1

Visor Vanity Mirror Lamps.................... 1

GENERAL INFORMATION

Circuit M1 supplies power to the glove box lamp,

dome lamp, reading lamps, cargo lamp and vanity

lamps. Circuit M1 is protected by fuse 16 in the

Power Distribution Center (PDC).

Circuit E2 supplies power for the instrument panel

illumination lamps.

INSTRUMENT PANEL ILLUMINATION LAMPS

Circuit E2 from the headlamp switch splices to

supply power to the following illumination lamps:

²Ash receiver lamp

²Cigar lighter lamp

²Transmission range indicator lamp

²Transfer case range indicator lamp

²A/C-Heater switch lamp

²Heated rear window switch lamp

²Rear wiper switch lamp

²Fog lamp switch lamp

Fuse 25 in the fuse block protects circuit E2. Cir-

cuit Z1 provides ground for all of the illumination

lamps except for the cigar lighter lamp. The cigar

lighter lamp is case grounded.

HELPFUL INFORMATION

Circuit E2 also supplies power to the radio, LCD

relay and the illumination lamps in the instrument

cluster.

IGNITION SWITCH LAMP

Circuit M50 supplies voltage to the ignition switch

lamp. Circuit Z1 provides ground for the lamp.

GLOVE BOX LAMP

Circuit M1 from fuse 16 in the Power Distribution

Center (PDC) powers the glove box lamp. A case

grounded switch, in series after the lamp, closes

when the glove box door is opened. The switch com-

pletes a path to ground on circuit Z1.

CARGO LAMP AND DOME LAMP

Circuit M1 from fuse 16 in the Power Distribution

Center (PDC) supplies power to the cargo lamp anddome lamp. The M1 circuit is HOT at all times. The

ground path for the lamp is provided in three differ-

ent ways.

One way is through the door jamb switches. Circuit

M2 connects to the door jamb switches to the dome

lamp and cargo lamp. The switches are connected to

ground circuit Z1. When a door is opened, the

plunger in the switch closes, completing a path to

ground.

The second way is through the liftgate switch. Cir-

cuit G71 connects to circuit M2 at the cargo lamp

connector. Circuit G71 connects to the liftgate switch.

The liftgate switch connects to ground circuit Z1.

When the lift gate opens, the plunger in the switch

closes, completing a path to ground.

The third ground path is through the headlamp

switch. Circuit M2 is spliced in with the headlamp

switch. When the operator turns the headlamp

switch to the dome lamp ON position, a ground path

is provided through the switch.

READING LAMPS

Circuit M1 from fuse 16 in the Power Distribution

Center (PDC) supplies power to the reading lamps.

Circuit M1 is HOT at all times. When the operator

depresses the reading lamp, the reading lamp switch

closes and supplies ground on circuit Z1.

VISOR VANITY MIRROR LAMPS

Circuit M1 from fuse 16 in the Power Distribution

Center (PDC) supplies power to the vanity lamps.

Circuit M1 is HOT at all times. When the vanity

lamps switch closes, voltage flows to vanity mirror

lamps. The vanity mirror is case grounded.

UNDERHOOD LAMP

Circuit A7 from fuse 16 in the Power Distribution

Center (PDC) supplies battery voltage for the under-

hood lamp. A mercury switch, in series after the

lamp, connects the lamp to ground on circuit Z1.

When the hood is raised, mercury inside the switch

moves to a position where it connects circuit M1 to

ground circuit Z1, illuminating the lamp.

J8W-44 INTERIOR LIGHTINGÐXJ-RHD 8W - 44 - 1

Page 909 of 2198

CHIME/BUZZER MODULE

The buzzer or optional chime module sounds an au-

dible warning tone. The tone sounds for seat belt

warning and when the ignition key is in the ignition

switch while the drivers door is open. The tone also

sounds when the ignition key is in the ON position

while the drivers side seat belt is not buckled. Lastly,

the tone sounds when the headlamps are ON when

the ignition is OFF. Refer to Group 8U for system op-

eration.

When the ignition switch is in the RUN or START

position, fuse F87 from fuse 26 in the fuse block sup-

plies power to the chime/buzzer module. Circuit A21

from the ignition switch supplies power to fuse 26.

Circuit L7 from fuse 9 in the fuse block also sup-

plies power to the chime/buzzer module. Circuit A3

from fuse 5 in the Power Distribution Center (PDC)

powers fuse 9.

When the parking lamps or headlamps are ON, the

headlamp switch connects circuit G26 with the driv-

ers side door jamb switch. Circuit G26 also connects

to the key-in switch. Circuit M11 connects the key-in

switch to the chime module and the headlamp

switch.

If the headlamps are ON, and the drivers door

opens, ground for the chime/buzzer is on circuit C26

from the headlamp switch through the door jamb

switch to circuit Z1.

If the headlamps are OFF with the key in the ig-

nition while the drivers side door is open, ground for

the chime/buzzer is supplied through the key-in

switch. The ground path is over circuit M11, through

the closed key-in switch to circuit C26. From circuit

C26, the ground path continues through the drivers

door jamb switch to circuit Z1.

Circuit G11 from the buzzer powers the seat belt

warning lamp in the instrument cluster. Circuit Z1

at the instrument cluster provides ground for the

lamp.Circuit G10 from the buzzer connects to the seat

belt switch. When the seat belt switch closes a path

to ground is completed on circuit Z1 and the tone

sounds momentarily.

Circuit Z1 also grounds the chime buzzer module.

HELPFUL INFORMATION

Circuit F87 also powers the instrument cluster and

the headlamp delay module.

DIAGRAM INDEX

Component Page

Cargo Lamp............................8W-44-6

Chime/Buzzer Module......................8W-44-3

Courtesy Lamps.........................8W-44-5

Dome Lamp............................8W-44-6

Door Jamb Switches......................8W-44-7

Fuse 3 (PDC)...........................8W-44-6

Fuse 5 (PDC).........................8W-44-5, 8

Fuse 6 (PDC)...........................8W-44-6

Fuse 9 (Fuse Block).....................8W-44-3, 8

Fuse 16 (PDC)........................8W-44-4, 6

Fuse 25 (Fuse Block)......................8W-44-8

Fuse 26 (Fuse Block)......................8W-44-3

Glove Box Lamp and Switch.................8W-44-5

Headlamp Switch....................8W-44-3, thru 8

Headlamp Delay Module....................8W-44-3

Ignition Switch..........................8W-44-3

Instrument Cluster......................8W-44-3, 9

Instrument Panel Illumination Lamps..........8W-44-8, 9

Key-In Switch...........................8W-44-4

Liftgate Switch..........................8W-44-6

Reading Lamps..........................8W-44-6

Seat Belt Switch.........................8W-44-3

Telltale Connector (Instrument Cluster)...........8W-44-3

Time Delay Relay........................8W-44-4

Underhood Lamp.........................8W-44-4

8W - 44 - 2 8W-44 INTERIOR LIGHTINGÐXJ-RHDJ

Page 1969 of 2198

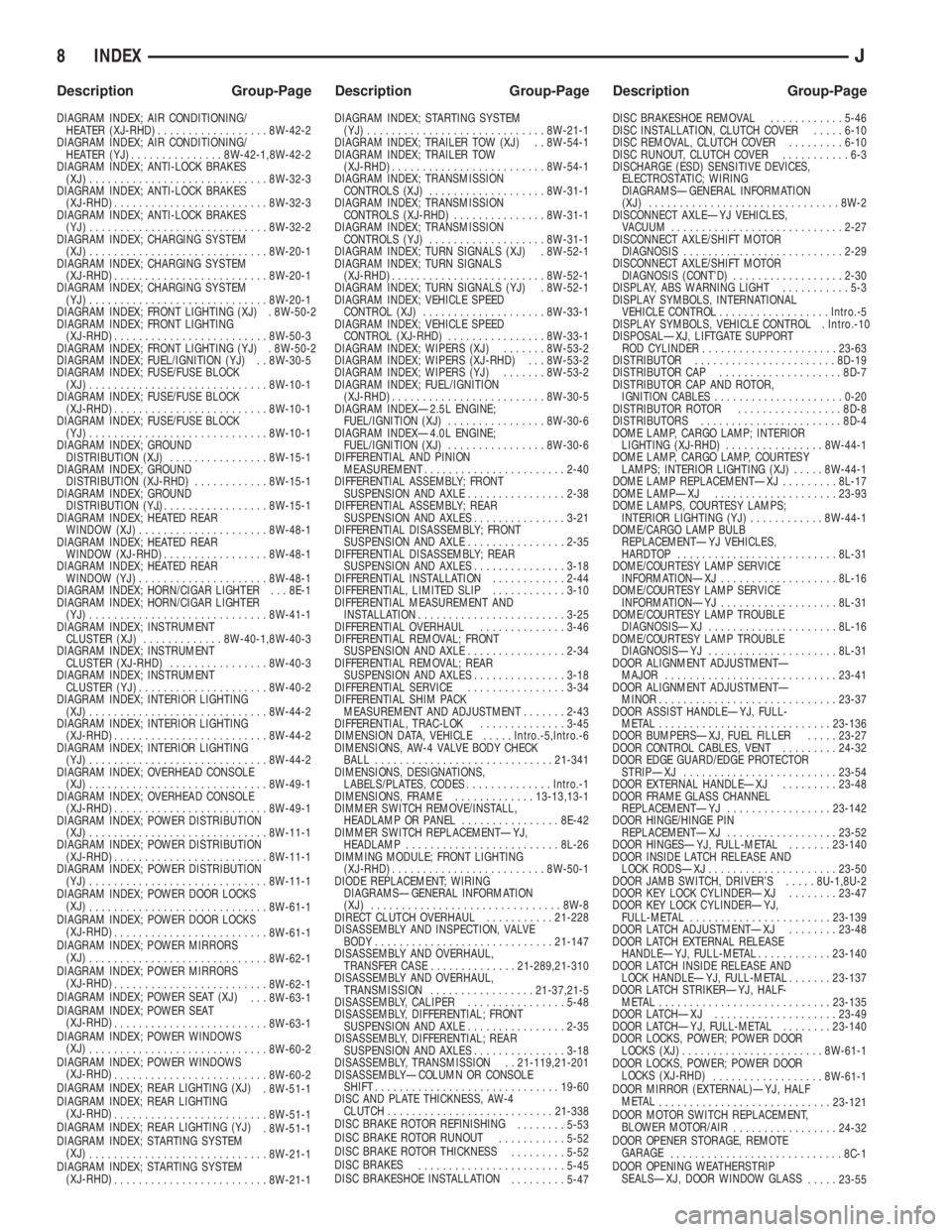

DIAGRAM INDEX; AIR CONDITIONING/

HEATER (XJ-RHD)..................8W-42-2

DIAGRAM INDEX; AIR CONDITIONING/

HEATER (YJ)...............8W-42-1,8W-42-2

DIAGRAM INDEX; ANTI-LOCK BRAKES

(XJ).............................8W-32-3

DIAGRAM INDEX; ANTI-LOCK BRAKES

(XJ-RHD).........................8W-32-3

DIAGRAM INDEX; ANTI-LOCK BRAKES

(YJ).............................8W-32-2

DIAGRAM INDEX; CHARGING SYSTEM

(XJ).............................8W-20-1

DIAGRAM INDEX; CHARGING SYSTEM

(XJ-RHD).........................8W-20-1

DIAGRAM INDEX; CHARGING SYSTEM

(YJ).............................8W-20-1

DIAGRAM INDEX; FRONT LIGHTING (XJ) . 8W-50-2

DIAGRAM INDEX; FRONT LIGHTING

(XJ-RHD).........................8W-50-3

DIAGRAM INDEX; FRONT LIGHTING (YJ) . 8W-50-2

DIAGRAM INDEX; FUEL/IGNITION (YJ) . . 8W-30-5

DIAGRAM INDEX; FUSE/FUSE BLOCK

(XJ).............................8W-10-1

DIAGRAM INDEX; FUSE/FUSE BLOCK

(XJ-RHD).........................8W-10-1

DIAGRAM INDEX; FUSE/FUSE BLOCK

(YJ).............................8W-10-1

DIAGRAM INDEX; GROUND

DISTRIBUTION (XJ)................8W-15-1

DIAGRAM INDEX; GROUND

DISTRIBUTION (XJ-RHD)............8W-15-1

DIAGRAM INDEX; GROUND

DISTRIBUTION (YJ)..................8W-15-1

DIAGRAM INDEX; HEATED REAR

WINDOW (XJ).....................8W-48-1

DIAGRAM INDEX; HEATED REAR

WINDOW (XJ-RHD).................8W-48-1

DIAGRAM INDEX; HEATED REAR

WINDOW (YJ).....................8W-48-1

DIAGRAM INDEX; HORN/CIGAR LIGHTER . . . 8E-1

DIAGRAM INDEX; HORN/CIGAR LIGHTER

(YJ).............................8W-41-1

DIAGRAM INDEX; INSTRUMENT

CLUSTER (XJ).............8W-40-1,8W-40-3

DIAGRAM INDEX; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-3

DIAGRAM INDEX; INSTRUMENT

CLUSTER (YJ).....................8W-40-2

DIAGRAM INDEX; INTERIOR LIGHTING

(XJ).............................8W-44-2

DIAGRAM INDEX; INTERIOR LIGHTING

(XJ-RHD).........................8W-44-2

DIAGRAM INDEX; INTERIOR LIGHTING

(YJ).............................8W-44-2

DIAGRAM INDEX; OVERHEAD CONSOLE

(XJ).............................8W-49-1

DIAGRAM INDEX; OVERHEAD CONSOLE

(XJ-RHD).........................8W-49-1

DIAGRAM INDEX; POWER DISTRIBUTION

(XJ).............................8W-11-1

DIAGRAM INDEX; POWER DISTRIBUTION

(XJ-RHD).........................8W-11-1

DIAGRAM INDEX; POWER DISTRIBUTION

(YJ).............................8W-11-1

DIAGRAM INDEX; POWER DOOR LOCKS

(XJ)

.............................8W-61-1

DIAGRAM INDEX; POWER DOOR LOCKS

(XJ-RHD)

.........................8W-61-1

DIAGRAM INDEX; POWER MIRRORS

(XJ)

.............................8W-62-1

DIAGRAM INDEX; POWER MIRRORS

(XJ-RHD)

.........................8W-62-1

DIAGRAM INDEX; POWER SEAT (XJ)

. . . 8W-63-1

DIAGRAM INDEX; POWER SEAT

(XJ-RHD)

.........................8W-63-1

DIAGRAM INDEX; POWER WINDOWS

(XJ)

.............................8W-60-2

DIAGRAM INDEX; POWER WINDOWS

(XJ-RHD)

.........................8W-60-2

DIAGRAM INDEX; REAR LIGHTING (XJ)

. 8W-51-1

DIAGRAM INDEX; REAR LIGHTING

(XJ-RHD)

.........................8W-51-1

DIAGRAM INDEX; REAR LIGHTING (YJ)

. 8W-51-1

DIAGRAM INDEX; STARTING SYSTEM

(XJ)

.............................8W-21-1

DIAGRAM INDEX; STARTING SYSTEM

(XJ-RHD)

.........................8W-21-1DIAGRAM INDEX; STARTING SYSTEM

(YJ).............................8W-21-1

DIAGRAM INDEX; TRAILER TOW (XJ) . . 8W-54-1

DIAGRAM INDEX; TRAILER TOW

(XJ-RHD).........................8W-54-1

DIAGRAM INDEX; TRANSMISSION

CONTROLS (XJ)...................8W-31-1

DIAGRAM INDEX; TRANSMISSION

CONTROLS (XJ-RHD)...............8W-31-1

DIAGRAM INDEX; TRANSMISSION

CONTROLS (YJ)...................8W-31-1

DIAGRAM INDEX; TURN SIGNALS (XJ) . 8W-52-1

DIAGRAM INDEX; TURN SIGNALS

(XJ-RHD).........................8W-52-1

DIAGRAM INDEX; TURN SIGNALS (YJ) . 8W-52-1

DIAGRAM INDEX; VEHICLE SPEED

CONTROL (XJ)....................8W-33-1

DIAGRAM INDEX; VEHICLE SPEED

CONTROL (XJ-RHD)................8W-33-1

DIAGRAM INDEX; WIPERS (XJ).......8W-53-2

DIAGRAM INDEX; WIPERS (XJ-RHD) . . . 8W-53-2

DIAGRAM INDEX; WIPERS (YJ).......8W-53-2

DIAGRAM INDEX; FUEL/IGNITION

(XJ-RHD).........................8W-30-5

DIAGRAM INDEXÐ2.5L ENGINE;

FUEL/IGNITION (XJ)................8W-30-6

DIAGRAM INDEXÐ4.0L ENGINE;

FUEL/IGNITION (XJ)................8W-30-6

DIFFERENTIAL AND PINION

MEASUREMENT.......................2-40

DIFFERENTIAL ASSEMBLY; FRONT

SUSPENSION AND AXLE.................2-38

DIFFERENTIAL ASSEMBLY; REAR

SUSPENSION AND AXLES...............3-21

DIFFERENTIAL DISASSEMBLY; FRONT

SUSPENSION AND AXLE................2-35

DIFFERENTIAL DISASSEMBLY; REAR

SUSPENSION AND AXLES...............3-18

DIFFERENTIAL INSTALLATION............2-44

DIFFERENTIAL, LIMITED SLIP............3-10

DIFFERENTIAL MEASUREMENT AND

INSTALLATION........................3-25

DIFFERENTIAL OVERHAUL..............3-46

DIFFERENTIAL REMOVAL; FRONT

SUSPENSION AND AXLE................2-34

DIFFERENTIAL REMOVAL; REAR

SUSPENSION AND AXLES...............3-18

DIFFERENTIAL SERVICE................3-34

DIFFERENTIAL SHIM PACK

MEASUREMENT AND ADJUSTMENT.......2-43

DIFFERENTIAL, TRAC-LOK..............3-45

DIMENSION DATA, VEHICLE.....Intro.-5,Intro.-6

DIMENSIONS, AW-4 VALVE BODY CHECK

BALL.............................21-341

DIMENSIONS, DESIGNATIONS,

LABELS/PLATES, CODES..............Intro.-1

DIMENSIONS, FRAME.............13-13,13-1

DIMMER SWITCH REMOVE/INSTALL,

HEADLAMP OR PANEL................8E-42

DIMMER SWITCH REPLACEMENTÐYJ,

HEADLAMP.........................8L-26

DIMMING MODULE; FRONT LIGHTING

(XJ-RHD).........................8W-50-1

DIODE REPLACEMENT; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-8

DIRECT CLUTCH OVERHAUL...........21-228

DISASSEMBLY AND INSPECTION, VALVE

BODY.............................21-147

DISASSEMBLY AND OVERHAUL,

TRANSFER CASE..............21-289,21-310

DISASSEMBLY AND OVERHAUL,

TRANSMISSION.................21-37,21-5

DISASSEMBLY, CALIPER................5-48

DISASSEMBLY, DIFFERENTIAL; FRONT

SUSPENSION AND AXLE................2-35

DISASSEMBLY, DIFFERENTIAL; REAR

SUSPENSION AND AXLES...............3-18

DISASSEMBLY, TRANSMISSION . . 21-119,21-201

DISASSEMBLYÐCOLUMN OR CONSOLE

SHIFT..............................19-60

DISC AND PLATE THICKNESS, AW-4

CLUTCH...........................21-338

DISC BRAKE ROTOR REFINISHING

........5-53

DISC BRAKE ROTOR RUNOUT

...........5-52

DISC BRAKE ROTOR THICKNESS

.........5-52

DISC BRAKES

........................5-45

DISC BRAKESHOE INSTALLATION

.........5-47DISC BRAKESHOE REMOVAL............5-46

DISC INSTALLATION, CLUTCH COVER.....6-10

DISC REMOVAL, CLUTCH COVER.........6-10

DISC RUNOUT, CLUTCH COVER...........6-3

DISCHARGE (ESD) SENSITIVE DEVICES,

ELECTROSTATIC; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-2

DISCONNECT AXLEÐYJ VEHICLES,

VACUUM............................2-27

DISCONNECT AXLE/SHIFT MOTOR

DIAGNOSIS..........................2-29

DISCONNECT AXLE/SHIFT MOTOR

DIAGNOSIS (CONT'D)..................2-30

DISPLAY, ABS WARNING LIGHT...........5-3

DISPLAY SYMBOLS, INTERNATIONAL

VEHICLE CONTROL..................Intro.-5

DISPLAY SYMBOLS, VEHICLE CONTROL . Intro.-10

DISPOSALÐXJ, LIFTGATE SUPPORT

ROD CYLINDER......................23-63

DISTRIBUTOR.......................8D-19

DISTRIBUTOR CAP....................8D-7

DISTRIBUTOR CAP AND ROTOR,

IGNITION CABLES.....................0-20

DISTRIBUTOR ROTOR.................8D-8

DISTRIBUTORS.......................8D-4

DOME LAMP, CARGO LAMP; INTERIOR

LIGHTING (XJ-RHD)................8W-44-1

DOME LAMP, CARGO LAMP, COURTESY

LAMPS; INTERIOR LIGHTING (XJ).....8W-44-1

DOME LAMP REPLACEMENTÐXJ.........8L-17

DOME LAMPÐXJ....................23-93

DOME LAMPS, COURTESY LAMPS;

INTERIOR LIGHTING (YJ)............8W-44-1

DOME/CARGO LAMP BULB

REPLACEMENTÐYJ VEHICLES,

HARDTOP..........................8L-31

DOME/COURTESY LAMP SERVICE

INFORMATIONÐXJ...................8L-16

DOME/COURTESY LAMP SERVICE

INFORMATIONÐYJ...................8L-31

DOME/COURTESY LAMP TROUBLE

DIAGNOSISÐXJ.....................8L-16

DOME/COURTESY LAMP TROUBLE

DIAGNOSISÐYJ.....................8L-31

DOOR ALIGNMENT ADJUSTMENTÐ

MAJOR............................23-41

DOOR ALIGNMENT ADJUSTMENTÐ

MINOR.............................23-37

DOOR ASSIST HANDLEÐYJ, FULL-

METAL............................23-136

DOOR BUMPERSÐXJ, FUEL FILLER.....23-27

DOOR CONTROL CABLES, VENT.........24-32

DOOR EDGE GUARD/EDGE PROTECTOR

STRIPÐXJ.........................23-54

DOOR EXTERNAL HANDLEÐXJ.........23-48

DOOR FRAME GLASS CHANNEL

REPLACEMENTÐYJ.................23-142

DOOR HINGE/HINGE PIN

REPLACEMENTÐXJ..................23-52

DOOR HINGESÐYJ, FULL-METAL.......23-140

DOOR INSIDE LATCH RELEASE AND

LOCK RODSÐXJ.....................23-50

DOOR JAMB SWITCH, DRIVER'S.....8U-1,8U-2

DOOR KEY LOCK CYLINDERÐXJ........23-47

DOOR KEY LOCK CYLINDERÐYJ,

FULL-METAL.......................23-139

DOOR LATCH ADJUSTMENTÐXJ........23-48

DOOR LATCH EXTERNAL RELEASE

HANDLEÐYJ, FULL-METAL............23-140

DOOR LATCH INSIDE RELEASE AND

LOCK HANDLEÐYJ, FULL-METAL.......23-137

DOOR LATCH STRIKERÐYJ, HALF-

METAL............................23-135

DOOR LATCHÐXJ....................23-49

DOOR LATCHÐYJ, FULL-METAL........23-140

DOOR LOCKS, POWER; POWER DOOR

LOCKS (XJ).......................8W-61-1

DOOR LOCKS, POWER; POWER DOOR

LOCKS (XJ-RHD)

..................8W-61-1

DOOR MIRROR (EXTERNAL)ÐYJ, HALF

METAL

............................23-121

DOOR MOTOR SWITCH REPLACEMENT,

BLOWER MOTOR/AIR

.................24-32

DOOR OPENER STORAGE, REMOTE

GARAGE

............................8C-1

DOOR OPENING WEATHERSTRIP

SEALSÐXJ, DOOR WINDOW GLASS

.....23-55

8 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 1972 of 2198

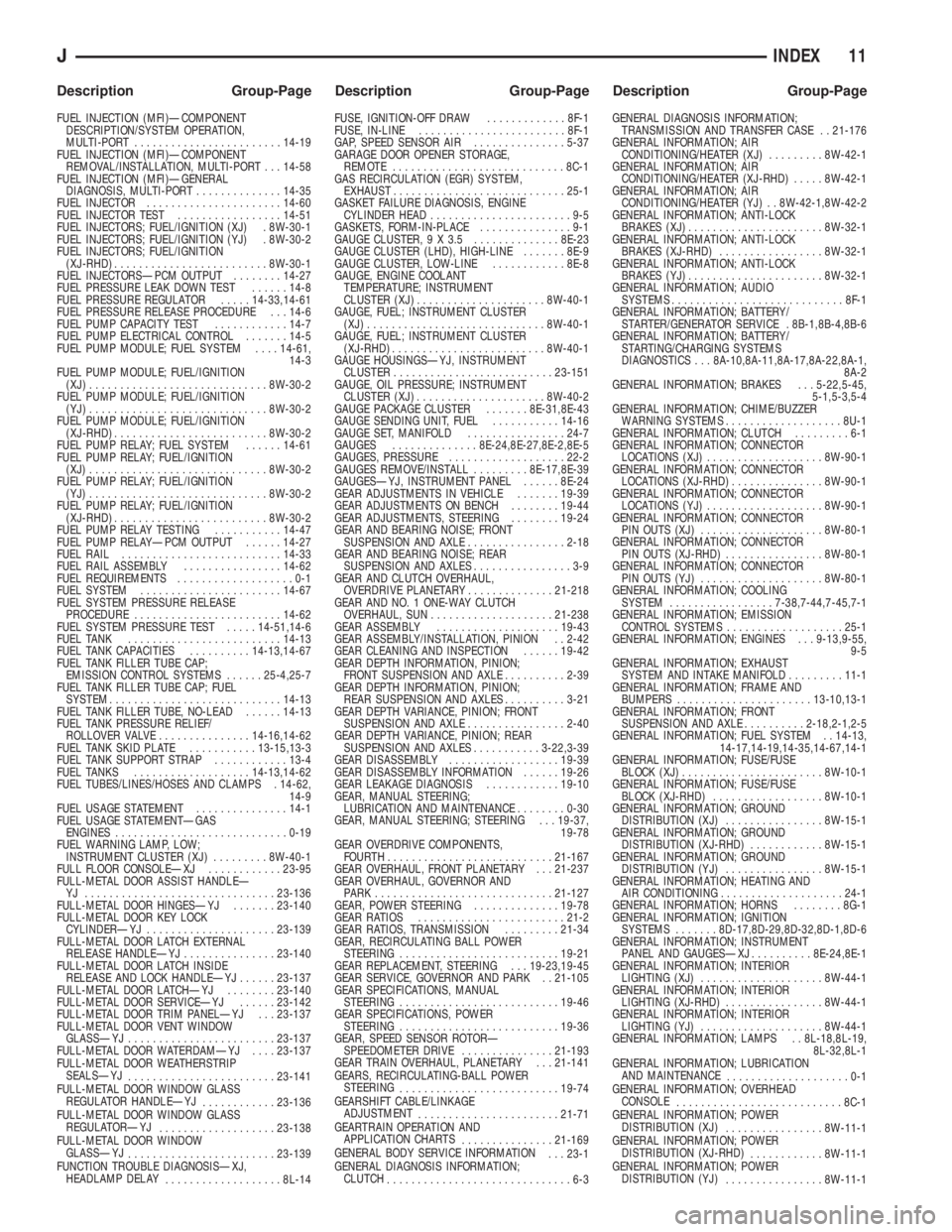

FUEL INJECTION (MFI)ÐCOMPONENT

DESCRIPTION/SYSTEM OPERATION,

MULTI-PORT........................14-19

FUEL INJECTION (MFI)ÐCOMPONENT

REMOVAL/INSTALLATION, MULTI-PORT . . . 14-58

FUEL INJECTION (MFI)ÐGENERAL

DIAGNOSIS, MULTI-PORT..............14-35

FUEL INJECTOR......................14-60

FUEL INJECTOR TEST.................14-51

FUEL INJECTORS; FUEL/IGNITION (XJ) . 8W-30-1

FUEL INJECTORS; FUEL/IGNITION (YJ) . 8W-30-2

FUEL INJECTORS; FUEL/IGNITION

(XJ-RHD).........................8W-30-1

FUEL INJECTORSÐPCM OUTPUT........14-27

FUEL PRESSURE LEAK DOWN TEST......14-8

FUEL PRESSURE REGULATOR.....14-33,14-61

FUEL PRESSURE RELEASE PROCEDURE . . . 14-6

FUEL PUMP CAPACITY TEST............14-7

FUEL PUMP ELECTRICAL CONTROL.......14-5

FUEL PUMP MODULE; FUEL SYSTEM....14-61,

14-3

FUEL PUMP MODULE; FUEL/IGNITION

(XJ).............................8W-30-2

FUEL PUMP MODULE; FUEL/IGNITION

(YJ).............................8W-30-2

FUEL PUMP MODULE; FUEL/IGNITION

(XJ-RHD).........................8W-30-2

FUEL PUMP RELAY; FUEL SYSTEM......14-61

FUEL PUMP RELAY; FUEL/IGNITION

(XJ).............................8W-30-2

FUEL PUMP RELAY; FUEL/IGNITION

(YJ).............................8W-30-2

FUEL PUMP RELAY; FUEL/IGNITION

(XJ-RHD).........................8W-30-2

FUEL PUMP RELAY TESTING...........14-47

FUEL PUMP RELAYÐPCM OUTPUT......14-27

FUEL RAIL..........................14-33

FUEL RAIL ASSEMBLY................14-62

FUEL REQUIREMENTS...................0-1

FUEL SYSTEM.......................14-67

FUEL SYSTEM PRESSURE RELEASE

PROCEDURE........................14-62

FUEL SYSTEM PRESSURE TEST.....14-51,14-6

FUEL TANK.........................14-13

FUEL TANK CAPACITIES..........14-13,14-67

FUEL TANK FILLER TUBE CAP;

EMISSION CONTROL SYSTEMS......25-4,25-7

FUEL TANK FILLER TUBE CAP; FUEL

SYSTEM............................14-13

FUEL TANK FILLER TUBE, NO-LEAD......14-13

FUEL TANK PRESSURE RELIEF/

ROLLOVER VALVE...............14-16,14-62

FUEL TANK SKID PLATE...........13-15,13-3

FUEL TANK SUPPORT STRAP............13-4

FUEL TANKS...................14-13,14-62

FUEL TUBES/LINES/HOSES AND CLAMPS . 14-62,

14-9

FUEL USAGE STATEMENT...............14-1

FUEL USAGE STATEMENTÐGAS

ENGINES............................0-19

FUEL WARNING LAMP, LOW;

INSTRUMENT CLUSTER (XJ).........8W-40-1

FULL FLOOR CONSOLEÐXJ............23-95

FULL-METAL DOOR ASSIST HANDLEÐ

YJ ...............................23-136

FULL-METAL DOOR HINGESÐYJ.......23-140

FULL-METAL DOOR KEY LOCK

CYLINDERÐYJ.....................23-139

FULL-METAL DOOR LATCH EXTERNAL

RELEASE HANDLEÐYJ...............23-140

FULL-METAL DOOR LATCH INSIDE

RELEASE AND LOCK HANDLEÐYJ......23-137

FULL-METAL DOOR LATCHÐYJ........23-140

FULL-METAL DOOR SERVICEÐYJ......23-142

FULL-METAL DOOR TRIM PANELÐYJ . . . 23-137

FULL-METAL DOOR VENT WINDOW

GLASSÐYJ........................23-137

FULL-METAL DOOR WATERDAMÐYJ....23-137

FULL-METAL DOOR WEATHERSTRIP

SEALSÐYJ

........................23-141

FULL-METAL DOOR WINDOW GLASS

REGULATOR HANDLEÐYJ

............23-136

FULL-METAL DOOR WINDOW GLASS

REGULATORÐYJ

...................23-138

FULL-METAL DOOR WINDOW

GLASSÐYJ

........................23-139

FUNCTION TROUBLE DIAGNOSISÐXJ,

HEADLAMP DELAY

...................8L-14FUSE, IGNITION-OFF DRAW.............8F-1

FUSE, IN-LINE........................8F-1

GAP, SPEED SENSOR AIR...............5-37

GARAGE DOOR OPENER STORAGE,

REMOTE............................8C-1

GAS RECIRCULATION (EGR) SYSTEM,

EXHAUST............................25-1

GASKET FAILURE DIAGNOSIS, ENGINE

CYLINDER HEAD.......................9-5

GASKETS, FORM-IN-PLACE...............9-1

GAUGE CLUSTER, 9 X 3.5 ..............8E-23

GAUGE CLUSTER (LHD), HIGH-LINE.......8E-9

GAUGE CLUSTER, LOW-LINE............8E-8

GAUGE, ENGINE COOLANT

TEMPERATURE; INSTRUMENT

CLUSTER (XJ).....................8W-40-1

GAUGE, FUEL; INSTRUMENT CLUSTER

(XJ).............................8W-40-1

GAUGE, FUEL; INSTRUMENT CLUSTER

(XJ-RHD).........................8W-40-1

GAUGE HOUSINGSÐYJ, INSTRUMENT

CLUSTER..........................23-151

GAUGE, OIL PRESSURE; INSTRUMENT

CLUSTER (XJ).....................8W-40-2

GAUGE PACKAGE CLUSTER.......8E-31,8E-43

GAUGE SENDING UNIT, FUEL...........14-16

GAUGE SET, MANIFOLD................24-7

GAUGES..............8E-24,8E-27,8E-2,8E-5

GAUGES, PRESSURE...................22-2

GAUGES REMOVE/INSTALL.........8E-17,8E-39

GAUGESÐYJ, INSTRUMENT PANEL......8E-24

GEAR ADJUSTMENTS IN VEHICLE.......19-39

GEAR ADJUSTMENTS ON BENCH........19-44

GEAR ADJUSTMENTS, STEERING........19-24

GEAR AND BEARING NOISE; FRONT

SUSPENSION AND AXLE................2-18

GEAR AND BEARING NOISE; REAR

SUSPENSION AND AXLES................3-9

GEAR AND CLUTCH OVERHAUL,

OVERDRIVE PLANETARY..............21-218

GEAR AND NO. 1 ONE-WAY CLUTCH

OVERHAUL, SUN....................21-238

GEAR ASSEMBLY....................19-43

GEAR ASSEMBLY/INSTALLATION, PINION . . 2-42

GEAR CLEANING AND INSPECTION......19-42

GEAR DEPTH INFORMATION, PINION;

FRONT SUSPENSION AND AXLE..........2-39

GEAR DEPTH INFORMATION, PINION;

REAR SUSPENSION AND AXLES..........3-21

GEAR DEPTH VARIANCE, PINION; FRONT

SUSPENSION AND AXLE................2-40

GEAR DEPTH VARIANCE, PINION; REAR

SUSPENSION AND AXLES...........3-22,3-39

GEAR DISASSEMBLY..................19-39

GEAR DISASSEMBLY INFORMATION......19-26

GEAR LEAKAGE DIAGNOSIS............19-10

GEAR, MANUAL STEERING;

LUBRICATION AND MAINTENANCE........0-30

GEAR, MANUAL STEERING; STEERING . . . 19-37,

19-78

GEAR OVERDRIVE COMPONENTS,

FOURTH...........................21-167

GEAR OVERHAUL, FRONT PLANETARY . . . 21-237

GEAR OVERHAUL, GOVERNOR AND

PARK .............................21-127

GEAR, POWER STEERING..............19-78

GEAR RATIOS........................21-2

GEAR RATIOS, TRANSMISSION.........21-34

GEAR, RECIRCULATING BALL POWER

STEERING..........................19-21

GEAR REPLACEMENT, STEERING . . . 19-23,19-45

GEAR SERVICE, GOVERNOR AND PARK . . 21-105

GEAR SPECIFICATIONS, MANUAL

STEERING..........................19-46

GEAR SPECIFICATIONS, POWER

STEERING..........................19-36

GEAR, SPEED SENSOR ROTORÐ

SPEEDOMETER DRIVE...............21-193

GEAR TRAIN OVERHAUL, PLANETARY . . . 21-141

GEARS, RECIRCULATING-BALL POWER

STEERING

..........................19-74

GEARSHIFT CABLE/LINKAGE

ADJUSTMENT

.......................21-71

GEARTRAIN OPERATION AND

APPLICATION CHARTS

...............21-169

GENERAL BODY SERVICE INFORMATION

. . . 23-1

GENERAL DIAGNOSIS INFORMATION;

CLUTCH

..............................6-3GENERAL DIAGNOSIS INFORMATION;

TRANSMISSION AND TRANSFER CASE . . 21-176

GENERAL INFORMATION; AIR

CONDITIONING/HEATER (XJ).........8W-42-1

GENERAL INFORMATION; AIR

CONDITIONING/HEATER (XJ-RHD).....8W-42-1

GENERAL INFORMATION; AIR

CONDITIONING/HEATER (YJ) . . 8W-42-1,8W-42-2

GENERAL INFORMATION; ANTI-LOCK

BRAKES (XJ)......................8W-32-1

GENERAL INFORMATION; ANTI-LOCK

BRAKES (XJ-RHD).................8W-32-1

GENERAL INFORMATION; ANTI-LOCK

BRAKES (YJ)......................8W-32-1

GENERAL INFORMATION; AUDIO

SYSTEMS............................8F-1

GENERAL INFORMATION; BATTERY/

STARTER/GENERATOR SERVICE . 8B-1,8B-4,8B-6

GENERAL INFORMATION; BATTERY/

STARTING/CHARGING SYSTEMS

DIAGNOSTICS . . . 8A-10,8A-11,8A-17,8A-22,8A-1,

8A-2

GENERAL INFORMATION; BRAKES . . . 5-22,5-45,

5-1,5-3,5-4

GENERAL INFORMATION; CHIME/BUZZER

WARNING SYSTEMS...................8U-1

GENERAL INFORMATION; CLUTCH.........6-1

GENERAL INFORMATION; CONNECTOR

LOCATIONS (XJ)...................8W-90-1

GENERAL INFORMATION; CONNECTOR

LOCATIONS (XJ-RHD)...............8W-90-1

GENERAL INFORMATION; CONNECTOR

LOCATIONS (YJ)...................8W-90-1

GENERAL INFORMATION; CONNECTOR

PIN OUTS (XJ)....................8W-80-1

GENERAL INFORMATION; CONNECTOR

PIN OUTS (XJ-RHD)................8W-80-1

GENERAL INFORMATION; CONNECTOR

PIN OUTS (YJ)....................8W-80-1

GENERAL INFORMATION; COOLING

SYSTEM.................7-38,7-44,7-45,7-1

GENERAL INFORMATION; EMISSION

CONTROL SYSTEMS...................25-1

GENERAL INFORMATION; ENGINES . . . 9-13,9-55,

9-5

GENERAL INFORMATION; EXHAUST

SYSTEM AND INTAKE MANIFOLD.........11-1

GENERAL INFORMATION; FRAME AND

BUMPERS......................13-10,13-1

GENERAL INFORMATION; FRONT

SUSPENSION AND AXLE..........2-18,2-1,2-5

GENERAL INFORMATION; FUEL SYSTEM . . 14-13,

14-17,14-19,14-35,14-67,14-1

GENERAL INFORMATION; FUSE/FUSE

BLOCK (XJ).......................8W-10-1

GENERAL INFORMATION; FUSE/FUSE

BLOCK (XJ-RHD)..................8W-10-1

GENERAL INFORMATION; GROUND

DISTRIBUTION (XJ)................8W-15-1

GENERAL INFORMATION; GROUND

DISTRIBUTION (XJ-RHD)............8W-15-1

GENERAL INFORMATION; GROUND

DISTRIBUTION (YJ)................8W-15-1

GENERAL INFORMATION; HEATING AND

AIR CONDITIONING....................24-1

GENERAL INFORMATION; HORNS........8G-1

GENERAL INFORMATION; IGNITION

SYSTEMS.......8D-17,8D-29,8D-32,8D-1,8D-6

GENERAL INFORMATION; INSTRUMENT

PANEL AND GAUGESÐXJ..........8E-24,8E-1

GENERAL INFORMATION; INTERIOR

LIGHTING (XJ)....................8W-44-1

GENERAL INFORMATION; INTERIOR

LIGHTING (XJ-RHD)................8W-44-1

GENERAL INFORMATION; INTERIOR

LIGHTING (YJ)....................8W-44-1

GENERAL INFORMATION; LAMPS . . 8L-18,8L-19,

8L-32,8L-1

GENERAL INFORMATION; LUBRICATION

AND MAINTENANCE

....................0-1

GENERAL INFORMATION; OVERHEAD

CONSOLE

...........................8C-1

GENERAL INFORMATION; POWER

DISTRIBUTION (XJ)

................8W-11-1

GENERAL INFORMATION; POWER

DISTRIBUTION (XJ-RHD)

............8W-11-1

GENERAL INFORMATION; POWER

DISTRIBUTION (YJ)

................8W-11-1

JINDEX 11

Description Group-Page Description Group-Page Description Group-Page