Radiator filling JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 230 of 2198

EXAMPLES:

²If the lamp (Figs. 5 or 6) flashes 1 time, pauses

and flashes 2 more times, a flashing Diagnostic Trou-

ble Code (DTC) number 12 is indicated. If this code is

observed, it is indicating that the battery has been

disconnected within the last 50 key-on cycles. It

could also indicate that battery voltage has been dis-

connected to the PCM. In either case, other DTC's

may have been erased.

²If the lamp flashes 1 time, pauses and flashes 7

more times, a flashing Diagnostic Trouble Code

(DTC) number 17 is indicated.

²If the lamp flashes 3 times, pauses and flashes 5

more times, a flashing Diagnostic Trouble Code

(DTC) number 35 is indicated.

After any stored DTC information has been ob-

served, the display will end with a flashing DTC

number 55. This will indicate the end of all stored in-

formation.

ERASING TROUBLE CODES

After the problem has been repaired, the DRB scan

tool must be used to erase a DTC. Refer to the ap-

propriate Powertrain Diagnostic Procedures service

manual for operation of the DRB scan tool.

DRB SCAN TOOL

For operation of the DRB scan tool, refer to the ap-

propriate Powertrain Diagnostic Procedures service

manual.

PRELIMINARY CHECKS

ENGINE COOLING SYSTEM OVERHEATING

Establish what driving conditions caused the com-

plaint. Abnormal loads on the cooling system such as

the following may be the cause.

1. PROLONGED IDLE, VERY HIGH AMBIENT

TEMPERATURE, SLIGHT TAIL WIND AT IDLE,

SLOW TRAFFIC, TRAFFIC JAMS, HIGH

SPEED, OR STEEP GRADES:

Driving techniques that avoid overheating are:

²Idle with A/C off when temperature gauge is at

end of normal range.

²Increasing engine speed for more air flow is recom-

mended.

2. TRAILER TOWING:

Consult Trailer Towing section of owners manual.

Do not exceed limits.

3. AIR CONDITIONING; ADD-ON OR AFTER

MARKET:

A maximum cooling package should have been or-

dered with vehicle if add-on or after market A/C is

installed. If not, maximum cooling system compo-

nents should be installed for model involved per

manufacturer's specifications.

4. RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been performed

on vehicle that may effect cooling system. This may

be:

²Engine adjustments (incorrect timing)

²Slipping engine accessory drive belt(s)

²Brakes (possibly dragging)

²Changed parts (incorrect water pump rotating in

wrong direction)

²Reconditioned radiator or cooling system refilling

(possibly under-filled or air trapped in system).

If investigation reveals none of the previous

items as a cause for an engine overheating com-

plaint, refer to following Cooling System Diag-

nosis charts.

These charts are to be used as a quick-reference

only. Refer to the group text for information.

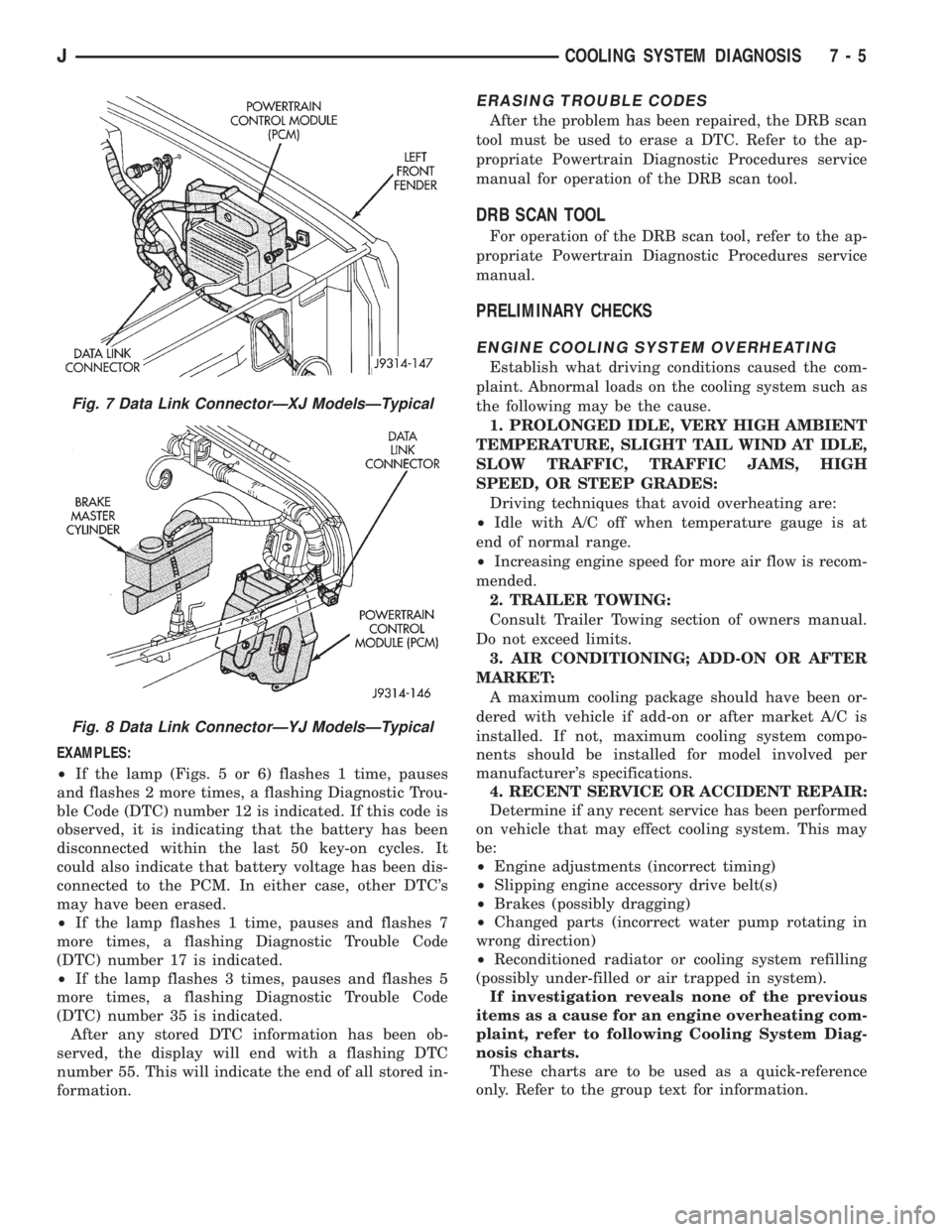

Fig. 7 Data Link ConnectorÐXJ ModelsÐTypical

Fig. 8 Data Link ConnectorÐYJ ModelsÐTypical

JCOOLING SYSTEM DIAGNOSIS 7 - 5

Page 238 of 2198

SERVICE PROCEDURES

INDEX

page page

Auxiliary Electric Cooling FanÐXJ Models with 4.0L

6-Cylinder Engine....................... 35

Coolant................................. 20

Coolant Reserve/Overflow System............. 24

Cooling System Cleaning/Reverse Flushing...... 22

Cooling System Fans...................... 32

Cooling System Hoses..................... 32

Draining Cooling System.................... 21

Radiator Pressure Cap..................... 25

Radiators............................... 26Refilling Cooling System.................... 21

Testing Cooling System for Leaks............. 22

Thermostat.............................. 17

Transmission Oil Coolers.................... 36

Viscous Fan Drive......................... 34

Water Pump Tests......................... 13

Water PumpsÐGeneral Information............ 13

Water PumpsÐRemoval/Installation........... 14

WATER PUMPSÐGENERAL INFORMATION

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core.

The pump is driven from the engine crankshaft by a

drive belt on all engines.

The water pump impeller is pressed onto the rear

of a shaft that rotates in bearings pressed into the

housing. The housing has a small hole to allow seep-

age to escape. The water pump seals are lubricated

by the antifreeze in the coolant mixture. No addi-

tional lubrication is necessary.

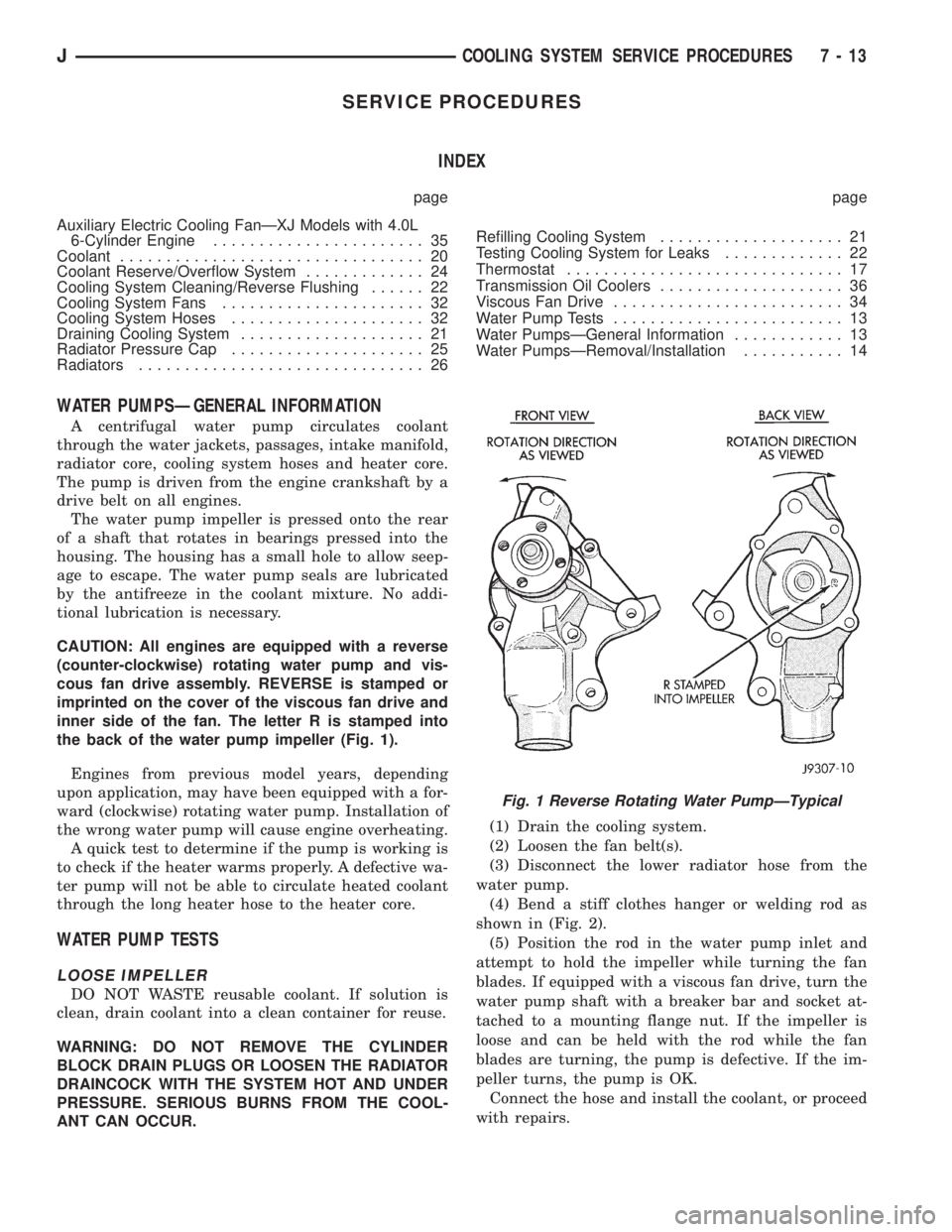

CAUTION: All engines are equipped with a reverse

(counter-clockwise) rotating water pump and vis-

cous fan drive assembly. REVERSE is stamped or

imprinted on the cover of the viscous fan drive and

inner side of the fan. The letter R is stamped into

the back of the water pump impeller (Fig. 1).

Engines from previous model years, depending

upon application, may have been equipped with a for-

ward (clockwise) rotating water pump. Installation of

the wrong water pump will cause engine overheating.

A quick test to determine if the pump is working is

to check if the heater warms properly. A defective wa-

ter pump will not be able to circulate heated coolant

through the long heater hose to the heater core.

WATER PUMP TESTS

LOOSE IMPELLER

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM THE COOL-

ANT CAN OCCUR.(1) Drain the cooling system.

(2) Loosen the fan belt(s).

(3) Disconnect the lower radiator hose from the

water pump.

(4) Bend a stiff clothes hanger or welding rod as

shown in (Fig. 2).

(5) Position the rod in the water pump inlet and

attempt to hold the impeller while turning the fan

blades. If equipped with a viscous fan drive, turn the

water pump shaft with a breaker bar and socket at-

tached to a mounting flange nut. If the impeller is

loose and can be held with the rod while the fan

blades are turning, the pump is defective. If the im-

peller turns, the pump is OK.

Connect the hose and install the coolant, or proceed

with repairs.

Fig. 1 Reverse Rotating Water PumpÐTypical

JCOOLING SYSTEM SERVICE PROCEDURES 7 - 13

Page 242 of 2198

INSTALLATIONÐALL MODELS

(1) If pump is being replaced, install the heater

hose fitting to the pump. Use a sealant on the fitting

such as MoparŸ Thread Sealant With Teflon. Refer

to the directions on the package.

(2) Clean the gasket mating surfaces. If the origi-

nal pump is used, remove any deposits or other for-

eign material. Inspect the cylinder block and water

pump mating surfaces for erosion or damage from

cavitation.

(3) Install the gasket and water pump. The silicone

bead on the gasket should be facing the water pump.

Also, the gasket is installed dry. Tighten mounting

bolts to 30 Nzm (22 ft. lbs.) torque. Rotate the shaft

by hand to be sure it turns freely.

(4) Connect the radiator and heater hoses to the

water pump.

(5) Position water pump pulley to water pump hub.

(6) If equipped with a water pump mounted fan,

install fan and four nuts to water pump hub. If not

equipped with a water pump mounted fan, install

four pump hub bolts. Tighten bolts (or nuts) to 27

Nzm (20 ft. lbs.) torque.

(7) Position power steering pump bracket to en-

gine. Install bolts E, F and G (Fig. 7). Tighten bolts F

andGto38Nzm (28 ft. lbs.) torque. Tighten bolt E to

27 Nzm (20 ft. lbs.) torque.

(8) Position power steering pump to mounting

bracket. Install pivot bolt B (Fig. 6) finger tight. In-

stall locknut C and adjustment bolt D (Figs. 6 or 7)

finger tight.

(9) Install two adjustment bolts A (Fig. 6) finger

tight.

(10) Install idler pulley.

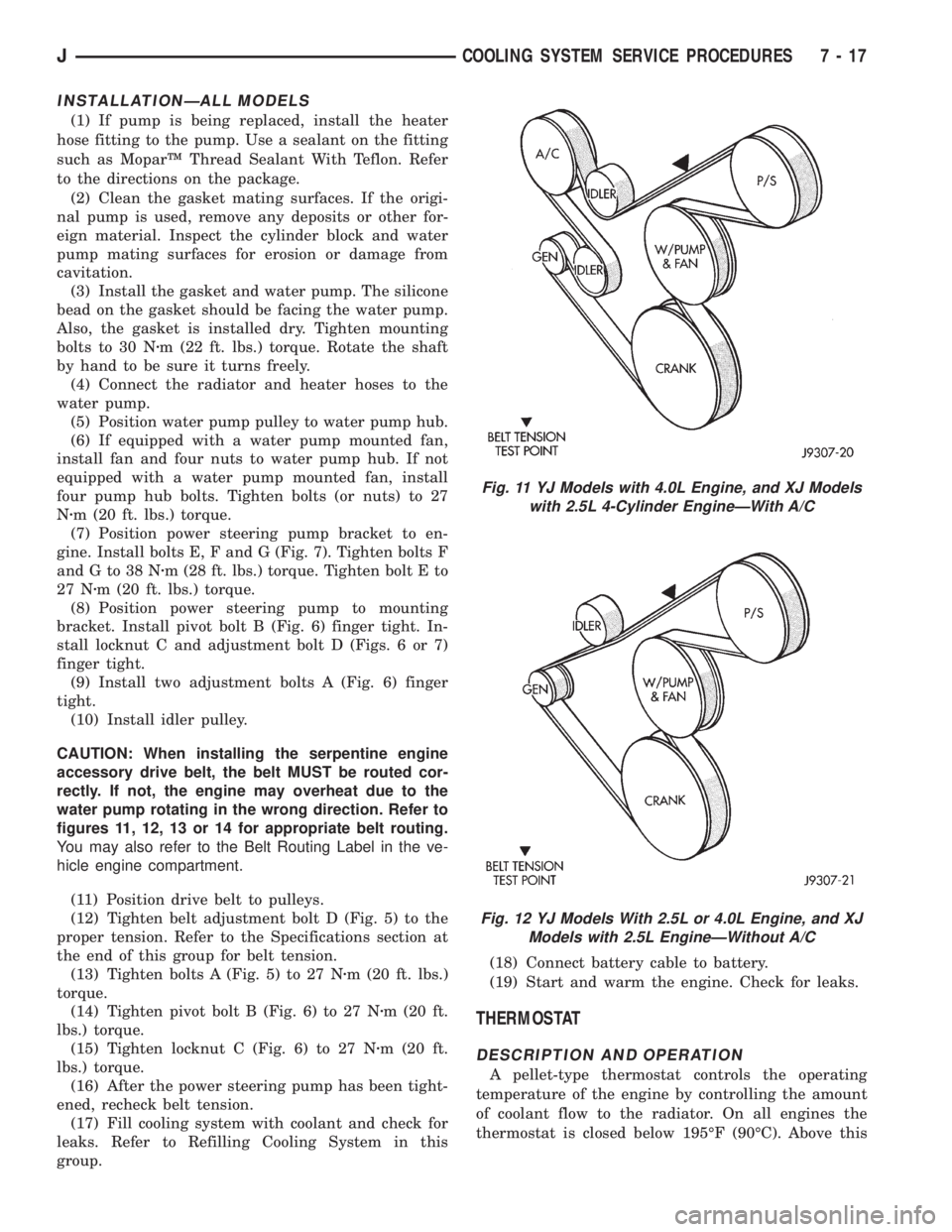

CAUTION: When installing the serpentine engine

accessory drive belt, the belt MUST be routed cor-

rectly. If not, the engine may overheat due to the

water pump rotating in the wrong direction. Refer to

figures 11, 12, 13 or 14 for appropriate belt routing.

You may also refer to the Belt Routing Label in the ve-

hicle engine compartment.

(11) Position drive belt to pulleys.

(12) Tighten belt adjustment bolt D (Fig. 5) to the

proper tension. Refer to the Specifications section at

the end of this group for belt tension.

(13) Tighten bolts A (Fig. 5) to 27 Nzm (20 ft. lbs.)

torque.

(14) Tighten pivot bolt B (Fig. 6) to 27 Nzm (20 ft.

lbs.) torque.

(15) Tighten locknut C (Fig. 6) to 27 Nzm (20 ft.

lbs.) torque.

(16) After the power steering pump has been tight-

ened, recheck belt tension.

(17) Fill cooling system with coolant and check for

leaks. Refer to Refilling Cooling System in this

group.(18) Connect battery cable to battery.

(19) Start and warm the engine. Check for leaks.

THERMOSTAT

DESCRIPTION AND OPERATION

A pellet-type thermostat controls the operating

temperature of the engine by controlling the amount

of coolant flow to the radiator. On all engines the

thermostat is closed below 195ÉF (90ÉC). Above this

Fig. 11 YJ Models with 4.0L Engine, and XJ Models

with 2.5L 4-Cylinder EngineÐWith A/C

Fig. 12 YJ Models With 2.5L or 4.0L Engine, and XJ

Models with 2.5L EngineÐWithout A/C

JCOOLING SYSTEM SERVICE PROCEDURES 7 - 17

Page 244 of 2198

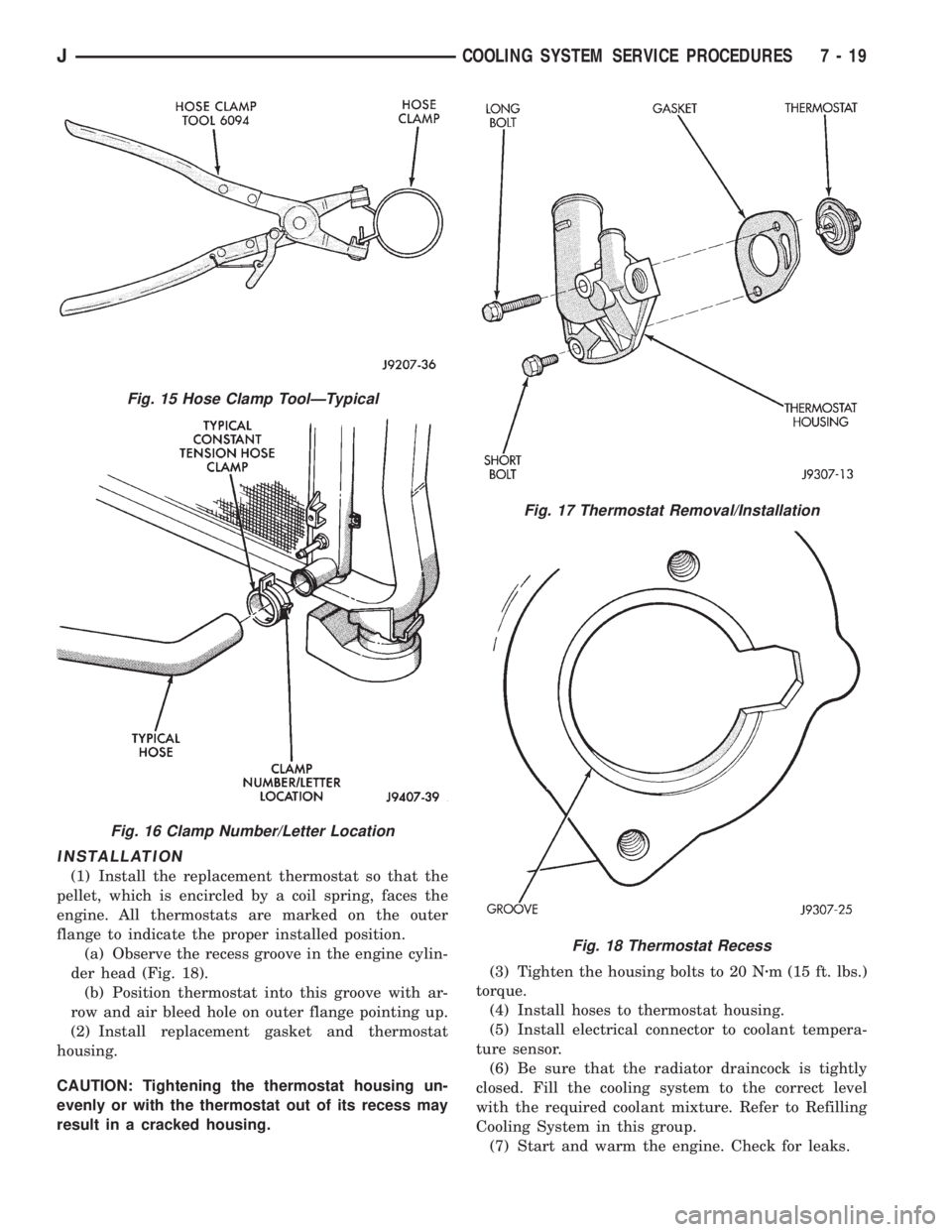

INSTALLATION

(1) Install the replacement thermostat so that the

pellet, which is encircled by a coil spring, faces the

engine. All thermostats are marked on the outer

flange to indicate the proper installed position.

(a) Observe the recess groove in the engine cylin-

der head (Fig. 18).

(b) Position thermostat into this groove with ar-

row and air bleed hole on outer flange pointing up.

(2) Install replacement gasket and thermostat

housing.

CAUTION: Tightening the thermostat housing un-

evenly or with the thermostat out of its recess may

result in a cracked housing.(3) Tighten the housing bolts to 20 Nzm (15 ft. lbs.)

torque.

(4) Install hoses to thermostat housing.

(5) Install electrical connector to coolant tempera-

ture sensor.

(6) Be sure that the radiator draincock is tightly

closed. Fill the cooling system to the correct level

with the required coolant mixture. Refer to Refilling

Cooling System in this group.

(7) Start and warm the engine. Check for leaks.

Fig. 15 Hose Clamp ToolÐTypical

Fig. 16 Clamp Number/Letter Location

Fig. 17 Thermostat Removal/Installation

Fig. 18 Thermostat Recess

JCOOLING SYSTEM SERVICE PROCEDURES 7 - 19

Page 245 of 2198

COOLANT

GENERAL INFORMATION

The cooling system is designed around the coolant.

Coolant flows through the engine water jackets ab-

sorbing heat produced during engine operation. The

coolant carries heat to the radiator and heater core.

Here it is transferred to the ambient air passing

through the radiator and heater core fins. The cool-

ant also removes heat from the automatic transmis-

sion fluid in vehicles equipped with an automatic

transmission.

COOLANT PERFORMANCE

The required ethylene-glycol (antifreeze) and water

mixture depends upon climate and vehicle operating

conditions. The coolant performance of various mix-

tures follows:

Pure Water-Water can absorb more heat than a

mixture of water and ethylene-glycol. This is for pur-

pose of heat transfer only. Water also freezes at a

higher temperature and allows corrosion.

100 percent Ethylene-Glycol-The corrosion in-

hibiting additives in ethylene-glycol need the pres-

ence of water to dissolve. Without water, additives

form deposits in system. These act as insulation

causing temperature to rise to as high as 149ÉC

(300ÉF). This temperature is hot enough to melt plas-

tic and soften solder. The increased temperature can

result in engine detonation. In addition, 100 percent

ethylene-glycol freezes at -22ÉC (-8ÉF).

50/50 Ethylene-Glycol and Water-Is the recom-

mended mixture, it provides protection against freez-

ing to -37ÉC (-35ÉF). The antifreeze concentration

must alwaysbe a minimum of 44 percent, year-

round in all climates. If percentage is lower, engine

parts may be eroded by cavitation. Maximum protec-

tion against freezing is provided with a 68 percent

antifreeze concentration, which prevents freezing

down to -67.7ÉC (-90ÉF). A higher percentage will

freeze at a warmer temperature. Also, a higher per-

centage of antifreeze can cause the engine to over-

heat because specific heat of antifreeze is lower than

that of water.

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

COOLANT SELECTION-ADDITIVES

Coolant should be maintained at the specified level

with a mixture of ethylene glycol-based antifreeze

and low mineral content water. Only use an anti-

freeze containing ALUGARD 340-2 Ÿ.CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

COOLANT SERVICE

It is recommended that the cooling system be

drained and flushed at 84,000 kilometers (52,500

miles), or 3 years, whichever occurs first. Then every

two years, or 48,000 kilometers (30,000 miles),

whichever occurs first.

COOLANT LEVEL CHECKÐROUTINE

Do not remove radiator cap for routine cool-

ant level inspections. The coolant level can be

checked at coolant reserve/overflow tank.

The coolant reserve/overflow system provides a

quick visual method for determining coolant level

without removing radiator pressure cap. With engine

idling and at normal operating temperature, observe

coolant level in reserve/overflow tank. The coolant

level should be between ADD and FULL marks.

ADDING ADDITIONAL COOLANTÐROUTINE

Do not remove radiator cap to add coolant to

system.When adding coolant to maintain correct

level, do so at coolant reserve/overflow tank. Use a

50/50 mixture of ethylene-glycol antifreeze containing

Alugard 340-2 Ÿ and low mineral content water. Re-

move radiator cap only for testing or when refilling

system after service. Removing cap unnecessarily can

cause loss of coolant and allow air to enter system,

which produces corrosion.

COOLANT LEVEL CHECK-SERVICE

The cooling system is closed and designed to main-

tain coolant level to top of radiator.

WARNING: DO NOT OPEN RADIATOR DRAINCOCK

WITH ENGINE RUNNING OR WHILE ENGINE IS HOT

AND COOLING SYSTEM IS UNDER PRESSURE.

When vehicle servicing requires a coolant level

check in radiator, drain several ounces of coolant

from radiator drain cock. Do this while observing

coolant reserve/overflow system tank. The coolant

level in reserve/overflow tank should drop slightly. If

not, inspect for a leak between radiator and coolant

reserve/overflow system connection. Remove radiator

cap. The coolant level should be to top of radiator. If

not and if coolant level in reserve/overflow tank is at

ADD mark, check for:

²An air leak in coolant reserve/overflow tank or its

hose

²An air leak in radiator filler neck

²Leak in pressure cap seal to radiator filler neck

LOW COOLANT LEVEL-AERATION

If the coolant level in radiator drops below top of

radiator core tubes, air will enter cooling system.

7 - 20 COOLING SYSTEM SERVICE PROCEDURESJ

Page 246 of 2198

Low coolant level can cause thermostat pellet to be

suspended in air instead of coolant. This will cause

thermostat to open later, which in turn causes higher

coolant temperature. Air trapped in cooling system

also reduces amount of coolant circulating in heater

core resulting in low heat output.

DEAERATION

As the engine operates, any air trapped in cooling

system gathers under the radiator cap. The next time

the engine is operated, thermal expansion of coolant

will push any trapped air past radiator cap into the

coolant reserve/overflow tank. Here it escapes to the

atmosphere into the tank. When the engine cools

down the coolant, it will be drawn from the reserve/

overflow tank into the radiator to replace any re-

moved air.

DRAINING COOLING SYSTEM

ALL MODELSÐEXCEPT XJ WITH 4.0L

6-CYLINDER ENGINE

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

DO NOT remove the radiator cap when draining

the coolant from the reserve/overflow tank. Open the

radiator draincock and when the tank is empty, re-

move the radiator cap. The coolant does not have to

be removed from the tank unless the system is being

refilled with a fresh mixture.

(1) Drain the coolant from the radiator by loosen-

ing the draincock.

(2) Drain coolant from engine as follows:

(a) On 2.5L 4-cylinder engines (all models) by re-

moving drain plug at left rear side of block.

(b) On 4.0L 6-cylinder engines by removing the

drain plug or coolant temperature sensor on the

left side of the block (Fig. 19).

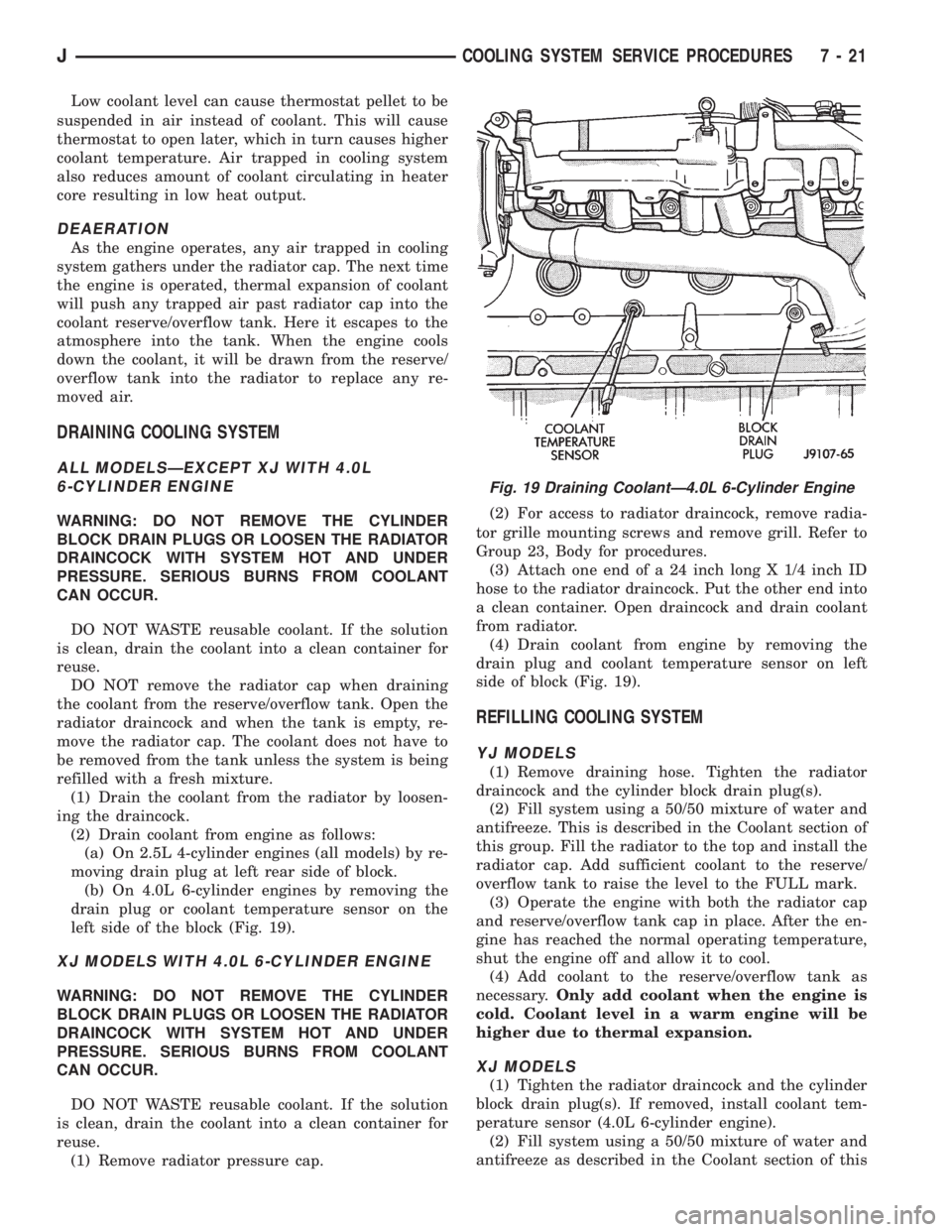

XJ MODELS WITH 4.0L 6-CYLINDER ENGINE

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

(1) Remove radiator pressure cap.(2) For access to radiator draincock, remove radia-

tor grille mounting screws and remove grill. Refer to

Group 23, Body for procedures.

(3) Attach one end of a 24 inch long X 1/4 inch ID

hose to the radiator draincock. Put the other end into

a clean container. Open draincock and drain coolant

from radiator.

(4) Drain coolant from engine by removing the

drain plug and coolant temperature sensor on left

side of block (Fig. 19).

REFILLING COOLING SYSTEM

YJ MODELS

(1) Remove draining hose. Tighten the radiator

draincock and the cylinder block drain plug(s).

(2) Fill system using a 50/50 mixture of water and

antifreeze. This is described in the Coolant section of

this group. Fill the radiator to the top and install the

radiator cap. Add sufficient coolant to the reserve/

overflow tank to raise the level to the FULL mark.

(3) Operate the engine with both the radiator cap

and reserve/overflow tank cap in place. After the en-

gine has reached the normal operating temperature,

shut the engine off and allow it to cool.

(4) Add coolant to the reserve/overflow tank as

necessary.Only add coolant when the engine is

cold. Coolant level in a warm engine will be

higher due to thermal expansion.

XJ MODELS

(1) Tighten the radiator draincock and the cylinder

block drain plug(s). If removed, install coolant tem-

perature sensor (4.0L 6-cylinder engine).

(2) Fill system using a 50/50 mixture of water and

antifreeze as described in the Coolant section of this

Fig. 19 Draining CoolantÐ4.0L 6-Cylinder Engine

JCOOLING SYSTEM SERVICE PROCEDURES 7 - 21

Page 261 of 2198

nostic Procedures manual for diagnostic information

and operation of the DRB scan tool.

To test operation of the fan relay only, refer to Re-

laysÐOperation/Testing. This can be found in Group

14, Fuel Systems.

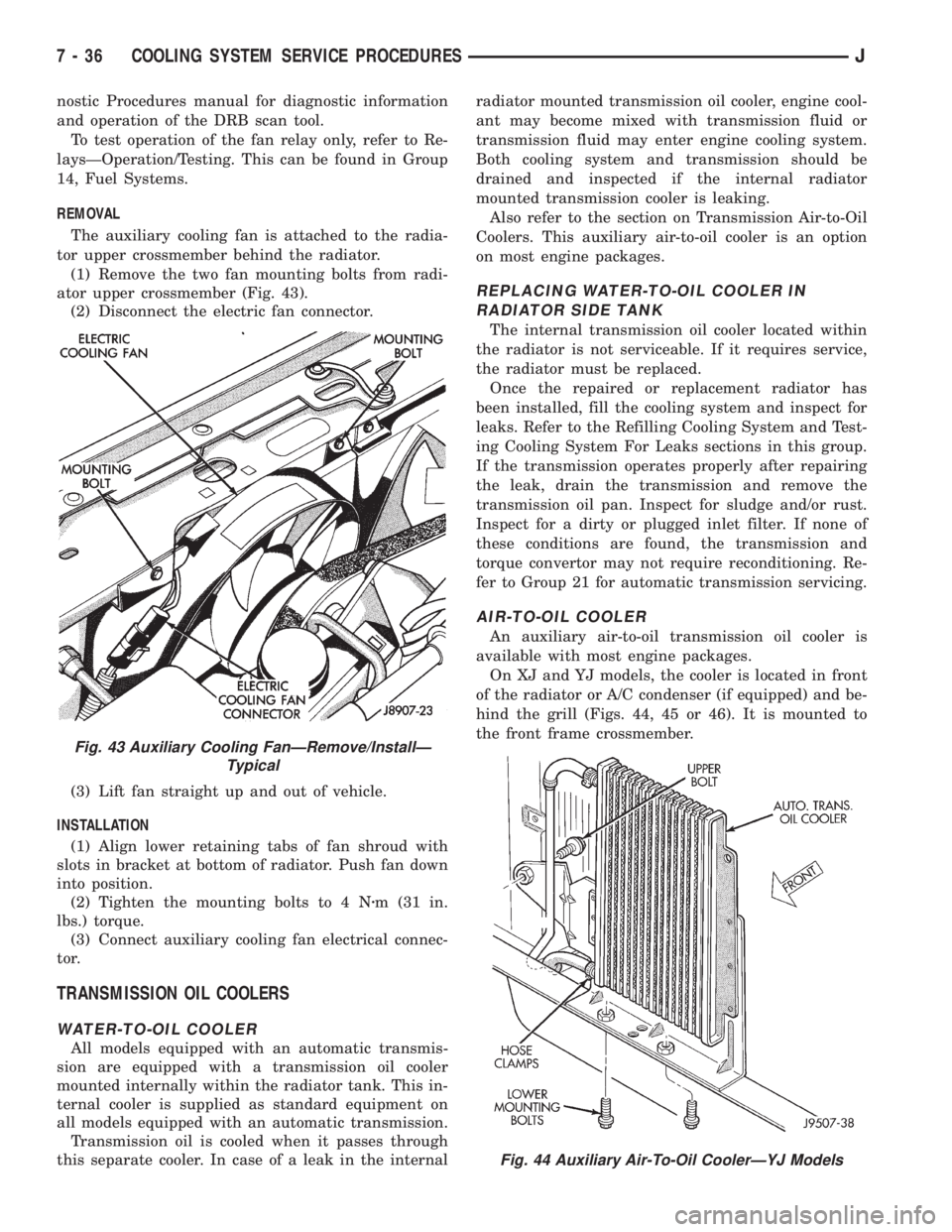

REMOVAL

The auxiliary cooling fan is attached to the radia-

tor upper crossmember behind the radiator.

(1) Remove the two fan mounting bolts from radi-

ator upper crossmember (Fig. 43).

(2) Disconnect the electric fan connector.

(3) Lift fan straight up and out of vehicle.

INSTALLATION

(1) Align lower retaining tabs of fan shroud with

slots in bracket at bottom of radiator. Push fan down

into position.

(2) Tighten the mounting bolts to 4 Nzm (31 in.

lbs.) torque.

(3) Connect auxiliary cooling fan electrical connec-

tor.

TRANSMISSION OIL COOLERS

WATER-TO-OIL COOLER

All models equipped with an automatic transmis-

sion are equipped with a transmission oil cooler

mounted internally within the radiator tank. This in-

ternal cooler is supplied as standard equipment on

all models equipped with an automatic transmission.

Transmission oil is cooled when it passes through

this separate cooler. In case of a leak in the internalradiator mounted transmission oil cooler, engine cool-

ant may become mixed with transmission fluid or

transmission fluid may enter engine cooling system.

Both cooling system and transmission should be

drained and inspected if the internal radiator

mounted transmission cooler is leaking.

Also refer to the section on Transmission Air-to-Oil

Coolers. This auxiliary air-to-oil cooler is an option

on most engine packages.

REPLACING WATER-TO-OIL COOLER IN

RADIATOR SIDE TANK

The internal transmission oil cooler located within

the radiator is not serviceable. If it requires service,

the radiator must be replaced.

Once the repaired or replacement radiator has

been installed, fill the cooling system and inspect for

leaks. Refer to the Refilling Cooling System and Test-

ing Cooling System For Leaks sections in this group.

If the transmission operates properly after repairing

the leak, drain the transmission and remove the

transmission oil pan. Inspect for sludge and/or rust.

Inspect for a dirty or plugged inlet filter. If none of

these conditions are found, the transmission and

torque convertor may not require reconditioning. Re-

fer to Group 21 for automatic transmission servicing.

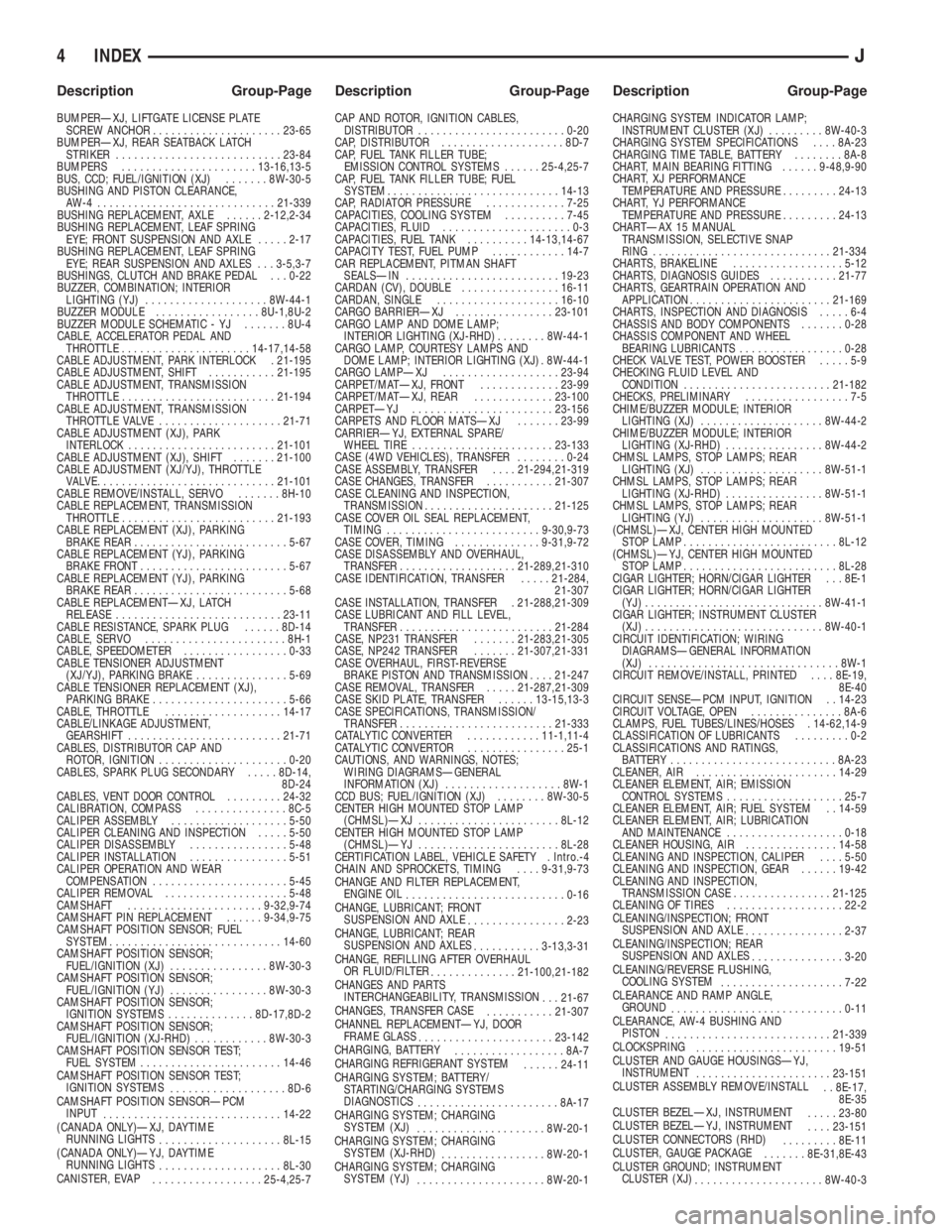

AIR-TO-OIL COOLER

An auxiliary air-to-oil transmission oil cooler is

available with most engine packages.

On XJ and YJ models, the cooler is located in front

of the radiator or A/C condenser (if equipped) and be-

hind the grill (Figs. 44, 45 or 46). It is mounted to

the front frame crossmember.

Fig. 43 Auxiliary Cooling FanÐRemove/InstallÐ

Typical

Fig. 44 Auxiliary Air-To-Oil CoolerÐYJ Models

7 - 36 COOLING SYSTEM SERVICE PROCEDURESJ

Page 1965 of 2198

BUMPERÐXJ, LIFTGATE LICENSE PLATE

SCREW ANCHOR.....................23-65

BUMPERÐXJ, REAR SEATBACK LATCH

STRIKER...........................23-84

BUMPERS......................13-16,13-5

BUS, CCD; FUEL/IGNITION (XJ).......8W-30-5

BUSHING AND PISTON CLEARANCE,

AW-4 .............................21-339

BUSHING REPLACEMENT, AXLE......2-12,2-34

BUSHING REPLACEMENT, LEAF SPRING

EYE; FRONT SUSPENSION AND AXLE.....2-17

BUSHING REPLACEMENT, LEAF SPRING

EYE; REAR SUSPENSION AND AXLES . . . 3-5,3-7

BUSHINGS, CLUTCH AND BRAKE PEDAL . . . 0-22

BUZZER, COMBINATION; INTERIOR

LIGHTING (YJ)....................8W-44-1

BUZZER MODULE.................8U-1,8U-2

BUZZER MODULE SCHEMATIC - YJ.......8U-4

CABLE, ACCELERATOR PEDAL AND

THROTTLE.....................14-17,14-58

CABLE ADJUSTMENT, PARK INTERLOCK . 21-195

CABLE ADJUSTMENT, SHIFT...........21-195

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE.........................21-194

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE VALVE....................21-71

CABLE ADJUSTMENT (XJ), PARK

INTERLOCK........................21-101

CABLE ADJUSTMENT (XJ), SHIFT.......21-100

CABLE ADJUSTMENT (XJ/YJ), THROTTLE

VALVE..............................21-101

CABLE REMOVE/INSTALL, SERVO.......8H-10

CABLE REPLACEMENT, TRANSMISSION

THROTTLE.........................21-193

CABLE REPLACEMENT (XJ), PARKING

BRAKE REAR.........................5-67

CABLE REPLACEMENT (YJ), PARKING

BRAKE FRONT........................5-67

CABLE REPLACEMENT (YJ), PARKING

BRAKE REAR.........................5-68

CABLE REPLACEMENTÐXJ, LATCH

RELEASE...........................23-11

CABLE RESISTANCE, SPARK PLUG......8D-14

CABLE, SERVO.......................8H-1

CABLE, SPEEDOMETER.................0-33

CABLE TENSIONER ADJUSTMENT

(XJ/YJ), PARKING BRAKE...............5-69

CABLE TENSIONER REPLACEMENT (XJ),

PARKING BRAKE......................5-66

CABLE, THROTTLE...................14-17

CABLE/LINKAGE ADJUSTMENT,

GEARSHIFT.........................21-71

CABLES, DISTRIBUTOR CAP AND

ROTOR, IGNITION.....................0-20

CABLES, SPARK PLUG SECONDARY.....8D-14,

8D-24

CABLES, VENT DOOR CONTROL.........24-32

CALIBRATION, COMPASS...............8C-5

CALIPER ASSEMBLY...................5-50

CALIPER CLEANING AND INSPECTION.....5-50

CALIPER DISASSEMBLY................5-48

CALIPER INSTALLATION................5-51

CALIPER OPERATION AND WEAR

COMPENSATION......................5-45

CALIPER REMOVAL....................5-48

CAMSHAFT......................9-32,9-74

CAMSHAFT PIN REPLACEMENT......9-34,9-75

CAMSHAFT POSITION SENSOR; FUEL

SYSTEM............................14-60

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (XJ)................8W-30-3

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (YJ)................8W-30-3

CAMSHAFT POSITION SENSOR;

IGNITION SYSTEMS..............8D-17,8D-2

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (XJ-RHD)............8W-30-3

CAMSHAFT POSITION SENSOR TEST;

FUEL SYSTEM.......................14-46

CAMSHAFT POSITION SENSOR TEST;

IGNITION SYSTEMS

...................8D-6

CAMSHAFT POSITION SENSORÐPCM

INPUT

.............................14-22

(CANADA ONLY)ÐXJ, DAYTIME

RUNNING LIGHTS

....................8L-15

(CANADA ONLY)ÐYJ, DAYTIME

RUNNING LIGHTS

....................8L-30

CANISTER, EVAP

..................25-4,25-7CAP AND ROTOR, IGNITION CABLES,

DISTRIBUTOR........................0-20

CAP, DISTRIBUTOR....................8D-7

CAP, FUEL TANK FILLER TUBE;

EMISSION CONTROL SYSTEMS......25-4,25-7

CAP, FUEL TANK FILLER TUBE; FUEL

SYSTEM............................14-13

CAP, RADIATOR PRESSURE.............7-25

CAPACITIES, COOLING SYSTEM..........7-45

CAPACITIES, FLUID.....................0-3

CAPACITIES, FUEL TANK..........14-13,14-67

CAPACITY TEST, FUEL PUMP............14-7

CAR REPLACEMENT, PITMAN SHAFT

SEALSÐIN.........................19-23

CARDAN (CV), DOUBLE................16-11

CARDAN, SINGLE....................16-10

CARGO BARRIERÐXJ................23-101

CARGO LAMP AND DOME LAMP;

INTERIOR LIGHTING (XJ-RHD)........8W-44-1

CARGO LAMP, COURTESY LAMPS AND

DOME LAMP; INTERIOR LIGHTING (XJ) . 8W-44-1

CARGO LAMPÐXJ...................23-94

CARPET/MATÐXJ, FRONT.............23-99

CARPET/MATÐXJ, REAR.............23-100

CARPETÐYJ.......................23-156

CARPETS AND FLOOR MATSÐXJ.......23-99

CARRIERÐYJ, EXTERNAL SPARE/

WHEEL TIRE.......................23-133

CASE (4WD VEHICLES), TRANSFER........0-24

CASE ASSEMBLY, TRANSFER....21-294,21-319

CASE CHANGES, TRANSFER...........21-307

CASE CLEANING AND INSPECTION,

TRANSMISSION.....................21-125

CASE COVER OIL SEAL REPLACEMENT,

TIMING.........................9-30,9-73

CASE COVER, TIMING..............9-31,9-72

CASE DISASSEMBLY AND OVERHAUL,

TRANSFER...................21-289,21-310

CASE IDENTIFICATION, TRANSFER.....21-284,

21-307

CASE INSTALLATION, TRANSFER . 21-288,21-309

CASE LUBRICANT AND FILL LEVEL,

TRANSFER.........................21-284

CASE, NP231 TRANSFER.......21-283,21-305

CASE, NP242 TRANSFER.......21-307,21-331

CASE OVERHAUL, FIRST-REVERSE

BRAKE PISTON AND TRANSMISSION....21-247

CASE REMOVAL, TRANSFER.....21-287,21-309

CASE SKID PLATE, TRANSFER......13-15,13-3

CASE SPECIFICATIONS, TRANSMISSION/

TRANSFER.........................21-333

CATALYTIC CONVERTER............11-1,11-4

CATALYTIC CONVERTOR................25-1

CAUTIONS, AND WARNINGS, NOTES;

WIRING DIAGRAMSÐGENERAL

INFORMATION (XJ)...................8W-1

CCD BUS; FUEL/IGNITION (XJ)........8W-30-5

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐXJ.......................8L-12

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐYJ.......................8L-28

CERTIFICATION LABEL, VEHICLE SAFETY . Intro.-4

CHAIN AND SPROCKETS, TIMING....9-31,9-73

CHANGE AND FILTER REPLACEMENT,

ENGINE OIL

..........................0-16

CHANGE, LUBRICANT; FRONT

SUSPENSION AND AXLE

................2-23

CHANGE, LUBRICANT; REAR

SUSPENSION AND AXLES

...........3-13,3-31

CHANGE, REFILLING AFTER OVERHAUL

OR FLUID/FILTER

..............21-100,21-182

CHANGES AND PARTS

INTERCHANGEABILITY, TRANSMISSION

. . . 21-67

CHANGES, TRANSFER CASE

...........21-307

CHANNEL REPLACEMENTÐYJ, DOOR

FRAME GLASS

......................23-142

CHARGING, BATTERY

..................8A-7

CHARGING REFRIGERANT SYSTEM

......24-11

CHARGING SYSTEM; BATTERY/

STARTING/CHARGING SYSTEMS

DIAGNOSTICS

.......................8A-17

CHARGING SYSTEM; CHARGING

SYSTEM (XJ)

.....................8W-20-1

CHARGING SYSTEM; CHARGING

SYSTEM (XJ-RHD)

.................8W-20-1

CHARGING SYSTEM; CHARGING

SYSTEM (YJ)

.....................8W-20-1CHARGING SYSTEM INDICATOR LAMP;

INSTRUMENT CLUSTER (XJ).........8W-40-3

CHARGING SYSTEM SPECIFICATIONS....8A-23

CHARGING TIME TABLE, BATTERY........8A-8

CHART, MAIN BEARING FITTING......9-48,9-90

CHART, XJ PERFORMANCE

TEMPERATURE AND PRESSURE.........24-13

CHART, YJ PERFORMANCE

TEMPERATURE AND PRESSURE.........24-13

CHARTÐAX 15 MANUAL

TRANSMISSION, SELECTIVE SNAP

RING.............................21-334

CHARTS, BRAKELINE..................5-12

CHARTS, DIAGNOSIS GUIDES...........21-77

CHARTS, GEARTRAIN OPERATION AND

APPLICATION.......................21-169

CHARTS, INSPECTION AND DIAGNOSIS.....6-4

CHASSIS AND BODY COMPONENTS.......0-28

CHASSIS COMPONENT AND WHEEL

BEARING LUBRICANTS.................0-28

CHECK VALVE TEST, POWER BOOSTER.....5-9

CHECKING FLUID LEVEL AND

CONDITION........................21-182

CHECKS, PRELIMINARY.................7-5

CHIME/BUZZER MODULE; INTERIOR

LIGHTING (XJ)....................8W-44-2

CHIME/BUZZER MODULE; INTERIOR

LIGHTING (XJ-RHD)................8W-44-2

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (XJ)....................8W-51-1

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (XJ-RHD)................8W-51-1

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (YJ)....................8W-51-1

(CHMSL)ÐXJ, CENTER HIGH MOUNTED

STOP LAMP.........................8L-12

(CHMSL)ÐYJ, CENTER HIGH MOUNTED

STOP LAMP.........................8L-28

CIGAR LIGHTER; HORN/CIGAR LIGHTER . . . 8E-1

CIGAR LIGHTER; HORN/CIGAR LIGHTER

(YJ).............................8W-41-1

CIGAR LIGHTER; INSTRUMENT CLUSTER

(XJ).............................8W-40-1

CIRCUIT IDENTIFICATION; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-1

CIRCUIT REMOVE/INSTALL, PRINTED....8E-19,

8E-40

CIRCUIT SENSEÐPCM INPUT, IGNITION . . 14-23

CIRCUIT VOLTAGE, OPEN...............8A-6

CLAMPS, FUEL TUBES/LINES/HOSES . 14-62,14-9

CLASSIFICATION OF LUBRICANTS.........0-2

CLASSIFICATIONS AND RATINGS,

BATTERY...........................8A-23

CLEANER, AIR.......................14-29

CLEANER ELEMENT, AIR; EMISSION

CONTROL SYSTEMS...................25-7

CLEANER ELEMENT, AIR; FUEL SYSTEM . . 14-59

CLEANER ELEMENT, AIR; LUBRICATION

AND MAINTENANCE...................0-18

CLEANER HOUSING, AIR...............14-58

CLEANING AND INSPECTION, CALIPER....5-50

CLEANING AND INSPECTION, GEAR......19-42

CLEANING AND INSPECTION,

TRANSMISSION CASE................21-125

CLEANING OF TIRES...................22-2

CLEANING/INSPECTION; FRONT

SUSPENSION AND AXLE

................2-37

CLEANING/INSPECTION; REAR

SUSPENSION AND AXLES

...............3-20

CLEANING/REVERSE FLUSHING,

COOLING SYSTEM

....................7-22

CLEARANCE AND RAMP ANGLE,

GROUND

............................0-11

CLEARANCE, AW-4 BUSHING AND

PISTON

...........................21-339

CLOCKSPRING

.......................19-51

CLUSTER AND GAUGE HOUSINGSÐYJ,

INSTRUMENT

......................23-151

CLUSTER ASSEMBLY REMOVE/INSTALL

. . 8E-17,

8E-35

CLUSTER BEZELÐXJ, INSTRUMENT

.....23-80

CLUSTER BEZELÐYJ, INSTRUMENT

....23-151

CLUSTER CONNECTORS (RHD)

.........8E-11

CLUSTER, GAUGE PACKAGE

.......8E-31,8E-43

CLUSTER GROUND; INSTRUMENT

CLUSTER (XJ)

.....................8W-40-3

4 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 1967 of 2198

CONTENTS; INSTRUMENT PANEL AND

GAUGESÐXJ........................8E-24

CONTENTS; LAMPS...................8L-19

CONTINUITY (LEFT POSITION), POWER

MIRROR SWITCH.....................8T-3

CONTINUITY, POWER SEAT SWITCH......8R-2

CONTINUITY (RIGHT POSITION), POWER

MIRROR SWITCH.....................8T-3

CONTINUITY TESTS, IGNITION SWITCH . . . 8D-30

CONTROL AND DISPLAY SYMBOLS,

INTERNATIONAL VEHICLE.............Intro.-5

CONTROL AND DISPLAY SYMBOLS,

VEHICLE.........................Intro.-10

CONTROL CABLES, VENT DOOR.........24-32

CONTROL DIAGNOSTIC TROUBLE CODE,

SPEED..............................8H-5

CONTROL, FUEL PUMP ELECTRICAL......14-5

CONTROL (IAC) MOTOR, IDLE AIR; FUEL

SYSTEM............................14-62

CONTROL (IAC) MOTOR, IDLE AIR;

FUEL/IGNITION (XJ)................8W-30-2

CONTROL (IAC) MOTOR, IDLE AIR;

FUEL/IGNITION (YJ)................8W-30-2

CONTROL (IAC) MOTOR, IDLE AIR;

FUEL/IGNITION (XJ-RHD)............8W-30-2

CONTROL (IAC) MOTORÐPCM OUTPUT,

IDLE AIR...........................14-27

CONTROL INFORMATION (VECI) LABEL,

VEHICLE EMISSION....................25-1

CONTROL MODULE (PCM) 60-WAY

CONNECTOR, POWERTRAIN............14-40

CONTROL MODULE (PCM),

POWERTRAIN; EMISSION CONTROL

SYSTEMS...........................25-7

CONTROL MODULE (PCM),

POWERTRAIN; FUEL SYSTEM......14-20,14-64

CONTROL MODULE (PCM),

POWERTRAIN; IGNITION SYSTEMS......8D-11,

8D-23,8D-5

CONTROL MODULE, POWERTRAIN . . . 8H-1,8H-7

CONTROL MODULE (TCM) SERVICE,

TRANSMISSION.....................21-183

CONTROL MODULE, TRANSMISSION;

TRANSMISSION CONTROLS (XJ-RHD) . . 8W-31-1

CONTROL MODULEÐ4.0L ENGINE ONLY,

TRANSMISSION; TRANSMISSION

CONTROLS (XJ)...................8W-31-1

CONTROL MOTOR TEST, IDLE AIR.......14-49

CONTROL PANEL LAMP, ACCESSORY

LAMP AND HEATER; INTERIOR

LIGHTING (YJ)....................8W-44-1

CONTROL REPLACEMENT, HEATER.......24-32

CONTROL REPLACEMENT, HEATER AND

A/C................................24-23

CONTROL SERVO REMOVE/INSTALL,

SPEED..............................8H-9

CONTROL SERVO, SPEED..........8H-1,8H-6

CONTROL SWITCH REMOVE/INSTALL,

SPEED..............................8H-9

CONTROL SWITCH, SPEED.........8H-1,8H-6

CONTROL SYSTEM, EMISSION...........0-20

CONTROL SYSTEM, EVAP

(EVAPORATION)......................25-4

CONTROL SYSTEM MAINTENANCE,

EMISSION............................0-4

CONTROL THERMOSTAT, TEMPERATURE . . 24-34

CONTROL, THERMOSTATIC.............24-16

CONTROL UNIT (ECU), ELECTRONIC......5-34

CONTROL UNIT (HCU), HYDRAULIC.......5-33

CONTROL UNIT, HYDRAULIC; ANTI-LOCK

BRAKES (XJ)......................8W-32-2

CONTROL UNIT, HYDRAULIC; ANTI-LOCK

BRAKES (XJ-RHD).................8W-32-2

CONTROL UNIT, HYDRAULIC; ANTI-LOCK

BRAKES (YJ)......................8W-32-2

CONTROL VALVE FITTING O-RING SEAL,

FLOW..............................19-14

CONTROL, VEHICLE SPEED; VEHICLE

SPEED CONTROL (XJ)..............8W-33-1

CONTROL, VEHICLE SPEED; VEHICLE

SPEED CONTROL (XJ-RHD)..........8W-33-1

CONTROLÐPCM INPUT, SPEED

.........14-25

CONTROLÐPCM OUTPUT, SPEED

.......14-29

CONTROLS AND COMPONENTS,

TRANSMISSION

......................21-67

CONTROLS, EMISSION

.................25-4

CONTROLSÐPCM INPUT, AIR

CONDITIONING (A/C)

..................14-21CONTROLSÐXJ VEHICLES, AIR

CONDITIONING......................24-15

CONTROLSÐYJ VEHICLES, AIR

CONDITIONING......................24-16

CONVERSION FORMULAS AND

EQUIVALENT VALUES...............Intro.-11

CONVERSION, METRIC..............Intro.-16

CONVERSION, METRIC AND ENGLISH/

SAE .............................Intro.-11

CONVERTER, CATALYTIC............11-1,11-4

CONVERTER CLUTCH RELAY TEST,

TORQUE............................14-48

CONVERTER CLUTCH RELAY, TORQUE....14-65

CONVERTER CLUTCH RELAYÐPCM

OUTPUT, TORQUE....................14-29

CONVERTER CLUTCH (TCC) SOLENOID

AND RELAY, TORQUE; FUEL/IGNITION

(XJ).............................8W-30-4

CONVERTER CLUTCH (TCC) SOLENOID

AND RELAY, TORQUE; TRANSMISSION

CONTROLS (YJ)...................8W-31-1

CONVERTER CLUTCH (TCC) SOLENOID

AND RELAYÐ2.5L ENGINE ONLY,

TORQUE; TRANSMISSION CONTROLS

(XJ).............................8W-31-1

CONVERTER DIAGNOSIS, TORQUE . 21-86,21-87,

21-88

CONVERTER HOUSING LEAK DIAGNOSIS . . 21-75

CONVERTER INSTALLATION,

TRANSMISSION.....................21-117

CONVERTER INSTALLATION,

TRANSMISSION AND TORQUE.........21-199

CONVERTER REMOVAL, TRANSMISSION . 21-115

CONVERTER REMOVAL, TRANSMISSION

AND TORQUE......................21-198

CONVERTER STALL TEST..............21-74

CONVERTER STALL TEST, TORQUE.....21-178

CONVERTER STATOR CLUTCH

INSPECTION, TORQUE................21-199

CONVERTER, TORQUE...........21-167,21-67

CONVERTERÐPUMP SEALÐDRIVE

PLATE SERVICE.....................21-116

CONVERTOR, CATALYTIC................25-1

COOLANT............................7-20

COOLANT RESERVE/OVERFLOW SYSTEM . . 7-24

COOLANT ROUTING, SYSTEM.............7-1

COOLANT TEMPERATURE GAUGE,

ENGINE; INSTRUMENT CLUSTER (XJ) . . 8W-40-1

COOLANT TEMPERATURE SENSOR.......25-7

COOLANT TEMPERATURE SENSOR,

ENGINE; FUEL SYSTEM................14-60

COOLANT TEMPERATURE SENSOR,

ENGINE; FUEL/IGNITION (XJ).........8W-30-3

COOLANT TEMPERATURE SENSOR,

ENGINE; FUEL/IGNITION (YJ).........8W-30-3

COOLANT TEMPERATURE SENSOR,

ENGINE; IGNITION SYSTEMS.......8D-19,8D-5

COOLANT TEMPERATURE SENSOR,

ENGINE; FUEL/IGNITION (XJ-RHD).....8W-30-3

COOLANT TEMPERATURE SENSOR TEST,

ENGINE; FUEL SYSTEM................14-46

COOLANT TEMPERATURE SENSOR TEST,

ENGINE; IGNITION SYSTEMS............8D-9

COOLANT TEMPERATURE SENSORÐ

PCM INPUT, ENGINE

..................14-23

COOLANT TEMPERATURE WARNING

LAMP, ENGINE; INSTRUMENT

CLUSTER (XJ)

.....................8W-40-1

COOLANT TEMPERATURE WARNING

LAMP, ENGINE; INSTRUMENT

CLUSTER (XJ-RHD)

................8W-40-1

COOLER FLOW TESTING,

TRANSMISSION

.....................21-113

COOLER LINE AND FITTING SERVICE,

TRANSMISSION

.....................21-111

COOLER LINE FITTINGS, TRANSMISSION

. 21-197

COOLER REVERSE FLUSHING,

TRANSMISSION

.....................21-114

COOLER SERVICE, TRANSMISSION

.....21-196

COOLERS, TRANSMISSION OIL

..........7-36

COOLING FANÐXJ MODELS WITH 4.0L

6-CYLINDER ENGINE, AUXILIARY

ELECTRIC

...........................7-35

COOLING SYSTEM; COOLING SYSTEM

......7-1

COOLING SYSTEM; HEATING AND AIR

CONDITIONING

......................24-10

COOLING SYSTEM CAPACITIES

..........7-45COOLING SYSTEM CLEANING/REVERSE

FLUSHING...........................7-22

COOLING SYSTEM COMPONENTS.........7-1

COOLING SYSTEM DIAGNOSIS............7-6

COOLING SYSTEM, DRAINING...........7-21

COOLING SYSTEM, ENGINE.............0-18

COOLING SYSTEM FANS................7-32

COOLING SYSTEM FOR LEAKS, TESTING . . . 7-22

COOLING SYSTEM HOSES..............7-32

COOLING SYSTEM, REFILLING...........7-21

CORE AND HOUSING, HEATER..........24-33

CORE, HEATER......................24-26

COURTESY LAMPS AND DOME LAMP,

CARGO LAMP; INTERIOR LIGHTING

(XJ).............................8W-44-1

COURTESY LAMPS AND DOME LAMPS;

INTERIOR LIGHTING (YJ)............8W-44-1

COURTESY LAMPS, READING...........8C-1

COVER AND DISC INSTALLATION,

CLUTCH.............................6-10

COVER AND DISC REMOVAL, CLUTCH.....6-10

COVER AND DISC RUNOUT, CLUTCH.......6-3

COVER AND FRAMEÐXJ, BUCKET

SEATBACK..........................23-81

COVER, ENGINE CYLINDER HEAD....9-22,9-64

COVER, FRAME CROSSMEMBER........13-16

COVER OIL SEAL REPLACEMENT,

TIMING CASE....................9-30,9-73

COVER REPLACEMENT, PITMAN SHAFT

AND SIDE..........................19-28

COVER, TIMING CASE..............9-31,9-72

COVERÐXJ, BUCKET SEAT CUSHION....23-81

COVERÐXJ, PARKING BRAKE HANDLE . . . 23-94

COVERÐXJ, REAR SEAT CUSHION......23-82

COVERÐXJ, REAR SEATBACK..........23-84

COVERSÐXJ, B/C-PILLAR AND

LIFTGATE PILLAR TRIM...............23-88

COWL GRILLE AND SCREENÐXJ........23-12

COWL GRILLE AND SCREENÐYJ.......23-109

COWL WEATHERSTRIP SEAL/

CROSSMEMBER AIR DEFLECTORÐXJ....23-11

COWL WEATHERSTRIP SEALÐYJ......23-109

CRANKCASE VENTILATION SYSTEM;

EMISSION CONTROL SYSTEMS..........25-5

CRANKCASE VENTILATION SYSTEM;

LUBRICATION AND MAINTENANCE........0-19

CRANKING SPECIFICATIONS, 2.5L

STARTING SYSTEM COLD..............8A-23

CRANKING SPECIFICATIONS, 4.0L

STARTING SYSTEM COLD..............8A-23

CRANKSHAFT MAIN BEARINGS......9-45,9-87

CRANKSHAFT POSITION SENSOR; FUEL

SYSTEM............................14-60

CRANKSHAFT POSITION SENSOR;

FUEL/IGNITION (XJ)................8W-30-3

CRANKSHAFT POSITION SENSOR;

FUEL/IGNITION (YJ)................8W-30-3

CRANKSHAFT POSITION SENSOR;

IGNITION SYSTEMS..............8D-17,8D-3

CRANKSHAFT POSITION SENSOR;

FUEL/IGNITION (XJ-RHD)............8W-30-3

CRANKSHAFT POSITION SENSOR TEST;

FUEL SYSTEM.......................14-47

CRANKSHAFT POSITION SENSOR TEST;

IGNITION SYSTEMS...................8D-7

CRANKSHAFT POSITION SENSORÐPCM

INPUT.............................14-22

CROSSMEMBER COVER, FRAME........13-16

CROSSMEMBERÐXJ, RADIATOR

SUPPORT...........................23-6

CUSHION AND COVERÐXJ, BUCKET

SEAT ..............................23-81

CUSHION COVERÐXJ, REAR SEAT......23-82

CUSHIONÐXJ, REAR SEAT.............23-82

CUT-OFF SWITCH, LOW-PRESSURE

HIGH-PRESSURE................24-15,24-16

CYCLING CLUTCH SWITCH, FIN

SENSING......................24-15,24-31

CYLINDER AND COMBINATION VALVE

INSTALLATION (WITH ABS), MASTER.....5-20

CYLINDER AND COMBINATION VALVE

REMOVAL (WITH ABS), MASTER.........5-17

CYLINDER BENCH BLEEDING, MASTER

....5-21

CYLINDER BLOCK

.................9-49,9-91

CYLINDER BORES, HONING

..............9-2

CYLINDER, CLUTCH MASTER

............0-22

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST

........................9-6

6 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 1971 of 2198

ENTRY MODULE REMOVE/INSTALL,

KEYLESS...........................8P-10

ENTRY RECEIVER, KEYLESS.............8C-1

ENTRY RECEIVERÐXJ, KEYLESS........23-93

ENTRY TRANSMITTER, KEYLESS . 8P-1,8P-7,8P-8

EQUIPMENT, REFRIGERANT.............24-7

EQUIVALENT VALUES, CONVERSION

FORMULAS.......................Intro.-11

EVACUATING REFRIGERANT SYSTEM.....24-11

EVAP CANISTER..................25-4,25-7

EVAP (EVAPORATION) CONTROL

SYSTEM............................25-4

EVAPORATIVE HOUSING

COMPONENTSÐYJ....................24-6

EVAPORATOR AND HOUSING...........24-35

EVAPORATOR COIL...................24-30

EVAPORATOR/BLOWER HOUSING........24-29

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM............................25-1

EXHAUST GRILLEÐXJ, AIR............23-25

EXHAUST HEAT SHIELDS...............11-1

EXHAUST MANIFOLDÐ2.5L ENGINE,

ENGINE.............................11-7

EXHAUST MANIFOLDÐ4.0L ENGINE,

ENGINE.............................11-7

EXHAUST PIPEÐXJ VEHICLES...........11-3

EXHAUST PIPEÐYJ VEHICLES...........11-4

EXHAUST SYSTEM; EXHAUST SYSTEM

AND INTAKE MANIFOLD................11-1

EXHAUST SYSTEM; LUBRICATION AND

MAINTENANCE.......................0-21

EXHAUST SYSTEM DIAGNOSIS..........11-2

EXHAUST TAILPIPEÐXJ VEHICLES,

MUFFLER............................11-5

EXHAUST TAILPIPEÐYJ VEHICLES,

MUFFLER............................11-6

EXPANSION VALVE..............24-31,24-35

EXTENDED IDLE SWITCH; FUEL/

IGNITION (XJ).....................8W-30-5

EXTENDED IDLE SWITCH TEST..........14-48

EXTENDED IDLE SWITCHÐPCM INPUT . . . 14-23

EXTENSIONÐXJ, QUARTER TRIM PANEL . 23-87

EXTERIOR COMPONENTS.........23-104,23-3

EXTERIOR LAMPSÐXJ................8L-18

EXTERIOR LAMPSÐYJ................8L-32

EXTERIOR MOLDINGSÐXJ, DOOR

WINDOW...........................23-54

EXTERIOR NAMEPLATES (ADHESIVE-

BACKED)ÐYJ......................23-120

EXTERIOR NAMEPLATESÐXJ...........23-26

EXTERNAL HANDLEÐXJ, DOOR.........23-48

EXTERNAL MIRRORSÐXJ.............23-27

EXTERNAL RELEASE HANDLEÐYJ,

FULL-METAL DOOR LATCH............23-140

EXTERNAL SPARE/WHEEL TIRE

CARRIERÐYJ......................23-133

(EXTERNAL)ÐYJ, HALF METAL DOOR

MIRROR..........................23-121

EYE BUSHING REPLACEMENT, LEAF

SPRING; FRONT SUSPENSION AND

AXLE...............................2-17

EYE BUSHING REPLACEMENT, LEAF

SPRING; REAR SUSPENSION AND

AXLES............................3-5,3-7

FAN RELAY AND MOTOR, RADIATOR;

AIR CONDITIONING/HEATER (XJ)......8W-42-2

FAN RELAY AND MOTOR, RADIATOR;

AIR CONDITIONING/HEATER (XJ-RHD) . . 8W-42-2

FAN RELAYÐPCM OUTPUT, RADIATOR . . . 14-28

FANÐXJ MODELS WITH 4.0L

6-CYLINDER ENGINE, AUXILIARY

ELECTRIC COOLING...................7-35

FANS, COOLING SYSTEM...............7-32

FEED, BATTERY; FUEL/IGNITION (XJ) . . . 8W-30-1

FEED, BATTERY; FUEL/IGNITION (YJ) . . . 8W-30-2

FEED, BATTERY; FUEL/IGNITION

(XJ-RHD).........................8W-30-1

FEED, IGNITION; FUEL/IGNITION

(XJ-RHD).........................8W-30-1

FENDER FLAREÐYJ.................23-114

FENDER INNER SPLASH SHIELDSÐYJ . . 23-116

FENDER SPLASH APRONSÐYJ........23-115

FENDERÐXJ, FRONT

.................23-14

FENDERSÐYJ

......................23-110

FIELDÐPCM OUTPUT, GENERATOR

......14-27

FILL LEVEL, TRANSFER CASE

LUBRICANT

........................21-284

FILLER DOOR BUMPERSÐXJ, FUEL

.....23-27FILLER HOSE SPLASH SHIELDÐXJ

VEHICLES, FUEL......................13-4

FILLER NOZZLE/TUBEÐXJ, FUEL........23-26

FILLER PROTECTOR/NOZZLEÐYJ, FUEL . 23-121

FILLER TUBE CAP, FUEL TANK;

EMISSION CONTROL SYSTEMS......25-4,25-7

FILLER TUBE CAP, FUEL TANK; FUEL

SYSTEM............................14-13

FILLER TUBE, NO-LEAD FUEL TANK......14-13

FILTER DRIERÐ2.5L ENGINES,

CONDENSER........................24-27

FILTER DRIERÐ4.0L ENGINES..........24-28

FILTER, ENGINE OIL...................0-17

FILTER, FUEL; FUEL SYSTEM.......14-60,14-9

FILTER, FUEL; LUBRICATION AND

MAINTENANCE.......................0-19

FILTER REPLACEMENT, ENGINE OIL

CHANGE............................0-16

FILTER REPLACEMENT, FLUID..........21-99

FILTER REPLACEMENT, OIL............21-103

FIN SENSING CYCLING CLUTCH SWITCH . 24-15,

24-31

FINAL ASSEMBLY; FRONT SUSPENSION

AND AXLE...........................2-46

FINAL ASSEMBLY; REAR SUSPENSION

AND AXLES..........................3-29

FIRING ORDERÐ2.5L 4-CYLINDER

ENGINE, ENGINE.....................8D-32

FIRING ORDERÐ4.0L 6-CYLINDER

ENGINE, ENGINE.....................8D-32

FIRST-REVERSE BRAKE PISTON AND

TRANSMISSION CASE OVERHAUL......21-247

FIRST/SECOND/THIRD/REVERSE

COMPONENTS......................21-168

FITTING CHART, CONNECTING ROD

BEARING........................9-41,9-83

FITTING CHART, MAIN BEARING......9-48,9-90

FITTING O-RING SEAL, FLOW CONTROL

VALVE .............................19-14

FITTING SERVICE, TRANSMISSION

COOLER LINE......................21-111

FITTINGS, TRANSMISSION COOLER LINE . 21-197

FLAREÐYJ, FENDER.................23-114

FLARES AND LINERSÐXJ, REAR

WHEELHOUSE.......................23-19

FLASHER, COMBINATION; TURN

SIGNALS (XJ).....................8W-52-1

FLASHERS, HAZARD; TURN SIGNALS

(XJ).............................8W-52-1

FLASHERS, HAZARD; TURN SIGNALS

(XJ-RHD).........................8W-52-1

FLASHERS, HAZARD; TURN SIGNALS

(YJ).............................8W-52-1

FLOOR BRACKETSÐXJ, SPARE

TIRE/WHEEL HOLDDOWN..............23-98

FLOOR CONSOLEÐXJ, FULL...........23-95

FLOOR CONSOLESÐYJ...............23-155

FLOOR MATSÐXJ, CARPETS...........23-99

FLOOR SHIFTÐXJ, MINI-CONSOLE WITH . 23-94

FLOW CONTROL VALVE FITTING O-RING

SEAL..............................19-14

FLOW TESTING, TRANSMISSION

COOLER...........................21-113

FLUID AND FILTER REPLACEMENT.......21-99

FLUID CAPACITIES.....................0-3

FLUID, CLUTCH LINKAGE................6-1

FLUID CONTAMINATION, BRAKE.......5-10,5-7

FLUID LEVEL AND CONDITION,

CHECKING.........................21-182

FLUID LEVEL, BRAKE..................5-10

FLUID LEVEL CHECK.............21-70,21-99

FLUID LEVEL, CLUTCH.................6-14

FLUID, RECOMMENDED BRAKE..........5-10

FLUID WARNING LAMP, LOW WASHER;

INSTRUMENT CLUSTER (XJ).........8W-40-2

FLUID WARNING LAMP, LOW WASHER;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

FLUID/FILTER CHANGE, REFILLING

AFTER OVERHAUL OR..........21-100,21-182

FLUID/LUBRICANTS/CLEANING

SOLVENTS, BRAKE

.....................5-2

FLUIDÐBRAKE BLEEDINGÐ

BRAKELINES AND HOSES, BRAKE

........5-10

FLUSHING, COOLING SYSTEM

CLEANING/REVERSE

...................7-22

FLUSHING, TRANSMISSION COOLER

REVERSE

..........................21-114

FLYWHEEL RUNOUT

....................6-3FLYWHEEL SERVICE...................6-16

FOG LAMP DIAGNOSIS............8L-21,8L-3

FOG LAMP REPLACEMENTÐXJ..........8L-9

FOG LAMP REPLACEMENTÐYJ.........8L-25

FOG LAMP SWITCH REPLACEMENTÐXJ . . 8L-10

FOG LAMP SWITCH REPLACEMENTÐYJ . . 8L-26

FOG LAMPS; FRONT LIGHTING (XJ) . . . 8W-50-1

FOG LAMPS; FRONT LIGHTING (XJ-RHD) . 8W-50-2

FOG LAMPS; FRONT LIGHTING (YJ) . . . 8W-50-1

FOG LAMPSÐXJ......................8L-7

FOG LAMPSÐYJ.....................8L-23

FORM-IN-PLACE GASKETS...............9-1

FORMULAS AND EQUIVALENT VALUES,

CONVERSION.....................Intro.-11

FORWARD CLUTCH OVERHAUL........21-232

FOURTH GEAR OVERDRIVE

COMPONENTS......................21-167

FOUR-WHEEL DRIVE (4WD) SWITCH;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

FOUR-WHEEL DRIVE (4WD) SWITCH;

TRANSMISSION CONTROLS (XJ-RHD) . . 8W-31-1

FOUR-WHEEL-DRIVE VEHICLE TOWING....0-12

FRAME.........................13-10,13-1

FRAME CROSSMEMBER COVER.........13-16

FRAME DIMENSIONS.............13-13,13-1

FRAME GLASS CHANNEL

REPLACEMENTÐYJ, DOOR...........23-142

FRAME REPAIRS......................13-13

FRAME STRAIGHTENING...............13-13

FRAME WEATHERSTRIP SEALÐYJ,

WINDSHIELD.......................23-146

FRAMEÐXJ, BUCKET SEATBACK COVER . . 23-81

FRAMEÐYJ, WINDSHIELD............23-145

FREQUENCY INTERFERENCE, RADIO......8F-5

FRESH AIR DOOR VACUUM MOTOR......24-34

FRESH AIR INTAKE DUCT..............24-34

FRONT AND REAR AXLES...............0-24

FRONT AXLE, MODEL 30...............2-49

FRONT BUCKET SEATSÐXJ............23-81

FRONT BUMPER.................13-16,13-5

FRONT CABLE REPLACEMENT (YJ),

PARKING BRAKE......................5-67

FRONT CARPET/MATÐXJ..............23-99

FRONT CLUTCH OVERHAUL...........21-134

FRONT DOOR SPACER BLOCKSÐTWO-

DOOR VEHICLES.....................23-53

FRONT DOOR WINDOW GLASS

REGULATORÐXJ....................23-42

FRONT DOOR WINDOW GLASSÐXJ.....23-43

FRONT DRIVE AXLE....................2-3

FRONT FENDERÐXJ..................23-14

FRONT INNER SCUFF PLATE/COWL SIDE

TRIM PANELÐXJ....................23-86

FRONT PARK/TURN SIGNAL LAMP BULB

REPLACEMENTÐXJ...................8L-9

FRONT PARK/TURN SIGNAL LAMP BULB

REPLACEMENTÐYJ..................8L-25

FRONT PLANETARY GEAR OVERHAUL . . . 21-237

FRONT SERVO AND BAND OVERHAUL . . . 21-146

FRONT SHOULDER BELT/BUCKLEÐXJ....23-90

FRONT SHOULDER BELTSÐYJ.........23-154

FRONT SKID PLATE

....................13-1

FRONT SUSPENSION

...................2-1

FRONT SUSPENSION COMPONENTS, XJ

. . . 2-49

FRONT SUSPENSION COMPONENTS, YJ

. . . 2-49

FRONT SUSPENSION, XJ

...............2-11

FRONT SUSPENSION, YJ

...............2-15

FRONT TOW HOOKS

...................13-7

FRONT WHEEL ALIGNMENT

..............2-5

FRONT WHEEL BEARINGS

..............0-28

FRONT WHEEL SENSOR INSTALLATION

....5-38

FRONT WHEEL SENSOR REMOVAL

.......5-38

FUEL DELIVERY SYSTEM

...............14-3

FUEL FILLER DOOR BUMPERSÐXJ

......23-27

FUEL FILLER HOSE SPLASH SHIELDÐXJ

VEHICLES

...........................13-4

FUEL FILLER NOZZLE/TUBEÐXJ

........23-26

FUEL FILLER PROTECTOR/NOZZLEÐYJ

. . 23-121

FUEL FILTER; FUEL SYSTEM

........14-60,14-9

FUEL FILTER; LUBRICATION AND

MAINTENANCE

.......................0-19

FUEL GAUGE; INSTRUMENT CLUSTER

(XJ)

.............................8W-40-1

FUEL GAUGE; INSTRUMENT CLUSTER

(XJ-RHD)

.........................8W-40-1

FUEL GAUGE SENDING UNIT

...........14-16

10 INDEXJ

Description Group-Page Description Group-Page Description Group-Page