center console JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 148 of 2198

bubbles that are distributed throughout the hydrau-

lic system. This will make extra bleeding operations

necessary.

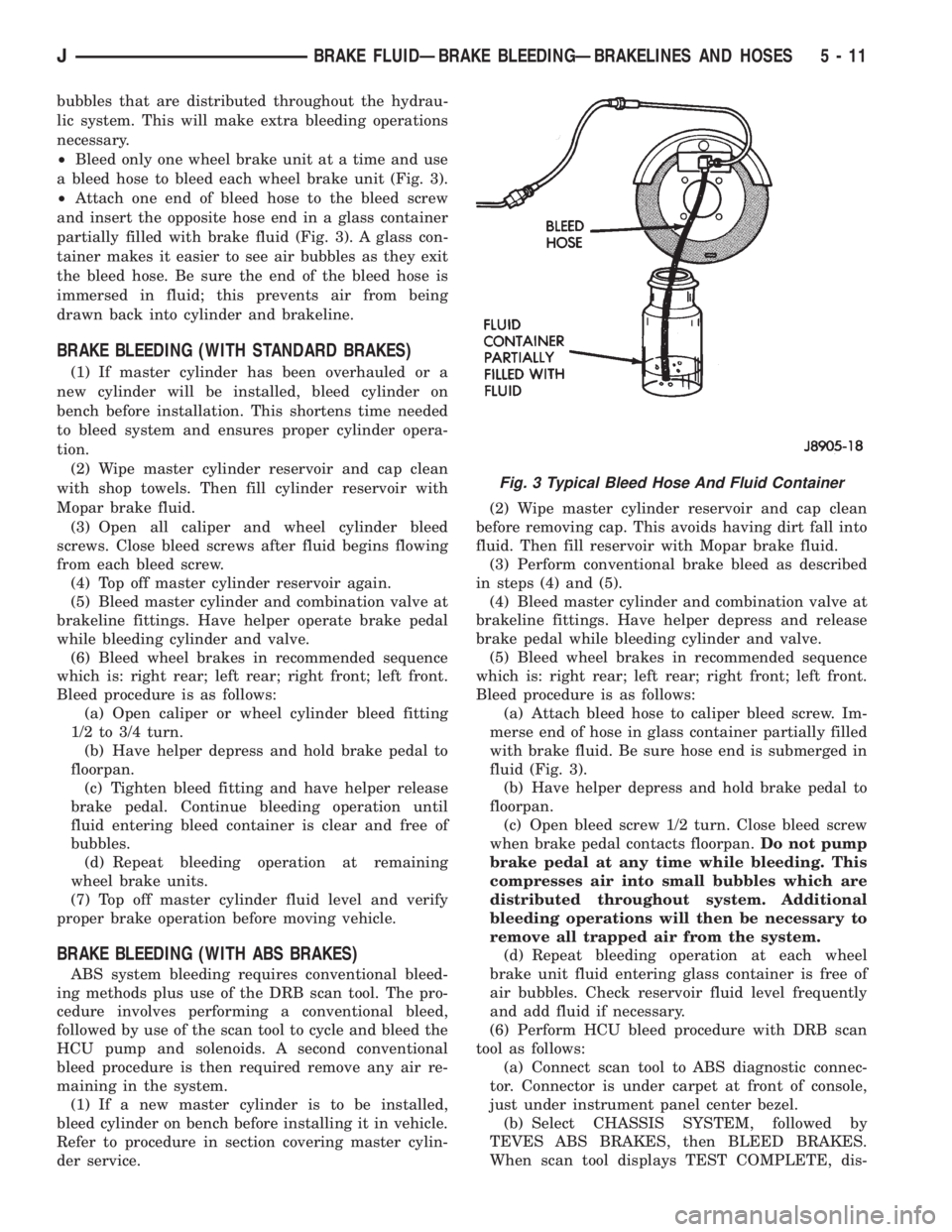

²Bleed only one wheel brake unit at a time and use

a bleed hose to bleed each wheel brake unit (Fig. 3).

²Attach one end of bleed hose to the bleed screw

and insert the opposite hose end in a glass container

partially filled with brake fluid (Fig. 3). A glass con-

tainer makes it easier to see air bubbles as they exit

the bleed hose. Be sure the end of the bleed hose is

immersed in fluid; this prevents air from being

drawn back into cylinder and brakeline.

BRAKE BLEEDING (WITH STANDARD BRAKES)

(1) If master cylinder has been overhauled or a

new cylinder will be installed, bleed cylinder on

bench before installation. This shortens time needed

to bleed system and ensures proper cylinder opera-

tion.

(2) Wipe master cylinder reservoir and cap clean

with shop towels. Then fill cylinder reservoir with

Mopar brake fluid.

(3) Open all caliper and wheel cylinder bleed

screws. Close bleed screws after fluid begins flowing

from each bleed screw.

(4) Top off master cylinder reservoir again.

(5) Bleed master cylinder and combination valve at

brakeline fittings. Have helper operate brake pedal

while bleeding cylinder and valve.

(6) Bleed wheel brakes in recommended sequence

which is: right rear; left rear; right front; left front.

Bleed procedure is as follows:

(a) Open caliper or wheel cylinder bleed fitting

1/2 to 3/4 turn.

(b) Have helper depress and hold brake pedal to

floorpan.

(c) Tighten bleed fitting and have helper release

brake pedal. Continue bleeding operation until

fluid entering bleed container is clear and free of

bubbles.

(d) Repeat bleeding operation at remaining

wheel brake units.

(7) Top off master cylinder fluid level and verify

proper brake operation before moving vehicle.

BRAKE BLEEDING (WITH ABS BRAKES)

ABS system bleeding requires conventional bleed-

ing methods plus use of the DRB scan tool. The pro-

cedure involves performing a conventional bleed,

followed by use of the scan tool to cycle and bleed the

HCU pump and solenoids. A second conventional

bleed procedure is then required remove any air re-

maining in the system.

(1) If a new master cylinder is to be installed,

bleed cylinder on bench before installing it in vehicle.

Refer to procedure in section covering master cylin-

der service.(2) Wipe master cylinder reservoir and cap clean

before removing cap. This avoids having dirt fall into

fluid. Then fill reservoir with Mopar brake fluid.

(3) Perform conventional brake bleed as described

in steps (4) and (5).

(4) Bleed master cylinder and combination valve at

brakeline fittings. Have helper depress and release

brake pedal while bleeding cylinder and valve.

(5) Bleed wheel brakes in recommended sequence

which is: right rear; left rear; right front; left front.

Bleed procedure is as follows:

(a) Attach bleed hose to caliper bleed screw. Im-

merse end of hose in glass container partially filled

with brake fluid. Be sure hose end is submerged in

fluid (Fig. 3).

(b) Have helper depress and hold brake pedal to

floorpan.

(c) Open bleed screw 1/2 turn. Close bleed screw

when brake pedal contacts floorpan.Do not pump

brake pedal at any time while bleeding. This

compresses air into small bubbles which are

distributed throughout system. Additional

bleeding operations will then be necessary to

remove all trapped air from the system.

(d) Repeat bleeding operation at each wheel

brake unit fluid entering glass container is free of

air bubbles. Check reservoir fluid level frequently

and add fluid if necessary.

(6) Perform HCU bleed procedure with DRB scan

tool as follows:

(a) Connect scan tool to ABS diagnostic connec-

tor. Connector is under carpet at front of console,

just under instrument panel center bezel.

(b) Select CHASSIS SYSTEM, followed by

TEVES ABS BRAKES, then BLEED BRAKES.

When scan tool displays TEST COMPLETE, dis-

Fig. 3 Typical Bleed Hose And Fluid Container

JBRAKE FLUIDÐBRAKE BLEEDINGÐBRAKELINES AND HOSES 5 - 11

Page 305 of 2198

DIAGNOSIS

COMPASS/DISPLAY SELF-DIAGNOSTIC TEST

This self-diagnostic test is used to determine that

the compass and all of its display segments are oper-

ating properly electrically. Initiate the self-diagnostic

test as follows:

(1) With the ignition switch in the OFF position,

simultaneously press and hold the COMP/TEMP but-

ton and the US/METRIC button.

(2) Turn ignition switch to the ON position.

(3) Continue to hold both buttons until the display

performs a walking segment test. In this test all of

the compass points are displayed, along with various

number combinations. These combinations verify that

all display segments are functional. If any segment

should fail to light during the test, the unit is faulty

and requires replacement. To repeat the test, momen-

tarily depress and release the COMP/TEMP button

one time.

(4) Momentarily depress and release the US/MET-

RIC button one time and all segments will light si-

multaneously for about 2 seconds. If any segment

should fail to light during the test, the unit is faulty

and requires replacement. To repeat the test, momen-

tarily depress and release the COMP/TEMP button

one time.

(5) Momentarily depress and release the US/MET-

RIC button one time or turn the ignition switch to

OFF to exit the self-diagnostic mode and return to

normal operation.

If the compass functions, but accuracy is sus-

pect, it may be necessary to perform a variation

adjustment. This procedure allows the unit to

accommodate variations in the earth's mag-

netic field strength based on geographic loca-

tion. See Compass Variation Adjustment, in this

group.

If the compass display has blanked out and

only CAL appears, demagnetizing may be nec-

essary to remove excessive residual magnetic

fields from the vehicle. See Compass Demagne-

tizing, in this group.

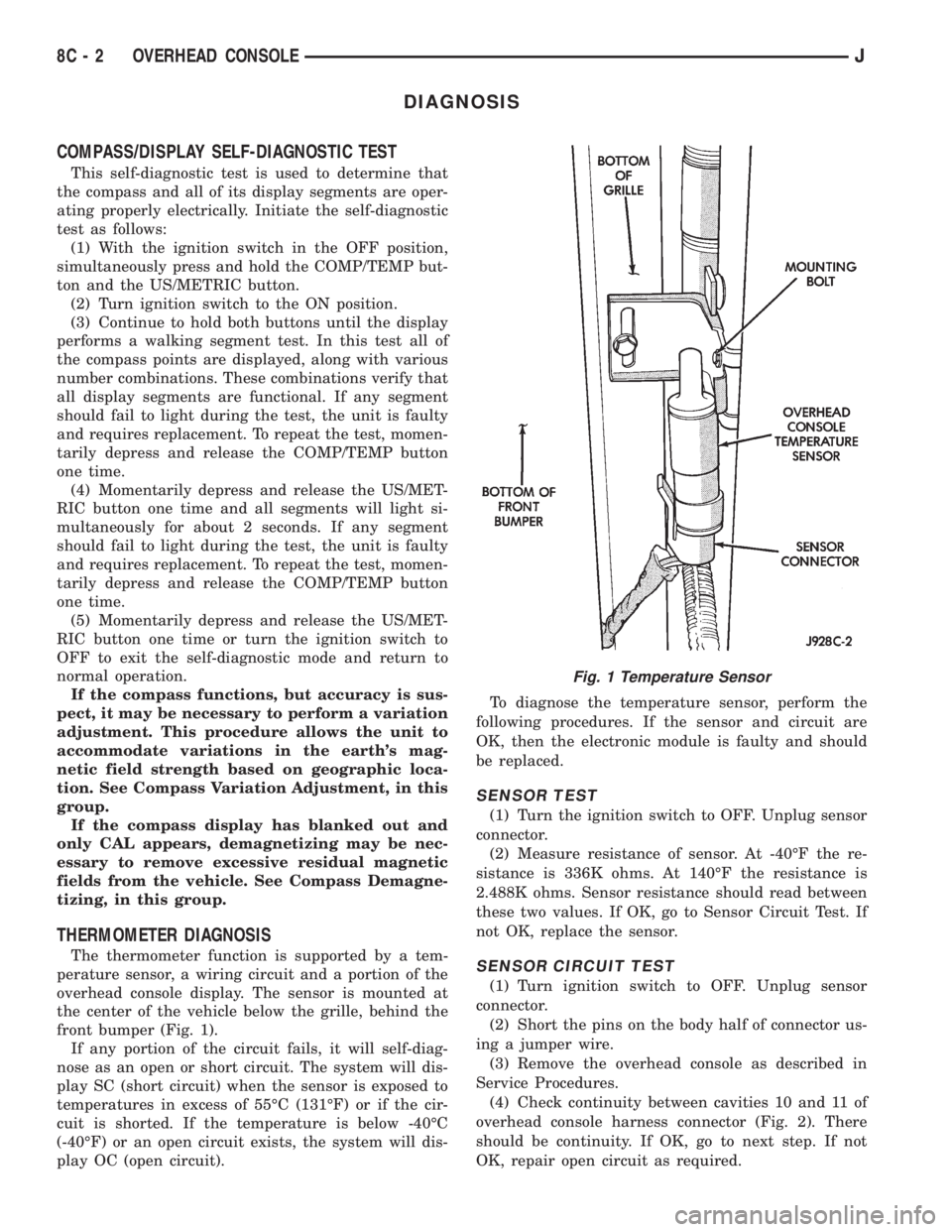

THERMOMETER DIAGNOSIS

The thermometer function is supported by a tem-

perature sensor, a wiring circuit and a portion of the

overhead console display. The sensor is mounted at

the center of the vehicle below the grille, behind the

front bumper (Fig. 1).

If any portion of the circuit fails, it will self-diag-

nose as an open or short circuit. The system will dis-

play SC (short circuit) when the sensor is exposed to

temperatures in excess of 55ÉC (131ÉF) or if the cir-

cuit is shorted. If the temperature is below -40ÉC

(-40ÉF) or an open circuit exists, the system will dis-

play OC (open circuit).To diagnose the temperature sensor, perform the

following procedures. If the sensor and circuit are

OK, then the electronic module is faulty and should

be replaced.

SENSOR TEST

(1) Turn the ignition switch to OFF. Unplug sensor

connector.

(2) Measure resistance of sensor. At -40ÉF the re-

sistance is 336K ohms. At 140ÉF the resistance is

2.488K ohms. Sensor resistance should read between

these two values. If OK, go to Sensor Circuit Test. If

not OK, replace the sensor.

SENSOR CIRCUIT TEST

(1) Turn ignition switch to OFF. Unplug sensor

connector.

(2) Short the pins on the body half of connector us-

ing a jumper wire.

(3) Remove the overhead console as described in

Service Procedures.

(4) Check continuity between cavities 10 and 11 of

overhead console harness connector (Fig. 2). There

should be continuity. If OK, go to next step. If not

OK, repair open circuit as required.

Fig. 1 Temperature Sensor

8C - 2 OVERHEAD CONSOLEJ

Page 309 of 2198

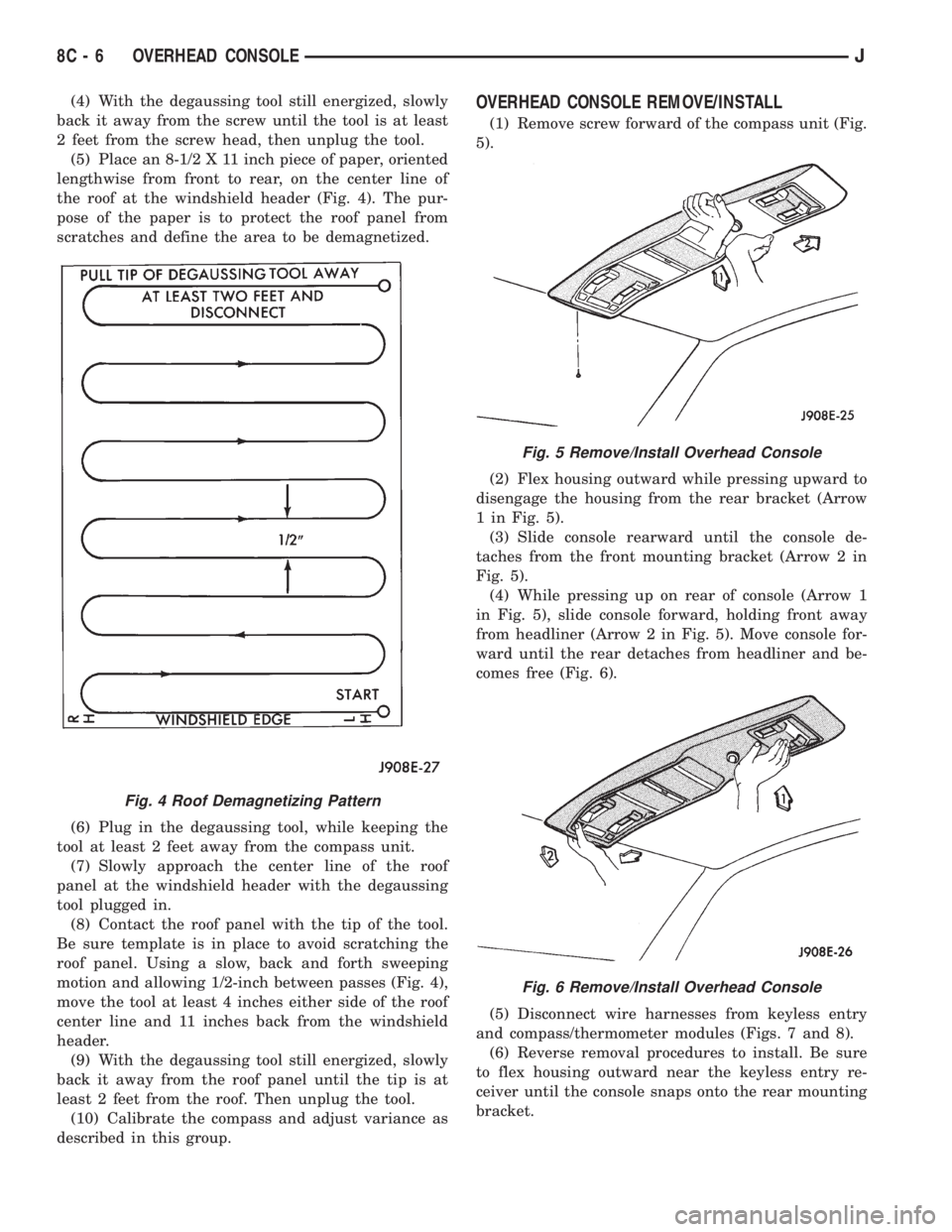

(4) With the degaussing tool still energized, slowly

back it away from the screw until the tool is at least

2 feet from the screw head, then unplug the tool.

(5) Place an 8-1/2 X 11 inch piece of paper, oriented

lengthwise from front to rear, on the center line of

the roof at the windshield header (Fig. 4). The pur-

pose of the paper is to protect the roof panel from

scratches and define the area to be demagnetized.

(6) Plug in the degaussing tool, while keeping the

tool at least 2 feet away from the compass unit.

(7) Slowly approach the center line of the roof

panel at the windshield header with the degaussing

tool plugged in.

(8) Contact the roof panel with the tip of the tool.

Be sure template is in place to avoid scratching the

roof panel. Using a slow, back and forth sweeping

motion and allowing 1/2-inch between passes (Fig. 4),

move the tool at least 4 inches either side of the roof

center line and 11 inches back from the windshield

header.

(9) With the degaussing tool still energized, slowly

back it away from the roof panel until the tip is at

least 2 feet from the roof. Then unplug the tool.

(10) Calibrate the compass and adjust variance as

described in this group.OVERHEAD CONSOLE REMOVE/INSTALL

(1) Remove screw forward of the compass unit (Fig.

5).

(2) Flex housing outward while pressing upward to

disengage the housing from the rear bracket (Arrow

1 in Fig. 5).

(3) Slide console rearward until the console de-

taches from the front mounting bracket (Arrow 2 in

Fig. 5).

(4) While pressing up on rear of console (Arrow 1

in Fig. 5), slide console forward, holding front away

from headliner (Arrow 2 in Fig. 5). Move console for-

ward until the rear detaches from headliner and be-

comes free (Fig. 6).

(5) Disconnect wire harnesses from keyless entry

and compass/thermometer modules (Figs. 7 and 8).

(6) Reverse removal procedures to install. Be sure

to flex housing outward near the keyless entry re-

ceiver until the console snaps onto the rear mounting

bracket.

Fig. 4 Roof Demagnetizing Pattern

Fig. 5 Remove/Install Overhead Console

Fig. 6 Remove/Install Overhead Console

8C - 6 OVERHEAD CONSOLEJ

Page 310 of 2198

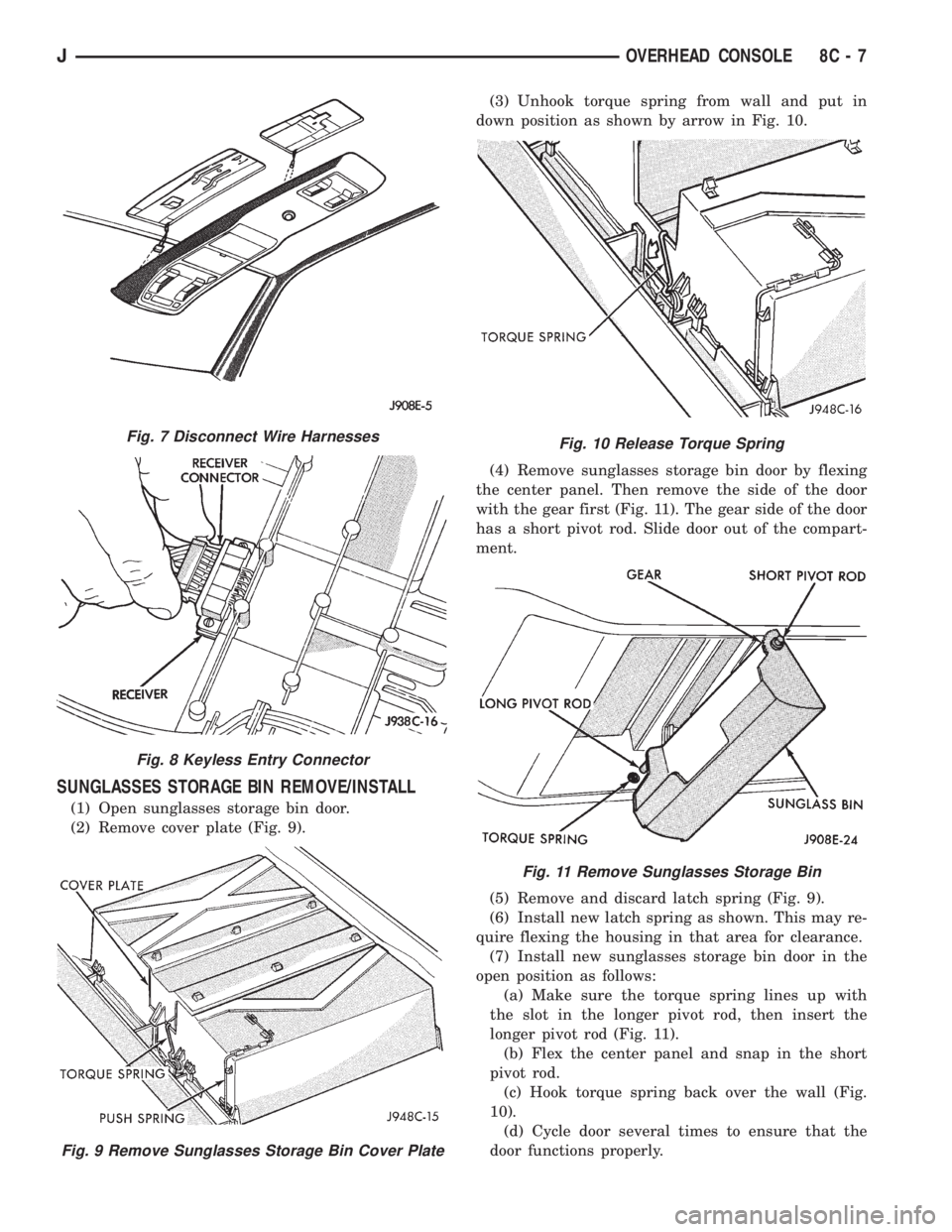

SUNGLASSES STORAGE BIN REMOVE/INSTALL

(1) Open sunglasses storage bin door.

(2) Remove cover plate (Fig. 9).(3) Unhook torque spring from wall and put in

down position as shown by arrow in Fig. 10.

(4) Remove sunglasses storage bin door by flexing

the center panel. Then remove the side of the door

with the gear first (Fig. 11). The gear side of the door

has a short pivot rod. Slide door out of the compart-

ment.

(5) Remove and discard latch spring (Fig. 9).

(6) Install new latch spring as shown. This may re-

quire flexing the housing in that area for clearance.

(7) Install new sunglasses storage bin door in the

open position as follows:

(a) Make sure the torque spring lines up with

the slot in the longer pivot rod, then insert the

longer pivot rod (Fig. 11).

(b) Flex the center panel and snap in the short

pivot rod.

(c) Hook torque spring back over the wall (Fig.

10).

(d) Cycle door several times to ensure that the

door functions properly.

Fig. 7 Disconnect Wire Harnesses

Fig. 8 Keyless Entry Connector

Fig. 9 Remove Sunglasses Storage Bin Cover Plate

Fig. 10 Release Torque Spring

Fig. 11 Remove Sunglasses Storage Bin

JOVERHEAD CONSOLE 8C - 7

Page 465 of 2198

BULB APPLICATIONÐXJ VEHICLES

GENERAL INFORMATION

The following Bulb Application Table lists the lamp

title on the left side of the column and trade number

or part number on the right.

CAUTION: Do not use bulbs that have a higher can-

dle power than the bulb listed in the Bulb Applica-

tion Table. Damage to lamp can result.

Do not touch halogen bulbs with fingers or other

oily surfaces. Bulb life will be reduced.

EXTERIOR LAMPSÐXJ

Back-up .................................................................1156

Center High Mounted Stoplamp ..........................922

Fog ............................................................................H3

Front Side Marker .................................................194

Headlamp/Sealed Beam....................................H6054

License Plate ..........................................................168

License Plate W/Outside Spare ..............................67

Park/Turn Signal ............................................2057NA

Tail/Stop ................................................................2057

Turn Signal ...........................................................1156

INTERIOR LAMPSÐXJ

Service procedures for most of the lamps in the in-

strument panel, Instrument cluster and switches are

located in Group 8E, Instrument Panel and Gauges.

Some components have lamps that can only be ser-

viced by an Authorized Service Center (ASC) after

the component is removed from the vehicle. Contact

local dealer for location of nearest ASC.

Cargo .......................................................................561

Dome .......................................................................561

Dome/Reading.........................................................906Glove Compartment ...............................................194

Overhead Console ..................................................912

Under Hood ............................................................105

Vanity Mirror ...........................................................74

Underpanel Courtesy.............................................168

INDICATOR LAMPS

Service procedures for most of the lamps in the in-

strument panel, instrument cluster and switches are

located in Group 8E, Instrument Panel and Gauges.

A/C Control ...............................................................74

Airbag ........................................................................74

Anti-lock Brake ........................................................74

Ash Receiver .........................................................1891

Brake Warning .........................................................74

Check Engine ...........................................................74

Cigar Lighter ............................................................53

Diesel Wait ...............................................................74

Fasten Seat Belts ....................................................74

Four Wheel Drive ....................................................74

Generator ................................................................194

Generator/Diesel.......................................................74

Heater Control .........................................................74

High Beam..............................................................194

Illumination ............................................................194

Low Fuel .................................................................194

Low Washer Fluid....................................................74

Radio ......................................................................ASC

Rocker Switch...........................................................37

Seat Belt ...................................................................74

Transfer Case .........................................................658

Transmission Floor Shift.......................................658

Turn Signal.............................................................194

Shift ...........................................................................74

Water In Fuel ...........................................................74

8L - 18 LAMPSÐXJ VEHICLESJ

Page 488 of 2198

POWER LOCKS

CONTENTS

page page

DIAGNOSIS............................. 2

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 8

GENERAL INFORMATION

Power locks are optional equipment on XJ (Chero-

kee) models. Power windows and the keyless entry

system are included on vehicles equipped with the

power lock option. All doors and the liftgate can be

locked and unlocked electrically by operating the

switch on either front door panel, or by operating the

lock and unlock buttons of the remote keyless entry

transmitter. The power lock and keyless entry sys-

tems operate with battery power supplied indepen-

dent of the ignition switch.

Following are general descriptions of the major

components in the power lock system. Refer to Group

8W - Wiring Diagrams for complete circuit descrip-

tions and diagrams. Refer to the owner's manual for

more information on the features and use of these

systems.

POWER LOCK SWITCH

The power locks are controlled by a two-way switch

mounted on the trim panel of each front door. The

switch controls battery feed to the lock and unlock

relays. The door lock switches can not be repaired. If

faulty, the entire switch must be replaced.

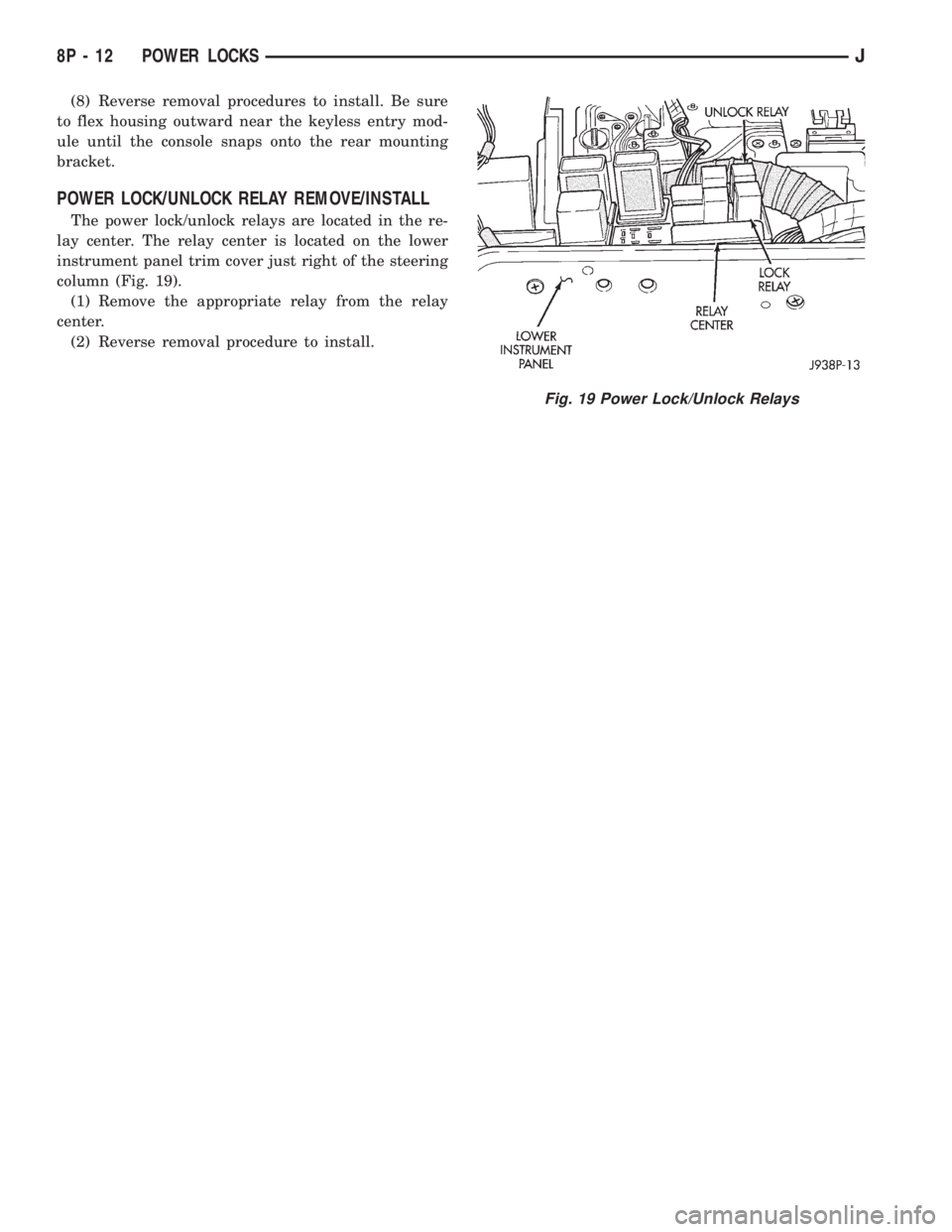

POWER LOCK/UNLOCK RELAYS

The power lock and unlock relays are located in the

relay center. The relay center is located on the lower

instrument panel reinforcement behind the lower in-

strument panel and just right of the steering column.

The relays respond to inputs from the power lock

switches and the keyless entry module by sending

the correct battery and ground feeds to the lock mo-

tors. The lock and unlock relays can not be repaired.

If faulty, they must be replaced.

POWER LOCK MOTOR

The locks are actuated by a reversible motor

mounted within each door. The motor direction iscontrolled by the battery and ground feeds from the

power lock/unlock relays. The motor can not be re-

paired. If faulty, the entire motor must be replaced.

KEYLESS ENTRY TRANSMITTER

The keyless entry transmitter is equipped with two

buttons labeled Lock and Unlock. It is also designed

to serve as a key fob and is equipped with a key ring.

Each transmitter has a different vehicle access code,

which must be programmed into the memory of the

keyless entry module in the vehicle in order to oper-

ate the locks. The operating range of the infrared

transmitter signal is up to 4.75 meters (15 feet) from

the receiver.

The transmitter operates on two CR1616 3-volt (or

equivalent) batteries. Typical battery life is from one

to two years.

KEYLESS ENTRY MODULE

The keyless entry module is mounted in a housing

on the headliner near the windshield between the

sunvisors, or inside and towards the rear of the over-

head console (if equipped). This module contains the

keyless entry receiver and program logic for the key-

less entry system.

The keyless entry module has a memory function

to retain the vehicle access code of at least one, and

up to four transmitters. The module receives input

from the remote keyless entry transmitter. In re-

sponse to that input, it is programmed to control out-

puts to the lock and unlock relays. The module can

not be repaired and, if faulty, must be replaced.

JPOWER LOCKS 8P - 1

Page 499 of 2198

(8) Reverse removal procedures to install. Be sure

to flex housing outward near the keyless entry mod-

ule until the console snaps onto the rear mounting

bracket.

POWER LOCK/UNLOCK RELAY REMOVE/INSTALL

The power lock/unlock relays are located in the re-

lay center. The relay center is located on the lower

instrument panel trim cover just right of the steering

column (Fig. 19).

(1) Remove the appropriate relay from the relay

center.

(2) Reverse removal procedure to install.

Fig. 19 Power Lock/Unlock Relays

8P - 12 POWER LOCKSJ

Page 512 of 2198

POWER MIRRORS

CONTENTS

page page

DIAGNOSIS............................. 1

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 4

GENERAL INFORMATION

Power outside rear view mirrors are an available

option on XJ (Cherokee) models. Following are gen-

eral descriptions of the major components in the

power mirror system. Refer to Group 8W - Wiring Di-

agrams for complete circuit descriptions and dia-

grams.

POWER MIRROR

The power mirrors are connected to battery feed at

all times. Each mirror head contains two electric mo-

tors, two drive mechanisms and the mirror glass.

One motor and drive controls mirror up-and-down

movement, and the other controls right-and-left

movement.

The mirror glass is the only serviced replacement

part for the power mirror assembly. If any other com-ponent of the mirror unit is faulty or damaged, the

entire assembly must be replaced.

POWER MIRROR SWITCH

Both the right and left mirror are controlled by a

multi-function switch located on the front of the cen-

ter console storage compartment, directly below the

armrest. The selector switch is moved right (right

mirror control), left (left mirror control), or center to

turn power mirrors off. Then one of four directional

control buttons is depressed to control movement of

the selected mirror up, down, right, or left. The

power mirror switch is serviced only as a complete

unit.

DIAGNOSIS

POWER MIRROR SYSTEM

(1) Check fuse 16 in Power Distribution Center

(PDC) and fuse 9 in fuseblock module. If OK, go to

next step. If not OK, replace fuse.

(2) Check for battery voltage at fuse 9 in fuseblock

module. If OK, go to next step. If not OK, repair cir-

cuit to fuse 16 in PDC.

(3) Remove power mirror switch from the center

console. See Power Mirror Switch Remove/Install.

(4) Disconnect wiring harness connector from

switch. Check for battery voltage at pink wire. If OK,

go to next step. If not OK, repair circuit to fuse 9 in

fuseblock module.

(5) Check for continuity between black wire in

switch harness connector and a good ground. There

should be continuity. If OK, go to next step. If not

OK, repair circuit to ground.

(6) Check switch continuity as shown in the Mirror

Switch Continuity charts. If OK, go to next step. If

not OK, replace switch.(7) See Power Mirror Switch illustration. Connect

a jumper wire from mirror switch connector cavity

for pin E to cavity for pin F. Now connect a second

jumper from connector cavity for pin G to each of the

following pin cavities: A, B, C, then D. In each case,

the selected mirror head should move. If OK, replace

switch. If not OK, go to next step.

(8) Remove door trim panel and unplug power mir-

ror connector inside door. Connect one jumper wire to

a good ground and a second jumper wire to a battery

feed. Connect other ends of jumpers to the mirror

side of connector in door (refer to Group 8W - Wiring

Diagrams for connector cavity identification). Mirror

head should move in each of the four directions. If

OK, repair wiring between mirror switch and door

connectors. If not OK, replace mirror.

JPOWER MIRRORS 8T - 1

Page 515 of 2198

SERVICE PROCEDURES

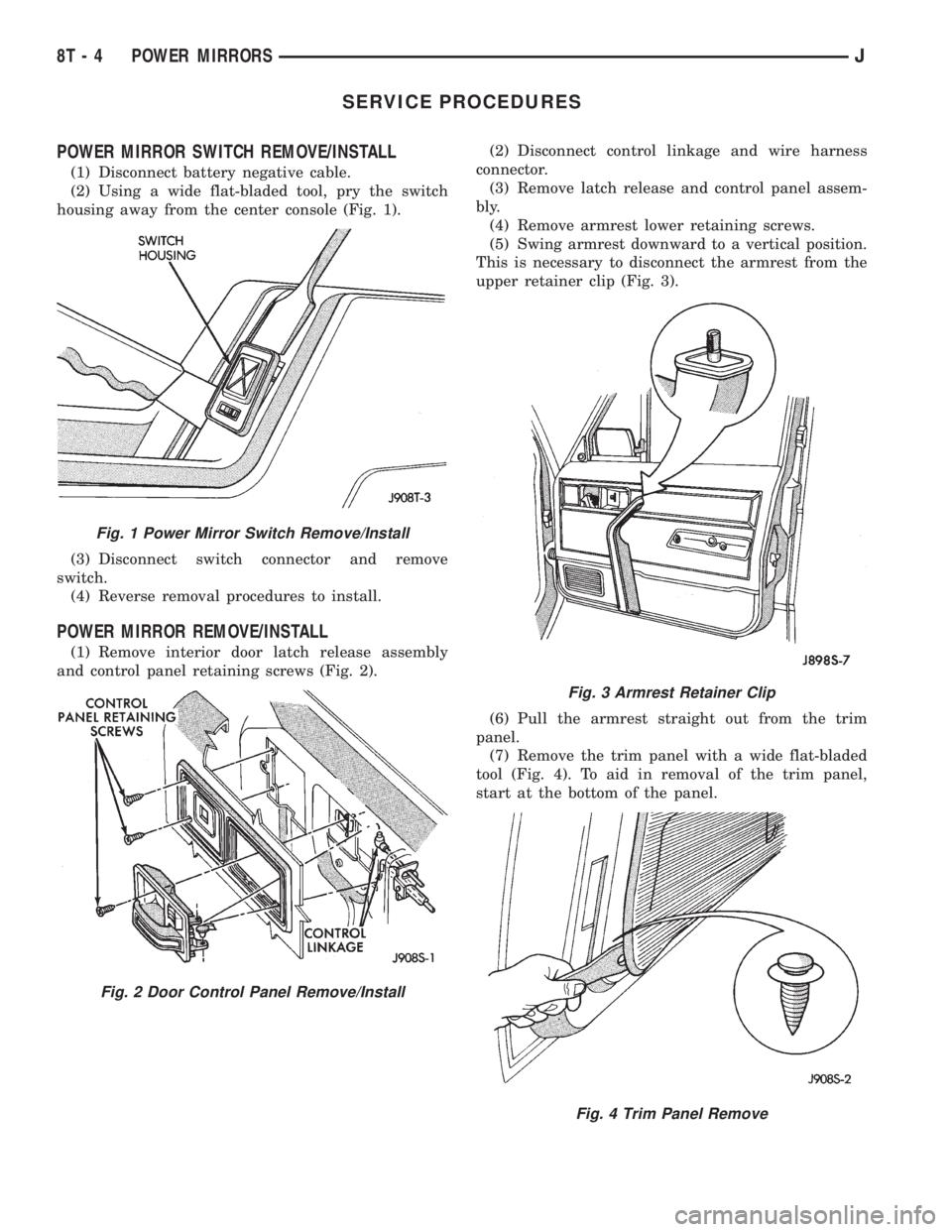

POWER MIRROR SWITCH REMOVE/INSTALL

(1) Disconnect battery negative cable.

(2) Using a wide flat-bladed tool, pry the switch

housing away from the center console (Fig. 1).

(3) Disconnect switch connector and remove

switch.

(4) Reverse removal procedures to install.

POWER MIRROR REMOVE/INSTALL

(1) Remove interior door latch release assembly

and control panel retaining screws (Fig. 2).(2) Disconnect control linkage and wire harness

connector.

(3) Remove latch release and control panel assem-

bly.

(4) Remove armrest lower retaining screws.

(5) Swing armrest downward to a vertical position.

This is necessary to disconnect the armrest from the

upper retainer clip (Fig. 3).

(6) Pull the armrest straight out from the trim

panel.

(7) Remove the trim panel with a wide flat-bladed

tool (Fig. 4). To aid in removal of the trim panel,

start at the bottom of the panel.

Fig. 1 Power Mirror Switch Remove/Install

Fig. 2 Door Control Panel Remove/Install

Fig. 3 Armrest Retainer Clip

Fig. 4 Trim Panel Remove

8T - 4 POWER MIRRORSJ

Page 544 of 2198

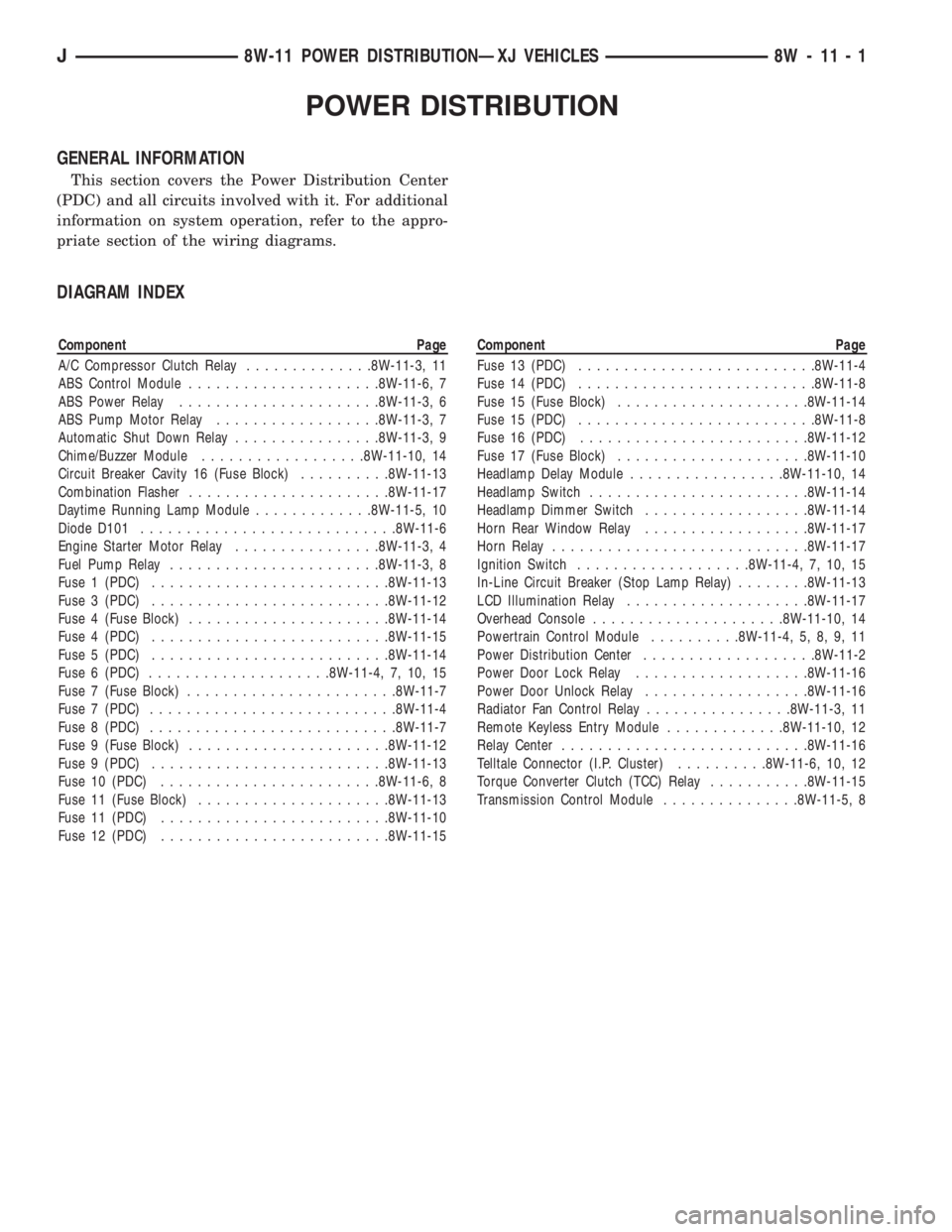

POWER DISTRIBUTION

GENERAL INFORMATION

This section covers the Power Distribution Center

(PDC) and all circuits involved with it. For additional

information on system operation, refer to the appro-

priate section of the wiring diagrams.

DIAGRAM INDEX

Component Page

A/C Compressor Clutch Relay..............8W-11-3, 11

ABS Control Module.....................8W-11-6, 7

ABS Power Relay......................8W-11-3, 6

ABS Pump Motor Relay..................8W-11-3, 7

Automatic Shut Down Relay................8W-11-3, 9

Chime/Buzzer Module..................8W-11-10, 14

Circuit Breaker Cavity 16 (Fuse Block)..........8W-11-13

Combination Flasher......................8W-11-17

Daytime Running Lamp Module.............8W-11-5, 10

Diode D101............................8W-11-6

Engine Starter Motor Relay................8W-11-3, 4

Fuel Pump Relay.......................8W-11-3, 8

Fuse 1 (PDC)..........................8W-11-13

Fuse 3 (PDC)..........................8W-11-12

Fuse 4 (Fuse Block)......................8W-11-14

Fuse 4 (PDC)..........................8W-11-15

Fuse 5 (PDC)..........................8W-11-14

Fuse 6 (PDC)....................8W-11-4, 7, 10, 15

Fuse 7 (Fuse Block).......................8W-11-7

Fuse 7 (PDC)...........................8W-11-4

Fuse 8 (PDC)...........................8W-11-7

Fuse 9 (Fuse Block)......................8W-11-12

Fuse 9 (PDC)..........................8W-11-13

Fuse 10 (PDC)........................8W-11-6, 8

Fuse 11 (Fuse Block).....................8W-11-13

Fuse 11 (PDC).........................8W-11-10

Fuse 12 (PDC).........................8W-11-15Component Page

Fuse 13 (PDC)..........................8W-11-4

Fuse 14 (PDC)..........................8W-11-8

Fuse 15 (Fuse Block).....................8W-11-14

Fuse 15 (PDC)..........................8W-11-8

Fuse 16 (PDC).........................8W-11-12

Fuse 17 (Fuse Block).....................8W-11-10

Headlamp Delay Module.................8W-11-10, 14

Headlamp Switch........................8W-11-14

Headlamp Dimmer Switch..................8W-11-14

Horn Rear Window Relay..................8W-11-17

Horn Relay............................8W-11-17

Ignition Switch...................8W-11-4, 7, 10, 15

In-Line Circuit Breaker (Stop Lamp Relay)........8W-11-13

LCD Illumination Relay....................8W-11-17

Overhead Console.....................8W-11-10, 14

Powertrain Control Module..........8W-11-4, 5, 8, 9, 11

Power Distribution Center...................8W-11-2

Power Door Lock Relay...................8W-11-16

Power Door Unlock Relay..................8W-11-16

Radiator Fan Control Relay................8W-11-3, 11

Remote Keyless Entry Module.............8W-11-10, 12

Relay Center...........................8W-11-16

Telltale Connector (I.P. Cluster)..........8W-11-6, 10, 12

Torque Converter Clutch (TCC) Relay...........8W-11-15

Transmission Control Module...............8W-11-5, 8

J8W-11 POWER DISTRIBUTIONÐXJ VEHICLES 8W - 11 - 1