fog light JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 451 of 2198

MULTI-FUNCTION SWITCH TESTING

PROCEDURESÐXJ

The multi-function switch contains electrical cir-

cuitry for:

²Headlamp Dimmer Switch.

²Passing Lights.

²Turn Signals.

²Hazard Warning.

²Windshield Wiper.

²Pulse Wiper.

²Windshield Washer.

This integrated switch is mounted to the left hand

side of the steering column. Should any function of

the switch fail, the entire switch must be replaced.

The multi-function switch also serves as a fog lamp

lock-out circuit. The circuit to the fog lamp switch is

completed only when the dimmer switch is in the low

beam position.

SWITCH TEST

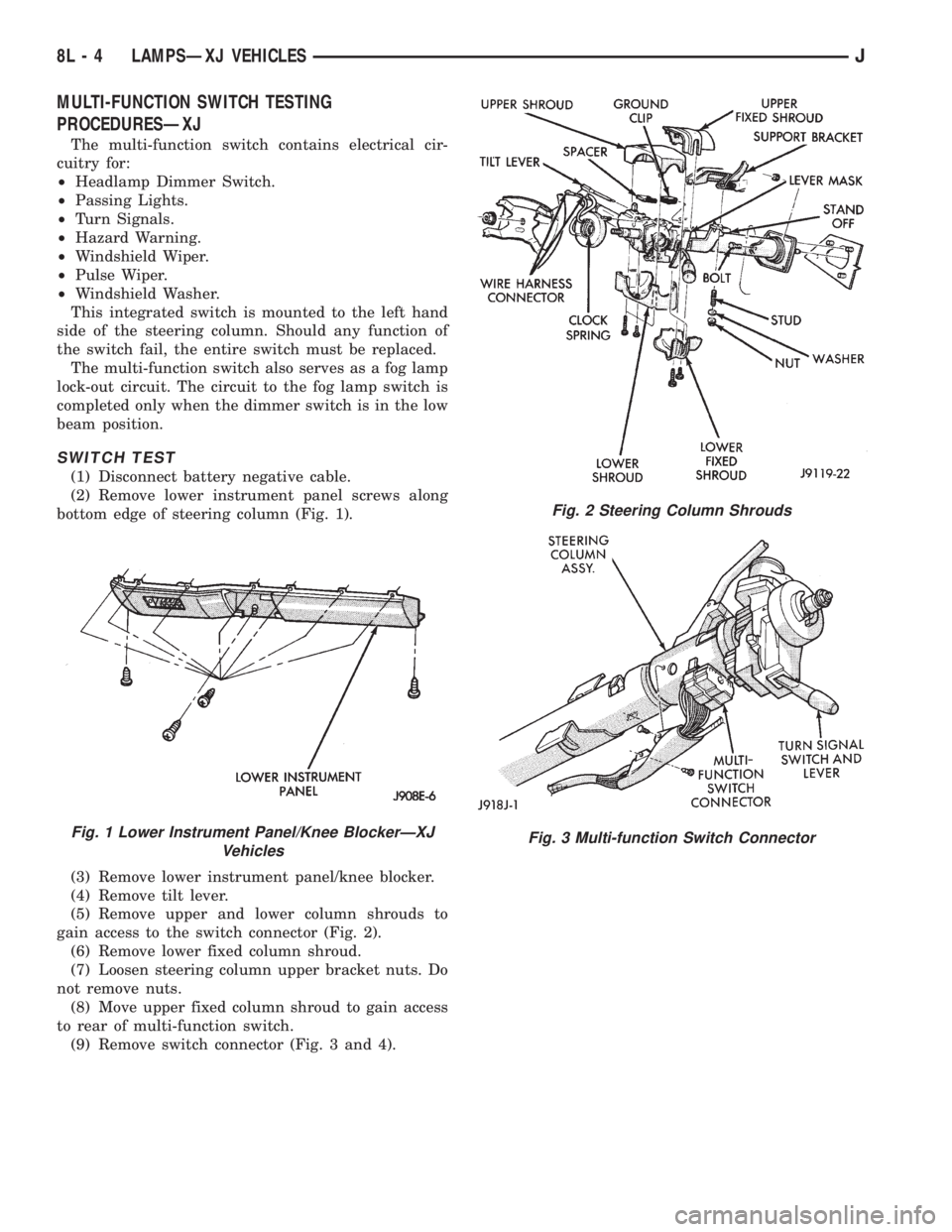

(1) Disconnect battery negative cable.

(2) Remove lower instrument panel screws along

bottom edge of steering column (Fig. 1).

(3) Remove lower instrument panel/knee blocker.

(4) Remove tilt lever.

(5) Remove upper and lower column shrouds to

gain access to the switch connector (Fig. 2).

(6) Remove lower fixed column shroud.

(7) Loosen steering column upper bracket nuts. Do

not remove nuts.

(8) Move upper fixed column shroud to gain access

to rear of multi-function switch.

(9) Remove switch connector (Fig. 3 and 4).

Fig. 1 Lower Instrument Panel/Knee BlockerÐXJ

Vehicles

Fig. 2 Steering Column Shrouds

Fig. 3 Multi-function Switch Connector

8L - 4 LAMPSÐXJ VEHICLESJ

Page 453 of 2198

SERVICE PROCEDURES

INDEX

page page

Back-Up/Rear Turn Signal/Tail Lamp Bulb

ReplacementÐXJ....................... 12

Center High Mounted Stop Lamp (CHMSL)ÐXJ . . 12

Daytime Running Lights (Canada Only)ÐXJ..... 15

Drl Module ReplacementÐXJ................ 15

Fog Lamp ReplacementÐXJ.................. 9

Fog Lamp Switch ReplacementÐXJ........... 10

Fog LampsÐXJ........................... 7

Front Park/Turn Signal Lamp Bulb

ReplacementÐXJ........................ 9

Headlamp Alignment PreparationÐXJ........... 6

Headlamp AlignmentÐXJ.................... 6

Headlamp Bulb ReplacementÐXJ.............. 7Headlamp Delay Function Trouble DiagnosisÐXJ . 14

Headlamp Delay Module ReplacementÐXJ...... 14

Headlamp SwitchÐXJ...................... 10

Headlamp/Fog Lamp Adjustment Using Alignment

ScreenÐXJ............................. 7

License Plate LampÐXJ.................... 12

Multi-Function Switch Service ProceduresÐXJ.... 11

Sentinel Headlamp Delay ModuleÐXJ.......... 14

Side Marker Lamp Bulb ReplacementÐXJ....... 10

Underhood Lamp Bulb ReplacementÐXJ....... 13

Underhood Lamp ReplacementÐXJ........... 13

Underhood Lamp Service InformationÐXJ....... 12

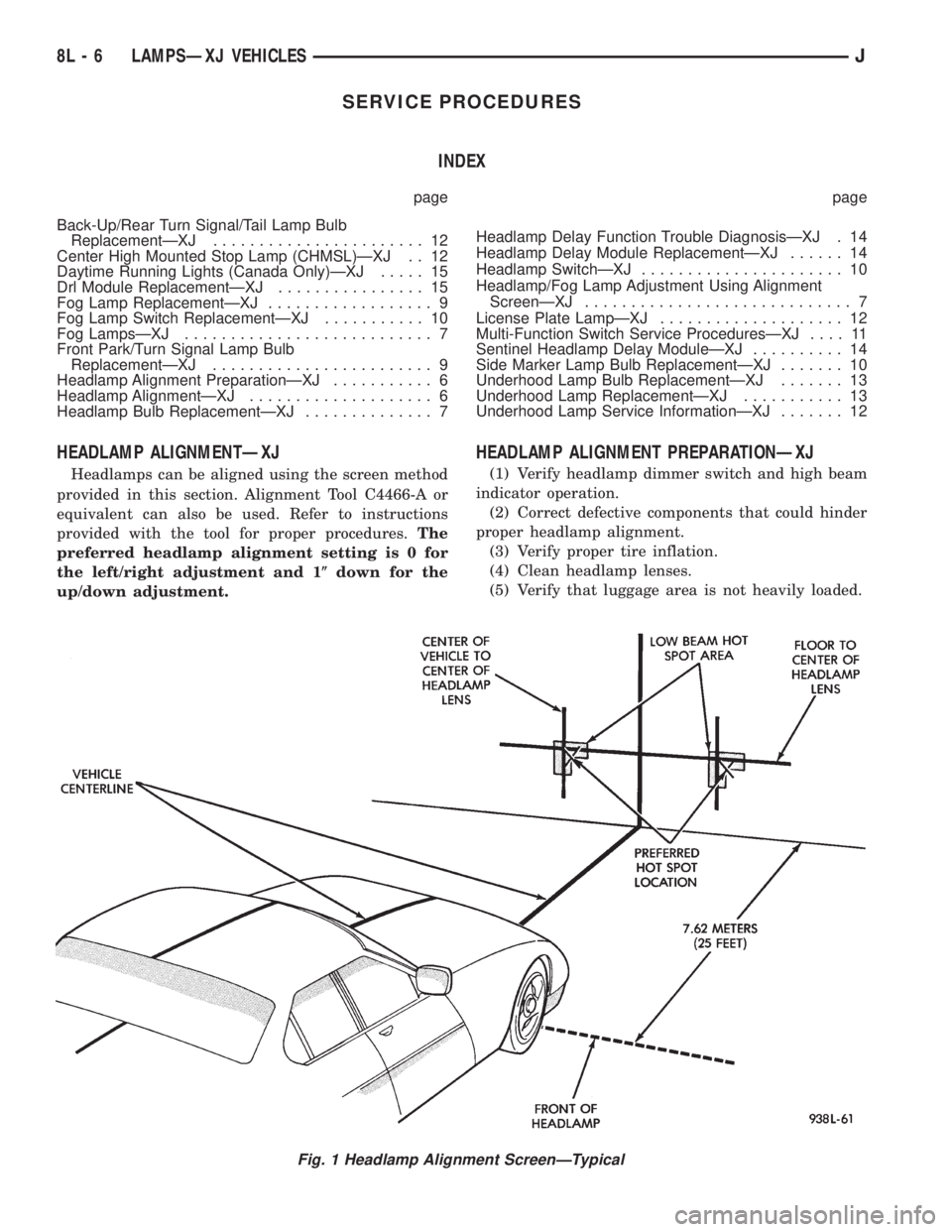

HEADLAMP ALIGNMENTÐXJ

Headlamps can be aligned using the screen method

provided in this section. Alignment Tool C4466-A or

equivalent can also be used. Refer to instructions

provided with the tool for proper procedures.The

preferred headlamp alignment setting is 0 for

the left/right adjustment and 1(down for the

up/down adjustment.

HEADLAMP ALIGNMENT PREPARATIONÐXJ

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Correct defective components that could hinder

proper headlamp alignment.

(3) Verify proper tire inflation.

(4) Clean headlamp lenses.

(5) Verify that luggage area is not heavily loaded.

Fig. 1 Headlamp Alignment ScreenÐTypical

8L - 6 LAMPSÐXJ VEHICLESJ

Page 465 of 2198

BULB APPLICATIONÐXJ VEHICLES

GENERAL INFORMATION

The following Bulb Application Table lists the lamp

title on the left side of the column and trade number

or part number on the right.

CAUTION: Do not use bulbs that have a higher can-

dle power than the bulb listed in the Bulb Applica-

tion Table. Damage to lamp can result.

Do not touch halogen bulbs with fingers or other

oily surfaces. Bulb life will be reduced.

EXTERIOR LAMPSÐXJ

Back-up .................................................................1156

Center High Mounted Stoplamp ..........................922

Fog ............................................................................H3

Front Side Marker .................................................194

Headlamp/Sealed Beam....................................H6054

License Plate ..........................................................168

License Plate W/Outside Spare ..............................67

Park/Turn Signal ............................................2057NA

Tail/Stop ................................................................2057

Turn Signal ...........................................................1156

INTERIOR LAMPSÐXJ

Service procedures for most of the lamps in the in-

strument panel, Instrument cluster and switches are

located in Group 8E, Instrument Panel and Gauges.

Some components have lamps that can only be ser-

viced by an Authorized Service Center (ASC) after

the component is removed from the vehicle. Contact

local dealer for location of nearest ASC.

Cargo .......................................................................561

Dome .......................................................................561

Dome/Reading.........................................................906Glove Compartment ...............................................194

Overhead Console ..................................................912

Under Hood ............................................................105

Vanity Mirror ...........................................................74

Underpanel Courtesy.............................................168

INDICATOR LAMPS

Service procedures for most of the lamps in the in-

strument panel, instrument cluster and switches are

located in Group 8E, Instrument Panel and Gauges.

A/C Control ...............................................................74

Airbag ........................................................................74

Anti-lock Brake ........................................................74

Ash Receiver .........................................................1891

Brake Warning .........................................................74

Check Engine ...........................................................74

Cigar Lighter ............................................................53

Diesel Wait ...............................................................74

Fasten Seat Belts ....................................................74

Four Wheel Drive ....................................................74

Generator ................................................................194

Generator/Diesel.......................................................74

Heater Control .........................................................74

High Beam..............................................................194

Illumination ............................................................194

Low Fuel .................................................................194

Low Washer Fluid....................................................74

Radio ......................................................................ASC

Rocker Switch...........................................................37

Seat Belt ...................................................................74

Transfer Case .........................................................658

Transmission Floor Shift.......................................658

Turn Signal.............................................................194

Shift ...........................................................................74

Water In Fuel ...........................................................74

8L - 18 LAMPSÐXJ VEHICLESJ

Page 469 of 2198

SERVICE PROCEDURES

INDEX

page page

Back-Up/Rear Turn Signal/Tail Lamp Bulb

ReplacementÐYJ....................... 28

Center High Mounted Stop Lamp (CHMSL)ÐYJ . . 28

Daytime Running Lights (Canada Only)ÐYJ..... 30

Drl Module ReplacementÐYJ................ 30

Fog Lamp ReplacementÐYJ................. 25

Fog Lamp Switch ReplacementÐYJ........... 26

Fog LampsÐYJ.......................... 23

Front Park/Turn Signal Lamp Bulb ReplacementÐ

YJ ................................... 25

Headlamp Alignment PreparationÐYJ.......... 22Headlamp AlignmentÐYJ................... 22

Headlamp Bulb ReplacementÐYJ............. 23

Headlamp Dimmer Switch ReplacementÐYJ..... 26

Headlamp SwitchÐYJ...................... 26

Headlamp/Fog Lamp Adjustment Using Alignment

ScreenÐYJ............................ 23

Side Marker Lamp Bulb ReplacementÐYJ....... 25

Underhood Lamp Bulb ReplacementÐYJ....... 29

Underhood Lamp ReplacementÐYJ........... 29

Underhood Lamp Service InformationÐYJ....... 28

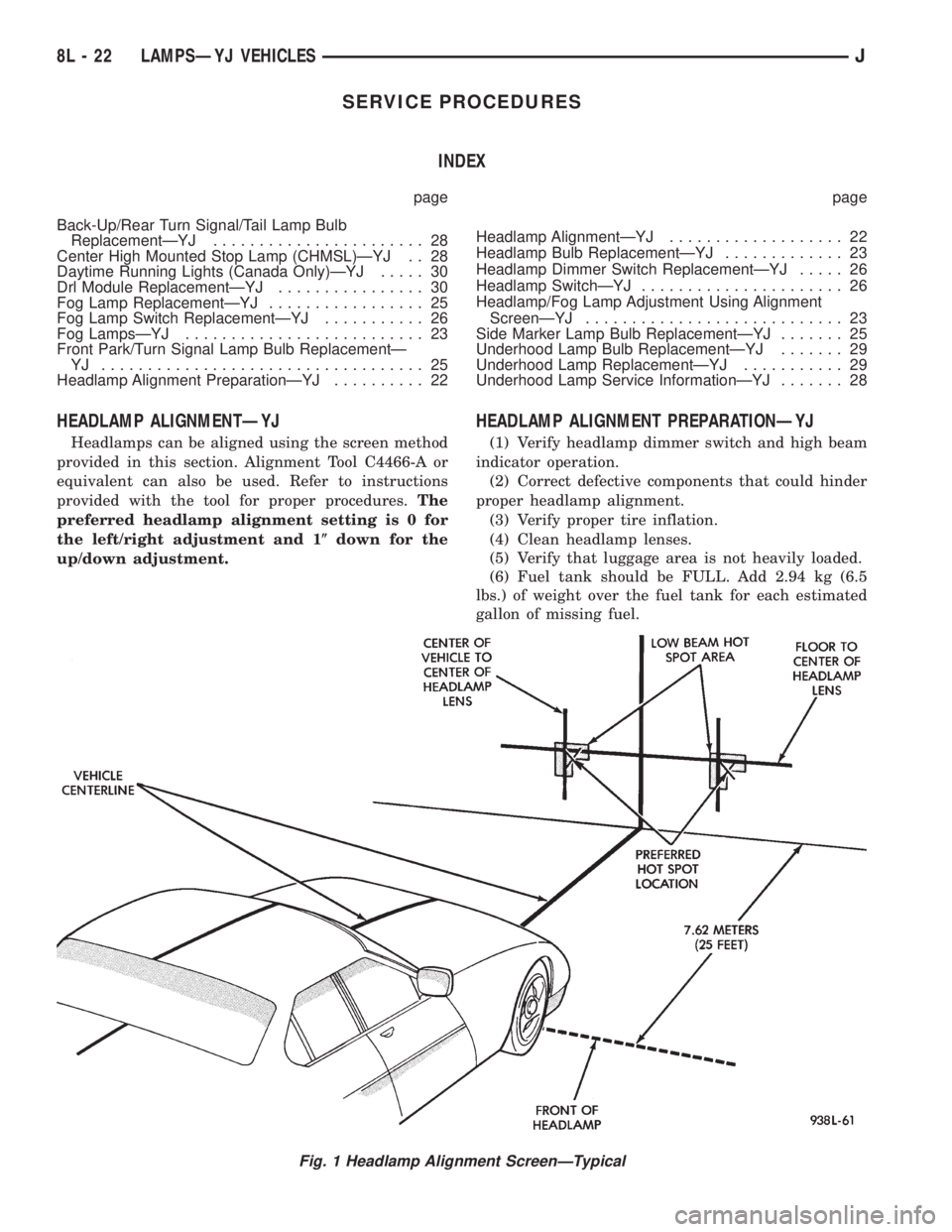

HEADLAMP ALIGNMENTÐYJ

Headlamps can be aligned using the screen method

provided in this section. Alignment Tool C4466-A or

equivalent can also be used. Refer to instructions

provided with the tool for proper procedures.The

preferred headlamp alignment setting is 0 for

the left/right adjustment and 1(down for the

up/down adjustment.

HEADLAMP ALIGNMENT PREPARATIONÐYJ

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Correct defective components that could hinder

proper headlamp alignment.

(3) Verify proper tire inflation.

(4) Clean headlamp lenses.

(5) Verify that luggage area is not heavily loaded.

(6) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

Fig. 1 Headlamp Alignment ScreenÐTypical

8L - 22 LAMPSÐYJ VEHICLESJ

Page 479 of 2198

BULB APPLICATIONÐYJ VEHICLES

GENERAL INFORMATION

The following Bulb Application Table lists the lamp

title on the left side of the column and trade number

or part number on the right.

CAUTION: Do not use bulbs that have a higher can-

dle power than the bulb listed in the Bulb Applica-

tion Table. Damage to lamp can result.

Do not touch halogen bulbs with fingers or other

oily surfaces. Bulb life will be reduced.

EXTERIOR LAMPSÐYJ

Back-up .................................................................1156

Center High Mounted Stoplamp ..........................912

Fog ............................................................................H3

Front Side Marker .................................................194

Headlamp/Sealed Beam....................................H6054

Park/Turn Signal..................................................3157

Tail/Stop ................................................................1157

INTERIOR LAMPSÐYJ

Service procedures for most of the lamps in the in-

strument panel, Instrument cluster and switches are

located in Group 8E, Instrument Panel and Gauges.

Some components have lamps that can only be ser-

viced by an Authorized Service Center (ASC) after

the component is removed from the vehicle. Contact

local dealer for location of nearest ASC.Dome/Cargo .........................................................212-2

Glove Compartment ...............................................194

Under Hood ............................................................105

Underpanel Courtesy...............................................89

INDICATOR LAMPS

Service procedures for most of the lamps in the in-

strument panel, instrument cluster and switches are

located in Group 8E, Instrument Panel and Gauges.

A/C Control ...............................................................74

Anti-lock Brake ........................................................74

Ash Receiver .........................................................1891

Brake Warning .........................................................74

Cigar Lighter ............................................................53

Fasten Seat Belts ....................................................74

Four Wheel Drive ....................................................74

Generator ................................................................194

Hazard.......................................................................74

Heater Control .......................................................194

High Beam..............................................................194

Illumination ............................................................194

Low Coolant..............................................................74

Radio ......................................................................ASC

Rocker Switch...........................................................74

Seat Belt ...................................................................74

Shift ...........................................................................74

Turn Signal.............................................................194

8L - 32 LAMPSÐYJ VEHICLESJ

Page 484 of 2198

REAR WINDOW DEFOGGER

CONTENTS

page page

DIAGNOSIS............................. 1

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 3

GENERAL INFORMATION

The electrically-heated rear window defogger is an

available option on XJ (Cherokee), and YJ (Wrangler)

models equipped with the hardtop roof option. Fol-

lowing are general descriptions of the major compo-

nents in the rear window defogger system. Refer to

Group 8W - Wiring Diagrams for complete circuit de-

scriptions and diagrams.

REAR WINDOW GLASS GRID

The heated rear window glass has two electrically-

conductive vertical bus bars and a series of horizon-

tal grid lines made of a silver-ceramic material,

which is baked on and bonded to the inside surface of

the glass. The grid lines and bus bars comprise a

parallel electrical circuit.

When the rear window defogger switch is placed in

the ON position, current is directed to the rear win-

dow grid lines through the bus bars. The grid lines

heat the rear window to clear the surface of fog or

snow. Circuit protection for the heated grid circuit is

provided by fuse 18 (XJ) or fuse 6 (YJ) in the fuse-

block module.

The grid lines and bus bars are highly resistant to

abrasion. However, it is possible for an open to occur

in an individual grid line resulting in no current flow

through the line. The grid lines can be damaged or

scraped off with sharp instruments. Care should be

taken in cleaning the glass or removing foreign ma-

terials, decals or stickers. Normal glass cleaning sol-

vents or hot water used with rags or toweling is

recommended.A repair kit is available to repair the grid lines and

bus bars, or to reinstall the heated glass pigtail

wires.

DEFOGGER SWITCH

The rear window defogger switch is mounted in the

instrument panel left of the steering column for XJ,

or right of the steering column for YJ. The switch cir-

cuit is protected by fuse 8 (XJ) or fuse 9 (YJ) in the

fuseblock module. Actuating the switch energizes the

relay and electronic timer. A light-emitting diode

(LED) in the switch (XJ), or a indicator lamp in the

switch (YJ), illuminates to indicate when the system

is turned on. The defogger switch can not be re-

paired. If faulty, the switch must be replaced.

DEFOGGER RELAY/TIMER

The defogger relay/timer is located in the relay cen-

ter on XJ models, or taped to the instrument panel

wiring harness behind the parking brake pedal in the

left cowl side area on YJ models. When the rear de-

fogger switch is actuated, the rear defogger relay is

energized. This causes current to flow through the

grid circuit for approximately 10 minutes, or until

the rear window defogger switch or ignition switch

are turned off.

DIAGNOSIS

SYSTEM TESTS

Electrically-heated rear window defogger operation

can be confirmed in the following manner:

(1) Turn the ignition switch to the ON position.

(2) Turn rear window defogger control switch ON.

(3) Monitor vehicle voltmeter. With the control

switch ON, a distinct needle deflection should be

noted.(4) The rear window defogger operation can be

checked by feeling the glass. A distinct difference in

temperature between the grid lines and adjacent

clear glass can be detected within 3 to 4 minutes of

operation.

(5) Using a DC voltmeter, contact terminal A (Fig.

1) (passenger side) with the negative lead, and termi-

JREAR WINDOW DEFOGGER 8N - 1

Page 485 of 2198

nal B (driver side) with the positive lead. The volt-

meter should read 10-14 volts.

Steps 3, 4 or 5 above will confirm system operation.

Indicator light illumination means that there is

power available at the output of the switch, but does

not confirm that power is reaching the rear window

grid lines.

If the rear window defogger does not operate, the

problem should be isolated in the following manner:

(1) Confirm that ignition switch is in ON position.

(2) Ensure that the heated rear window feed and

ground wires are connected to the glass. Confirm

that the ground wire has continuity to ground.

(3) Check fuses 8 and 18 (XJ), or fuses 6 and 9

(YJ) in fuseblock module. Fuses must be tight in

their receptacles and all electrical connections must

be secure.

When the above steps have been completed and the

system is still inoperative, one or more of the follow-

ing is faulty:

²defogger switch²relay/timer

²rear window grid lines (all grid lines would have

to be broken or one of the feed wires disconnected for

the entire system to be inoperative).

If turning the switch ON produces severe voltmeter

deflection, check for a short circuit.

REAR WINDOW GLASS GRID

To detect breaks in grid lines, the following proce-

dure is required:

(1) Turn ignition switch to the ON position. Turn

rear defogger switch ON. The indicator lamp should

light.

(2) Using a 12-volt DC voltmeter, contact vertical

bus bar on passenger side of vehicle (point A of Fig.

1) with negative lead of voltmeter. With positive lead

of voltmeter, contact vertical bus bar on driver side of

vehicle (point B of Fig. 1). The voltmeter should read

10-14 volts.

(3) With negative lead of voltmeter, contact a good

body ground point. The voltage reading should not

change. A different reading indicates a poor ground

connection.

(4) Connect negative lead of voltmeter to point A

on passenger side bus bar and touch each grid line at

mid-point with positive lead. A reading of approxi-

mately 6 volts indicates a line is good. A reading of

zero volts indicates a break in the grid line between

mid-point C and point B. A reading of 10-14 volts in-

dicates a break between mid-point C and point A.

Move toward break and voltage will change as soon

as break is crossed.

Fig. 1 Rear Window Glass Grid Test

8N - 2 REAR WINDOW DEFOGGERJ

Page 487 of 2198

(9) Allow epoxy to cure 24 hours at room tempera-

ture or use heat gun with a 260É-371ÉC (500É-700ÉF)

range for 15 minutes. Hold gun approximately

254mm (10 inches) from repaired area.

(10) After conductive epoxy is properly cured re-

move wedge or clamp from terminal or pigtail and

check operation of rear window defogger. Do not at-

tach connectors until curing is complete.

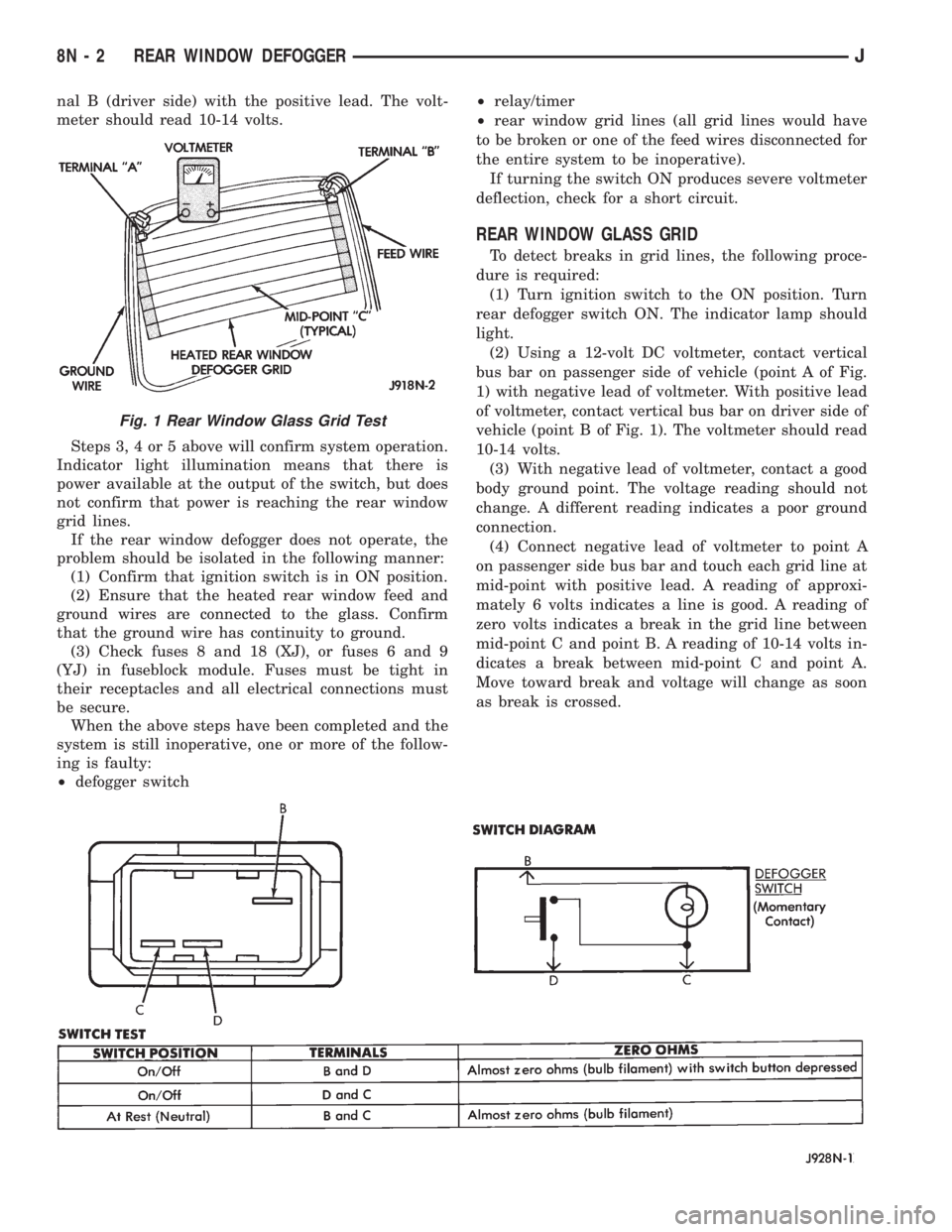

DEFOGGER SWITCH REMOVE/INSTALL

XJ MODELS

(1) Remove the instrument cluster bezel. Refer to

Group 8E - Instrument Panel and Gauges for proce-

dure.

(2) Remove the switch housing panel.

(3) Unplug the switch connector. Slightly depress

the switch mounting tabs and remove the switch.

(4) Reverse removal procedures to install.

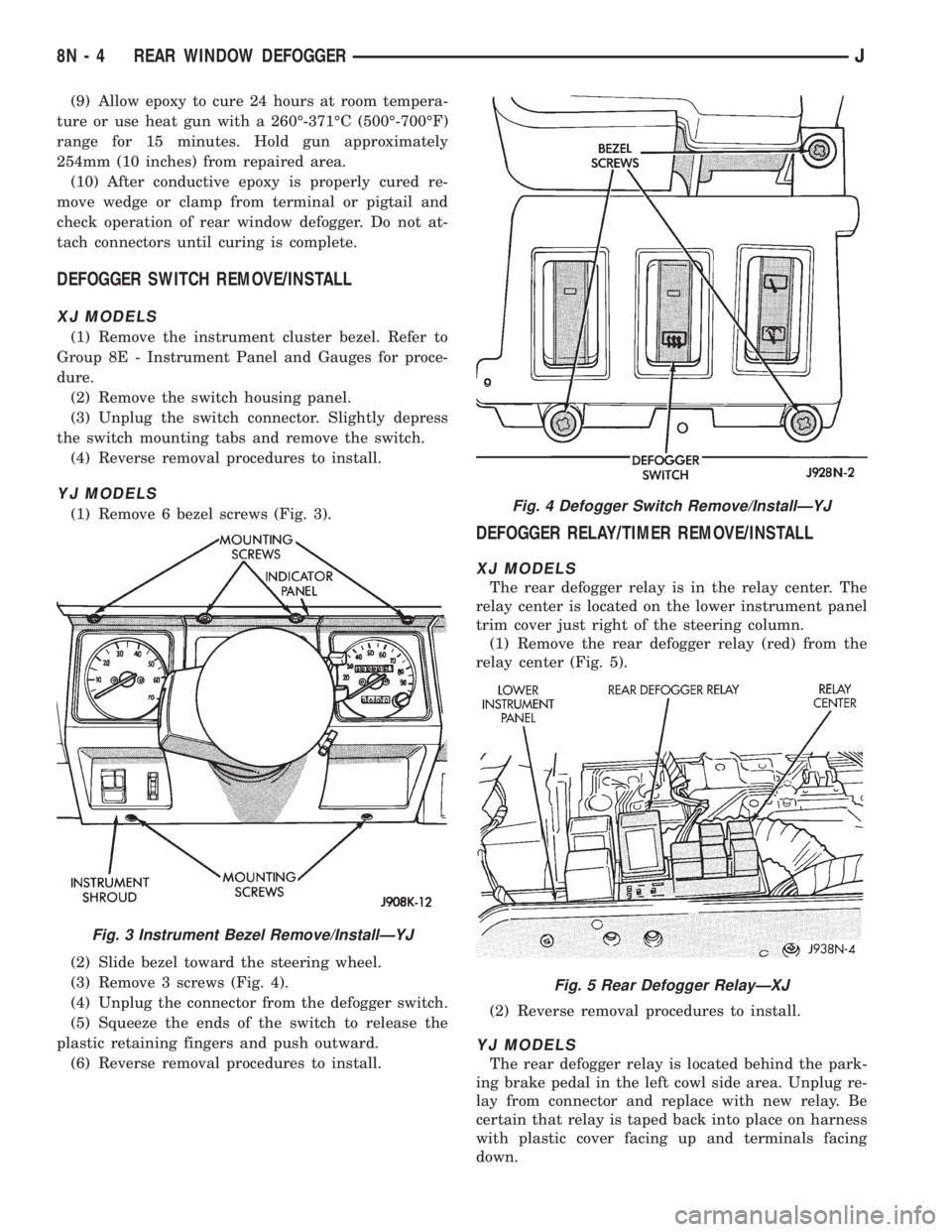

YJ MODELS

(1) Remove 6 bezel screws (Fig. 3).

(2) Slide bezel toward the steering wheel.

(3) Remove 3 screws (Fig. 4).

(4) Unplug the connector from the defogger switch.

(5) Squeeze the ends of the switch to release the

plastic retaining fingers and push outward.

(6) Reverse removal procedures to install.

DEFOGGER RELAY/TIMER REMOVE/INSTALL

XJ MODELS

The rear defogger relay is in the relay center. The

relay center is located on the lower instrument panel

trim cover just right of the steering column.

(1) Remove the rear defogger relay (red) from the

relay center (Fig. 5).

(2) Reverse removal procedures to install.

YJ MODELS

The rear defogger relay is located behind the park-

ing brake pedal in the left cowl side area. Unplug re-

lay from connector and replace with new relay. Be

certain that relay is taped back into place on harness

with plastic cover facing up and terminals facing

down.

Fig. 3 Instrument Bezel Remove/InstallÐYJ

Fig. 4 Defogger Switch Remove/InstallÐYJ

Fig. 5 Rear Defogger RelayÐXJ

8N - 4 REAR WINDOW DEFOGGERJ

Page 632 of 2198

INTERIOR LIGHTING

INDEX

page page

Cargo Lamp, Courtesy Lamps and Dome Lamp.... 1

Chime/Buzzer Module....................... 2

Diagram Index............................ 2

General Information........................ 1

Glove Box Lamp........................... 1

Ignition Switch Lamp........................ 1Instrument Panel Illumination Lamps............ 1

Reading Lamps........................... 2

Time Delay Relay.......................... 1

Underhood Lamp.......................... 2

Visor Vanity Mirror Lamps.................... 2

GENERAL INFORMATION

Circuit M1 supplies power to the glove box lamp,

left courtesy lamp, right courtesy lamp, dome lamp,

and cargo lamp. The M1 circuit also connects to the

remote keyless entry module. Circuit M1 is protected

by the ignition off draw (IOD) fuse (fuse 9) in the fuse

block.

Circuit E2 supplies power for the instrument panel

illumination lamps.

INSTRUMENT PANEL ILLUMINATION LAMPS

Circuit E2 from the headlamp switch splices to

supply power to the following illumination lamps:

²Ash receiver lamp

²Cigar lighter lamp

²Transmission range indicator lamp

²Transfer case range indicator lamp

²A/C-Heater switch lamp

²Heated rear window lamp

²Rear wiper switch lamp

²Fog lamp switch lamp

Fuse 19 in the fuse block protects circuit E2. Circuit

Z1 provides ground for all of the illumination lamps

except for the cigar lighter lamp. The cigar lighter

lamp is case grounded.

HELPFUL INFORMATION

Circuit E2 also supplies power to the radio, LCD

relay and the illumination lamps in the instrument

cluster.

IGNITION SWITCH LAMP

The time delay relay is used to allow a time-ON

function for the ignition switch lamp and the courtesy

lamp. Power for the relay is received on the M1

circuit from the IOD fuse (fuse F9) in the fuse block.

Circuit M2 provides ground for the time delay relay

through the right and left door ajar switches and the

headlamp switch. When a door is opened, or the

headlamp switch is moved to the dome lamp position,a ground path is provided for the relay on circuit M2.

This energizes the relay, causing the contacts to close.

When the relay contacts close, power is provided

through the relay to circuit M50. The M50 circuit

supplies current to the ignition switch lamp. Circuit

Z1 provides ground for the lamp.

GLOVE BOX LAMP

Circuit M1 from the IOD fuse (fuse F9) in the fuse

block powers the glove box lamp. A case grounded

switch, in series after the lamp, closes when the glove

box door is opened. The switch completes a path to

ground on circuit Z1.

CARGO LAMP, COURTESY LAMPS AND DOME

LAMP

Circuit M1 from the IOD fuse (fuse F9) in the fuse

block supplies power to the cargo, courtesy lamps and

dome lamp. This circuit is HOT at all times. The

ground path for the lamp is provided in three differ-

ent ways.

One way is through the door jamb switches. Circuit

M2 connects to the door jamb switches from the cour-

tesy and dome lamps. The switches are connected to

ground circuit Z1. When a door is opened, the plunger

in the switch closes, completing a path to ground.

The second way is through the liftgate switch. Cir-

cuit M2 connects to circuit M4 at the cargo lamp.

Circuit M4 connects to the liftgate switch. The lift-

gate switch connects to ground circuit Z1. When the

lift gate opens, the plunger in the switch closes, com-

pleting a path to ground.

The third ground path is through the headlamp

switch. Circuit M2 is spliced in with the headlamp

switch. When the operator turns the headlamp switch

to the dome lamp ON position, a ground path is

provided through the switch.

J8W-44 INTERIOR LIGHTINGÐXJ VEHICLES 8W - 44 - 1

Page 660 of 2198

FRONT LIGHTING

INDEX

page page

Daytime Running Lamp (DRL) Module........... 2

Diagram Index............................ 2

Fog Lamps............................... 1Headlamp Delay Module..................... 2

Headlamps............................... 1

Parking Lamps............................ 1

HEADLAMPS

The headlamp switch has three positions: ON,

PARK (parking lamps) and OFF. Circuit A3 from fuse

5 in the PDC connects to the headlamp switch and

feeds the circuit L7 through fuse 15 in the fuse block.

Circuit L7 connects to the headlamp switch.

Circuit A3 also splices to feed circuit L11 through

fuse 4 in the fuse block. Circuit L11 connects to the

dimmer switch circuitry in the multi-function switch.

Circuit A3 from fuse 5 in the PDC supplies battery

voltage to the headlamp switch. The headlamp switch

has an internal circuit breaker that connects circuit

A3 to circuit F34. Circuit F34 connects to the dimmer

switch circuitry in the multi-function switch.

HEADLAMP SWITCH IN OFF OR PARKING

LAMP POSITION

Circuit L11 connects to the dimmer switch portion

of the multi-function switch. Circuit L11 supplies

power for the high beams on circuit L3 when the

operator flashes the headlamps with the turn signal

stalk of the multi-function switch.

HEADLAMP SWITCH IN ON POSITION

When the headlamp switch is in the ON position,

circuit A3 from fuse 5 in the Power Distribution Cen-

ter (PDC) connects to circuit F34. Circuit F34 con-

nects to the dimmer switch portion of the multi-

function switch and feeds circuit L4. Circuit L4

powers the low beam of the headlamps.

When the operator selects high beam operation

with the turn signal stalk of the multi-function

switch, circuit L11 connects to the L3 circuit. Circuit

L3 powers high beam operation.

HEADLAMP GROUND

Circuit Z1 provides ground for both the right and

left headlamps. Circuit Z1 also supplies ground for

the fog lamps, if equipped.

HELPFUL INFORMATION

²Check fuse 5 in the PDC.

²The headlamp switch has an internal circuit

breaker.

PARKING LAMPS

Circuit A3 from fuse 5 in the Power DistributionCenter (PDC) connects to a bus bar in the fuse block

which feeds circuit L7. Fuse 15 in the fuse block

protects circuit L7.

The headlamp switch has three positions: ON,

PARK (parking lamps) and OFF, plus a dimmer

switch. When the headlamp switch is in the PARK or

ON position, the switch connects circuit L7 to circuit

L90. From the headlamp switch, circuit L90 branches

to power the front parking lamps and rear tail lamps,

side marker lamps, and rear license plate lamps.

GROUND CIRCUIT

Circuit Z1 provides a ground for the parking lamps

and turn signal lamps. The Z1 circuit also provide

ground for the headlamps.

HELPFUL INFORMATION

²Check fuse 5 in the PDC.

²Check fuse 15 in the fuse block.

²When the headlamp switch is in the PARK or ON

position, the dimmer circuit, L7, also connects to cir-

cuit E2. Circuit E2 continues through fuse 19 in the

fuse block. Circuit E2 powers the illumination lamps.

FOG LAMPS

The fog lamps are controlled by the fog lamp

switch, park lamp relay and high beam relay. The fog

lamps operate only when the headlamp switch is in

the ON position, and the operator has selected low-

beam operation. When the headlamps are in high-

beam operation, the fog lamps will not operate.

Circuit F39 from fuse 5 in the Power Distribution

Center (PDC) supplies voltage to the contact side of

the park lamp relay.

Circuit L90 supplies power to the coil side of the

park lamp relay. Circuit L35 connects to the coil side

of the relay and to circuit Z1 through the fog lamp

switch. Ground for the coil side of the relay is pro-

vided on circuit Z1 through the fog lamp switch.

When the fog lamp switch closes, the park lamp

relay contacts close and circuit F39 passes through

the relay to power the contact side of the high beam

relay. When the headlamp high beams are OFF, the

high beam relay is not energized and voltage flows

through the normally closed contacts to circuit L39.

J8W-50 FRONT LIGHTINGÐXJ VEHICLES 8W - 50 - 1