transmission repair JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 54 of 2198

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn U-

joint or by worn side-gear thrust washers. A worn

pinion gear shaft bore will also cause low speed

knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft

²Missing drive shaft balance weight

²Worn, out-of-balance wheels

²Loose wheel lug nuts

²Worn U-joint

²Loose spring U-bolts

²Loose/broken springs

²Damaged axle shaft bearings

²Loose pinion gear nut

²Excessive pinion yoke run out²Bent axle shaft

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear-end vi-

bration. Do not overlook engine accessories, brackets

and drive belts.

All driveline components should be examined be-

fore starting any repair.

Refer to Group 22ÐTires And Wheels for addi-

tional information involving vibration diagnosis.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed

²Loose engine/transmission/transfer case mounts

²Worn U-joints

²Loose spring mounts

²Loose pinion gear nut and yoke

²Excessive ring gear backlash

²Excessive differential side gear-to-case clearance

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the ve-

hicle on a hoist with the wheels free to rotate.

Instruct the helper to shift the transmission into

gear. Listen for the noise, a mechanics stethoscope is

helpful in isolating the source of a noise.

JFRONT SUSPENSION AND AXLE 2 - 19

Page 95 of 2198

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side-gear thrust washers. A worn

pinion gear shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft

²Missing drive shaft balance weight

²Worn, out-of-balance wheels

²Loose wheel lug nuts

²Worn U-joint

²Loose spring U-bolts

²Loose/broken springs

²Damaged axle shaft bearings

²Loose pinion gear nut

²Excessive pinion yoke run out

²Bent axle shaft

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear-end vi-

bration. Do not overlook engine accessories, brackets

and drive belts.

All driveline components should be examined be-

fore starting any repair.

Refer to Group 22, Wheels and Tires for additional

information.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed

²Loose engine/transmission/transfer case mounts

²Worn U-joints

²Loose spring mounts

²Loose pinion gear nut and yoke

²Excessive ring gear backlash

²Excessive side gear\ase clearance

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the ve-

hicle on a hoist with the wheels free to rotate.

Instruct the helper to shift the transmission into

gear. Listen for the noise, a mechanics stethoscope is

helpful in isolating the source of a noise.

REAR AXLE ALIGNMENT

MEASUREMENT

The following procedure can be used to determine

if abnormal rear tire tread wear is the result of a

bent or deformed rear axle shaft.

(1) Raise both rear wheels off the surface with a

frame contact hoist.

(2) Attach a one-inch long piece of masking tape at

the center of each tire tread for use as reference marks.

(3) Rotate the rear wheels until both reference

marks face the front of the vehicle. Measure the dis-

tance between the outside edges of the two pieces of

tape. Record this measurement as the front of tire

(FTR) measurement.

(4) Rotate the rear wheels until both reference

marks face the rear of the vehicle. Measure the dis-

tance between the outside edges of the two pieces of

tape. Record this measurement as the rear of tire

(RTR) measurement.

(5) Subtract the (RTR) measurement from the

(FTR) measurement to obtain the amount of wheel

toe. The acceptable rear wheel toe-in position is 1/16

inch (1.6 mm) to 3/16 inch (4.8 mm) toe-out.

(6) Rotate the rear wheels until the reference

marks are facing downward. Measure the distance

between the outside edges of the two pieces of tape.

Record this measurement as the bottom of tire (BTR)

measurement.

(7) Average the (FTR) and the (RTR) distance mea-

surements. Subtract the (BTR) measurement from

this average distance to obtain the camber. The ac-

ceptable amount of camber is 1/16 inch to 3/32 inch

(1.6 to 2.4 mm).

(FTR + RTR) DIVIDED BY 2 (TWO) MINUS

BTR EQUALS CAMBER

If the (BTR) distance measurement is less

than the average FTR and RTR distance mea-

surement, the camber will be positive(+).If

the (BTR) distance measurement is greater

than the average FTR and RTR distance, the

camber will be negative(-).

If the toe position or camber is not acceptable, a bent

or deformed rear axle shaft is most likely the cause.

LIMITED SLIP DIFFERENTIAL

Under normal traction conditions, engine torque is di-

vided evenly. With low-traction surfaces, engine torque

is transferred to the wheel with the most tire traction.

When diagnosing a limited-slip differential the wheel

with the least traction can continue spinning.

The most common problem is a chatter noise when

turning corners. Check for incorrect or contaminated

lubricant. Replace the gear lubricant if necessary.

²With Trac-LokŸ differentials add a container of

MOPAR Trac-Lok Lubricant.

This will correct the condition in most instances. If

the chatter persists, clutch damage could have oc-

curred.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches.

3 - 10 REAR SUSPENSION AND AXLESJ

Page 130 of 2198

TRAC-LOK DIFFERENTIAL

OPERATION

In a conventional differential, the torque applied to

the ring gear is transmitted to the axle shafts through

the differential gears. During normal operation, the

torque transmitted to each wheel is equal at all times.

However, if one wheel spins, the opposite wheel will

generate only as much torque as the spinning wheel.

In the Trac-Lok differential, part of the ring gear

torque is transmitted through clutch packs. The clutch

packs contain multiple disc. The clutch will have radial

grooves on the plates, and concentric grooves on the

discs or bonded fiber material which is smooth.

In operation, the Trac-Lok clutches are engaged by

two concurrent forces. The first being preload force ex-

erted through Belleville spring washers. The second is

from separating forces generated by the side gears (Fig.

1).

The Trac-Lok design provides the normal differential

action needed for turning corners. It also provides for

the transmission of equal torque to both wheels when

driving straight ahead. When one wheel loses traction,

the clutch packs transfer torque to the wheel having the

most traction. Trac-lok differentials resist wheel spin on

bumpy roads. It also provides more pulling power when

one wheel loses traction. Pulling power is continuous

until both wheels lose traction. If both wheels slip due

to unequal traction, Trac-Lok operation is normal. In ex-

treme cases of differences of traction, the wheel with

the least traction may spin. This occurs after the Trac-

Lok has transferred as much torque as possible to the

non-spinning wheel.

NOISE DIAGNOSIS

If chatter occurs when turning corners, the most

probable cause is incorrect or contaminated lubri-

cant. Before removing the Trac-Lok unit for repair,

drain, flush and refill the axle with the specified lu-

bricant. Refer to Lubricant change in this Group.

A container of Trac-Lok Lubricant (friction modi-

fier) should be added after.

Vehicles with a limited slip differential should be

road tested by making 10 to 12 slow figure-eight

turns. This maneuver will pump the lubricant

through the clutch discs.

Refer to Group 0, Lubrication and Maintenance for

additional information.

DIFFERENTIAL TEST

WARNING: WHEN SERVICING VEHICLES WITH A

LIMITED SLIP DIFFERENTIAL DO NOT USE THE EN-

GINE TO TURN THE AXLE AND WHEELS. BOTH

REAR WHEELS MUST BE RAISED AND THE VEHI-

CLE SUPPORTED. A LIMITED SLIP AXLE CAN EX-

ERT ENOUGH FORCE (IF ONE WHEEL IS IN

CONTACT WITH THE SURFACE) TO CAUSE THE

VEHICLE TO MOVE.

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Engine off, transmission in neutral, and park-

ing brake off.

(2) Place blocks in front and rear of both front

wheels.

(3) Jack up one rear wheel until it is completely off

the ground.

(4) Remove wheel and bolt special tool to studs.

Fig. 1 Limited Slip Differential OperationÐBoth

Wheels Driving

JREAR SUSPENSION AND AXLES 3 - 45

Page 140 of 2198

ABS BRAKE DIAGNOSIS

INDEX

page page

ABS Diagnostic Connector................... 3

ABS Warning Light Display................... 3

Antilock ECU and Hcu Diagnosis............... 3

DRB Scan Tool............................ 3General Information........................ 3

Normal Operating Conditions.................. 3

Wheel/Tire Size and Input Signals.............. 3

GENERAL INFORMATION

The DRB scan tool is required for ABS diagnosis.

The scan tool is used to identify ABS circuit faults.

Once a faulty circuit has been identified, refer to

the appropriate chassis/body diagnostic manual for

individual component testing.

ABS WARNING LIGHT DISPLAY

The amber antilock light illuminates at startup as

part of the system self check feature. The light illu-

minates for 2-3 seconds then goes off as part of the

normal check routine.

An ABS circuit fault is indicated when the amber

light remains on after startup, or illuminates during

vehicle operation.

Verify that a fault is actually related to the ABS

system before making repairs. For example, if the

red warning illuminates but the ABS light does not,

the problem is related to a service brake component

and not the ABS system. Or, if neither light illumi-

nates but a brake problem is noted, again, the prob-

lem is with a service brake component and not with

the ABS system.

ABS DIAGNOSTIC CONNECTOR

The ABS diagnostic connector is inside the vehicle.

The connector is the access point for the DRB scan tool.

On XJ models, the connector is located under the

instrument panel to the right of the steering column.

On some models, the connecter may be tucked under

the carpeting on the transmission tunnel. The con-

necter is a black, 6-way type.

On YJ models, the connector is under the instru-

ment panel by the the driver side kick panel. The

connecter is a black, 6 or 8-way type.

The DRB scan tool kit contains adapter cords for

both types of connecter. Use the appropriate cord for

test hookup.

DRB SCAN TOOL

ABS diagnosis is performed with the DRB scan tool.

Refer to the DRB scan tool manual for test hookup and

procedures. Diagnosis information is provided in the ap-

propriate chassis/body diagnostic manual.

WHEEL/TIRE SIZE AND INPUT SIGNALS

Antilock system operation is dependant on accurate

signals from the wheel speed sensors. Ideally, the ve-

hicle wheels and tires should all be the same size

and type. However, the Jeep ABS system is designed

to operate with a compact spare tire installed.

NORMAL OPERATING CONDITIONS

Sound Levels

The hydraulic control unit pump and solenoid valves

may produce some sound as they cycle on and off. This

is a normal condition and should not be mistaken for

faulty operation. Under most conditions, pump and so-

lenoid valve operating sounds will not be audible.

Vehicle Response In Antilock Mode

During antilock braking, the hydraulic control unit

solenoid valves cycle rapidly in response to antilock

electronic control unit signals.

The driver will experience a pulsing sensation

within the vehicle as the solenoids decrease, hold, or

increase pressure as needed. Brake pedal pulsing will

also be noted and is anormal condition.

Steering Response

A modest amount of steering input is required dur-

ing extremely high deceleration braking, or when

braking on differing traction surfaces. An example of

differing traction surfaces would be when the left

side wheels are on ice and the right side wheels are

on dry pavement.

Owner Induced Faults

Driving away with the parking brakes still applied

will cause warning light illumination. Pumping the

brake pedal will also generate a system fault and in-

terfere with ABS system operation.

ANTILOCK ECU AND HCU DIAGNOSIS

An ECU or HCU fault can only be determined

through testing with the DRB scan tool. Do not re-

place either component unless a fault is actually in-

dicated.

JABS BRAKE DIAGNOSIS 5 - 3

Page 142 of 2198

hand lever. Also note if vehicle was being operated

with parking brake partially applied (this will cause

red light to remain on).

(7) Check brake pedal operation. Verify that pedal

does not bind and has adequate free play. If pedal

lacks free play, check pedal and power booster for be-

ing loose or for bind condition. Do not road test until

condition is corrected.

(8) If components inspected look OK, road test ve-

hicle.

ROAD TESTING

(1) If amber warning light is on, problem is with

antilock system component. Refer to antilock diagno-

sis section.

(2) If red warning light is not on, proceed to step

(4).

(3) If red warning light is on, proceed as follows:

(a) See if parking brakes are applied. If brakes

are applied, release them and proceed to step (4).

(b) Note if brake pedal is abnormally low. If

pedal is definitely low and red light is still on,

check front/rear hydraulic circuits for leak.Do not

road test. Inspect and repair as needed.

(4) Check brake pedal response with transmission

in Neutral and engine running. Pedal should remain

firm under steady foot pressure. If pedal falls away,

do not road test as problem is in master cylinder, or

HCU on ABS models. If pedal holds firm, proceed to

next step.

(5) During road test, make normal and firm brake

stops in 25-35 mph range. Note faulty brake opera-

tion such as hard pedal, pull, grab, drag, noise, fade,

etc.

(6) Return to shop and inspect brake components.

Refer to inspection and diagnosis information.

COMPONENT INSPECTION

Fluid leak points and dragging brake units can

usually be located without removing any components.

The area around a leak point will be wet with fluid.

The components at a dragging brake unit (wheel,

tire, rotor) will be quite warm or hot to the touch.

Other brake problem conditions will require compo-

nent removal for proper inspection. Raise the vehicle

and remove the necessary wheels for better visual ac-

cess.

During component inspection, pay particular atten-

tion to heavily rusted/corroded brake components

(e.g. rotors, caliper pistons, brake return/holddown

springs, support plates, etc.).

Heavy accumulations of rust may be covering se-

vere damage to a brake component. It is wise to re-

move surface rust in order to accurately determine

the depth of rust penetration and damage. Light sur-

face rust is fairly normal and not a major concern (as

long as it is removed). However, heavy rust buildup,especially on high mileage vehicles may cover struc-

tural damage to such important components as

brakelines, rotors, support plates, and brake boost-

ers. Refer to the wheel brake service procedures in

this group for more information.

BRAKE WARNING LIGHT OPERATION

The red brake warning light will illuminate under

the following conditions:

²for 2-3 seconds at startup as part of normal bulb

check

²when parking brakes are applied

²low pedal caused by leak in front/rear brake hy-

draulic circuit

If the red light remains on after startup, first ver-

ify that the parking brakes are fully released. Then

check pedal action and fluid level. A red light plus

low pedal indicates the pressure differential switch

and valve have been actuated due to a system leak.

On models with ABS brakes, the amber warning

light only illuminates when an ABS malfunction has

occurred. The ABS light operates independently of

the red warning light.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brakeline, fitting, hose,

wheel cylinder, or caliper. Internal leakage in the

master cylinder caused by worn or damaged piston

cups, may also be the problem cause.

If leakage is severe, fluid will be evident at or

around the leaking component. However internal

leakage in the master cylinder will not be physically

evident. Refer to the cylinder test procedure at the

end of this section.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up, worn lining

and worn rotors or drums are the most likely causes.

However, if the pedal remains low and the red warn-

ing light is on, the likely cause is a leak in the hy-

draulic system.

A decrease in master cylinder fluid level may only

be the result of normal lining wear. Fluid level will

drop somewhat as lining wear occurs. It is a result of

the outward movement of caliper and wheel cylinder

pistons to compensate for normal wear.

SPONGY PEDAL

Air in the system is the usual cause of a spongy

pedal. Brake drums machined way beyond allowable

limits (too thin), or substandard brake lines and

hoses can also cause a condition similar to a spongy

JSERVICE BRAKE DIAGNOSIS 5 - 5

Page 238 of 2198

SERVICE PROCEDURES

INDEX

page page

Auxiliary Electric Cooling FanÐXJ Models with 4.0L

6-Cylinder Engine....................... 35

Coolant................................. 20

Coolant Reserve/Overflow System............. 24

Cooling System Cleaning/Reverse Flushing...... 22

Cooling System Fans...................... 32

Cooling System Hoses..................... 32

Draining Cooling System.................... 21

Radiator Pressure Cap..................... 25

Radiators............................... 26Refilling Cooling System.................... 21

Testing Cooling System for Leaks............. 22

Thermostat.............................. 17

Transmission Oil Coolers.................... 36

Viscous Fan Drive......................... 34

Water Pump Tests......................... 13

Water PumpsÐGeneral Information............ 13

Water PumpsÐRemoval/Installation........... 14

WATER PUMPSÐGENERAL INFORMATION

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core.

The pump is driven from the engine crankshaft by a

drive belt on all engines.

The water pump impeller is pressed onto the rear

of a shaft that rotates in bearings pressed into the

housing. The housing has a small hole to allow seep-

age to escape. The water pump seals are lubricated

by the antifreeze in the coolant mixture. No addi-

tional lubrication is necessary.

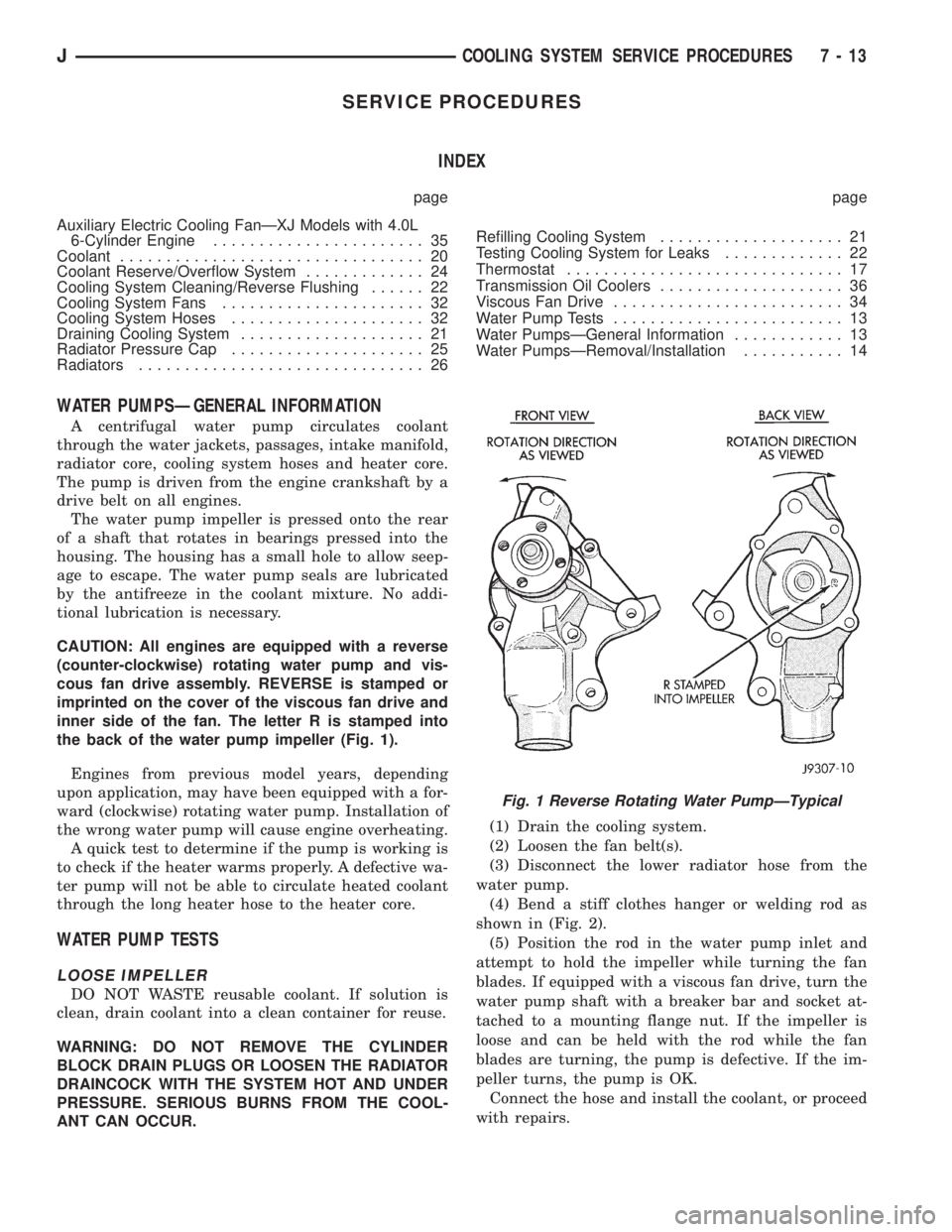

CAUTION: All engines are equipped with a reverse

(counter-clockwise) rotating water pump and vis-

cous fan drive assembly. REVERSE is stamped or

imprinted on the cover of the viscous fan drive and

inner side of the fan. The letter R is stamped into

the back of the water pump impeller (Fig. 1).

Engines from previous model years, depending

upon application, may have been equipped with a for-

ward (clockwise) rotating water pump. Installation of

the wrong water pump will cause engine overheating.

A quick test to determine if the pump is working is

to check if the heater warms properly. A defective wa-

ter pump will not be able to circulate heated coolant

through the long heater hose to the heater core.

WATER PUMP TESTS

LOOSE IMPELLER

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM THE COOL-

ANT CAN OCCUR.(1) Drain the cooling system.

(2) Loosen the fan belt(s).

(3) Disconnect the lower radiator hose from the

water pump.

(4) Bend a stiff clothes hanger or welding rod as

shown in (Fig. 2).

(5) Position the rod in the water pump inlet and

attempt to hold the impeller while turning the fan

blades. If equipped with a viscous fan drive, turn the

water pump shaft with a breaker bar and socket at-

tached to a mounting flange nut. If the impeller is

loose and can be held with the rod while the fan

blades are turning, the pump is defective. If the im-

peller turns, the pump is OK.

Connect the hose and install the coolant, or proceed

with repairs.

Fig. 1 Reverse Rotating Water PumpÐTypical

JCOOLING SYSTEM SERVICE PROCEDURES 7 - 13

Page 248 of 2198

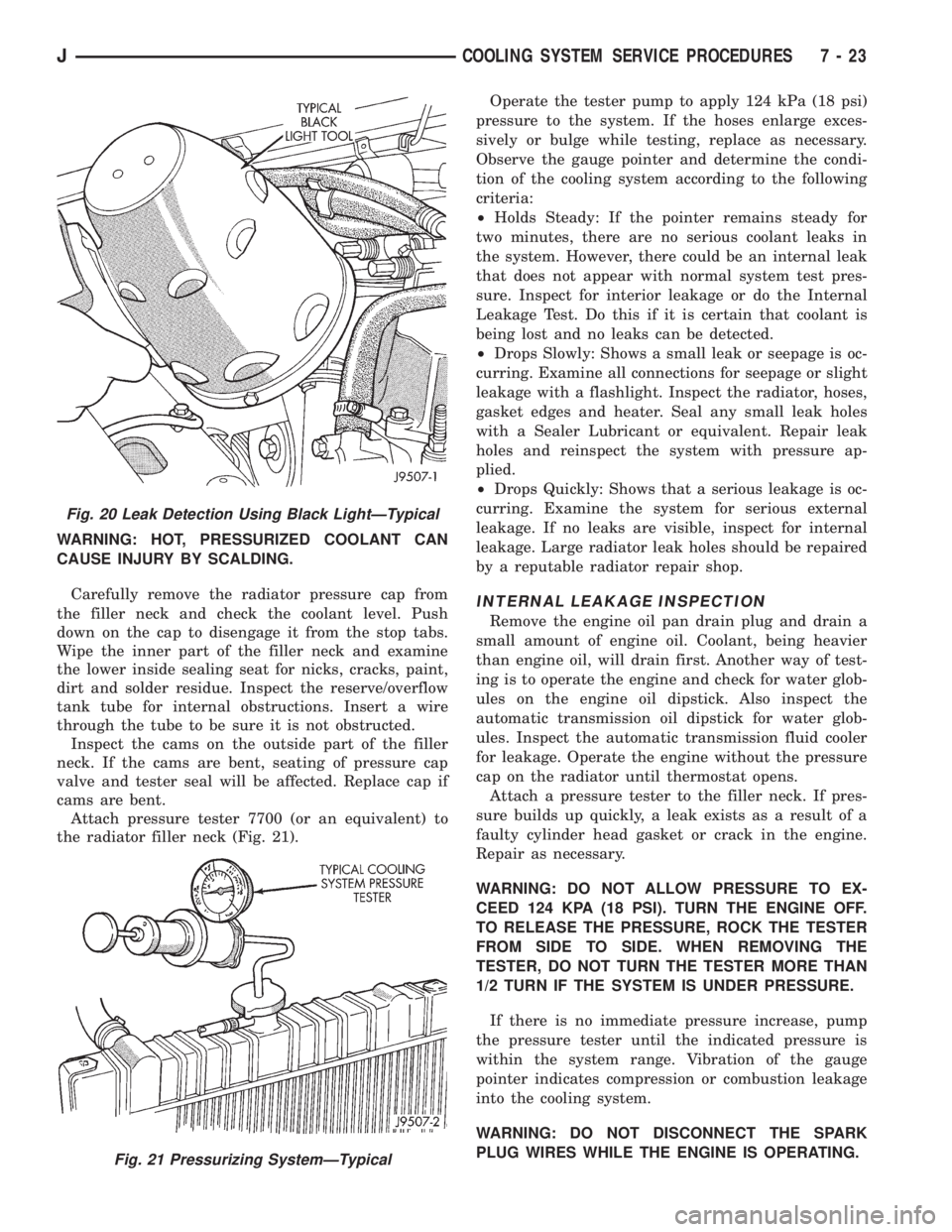

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING.

Carefully remove the radiator pressure cap from

the filler neck and check the coolant level. Push

down on the cap to disengage it from the stop tabs.

Wipe the inner part of the filler neck and examine

the lower inside sealing seat for nicks, cracks, paint,

dirt and solder residue. Inspect the reserve/overflow

tank tube for internal obstructions. Insert a wire

through the tube to be sure it is not obstructed.

Inspect the cams on the outside part of the filler

neck. If the cams are bent, seating of pressure cap

valve and tester seal will be affected. Replace cap if

cams are bent.

Attach pressure tester 7700 (or an equivalent) to

the radiator filler neck (Fig. 21).Operate the tester pump to apply 124 kPa (18 psi)

pressure to the system. If the hoses enlarge exces-

sively or bulge while testing, replace as necessary.

Observe the gauge pointer and determine the condi-

tion of the cooling system according to the following

criteria:

²Holds Steady: If the pointer remains steady for

two minutes, there are no serious coolant leaks in

the system. However, there could be an internal leak

that does not appear with normal system test pres-

sure. Inspect for interior leakage or do the Internal

Leakage Test. Do this if it is certain that coolant is

being lost and no leaks can be detected.

²Drops Slowly: Shows a small leak or seepage is oc-

curring. Examine all connections for seepage or slight

leakage with a flashlight. Inspect the radiator, hoses,

gasket edges and heater. Seal any small leak holes

with a Sealer Lubricant or equivalent. Repair leak

holes and reinspect the system with pressure ap-

plied.

²Drops Quickly: Shows that a serious leakage is oc-

curring. Examine the system for serious external

leakage. If no leaks are visible, inspect for internal

leakage. Large radiator leak holes should be repaired

by a reputable radiator repair shop.

INTERNAL LEAKAGE INSPECTION

Remove the engine oil pan drain plug and drain a

small amount of engine oil. Coolant, being heavier

than engine oil, will drain first. Another way of test-

ing is to operate the engine and check for water glob-

ules on the engine oil dipstick. Also inspect the

automatic transmission oil dipstick for water glob-

ules. Inspect the automatic transmission fluid cooler

for leakage. Operate the engine without the pressure

cap on the radiator until thermostat opens.

Attach a pressure tester to the filler neck. If pres-

sure builds up quickly, a leak exists as a result of a

faulty cylinder head gasket or crack in the engine.

Repair as necessary.

WARNING: DO NOT ALLOW PRESSURE TO EX-

CEED 124 KPA (18 PSI). TURN THE ENGINE OFF.

TO RELEASE THE PRESSURE, ROCK THE TESTER

FROM SIDE TO SIDE. WHEN REMOVING THE

TESTER, DO NOT TURN THE TESTER MORE THAN

1/2 TURN IF THE SYSTEM IS UNDER PRESSURE.

If there is no immediate pressure increase, pump

the pressure tester until the indicated pressure is

within the system range. Vibration of the gauge

pointer indicates compression or combustion leakage

into the cooling system.

WARNING: DO NOT DISCONNECT THE SPARK

PLUG WIRES WHILE THE ENGINE IS OPERATING.

Fig. 20 Leak Detection Using Black LightÐTypical

Fig. 21 Pressurizing SystemÐTypical

JCOOLING SYSTEM SERVICE PROCEDURES 7 - 23

Page 261 of 2198

nostic Procedures manual for diagnostic information

and operation of the DRB scan tool.

To test operation of the fan relay only, refer to Re-

laysÐOperation/Testing. This can be found in Group

14, Fuel Systems.

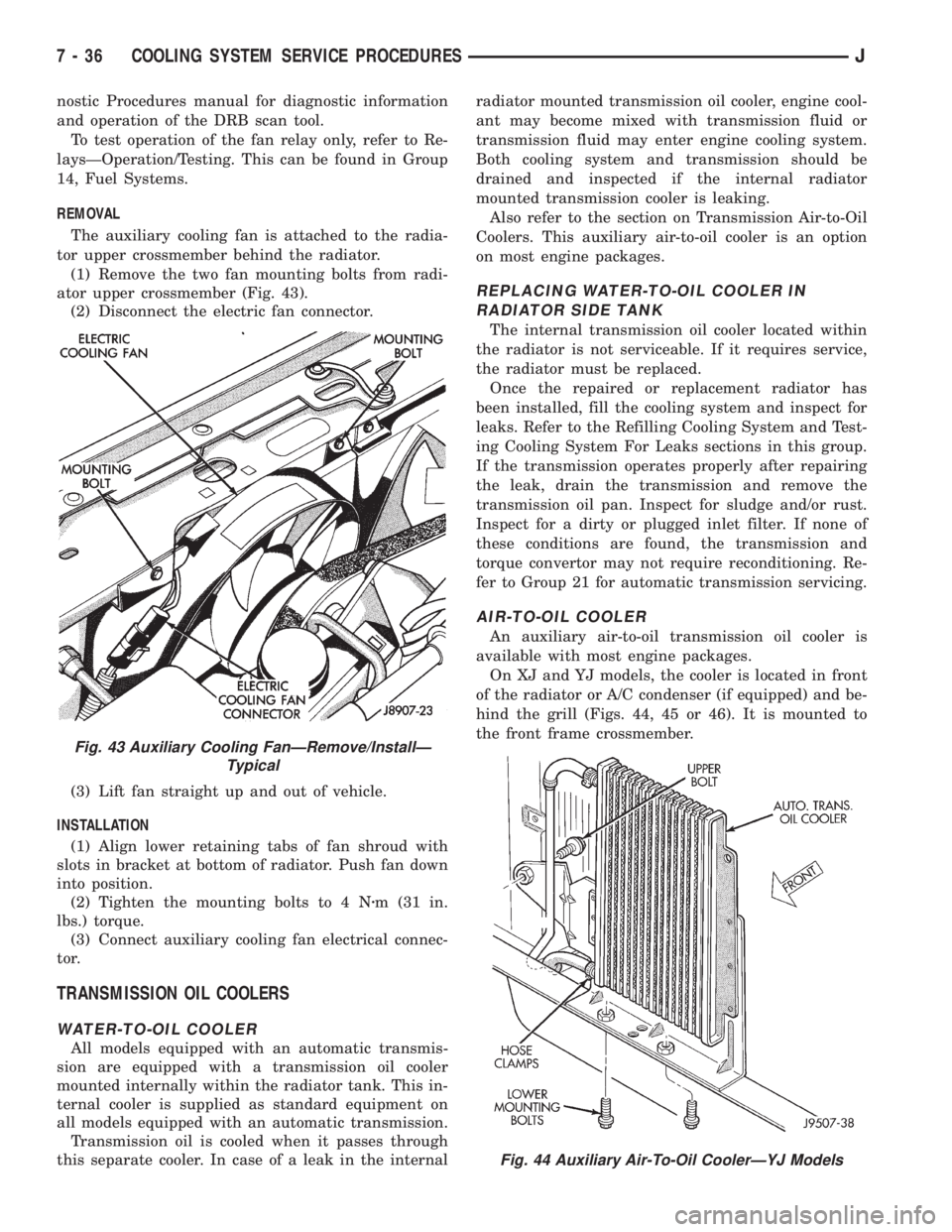

REMOVAL

The auxiliary cooling fan is attached to the radia-

tor upper crossmember behind the radiator.

(1) Remove the two fan mounting bolts from radi-

ator upper crossmember (Fig. 43).

(2) Disconnect the electric fan connector.

(3) Lift fan straight up and out of vehicle.

INSTALLATION

(1) Align lower retaining tabs of fan shroud with

slots in bracket at bottom of radiator. Push fan down

into position.

(2) Tighten the mounting bolts to 4 Nzm (31 in.

lbs.) torque.

(3) Connect auxiliary cooling fan electrical connec-

tor.

TRANSMISSION OIL COOLERS

WATER-TO-OIL COOLER

All models equipped with an automatic transmis-

sion are equipped with a transmission oil cooler

mounted internally within the radiator tank. This in-

ternal cooler is supplied as standard equipment on

all models equipped with an automatic transmission.

Transmission oil is cooled when it passes through

this separate cooler. In case of a leak in the internalradiator mounted transmission oil cooler, engine cool-

ant may become mixed with transmission fluid or

transmission fluid may enter engine cooling system.

Both cooling system and transmission should be

drained and inspected if the internal radiator

mounted transmission cooler is leaking.

Also refer to the section on Transmission Air-to-Oil

Coolers. This auxiliary air-to-oil cooler is an option

on most engine packages.

REPLACING WATER-TO-OIL COOLER IN

RADIATOR SIDE TANK

The internal transmission oil cooler located within

the radiator is not serviceable. If it requires service,

the radiator must be replaced.

Once the repaired or replacement radiator has

been installed, fill the cooling system and inspect for

leaks. Refer to the Refilling Cooling System and Test-

ing Cooling System For Leaks sections in this group.

If the transmission operates properly after repairing

the leak, drain the transmission and remove the

transmission oil pan. Inspect for sludge and/or rust.

Inspect for a dirty or plugged inlet filter. If none of

these conditions are found, the transmission and

torque convertor may not require reconditioning. Re-

fer to Group 21 for automatic transmission servicing.

AIR-TO-OIL COOLER

An auxiliary air-to-oil transmission oil cooler is

available with most engine packages.

On XJ and YJ models, the cooler is located in front

of the radiator or A/C condenser (if equipped) and be-

hind the grill (Figs. 44, 45 or 46). It is mounted to

the front frame crossmember.

Fig. 43 Auxiliary Cooling FanÐRemove/InstallÐ

Typical

Fig. 44 Auxiliary Air-To-Oil CoolerÐYJ Models

7 - 36 COOLING SYSTEM SERVICE PROCEDURESJ

Page 282 of 2198

STARTING SYSTEM

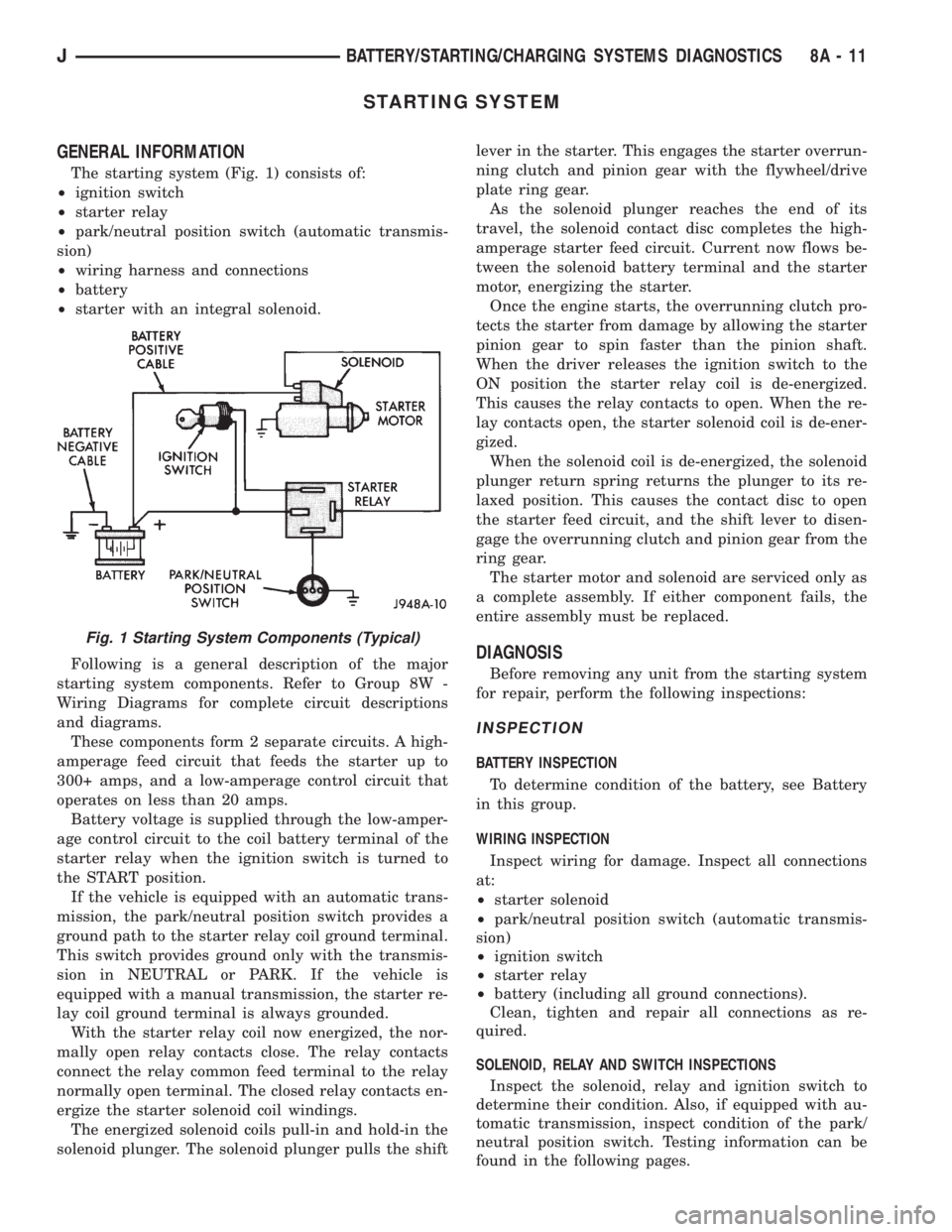

GENERAL INFORMATION

The starting system (Fig. 1) consists of:

²ignition switch

²starter relay

²park/neutral position switch (automatic transmis-

sion)

²wiring harness and connections

²battery

²starter with an integral solenoid.

Following is a general description of the major

starting system components. Refer to Group 8W -

Wiring Diagrams for complete circuit descriptions

and diagrams.

These components form 2 separate circuits. A high-

amperage feed circuit that feeds the starter up to

300+ amps, and a low-amperage control circuit that

operates on less than 20 amps.

Battery voltage is supplied through the low-amper-

age control circuit to the coil battery terminal of the

starter relay when the ignition switch is turned to

the START position.

If the vehicle is equipped with an automatic trans-

mission, the park/neutral position switch provides a

ground path to the starter relay coil ground terminal.

This switch provides ground only with the transmis-

sion in NEUTRAL or PARK. If the vehicle is

equipped with a manual transmission, the starter re-

lay coil ground terminal is always grounded.

With the starter relay coil now energized, the nor-

mally open relay contacts close. The relay contacts

connect the relay common feed terminal to the relay

normally open terminal. The closed relay contacts en-

ergize the starter solenoid coil windings.

The energized solenoid coils pull-in and hold-in the

solenoid plunger. The solenoid plunger pulls the shiftlever in the starter. This engages the starter overrun-

ning clutch and pinion gear with the flywheel/drive

plate ring gear.

As the solenoid plunger reaches the end of its

travel, the solenoid contact disc completes the high-

amperage starter feed circuit. Current now flows be-

tween the solenoid battery terminal and the starter

motor, energizing the starter.

Once the engine starts, the overrunning clutch pro-

tects the starter from damage by allowing the starter

pinion gear to spin faster than the pinion shaft.

When the driver releases the ignition switch to the

ON position the starter relay coil is de-energized.

This causes the relay contacts to open. When the re-

lay contacts open, the starter solenoid coil is de-ener-

gized.

When the solenoid coil is de-energized, the solenoid

plunger return spring returns the plunger to its re-

laxed position. This causes the contact disc to open

the starter feed circuit, and the shift lever to disen-

gage the overrunning clutch and pinion gear from the

ring gear.

The starter motor and solenoid are serviced only as

a complete assembly. If either component fails, the

entire assembly must be replaced.

DIAGNOSIS

Before removing any unit from the starting system

for repair, perform the following inspections:

INSPECTION

BATTERY INSPECTION

To determine condition of the battery, see Battery

in this group.

WIRING INSPECTION

Inspect wiring for damage. Inspect all connections

at:

²starter solenoid

²park/neutral position switch (automatic transmis-

sion)

²ignition switch

²starter relay

²battery (including all ground connections).

Clean, tighten and repair all connections as re-

quired.

SOLENOID, RELAY AND SWITCH INSPECTIONS

Inspect the solenoid, relay and ignition switch to

determine their condition. Also, if equipped with au-

tomatic transmission, inspect condition of the park/

neutral position switch. Testing information can be

found in the following pages.

Fig. 1 Starting System Components (Typical)

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 11

Page 286 of 2198

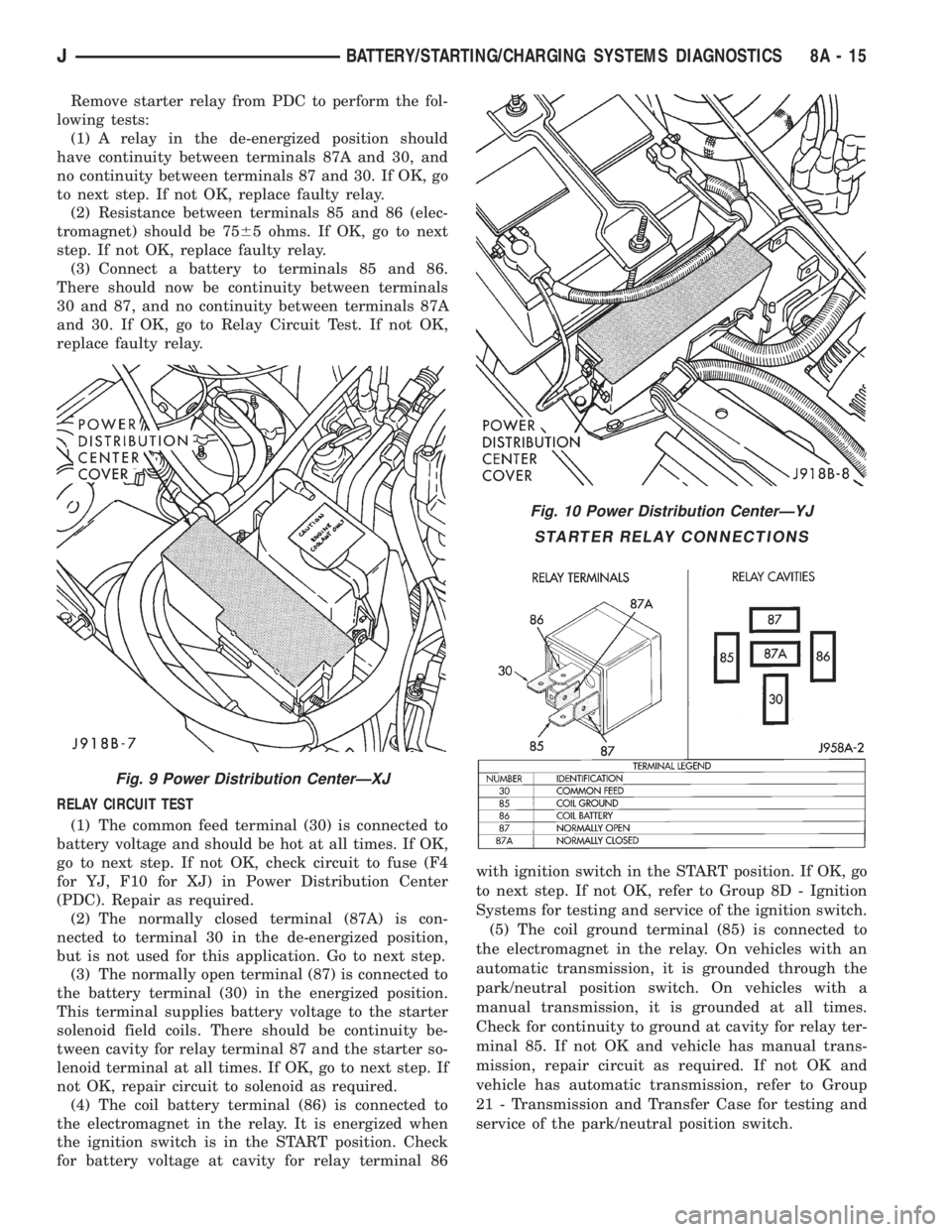

Remove starter relay from PDC to perform the fol-

lowing tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to next step. If not OK, replace faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 7565 ohms. If OK, go to next

step. If not OK, replace faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, go to Relay Circuit Test. If not OK,

replace faulty relay.

RELAY CIRCUIT TEST

(1) The common feed terminal (30) is connected to

battery voltage and should be hot at all times. If OK,

go to next step. If not OK, check circuit to fuse (F4

for YJ, F10 for XJ) in Power Distribution Center

(PDC). Repair as required.

(2) The normally closed terminal (87A) is con-

nected to terminal 30 in the de-energized position,

but is not used for this application. Go to next step.

(3) The normally open terminal (87) is connected to

the battery terminal (30) in the energized position.

This terminal supplies battery voltage to the starter

solenoid field coils. There should be continuity be-

tween cavity for relay terminal 87 and the starter so-

lenoid terminal at all times. If OK, go to next step. If

not OK, repair circuit to solenoid as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is energized when

the ignition switch is in the START position. Check

for battery voltage at cavity for relay terminal 86with ignition switch in the START position. If OK, go

to next step. If not OK, refer to Group 8D - Ignition

Systems for testing and service of the ignition switch.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. On vehicles with an

automatic transmission, it is grounded through the

park/neutral position switch. On vehicles with a

manual transmission, it is grounded at all times.

Check for continuity to ground at cavity for relay ter-

minal 85. If not OK and vehicle has manual trans-

mission, repair circuit as required. If not OK and

vehicle has automatic transmission, refer to Group

21 - Transmission and Transfer Case for testing and

service of the park/neutral position switch.

Fig. 9 Power Distribution CenterÐXJ

Fig. 10 Power Distribution CenterÐYJ

STARTER RELAY CONNECTIONS

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 15