light JEEP CHEROKEE 2016 KL / 5.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2016, Model line: CHEROKEE, Model: JEEP CHEROKEE 2016 KL / 5.GPages: 770, PDF Size: 5.48 MB

Page 588 of 770

•When the fuel nozzle “clicks” or shuts off, the fuel tank

is full.

• Tighten the gas cap about one quarter turn until you

hear one click. This is an indication that the cap is

properly tightened.

• If the gas cap is not tightened properly, the MIL will

come on. Be sure the gas cap is tightened every time

the vehicle is refueled.CAUTION!

• Damage to the fuel system or emission control

system could result from using an improper fuel

filler cap. A poorly fitting cap could let impurities

into the fuel system. Also, a poorly fitting aftermar-

ket cap can cause the “Malfunction Indicator Light

(MIL)” to illuminate, due to fuel vapors escaping

from the system.

• A poorly fitting fuel filler cap may cause the MIL to

turn on.

• To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling.

586 STARTING AND OPERATING

Page 596 of 770

WARNING!(Continued)

•Weight Distributing Systems may not be compat-

ible with Surge Brake Couplers. Consult with your

hitch and trailer manufacturer or a reputable Rec-

reational Vehicle dealer for additional information.

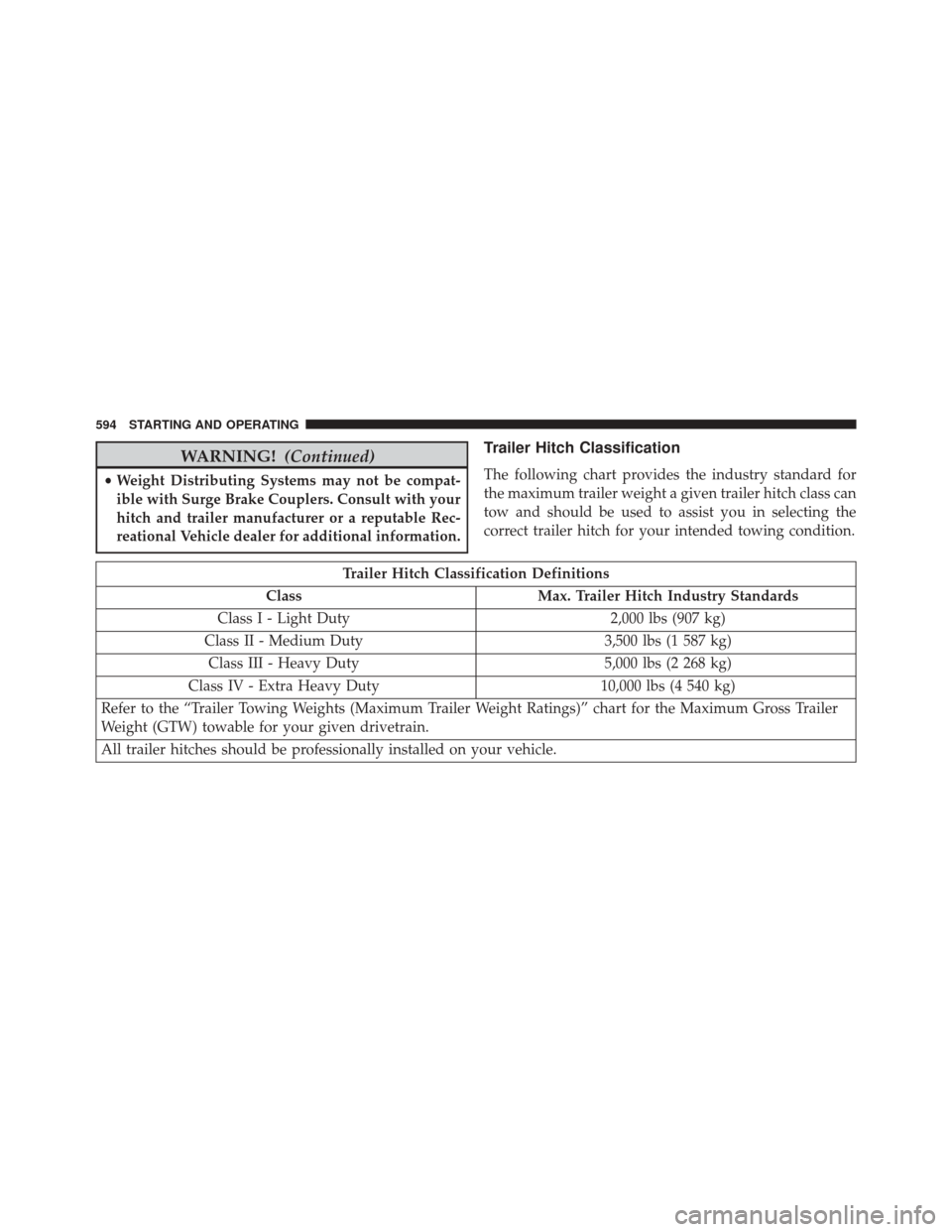

Trailer Hitch Classification

The following chart provides the industry standard for

the maximum trailer weight a given trailer hitch class can

tow and should be used to assist you in selecting the

correct trailer hitch for your intended towing condition.

Trailer Hitch Classification Definitions

Class Max. Trailer Hitch Industry Standards

Class I - Light Duty 2,000 lbs (907 kg)

Class II - Medium Duty 3,500 lbs (1 587 kg)

Class III - Heavy Duty 5,000 lbs (2 268 kg)

Class IV - Extra Heavy Duty 10,000 lbs (4 540 kg)

Refer to the “Trailer Towing Weights (Maximum Trailer Weight Ratings)” chart for the Maximum Gross Trailer

Weight (GTW) towable for your given drivetrain.

All trailer hitches should be professionally installed on your vehicle.

594 STARTING AND OPERATING

Page 603 of 770

Towing Requirements — Trailer Lights And Wiring

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may include a four- and seven-

pin wiring harness. Use a factory approved trailer har-

ness and connector.

NOTE:Do not cut or splice wiring into the vehicles

wiring harness.

The electrical connections are all complete to the vehicle

but you must mate the harness to a trailer connector.

Refer to the following illustrations.

Four-Pin Connector

1 — Female Pins

2 — Male Pin

3 — Ground4 — Park

5 — Left Stop/Turn

6 — Right Stop/Turn

5

STARTING AND OPERATING 601

Page 605 of 770

NOTE:Using a lower gear range while operating the

vehicle under heavy loading conditions will improve

performance and extend transmission life by reducing

excessive shifting and heat build up. This action will also

provide better engine braking.

Electronic Speed Control — If Equipped

• Do not use in hilly terrain or with heavy loads.

• When using the speed control, if you experience speed

drops greater than 10 mph (16 km/h), disengage until

you can get back to cruising speed.

• Use speed control in flat terrain and with light loads to

maximize fuel efficiency.

Cooling System

To reduce potential for engine and transmission over-

heating, take the following actions:

City Driving

When stopped for short periods of time, shift the trans-

mission into NEUTRAL and increase engine idle speed.

Highway Driving

Reduce speed.

Air Conditioning

Turn off temporarily.

5

STARTING AND OPERATING 603

Page 612 of 770

4. Press and hold the brake pedal.

5. Shift the transmission into NEUTRAL.

6. Using a ballpoint pen or similar object, push and holdthe recessed NEUTRAL (N) button (located by the

selector switch) for four seconds. The light behind the

NEUTRAL (N) symbol will blink, indicating shift in

progress. The light will stop blinking (stay on solid)

when the shift to NEUTRAL (N) is complete.

7. After the shift is completed and the NEUTRAL (N)light stays on, release the NEUTRAL (N) button.

8. Start the engine.

9. Release the parking brake.

10. Shift the transmission into REVERSE.

Neutral Switch

610 STARTING AND OPERATING

Page 613 of 770

11. Release the brake pedal for five seconds and ensurethat there is no vehicle movement.

12. Shift the transmission to NEUTRAL.

13. Apply the parking brake.

14. Shift the transmission into PARK, turn the engine OFF, and remove the key fob.

15. Attach the vehicle to the tow vehicle using a suitable tow bar.

16. Turn the ignition to the ON/RUN position, but do not start the engine.

17. Press and hold the brake pedal.

18. Release the parking brake.

19. Turn the ignition OFF, remove the Key Fob, and release the brake pedal. NOTE:

•

Steps 1 through 5 are requirements that must be met

before pushing the NEUTRAL (N) button, and must

continue to be met until the shift has been completed.

If any of these requirements are not met before push-

ing the NEUTRAL (N) button or are no longer met

during the shift, then the NEUTRAL (N) indicator light

will flash continuously until all requirements are met

or until the NEUTRAL (N) button is released.

• The ignition switch must be in the ON/RUN position

for a shift to take place and for the position indicator

lights to be operable. If the ignition switch is not in the

ON/RUN position, the shift will not take place and no

position indicator lights will be on or flashing.

• A flashing NEUTRAL (N) position indicator light

indicates that shift requirements have not been met.

5

STARTING AND OPERATING 611

Page 614 of 770

Shifting Out Of NEUTRAL (N)

Use the following procedure to prepare your vehicle for

normal usage.

1. Bring the vehicle to a complete stop, leaving it con-nected to the tow vehicle.

2. Apply the parking brake.

3. Turn the ignition switch to the ON/RUN position, but do not start the engine.

4. Press and hold the brake pedal.

5. Shift the transmission into NEUTRAL.

6. Using a ballpoint pen or similar object, push and hold the recessed power transfer unit NEUTRAL (N) button

(located by the selector switch) for one second. 7. When the NEUTRAL (N) indicator light turns off,

release the NEUTRAL (N) button.

8. After the NEUTRAL (N) button has been released, the power transfer unit will shift to the position indicated

by the selector switch.

Neutral Switch

612 STARTING AND OPERATING

Page 615 of 770

NOTE:When shifting the power transfer unit out of

NEUTRAL (N), the engine should remain OFF to avoid

gear clash.

9. Shift the transmission into PARK.

10. Release the brake pedal.

11. Disconnect vehicle from the tow vehicle.

12. Start the engine.

13. Press and hold the brake pedal.

14. Release the parking brake.

15. Shift the transmission into DRIVE, release the brake pedal, and check that the vehicle operates normally.

16. Re-enable the Auto Park Brake feature, if desired. NOTE:

•

Steps 1 through 5 are requirements that must be met

before pushing the NEUTRAL (N) button, and must

continue to be met until the shift has been completed.

If any of these requirements are not met before push-

ing the NEUTRAL (N) button or are no longer met

during the shift, the NEUTRAL (N) indicator light will

flash continuously until all requirements are met or

until the NEUTRAL (N) button is released.

• The ignition switch must be in the ON/RUN position

for a shift to take place and for the position indicator

lights to be operable. If the ignition switch is not in the

ON/RUN position, the shift will not take place and no

position indicator lights will be on or flashing.

• A flashing NEUTRAL (N) position indicator light

indicates that shift requirements have not been met.

5

STARTING AND OPERATING 613

Page 643 of 770

NOTE:•For vehicles so equipped, do not attempt to install a

center cap or wheel cover on the compact spare.

• Refer to “Compact Spare Tire” and to “Limited-Use

Spare” under “Tires—General Information” in

“Starting and Operating” for additional warnings,

cautions, and information about the spare tire, its

use, and operation.

9. Install the wheel bolts with the threaded end of the wheel bolt toward the wheel. Lightly tighten the

wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not fully tighten the wheel bolts until the vehicle

has been lowered. Failure to follow this warning may

result in serious injury. 10. Lower the vehicle to the ground by turning the jack

handle counterclockwise.

11. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened twice. Refer

to “Torque Specifications” in this section for the

proper lug bolt torque. If in doubt about the correct

tightness, have them checked with a torque wrench

by your authorized dealer or at a service station.

6

WHAT TO DO IN EMERGENCIES 641

Page 645 of 770

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided. Have the deflated (flat) tire

repaired or replaced immediately.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the threadedend of the wheel bolt toward the wheel. Lightly

tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the lug nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern until

each wheel bolt has been tightened twice. Refer to

“Torque Specifications” in this section for the proper

lug bolt torque. If in doubt about the correct tightness,

have them checked with a torque wrench by your

authorized dealer or service station.

6

WHAT TO DO IN EMERGENCIES 643