lock JEEP CHEROKEE 2017 KL / 5.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2017, Model line: CHEROKEE, Model: JEEP CHEROKEE 2017 KL / 5.GPages: 615, PDF Size: 5.72 MB

Page 400 of 615

Replacing Exterior Bulbs

Bi-Xenon High Intensity Discharge (HID)

Headlamps — If Equipped

The headlamps contain a type of high voltage discharge

light source. High voltage can remain in the circuit even

with the headlamp switch off. Because of this, you should

not attempt to service a HID headlamp light source your-

self. If an HID headlamp light source fails, take your

vehicle to an authorized dealer for service.

NOTE:On vehicles equipped with HID headlamps, when

the headlamps are turned on, there is a blue hue to the

lights. This diminishes and becomes more white after

approximately 10 seconds, as the system charges.

WARNING!

A transient high voltage occurs at the bulb sockets of

HID headlamps when the headlamp switch is turned

ON. It may cause serious electrical shock or electrocu-

tion if not serviced properly. See your authorized

dealer for service.

Bi-Halogen Headlamps

1. Remove the 3 hex head screws from the wheel liner.

2. Pull the exterior edge of the liner towards the tire to gain access to the headlamp bulb cap.

3.

Firmly grasp the cap and rotate it counterclockwise to

unlock it.

4. Firmly grasp the bulb and connector assembly and rotate counterclockwise to remove from the housing.

5. Disconnect the bulb from the electrical connector and then connect the replacement bulb.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with any oily surface, clean the

bulb with rubbing alcohol.

6. Install the bulb and connector assembly into the head- lamp housing and rotate clockwise to lock it in place.

7. Install the bulb cap in the headlamp housing and rotate clockwise to lock it in place.

8. Install the 3 hex head screws into the wheel liner.

398 IN CASE OF EMERGENCY

Page 401 of 615

Front Turn Signals And Front Side Marker Lamps

1. Open the hood.

NOTE:Removal of the air cleaner filter housing may be

necessary prior to replacing bulbs in the upper lamp

assembly on the passenger side of the vehicle.

2. Twist the appropriate bulb and socket assembly coun- terclockwise, and then remove the bulb and socket

assembly from the lamp housing.

3. Pull the bulb out of the socket and insert the replace- ment bulb.

4. Install the bulb and socket assembly into the housing, and rotate the socket clockwise to lock it in place.

5. Re-install air cleaner filter housing if removed.

Front Fog Lamp

1. Remove the three hex head screws from the wheel liner.

2. Pull the exterior edge of the wheel liner towards the tire to gain access to the bulb.

3. Squeeze the two tabs on the side of the bulb socket and pull straight out from the fog lamp. 4. Disconnect the wire harness from the bulb.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with any oily surface, clean the

bulb with rubbing alcohol.

5. Reconnect the wiring harness to the new bulb and reinstall by inserting the new bulb straight into the fog

lamp housing until it locks in place.

6. Lock the lower door in the wheel liner.

Bodyside Mounted Back-up Lamp

1. Open the liftgate.

2. Remove the screws that fasten the tail lamp housing to the vehicle.

3. Grasp the tail lamp and pull firmly rearward to disen- gage the lamp from the vehicle.

4. Disconnect the electrical connector.

5. Twist the socket counterclockwise and remove from housing.

7

IN CASE OF EMERGENCY 399

Page 402 of 615

6. Pull the bulb to remove it from the socket.

7. Replace the bulb and install the socket.

8. Reconnect the electrical connector.

9. Reinstall the tail lamp housing and screws.

10. Close the liftgate.

Liftgate Mounted Back-up Lamp

1. Open the liftgate.

2. Use a fiber stick or flat blade screw driver to pry thelower trim from the liftgate.

3. Once the trim is loose, pull it back exposing the trim panel.

4. Using a fiber stick or flat blade screw driver, open the trim panel exposing the back of the liftgate lamp.

5. Disconnect the electrical connector.

6.

Twist the socket counterclockwise and remove from lamp.

7. Pull the bulb to remove it from the socket.

8. Replace the bulb, reinstall the socket.

9. Connect the electrical connector. 10. Reinstall the trim panel and the lower trim.

11. Close the liftgate.

License Plate Lamp

1. Using a small screwdriver, press inward the locking tab

on the side of the lamp assembly and pull down on the

lamp assembly for removal.

2. Pull bulb from socket, replace, and reinstall the lamp assembly into place ensuring the locking tab is secure.

FUSES

WARNING!

•When replacing a blown fuse, always use an appropri-

ate replacement fuse with the same amp rating as the

original fuse. Never replace a fuse with another fuse of

higher amp rating. Never replace a blown fuse with

metal wires or any other material. Failure to use proper

fuses may result in serious personal injury, fire and/or

property damage.

•Before replacing a fuse, make sure that the ignition is

off and that all the other services are switched off

and/or disengaged.

(Continued)

400 IN CASE OF EMERGENCY

Page 409 of 615

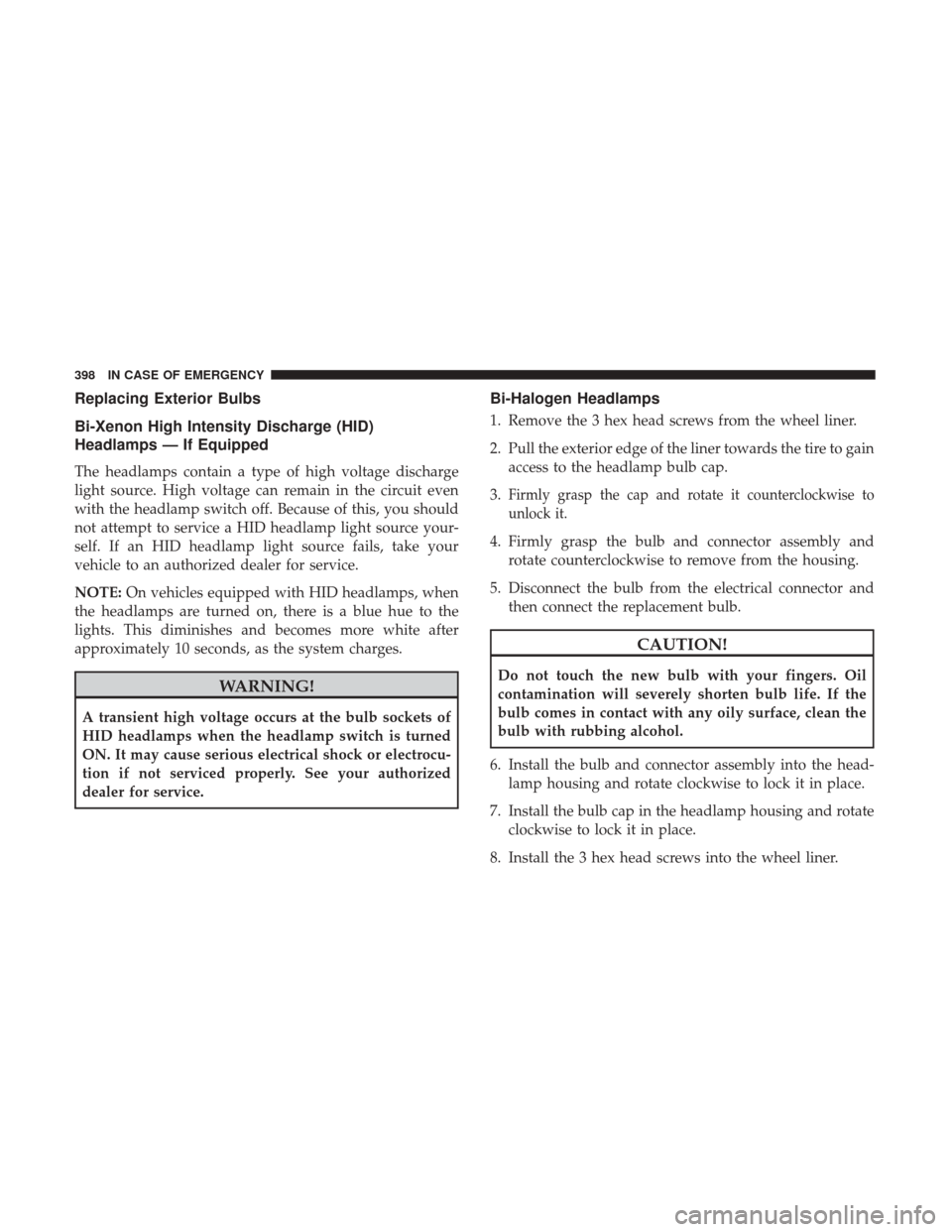

CavityBlade Fuse Cartridge Fuse Description

F52 –30 Amp Pink Front Wipers —

If Equipped With Stop/ Start Engine Option

F53 –30 Amp Pink Brake System Module &

Valves

F54 –30 Amp Pink Body Control Module

(BCM) Feed 3

F55 10 Amp Red –Blind Spot Sensors/

Compass/Rearview

Camera/Trunk Lamp With Flashlamp Charger — If Equipped

F56 15 Amp Blue –Ignition Node Module

(IGNM)/KIN/RF Hub/

Electric Steering Column Lock (ESL)

F57 20 Amp Yellow –Trailer Tow Lights Left —

If Equipped

F58 10 Amp Red –Occupant Classification

Module/VSM/ESC

F59 –30 Amp Pink Drivetrain Control Module

(DTCM) — If Equipped

7

IN CASE OF EMERGENCY 407

Page 415 of 615

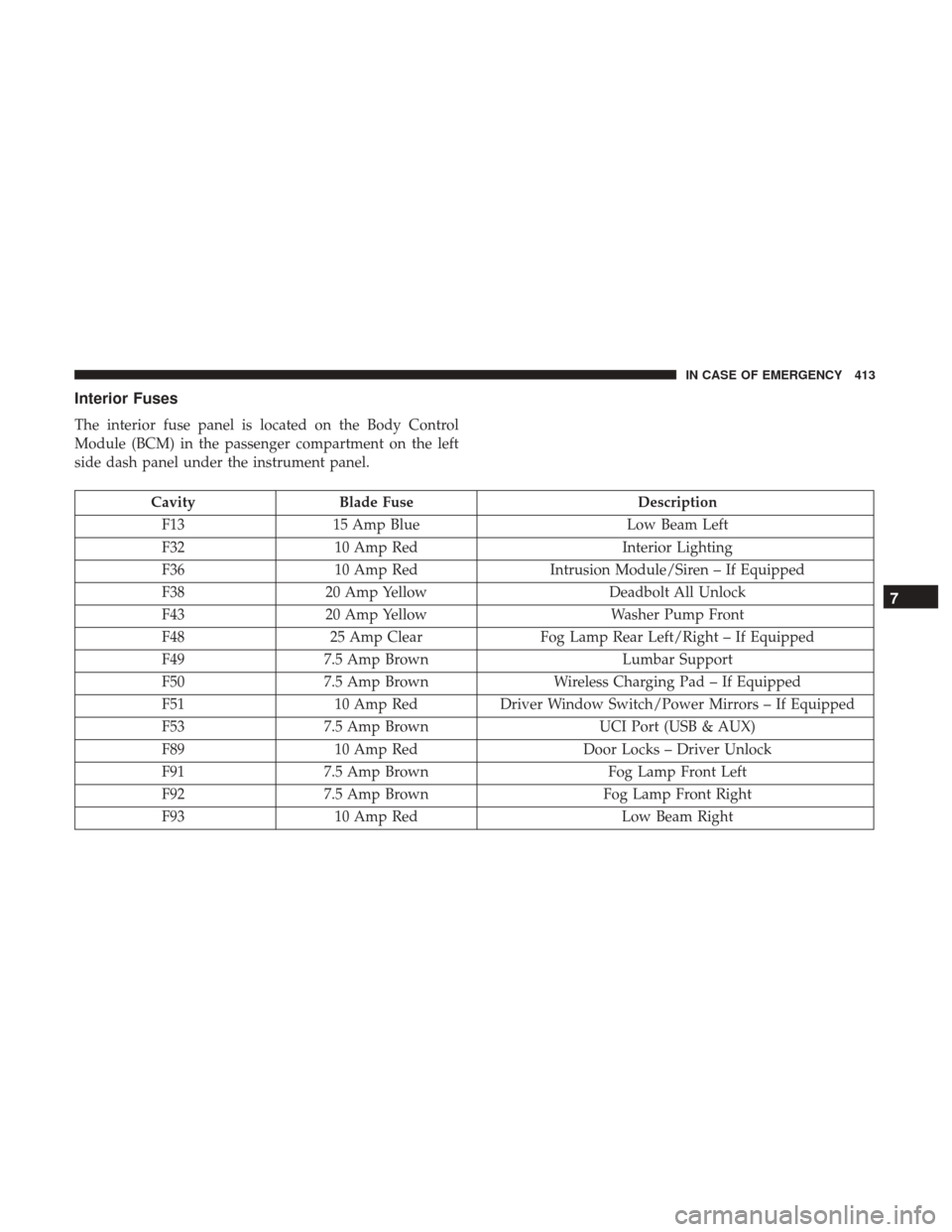

Interior Fuses

The interior fuse panel is located on the Body Control

Module (BCM) in the passenger compartment on the left

side dash panel under the instrument panel.

CavityBlade Fuse Description

F13 15 Amp Blue Low Beam Left

F32 10 Amp Red Interior Lighting

F36 10 Amp Red Intrusion Module/Siren – If Equipped

F38 20 Amp Yellow Deadbolt All Unlock

F43 20 Amp Yellow Washer Pump Front

F48 25 Amp Clear Fog Lamp Rear Left/Right – If Equipped

F49 7.5 Amp Brown Lumbar Support

F50 7.5 Amp Brown Wireless Charging Pad – If Equipped

F51 10 Amp RedDriver Window Switch/Power Mirrors – If Equipped

F53 7.5 Amp Brown UCI Port (USB & AUX)

F89 10 Amp Red Door Locks – Driver Unlock

F91 7.5 Amp Brown Fog Lamp Front Left

F92 7.5 Amp Brown Fog Lamp Front Right

F93 10 Amp Red Low Beam Right

7

IN CASE OF EMERGENCY 413

Page 418 of 615

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired

or replaced immediately.

Preparations For Jacking

1. Park the vehicle on a firm level surface as far from theedge of the roadway as possible. Avoid icy or slippery

areas.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic, pull far enough off the

road to avoid being hit when operating the jack or

changing the wheel. 2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the gear selector into PARK.

5. Turn the ignition off to the LOCK position.

6. Chock both the front and rear of the wheel diagonally

opposite of the jacking position. For

example, if changing the right front

tire, chock the left rear wheel.

NOTE: Passengers should not remain in the vehicle when

the vehicle is being jacked.

416 IN CASE OF EMERGENCY

Page 420 of 615

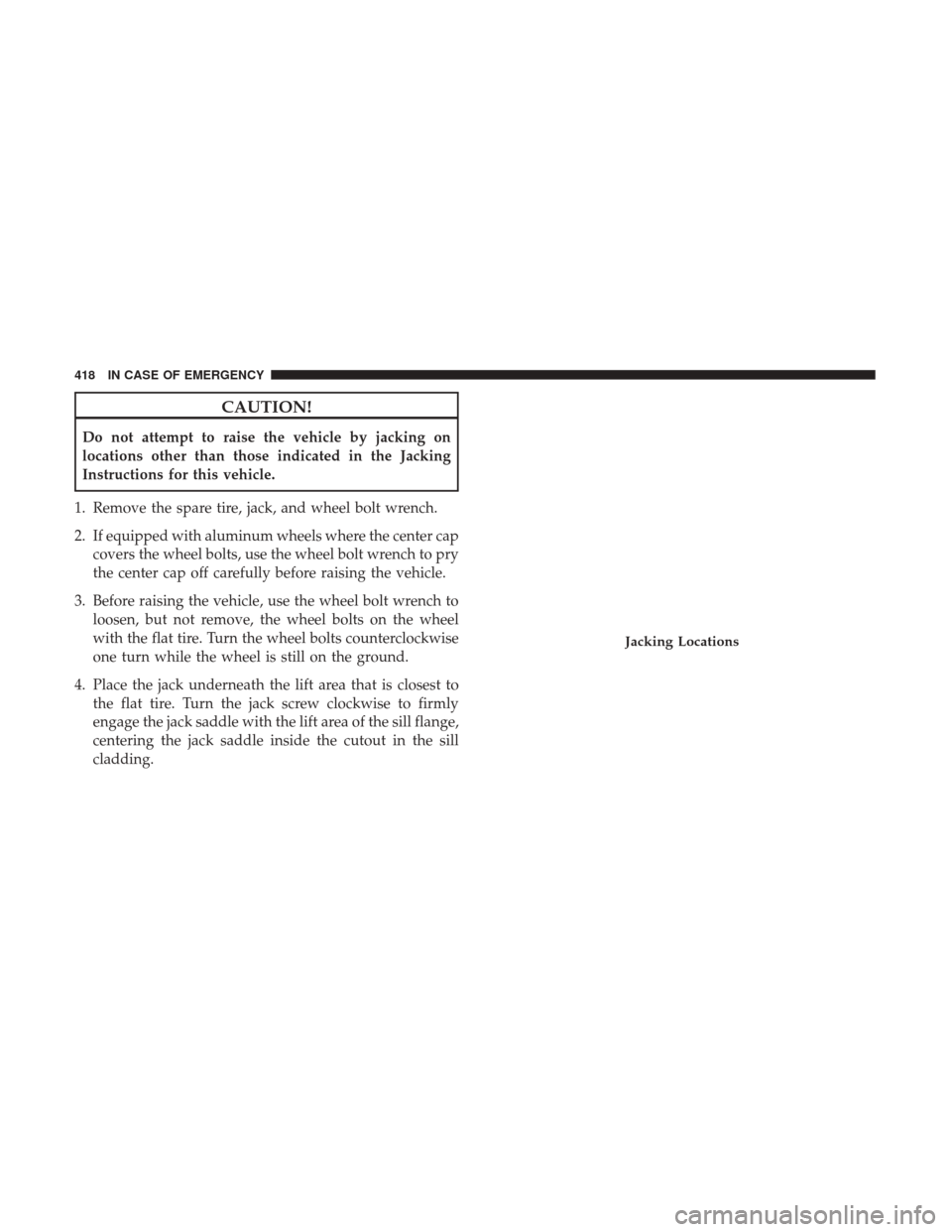

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the Jacking

Instructions for this vehicle.

1. Remove the spare tire, jack, and wheel bolt wrench.

2. If equipped with aluminum wheels where the center cap covers the wheel bolts, use the wheel bolt wrench to pry

the center cap off carefully before raising the vehicle.

3. Before raising the vehicle, use the wheel bolt wrench to loosen, but not remove, the wheel bolts on the wheel

with the flat tire. Turn the wheel bolts counterclockwise

one turn while the wheel is still on the ground.

4. Place the jack underneath the lift area that is closest to the flat tire. Turn the jack screw clockwise to firmly

engage the jack saddle with the lift area of the sill flange,

centering the jack saddle inside the cutout in the sill

cladding.

Jacking Locations

418 IN CASE OF EMERGENCY

Page 423 of 615

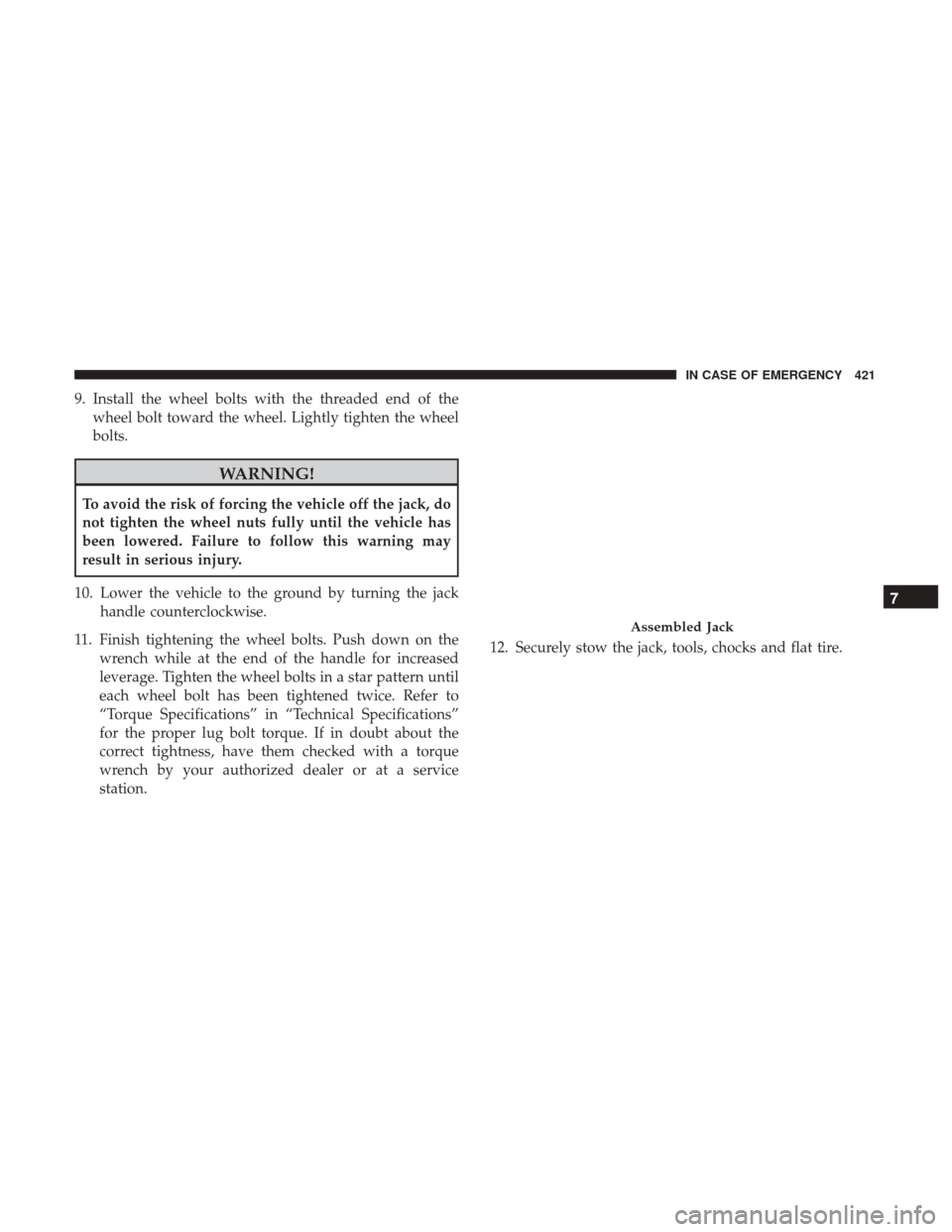

9. Install the wheel bolts with the threaded end of thewheel bolt toward the wheel. Lightly tighten the wheel

bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

10. Lower the vehicle to the ground by turning the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern until

each wheel bolt has been tightened twice. Refer to

“Torque Specifications” in “Technical Specifications”

for the proper lug bolt torque. If in doubt about the

correct tightness, have them checked with a torque

wrench by your authorized dealer or at a service

station. 12. Securely stow the jack, tools, chocks and flat tire.

Assembled Jack

7

IN CASE OF EMERGENCY 421

Page 424 of 615

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired

or replaced immediately.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the threaded endof the wheel bolt toward the wheel. Lightly tighten the

wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern until

each wheel bolt has been tightened twice. Refer to

“Torque Specifications” in “Technical Specifications” for

the proper lug bolt torque. If in doubt about the correct

tightness, have them checked with a torque wrench by

your authorized dealer or service station.

Stowed Tire, Jack And Chock

422 IN CASE OF EMERGENCY

Page 433 of 615

4. Have the tire inspected and repaired or replaced at theearliest opportunity at an authorized dealer or tire

service center.

5. Remove the Speed Limit sticker from the instrument panel after the tire has been repaired.

6. Replace the Sealant Bottle (1) and Sealant Hose (6) assembly at your authorized dealer as soon as possible.

Refer to (F) “Sealant Bottle and Hose Replacement”.

NOTE: When having the tire serviced, advise the autho-

rized dealer or service center that the tire has been sealed

using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (6) (clear in color).

2. Locate the round Sealant Bottle release button in the recessed area under the sealant bottle.

3. Push the Sealant Bottle release button. The Sealant Bottle (1) will pop up. Remove the bottle and dispose of it

accordingly.

4. Clean any remaining sealant from the Tire Service Kit housing. 5.

Position the new Sealant Bottle (1) in the housing so that

the Sealant Hose (6) aligns with the hose slot in the front

of the housing. Push the bottle into the housing. An

audible click will be heard indicating the bottle is locked

into place.

6. Verify that the cap is installed on the fitting at the end of

the Sealant Hose (6) and return the hose to its storage

area (located on the bottom of the air pump).

7.

Return the Tire Service Kit to its storage location in the

vehicle.

JUMP-STARTING PROCEDURES

If your vehicle has a discharged battery, it can be jump-

started using a set of jumper cables and a battery in another

vehicle or by using a portable battery booster pack. Jump-

starting can be dangerous if done improperly so please

follow the procedures in this section carefully.

NOTE: When using a portable battery booster pack, follow

the manufacturer ’s operating instructions and precautions.

7

IN CASE OF EMERGENCY 431