wheel bolts JEEP CHEROKEE 2017 KL / 5.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2017, Model line: CHEROKEE, Model: JEEP CHEROKEE 2017 KL / 5.GPages: 615, PDF Size: 5.72 MB

Page 420 of 615

CAUTION!

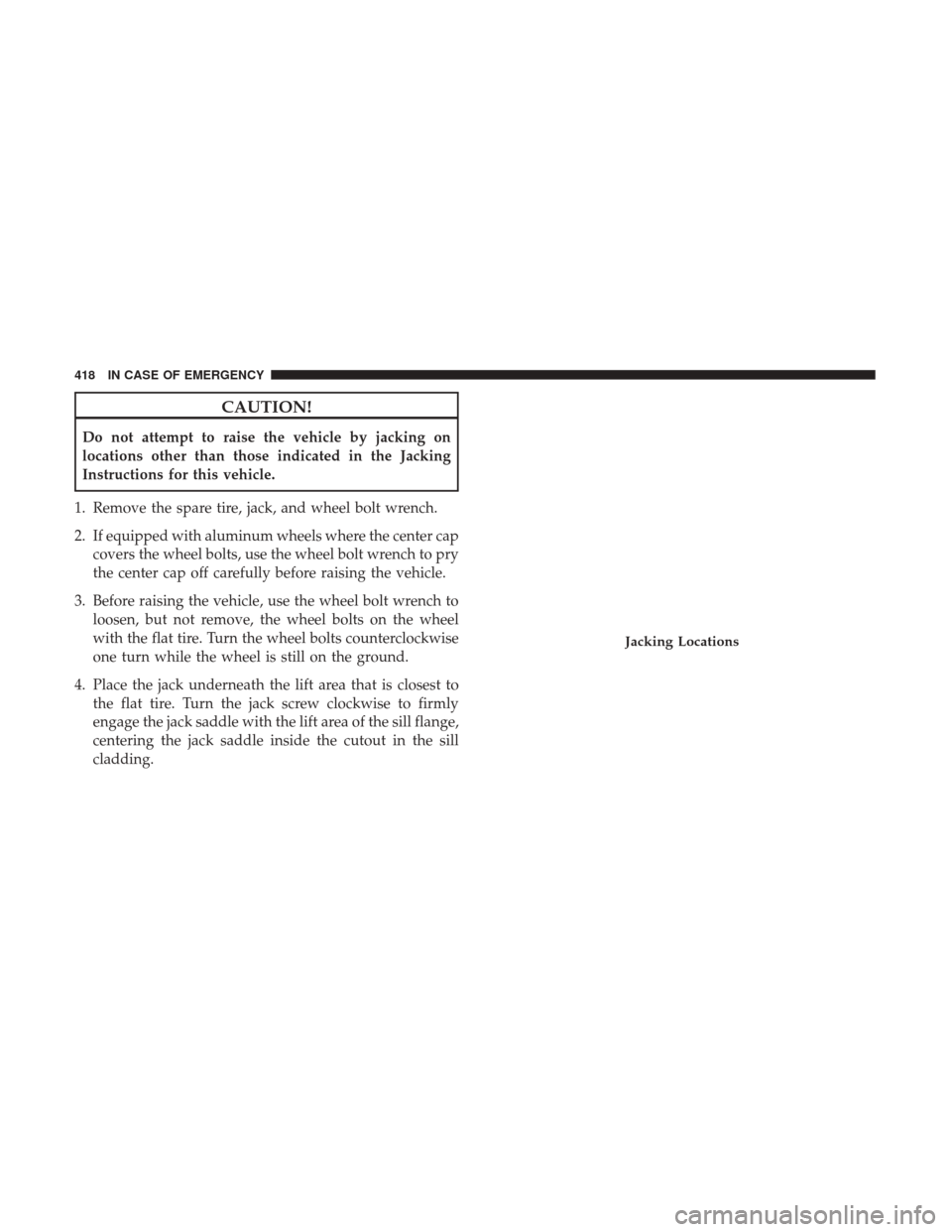

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the Jacking

Instructions for this vehicle.

1. Remove the spare tire, jack, and wheel bolt wrench.

2. If equipped with aluminum wheels where the center cap covers the wheel bolts, use the wheel bolt wrench to pry

the center cap off carefully before raising the vehicle.

3. Before raising the vehicle, use the wheel bolt wrench to loosen, but not remove, the wheel bolts on the wheel

with the flat tire. Turn the wheel bolts counterclockwise

one turn while the wheel is still on the ground.

4. Place the jack underneath the lift area that is closest to the flat tire. Turn the jack screw clockwise to firmly

engage the jack saddle with the lift area of the sill flange,

centering the jack saddle inside the cutout in the sill

cladding.

Jacking Locations

418 IN CASE OF EMERGENCY

Page 422 of 615

5. Raise the vehicle just enough to remove the flat tire.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.

6. Remove the wheel bolts and tire.

7. Remove the alignment pin from the jack assembly and thread the pin into the wheel hub to assist in mounting

the spare tire.

8. Mount the spare tire.

CAUTION!

Be sure to mount the spare tire with the valve stem

facing outward. The vehicle could be damaged if the

spare tire is mounted incorrectly. NOTE:

•For vehicles so equipped, do not attempt to install a

center cap or wheel cover on the compact spare.

• Refer to “Compact Spare Tire” and to “Limited-Use

Spare” under “Tires—General Information” in “Servic-

ing and Maintenance” for additional warnings, cau-

tions, and information about the spare tire, its use, and

operation.

Mounting Spare Tire

420 IN CASE OF EMERGENCY

Page 423 of 615

9. Install the wheel bolts with the threaded end of thewheel bolt toward the wheel. Lightly tighten the wheel

bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

10. Lower the vehicle to the ground by turning the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern until

each wheel bolt has been tightened twice. Refer to

“Torque Specifications” in “Technical Specifications”

for the proper lug bolt torque. If in doubt about the

correct tightness, have them checked with a torque

wrench by your authorized dealer or at a service

station. 12. Securely stow the jack, tools, chocks and flat tire.

Assembled Jack

7

IN CASE OF EMERGENCY 421

Page 424 of 615

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired

or replaced immediately.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the threaded endof the wheel bolt toward the wheel. Lightly tighten the

wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern until

each wheel bolt has been tightened twice. Refer to

“Torque Specifications” in “Technical Specifications” for

the proper lug bolt torque. If in doubt about the correct

tightness, have them checked with a torque wrench by

your authorized dealer or service station.

Stowed Tire, Jack And Chock

422 IN CASE OF EMERGENCY

Page 425 of 615

5. Lower the jack until it is free. Remove the wheel chocks.Reassemble the lug wrench to the jack assembly and

stow it in the spare tire area. Secure the assembly using

the means provided. Release the parking brake before

driving the vehicle.

6. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure that all wheel bolts are

properly seated against the wheel.

TIRE SERVICE KIT — IF EQUIPPED

Small punctures up to 1/4 inch (6 mm) in the tire tread can

be sealed with Tire Service Kit. Foreign objects (e.g., screws

or nails) should not be removed from the tire. Tire Service

Kit can be used in outside temperatures down to approxi-

mately -4°F (-20°C).

This kit will provide a temporary tire seal, allowing you to

drive your vehicle up to 100 miles (160 km) with a

maximum speed of 55 mph (90 km/h).

Tire Service Kit Storage

The Tire Service Kit is stowed under the load floor behind

the rear seat.

1. Open the liftgate.

2. Lift the access cover using the load floor handle.

Load Floor Handle

7

IN CASE OF EMERGENCY 423

Page 515 of 615

In the event power assist is lost for any reason (i.e.,

repeated brake applications with the engine off) the brakes

will still function. However, the effort required to brake the

vehicle will be much greater than that required with the

power system operating.

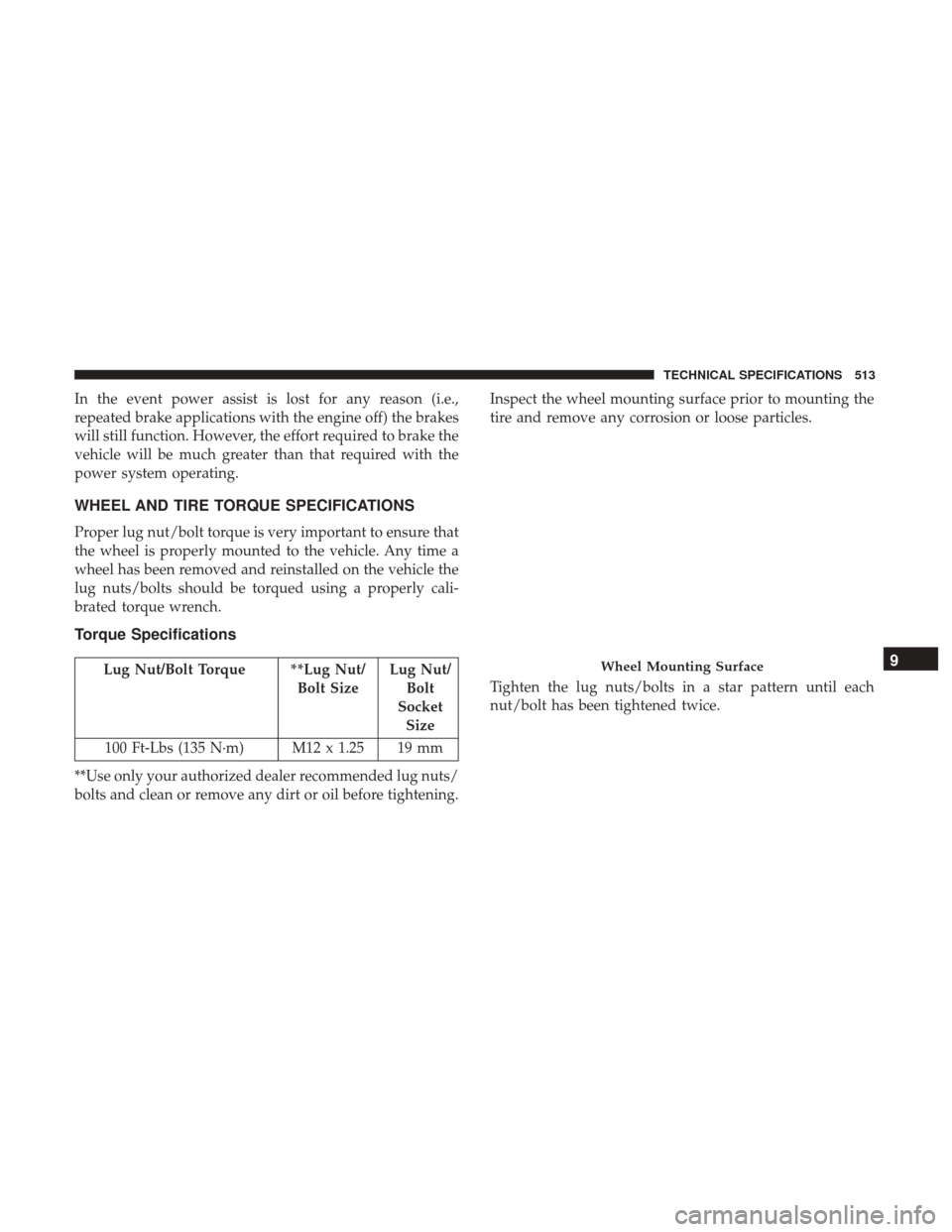

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure that

the wheel is properly mounted to the vehicle. Any time a

wheel has been removed and reinstalled on the vehicle the

lug nuts/bolts should be torqued using a properly cali-

brated torque wrench.

Torque Specifications

Lug Nut/Bolt Torque **Lug Nut/Bolt SizeLug Nut/

Bolt

Socket Size

100 Ft-Lbs (135 N·m) M12 x 1.25 19 mm

**Use only your authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening. Inspect the wheel mounting surface prior to mounting the

tire and remove any corrosion or loose particles.

Tighten the lug nuts/bolts in a star pattern until each

nut/bolt has been tightened twice.Wheel Mounting Surface9

TECHNICAL SPECIFICATIONS 513

Page 516 of 615

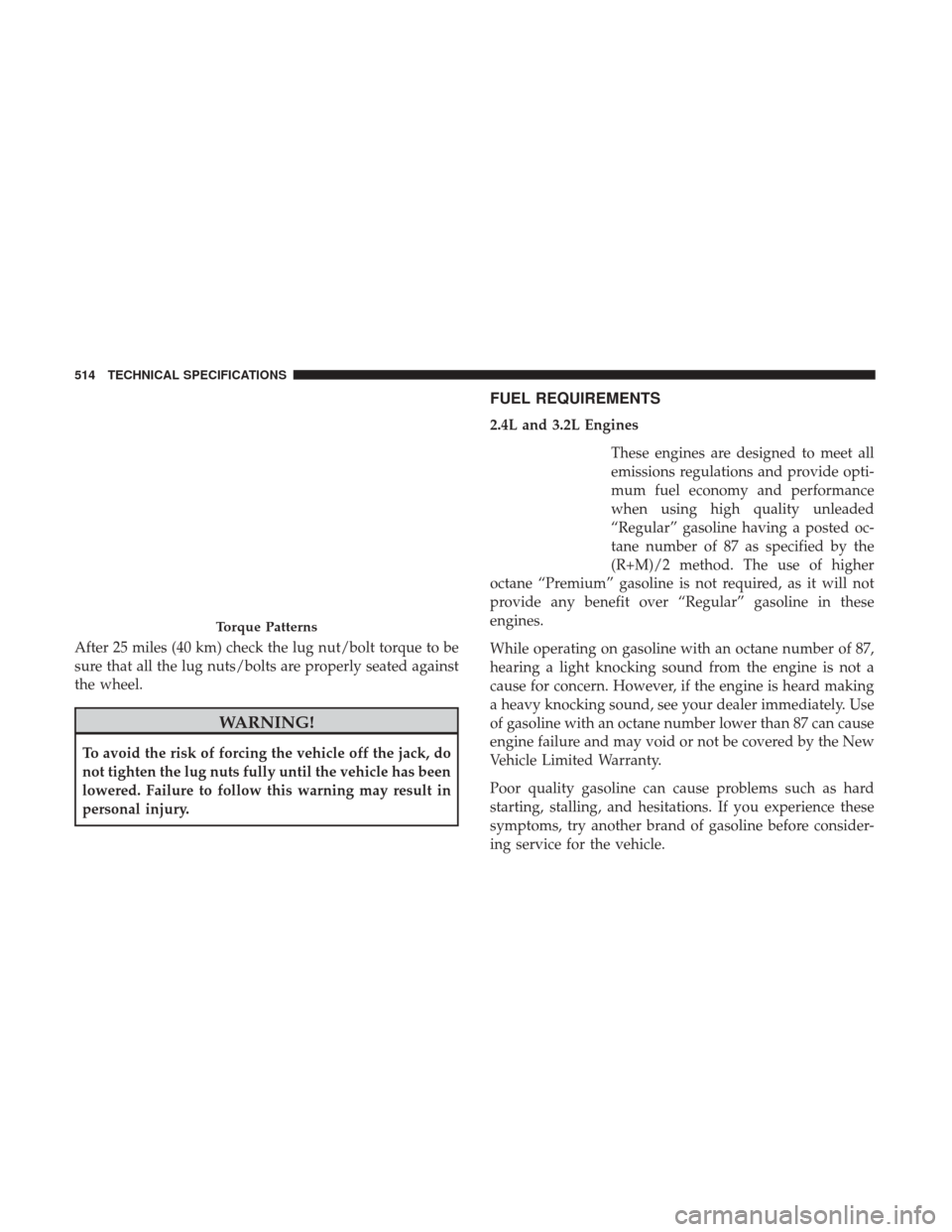

After 25 miles (40 km) check the lug nut/bolt torque to be

sure that all the lug nuts/bolts are properly seated against

the wheel.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the lug nuts fully until the vehicle has been

lowered. Failure to follow this warning may result in

personal injury.

FUEL REQUIREMENTS

2.4L and 3.2L EnginesThese engines are designed to meet all

emissions regulations and provide opti-

mum fuel economy and performance

when using high quality unleaded

“Regular” gasoline having a posted oc-

tane number of 87 as specified by the

(R+M)/2 method. The use of higher

octane “Premium” gasoline is not required, as it will not

provide any benefit over “Regular” gasoline in these

engines.

While operating on gasoline with an octane number of 87,

hearing a light knocking sound from the engine is not a

cause for concern. However, if the engine is heard making

a heavy knocking sound, see your dealer immediately. Use

of gasoline with an octane number lower than 87 can cause

engine failure and may void or not be covered by the New

Vehicle Limited Warranty.

Poor quality gasoline can cause problems such as hard

starting, stalling, and hesitations. If you experience these

symptoms, try another brand of gasoline before consider-

ing service for the vehicle.

Torque Patterns

514 TECHNICAL SPECIFICATIONS