ECU JEEP CHEROKEE 2019 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2019, Model line: CHEROKEE, Model: JEEP CHEROKEE 2019Pages: 344, PDF Size: 6.35 MB

Page 185 of 344

Recreational Towing — Front-Wheel Drive

(FWD) Models

DO NOTflat tow this vehicle.

Recreational towing (for front-wheel drive

models) is allowed ONLY if the front wheels

areOFFthe ground. This may be accom-

plished using a tow dolly or vehicle trailer. If

using a tow dolly, follow this procedure:

1. Properly secure the dolly to the tow ve-

hicle, following the dolly manufacturer's

instructions.

2. Drive the front wheels onto the tow dolly.

3. Apply the parking brake. Place automatic

transmission in PARK, or manual trans-

mission in gear. Turn the engine OFF.

4. Properly secure the front wheels to the

dolly, following the dolly manufacturer's

instructions.

5. Turn the ignition to the ON/RUN mode,

but do not start the engine.6. Press and hold the brake pedal.

7. Release the parking brake.

8. Turn the ignition OFF, remove the key fob,

and release the brake pedal.

CAUTION!

• Towing with the front wheels on the

ground will cause severe transmission

damage. Damage from improper towing

is not covered under the New Vehicle

Limited Warranty.

• Ensure that the Electric Park Brake is

released, and remains released, while

being towed.

Recreational Towing — 4x4 Models

Recreational towing is not allowed.

NOTE:

This vehicle may be towed on a flatbed or

vehicle trailer provided all four wheels are

OFF the ground.

CAUTION!

Towing this vehicle withANYof its wheels

on the ground can cause severe transmis-

sion and/or power transfer unit damage.

Damage from improper towing is not cov-

ered under the New Vehicle Limited War-

ranty.

183

Page 192 of 344

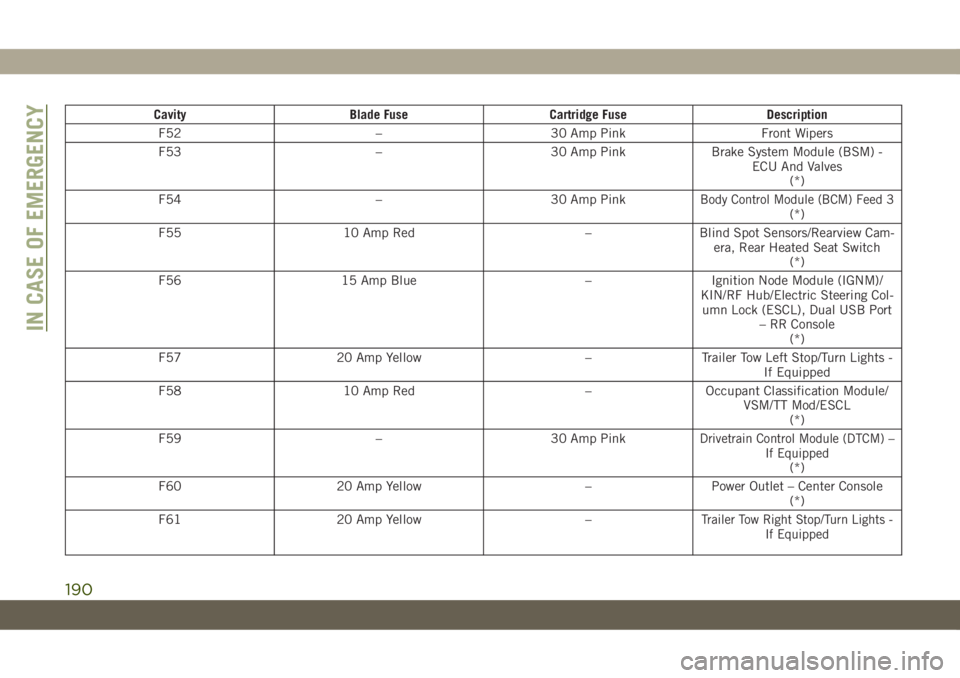

Cavity Blade Fuse Cartridge Fuse Description

F52 – 30 Amp Pink Front Wipers

F53 – 30 Amp Pink Brake System Module (BSM) -

ECU And Valves

(*)

F54 – 30 Amp Pink

Body Control Module (BCM) Feed 3(*)

F55 10 Amp Red – Blind Spot Sensors/Rearview Cam-

era, Rear Heated Seat Switch

(*)

F56 15 Amp Blue – Ignition Node Module (IGNM)/

KIN/RF Hub/Electric Steering Col-

umn Lock (ESCL), Dual USB Port

– RR Console

(*)

F57 20 Amp Yellow – Trailer Tow Left Stop/Turn Lights -

If Equipped

F58 10 Amp Red – Occupant Classification Module/

VSM/TT Mod/ESCL

(*)

F59 – 30 Amp Pink

Drivetrain Control Module (DTCM) –

If Equipped

(*)

F60 20 Amp Yellow – Power Outlet – Center Console

(*)

F61 20 Amp Yellow –

Trailer Tow Right Stop/Turn Lights -

If Equipped

IN CASE OF EMERGENCY

190

Page 194 of 344

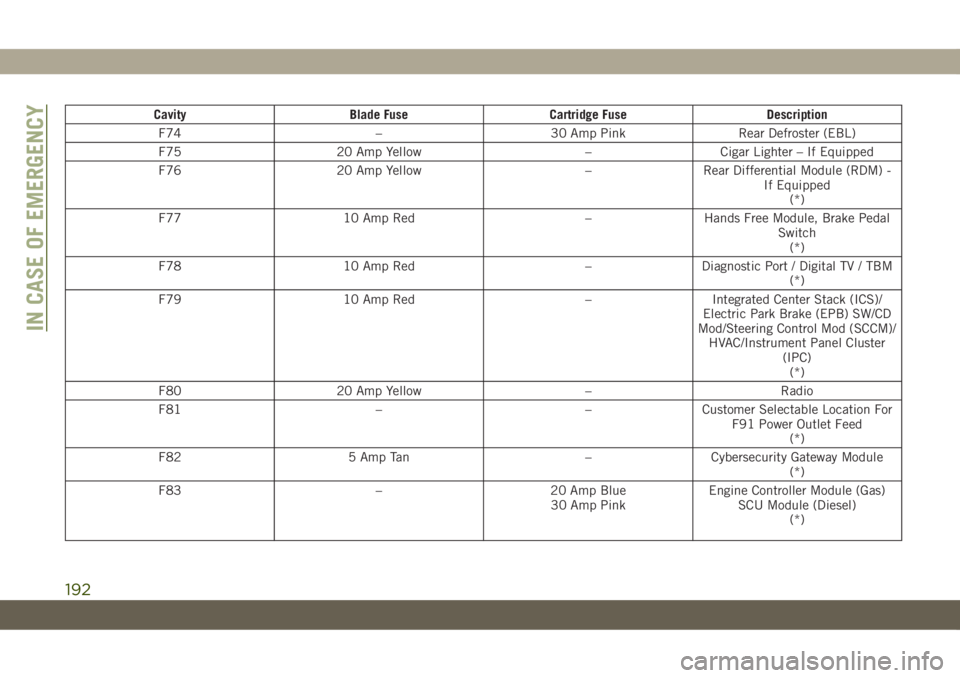

Cavity Blade Fuse Cartridge Fuse Description

F74 – 30 Amp Pink Rear Defroster (EBL)

F75 20 Amp Yellow – Cigar Lighter – If Equipped

F76 20 Amp Yellow – Rear Differential Module (RDM) -

If Equipped

(*)

F77 10 Amp Red – Hands Free Module, Brake Pedal

Switch

(*)

F78 10 Amp Red – Diagnostic Port / Digital TV / TBM

(*)

F79 10 Amp Red – Integrated Center Stack (ICS)/

Electric Park Brake (EPB) SW/CD

Mod/Steering Control Mod (SCCM)/

HVAC/Instrument Panel Cluster

(IPC)

(*)

F80 20 Amp Yellow – Radio

F81 – – Customer Selectable Location For

F91 Power Outlet Feed

(*)

F82 5 Amp Tan – Cybersecurity Gateway Module

(*)

F83 – 20 Amp Blue

30 Amp PinkEngine Controller Module (Gas)

SCU Module (Diesel)

(*)

IN CASE OF EMERGENCY

192

Page 198 of 344

JACKING AND TIRE

CHANGING

WARNING!

• Do not attempt to change a tire on the

side of the vehicle close to moving traf-

fic. Pull far enough off the road to avoid

the danger of being hit when operating

the jack or changing the wheel.

• Being under a jacked-up vehicle is dan-

gerous. The vehicle could slip off the

jack and fall on you. You could be

crushed. Never put any part of your body

under a vehicle that is on a jack. If you

need to get under a raised vehicle, take

it to a service center where it can be

raised on a lift.

• Never start or run the engine while the

vehicle is on a jack.

• The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

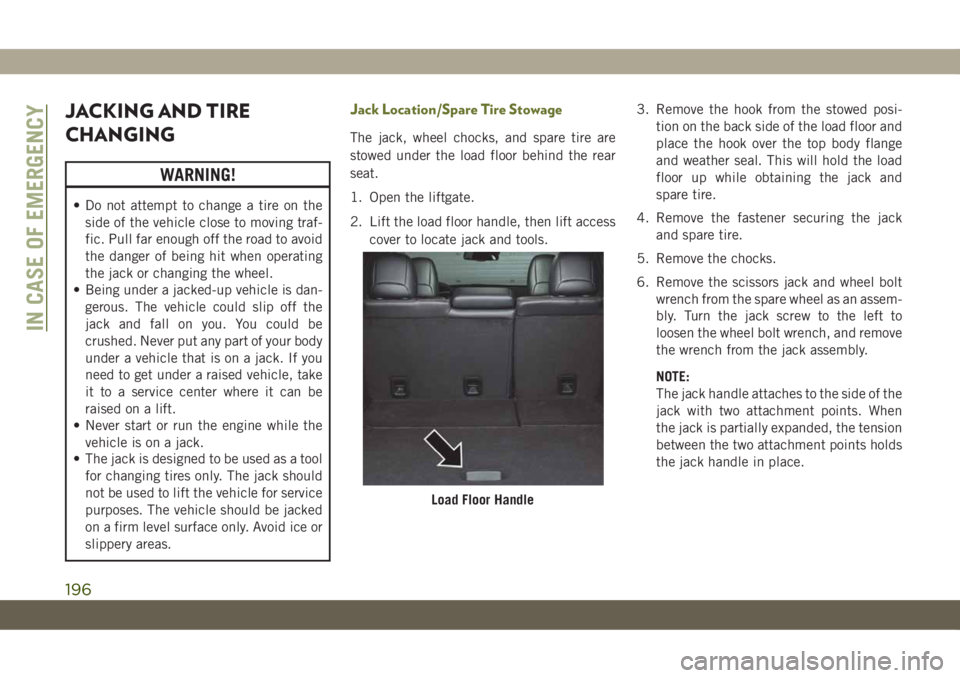

Jack Location/Spare Tire Stowage

The jack, wheel chocks, and spare tire are

stowed under the load floor behind the rear

seat.

1. Open the liftgate.

2. Lift the load floor handle, then lift access

cover to locate jack and tools.3. Remove the hook from the stowed posi-

tion on the back side of the load floor and

place the hook over the top body flange

and weather seal. This will hold the load

floor up while obtaining the jack and

spare tire.

4. Remove the fastener securing the jack

and spare tire.

5. Remove the chocks.

6. Remove the scissors jack and wheel bolt

wrench from the spare wheel as an assem-

bly. Turn the jack screw to the left to

loosen the wheel bolt wrench, and remove

the wrench from the jack assembly.

NOTE:

The jack handle attaches to the side of the

jack with two attachment points. When

the jack is partially expanded, the tension

between the two attachment points holds

the jack handle in place.

Load Floor Handle

IN CASE OF EMERGENCY

196

Page 200 of 344

WARNING!

• If working on or near a roadway, be

extremely careful of motor traffic.

• To assure that spare tires, flat or in-

flated, are securely stowed, spares must

be stowed with the valve stem facing the

ground.

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated in the Jacking Instructions for this

vehicle.

1. Remove the spare tire, jack, wheel

chocks, and wheel bolt wrench.

2. If equipped with aluminum wheels where

the center cap covers the wheel bolts, use

the wheel bolt wrench to pry the center

cap off carefully before raising the

vehicle.

3. Before raising the vehicle, use the wheel

bolt wrench to loosen, but not remove, the

wheel bolts on the wheel with the flat tire.

Turn the wheel bolts counterclockwise

one turn while the wheel is still on the

ground.

4. Place the jack underneath the lift area

that is closest to the flat tire. Turn the jack

screw clockwise to firmly engage the jack

saddle with the lift area of the sill flange,

centering the jack saddle inside the cut-

out in the sill cladding.

Warning Label

Jacking Locations

Rear Jack Location Engaged

IN CASE OF EMERGENCY

198

Page 201 of 344

5. Raise the vehicle just enough to remove

the flat tire.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

6. Remove the wheel bolts and tire.7. Remove the alignment pin from the jack

assembly and thread the pin into the

wheel hub to assist in mounting the spare

tire.

8. Mount the spare tire.

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.

NOTE:

• For vehicles so equipped, do not at-

tempt to install a center cap or wheel

cover on the compact spare.

• Refer to “Tires” in “Servicing And

Maintenance” in the Owner's Manual

for further information about the spare

tire, its use, and operation.

9. Install the wheel bolts with the threaded

end of the wheel bolt toward the wheel.

Lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

10. Lower the vehicle to the ground by turn-

ing the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. If in doubt about the correct tight-

ness, have them checked with a torque

wrench by an authorized dealer or at a

service station.

NOTE:

Refer to “Torque Specifications” in

“Technical Specifications” for the proper

lug bolt torque.

12. Securely stow the jack, tools, chocks,

and flat tire.

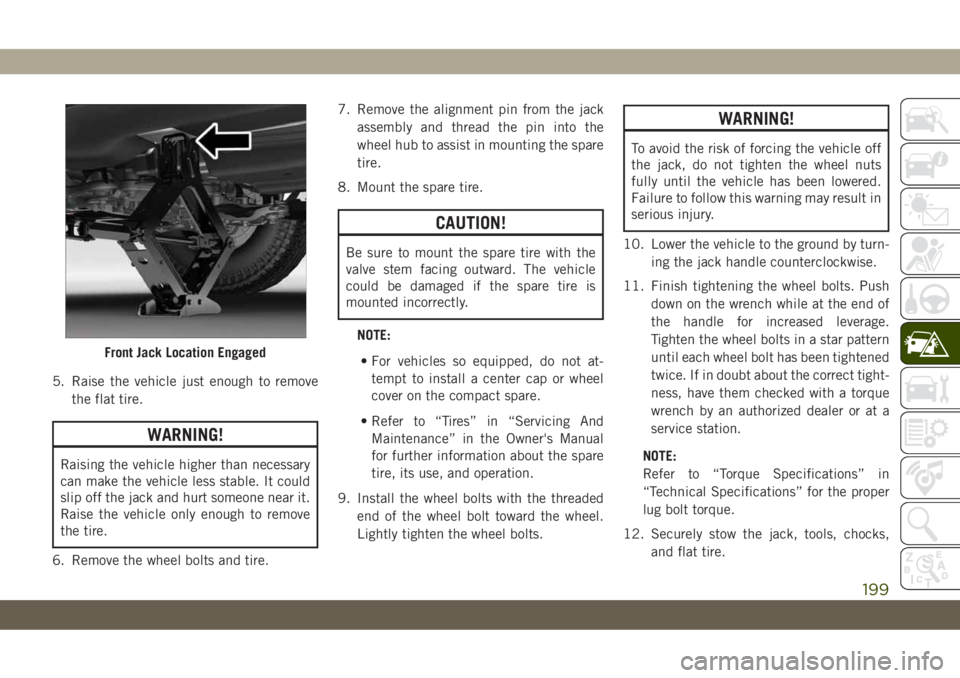

Front Jack Location Engaged

199

Page 202 of 344

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the

threaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.4. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage. Tighten

the wheel bolts in a star pattern until each

wheel bolt has been tightened twice. If in

doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station.

Refer to “Torque Specifications” in

“Technical Specifications” for the proper

lug bolt torque.

5. Lower the jack until it is free. Remove the

wheel chocks. Reassemble the lug wrench

to the jack assembly and stow it in the

spare tire area. Secure the assembly using

the means provided. Release the parking

brake before driving the vehicle.

6. After 25 miles (40 km), check the wheel

bolt torque with a torque wrench to ensure

that all wheel bolts are properly seated

against the wheel.

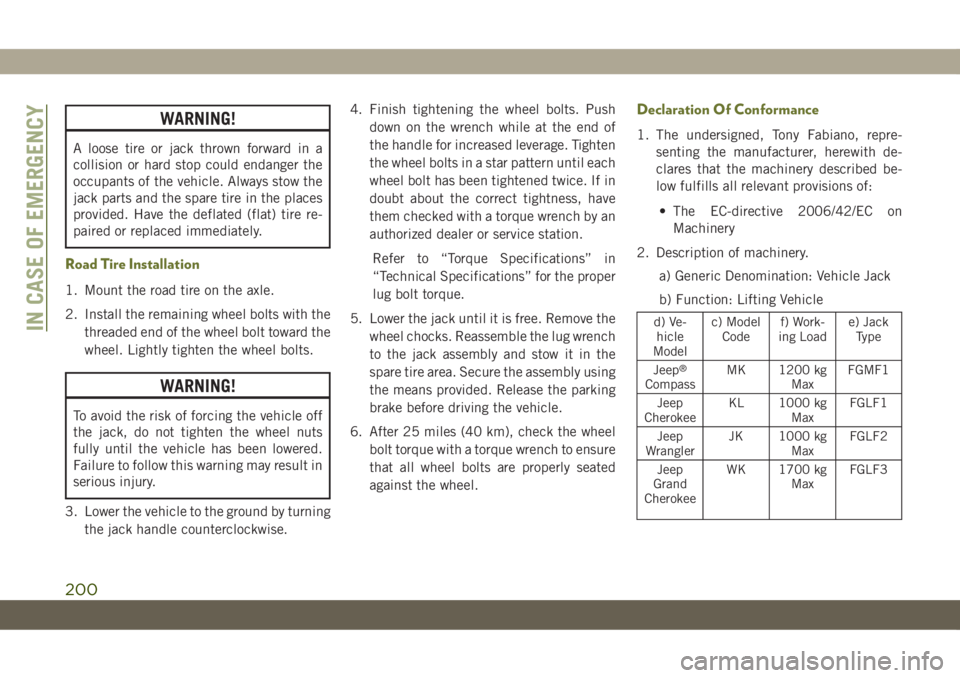

Declaration Of Conformance

1. The undersigned, Tony Fabiano, repre-

senting the manufacturer, herewith de-

clares that the machinery described be-

low fulfills all relevant provisions of:

• The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a) Generic Denomination: Vehicle Jack

b) Function: Lifting Vehicle

d) Ve-

hicle

Modelc) Model

Codef) Work-

ing Loade) Jack

Type

Jeep

®

CompassMK 1200 kg

MaxFGMF1

Jeep

CherokeeKL 1000 kg

MaxFGLF1

Jeep

WranglerJK 1000 kg

MaxFGLF2

Jeep

Grand

CherokeeWK 1700 kg

MaxFGLF3

IN CASE OF EMERGENCY

200

Page 217 of 344

NOTE:

• You must ensure that the Auto Park Brake

feature is disabled before towing this ve-

hicle, to avoid inadvertent Electric Park

Brake engagement. The Auto Park Brake

feature is enabled or disabled via the cus-

tomer programmable features in the

Uconnect Settings.

• Vehicles with a discharged battery or total

electrical failure when the electric park

brake (EPB) is engaged, will need a wheel

dolly or jack to raise the rear wheels off the

ground when moving the vehicle onto a

flatbed.

If you must use the accessories (wipers, de-

frosters, etc.) while being towed, the ignition

must be in the ON/RUN mode, not the ACC

mode.

Note that the Safehold feature will engage

the Electric Park Brake whenever the driver's

door is opened (if the battery is connected,

ignition is ON, transmission is not in PARK,

and brake pedal is released). If you are towing

this vehicle with the ignition in the ON/RUNmode, you must manually disable the Elec-

tric Park Brake each time the driver's door is

opened, by pressing the brake pedal and then

releasing the EPB.

If the vehicle’s battery is discharged, refer to

“Gear Selector Override” in this section for

instructions on shifting the automatic trans-

mission out of PARK so that the vehicle can

be moved.

CAUTION!

• Do not use sling-type equipment when

towing. Vehicle damage may occur.

• When securing the vehicle to a flatbed

truck, do not attach to front or rear

suspension components. Damage to

your vehicle may result from improper

towing.

• Ensure that the Electric Park Brake is

released, and remains released, while

being towed.

Without The Key Fob

Special care must be taken when the vehicle

is towed with the ignition in the LOCK/OFF

mode. The only approved method of towing

without the key fob is with a flatbed truck.

Proper towing equipment is necessary to pre-

vent damage to the vehicle.

Front-Wheel Drive (FWD) Models

The manufacturer recommends towing your

vehicle with all four wheelsOFFthe ground

using a flatbed.

If flatbed equipment is not available, this

vehicle must be towed with the front wheels

OFF the ground (using a towing dolly, or

wheel lift equipment with the front wheels

raised).

Ensure that the Electric Park Brake is re-

leased, and remains released, while being

towed. The Electric Park Brake does not need

to be released, if all four wheels are off the

ground.

215

Page 218 of 344

CAUTION!

Towing this vehicle in violation of the

above requirements can cause severe en-

gine and/or transmission damage. Damage

from improper towing is not covered under

the New Vehicle Limited Warranty.

4x4 Models

The manufacturer requires towing with all

four wheelsOFFthe ground.

Acceptable methods are to tow the vehicle on

a flatbed, or with one end of vehicle raised

and the opposite end on a towing dolly.

CAUTION!

• Front or rear wheel lifts must not be used

(if the remaining wheels are on the

ground). Internal damage to the trans-

mission or power transfer unit will occur

if a front or rear wheel lift is used when

towing.

• Towing this vehicle in violation of the

above requirements can cause severe

transmission and/or power transfer unit

CAUTION!

damage. Damage from improper towing

is not covered under the New Vehicle

Limited Warranty.

Recovery Strap — If Equipped

Your vehicle may be included with a recovery

strap. Recovery straps do not act like tradi-

tional tow straps, chains, or winch cables.

WARNING!

Recovery straps should only be used in

emergencies to rescue stranded vehicles.

Only use Recovery straps on vehicles that

fit within the recommended GVW of your

recovery strap. Only attach recovery straps

to OE recommended anchor points or

emergency towing anchor points. Never

attach to tow ball or vehicle tie down point,

these are not designed for this purpose.

Never attach to vehicle steering, drive

train, or any other suspension compo-

nents. NEVER pull a strap over sharp

edges or abrasive surfaces that can dam-

age the recovery strap. NEVER use a dam-

WARNING!

aged strap, it has reduced strength. DO

NOT attempt to repair straps. ONLY per-

sons involved in the recovery should be in

either vehicle. No passengers. Anyone in-

side the vehicles can be struck by strap

recoil, causing serious injury. MOVE by-

standers at least 40 ft (12.2 m) from the

recovery area when using the recovery

strap.

Using Recovery Strap

1. Review all warnings and instructions first.

2. Position the recovery vehicle.

3. Connect the recovery strap.

4. Add a recovery damper or blanket.

5. Clear the danger zone.

6. Safely and slowly start pulling.

7. Disconnect the recovery strap after both

vehicles are secure and parked.

IN CASE OF EMERGENCY

216

Page 235 of 344

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your

foot resting or riding on the brake pedal

can result in abnormally high brake tem-

peratures, excessive lining wear, and pos-

sible brake damage. You would not have

your full braking capacity in an emergency.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should

be checked whenever the vehicle is serviced,

or immediately if the brake system warning

light is on. If necessary, add fluid to bring

level within the designated marks on the side

of the reservoir of the brake master cylinder.

Be sure to clean the top of the master cylin-

der area before removing cap. With disc

brakes, fluid level can be expected to fall as

the brake pads wear. Brake fluid level should

be checked when pads are replaced. If the

brake fluid is abnormally low, check the sys-

tem for leaks.

Refer to “Fluids And Lubricants” in “Techni-

cal Specifications” for further information.

WARNING!

• Brake fluid is poisonous and highly cor-

rosive. In the event of accidental con-

tact, immediately wash the affected

parts with water and neutral soap. Then

rinse thoroughly. Call a doctor immedi-

ately if swallowed.

• Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri-

cants” in “Technical Specifications” for

further information. Using the wrong

type of brake fluid can severely damage

your brake system and/or impair its per-

formance. The proper type of brake fluid

for your vehicle is also identified on the

original factory installed hydraulic mas-

ter cylinder reservoir.

• To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

closed container. Keep the master cylin-

der reservoir cap secured at all times.

Brake fluid in a open container absorbs

moisture from the air resulting in a lower

boiling point. This may cause it to boil

WARNING!

unexpectedly during hard or prolonged

braking, resulting in sudden brake fail-

ure. This could result in a collision.

• Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot en-

gine parts, causing the brake fluid to

catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should

be taken to avoid its contact with these

surfaces.

• Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This

could result in a collision.

Manual Transmission — If Equipped

Fluid Level Check

Check the fluid level by removing the fill

plug. The fluid level should be between the

bottom of the fill hole and a point not more

than 3/16 inch (4.7 mm) below the bottom of

the hole.

233