technical specifications JEEP CHEROKEE 2020 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2020, Model line: CHEROKEE, Model: JEEP CHEROKEE 2020Pages: 332, PDF Size: 8.87 MB

Page 7 of 332

GETTING TO KNOW YOUR VEHICLE

GETTING TO KNOW YOUR INSTRUMENT PANEL SAFETY

STARTING AND OPERATING IN CASE OF EMERGENCY

SERVICING AND MAINTENANCE TECHNICAL SPECIFICATIONS MULTIMEDIA

CUSTOMER ASSISTANCE INDEX

2020_JEEP_CHEROKEE_UG_RHD_UK.book Page 5

Page 12 of 332

10

IF YOUR ENGINE OVERHEATS ............... 212

GEAR SELECTOR OVERRIDE .................. 213FREEING A STUCK VEHICLE .................. 214TOWING A DISABLED VEHICLE ............. 215

Without The Key Fob .................... 216

Front-Wheel Drive (FWD) Models .... 216

4x4 Models .................................. 216

Recovery Strap — If Equipped ....... 217

ENHANCED ACCIDENT RESPONSE

SYSTEM (EARS) .................................. 217

EVENT DATA RECORDER (EDR) .............. 217

SERVICING AND MAINTENANCE

SCHEDULED SERVICING ....................... 218

Scheduled Servicing —

Gasoline Engine .......................... 218 Scheduled Servicing —

Diesel Engine ............................... 224

ENGINE COMPARTMENT ....................... 229

2.0L Engine ................................ 229

2.4L Engine ................................ 230

3.2L Engine ................................ 231

2.2L Diesel Engine ...................... 232

Checking Oil Level ........................ 233

Cooling System ............................ 234

Adding Washer Fluid .................... 234

Brake System .............................. 234 Manual Transmission —

If Equipped ................................. 236 Automatic Transmission —

If Equipped ................................. 236 Maintenance-Free Battery ............ 236

Pressure Washing ......................... 237

DEALER SERVICE ................................237

Windshield Wiper Blades ............. 237

RAISING THE VEHICLE ..........................241

TIRES .................................................241

Tires — General Information ........ 241

Tire Types ................................... 246

Spare Tires — If Equipped ........... 246

Wheel And Wheel Trim Care ......... 248

Tire Chains And Traction

Devices ...................................... 249 Tire Rotation Recommendations .... 250

STORING THE VEHICLE .........................251BODYWORK .........................................252

Preserving The Bodywork .............. 252

INTERIORS .........................................253

Seats And Fabric Parts ................. 253

Plastic And Coated Parts............... 254

Leather Parts ............................... 254

Glass Surfaces ............................ 254

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER........255BRAKE SYSTEM ...................................255

WHEEL AND TIRE TORQUE

SPECIFICATIONS ..................................256

Torque Specifications ....................256

WHEELS ..............................................256

WEIGHTS.............................................256

FUEL REQUIREMENTS —

GASOLINE ENGINES ..............................257

2.0L Engine .................................257

2.4L And 3.2L Engines .................257

Materials Added To Fuel ................257

Fuel Icon Identification Compliant

To EN16942 ................................257

FUEL REQUIREMENTS —

DIESEL ENGINE ....................................259

Fuel Icon Identification Compliant

To EN16942 ................................259

FLUID CAPACITIES ..............................261

FLUIDS AND LUBRICANTS .....................262

Engine .........................................262

Chassis ........................................265

FUEL CONSUMPTION AND

CO

2 EMISSIONS ..................................266

MOPAR ACCESSORIES .........................266

Authentic Accessories By Mopar .....266

2020_JEEP_CHEROKEE_UG_RHD_UK.book Page 10

Page 142 of 332

STARTING AND OPERATING

140

during the pre-heat process, When the

engine “Wait To Start” telltale goes off the

engine will automatically crank.

3. The system will automatically engage thestarter to crank the engine. If the vehicle

fails to start, the starter will disengage

automatically after 30 seconds.

4. If you wish to stop the cranking of the engine prior to the engine starting, push

the ENGINE START/STOP button again.

5. Check that the oil pressure warning light has turned off.

6. Release the parking brake.Engine Warm Up

Avoid full throttle operation when the engine

is cold. When starting a cold engine, bring

the engine up to operating speed slowly to

allow the oil pressure to stabilize as the

engine warms up.

NOTE:

High-speed, no-load running of a cold engine

can result in excessive white smoke and poor

engine performance. No-load engine speeds

should be kept under 1,200 RPM during the

warm-up period, especially in cold ambient

temperature conditions.

ENGINE BREAK-IN

RECOMMENDATIONS

A long break-in period is not required for the

engine and drivetrain (transmission and axle)

in your vehicle.

Drive moderately during the first 300 miles

(500 km). After the initial 60 miles

(100 km), speeds up to 50 or 55 mph (80 or

90 km/h) are desirable. While cruising, brief full-throttle accelera

-

tion within the limits of local traffic laws

contributes to a good break-in. Wide-open

throttle acceleration in low gear can be detri -

mental and should be avoided.

The engine oil installed in the engine at the

factory is a high-quality energy conserving

type lubricant. Oil changes should be consis -

tent with anticipated climate conditions

under which vehicle operations will occur.

For the recommended viscosity and quality

grades, refer to “Fluids And Lubricants” in

“Technical Specifications”.

NOTE:

A new engine may consume some oil during

its first few thousand miles (kilometers) of

operation. This should be considered a

normal part of the break-in and not inter -

preted as a problem.

CAUTION!

To prevent damage to the starter, do not

crank continuously for more than 10

seconds at a time. Wait 10 to 15 seconds

before trying again.

CAUTION!

Never use Non-Detergent Oil or Straight

Mineral Oil in the engine or damage may

result.

2020_JEEP_CHEROKEE_UG_RHD_UK.book Page 140

Page 177 of 332

175

Adblue® (UREA) — If Equipped

The vehicle is equipped with an UREA injec-

tion system and Selective Catalytic Reduc -

tion to meet emission standards. These two

systems ensure compliance with the diesel

emissions requirements; at the same time,

they ensure fuel-efficiency, handling, torque

and power. For messages and system warn -

ings, refer to the “Warning Lights And

Messages” in the “Getting To Know Your

Instrument Panel” section. AdBlue® (UREA)

is a very stable product with a long shelf life.

Stored at temperatures LOWER than 90 °F

(32 °C), it has a shelf life of at least one year.

For more information on the AdBlue® liquid

type, see the “Fluids and lubricants” in the

“Technical specifications” section. The

vehicle is equipped with an automatic

AdBlue® heating system when the engine

starts allowing the system to work correctly

at temperatures lower than 12 °F (-11 °C).

NOTE:

AdBlue® freezes at temperatures lower than

12 °F (-11 °C).

AdBlue® (UREA) Storage

AdBlue® (UREA) is considered a very stable

product with a long shelf life. If AdBlue®

(UREA) is kept in temperatures between 10°

and 90°F (-12° and 32°C), it will last a

minimum of one year.

AdBlue® (UREA) is subject to freezing at the

lowest temperatures. For example, AdBlue®

(UREA) may freeze at temperatures at or

below 12° F (-11° C). The system has been

designed to operate in this environment.

NOTE:

When working with AdBlue® (UREA), it is

important to know that:

Any containers or parts that come into

contact with AdBlue® (UREA) must be

AdBlue® (UREA) compatible (plastic or

stainless steel). Copper, brass, aluminum,

iron or non-stainless steel should be

avoided as they are subject to corrosion by

AdBlue® (UREA).

If AdBlue® (UREA) is spilled, it should be

wiped up completely.

Adding AdBlue® (UREA)

Preliminary Conditions

AdBlue® (UREA) freezes at temperatures

lower than 12° F (-11° C). If the car stands

for a long time at this temperature refilling

could be difficult. For this reason, it is

advised to park the vehicle in a garage and/

or heated environment and wait for the

UREA to return to liquid state before topping

up.

Proceed as follows:

Park the car on flat ground and stop the

engine by placing the ignition in the OFF

position.

Open the fuel door, undo and remove the

cap (blue) from the AdBlue® (UREA)

filler.

2020_JEEP_CHEROKEE_UG_RHD_UK.book Page 175

Page 201 of 332

199

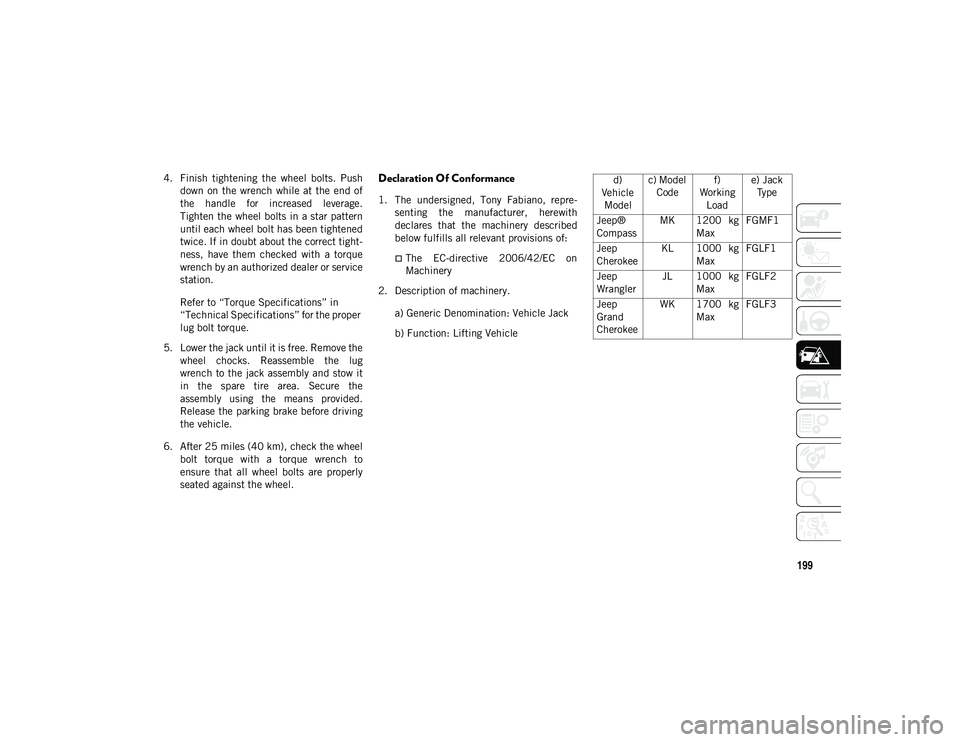

4. Finish tightening the wheel bolts. Pushdown on the wrench while at the end of

the handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. If in doubt about the correct tight -

ness, have them checked with a torque

wrench by an authorized dealer or service

station.

Refer to “Torque Specifications” in

“Technical Specifications” for the proper

lug bolt torque.

5. Lower the jack until it is free. Remove the wheel chocks. Reassemble the lug

wrench to the jack assembly and stow it

in the spare tire area. Secure the

assembly using the means provided.

Release the parking brake before driving

the vehicle.

6. After 25 miles (40 km), check the wheel bolt torque with a torque wrench to

ensure that all wheel bolts are properly

seated against the wheel.Declaration Of Conformance

1. The undersigned, Tony Fabiano, repre -

senting the manufacturer, herewith

declares that the machinery described

below fulfills all relevant provisions of:

The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a) Generic Denomination: Vehicle Jack

b) Function: Lifting Vehicle d)

Vehicle Model c) Model

Code f)

Working Load e) Jack

Type

Jeep®

Compass MK 1200 kg

Max FGMF1

Jeep

Cherokee KL 1000 kg

Max FGLF1

Jeep

Wrangler JL 1000 kg

Max FGLF2

Jeep

Grand

Cherokee WK 1700 kg

Max FGLF3

2020_JEEP_CHEROKEE_UG_RHD_UK.book Page 199

Page 237 of 332

235

(Continued)

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should

be checked whenever the vehicle is serviced,

or immediately if the brake system warning

light is on. If necessary, add fluid to bring

level within the designated marks on the side

of the reservoir of the brake master cylinder.

Be sure to clean the top of the master

cylinder area before removing cap. With disc

brakes, fluid level can be expected to fall as

the brake pads wear. Brake fluid level should

be checked when pads are replaced. If the

brake fluid is abnormally low, check the

system for leaks.

Refer to “Fluids And Lubricants” in “Tech-

nical Specifications” for further information.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your

foot resting or riding on the brake pedal

can result in abnormally high brake

temperatures, excessive lining wear, and

possible brake damage. You would not

have your full braking capacity in an

emergency.

WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri -

cants” in “Technical Specifications” for

further information. Using the wrong

type of brake fluid can severely damage

your brake system and/or impair its

performance. The proper type of brake

fluid for your vehicle is also identified on

the original factory installed hydraulic

master cylinder reservoir.

To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

closed container. Keep the master

cylinder reservoir cap secured at all

times. Brake fluid in a open container

absorbs moisture from the air resulting

in a lower boiling point. This may cause

it to boil unexpectedly during hard or

prolonged braking, resulting in sudden

brake failure. This could result in a colli -

sion.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot

engine parts, causing the brake fluid to

catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should

be taken to avoid its contact with these

surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This

could result in a collision.

WARNING! (Continued)

2020_JEEP_CHEROKEE_UG_RHD_UK.book Page 235

Page 257 of 332

255

TECHNICAL SPECIFICATIONS

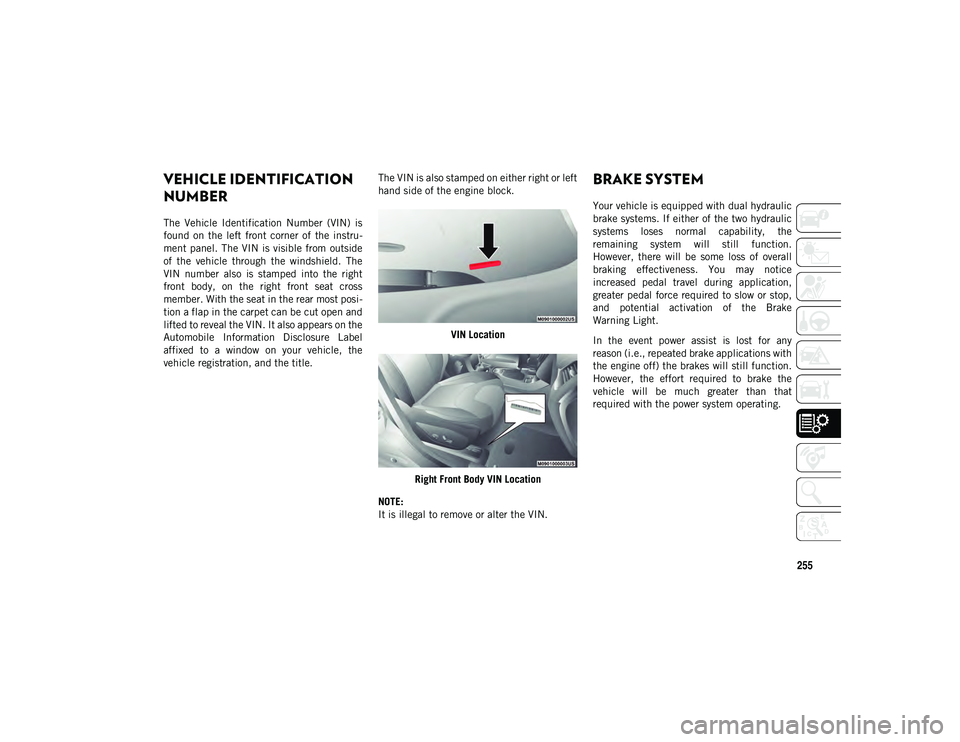

VEHICLE IDENTIFICATION

NUMBER

The Vehicle Identification Number (VIN) is

found on the left front corner of the instru-

ment panel. The VIN is visible from outside

of the vehicle through the windshield. The

VIN number also is stamped into the right

front body, on the right front seat cross

member. With the seat in the rear most posi -

tion a flap in the carpet can be cut open and

lifted to reveal the VIN. It also appears on the

Automobile Information Disclosure Label

affixed to a window on your vehicle, the

vehicle registration, and the title. The VIN is also stamped on either right or left

hand side of the engine block.

VIN Location

Right Front Body VIN Location

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic

brake systems. If either of the two hydraulic

systems loses normal capability, the

remaining system will still function.

However, there will be some loss of overall

braking effectiveness. You may notice

increased pedal travel during application,

greater pedal force required to slow or stop,

and potential activation of the Brake

Warning Light.

In the event power assist is lost for any

reason (i.e., repeated brake applications with

the engine off) the brakes will still function.

However, the effort required to brake the

vehicle will be much greater than that

required with the power system operating.

2020_JEEP_CHEROKEE_UG_RHD_UK.book Page 255

Page 258 of 332

TECHNICAL SPECIFICATIONS

256

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important

to ensure that the wheel is properly mounted

to the vehicle. Any time a wheel has been

removed and reinstalled on the vehicle, the

lug nuts/bolts should be torqued using a

properly calibrated torque wrench using a

high quality six sided (hex) deep wall socket.

Torque Specifications

**Use only authorized dealer recommended

lug nuts/bolts and clean or remove any dirt or

oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles.

Tighten the lug nuts/bolts in a star pattern

until each nut/bolt has been tightened twice.

Ensure that the socket is fully engaged on

the lug nut/bolt (do not insert it halfway).Torque Pattern

After 25 miles (40 km), check the lug nut/

bolt torque to be sure that all the lug nuts/

bolts are properly seated against the wheel.

WHEELS

Refer to the tire placard label located on the

door sill of the vehicle or to the Registration

Document for the tire size and pressure.

Refer to “Tires” in the “Servicing and main -

tenance” for further information.

WEIGHTS

For further information refer to “Vehicle

Loading” in the “Starting And Operating”

chapter.

Lug Nut/Bolt

Torque **Lug Nut/

Bolt SizeLug Nut/Bolt

Socket Size

100 Ft-Lbs

(135 N·m) M12 x 1.25 17 mm

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts/bolts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

personal injury.

2020_JEEP_CHEROKEE_UG_RHD_UK.book Page 256

Page 260 of 332

TECHNICAL SPECIFICATIONS

258Fuel Icons

What It Means

Unleaded fuel containing up to 2,7% (m/m) oxygen and a maximum ethanol content of 5,0% (V/V) EN228 compliant

fuel

Unleaded fuel containing up to 3,7% (m/m) oxygen and a maximum ethanol content of 10,0% ( V/V) EN228

compliant fuel

Compressed Natural Gas and biomethane for automotive applications EN16723 compliant fuel

Liquefied Petroleum Gas for automotive applications EN589 compliant fuel

Diesel fuel containing up to 7% ( V/V) Fatty Acid Methyl Esters (FAME) EN590 compliant fuel

Diesel fuel containing up to 10% (V/V) Fatty Acid Methyl Esters (FAME) EN16734 compliant fuel

2020_JEEP_CHEROKEE_UG_RHD_UK.book Page 258

Page 262 of 332

TECHNICAL SPECIFICATIONS

260Fuel Icons

What It Means

Unleaded fuel containing up to 2,7% (m/m) oxygen and a maximum ethanol content of 5,0% (V/V) EN228 compliant

fuel

Unleaded fuel containing up to 3,7% (m/m) oxygen and a maximum ethanol content of 10,0% ( V/V) EN228

compliant fuel

Compressed Natural Gas and biomethane for automotive applications EN16723 compliant fuel

Liquefied Petroleum Gas for automotive applications EN589 compliant fuel

Diesel fuel containing up to 7% ( V/V) Fatty Acid Methyl Esters (FAME) EN590 compliant fuel

Diesel fuel containing up to 10% (V/V) Fatty Acid Methyl Esters (FAME) EN16734 compliant fuel

2020_JEEP_CHEROKEE_UG_RHD_UK.book Page 260