maintenance JEEP CHEROKEE 2023 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: CHEROKEE, Model: JEEP CHEROKEE 2023Pages: 276, PDF Size: 12.55 MB

Page 126 of 276

124STARTING AND OPERATING

Driving Through Water

Although your vehicle is capable of driving through water,

there are a number of precautions that must be

considered before entering the water:

Driving through water more than a few inches/

centimeters deep will require extra caution to ensure

safety and prevent damage to your vehicle. If you must

drive through water, try to determine the depth and the

bottom condition (and location of any obstacles) prior to

entering. Proceed with caution and maintain a steady

controlled speed less than 5 mph (8 km/h) in deep water

to minimize wave effects.

Flowing Water

If the water is swift flowing and rising (as in storm run-off)

avoid crossing until the water level recedes and/or the

flow rate is reduced. If you must cross flowing-water, avoid

depths in excess of 9 inches (22 cm). The flowing water

can erode the streambed causing your vehicle to sink into

deeper water. Determine exit point(s) that are

downstream of your entry point to allow for drifting. Standing Water

Avoid driving in standing water deeper than 16 inches

(40.5 cm), and reduce speed appropriately to minimize

wave effects. Maximum speed in 16 inches (40.5 cm) of

water is less than 5 mph (8 km/h).

(Trailhawk only): Avoid driving in standing water deeper

than 19 inches (48 cm), and reduce speed appropriately

to minimize wave effects. Maximum speed in 19 inches

(48 cm) of water is less than 5 mph (8 km/h).

Maintenance

After driving through deep water, inspect your vehicle

fluids and lubricants (engine, transmission, Power

Transfer Unit, and Rear Drive Module) to ensure they have

not been contaminated. Contaminated fluids and

lubricants (milky, foamy in appearance) should be

flushed/changed as soon as possible to prevent

component damage.

Driving In Snow, Mud And Sand

In heavy snow, when pulling a load, or for additional

control at slower speeds, shift the transmission to a low

gear and shift the 4WD system to the appropriate terrain

mode, using 4WD LOW if necessary

Úpage 85. Only shift

into a lower gear to maintain forward motion. Over-revving

the engine can spin the wheels and traction will be lost.

Avoid abrupt downshifts on icy or slippery roads because

engine braking may cause skidding and loss of control.

Hill Climbing

NOTE:Before attempting to climb a hill, determine the conditions

at the crest and/or on the other side.

Before climbing a steep hill, shift the transmission to a

lower gear and shift the 4WD system to 4WD LOW. Use

FIRST gear and 4WD LOW for very steep hills.

NOTE:Brakes should be applied at increased slippage, but

before coming to a stop to avoid digging into the loose

surface and rendering the operator of the vehicle stuck/

immobile.

If you stall or begin to lose headway while climbing a steep

hill, allow your vehicle to come to a stop and immediately

apply the brakes. Once stopped, shift to REVERSE. Back

slowly down the hill allowing the compression braking of

the engine to help regulate your speed. If the brakes are

required to control vehicle speed, apply them lightly and

avoid locking or skidding the tires.

CAUTION!

When driving through water, do not exceed 5 mph

(8 km/h). Always check water depth before entering as

a precaution, and check all fluids afterward. Driving

through water may cause damage that may not be

covered by the New Vehicle Limited Warranty.

WARNING!

If the engine stalls or you lose headway or cannot make

it to the top of a steep hill or grade, never attempt to

turn around. To do so may result in tipping and rolling

the vehicle. Always back straight down a hill in

REVERSE gear carefully. Never back down a hill in

NEUTRAL using only the brake.

23_KL_OM_EN_USC_t.book Page 124

Page 147 of 276

SAFETY145

Electronic Stability Control (ESC)

ESC enhances directional control and stability of the

vehicle under various driving conditions. ESC corrects for

oversteering or understeering of the vehicle by applying

the brake of the appropriate wheel(s) to counteract these

conditions. Engine power may also be reduced to help the

vehicle maintain the desired path.

Oversteer — when the vehicle is turning more than

appropriate for the steering wheel position.

Understeer — when the vehicle is turning less than

appropriate for the steering wheel position.

ESC uses sensors in the vehicle to determine the vehicle

path intended by the driver and compares it to the actual

path of the vehicle. When the actual path does not match

the intended path, ESC applies the brake of the

appropriate wheel to assist in counteracting the oversteer

or understeer condition.

The ESC Activation/Malfunction Indicator Light located in

the instrument cluster will start to flash as soon as the ESC

system becomes active. The ESC Activation/Malfunction

Indicator Light also flashes when the TCS is active. If the

ESC Activation/Malfunction Indicator Light begins to flash

during acceleration, ease up on the accelerator and apply

as little throttle as possible. Be sure to adapt your speed

and driving to the prevailing road conditions.

ESC Operating Modes

Depending upon model and mode of operation, the ESC

system may have multiple operating modes. ESC On

This is the normal operating mode for ESC. Whenever the

vehicle is started, the ESC system will be in this mode. This

mode should be used for most driving conditions.

Alternate ESC modes should only be used for specific

reasons as noted in the following paragraphs.

Partial Off

This mode may be useful if the vehicle becomes stuck.

This mode may modify TCS and ESC thresholds for

activation, which allows for more wheel spin than normally

allowed.

To enter the “Partial Off” mode, momentarily push the ESC

OFF button and the ESC OFF Indicator Light will illuminate.

To turn the ESC on again, momentarily push the ESC OFF

button and the ESC OFF Indicator Light will turn off.

NOTE:For vehicles with multiple partial ESC modes, the push and

release of the button will toggle the ESC modes. Multiple

attempts may be required to return to “ESC On”.

WARNING!

Electronic Stability Control (ESC) cannot prevent the

natural laws of physics from acting on the vehicle,

nor can it increase the traction afforded by prevailing

road conditions. ESC cannot prevent accidents,

including those resulting from excessive speed in

turns, driving on very slippery surfaces, or hydro -

planing. ESC also cannot prevent accidents resulting

from loss of vehicle control due to inappropriate

driver input for the conditions. Only a safe, attentive,

and skillful driver can prevent accidents. The capabil -

ities of an ESC equipped vehicle must never be

exploited in a reckless or dangerous manner which

could jeopardize the user’s safety or the safety of

others.

Vehicle modifications, or failure to properly maintain

your vehicle, may change the handling characteris -

tics of your vehicle, and may negatively affect the

performance of the ESC system. Changes to the

steering system, suspension, braking system, tire

type and size or wheel size may adversely affect ESC

performance. Improperly inflated and unevenly worn

tires may also degrade ESC performance. Any vehicle

modification or poor vehicle maintenance that

reduces the effectiveness of the ESC system can

increase the risk of loss of vehicle control, vehicle

rollover, personal injury and death.

WARNING!

When in “Partial Off” mode, the TCS functionality of

ESC (except for the limited slip feature described in

the TCS section) has been disabled and the ESC OFF

Indicator Light will be illuminated. When in “Partial

Off” mode, the engine power reduction feature of

TCS is disabled, and the enhanced vehicle stability

offered by the ESC system is reduced.

Trailer Sway Control (TSC) is disabled when the ESC

system is in the “Partial Off” mode.

6

23_KL_OM_EN_USC_t.book Page 145

Page 158 of 276

156SAFETY

The TPMS will continue to warn the driver of low tire

pressure as long as the condition exists, and will not turn

off until the tire pressure is at or above the recommended

cold placard pressure. Once the low tire pressure warning

(Tire Pressure Monitoring System Warning Light)

illuminates, you must increase the tire pressure to the

recommended cold placard pressure in order for the

TPMS Warning Light to turn off.

The system will automatically update and the TPMS

Warning Light will turn off once the system receives the

updated tire pressures. The vehicle may need to be driven

for up to 20 minutes above 15 mph (24 km/h) in order for

the TPMS to receive this information.

For example, your vehicle may have a recommended cold

(parked for more than three hours) placard pressure of

33 psi (227 kPa). If the ambient temperature is 68°F

(20°C) and the measured tire pressure is 28 psi

(193 kPa), a temperature drop to 20°F (-7°C) will

decrease the tire pressure to approximately 24 psi

(165 kPa). This tire pressure is low enough to turn on the

TPMS Warning Light. Driving the vehicle may cause the tire

pressure to rise to approximately 28 psi (193 kPa), but the

TPMS Warning Light will still be on. In this situation, the

TPMS Warning Light will turn off only after the tires are

inflated to the vehicle’s recommended cold placard

pressure value

Úpage 262.

NOTE:When filling warm tires, the tire pressure may need to be

increased up to an additional 4 psi (28 kPa) above the

recommended cold placard pressure in order to turn the

TPMS Warning Light off.

NOTE:

The TPMS is not intended to replace normal tire care

and maintenance, or to provide warning of a tire failure

or condition.

Driving on a significantly underinflated tire causes the

tire to overheat and can lead to tire failure. Underinfla -

tion also reduces fuel efficiency and tire tread life, and

may affect the vehicle’s handling and stopping ability.

The TPMS is not a substitute for proper tire mainte -

nance, and it is the driver’s responsibility to maintain

correct tire pressure using an accurate tire pressure

gauge, even if underinflation has not reached the level

to trigger illumination of the TPMS Warning Light.

Seasonal temperature changes will affect tire pres -

sure, and the TPMS will monitor the actual tire pres -

sure in the tire.

Premium System

The Tire Pressure Monitoring System (TPMS) uses wireless

technology with wheel rim mounted electronic sensors to

monitor tire pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire pressure

readings to the receiver module.

NOTE:It is particularly important for you to check the tire

pressure in all of the tires on your vehicle monthly and to

maintain the proper pressure.

The TPMS consists of the following components:

Receiver module

Four TPMS sensors

Various TPMS messages, which display in the instru -

ment cluster

TPMS Warning Light

CAUTION!

The TPMS has been optimized for the original equip -

ment tires and wheels. TPMS pressures and warning

have been established for the tire size equipped on

your vehicle. Undesirable system operation or sensor

damage may result when using replacement equip -

ment that is not of the same size, type, and/or style.

The TPMS sensor is not designed for use on after -

market wheels, and may contribute to a poor overall

system performance. Customers are encouraged to

use Original Equipment Manufacturer (OEM) wheels

to ensure TPMS feature operation.

Using aftermarket tire sealants may cause the Tire

Pressure Monitoring System (TPMS) sensor to

become inoperable. After using an aftermarket tire

sealant it is recommended that you take your vehicle

to an authorized dealer to have your sensor function

checked.

After inspecting or adjusting the tire pressure always

reinstall the valve stem cap. This will prevent mois -

ture and dirt from entering the valve stem, which

could damage the TPMS sensor.

23_KL_OM_EN_USC_t.book Page 156

Page 169 of 276

SAFETY167

(Continued)

The ORC contains a backup power supply system that may

deploy the air bag system even if the battery loses power

or it becomes disconnected prior to deployment.

The ORC turns on the Air Bag Warning Light in the

instrument panel for approximately four to eight seconds

for a self-check when the ignition switch is first in the ON/

RUN position. After the self-check, the Air Bag Warning

Light will turn off. If the ORC detects a malfunction in any

part of the system, it turns on the Air Bag Warning Light,

either momentarily or continuously. A single chime will

sound to alert you if the light comes on again after initial

startup.

The ORC also includes diagnostics that will illuminate the

instrument panel Air Bag Warning Light if a malfunction is

detected that could affect the air bag system. The

diagnostics also record the nature of the malfunction.

While the air bag system is designed to be maintenance

free, if any of the following occurs, have an authorized

dealer service the air bag system immediately.

The Air Bag Warning Light does not come on during the

four to eight seconds when the ignition switch is first in

the ON/RUN position.

The Air Bag Warning Light remains on after the four to

eight-second interval.

The Air Bag Warning Light comes on intermittently or

remains on while driving.

NOTE:If the speedometer, tachometer, or any engine related

gauges are not working, the Occupant Restraint Controller

(ORC) may also be disabled. In this condition the air bags

may not be ready to inflate for your protection. Have an

authorized dealer service the air bag system immediately.

Redundant Air Bag Warning Light

If a fault with the Air Bag Warning Light is

detected, which could affect the Supplemental

Restraint System (SRS), the Redundant Air Bag

Warning Light will illuminate on the instrument

panel. The Redundant Air Bag Warning Light will stay on

until the fault is cleared. In addition, a single chime will

sound to alert you that the Redundant Air Bag Warning

Light has come on and a fault has been detected. If the

Redundant Air Bag Warning Light comes on intermittently

or remains on while driving have an authorized dealer

service the vehicle immediately

Úpage 68.

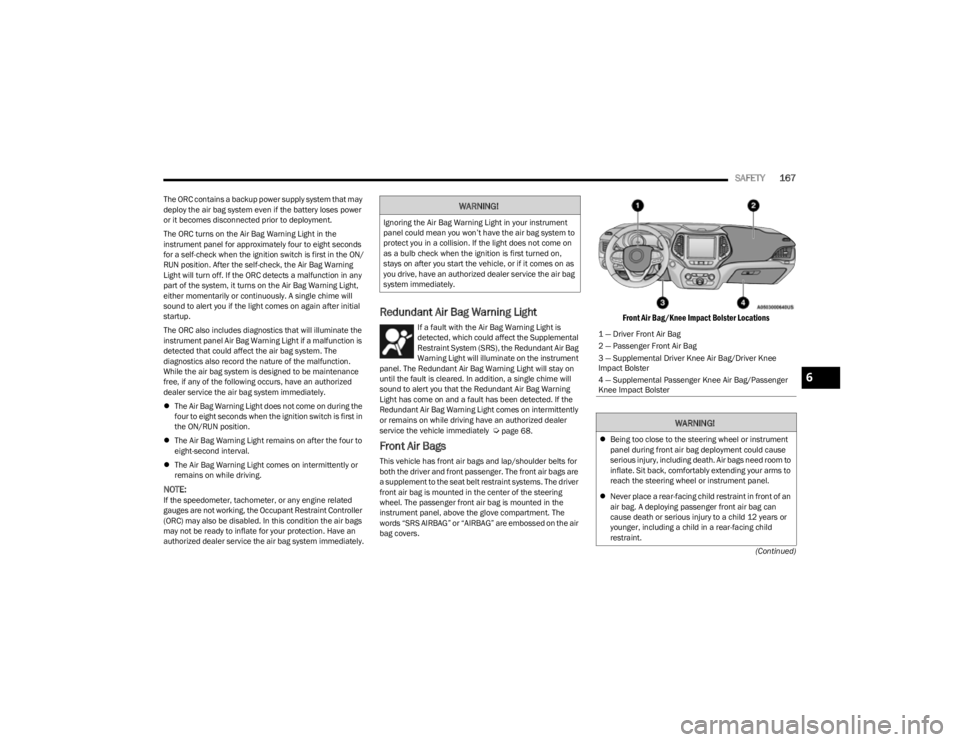

Front Air Bags

This vehicle has front air bags and lap/shoulder belts for

both the driver and front passenger. The front air bags are

a supplement to the seat belt restraint systems. The driver

front air bag is mounted in the center of the steering

wheel. The passenger front air bag is mounted in the

instrument panel, above the glove compartment. The

words “SRS AIRBAG” or “AIRBAG” are embossed on the air

bag covers.

Front Air Bag/Knee Impact Bolster Locations

WARNING!

Ignoring the Air Bag Warning Light in your instrument

panel could mean you won’t have the air bag system to

protect you in a collision. If the light does not come on

as a bulb check when the ignition is first turned on,

stays on after you start the vehicle, or if it comes on as

you drive, have an authorized dealer service the air bag

system immediately.

1 — Driver Front Air Bag

2 — Passenger Front Air Bag

3 — Supplemental Driver Knee Air Bag/Driver Knee

Impact Bolster

4 — Supplemental Passenger Knee Air Bag/Passenger

Knee Impact Bolster

WARNING!

Being too close to the steering wheel or instrument

panel during front air bag deployment could cause

serious injury, including death. Air bags need room to

inflate. Sit back, comfortably extending your arms to

reach the steering wheel or instrument panel.

Never place a rear-facing child restraint in front of an

air bag. A deploying passenger front air bag can

cause death or serious injury to a child 12 years or

younger, including a child in a rear-facing child

restraint.

6

23_KL_OM_EN_USC_t.book Page 167

Page 210 of 276

208

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil change

indicator system. The oil change indicator system will

remind you that it is time to take your vehicle in for

scheduled maintenance.

Based on engine operation conditions, the oil change

indicator message will illuminate. This means that service

is required for your vehicle. Operating conditions such as

frequent short-trips, trailer tow, or extremely hot or cold

ambient temperatures will influence when the “Oil Change

Required” message is displayed. Have your vehicle

serviced as soon as possible, within the next 500 miles

(805 km).An authorized dealer will reset the oil change indicator

message after completing the scheduled oil change. If a

scheduled oil change is performed by someone other than

an authorized dealer, the message can be reset by

referring to the steps described under Instrument Cluster

Display

Úpage 64.

NOTE:Under no circumstances should oil change intervals

exceed 10,000 miles (16,000 km), 12 months or

350 hours of engine run time, whichever comes first. The

350 hours of engine run or idle time is generally only a

concern for fleet customers.

At Every Fuel Stop:

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual wear or

damage. Rotate tires at the first sign of irregular wear,

even if it occurs before the oil indicator system turns

on.

Check the fluid levels of the coolant reservoir and

brake master cylinder; fill as needed.

Check function of all interior and exterior lights.

23_KL_OM_EN_USC_t.book Page 208

Page 211 of 276

SERVICING AND MAINTENANCE209

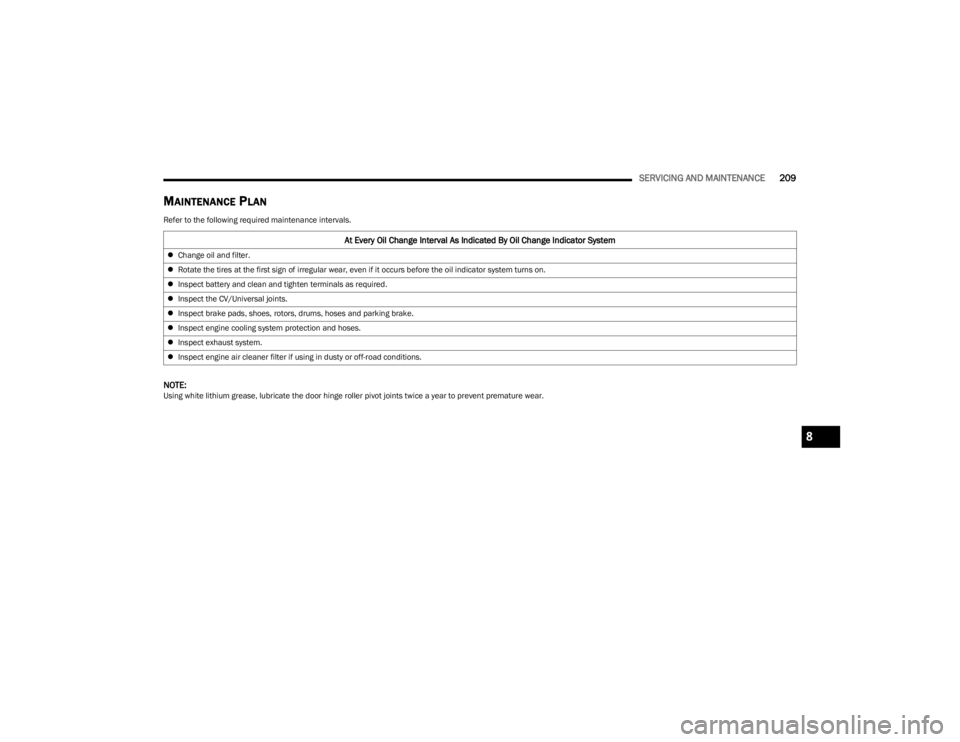

MAINTENANCE PLAN

Refer to the following required maintenance intervals.

NOTE:Using white lithium grease, lubricate the door hinge roller pivot joints twice a year to prevent premature wear.

At Every Oil Change Interval As Indicated By Oil Change Indicator System

Change oil and filter.

Rotate the tires at the first sign of irregular wear, even if it occurs before the oil indicator system turns on.

Inspect battery and clean and tighten terminals as required.

Inspect the CV/Universal joints.

Inspect brake pads, shoes, rotors, drums, hoses and parking brake.

Inspect engine cooling system protection and hoses.

Inspect exhaust system.

Inspect engine air cleaner filter if using in dusty or off-road conditions.

8

23_KL_OM_EN_USC_t.book Page 209

Page 212 of 276

210SERVICING AND MAINTENANCE

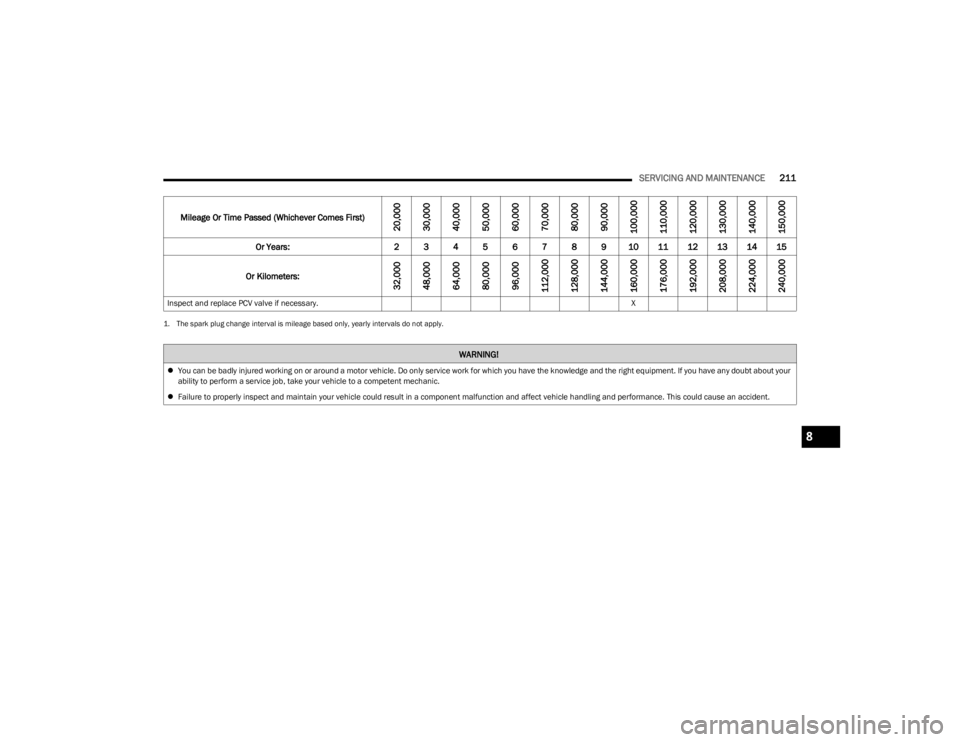

Mileage Or Time Passed (Whichever Comes First)20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Inspect the CV/Universal joints. X X X X X X X X X X X X X X

Inspect front suspension, boot seals. tie rod ends, and

replace if necessary. X

XXXXXX

Inspect the brake linings, parking brake function. XXXXXXX

Inspect front accessory drive belt, tensioner, idler pulley, and

replace if necessary. X

Additional Maintenance

Replace engine air cleaner filter. XXXXX

Clean and lube sun roof tracks. XXXXXXX

Replace the cabin air filter. To be replaced every 12,000 miles (19,000 km).

Replace spark plugs — 2.0L Engine.

1X X

Replace spark plugs — 2.4L Engine.

1X

Flush and replace the engine coolant at 10 years or

150,000 miles (240,000 km) whichever comes first. X

X

23_KL_OM_EN_USC_t.book Page 210

Page 213 of 276

SERVICING AND MAINTENANCE211

Inspect and replace PCV valve if necessary. X

1. The spark plug change interval is mileage based only, yearly intervals do not apply.

Mileage Or Time Passed (Whichever Comes First)20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

WARNING!

You can be badly injured working on or around a motor vehicle. Do only service work for which you have the knowledge and the right equipment. If you have any doubt about your

ability to perform a service job, take your vehicle to a competent mechanic.

Failure to properly inspect and maintain your vehicle could result in a component malfunction and affect vehicle handling and performance. This could cause an accident.

8

23_KL_OM_EN_USC_t.book Page 211

Page 214 of 276

212SERVICING AND MAINTENANCE

ENGINE COMPARTMENT

2.0L ENGINE

1 — Engine Air Cleaner Filter 5 — Engine Oil Dipstick

2 — Oil Fill Cap 6 — Engine Coolant Reservoir

3 — Brake Fluid Reservoir Cap 7 — Battery

4 — Power Distribution Center (Fuses) 8 — Washer Fluid Reservoir Cap

23_KL_OM_EN_USC_t.book Page 212

Page 215 of 276

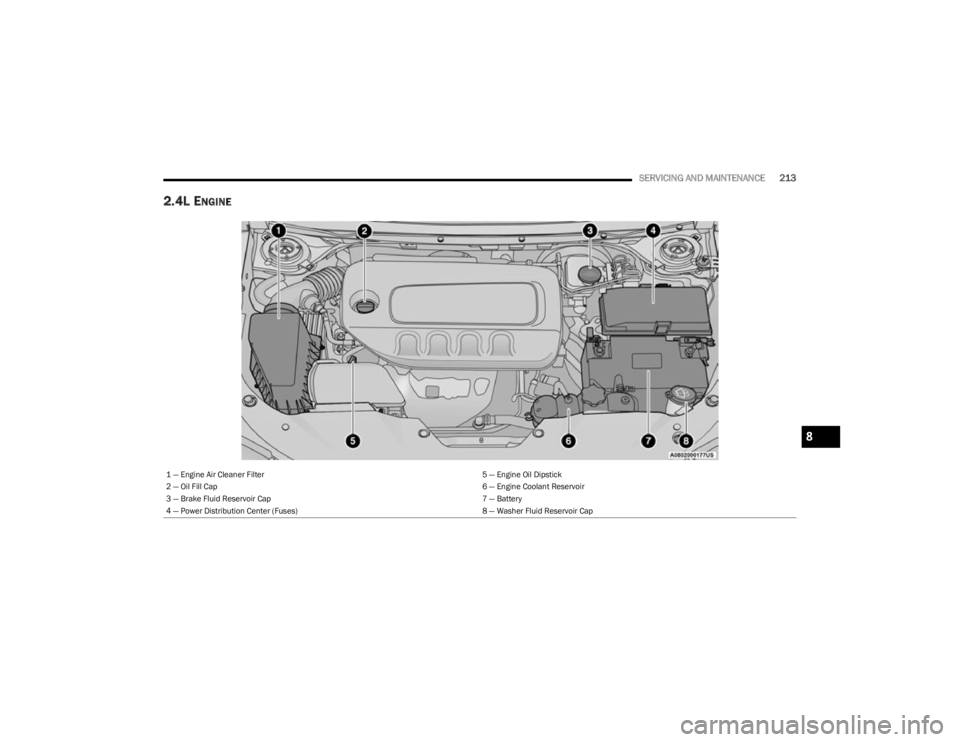

SERVICING AND MAINTENANCE213

2.4L ENGINE

1 — Engine Air Cleaner Filter 5 — Engine Oil Dipstick

2 — Oil Fill Cap 6 — Engine Coolant Reservoir

3 — Brake Fluid Reservoir Cap 7 — Battery

4 — Power Distribution Center (Fuses) 8 — Washer Fluid Reservoir Cap

8

23_KL_OM_EN_USC_t.book Page 213