wheel bolts JEEP CHEROKEE 2023 Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: CHEROKEE, Model: JEEP CHEROKEE 2023Pages: 276, PDF Size: 12.55 MB

Page 195 of 276

IN CASE OF EMERGENCY193

(Continued)

5. Remove the chocks.

6. Remove the scissor jack and wheel bolt wrench from

the spare wheel as an assembly. Turn the jack screw

to the left to loosen the wheel bolt wrench, and

remove the wrench from the jack assembly.

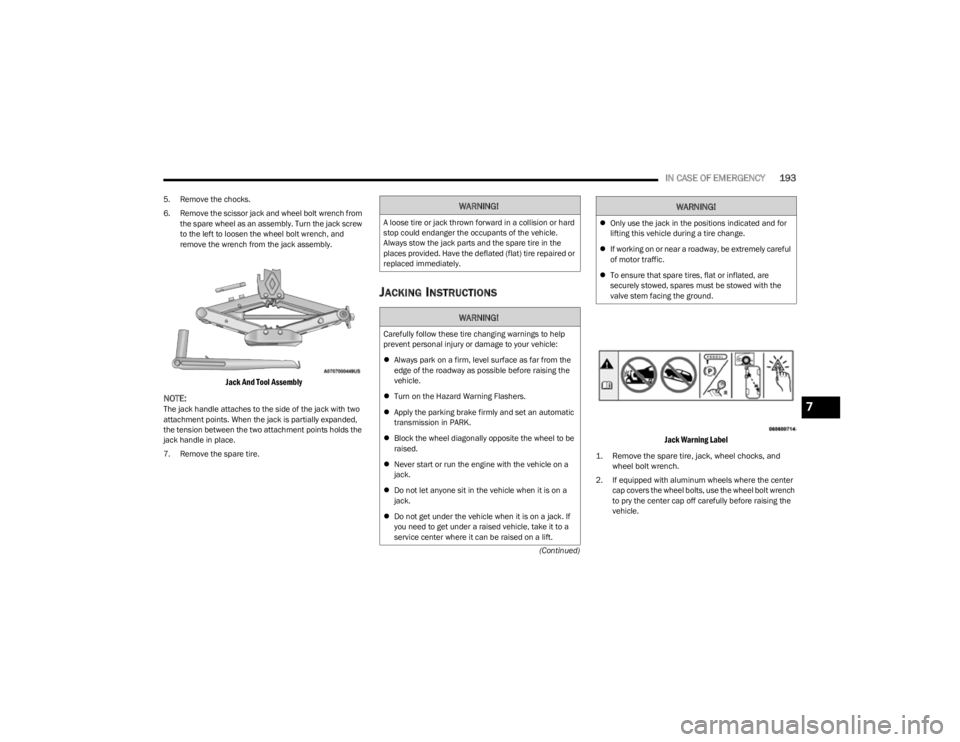

Jack And Tool Assembly

NOTE:

The jack handle attaches to the side of the jack with two

attachment points. When the jack is partially expanded,

the tension between the two attachment points holds the

jack handle in place.

7. Remove the spare tire.

JACKING INSTRUCTIONS

Jack Warning Label

1. Remove the spare tire, jack, wheel chocks, and wheel bolt wrench.

2. If equipped with aluminum wheels where the center cap covers the wheel bolts, use the wheel bolt wrench

to pry the center cap off carefully before raising the

vehicle.

WARNING!

A loose tire or jack thrown forward in a collision or hard

stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired or

replaced immediately.

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set an automatic

transmission in PARK.

Block the wheel diagonally opposite the wheel to be

raised.

Never start or run the engine with the vehicle on a

jack.

Do not let anyone sit in the vehicle when it is on a

jack.

Do not get under the vehicle when it is on a jack. If

you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

Only use the jack in the positions indicated and for

lifting this vehicle during a tire change.

If working on or near a roadway, be extremely careful

of motor traffic.

To ensure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with the

valve stem facing the ground.

WARNING!

7

23_KL_OM_EN_USC_t.book Page 193

Page 196 of 276

194IN CASE OF EMERGENCY

3. Before raising the vehicle, use the wheel bolt wrench

to loosen, but not remove, the wheel bolts on the

wheel with the flat tire. Turn the wheel bolts counter -

clockwise one turn while the wheel is still on the

ground.

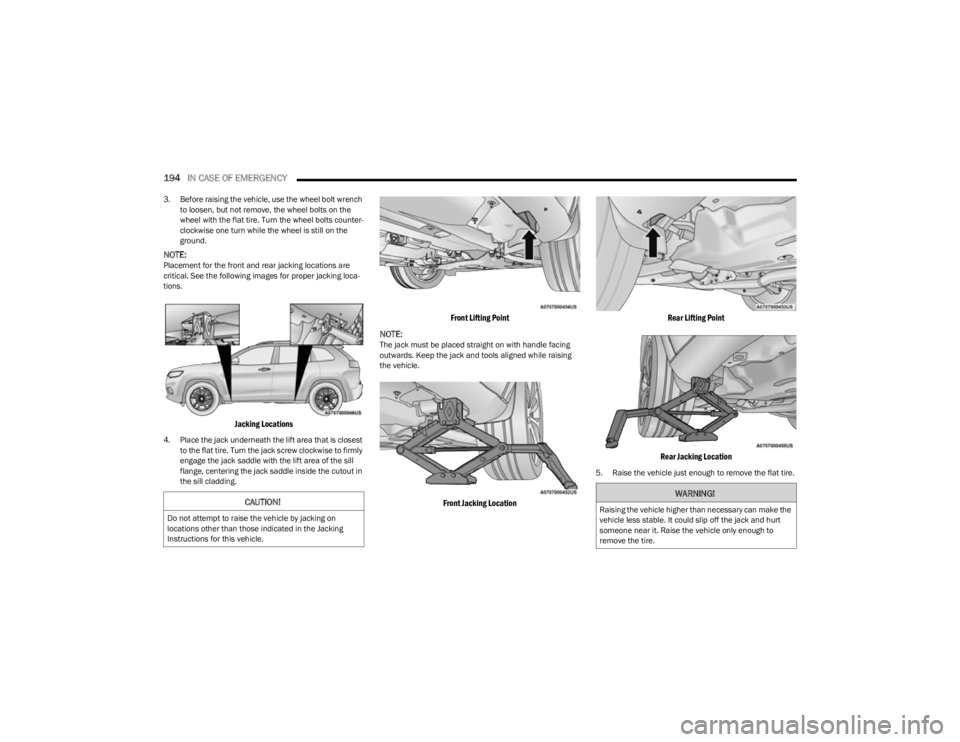

NOTE:Placement for the front and rear jacking locations are

critical. See the following images for proper jacking loca -

tions.

Jacking Locations

4. Place the jack underneath the lift area that is closest to the flat tire. Turn the jack screw clockwise to firmly

engage the jack saddle with the lift area of the sill

flange, centering the jack saddle inside the cutout in

the sill cladding.

Front Lifting Point

NOTE:

The jack must be placed straight on with handle facing

outwards. Keep the jack and tools aligned while raising

the vehicle.

Front Jacking Location Rear Lifting Point

Rear Jacking Location

5. Raise the vehicle just enough to remove the flat tire.

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the Jacking

Instructions for this vehicle.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.

23_KL_OM_EN_USC_t.book Page 194

Page 197 of 276

IN CASE OF EMERGENCY195

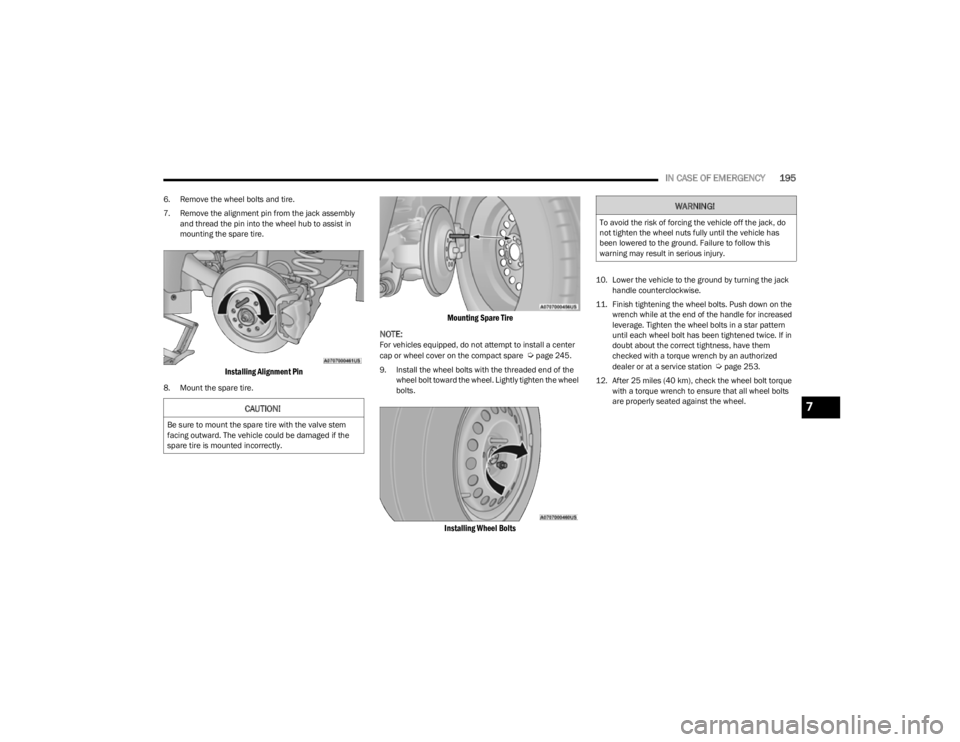

6. Remove the wheel bolts and tire.

7. Remove the alignment pin from the jack assembly

and thread the pin into the wheel hub to assist in

mounting the spare tire.

Installing Alignment Pin

8. Mount the spare tire.

Mounting Spare Tire

NOTE:

For vehicles equipped, do not attempt to install a center

cap or wheel cover on the compact spare Úpage 245.

9. Install the wheel bolts with the threaded end of the wheel bolt toward the wheel. Lightly tighten the wheel

bolts.

Installing Wheel Bolts

10. Lower the vehicle to the ground by turning the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened twice. If in

doubt about the correct tightness, have them

checked with a torque wrench by an authorized

dealer or at a service station

Úpage 253.

12. After 25 miles (40 km), check the wheel bolt torque with a torque wrench to ensure that all wheel bolts

are properly seated against the wheel.

CAUTION!

Be sure to mount the spare tire with the valve stem

facing outward. The vehicle could be damaged if the

spare tire is mounted incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered to the ground. Failure to follow this

warning may result in serious injury.

7

23_KL_OM_EN_USC_t.book Page 195

Page 255 of 276

253

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is found on the left front corner of the instrument

panel. The VIN is visible from outside of the vehicle

through the windshield.

Vehicle Identification Number

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic brake

systems. If either of the two hydraulic systems lose normal

capability, the remaining system will still function.

However, there will be some loss of overall braking

effectiveness. You may notice increased pedal travel

during application, greater pedal force required to slow or

stop, and potential activation of the Brake Warning Light.

In the event power assist is lost for any reason (i.e.,

repeated brake applications with the engine OFF) the

brakes will still function. However, the effort required to

brake the vehicle will be much greater than that required

with the power system operating.

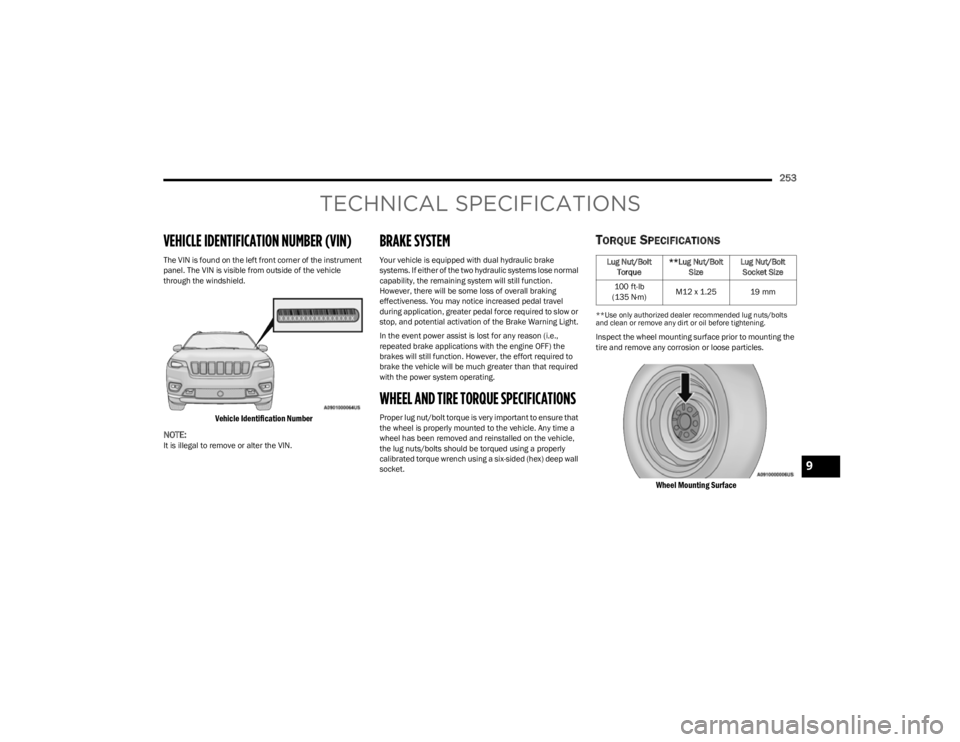

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure that

the wheel is properly mounted to the vehicle. Any time a

wheel has been removed and reinstalled on the vehicle,

the lug nuts/bolts should be torqued using a properly

calibrated torque wrench using a six-sided (hex) deep wall

socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug nuts/bolts

and clean or remove any dirt or oil before tightening.

Inspect the wheel mounting surface prior to mounting the

tire and remove any corrosion or loose particles.

Wheel Mounting Surface

Lug Nut/Bolt Torque **Lug Nut/Bolt

Size Lug Nut/Bolt

Socket Size

100 ft-lb

(135 N·m) M12 x 1.25 19 mm

9

23_KL_OM_EN_USC_t.book Page 253