lock JEEP COMMANDER 2008 1.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2008, Model line: COMMANDER, Model: JEEP COMMANDER 2008 1.GPages: 478, PDF Size: 6.97 MB

Page 370 of 478

CAUTION!

The winch mechanism is designed for use with the

jack extension tube only. Use of an air wrench or

other power tools is not recommended and can dam-

age the winch.

When the spare is clear, tilt the retainer at the end of the

cable and pull it through the center of the wheel.

Preparations For Jacking

Park the vehicle on a firm level surface, avoid ice or

slippery areas,set the parking brakeand place the gear

selector in P (Park). Turn OFF the ignition.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid being hit when operating the jack

or changing the wheel.

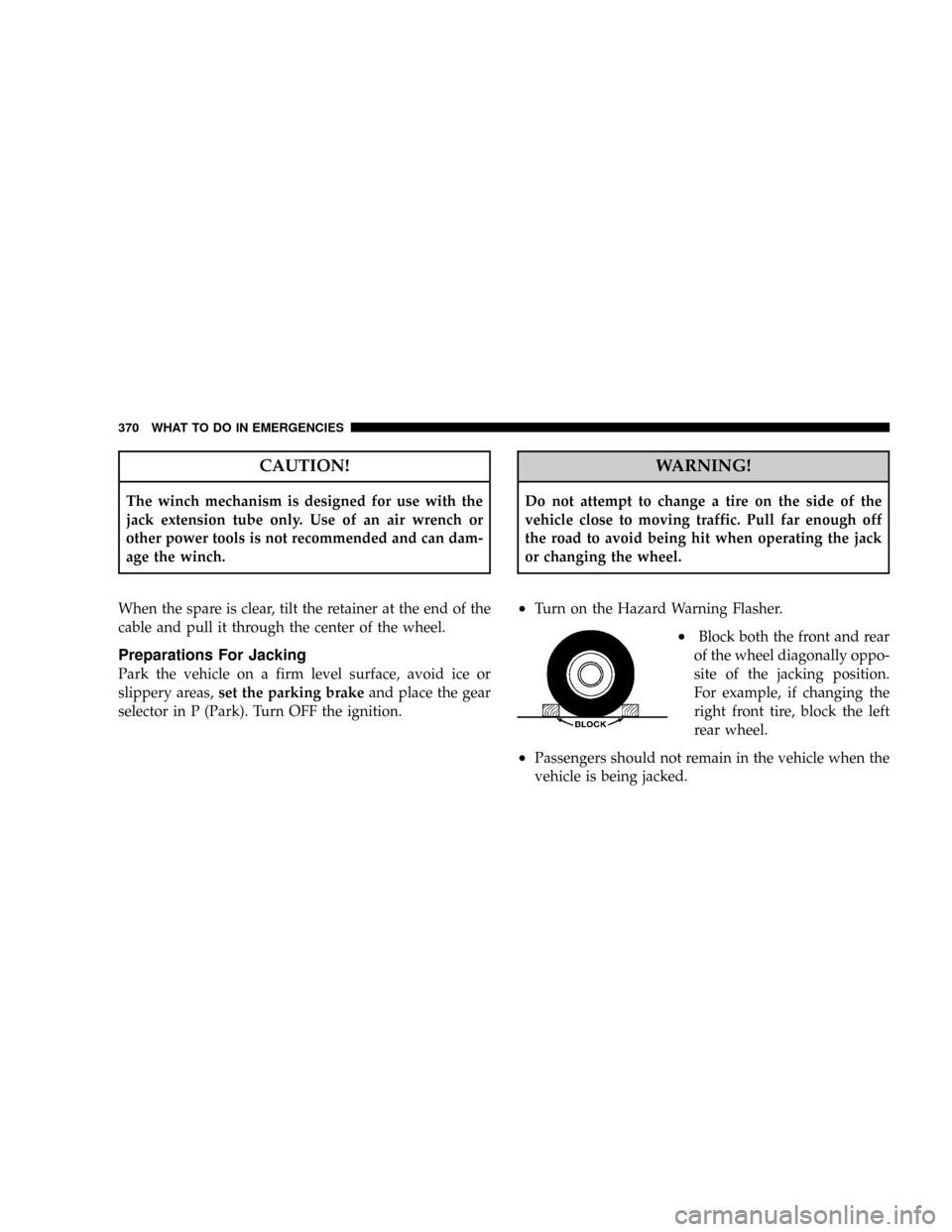

²Turn on the Hazard Warning Flasher.

²Block both the front and rear

of the wheel diagonally oppo-

site of the jacking position.

For example, if changing the

right front tire, block the left

rear wheel.

²Passengers should not remain in the vehicle when the

vehicle is being jacked.

370 WHAT TO DO IN EMERGENCIES

Page 372 of 478

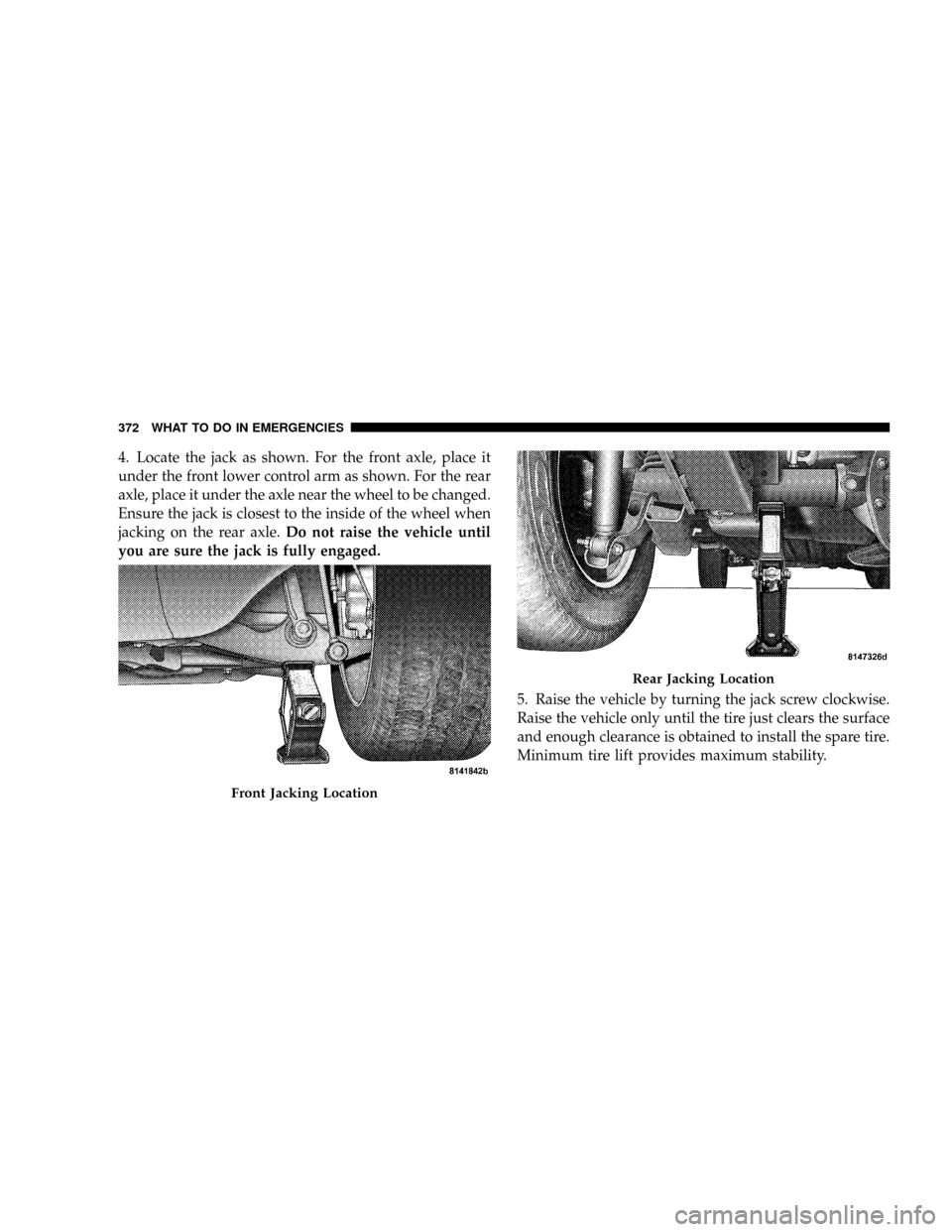

4. Locate the jack as shown. For the front axle, place it

under the front lower control arm as shown. For the rear

axle, place it under the axle near the wheel to be changed.

Ensure the jack is closest to the inside of the wheel when

jacking on the rear axle.Do not raise the vehicle until

you are sure the jack is fully engaged.

5. Raise the vehicle by turning the jack screw clockwise.

Raise the vehicle only until the tire just clears the surface

and enough clearance is obtained to install the spare tire.

Minimum tire lift provides maximum stability.

Front Jacking Location

Rear Jacking Location

372 WHAT TO DO IN EMERGENCIES

Page 373 of 478

WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

6. Remove the lug nuts and wheel.

7. Position the spare wheel/tire on the vehicle and install

the lug nuts with the cone-shaped end toward the wheel.

Lightly tighten the nuts. To avoid the risk of forcing the

vehicle off the jack, do not tighten the nuts fully until the

vehicle has been lowered.

8. Lower the vehicle by turning the jack screw counter

clockwise, and remove the jack and wheel blocks.9. Finish tightening the lug nuts. Push down on the

wrench while tightening for increased leverage. Alternate

nuts until each nut has been tightened twice. Correct

wheel nut tightness is 130 N´m (95 ft. lbs). If in doubt

about the correct tightness, have them checked with a

torque wrench by your authorized dealer or at a service

station.

10. Lower the jack to it's fully closed position.

WARNING!

A loose tire or jack, thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided.

11. Secure the tire, jack, and tools in their proper loca-

tions.

WHAT TO DO IN EMERGENCIES 373

6

Page 399 of 478

WARNING!

Fluid level should be checked on a level surface with

the engine off to prevent injury from moving parts,

and to insure accurate fluid level reading. Do not

overfill. Use only the manufacturer's recommended

fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to Fluids, Lubricants, and Genuine Parts

for correct fluid type.

NOTE:Upon initial start-up in cold weather, the power

steering pump may make noise for a short period of time.

This is due to the cold, thick fluid in the steering system.

This noise should be considered normal, and does not in

any way damage the steering system.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, doors, tailgate and hood hinges, should be

lubricated periodically to assure quiet, easy operation

and to protect against rust and wear. Prior to the appli-

cation of any lubricant, the parts concerned should be

wiped clean to remove dust and grit; after lubricating

excess oil and grease should be removed. Particular

attention should also be given to hood latching compo-

nents to insure proper function. When performing other

underhood services, the hood latch, release mechanism

and safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the fall and spring. Apply a small

amount of a high quality lubricant such as MopartLock

Cylinder Lubricant directly into the lock cylinder.

MAINTAINING YOUR VEHICLE 399

7

Page 420 of 478

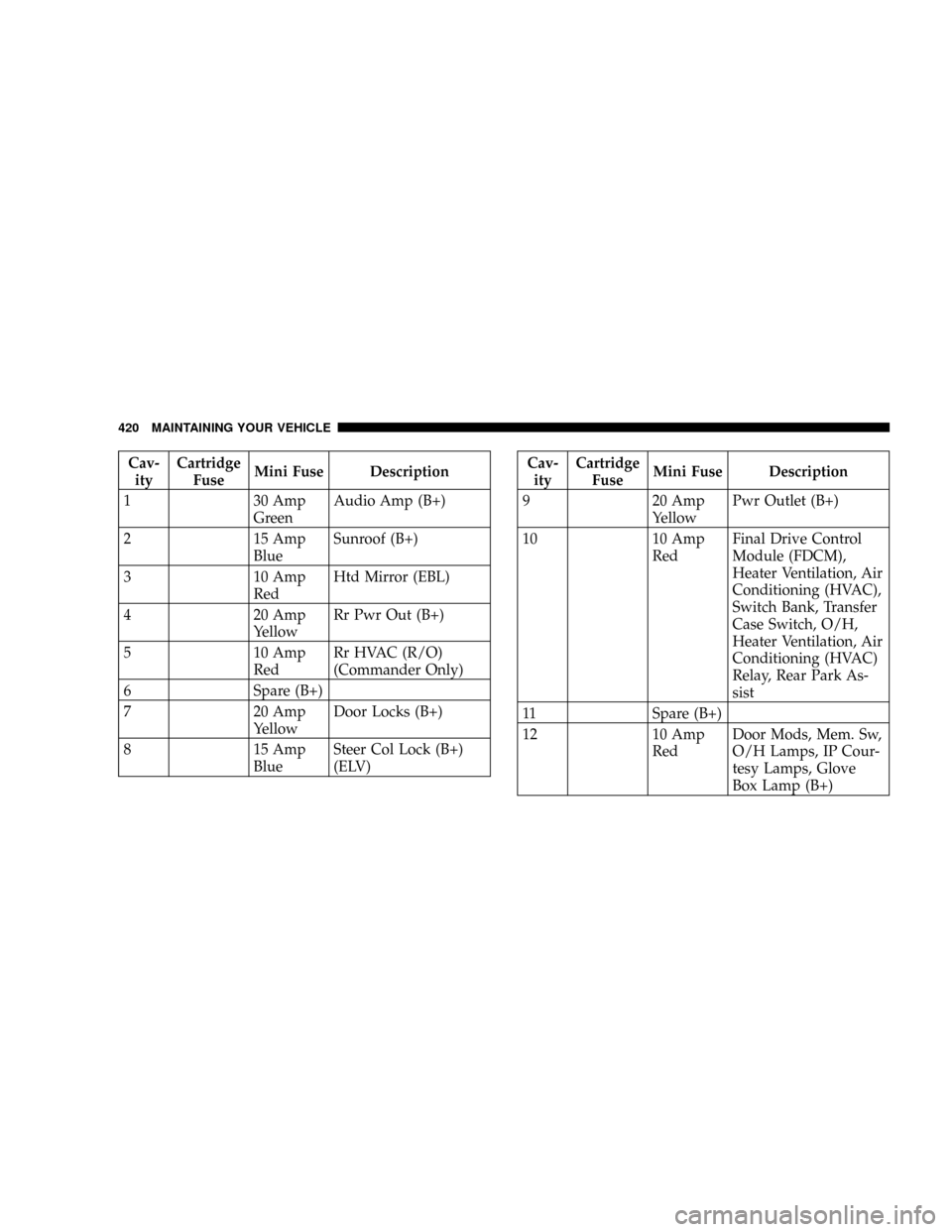

Cav-

ityCartridge

FuseMini Fuse Description

1 30 Amp

GreenAudio Amp (B+)

2 15 Amp

BlueSunroof (B+)

3 10 Amp

RedHtd Mirror (EBL)

4 20 Amp

YellowRr Pwr Out (B+)

5 10 Amp

RedRr HVAC (R/O)

(Commander Only)

6 Spare (B+)

7 20 Amp

YellowDoor Locks (B+)

8 15 Amp

BlueSteer Col Lock (B+)

(ELV)Cav-

ityCartridge

FuseMini Fuse Description

9 20 Amp

YellowPwr Outlet (B+)

10 10 Amp

RedFinal Drive Control

Module (FDCM),

Heater Ventilation, Air

Conditioning (HVAC),

Switch Bank, Transfer

Case Switch, O/H,

Heater Ventilation, Air

Conditioning (HVAC)

Relay, Rear Park As-

sist

11 Spare (B+)

12 10 Amp

RedDoor Mods, Mem. Sw,

O/H Lamps, IP Cour-

tesy Lamps, Glove

Box Lamp (B+)

420 MAINTAINING YOUR VEHICLE

Page 428 of 478

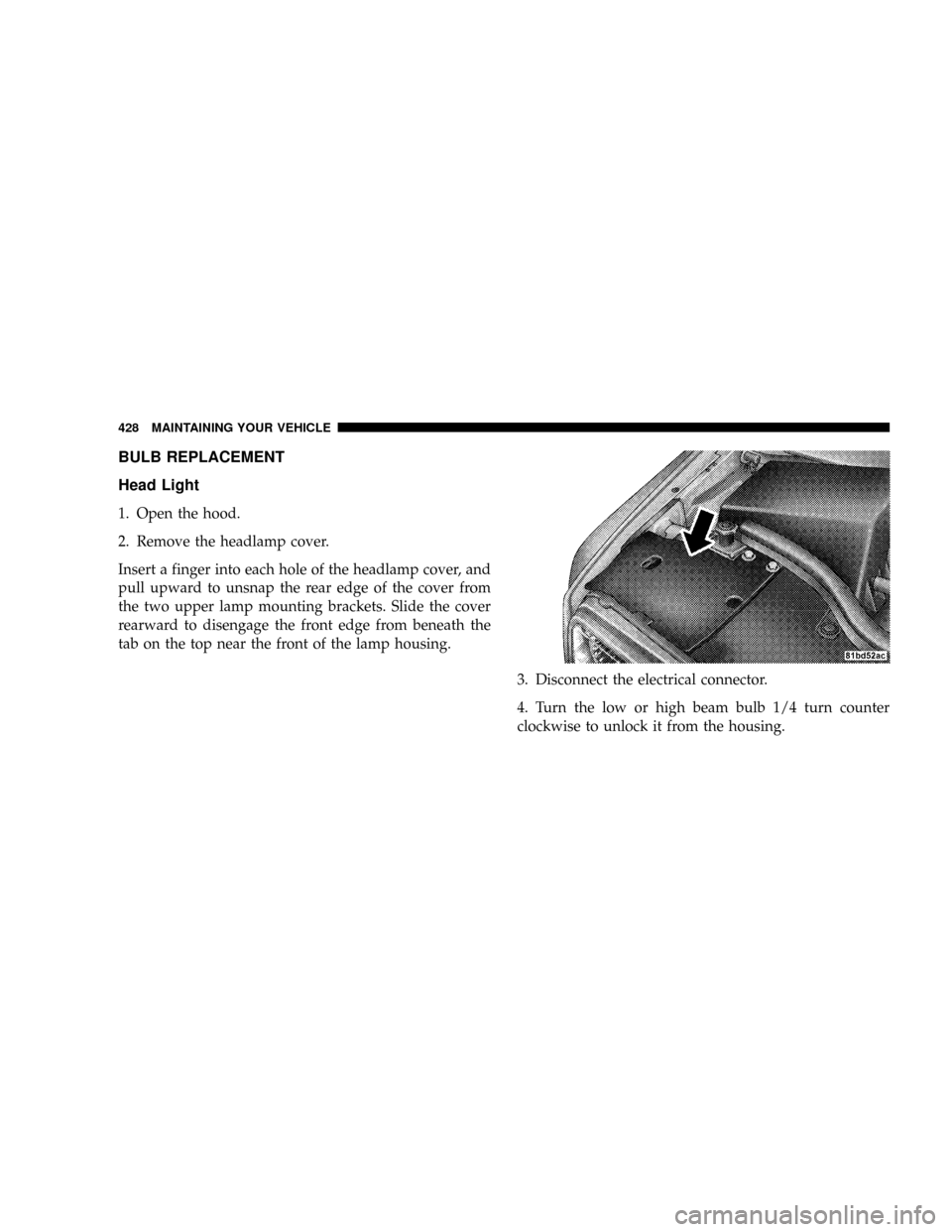

BULB REPLACEMENT

Head Light

1. Open the hood.

2. Remove the headlamp cover.

Insert a finger into each hole of the headlamp cover, and

pull upward to unsnap the rear edge of the cover from

the two upper lamp mounting brackets. Slide the cover

rearward to disengage the front edge from beneath the

tab on the top near the front of the lamp housing.

3. Disconnect the electrical connector.

4. Turn the low or high beam bulb 1/4 turn counter

clockwise to unlock it from the housing.

428 MAINTAINING YOUR VEHICLE

Page 431 of 478

4. Turn the socket on the bottom of the front lamp unit

housing 1/4 turn counter clockwise to unlock it.

5. Pull the socket and bulb straight out from the opening

in the housing.

6. Disconnect the electrical connector.

7. Pull the base of the bulb straight out of the socket.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with any oily surface, clean the

bulb with rubbing alcohol.

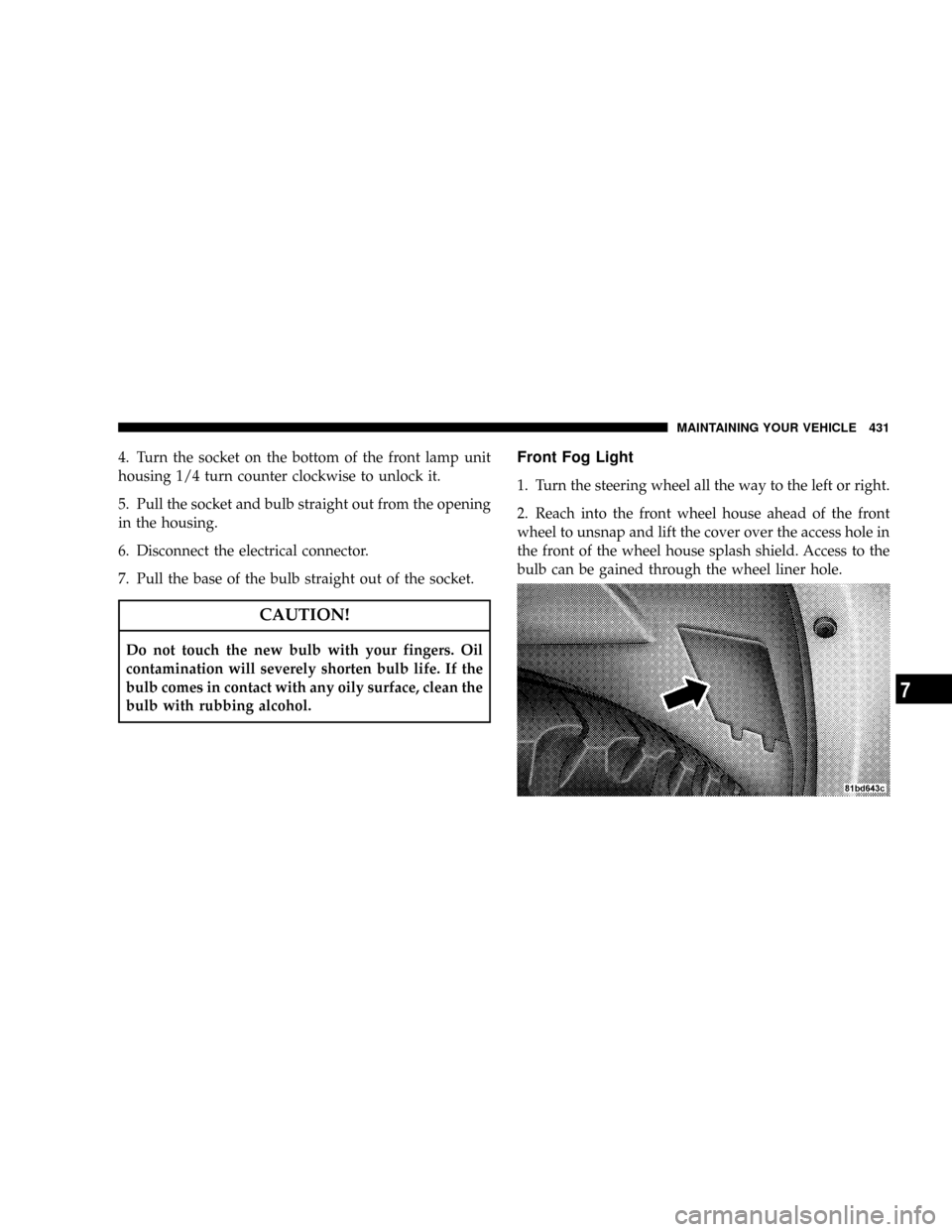

Front Fog Light

1. Turn the steering wheel all the way to the left or right.

2. Reach into the front wheel house ahead of the front

wheel to unsnap and lift the cover over the access hole in

the front of the wheel house splash shield. Access to the

bulb can be gained through the wheel liner hole.

MAINTAINING YOUR VEHICLE 431

7

Page 432 of 478

3. Reach through the access hole to access the back of the

front fog light housing on the back of the front fascia.

4. Disconnect the electrical connector.

5. Turn the socket on the back of the housing 1/4 turn

counter clockwise to unlock it.

6. Pull the socket and bulb straight out from the opening

in the housing.

7. Pull the base of the bulb straight out of the socket.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with any oily surface, clean the

bulb with rubbing alcohol.

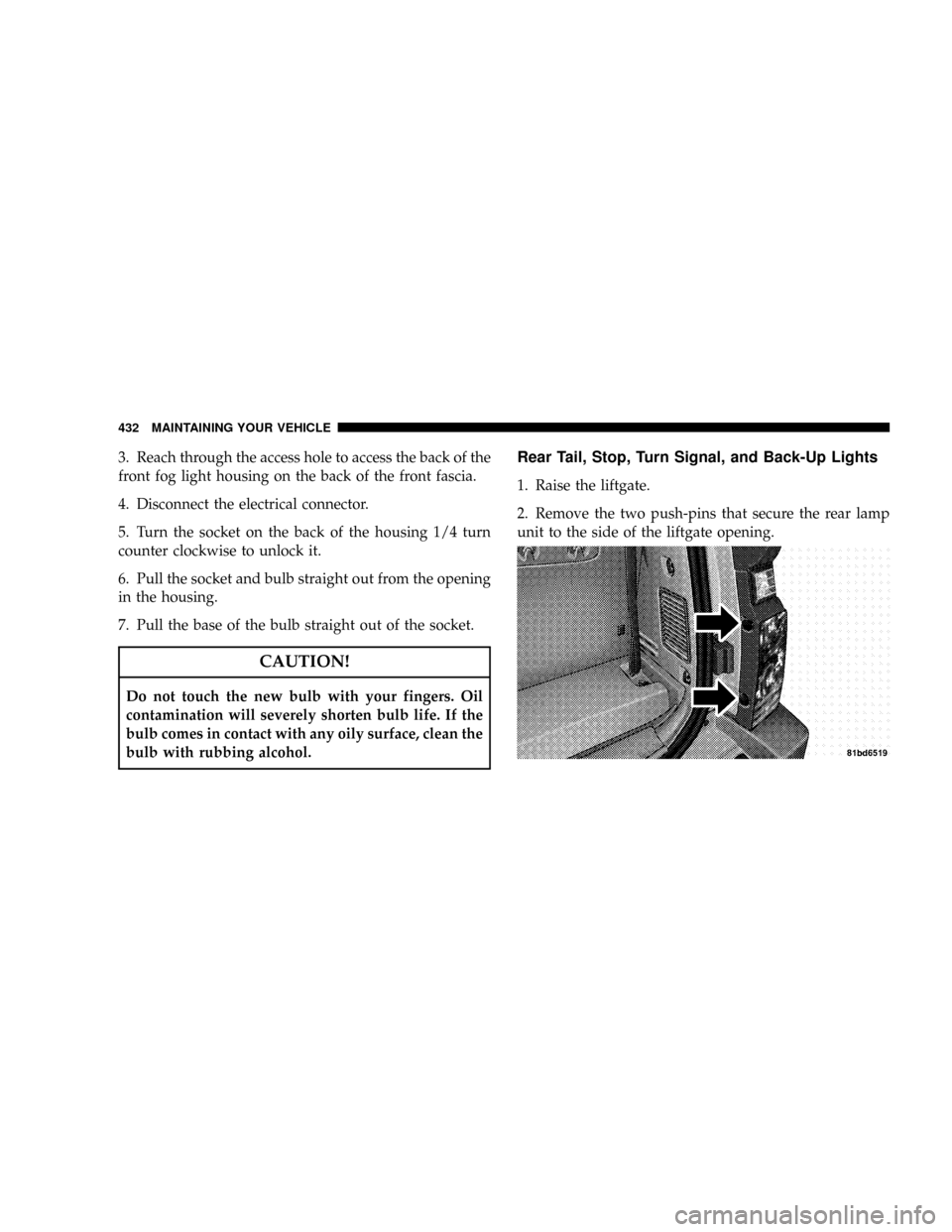

Rear Tail, Stop, Turn Signal, and Back-Up Lights

1. Raise the liftgate.

2. Remove the two push-pins that secure the rear lamp

unit to the side of the liftgate opening.

432 MAINTAINING YOUR VEHICLE

Page 433 of 478

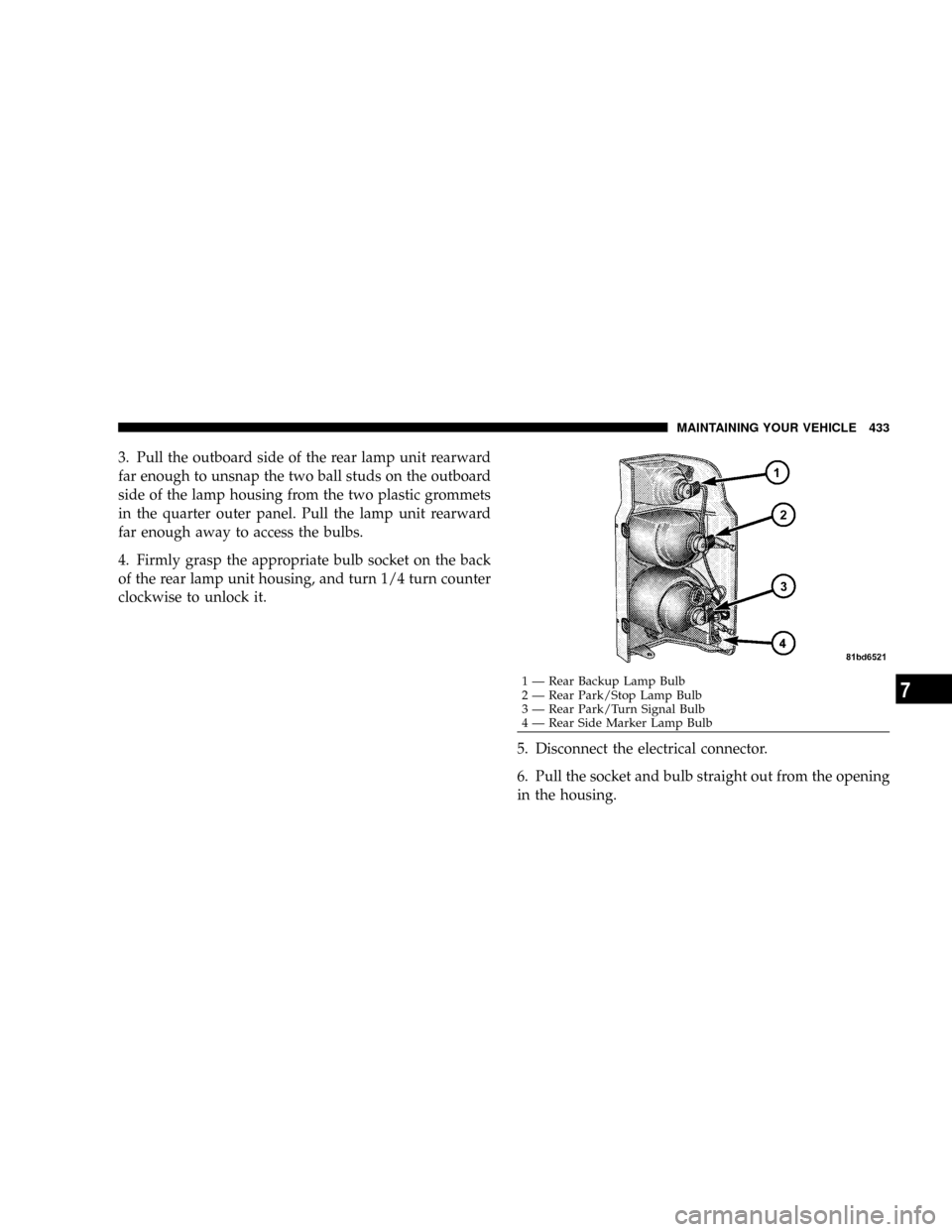

3. Pull the outboard side of the rear lamp unit rearward

far enough to unsnap the two ball studs on the outboard

side of the lamp housing from the two plastic grommets

in the quarter outer panel. Pull the lamp unit rearward

far enough away to access the bulbs.

4. Firmly grasp the appropriate bulb socket on the back

of the rear lamp unit housing, and turn 1/4 turn counter

clockwise to unlock it.

5. Disconnect the electrical connector.

6. Pull the socket and bulb straight out from the opening

in the housing.

1 Ð Rear Backup Lamp Bulb

2 Ð Rear Park/Stop Lamp Bulb

3 Ð Rear Park/Turn Signal Bulb

4 Ð Rear Side Marker Lamp BulbMAINTAINING YOUR VEHICLE 4337

Page 458 of 478

ABS (Anti-Lock Brake System)............188,302

Adding Fuel........................... 341

Adding Washer Fluid..................... 177

Adjustable Pedals....................... 135

Air Cleaner, Engine (Engine Air Cleaner Filter) . . . 393

Air Conditioner Maintenance............... 397

Air Conditioning........................ 259

Air Conditioning, Operating Tips............ 269

Air Conditioning, Rear Zone................ 267

Air Conditioning Refrigerant............... 398

Air Conditioning System.................. 259

Air Filter.............................. 393

Air Pressure, Tires....................... 316

Airbag................................ 48

Airbag Deployment....................... 55

Airbag Light.......................57,71,188

Airbag Maintenance....................... 57

Alarm, Panic............................ 24

Alarm (Security Alarm).................20,189Alarm System (Security Alarm)............... 20

Alignment and Balance................... 321

Alterations/Modifications, Vehicle............. 9

Antenna, Satellite Radio................... 250

Antifreeze (Engine Coolant)................ 435

Disposal............................ 405

Anti-Lock Brake System (ABS)............139,302

Anti-Lock Warning Light.................. 188

Anti-Theft System.....................20,189

Appearance Care........................ 415

Assist, Hill Start........................ 148

Audio Systems (Radio).................... 239

Auto Down Power Windows................ 32

Automatic Dimming Mirror................. 78

Automatic Door Locks..................... 29

Automatic Headlights.................... 126

Automatic Temperature Control (ATC)......... 260

Automatic Transmission................283,411

Adding Fluid......................... 412

458 INDEX