steering JEEP COMMANDER 2008 1.G Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2008, Model line: COMMANDER, Model: JEEP COMMANDER 2008 1.GPages: 478, PDF Size: 6.97 MB

Page 398 of 478

NOTE:Use only manufacturer approved A/C System

Sealers, Stop Leak Products, Seal Conditioners, Compres-

sor Oil, and Refrigerants.

Refrigerant Recovery and Recycling

R-134a Air Conditioning Refrigerant is a hydrofluorocar-

bon (HFC) that is endorsed by the Environmental Pro-

tection Agency and is an ozone-saving product. How-

ever, the manufacturer recommends that air conditioning

service be performed by dealers or other service facilities

using recovery and recycling equipment.

Power Steering Fluid Check

The power steering system requires the use of Mopart

Hydraulic System Power Steering Fluid (P/N

05142893AA), or equivalent, which meets

DaimlerChrysler Material Standard MS-10838.

CAUTION!

Do not use Automatic Transmission Fluid (ATF) or

other types of power steering fluids when servicing

the power steering system of this vehicle. Damage to

the power steering system can result from the use of

the wrong power steering fluid.

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

ªDaimlerChrysler Dealership.º

398 MAINTAINING YOUR VEHICLE

Page 399 of 478

WARNING!

Fluid level should be checked on a level surface with

the engine off to prevent injury from moving parts,

and to insure accurate fluid level reading. Do not

overfill. Use only the manufacturer's recommended

fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to Fluids, Lubricants, and Genuine Parts

for correct fluid type.

NOTE:Upon initial start-up in cold weather, the power

steering pump may make noise for a short period of time.

This is due to the cold, thick fluid in the steering system.

This noise should be considered normal, and does not in

any way damage the steering system.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, doors, tailgate and hood hinges, should be

lubricated periodically to assure quiet, easy operation

and to protect against rust and wear. Prior to the appli-

cation of any lubricant, the parts concerned should be

wiped clean to remove dust and grit; after lubricating

excess oil and grease should be removed. Particular

attention should also be given to hood latching compo-

nents to insure proper function. When performing other

underhood services, the hood latch, release mechanism

and safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the fall and spring. Apply a small

amount of a high quality lubricant such as MopartLock

Cylinder Lubricant directly into the lock cylinder.

MAINTAINING YOUR VEHICLE 399

7

Page 408 of 478

Brake and Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses for evidence of heat and me-

chanical damage. Hard and brittle rubber, cracking, tears,

cuts, abrasion, and excessive swelling suggest deteriora-

tion of the rubber. Particular attention should be made to

examining those hose surfaces nearest to high heat

sources, such as the exhaust manifold.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

NOTE:Often fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before hose is replaced based

on leakage.NOTE:Inspection of brake hoses should be done when-

ever the brake system is serviced and every engine oil

change.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Brake Master Cylinder Ð Brake Fluid Level Check

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning lamp shows system failure

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the

fluid level up to the requirements described on the brake

408 MAINTAINING YOUR VEHICLE

Page 414 of 478

Special Additives

Automatic Transmission Fluid (ATF) is an engineered

product and its performance may be impaired by supple-

mental additives. Therefore, do not add any fluid addi-

tives to the transmission. The only exception to this

policy is the use of special dyes to aid in detecting fluid

leaks. In addition, avoid using transmission sealers as

they may adversely affect seals.

Maintenance After Off-Road Driving

After extended operation in mud, sand or water, or

similar dirty conditions, have your brake discs, brake

linings, and axle joints inspected and cleaned as soon as

possible. This will prevent any abrasive material from

causing excessive wear or unpredictable braking action.After off-road driving, completely inspect the underbody

of your vehicle. Check tires, body structure, steering,

suspension and exhaust system for damage. Check

threaded fasteners for looseness, particularly on the

chassis, drivetrain components, steering and suspension.

Retighten, if required, to torque values specified in the

Service Manual. Also check for accumulations of vegeta-

tion or brush that could become a fire hazard, or conceal

damage to fuel lines, brake hoses, axle pinion seals, and

propeller shafts.

CAUTION!

Under frequent heavy-duty driving conditions,

change all lubricants and lubricate body compo-

nents, all driveline joints and steering linkage more

often than in normal service to prevent excessive

wear.

414 MAINTAINING YOUR VEHICLE

Page 419 of 478

2. Dry with a soft tissue.

Seat Belt Maintenance

Do not bleach, dye or clean the belts with chemical

solvents or abrasive cleaners. This will weaken the fabric.

Sun damage will also weaken the fabric.

If the belts need cleaning, use MopartTotal Clean, a mild

soap solution, or lukewarm water. Do not remove the

belts from the vehicle to wash them.

Replace the belts if they appear frayed or worn or if the

buckles do not work properly.

Dry with a soft tissue.

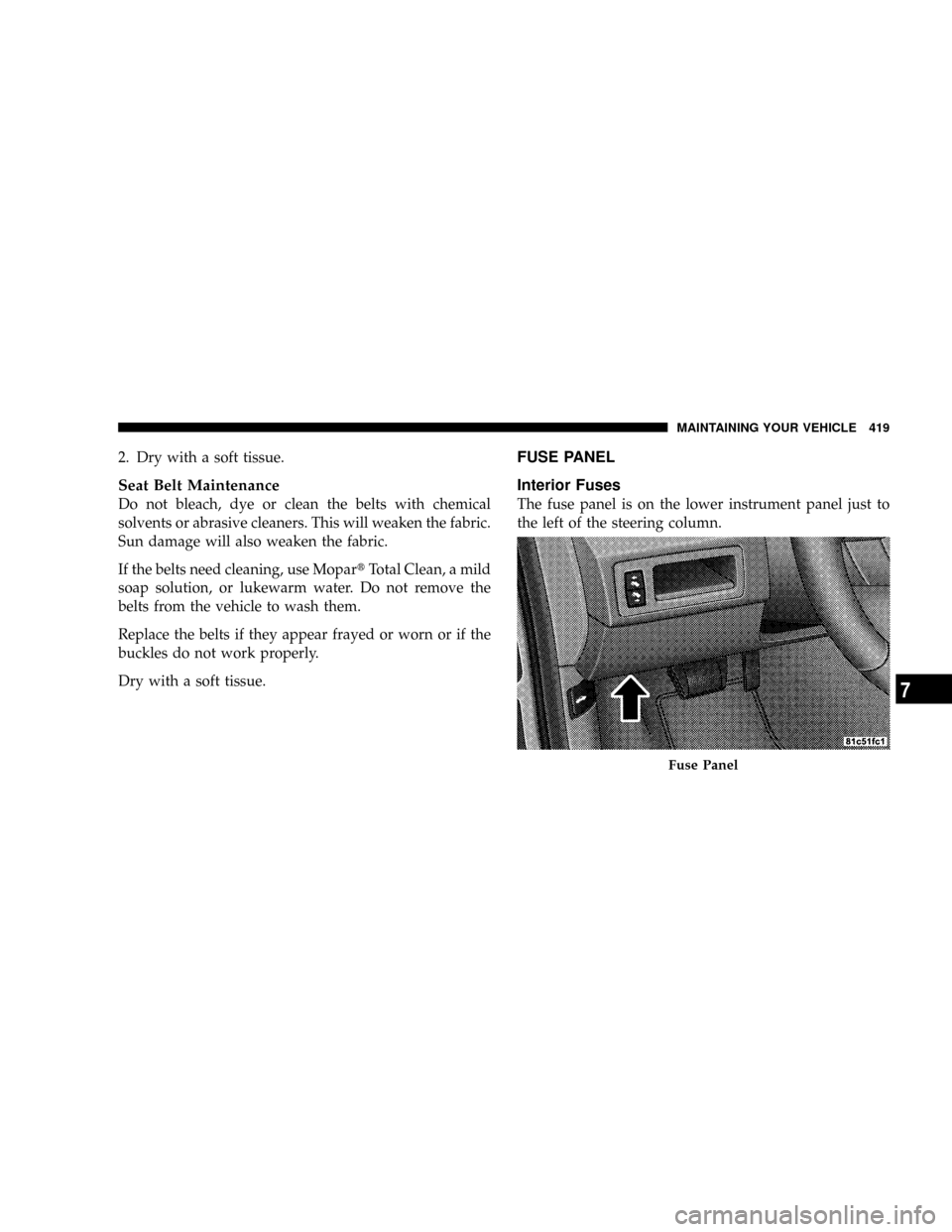

FUSE PANEL

Interior Fuses

The fuse panel is on the lower instrument panel just to

the left of the steering column.

Fuse Panel

MAINTAINING YOUR VEHICLE 419

7

Page 421 of 478

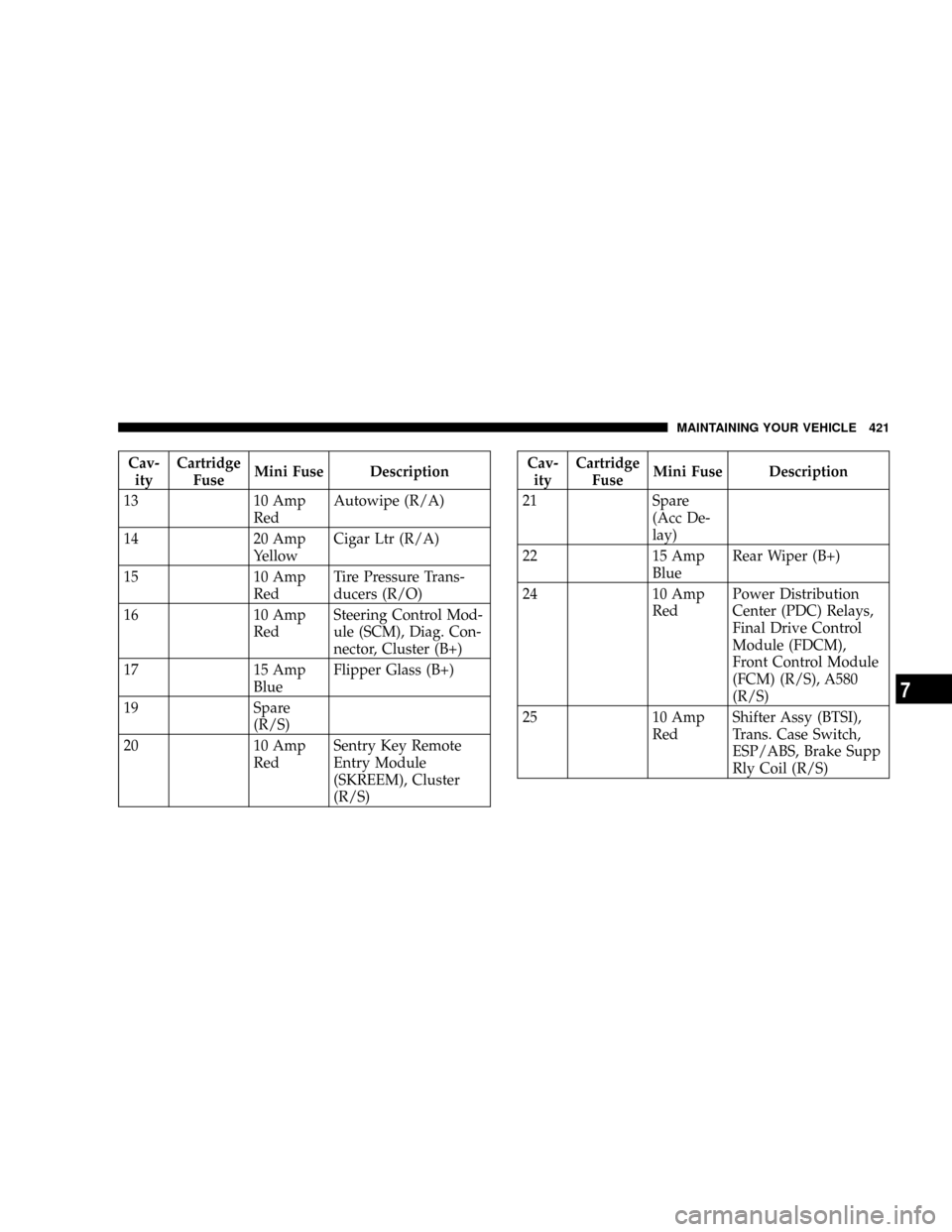

Cav-

ityCartridge

FuseMini Fuse Description

13 10 Amp

RedAutowipe (R/A)

14 20 Amp

YellowCigar Ltr (R/A)

15 10 Amp

RedTire Pressure Trans-

ducers (R/O)

16 10 Amp

RedSteering Control Mod-

ule (SCM), Diag. Con-

nector, Cluster (B+)

17 15 Amp

BlueFlipper Glass (B+)

19 Spare

(R/S)

20 10 Amp

RedSentry Key Remote

Entry Module

(SKREEM), Cluster

(R/S)Cav-

ityCartridge

FuseMini Fuse Description

21 Spare

(Acc De-

lay)

22 15 Amp

BlueRear Wiper (B+)

24 10 Amp

RedPower Distribution

Center (PDC) Relays,

Final Drive Control

Module (FDCM),

Front Control Module

(FCM) (R/S), A580

(R/S)

25 10 Amp

RedShifter Assy (BTSI),

Trans. Case Switch,

ESP/ABS, Brake Supp

Rly Coil (R/S)

MAINTAINING YOUR VEHICLE 421

7

Page 430 of 478

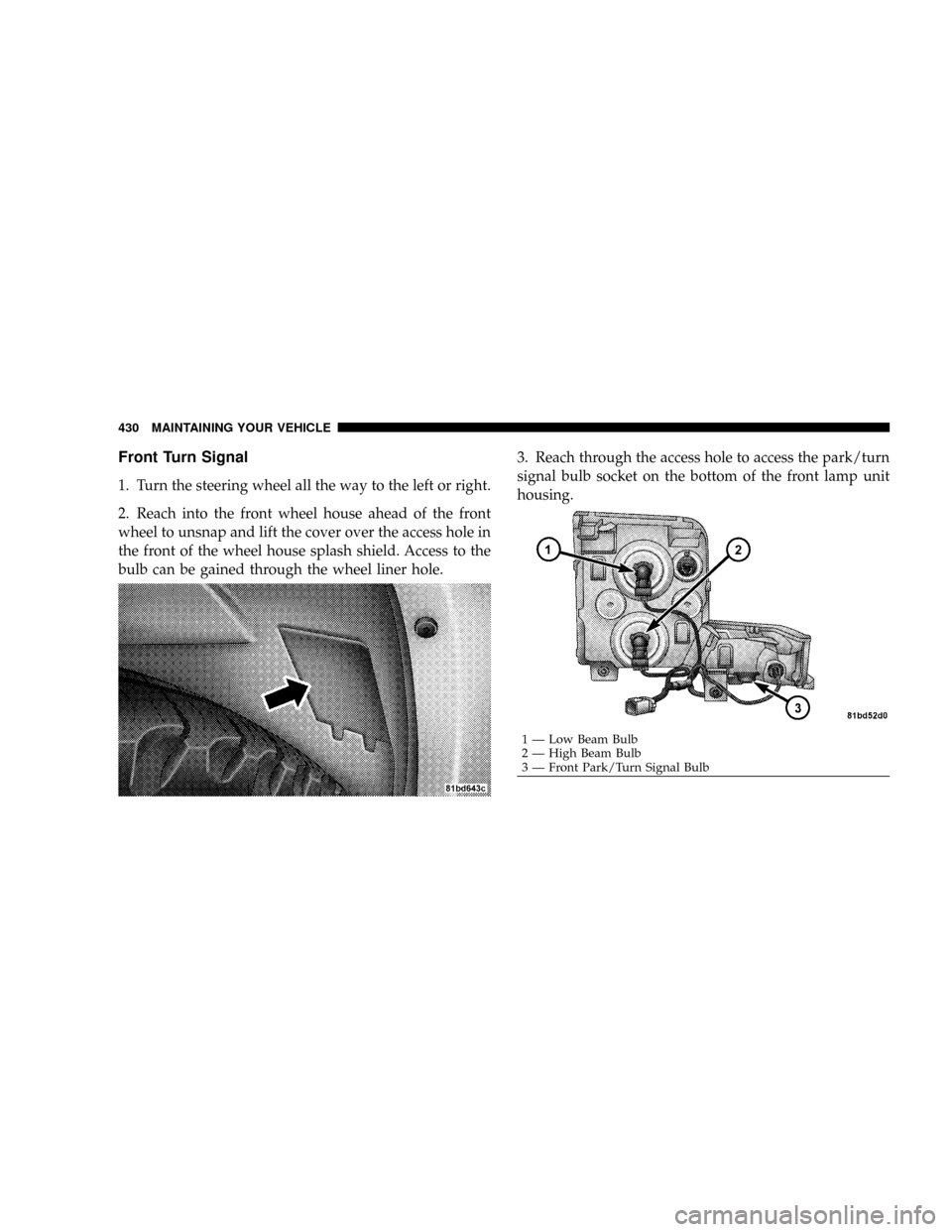

Front Turn Signal

1. Turn the steering wheel all the way to the left or right.

2. Reach into the front wheel house ahead of the front

wheel to unsnap and lift the cover over the access hole in

the front of the wheel house splash shield. Access to the

bulb can be gained through the wheel liner hole.3. Reach through the access hole to access the park/turn

signal bulb socket on the bottom of the front lamp unit

housing.

1 Ð Low Beam Bulb

2 Ð High Beam Bulb

3 Ð Front Park/Turn Signal Bulb 430 MAINTAINING YOUR VEHICLE

Page 431 of 478

4. Turn the socket on the bottom of the front lamp unit

housing 1/4 turn counter clockwise to unlock it.

5. Pull the socket and bulb straight out from the opening

in the housing.

6. Disconnect the electrical connector.

7. Pull the base of the bulb straight out of the socket.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with any oily surface, clean the

bulb with rubbing alcohol.

Front Fog Light

1. Turn the steering wheel all the way to the left or right.

2. Reach into the front wheel house ahead of the front

wheel to unsnap and lift the cover over the access hole in

the front of the wheel house splash shield. Access to the

bulb can be gained through the wheel liner hole.

MAINTAINING YOUR VEHICLE 431

7

Page 437 of 478

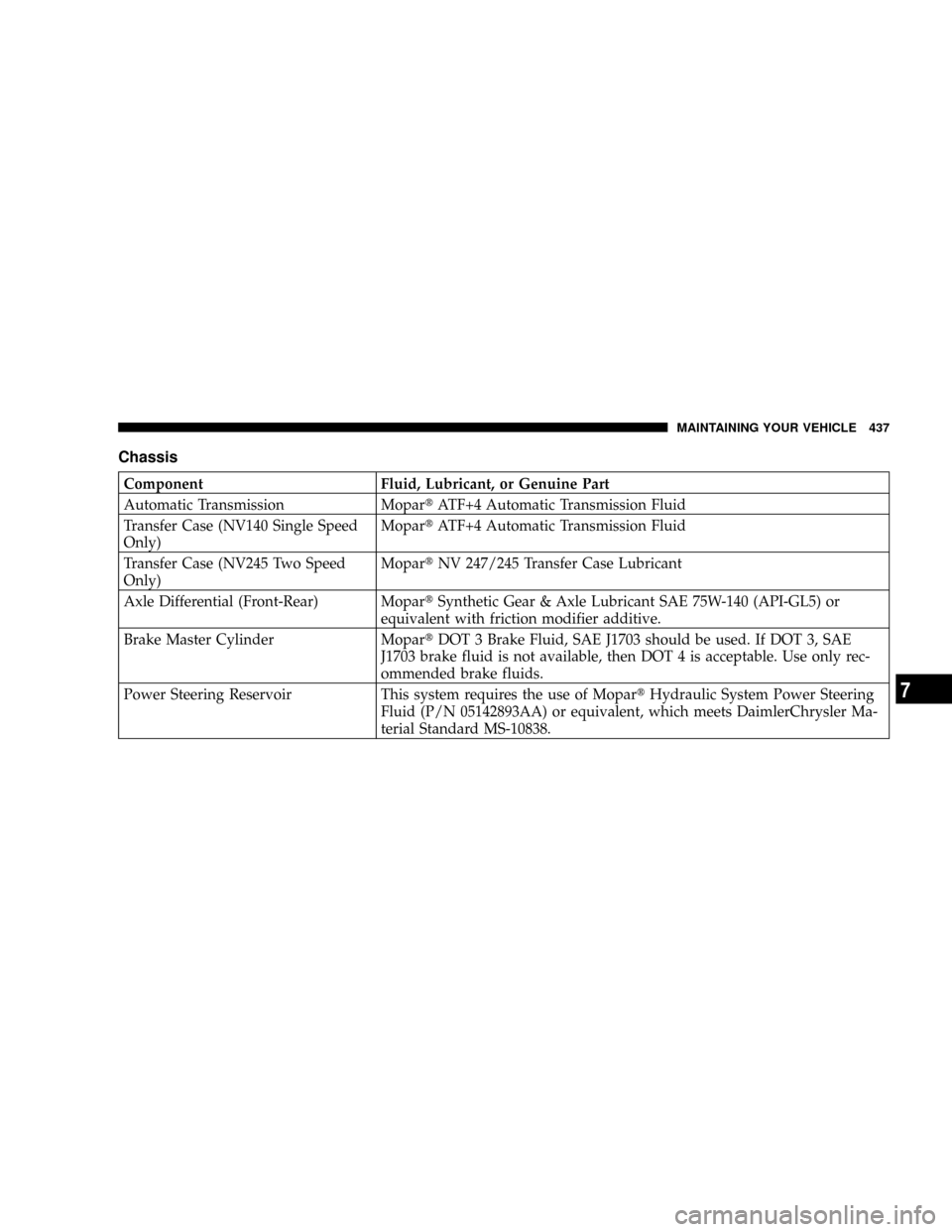

Chassis

Component Fluid, Lubricant, or Genuine Part

Automatic Transmission MopartATF+4 Automatic Transmission Fluid

Transfer Case (NV140 Single Speed

Only)MopartATF+4 Automatic Transmission Fluid

Transfer Case (NV245 Two Speed

Only)MopartNV 247/245 Transfer Case Lubricant

Axle Differential (Front-Rear) MopartSynthetic Gear & Axle Lubricant SAE 75W-140 (API-GL5) or

equivalent with friction modifier additive.

Brake Master Cylinder MopartDOT 3 Brake Fluid, SAE J1703 should be used. If DOT 3, SAE

J1703 brake fluid is not available, then DOT 4 is acceptable. Use only rec-

ommended brake fluids.

Power Steering Reservoir This system requires the use of MopartHydraulic System Power Steering

Fluid (P/N 05142893AA) or equivalent, which meets DaimlerChrysler Ma-

terial Standard MS-10838.

MAINTAINING YOUR VEHICLE 437

7

Page 441 of 478

²Change your engine oil more often if you drive your

vehicle off-road for an extended period of time.

²Under no circumstances should oil change intervals

exceed 6,000 miles (10,000 km) or 6 months, whichever

comes first.

Your dealer will reset the oil change indicator message

after completing the scheduled oil change. If this sched-

uled oil change is performed by someone other than your

dealer the message can be reset by referring to the steps

described under ªOil Change Requiredº in ªUse Factory

Settingsº of the EVIC section in this manual.

At Each Stop for Fuel

²Check the engine oil level about 5 minutes after a fully

warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accu-

racy of the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear or

damage.

²Inspect the battery and clean and tighten the terminals

as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transmission and

add as needed.

²Check all lights and other electrical items for correct

operation.

MAINTENANCE SCHEDULES 441

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S