power steering fluid JEEP COMMANDER 2008 1.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2008, Model line: COMMANDER, Model: JEEP COMMANDER 2008 1.GPages: 478, PDF Size: 6.97 MB

Page 305 of 478

build up between the tire tread and the road. This

hydroplaning action can cause loss of traction, braking

ability, and control.

²After going through deep water or a car wash, brakes

may become wet, resulting in decreased performance

and unpredictable braking action. Dry the brakes by

gentle, intermittent pedal action while driving at very

slow speeds.

POWER STEERING

The standard power steering system will give you good

vehicle response and increased ease of maneuverability

in tight spaces. The system will provide mechanical

steering capability if power assist is lost.

If for some reason the power assist is interrupted, it will

still be possible to steer your vehicle. Under these condi-

tions, you will observe a substantial increase in steering

effort, especially at very low vehicle speeds and during

parking maneuvers.NOTE:Increased noise levels at the end of the steering

wheel travel are considered normal and do not indicate

that there is a problem with the power steering system.

Upon initial start-up in cold weather, the power steering

pump may make noise for a short amount of time. This is

due to the cold, thick fluid in the steering system. This

noise should be considered normal, and it does not in any

way damage the steering system.WARNING!

Continued operation with reduced power steering

assist could pose a safety risk to yourself and others.

Service should be obtained as soon as possible.

STARTING AND OPERATING 305

5

Page 306 of 478

CAUTION!

Prolonged operation of the steering system at the end

of the steering wheel travel will increase the steering

fluid temperature and it should be avoided when

possible. Damage to the power steering pump may

occur.

MULTI DISPLACEMENT SYSTEM (MDS) Ð 5.7L

Engine Only

This feature offers improved fuel economy by shutting

off four of the engine's eight cylinders during light load

and cruise conditions. The system is automatic with no

driver inputs or additional driving skills required.

NOTE:The MDS system may take some time to return

to full functionality after a battery disconnect.

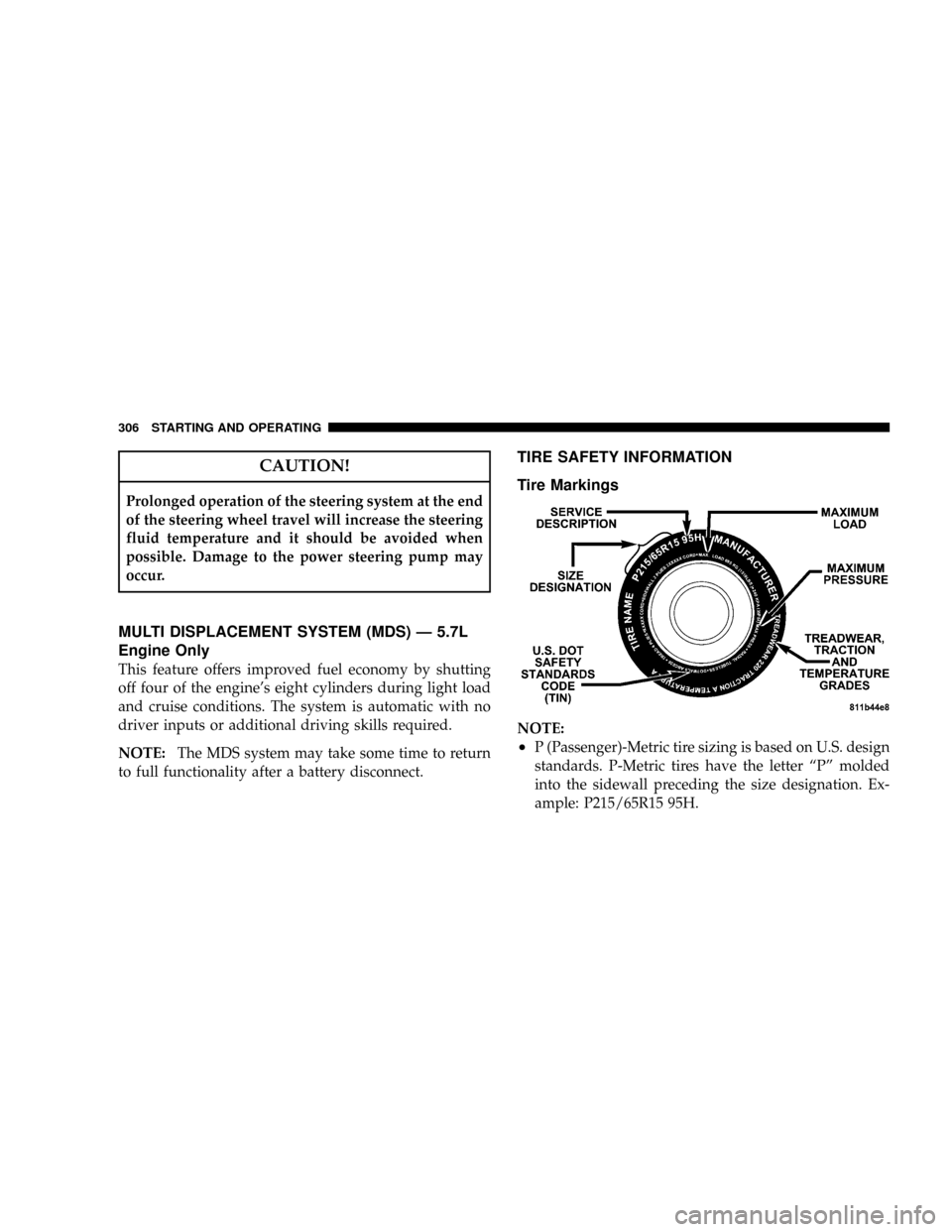

TIRE SAFETY INFORMATION

Tire Markings

NOTE:

²P (Passenger)-Metric tire sizing is based on U.S. design

standards. P-Metric tires have the letter ªPº molded

into the sidewall preceding the size designation. Ex-

ample: P215/65R15 95H.

306 STARTING AND OPERATING

Page 380 of 478

NAir Conditioner Maintenance.............397

NPower Steering Fluid Check..............398

NBody Lubrication.....................399

NWindshield Wiper Blades................400

NWindshield Washers Ð Front And Rear.....400

NExhaust System......................401

NCooling System.......................401

NHoses And Vacuum/Vapor Harnesses.......406

NFuel System Connections................407

NBrake System........................407

NFront/Rear Axle Fluid..................410

NTransfer Case........................410

NAutomatic Transmission................411NMaintenance After Off-Road Driving........414

NAppearance Care And Protection From

Corrosion...........................415

mFuse Panel...........................419

NInterior Fuses........................419

NUnderhood Fuses (Power Distribution

Center)............................422

NUnderhood Fuses (Integrated Power

Module)............................425

mVehicle Storage........................426

mReplacement Bulbs......................427

mBulb Replacement......................428

NHead Light..........................428

NFront Turn Signal.....................430

380 MAINTAINING YOUR VEHICLE

Page 398 of 478

NOTE:Use only manufacturer approved A/C System

Sealers, Stop Leak Products, Seal Conditioners, Compres-

sor Oil, and Refrigerants.

Refrigerant Recovery and Recycling

R-134a Air Conditioning Refrigerant is a hydrofluorocar-

bon (HFC) that is endorsed by the Environmental Pro-

tection Agency and is an ozone-saving product. How-

ever, the manufacturer recommends that air conditioning

service be performed by dealers or other service facilities

using recovery and recycling equipment.

Power Steering Fluid Check

The power steering system requires the use of Mopart

Hydraulic System Power Steering Fluid (P/N

05142893AA), or equivalent, which meets

DaimlerChrysler Material Standard MS-10838.

CAUTION!

Do not use Automatic Transmission Fluid (ATF) or

other types of power steering fluids when servicing

the power steering system of this vehicle. Damage to

the power steering system can result from the use of

the wrong power steering fluid.

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

ªDaimlerChrysler Dealership.º

398 MAINTAINING YOUR VEHICLE

Page 399 of 478

WARNING!

Fluid level should be checked on a level surface with

the engine off to prevent injury from moving parts,

and to insure accurate fluid level reading. Do not

overfill. Use only the manufacturer's recommended

fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to Fluids, Lubricants, and Genuine Parts

for correct fluid type.

NOTE:Upon initial start-up in cold weather, the power

steering pump may make noise for a short period of time.

This is due to the cold, thick fluid in the steering system.

This noise should be considered normal, and does not in

any way damage the steering system.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, doors, tailgate and hood hinges, should be

lubricated periodically to assure quiet, easy operation

and to protect against rust and wear. Prior to the appli-

cation of any lubricant, the parts concerned should be

wiped clean to remove dust and grit; after lubricating

excess oil and grease should be removed. Particular

attention should also be given to hood latching compo-

nents to insure proper function. When performing other

underhood services, the hood latch, release mechanism

and safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the fall and spring. Apply a small

amount of a high quality lubricant such as MopartLock

Cylinder Lubricant directly into the lock cylinder.

MAINTAINING YOUR VEHICLE 399

7

Page 408 of 478

Brake and Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses for evidence of heat and me-

chanical damage. Hard and brittle rubber, cracking, tears,

cuts, abrasion, and excessive swelling suggest deteriora-

tion of the rubber. Particular attention should be made to

examining those hose surfaces nearest to high heat

sources, such as the exhaust manifold.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

NOTE:Often fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before hose is replaced based

on leakage.NOTE:Inspection of brake hoses should be done when-

ever the brake system is serviced and every engine oil

change.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Brake Master Cylinder Ð Brake Fluid Level Check

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning lamp shows system failure

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the

fluid level up to the requirements described on the brake

408 MAINTAINING YOUR VEHICLE

Page 437 of 478

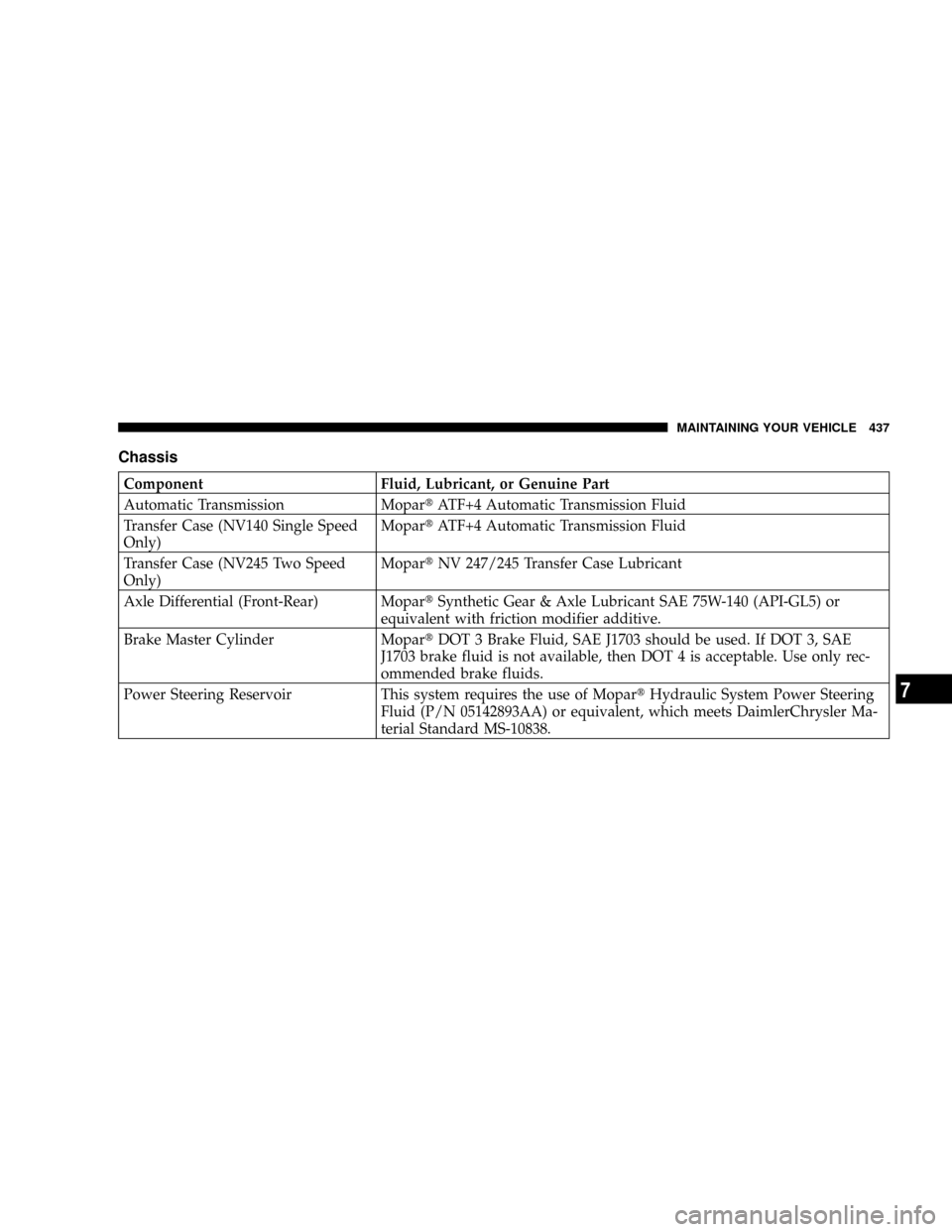

Chassis

Component Fluid, Lubricant, or Genuine Part

Automatic Transmission MopartATF+4 Automatic Transmission Fluid

Transfer Case (NV140 Single Speed

Only)MopartATF+4 Automatic Transmission Fluid

Transfer Case (NV245 Two Speed

Only)MopartNV 247/245 Transfer Case Lubricant

Axle Differential (Front-Rear) MopartSynthetic Gear & Axle Lubricant SAE 75W-140 (API-GL5) or

equivalent with friction modifier additive.

Brake Master Cylinder MopartDOT 3 Brake Fluid, SAE J1703 should be used. If DOT 3, SAE

J1703 brake fluid is not available, then DOT 4 is acceptable. Use only rec-

ommended brake fluids.

Power Steering Reservoir This system requires the use of MopartHydraulic System Power Steering

Fluid (P/N 05142893AA) or equivalent, which meets DaimlerChrysler Ma-

terial Standard MS-10838.

MAINTAINING YOUR VEHICLE 437

7

Page 441 of 478

²Change your engine oil more often if you drive your

vehicle off-road for an extended period of time.

²Under no circumstances should oil change intervals

exceed 6,000 miles (10,000 km) or 6 months, whichever

comes first.

Your dealer will reset the oil change indicator message

after completing the scheduled oil change. If this sched-

uled oil change is performed by someone other than your

dealer the message can be reset by referring to the steps

described under ªOil Change Requiredº in ªUse Factory

Settingsº of the EVIC section in this manual.

At Each Stop for Fuel

²Check the engine oil level about 5 minutes after a fully

warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accu-

racy of the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear or

damage.

²Inspect the battery and clean and tighten the terminals

as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transmission and

add as needed.

²Check all lights and other electrical items for correct

operation.

MAINTENANCE SCHEDULES 441

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 461 of 478

Pressure Cap......................... 404

Radiator Cap......................... 404

Selection of Coolant (Antifreeze).........402,435

Courtesy Lights......................... 130

Crankcase Emission Control System.......... 395

Cruise Light........................... 193

Cup Holder............................ 172

Customer Assistance..................... 448

Data Recorder, Event...................... 58

Daytime Running Lights................... 128

Dealer Service.......................... 388

Defroster, Rear Window................... 177

Defroster, Windshield................71,258,265

Diagnostic System, Onboard................ 385

Digital Video Disc (DVD) Player............. 239

Dimmer Switch, Headlight................. 129

Dipsticks

Automatic Transmission................. 412Oil (Engine).......................... 389

Power Steering........................ 398

Disabled Vehicle Towing................... 378

Disposal

Antifreeze (Engine Coolant)............... 405

Engine Oil........................... 391

Used Engine Fluids..................... 391

Door Locks............................. 28

Door Locks, Automatic.................... 29

Door Opener, Garage..................... 159

Drive Belts............................ 392

Driving............................... 296

Off-Pavement......................... 296

Off-Road............................ 296

DVD Player (Video Entertainment System)...... 253

E-85 Fuel............................. 337

Electric Remote Mirrors.................... 80

Electrical Outlet, Auxiliary (Power Outlet)...... 169

INDEX 461

10

Page 463 of 478

Starting............................. 277

Temperature Gauge..................... 191

Engine Oil Viscosity...................... 390

Engine Oil Viscosity Chart................. 390

Enhanced Accident Response Feature.......... 56

Entry System, Illuminated.................. 21

Event Data Recorder...................... 58

Exhaust Gas Caution.................38,70,337

Exhaust System......................... 401

Extender, Seat Belt........................ 48

Exterior Finish Care...................... 415

Filters

Air Cleaner.......................... 393

Engine Oil........................... 391

Engine Oil Disposal.................... 391

Finish Care............................ 415

Flashers.............................. 366

Hazard Warning....................... 366Turn Signal.....................187,430,432

Flexible Fuel Vehicles

Cruising Range........................ 340

Engine Oil........................... 340

Fuel Requirements..................337,339

Replacement Parts..................... 340

Starting............................. 340

Flipper Glass, Liftgate..................... 35

Flooded Engine Starting................... 279

Fluid Capacities......................... 435

Fluid Leaks............................. 72

Fluid Level Checks

Automatic Transmission............... 411,412

Engine Oil........................... 389

Power Steering........................ 398

Fluids, Lubricants and Genuine Parts.......... 436

Fog Light Service........................ 431

Fog Lights.......................128,194,431

Fold and Tumble Rear Seat................. 113

INDEX 463

10