ECU JEEP COMMANDER 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2010, Model line: COMMANDER, Model: JEEP COMMANDER 2010 1.GPages: 460, PDF Size: 7.11 MB

Page 163 of 460

6. Airbag Warning LightThis light turns on and remains on for six to

eight seconds as a bulb check when the ignition

switch is first turned ON. If the light is not on

during starting, stays on, or turns on while

driving, have the system inspected by an authorized

dealer as soon as possible.

7. Anti-Lock Brake (ABS) Light This light monitors the Anti-Lock Brake System

(ABS). The light will turn on when the ignition

switch is turned to the ON position and may

stay on for as long as four seconds.

If the ABS light remains on or turns on while driving, it

indicates that the Anti-Lock portion of the brake system

is not functioning and that service is required. However,

the conventional brake system will continue to operate

normally if the BRAKE warning light is not on. If the ABS light is on, the brake system should be serviced

as soon as possible to restore the benefits of Anti-Lock

brakes. If the ABS light does not turn on when the

Ignition switch is turned to the ON position, have the

light inspected by an authorized dealer.

8. Tachometer

Indicates the engine speed in revolutions per minute

(RPM).

9. Vehicle Security Light

This light will flash rapidly for approximately

15 seconds when the vehicle theft alarm is

arming. The light will flash at a slower speed

continuously after the alarm is set. The security

light will also come on for about three seconds when the

ignition is first turned on.

4

UNDERSTANDING YOUR INSTRUMENT PANEL 163

Page 172 of 460

Electronic Vehicle Information Center (EVIC)

Displays

When the appropriate conditions exist, the EVIC displays

the following messages:

•TURN SIGNAL ON

•PERFORM SERVICE

•DAMAGED KEY — KEY DOES NOT COMMUNI-

CATE

•KEY NOT PROGRAMMED — KEY NOT PRO-

GRAMMED

•WRONG KEY — KEY DOES NOT BELONG TO

VEHICLE

•KEY NOT PROGRAMMED — EXCEEDED KEY PRO-

GRAM LIMIT

•PROGRAMMING ACTIVE — NEW KEY PRO-

GRAMMED

•SERVICE SECURITY KEY

•DRIVER/PASSENGER DOOR OPEN (with graphic)

•LEFT/RIGHT REAR DOOR OPEN (with graphic)

•X DOORS OPEN (with graphic)

•LIFTGATE OPEN (with graphic)

•LIFTGATE/DOOR OPEN (with graphic)

•LIFTGATE/DOORS OPEN (with graphic)

•LIFTGLASS OPEN (with graphic)

•HOOD OPEN (with graphic)

•HOOD/DOOR OPEN (with graphic)

•HOOD/DOORS OPEN (with graphic)

•LIFTGATE/HOOD OPEN (with graphic)

•HOOD/GLASS/DOOR OPEN (with graphic)

172 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 322 of 460

Inflation Pressure

This is the cold tire inflation pressure for your vehicle for

all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total weight

of the vehicle with all fluids, including vehicle fuel, at full

capacity conditions, and with no occupants or cargo

loaded into the vehicle. The front and rear curb weight

values are determined by weighing your vehicle on a

commercial scale before any occupants or cargo are

added.

Loading

The actual total weight and the weight of the front and

rear of your vehicle at the ground can best be determined

by weighing it when it is loaded and ready for operation.

The entire vehicle should first be weighed on a commer-

cial scale to ensure that the GVWR has not been ex-

ceeded. The weight on the front and rear of the vehicleshould then be determined separately to be sure that the

load is properly distributed over front and rear axle.

Weighing the vehicle may show that the GAWR of either

the front or rear axles has been exceeded, but the total

load is within the specified GVWR. If so, weight must be

shifted from front to rear, or rear to front, as appropriate

until the specified weight limitations are met. Store the

heavier items down low and be sure that the weight is

distributed equally. Stow all loose items securely before

driving.

Improper weight distributions can have an adverse affect

on the way your vehicle steers and handles, and the way

the brakes operate.

322 STARTING AND OPERATING

Page 330 of 460

NOTE:Remember that everything put into or on the

trailer adds to the load on your vehicle. Also, additional

factory-installed options, or dealer-installed options,

must be considered as part of the total load on your

vehicle. Refer to the Tire and Loading Information plac-

ard in the “Tire—Safety Information” section of this

manual for the maximum combined weight of occupants

and cargo for your vehicle.

Towing Requirements

To promote proper break-in of your new vehicle drive-

train components the following guidelines are recom-

mended:

CAUTION!

•Avoid towing a trailer for the first 500 miles

(805 km) of vehicle operation. Doing so may dam-

age your vehicle.

(Continued)

CAUTION! (Continued)

•During the first 500 miles (805 km) of trailer

towing, limit your speed to 50 mph (80 km/h).

WARNING!

Improper towing can lead to an injury accident.

Follow these guidelines to make your trailer towing

as safe as possible:

Make certain that the load is secured in the trailer

and will not shift during travel. When trailering

cargo that is not fully secured, dynamic load shifts

can occur that may be difficult for the driver to

control. You could lose control of your vehicle and

have an accident.

330 STARTING AND OPERATING

Page 347 of 460

WARNING! (Continued)

•Never start or run the engine with the vehicle on a

jack.

•Do not let anyone sit in the vehicle when it is on a

jack.

•Do not get under the vehicle when it is on a jack.

•Only use the jack in the positions indicated and

for lifting this vehicle during a tire change.

•If working on or near a roadway, be extremely

careful of motor traffic.

•To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with the

valve stem facing the ground.

•Turn on the Hazard Warning flasher.1. Remove the spare tire, jack, and tools from storage.

2. Loosen (but do not remove) the wheel lug nuts by

turning them to the left one turn while the wheel is still

on the ground.

3. Assemble the jack and jacking tools as shown. Connect

jack handle driver (1) to two extensions (2), then to the

lug wrench (3).

Jack Warning Label

6

WHAT TO DO IN EMERGENCIES 347

Page 350 of 460

9. Finish tightening the lug nuts. Push down on the

wrench while tightening for increased leverage. Alternate

nuts until each nut has been tightened twice. The correct

wheel nut tightness is 95 ft lbs (130 N·m). If in doubt

about the correct tightness, have them checked with a

torque wrench by your authorized dealer or at a service

station.

10. Lower the jack to it’s fully closed position.

WARNING!

A loose tire or jack, thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided.

11. Secure the tire, jack, and tools in their proper loca-

tions. NOTE:

Tire should be stowed with the “beauty” side

up. Storing the tire upside down may result in scratching

or damage to the wheel face. Continue winching up the

tire until you hear the winch “ratchet” three times.

Double check to ensure the tire is snug against the

underbody of the vehicle. Damage to the winch cable

may result if the vehicle is driven with the tire loose.

WARNING!

Do not use power tools to winch the tire up or down.

Impact type tools may damage the winch mechanism.

12. Reinstall the rubber plug into the floor of the cargo

area.

350 WHAT TO DO IN EMERGENCIES

Page 381 of 460

WARNING! (Continued)

•To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep the

master cylinder reservoir cap secured at all times.

Brake fluid in a open container absorbs moisture

from the air resulting in a lower boiling point.

This may cause it to boil unexpectedly during hard

or prolonged braking, resulting in sudden brake

failure. This could result in a accident.

•Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing

the brake fluid to catch fire. Brake fluid can also

damage painted and vinyl surfaces, care should be

taken to avoid its contact with these surfaces.(Continued)

WARNING! (Continued)

•Do not allow petroleum based fluid to contami-

nate the brake fluid. Brake seal components could

be damaged, causing partial or complete brake

failure. This could result in an accident.

Front/Rear Axle Fluid

Front Axle Fluid Level Check

Lubricant should be to the bottom of the oil fill hole.

Rear Axle Fluid Level Check

Lubricant should be 1/2 inch (1 cm) below the oil fill

hole.

Adding Fluid

Add lubricant only at the fill hole and only to the level

specified above.

7

MAINTAINING YOUR VEHICLE 381

Page 404 of 460

2. Reach into the front wheel house ahead of the front

wheel to unsnap and lift the cover over the access hole in

the front of the wheel house splash shield. Access to the

bulb can be gained through the wheel liner hole.

3. Reach through the access hole to access the back of the

front fog lamp housing on the back of the front fascia.

4. Disconnect the electrical connector.5. Turn the socket on the back of the housing 1/4 turn

counterclockwise to unlock it.

6. Pull the socket and bulb straight out from the opening

in the housing.

7. Pull the base of the bulb straight out of the socket.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with any oily surface, clean the

bulb with rubbing alcohol.

Rear Tail, Stop, Turn Signal, and Backup Lamps

1. Raise the liftgate.

2. Remove the two push-pins that secure the rear lamp

unit to the side of the liftgate opening.

404 MAINTAINING YOUR VEHICLE

Page 406 of 460

5. Disconnect the electrical connector.

6. Pull the socket and bulb straight out from the opening

in the housing.

7. Pull the base of the bulb straight out of the socket.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with any oily surface, clean the

bulb with rubbing alcohol.

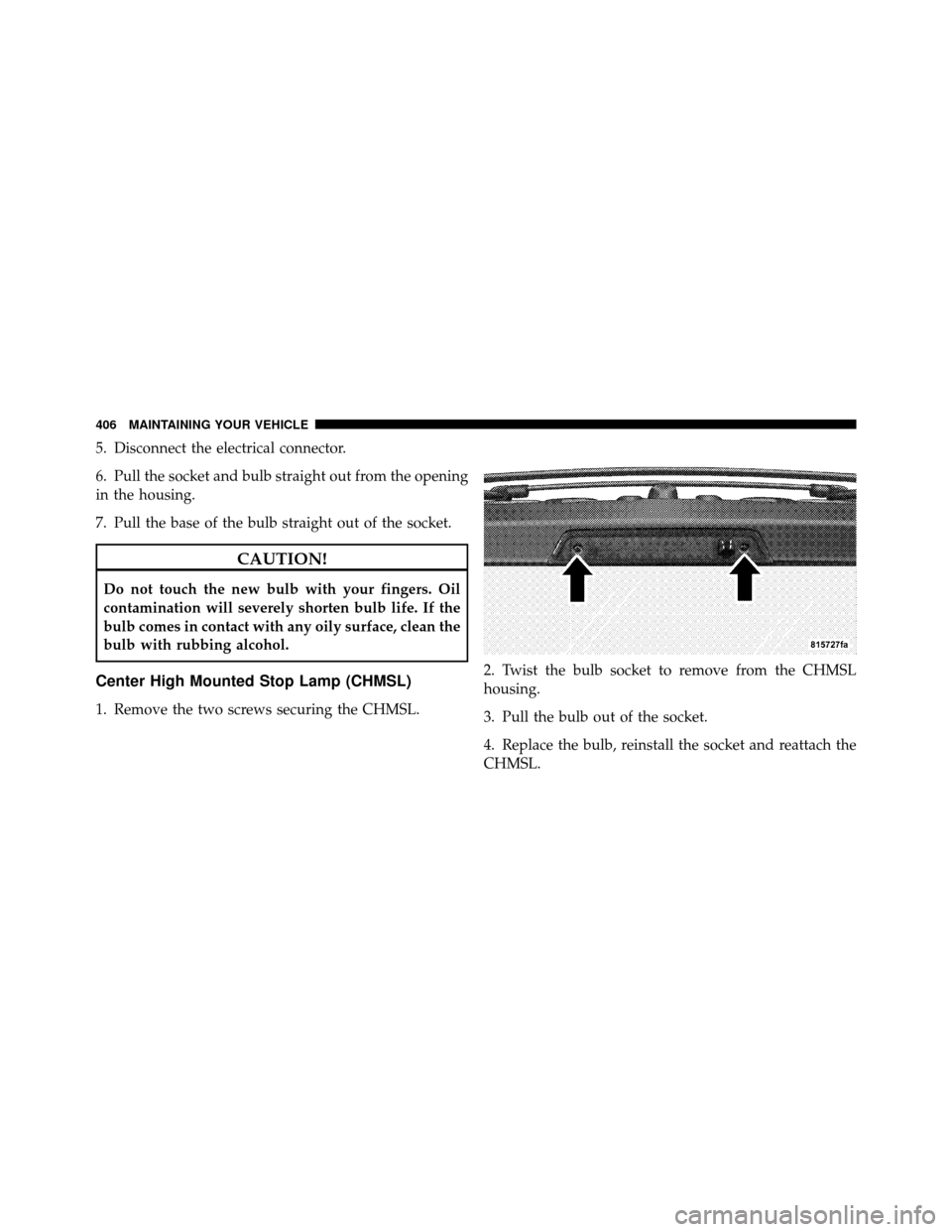

Center High Mounted Stop Lamp (CHMSL)

1. Remove the two screws securing the CHMSL.2. Twist the bulb socket to remove from the CHMSL

housing.

3. Pull the bulb out of the socket.

4. Replace the bulb, reinstall the socket and reattach the

CHMSL.

406 MAINTAINING YOUR VEHICLE

Page 442 of 460

ABS (Anti-Lock Brake System).............. 269

Adding Fuel ........................... 318

Adjustable Pedals ........................ 117

Air Cleaner, Engine (Engine Air Cleaner Filter) . . . 366

Air Conditioner Maintenance ............... 368

Air Conditioning ........................ 226

Air Conditioning, Operating Tips ............ 235

Air Conditioning, Rear Zone ................ 233

Air Conditioning Refrigerant ............... 369

Air Conditioning System .................. 226

Air Filter .............................. 366

Air Pressure, Tires ....................... 295

Airbag .............................. 49,57

Airbag Deployment ....................... 58

Airbag Light ................... 50,56,61,75,163

Airbag Maintenance ....................... 60

Airbag, Side .......................... 55,57

Airbag, Window (Side Curtain) ...........51,55,57

Alarm, Panic ............................ 24 Alarm (Security Alarm)

.................19,163

Alterations/Modifications, Vehicle ............. 9

Antenna, Satellite Radio ................... 216

Antifreeze (Engine Coolant) ................ 407

Anti-Lock Brake System (ABS) ............269,272

Anti-Lock Warning Light .................. 163

Anti-Theft System ....................... 163

Appearance Care ........................ 387

Arming Theft System (Security Alarm) ......... 19

Assist, Hill Start ........................ 280

Auto Down Power Windows ................ 31

Automatic Dimming Mirror ................. 82

Automatic Door Locks ..................... 29

Automatic Headlights .................... 105

Automatic Temperature Control (ATC) ......... 226

Automatic Transmission ................248,383

Adding Fluid ......................... 385

Fluid and Filter Changes ................. 383

Fluid Level Check ................... 384,385

442 INDEX