maintenance schedule JEEP COMPASS 2008 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2008, Model line: COMPASS, Model: JEEP COMPASS 2008 1.GPages: 399, PDF Size: 6.59 MB

Page 330 of 399

Coolant Checks

Check engine coolant (antifreeze) protection every 12

months (before the onset of freezing weather, where

applicable). If coolant is dirty or rusty in appearance, the

system should be drained, flushed and refilled with fresh

coolant. Check the front of the A/C condenser for any

accumulation of bugs, leaves, etc. If dirty, clean by gently

spraying water from a garden hose vertically down the

face of the condenser.

Check the coolant recovery bottle tubing for brittle rub-

ber, cracking, tears, cuts and tightness of the connection

at the bottle and radiator. Inspect the entire system for

leaks.

Cooling System Ð Drain, Flush and Refill

At the intervals shown in the ªMaintenance Schedule,º

the system should be drained, flushed and refilled. Refer

to Section 8 of this manual.

If the solution is dirty or contains a considerable amount

of sediment, clean and flush with a reliable cooling

system cleaner. Follow with a thorough rinsing to remove

all deposits and chemicals. Properly dispose of old

antifreeze solution.

Selection Of Coolant

Use only the manufacturers recommended coolant, refer

to ª Fluids, Lubricants and Genuine Partsº for correct

coolant type.

330 MAINTAINING YOUR VEHICLE

Page 336 of 399

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake And Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect the surface of the hoses and nylon tubing for

evidence of heat and mechanical damage. Hard and

brittle rubber, cracking, tears, cuts, abrasions, and exces-

sive swelling suggest deterioration of the rubber. Particu-

lar attention should be made to examining those hose

surfaces nearest to high heat sources, such as the exhaust

manifold.Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

Insure nylon tubing in these areas has not melted or

collapsed.

NOTE:Often, fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before a hose is replaced

based on leakage.

NOTE:Inspection of brake hoses should be done when-

ever the brake system is serviced and at every engine oil

change.

336 MAINTAINING YOUR VEHICLE

Page 339 of 399

Automatic Transaxle (CVT)

Selection Of Lubricant

It is important that the proper lubricant is used in the

transaxle to assure optimum transaxle performance. Use

only the manufacturer's recommended transmission

fluid which has been formulated with special metal to

metal friction coefficient additives to provide the proper

steel belt traction on the drive and driven pulleys. Refer

to ªFluids, Lubricants and Genuine Partsº for correct

fluid type.

CAUTION!

Using a transmission fluid other than the manufac-

turers recommended fluid will cause belt slip and

result in a complete transmission failure! Refer to

ªFluids, Lubricants, and Genuine Partsº for correct

fluid type.

Fluid Level Check

The fluid level in the automatic transaxle should be

checked only by a trained technician.

Fluid and Filter Changes

Refer to the ªMaintenance Scheduleº in Section 8 of this

manual for the correct change interval.

Special Additives

Do not add any materials (other than leak detection dyes)

to Continuously Variable Transaxle (CVT) Fluid

(CVTF+4). CVTF+4 is an engineered product and its

performance may be impaired by supplemental addi-

tives.

Manual Transaxle

Lubricant Selection

Use only the manufacturers recommended transmission

fluid. Refer to ªFluids, Lubricants, and Genuine Partsº

for correct fluid type.

MAINTAINING YOUR VEHICLE 339

7

Page 340 of 399

Fluid Level Check

Check the fluid level by removing the fill plug. The fluid

level should be between the bottom of the fill hole and a

point not more that 3/16º (4.7 mm) below the bottom of

the hole.

Add fluid, if necessary, to maintain the proper level.

Frequency Of Fluid Change

Under normal operating conditions, the fluid installed at

the factory will give satisfactory lubrication for the life of

the vehicle. Fluid changes are not necessary unless the

following conditions exist:

²The lubricant has become contaminated with water. If

contaminated with water, the fluid should be changed

immediately.

Rear Drive Assembly (RDA) ± AWD/4WD Models

Only

Lubricant Selection

Use only the manufacturers recommended fluid. Refer to

ªFluids, Lubricants and Genuine Partsº for correct fluid

type.

Fluid Level Check

Visually inspected the unit at each oil change for leakage.

If leakage is detected, Check the fluid level by removing

the fill plug. The fluid level should be maintained be-

tween the bottom of the fill hole to 1/8 inch (4 mm)

below the fill hole.

Add fluid, if necessary, to maintain the proper level.

Frequency Of Fluid Change

Refer to the ªMaintenance Scheduleº located in Section 8

of this manual for the correct change interval.

340 MAINTAINING YOUR VEHICLE

Page 341 of 399

Power Transfer Unit (PTU) ± AWD/4WD Models

Only

Lubricant Selection

Use only the manufacturers recommended fluid. Refer to

ªFluids, Lubricants, and Genuine Partsº for correct fluid

type.

Fluid Level Check

Visually inspected the unit at each oil change for leakage.

If leakage is detected, Check the fluid level by removing

the fill plug. The fluid level should be maintained be-

tween the bottom of the fill hole to 1/8 inch (4 mm)

below the fill hole.

Add fluid, if necessary, to maintain the proper level.

Frequency Of Fluid Change

Refer to the ªMaintenance Scheduleº located in Section 8

of this manual for the correct change interval.

Appearance Care And Protection From Corrosion

Protection Of Body And Paint from Corrosion

Vehicle body care requirements vary according to geo-

graphic locations and usage. Chemicals that make roads

passable in snow and ice, and those that are sprayed on

trees and road surfaces during other seasons, are highly

corrosive to the metal in your vehicle. Outside parking,

which exposes your vehicle to airborne contaminants,

road surfaces on which the vehicle is operated, extreme

hot or cold weather and other extreme conditions will

have an adverse effect on paint, metal trim, and under-

body protection.

The following maintenance recommendations will enable

you to obtain maximum benefit from the corrosion

resistance built into your vehicle.

MAINTAINING YOUR VEHICLE 341

7

Page 363 of 399

MAINTENANCE SCHEDULES

CONTENTS

mEmission Control System Maintenance........364

mMaintenance Schedule...................365NRequired Maintenance Intervals...........367

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 364 of 399

EMISSION CONTROL SYSTEM MAINTENANCE

The ªScheduledº maintenance services, listed inbold

typemust be done at the times or mileages specified to

assure the continued proper functioning of the emission

control system. These, and all other maintenance services

included in this manual, should be done to provide best

vehicle performance and reliability. More frequent main-

tenance may be needed for vehicles in severe operating

conditions such as dusty areas and very short trip

driving.

Inspection and service also should be done any time a

malfunction is suspected.NOTE:Maintenance, replacement, or repair of the emis-

sion control devices and systems on your vehicle may be

performed by any automotive repair establishment or

individual using any automotive part, which has been

certified pursuant to U.S. EPA or, in the State of Califor-

nia, California Air Resources Board regulations.

364 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 365 of 399

MAINTENANCE SCHEDULE

The oil change indicator system will remind you that it is

time to take your vehicle in for scheduled maintenance.

On Electronic Vehicle Information Center (EVIC)

equipped vehicles ªOil Change Requiredº will be dis-

played in the EVIC and a single chime will sound,

indicating that an oil change is necessary.

On Non-EVIC equipped vehicles ªChange Oilº will flash

in the instrument cluster odometer and a single chime

will sound, indicating that an oil change is necessary.

Based on engine operation condition the oil change

indicator message will illuminate, this means that service

is required for your vehicle. Have your vehicle serviced

as soon as possible, within the next 500 miles (805 km).

NOTE:

²The oil change indicator message will not monitor the

time since the last oil change. Change your vehicles oilif it has been 6 months since your last oil change even

if the oil change indicator message is NOT illumi-

nated.

²Change your engine oil more often if you drive your

vehicle off-road for an extended period of time.

²Under no circumstances should oil change intervals

exceed 6,000 miles (10,000 km) or 6 months, whichever

comes first.

Your dealer will reset the oil change indicator message

after completing the scheduled oil change. If this sched-

uled oil change is performed by someone other than your

dealer the message can be reset by referring to the steps

described under ªOil Change Requiredº in ªUse Factory

Settingsº of the EVIC section in this manual or under

ªOdometer/Trip Odometerº in the ªInstrument Cluster

Descriptions section of this manual.

MAINTENANCE SCHEDULES 365

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 366 of 399

At Each Stop for Fuel

²Check the engine oil level about 5 minutes after a fully

warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accu-

racy of the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear or

damage.

²Inspect the battery and clean and tighten the terminals

as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transmission and

add as needed.

²Check all lights and other electrical items for correct

operation.

At Each Oil Change

²Change the engine oil filter.

²Inspect the brake hoses and lines.

²Check the Manual Transmission fluid level.

CAUTION!

Failure to perform the required maintenance items

may result in damage to the vehicle.

366 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 367 of 399

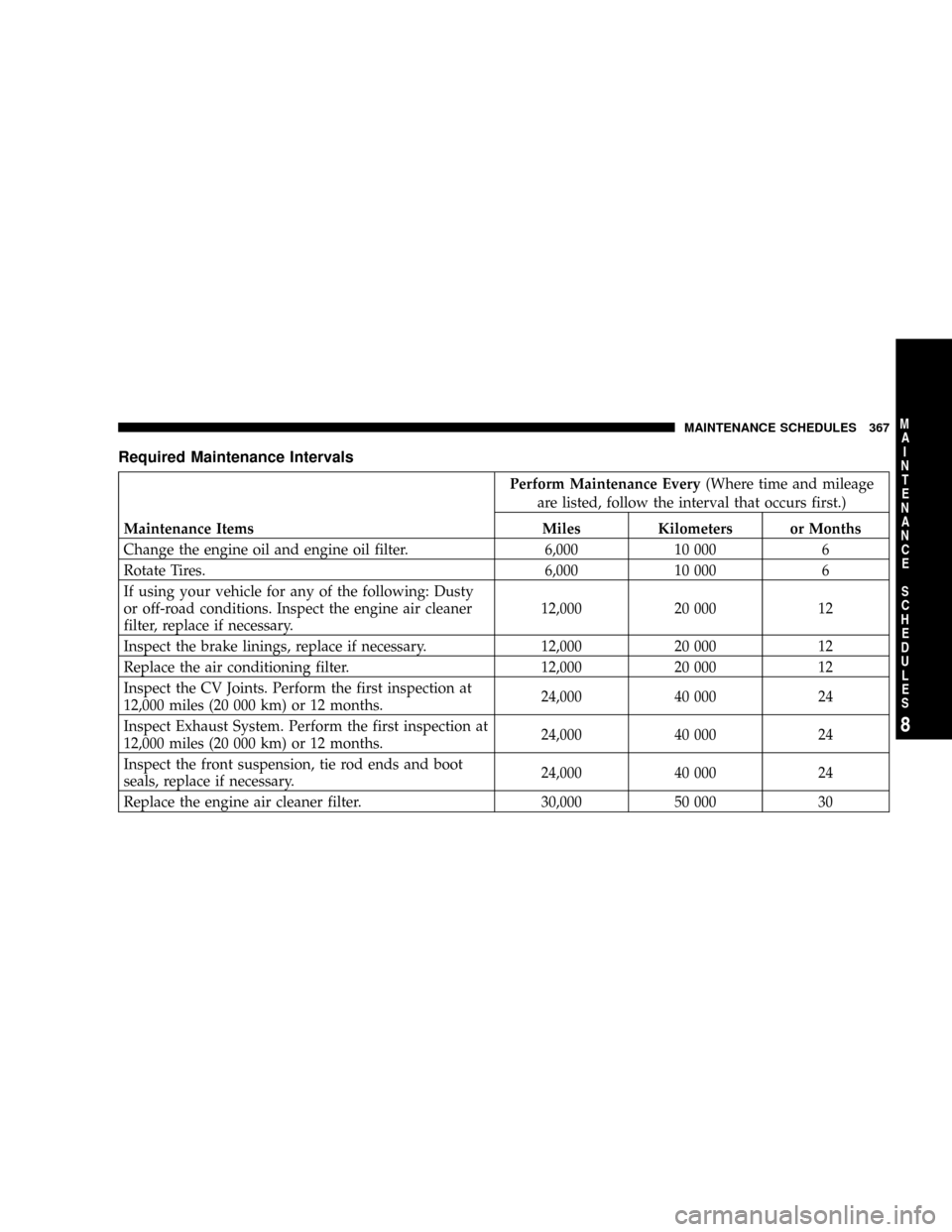

Required Maintenance Intervals

Perform Maintenance Every(Where time and mileage

are listed, follow the interval that occurs first.)

Maintenance Items Miles Kilometers or Months

Change the engine oil and engine oil filter. 6,000 10 000 6

Rotate Tires. 6,000 10 000 6

If using your vehicle for any of the following: Dusty

or off-road conditions. Inspect the engine air cleaner

filter, replace if necessary.12,000 20 000 12

Inspect the brake linings, replace if necessary. 12,000 20 000 12

Replace the air conditioning filter. 12,000 20 000 12

Inspect the CV Joints. Perform the first inspection at

12,000 miles (20 000 km) or 12 months.24,000 40 000 24

Inspect Exhaust System. Perform the first inspection at

12,000 miles (20 000 km) or 12 months.24,000 40 000 24

Inspect the front suspension, tie rod ends and boot

seals, replace if necessary.24,000 40 000 24

Replace the engine air cleaner filter. 30,000 50 000 30

MAINTENANCE SCHEDULES 367

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S