light JEEP COMPASS 2009 1.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2009, Model line: COMPASS, Model: JEEP COMPASS 2009 1.GPages: 439, PDF Size: 12.51 MB

Page 310 of 439

Light spark knock at low engine speeds is not harmful to

your engine. However, continued heavy spark knock at high

speeds can cause damage and immediate service is required.

Poor quality gasoline can cause problems such as hard

starting, stalling and hesitations. If you experience these

symptoms, try another brand of gasoline (with the ap-

propriate octane rating for your engine) before consider-

ing service for the vehicle.

Reformulated Gasoline

Many areas of the country require the use of cleaner

burning gasoline referred to as “reformulated gasoline”.

“Reformulated gasolines” contain oxygenates and are

specifically blended to reduce vehicle emissions and

improve air quality.

The manufacturer supports the use of “reformulated

gasolines”. Properly blended “reformulated gasolines”

will provide excellent performance and durability of

engine and fuel system components.

Gasoline/Oxygenate Blends

Some fuel suppliers blend unleaded gasoline with oxy-

genates such as 10% ethanol, MTBE, and ETBE. Oxygen-

ates are required in some areas of the country during the

winter months to reduce carbon monoxide emissions.

Fuels blended with these oxygenates may be used in

your vehicle.

CAUTION!

DO NOT use gasolines containing Methanol or E85

Ethanol. Use of these blends may result in starting

and drivability problems and may damage critical

fuel system components.

Problems that result from using methanol/gasoline

blends are not the responsibility of the manufacturer.

While MTBE is an oxygenate made from Methanol, it

does not have the negative effects of Methanol.

308 STARTING AND OPERATING

Page 311 of 439

E-85 Usage In Non-Flex Fuel Vehicles

Non-FFV vehicles are compatible with gasoline contain-

ing 10% ethanol (E10). Gasoline with higher ethanol

content may void the vehicle’s warranty.

If a Non-FFV vehicle is inadvertently fueled with E-85

fuel, the engine will have some or all of these symptoms:

•operate in a lean mode

•OBD II “Malfunction Indicator Light” on

•poor engine performance

•poor cold start and cold drivability

•increased risk for fuel system component corrosion

To fix a Non-FFV vehicle inadvertently fueled once with

E-85 perform the following:

•drain the fuel tank (see your authorized dealer)

•change the engine oil and oil filter

•disconnect and reconnect the battery to reset the

engine controller memory

More extensive repairs will be required for prolonged

exposure to E-85 fuel.

MMT In Gasoline

MMT is a manganese containing metallic additive that is

blended into some gasoline to increase the octane num-

ber. Gasolines blended with MMT offer no performance

advantage beyond gasolines of the same octane number

without MMT. Gasolines blended with MMT have been

shown to reduce spark plug life and reduce emission

system performance in some vehicles. The manufacturer

recommends using gasolines without MMT. Since the

MMT content of gasoline may not be indicated on the

pump, you should ask your gasoline retailer whether or

not their gasoline contains MMT.

STARTING AND OPERATING 309

5

Page 312 of 439

It is even more important to look for gasolines without

MMT in Canada, because MMT can be used at levels

higher than those allowed in the United States.

MMT is prohibited in Federal and California reformu-

lated gasolines.

Materials Added To Fuel

All gasoline sold in the United States is required to

contain effective detergent additives. Use of additional

detergents or other additives is not needed under normal

conditions and would result in additional cost. Therefore

you should not have to add anything to the fuel.

Fuel System Cautions

CAUTION!

Follow these guidelines to maintain your vehicle’s

performance:

•The use of leaded gas is prohibited by Federal law.

Using leaded gasoline can impair engine performance

and damage the emission control system.

•An out-of-tune engine, or certain fuel or ignition

malfunctions, can cause the catalytic converter to

overheat. If you notice a pungent burning odor or

some light smoke, your engine may be out of tune or

malfunctioning and may require immediate service.

Contact your authorized dealer for service assistance.

•The use of fuel additives, which are now being sold as

octane enhancers, is not recommended. Most of these

products contain high concentrations of Methanol.

Fuel system damage or vehicle performance problems

resulting from the use of such fuels or additives is not

the responsibility of the manufacturer.

NOTE:Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

310 STARTING AND OPERATING

Page 314 of 439

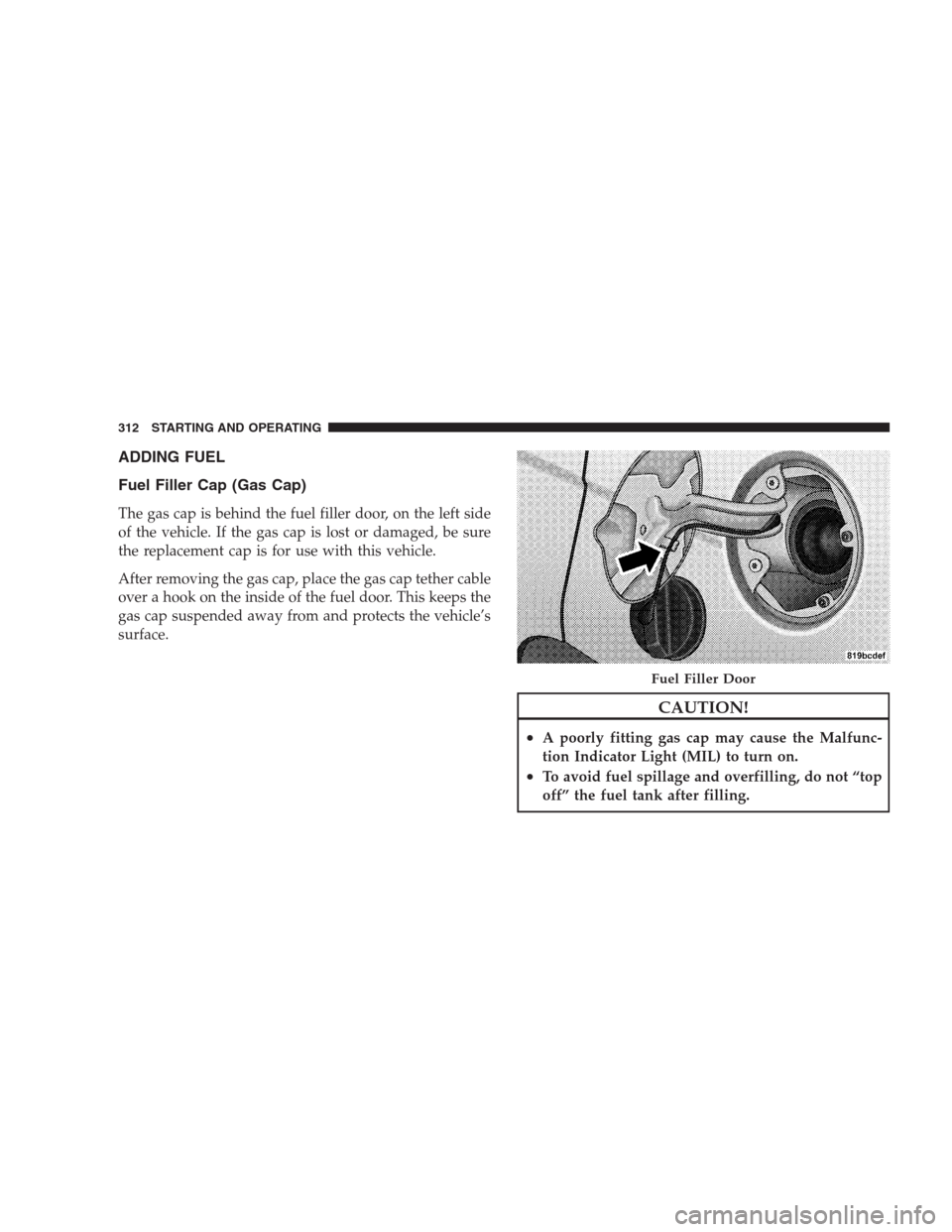

ADDING FUEL

Fuel Filler Cap (Gas Cap)

The gas cap is behind the fuel filler door, on the left side

of the vehicle. If the gas cap is lost or damaged, be sure

the replacement cap is for use with this vehicle.

After removing the gas cap, place the gas cap tether cable

over a hook on the inside of the fuel door. This keeps the

gas cap suspended away from and protects the vehicle’s

surface.

CAUTION!

•A poorly fitting gas cap may cause the Malfunc-

tion Indicator Light (MIL) to turn on.

•To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling.

Fuel Filler Door

312 STARTING AND OPERATING

Page 315 of 439

NOTE:When the fuel nozzle “clicks” or shuts off, the

fuel tank is full.

WARNING!

•Never have any smoking materials lit in or near

the vehicle when the gas cap is removed or the

tank filled.

•Never add fuel when the engine is running. This is

in violation of most state and Federal fire regula-

tions and will cause the Malfunction Indicator

Light (MIL) to turn on.

NOTE:Tighten the gas cap about 1/4 turn until you

hear one click. This is an indication that cap is properly

tightened.

If the gas cap is not tighten properly, the MIL will come

on. Be sure the gas cap is tightened every time the vehicle

is refueled.

WARNING!

A fire may result if gasoline is pumped into a

portable container that is inside of a vehicle. You

could be burned. Always place gas containers on the

ground while filling.

Loose Fuel Filler Cap Message

If the vehicle diagnostic system determines that the fuel

filler cap is loose or improperly installed, a “gASCAP”

message will be displayed in the Odometer/Trip Odom-

eter in the instrument cluster. Refer to “Instrument

Cluster Description” in Section 4 of this manual. Tighten

the fuel filler cap properly and press the odometer/trip

odometer RESET button to turn the message off. If the

problem continues, the message will appear the next time

the vehicle is started. Refer to “Onboard Diagnostic

System — OBD II” in Section 7 of this manual for more

information.

STARTING AND OPERATING 313

5

Page 321 of 439

Trailer Hitch Classification

Class Max. GTW

(Gross Trailer Wt.)

Class I - Light Duty 2,000 lbs (907 kg)

Refer to the “Trailer Towing Weights (Maximum

Trailer Weight Ratings)” chart for the Maximum

Gross Trailer Weight (GTW) towable for your given

drivetrain.All trailer hitches should be professionally installed on

your vehicle.

Trailer Towing Weights (Maximum Trailer Weight Ratings)

The following chart provides the maximum trailer weight ratings towable for your given drivetrain.

Engine/Transmission Frontal Area Max. GTW (Gross Trailer Wt.) Max. Tongue Wt. (See Note

1)

2.0L Auto/Man 22 sq ft (2.04 sq m) 1,000 lbs (450 kg) 150 lbs (50 kg)

2.4L Auto/Man 22 sq ft (2.04 sq m) 1,000 lbs (450 kg) 150 lbs (50 kg)

2.4L Auto/Man with

Trailer Tow Prep Pack-

age (AHC)32 sq ft (3.0 sq m) 2,000 lbs (907 kg) 300 lbs (136 kg)

Refer to local laws for maximum trailer towing speeds.

STARTING AND OPERATING 319

5

Page 326 of 439

CAUTION!

If the trailer weighs more than 1,000 lbs (454 kg)

loaded, it should have its own brakes and they

should be of adequate capacity. Failure to do this

could lead to accelerated brake lining wear, higher

brake pedal effort, and longer stopping distances.

WARNING!

Do not connect trailer brakes to your vehicle’s hy-

draulic brake lines. It can overload your brake sys-

tem and cause it to fail. You might not have brakes

when you need them and could have an accident.

Towing any trailer will increase your stopping dis-

tance. When towing you should allow for additional

space between your vehicle and the vehicle in front

of you. Failure to do so could result in an accident.

Towing Requirements — Trailer Lights and Wiring

Whenever you pull a trailer, regardless of the trailer size,

stop lights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may include a 4- and 7-pin

wiring harness. Use a factory approved trailer harness

and connector.

NOTE:Do not cut or splice wiring into the vehicles

wiring harness.

The electrical connections are all complete to the vehicle

but you must mate the harness to a trailer connector.

Refer to the following illustrations.

324 STARTING AND OPERATING

Page 328 of 439

Towing Tips

Before setting out on a trip, practice turning, stopping

and backing the trailer in an area away from heavy

traffic.

Towing Tips — Automatic Transmission

The automatic transmission fluid and filter should be

changed if you REGULARLY tow a trailer for more than

45 minutes of continuous operation. Refer to the “Main-

tenance Schedule” in Section 8 for transmission fluid

change intervals.

NOTE:Check the automatic transmission fluid level

before towing.

Towing Tips — Electronic Speed Control (If

Equipped)

�

Do not use in hilly terrain or with heavy loads.

�When using the speed control, if you experience speed

drops greater than 10 mph (16 km/h), disengage until

you can get back to cruising speed.

�Use speed control in flat terrain and with light loads to

maximize fuel efficiency.

Towing Tips — Cooling System

To reduce the potential for engine and transmission

overheating, take the following actions:

�City Driving

When stopped for short periods of time, put transmission

in NEUTRAL but do not increase engine idle speed.

�Highway Driving

Reduce speed.

�Air Conditioning

Turn off temporarily.

326 STARTING AND OPERATING

Page 334 of 439

WARNING!

A hot engine cooling system is dangerous. You or

others could be badly burned by steam or boiling

coolant. You may want to call a service center if your

vehicle overheats. If you decide to look under the

hood yourself, refer to “Maintenance”, Section 7 of

this manual. Follow the warnings under the “Cooling

System Pressure Cap” paragraph.

AUTOMATIC TRANSAXLE OVERHEATING

During sustained high speed driving or trailer towing up

long grades on hot days, the automatic transaxle oil may

become too hot.

If this happens, the transmission overheat in-

dicator light will come on, and the vehicle will

slow slightly until the automatic transaxle

cools down enough to allow a return to therequested speed. If the high speed is maintained, the

overheating will reoccur, as before, in a cyclic fashion.

JACKING AND TIRE CHANGING

WARNING!

•Being under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never put any part of your body

under a vehicle that is on a jack. Never start or run

the engine while the vehicle is on a jack. If you

need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

•The jack is designed to use as a tool for changing

tires only. The jack should not be used to lift the

vehicle for service purposes. The vehicle should

be jacked on a firm level surface only. Avoid ice or

slippery areas.

332 WHAT TO DO IN EMERGENCIES

Page 338 of 439

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in Step 3.

3. There are two front jacking locations and two rear

jacking locations on each side of the body. The front

locations are outlined by two triangular cutouts, the rear

ones by two rectangular cutouts. For vehicles equipped

with plastic trim, the plastic has been cut away to expose

the jacking locations in the body.

Do not raise the vehicle until you are sure the jack is

securely engaged.

4. Turn the jack screw to the left until the jack can be

placed under the jacking location. Once the jack is

positioned, turn the jack screw to the right until the jack

head is properly engaged with the lift area closest to the

wheel to be changed.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

5. Using the swivel wrench raise the vehicle by turning

the jack screw to the right. Raise the vehicle only until the

tire just clears the surface and enough clearance is

obtained to install the spare tire. Minimum tire lift

provides maximum stability.

6. Remove the wheel nuts and pull the wheel and wheel

covers, where applicable, off the hub. Install the spare

wheel and wheel nuts with the cone shaped end of the

nuts toward the wheel. Lightly tighten the nuts. To avoid

the risk of forcing the vehicle off the jack, do not tighten

the nuts fully until the vehicle has been lowered.

336 WHAT TO DO IN EMERGENCIES