tow JEEP COMPASS 2016 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2016, Model line: COMPASS, Model: JEEP COMPASS 2016 1.GPages: 148, PDF Size: 8.42 MB

Page 96 of 148

JACKING AND TIRE CHANGING

WARNING!

• Do not attempt to change a tire on the side of the vehicle close to movingtraffic. Pull far enough off the road to avoid the danger of being hit when

operating the jack or changing the wheel.

• Being under a jacked-up vehicle is dangerous. The vehicle could slip off the

jack and fall on you. You could be crushed. Never put any part of your body

under a vehicle that is on a jack. If you need to get under a raised vehicle, take

it to a service center where it can be raised on a lift.

• Never start or run the engine while the vehicle is on a jack.

• The jack is designed to be used as a tool for changing tires only. The jack

should not be used to lift the vehicle for service purposes. The vehicle should

be jacked on a firm level surface only. Avoid ice or slippery areas.

Jack Location

The jack and jack-handle are stowed under the load floor in the cargo area.

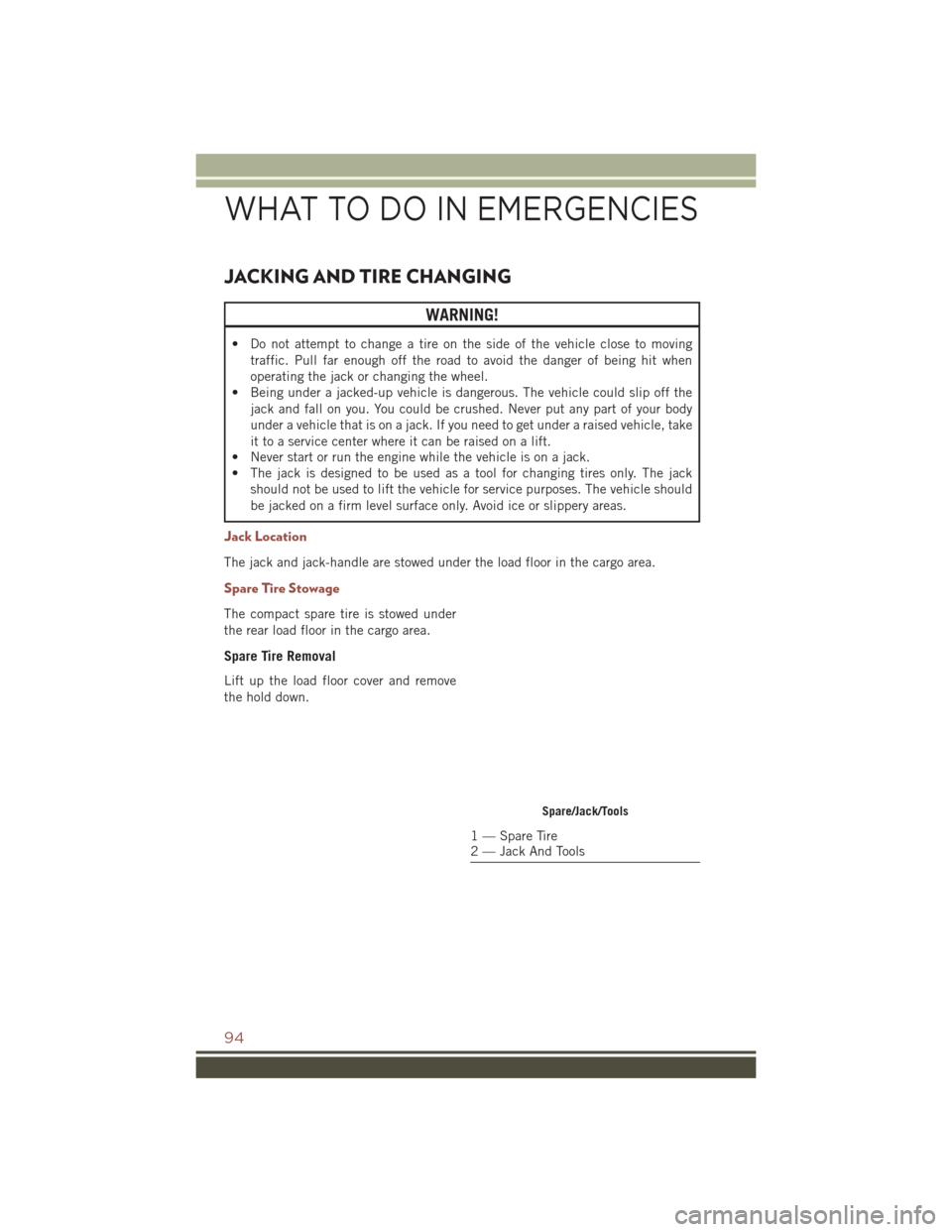

Spare Tire Stowage

The compact spare tire is stowed under

the rear load floor in the cargo area.

Spare Tire Removal

Lift up the load floor cover and remove

the hold down.

Spare/Jack/Tools

1 — Spare Tire

2 — Jack And Tools

WHAT TO DO IN EMERGENCIES

94

Page 98 of 148

Jacking Instructions

WARNING!

Carefully follow these tire changing warnings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway aspossible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the wheel to be raised.

• Set the parking brake firmly and set an automatic transmission in PARK; a

manual transmission in REVERSE.

• Never start or run the engine with the vehicle on a jack.

• Do not let anyone sit in the vehicle when it is on a jack.

• Do not get under the vehicle when it is on a jack. If you need to get under a

raised vehicle, take it to a service center where it can be raised on a lift.

• Only use the jack in the positions indicated and for lifting this vehicle during

a tire change.

• If working on or near a roadway, be extremely careful of motor traffic.

• To assure that spare tires, flat or inflated, are securely stowed, spares must be

stowed with the valve stem facing the ground.

Warning Label

WHAT TO DO IN EMERGENCIES

96

Page 101 of 148

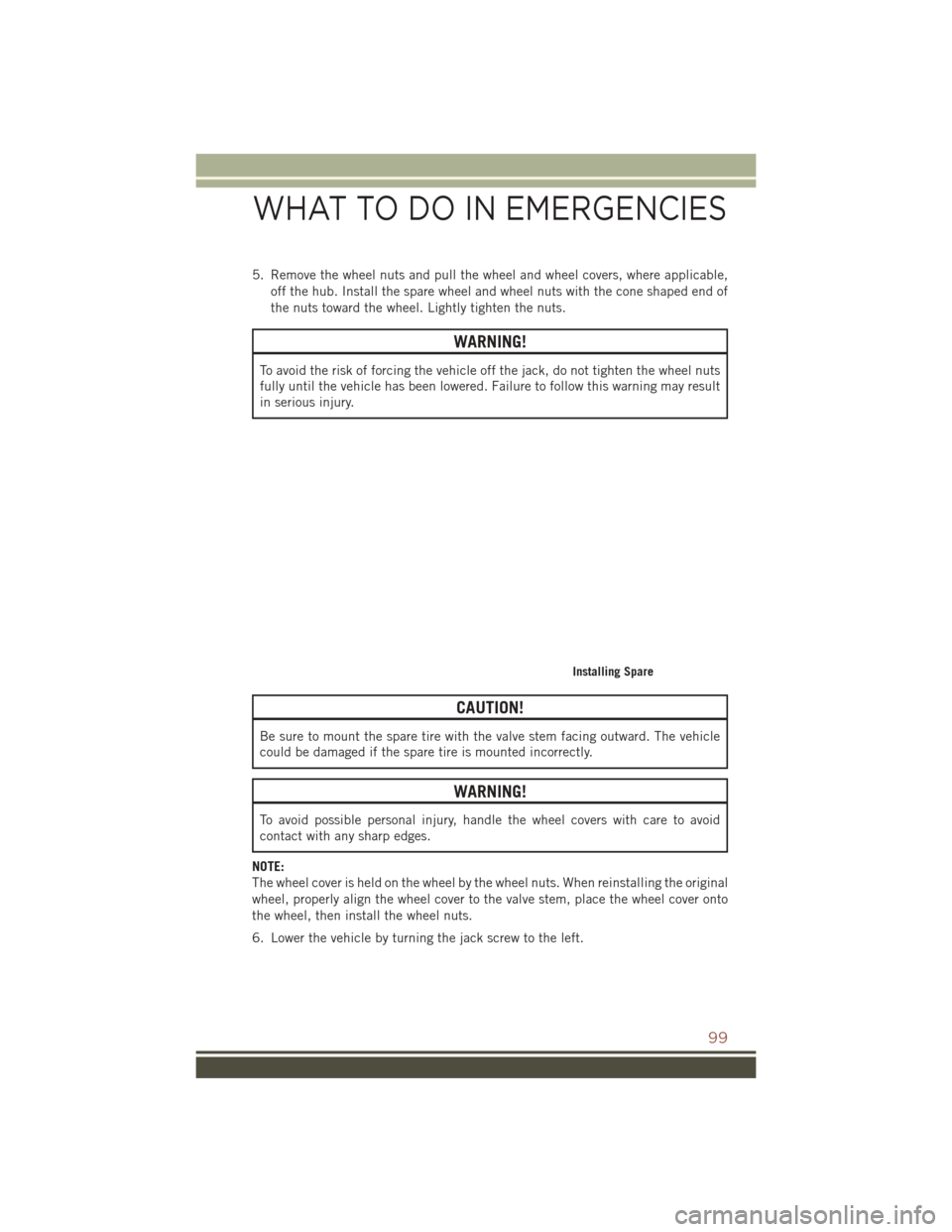

5. Remove the wheel nuts and pull the wheel and wheel covers, where applicable,off the hub. Install the spare wheel and wheel nuts with the cone shaped end of

the nuts toward the wheel. Lightly tighten the nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered. Failure to follow this warning may result

in serious injury.

CAUTION!

Be sure to mount the spare tire with the valve stem facing outward. The vehicle

could be damaged if the spare tire is mounted incorrectly.

WARNING!

To avoid possible personal injury, handle the wheel covers with care to avoid

contact with any sharp edges.

NOTE:

The wheel cover is held on the wheel by the wheel nuts. When reinstalling the original

wheel, properly align the wheel cover to the valve stem, place the wheel cover onto

the wheel, then install the wheel nuts.

6. Lower the vehicle by turning the jack screw to the left.

Installing Spare

WHAT TO DO IN EMERGENCIES

99

Page 102 of 148

7. Finish tightening the nuts. Push down on the wrench while at the end of thehandle for increased leverage. Tighten the lug nuts in a star pattern until each nut

has been tightened twice. The correct wheel nut torque is 100 ft/lbs (135 N·m).

If you doubt that you have tightened the nuts correctly, have them checked with

a torque wrench by your authorized dealer or service station

8. Remove the wheel blocks and lower the jack until it is free. Release the parking brake. Reassemble the lug wrench to the jack assembly and stow it in the spare

tire area. Secure the assembly using the means provided.

WARNING!

A loose tire or jack thrown forward in a collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack parts and the spare tire in the

places provided.

9. Place the deflated (flat) tire in the cargo area, have the tire repaired or replaced as

soon as possible.

WARNING!

A loose tire thrown forward in a collision or hard stop could injure the occupants

in the vehicle. Have the deflated (flat) tire repaired or replaced immediately.

10. Check the spare tire pressure as soon as possible. Correct the tire pressure as required.

11. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

WHAT TO DO IN EMERGENCIES

100

Page 103 of 148

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. Align the valve notch in the wheel cover with the valve stem on the wheel. Installthe cover by hand. Do not use a hammer or excessive force to install the cover.

3. Install the five wheel lug nuts with the cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure to follow this warning may result in

serious injury.

4. Lower the vehicle to the ground by turning the jack handle counterclockwise.

5. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tighten the lug nuts in a star pattern until each nut

has been tightened twice. The correct tightness of each lug nut is 100 ft/lbs

(135 N·m). If in doubt about the correct tightness, have them checked with a

torque wrench by your authorized dealer or service station.

6. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

Wheel Cover Installation

1 — Valve Stem

2 — Valve Notch

3 — Wheel Lug Nut

4 — Wheel Cover

5 — Mounting Stud

WHAT TO DO IN EMERGENCIES

101

Page 104 of 148

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward thewheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do not fully tighten the lug nuts

until the vehicle has been lowered. Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tighten the lug nuts in a star pattern until each nut

has been tightened twice. The correct tightness of each lug nut is 100 ft/lbs

(135 N·m). If in doubt about the correct tightness, have them checked with a

torque wrench by your authorized dealer or service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

JUMP-STARTING PROCEDURES

If your vehicle has a discharged battery it can be jump-started using a set of jumper

cables and a battery in another vehicle or by using a portable battery booster pack.

Jump-starting can be dangerous if done improperly so please follow the procedures

in this section carefully.

NOTE:

When using a portable battery booster pack follow the manufacturer’s operating

instructions and precautions.

CAUTION!

Do not use a portable battery booster pack or any other booster source with a

system voltage greater than 12 Volts or damage to the battery, starter motor,

alternator or electrical system may occur.

WARNING!

Do not attempt jump-starting if the battery is frozen. It could rupture or explode

and cause personal injury.

WHAT TO DO IN EMERGENCIES

102

Page 108 of 148

4. Turn the ignition switch to the ACC or ON/RUN position, but do not start theengine.

5. Press and maintain firm pressure on the brake pedal.

6. Insert the screwdriver or similar tool into the access port, and push and hold the override release lever forward.

7. Move the shift lever to the NEUTRAL position.

8. The vehicle may then be started in NEUTRAL.

9. Reinstall the shift lever override access cover.

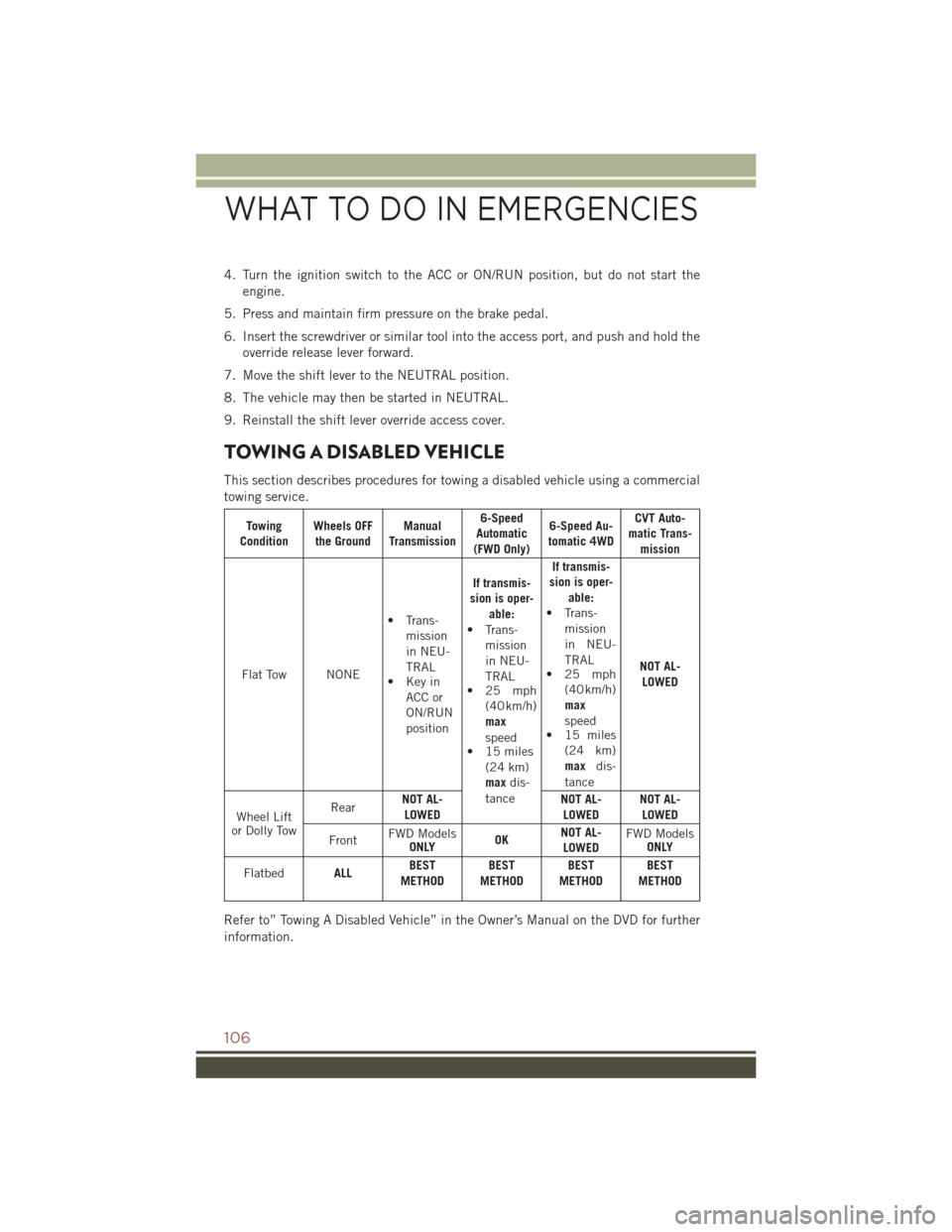

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled vehicle using a commercial

towing service.

Towing

Condition Wheels OFF

the Ground Manual

Transmission 6-Speed

Automatic

(FWD Only) 6-Speed Au-

tomatic 4WD CVT Auto-

matic Trans- mission

Flat Tow NONE • Trans-

mission

in NEU-

TRAL

• Key in

ACC or

ON/RUN

position If transmis-

sion is oper- able:

• Trans- mission

in NEU-

TRAL

• 25 mph

(40 km/h)

max

speed

• 15 miles

(24 km)

max dis-

tance If transmis-

sion is oper- able:

• Trans- mission

in NEU-

TRAL

• 25 mph

(40 km/h)

max

speed

• 15 miles

(24 km)

max dis-

tance NOT AL-

LOWED

Wheel Lift

or Dolly Tow Rear

NOT AL-

LOWED NOT AL-

LOWED NOT AL-

LOWED

Front FWD Models

ONLY OKNOT AL-

LOWED FWD Models

ONLY

Flatbed ALLBEST

METHOD BEST

METHOD BEST

METHOD BEST

METHOD

Refer to” Towing A Disabled Vehicle” in the Owner’s Manual on the DVD for further

information.

WHAT TO DO IN EMERGENCIES

106

Page 111 of 148

TO OPEN AND CLOSE THE HOOD

To open the hood, two latches must be released.

1. Pull the hood release lever located on the left kick panel.

2. Move the safety latch, located outsidethe vehicle under the front edge of the

hood, toward the center and raise the

hood.

Lift the hood prop rod, clipped to the

right side (left side facing hood) of the

engine compartment to secure the hood

in the open position. Place the hood prop

at the location stamped into the inner

hood surface.

CAUTION!

To prevent possible damage:

• Before closing hood, make sure the hood prop rod is fully seated into its storage retaining clips.

• Do not slam the hood to close it. Use a firm downward push at the center front

edge of the hood to ensure that both latches engage. Never drive your vehicle

unless the hood is fully closed, with both latches engaged.

WARNING!

Be sure the hood is fully latched before driving your vehicle. If the hood is not fully

latched, it could open when the vehicle is in motion and block your vision. Failure

to follow this warning could result in serious injury or death.

Hood Release Lever

MAINTAINING YOUR VEHICLE

109

Page 118 of 148

MAINTENANCE PROCEDURES

For information on the maintenance procedures for your vehicle, please refer to

“Maintenance Procedures” in “Maintaining Your Vehicle” in your Owner’s Manual or

applicable supplement on the DVD for further details.

MAINTENANCE SCHEDULE

Your vehicle is equipped with an automatic oil change indicator system. The oil

change indicator system will remind you that it is time to take your vehicle in for

scheduled maintenance.

Based on engine operation conditions, the oil change indicator message will

illuminate. This means that service is required for your vehicle. Operating conditions

such as frequent short-trips, trailer tow, extremely hot or cold ambient temperatures

will influence when the “Change Oil” or “Oil Change Required” message is dis-

played. Severe Operating Conditions can cause the change oil message to illuminate

as early as 3,500 miles (5,600 km) since last reset. Have your vehicle serviced as

soon as possible, within the next 500 miles (805 km).

On Electronic Vehicle Information Center (EVIC) equipped vehicles, “Oil Change

Required” will be displayed in the EVIC and a single chime will sound, indicating that

an oil change is necessary.

On Non-EVIC equipped vehicles, “Change Oil” will flash in the instrument cluster

odometer and a single chime will sound, indicating that an oil change is necessary.

Your authorized dealer will reset the oil change indicator message after completing

the scheduled oil change. If a scheduled oil change is performed by someone other

than your authorized dealer, the message can be reset by referring to the steps

described under “Instrument Cluster Warning Lights” in “What To Do In Emergen-

cies” in this guide or “Instrument Cluster Descriptions” or “Electronic Vehicle

Information Center (EVIC)” in “Understanding Your Instrument Panel” in the

Owner’s Manual on your DVD for further information.

NOTE:

Under no circumstances should oil change intervals exceed 10,000 miles

(16,000 km), twelve months or 350 hours of engine run time, whichever comes first.

The 350 hours of engine run or idle time is generally only a concern for fleet

customers.

Severe Duty All Models

Change Engine Oil at 4,000 miles (6,500 km) if the vehicle is operated in a dusty

and off road environment or is operated predominately at idle or only very low engine

RPM’s. This type of vehicle use is considered Severe Duty.

MAINTAINING YOUR VEHICLE

116

Page 120 of 148

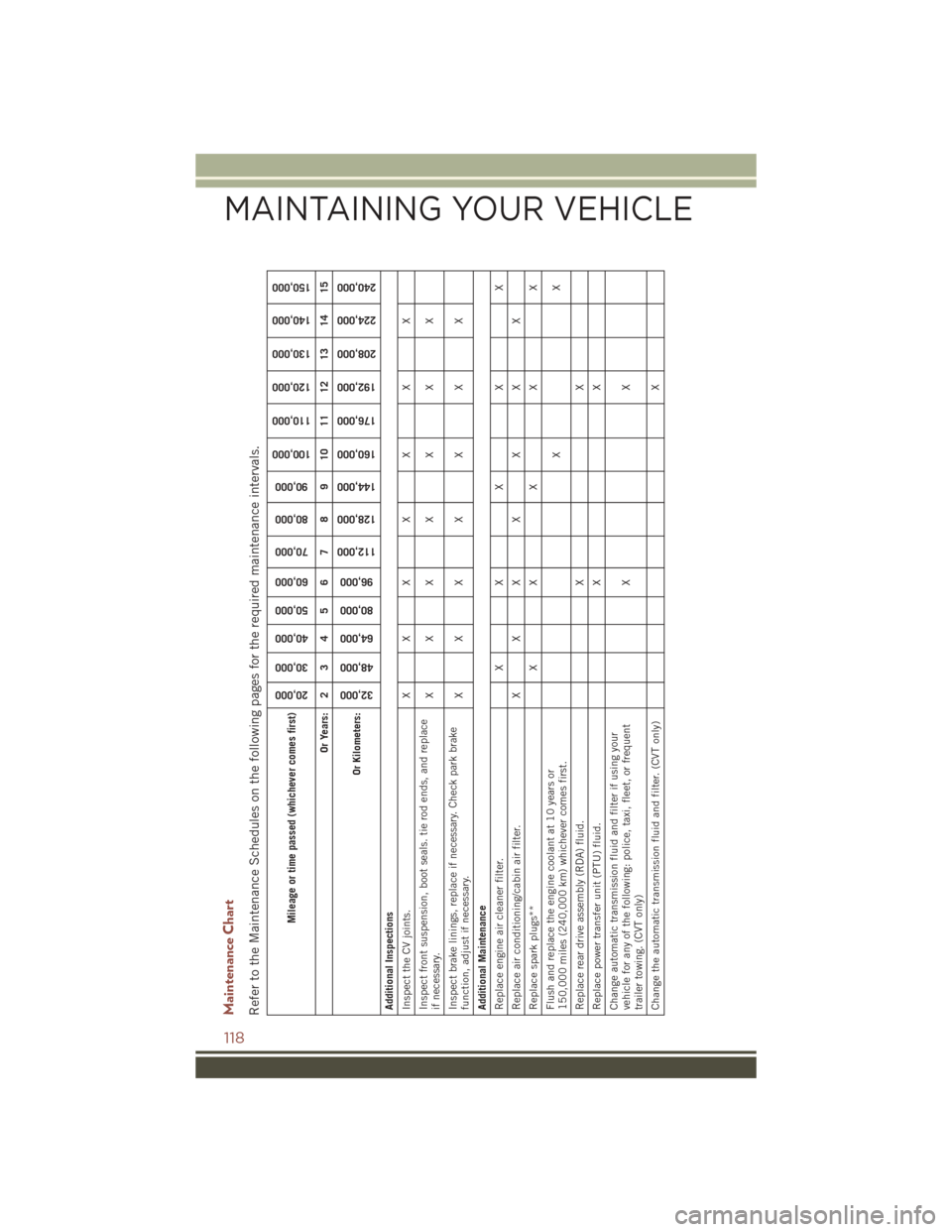

Maintenance ChartRefer to the Maintenance Schedules on the following pages for the required maintenance intervals.

Mileage or time passed (whichever comes first)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Inspect the CV joints. X X X X X X X

Inspect front suspension, boot seals. tie rod ends, and replace

if necessary. XXX X X X X

Inspect brake linings, replace if necessary. Check park brake

function, adjust if necessary. XXX X X X X

Additional Maintenance

Replace engine air cleaner filter. X X X X X

Replace air conditioning/cabin air filter. X X X X X X X

Replace spark plugs** X X X X X

Flush and replace the engine coolant at 10 years or

150,000 miles (240,000 km) whichever comes first. XX

Replace rear drive assembly (RDA) fluid. X X

Replace power transfer unit (PTU) fluid. X X

Change automatic transmission fluid and filter if using your

vehicle for any of the following: police, taxi, fleet, or frequent

trailer towing. (CVT only) XX

Change the automatic transmission fluid and filter. (CVT only) X

MAINTAINING YOUR VEHICLE

118