warning JEEP COMPASS 2017 2.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2017, Model line: COMPASS, Model: JEEP COMPASS 2017 2.GPages: 429, PDF Size: 3.46 MB

Page 259 of 429

WARNING!

To avoid possible personal injury, handle the wheel

covers with care to avoid contact with any sharp edges.

CAUTION!

Be sure to mount the spare tire with the valve stem

facing outward. The vehicle could be damaged if the

spare tire is mounted incorrectly.NOTE:

The wheel cover is held on the wheel by the wheel

nuts. When reinstalling the original wheel, properly align

the wheel cover to the valve stem, place the wheel cover

onto the wheel, then install the wheel nuts.

6. Lower the vehicle by turning the jack screw to the left.

7. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until each

lug nut has been tightened twice. Refer to “Torque

Specifications” in “Technical Specifications” for proper

lug nut torque.

8. Remove the wheel blocks and lower the jack until it is free. Release the parking brake. Reassemble the lug

wrench to the jack assembly and stow it in the spare tire

area. Secure the assembly using the means provided.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided.

Mounting Spare Tire

7

IN CASE OF EMERGENCY 257

Page 260 of 429

9. Place the deflated (flat) tire in the cargo area,have the

tire repaired or replaced as soon as possible.

WARNING!

A loose tire thrown forward in a collision or hard stop

could injure the occupants in the vehicle. Have the

deflated (flat) tire repaired or replaced immediately.

10. Check the spare tire pressure as soon as possible. Correct the tire pressure as required.

11. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly

seated against the wheel.

Road Tire Installation

Vehicles Equipped With Wheel Covers

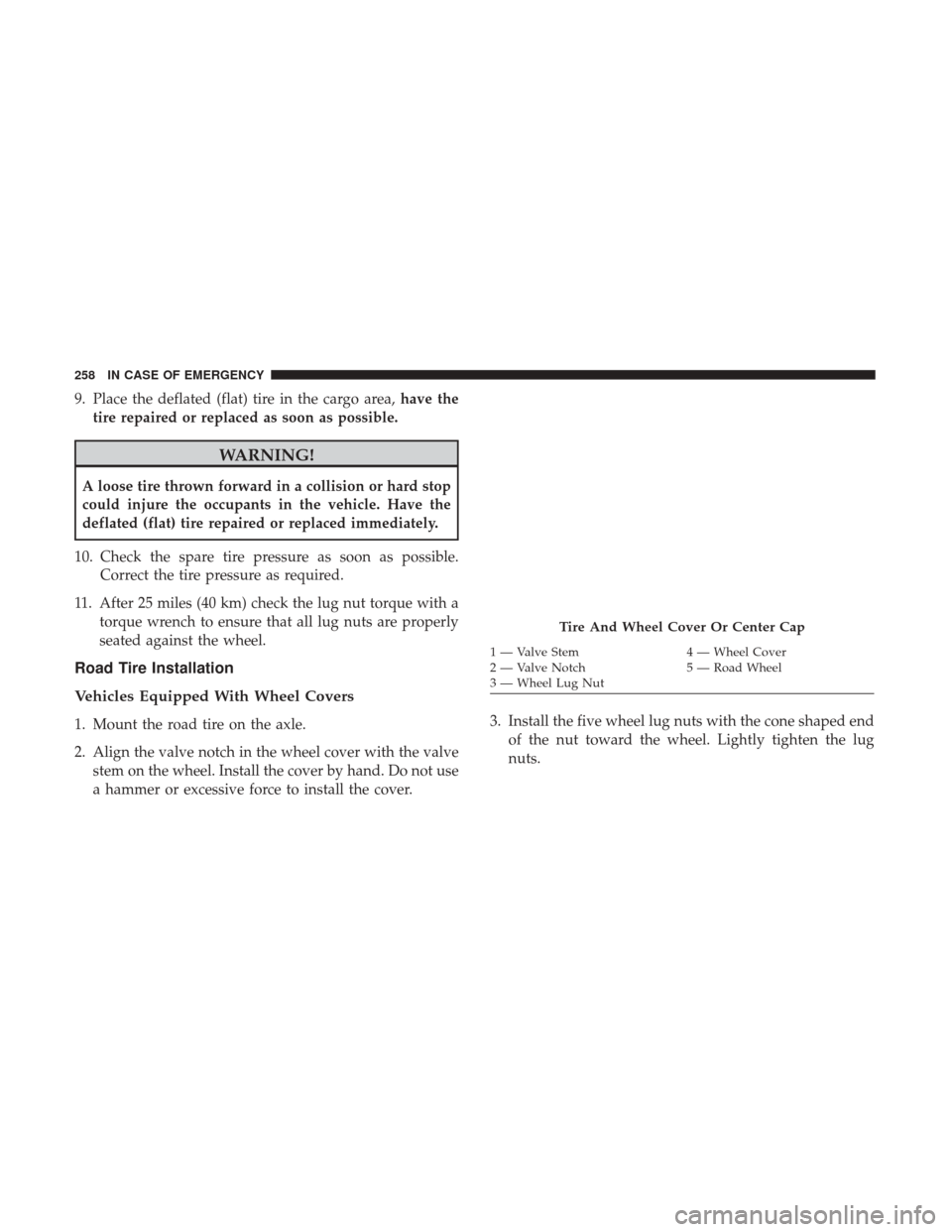

1. Mount the road tire on the axle.

2. Align the valve notch in the wheel cover with the valvestem on the wheel. Install the cover by hand. Do not use

a hammer or excessive force to install the cover. 3. Install the five wheel lug nuts with the cone shaped end

of the nut toward the wheel. Lightly tighten the lug

nuts.

Tire And Wheel Cover Or Center Cap

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Road Wheel

3 — Wheel Lug Nut

258 IN CASE OF EMERGENCY

Page 261 of 429

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the lug nuts fully until the vehicle has been

lowered. Failure to follow this warning may result in

serious injury.

4. Lower the vehicle to the ground by turning the jack handle counterclockwise.

5. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Refer to “Torque Specifications” in “Technical

Specifications” for correct lug nut torque.

6. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly

seated against the wheel.

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped endof the nut toward the wheel. Lightly tighten the lug

nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not fully tighten the lug nuts until the vehicle has been

lowered. Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Refer to “Torque Specifications” in “Technical

Specifications” for correct lug nut torque.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly

seated against the wheel.

7

IN CASE OF EMERGENCY 259

Page 264 of 429

•When the Tire Service Kit sealant is in a liquid form,

clean water, and a damp cloth will remove the material

from the vehicle or tire and wheel components. Once the

sealant dries, it can easily be peeled off and properly

discarded.

• For optimum performance, make sure the valve stem on

the wheel is free of debris before connecting the Tire

Service Kit.

• You can use the Tire Service Kit air pump to inflate

bicycle tires. The kit also comes with two needles,

located in the Accessory Storage Compartment (on the

bottom of the air pump) for inflating sport balls, rafts, or

similar inflatable items. However, use only the Air Pump

Hose (7) and make sure the Mode Select Knob (5) is in

the Air Mode when inflating such items to avoid inject-

ing sealant into them. The Tire Service Kit Sealant is only

intended to seal punctures less than 1/4 inch (6 mm)

diameter in the tread of your tire.

• Do not lift or carry the Tire Service Kit by the hoses.WARNING!

•Do not attempt to seal a tire on the side of the vehicle

closest to traffic. Pull far enough off the road to avoid

the danger of being hit when using the Tire Service

Kit.

• Do not use Tire Service Kit or drive the vehicle under

the following circumstances:

– If the puncture in the tire tread is approximately 1/4 inch (6 mm) or larger.

– If the tire has any sidewall damage.

– If the tire has any damage from driving with extremely low tire pressure.

– If the tire has any damage from driving on a flat tire.

– If the wheel has any damage.

– If you are unsure of the condition of the tire or the wheel.

• Keep Tire Service Kit away from open flames or heat

source.

• A loose Tire Service Kit thrown forward in a collision

or hard stop could endanger the occupants of the

vehicle. Always stow the Tire Service Kit in the place

provided. Failure to follow these warnings can result

(Continued)

262 IN CASE OF EMERGENCY

Page 265 of 429

WARNING!(Continued)

in injuries that are serious or fatal to you, your

passengers, and others around you.

• Take care not to allow the contents of Tire Service Kit

to come in contact with hair, eyes, or clothing. Tire

Service Kit sealant is harmful if inhaled, swallowed,

or absorbed through the skin. It causes skin, eye, and

respiratory irritation. Flush immediately with plenty

of water if there is any contact with eyes or skin.

Change clothing as soon as possible, if there is any

contact with clothing.

• Tire Service Kit Sealant solution contains latex. In

case of an allergic reaction or rash, consult a physi-

cian immediately. Keep Tire Service Kit out of reach

of children. If swallowed, rinse mouth immediately

with plenty of water and drink plenty of water. Do

not induce vomiting! Consult a physician immedi-

ately.

Sealing A Tire With Tire Service Kit

(A) Whenever You Stop To Use Tire Service Kit:

1. Pull over to a safe location and turn on the vehicle’s

Hazard Warning flashers. 2. Verify that the valve stem (on the wheel with the

deflated tire) is in a position that is near to the ground.

This will allow the Tire Service Kit Hoses (6) and (7) to

reach the valve stem and keep the Tire Service Kit flat on

the ground. This will provide the best positioning of the

kit when injecting the sealant into the deflated tire and

running the air pump. Move the vehicle as necessary to

place the valve stem in this position before proceeding.

3. Place the transmission in PARK (auto transmission) or in Gear (manual transmission) and place the ignition in the

OFF position.

4. Set the parking brake.

(B) Setting Up To Use Tire Service Kit:

1. Push in the Mode Select Knob (5) and turn to the Sealant Mode position.

2. Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of the hose.

3. Place the Tire Service Kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose (6) onto the valve

stem.

7

IN CASE OF EMERGENCY 263

Page 268 of 429

WARNING!

Tire Service Kit is not a permanent flat tire repair. Have

the tire inspected and repaired or replaced after using

Tire Service Kit. Do not exceed 55 mph (90 km/h) until

the tire is repaired or replaced. Failure to follow this

warning can result in injuries that are serious or fatal

to you, your passengers, and others around you.

(E) After Driving:

Pull over to a safe location. Refer to “Whenever You Stop to

Use Tire Service Kit” before continuing.

1. Push in the Mode Select Knob (5) and turn to the AirMode position.

2. Uncoil the power plug and insert the plug into the vehicle’s 12 Volt power outlet.

3. Uncoil the Air Pump Hose (7) (black in color) and screw the fitting at the end of hose (7) onto the valve stem.

4. Check the pressure in the tire by reading the Pressure Gauge (3). If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not attempt to drive the

vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Push the Power Button (4) to turn on Tire Service Kit

and inflate the tire to the pressure indicated on the tire

and loading information label on the driver-side door

opening.

NOTE: If the tire becomes over-inflated, push the Deflation

Button to reduce the tire pressure to the recommended

inflation pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem, reinstall the cap on the valve stem and unplug from 12

Volt outlet.

3. Place the Tire Service Kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an authorized dealer or tire

service center.

5. Remove the Speed Limit sticker from the instrument panel after the tire has been repaired.

266 IN CASE OF EMERGENCY

Page 269 of 429

6. Replace the Sealant Bottle (1) and Sealant Hose (6)assembly at your authorized dealer as soon as possible.

Refer to (F) “Sealant Bottle and Hose Replacement”.

NOTE: When having the tire serviced, advise the autho-

rized dealer or service center that the tire has been sealed

using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (6) (clear in color).

2. Locate the round Sealant Bottle release button in the recessed area under the sealant bottle.

3. Push the Sealant Bottle release button. The Sealant Bottle (1) will pop up. Remove the bottle and dispose of it

accordingly.

4. Clean any remaining sealant from the Tire Service Kit housing.

5. Position the new Sealant Bottle (1) in the housing so that the Sealant Hose (6) aligns with the hose slot in the front

of the housing. Push the bottle into the housing. An

audible click will be heard indicating the bottle is locked

into place. 6. Verify that the cap is installed on the fitting at the end of

the Sealant Hose (6) and return the hose to its storage

area (located on the bottom of the air pump).

7. Return the Tire Service Kit to its storage location in the vehicle.

JUMP-STARTING PROCEDURES

If your vehicle has a discharged battery, it can be jump-

started using a set of jumper cables and a battery in another

vehicle or by using a portable battery booster pack. Jump-

starting can be dangerous if done improperly so please

follow the procedures in this section carefully.

NOTE: When using a portable battery booster pack follow

the manufacturer ’s operating instructions and precautions.

WARNING!

Do not attempt jump-starting if the battery is frozen. It

could rupture or explode and cause personal injury.

7

IN CASE OF EMERGENCY 267

Page 270 of 429

CAUTION!

Do not use a portable battery booster pack or any other

booster source with a system voltage greater than 12

Volts or damage to the battery, starter motor, alternator

or electrical system may occur.

Preparations For Jump-Start

The battery in your vehicle is located in the front of the

engine compartment below the air intake duct. To access

the battery remove the air intake duct by turning the two

finger screws, located on the radiator support.

WARNING!

•Take care to avoid the radiator cooling fan whenever

the hood is raised. It can start anytime the ignition

switch is ON. You can be injured by moving fan

blades.

• Remove any metal jewelry such as rings, watch

bands and bracelets that could make an inadvertent

electrical contact. You could be seriously injured.

(Continued)

Air Intake Finger Screws

Positive Battery Post

268 IN CASE OF EMERGENCY

Page 271 of 429

WARNING!(Continued)

•Batteries contain sulfuric acid that can burn your

skin or eyes and generate hydrogen gas which is

flammable and explosive. Keep open flames or

sparks away from the battery.

1. Set the parking brake, shift the automatic transmission into PARK (manual transmission to NEUTRAL) and

turn the ignition to LOCK.

2. Turn off the heater, radio, and all unnecessary electrical accessories.

3. If using another vehicle to jump-start the battery, park the vehicle within the jumper cables reach, set the

parking brake and make sure the ignition is OFF.

WARNING!

Do not allow vehicles to touch each other as this could

establish a ground connection and personal injury

could result.

Jump-Starting Procedure

WARNING!

Failure to follow this jump-starting procedure could

result in personal injury or property damage due to

battery explosion.

CAUTION!

Failure to follow these procedures could result in

damage to the charging system of the booster vehicle

or the discharged vehicle.

NOTE: Remove Air Intake before proceeding with this

Jump-Starting procedure.

Connecting The Jumper Cables

1. Connect the positive (+)end of the jumper cable to the

positive (+)post of the discharged vehicle.

2. Connect the opposite end of the positive (+)jumper

cable to the positive (+)post of the booster battery.

3. Connect the negative end (-)of the jumper cable to the

negative (-)post of the booster battery.

7

IN CASE OF EMERGENCY 269

Page 272 of 429

4. Connect the opposite end of the negative(-)jumper

cable to a good engine ground (exposed metal part of

the discharged vehicle’s engine) away from the battery

and the fuel injection system.

WARNING!

Do not connect the jumper cable to the negative (-) post

of the discharged battery. The resulting electrical spark

could cause the battery to explode and could result in

personal injury. Only use the specific ground point, do

not use any other exposed metal parts.

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few minutes, and then start

the engine in the vehicle with the discharged battery.

6. Once the engine is started, remove the jumper cables in the reverse sequence:

Disconnecting The Jumper Cables

1. Disconnect the negative (-)end of the jumper cable from

the engine ground of the vehicle with the discharged

battery.

2. Disconnect the opposite end of the negative (-)jumper

cable from the negative (-)post of the booster battery. 3. Disconnect the positive

(+)end of the jumper cable from

the positive (+)post of the booster battery.

4. Disconnect the opposite end of the positive (+)jumper

cable from the positive (+)post of the vehicle with the

discharged battery.

5. Reinstall the air intake duct.

If frequent jump-starting is required to start your vehicle

you should have the battery and charging system in-

spected at your authorized dealer.

CAUTION!

Accessories plugged into the vehicle power outlets

draw power from the vehicle’s battery, even when not

in use (i.e., cellular devices, etc.). Eventually, if plugged

in long enough without engine operation, the vehicle’s

battery will discharge sufficiently to degrade battery

life and/or prevent the engine from starting.

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can reduce the

potential for overheating by taking the appropriate action.

• On the highways — slow down.

270 IN CASE OF EMERGENCY