wheel torque JEEP COMPASS 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2018, Model line: COMPASS, Model: JEEP COMPASS 2018Pages: 348, PDF Size: 6.03 MB

Page 205 of 348

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

6. Remove the wheel bolts and tire.

7. Remove the alignment pin from the jack

assembly and thread the pin into the

wheel hub to assist in mounting the spare

tire.

8. Mount the spare tire.

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.NOTE:

• For vehicles equipped, do not attempt

to install a center cap or wheel cover on

the compact spare.

• Refer to “Compact Spare Tire” and to

“Limited-Use Spare” under “Tires—

General Information” in “Servicing And

Maintenance” in the Owner's Manual

for additional warnings, cautions, and

information about the spare tire, its

use, and operation.

9. Install and lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

10. Lower the vehicle to the ground by turn-

ing the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push

down on the wrench while at the end ofthe handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. Refer to “Wheel And Tire Torque

Specifications” in “Technical Specifica-

tions” for the proper lug bolt torque. If in

doubt about the correct tightness, have

them checked with a torque wrench by

your authorized dealer or at a service

station.

12. Place the jack on the foam tray and open

it far enough so that it is secured. Once

placed in position, rotate it clockwise to

lock it in. Replace the alignment pin in

the center hole to lock the jack in place.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

203

Page 206 of 348

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the

threaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel bolts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage. Tighten

the wheel bolts in a star pattern until each

wheel bolt has been tightened twice. Re-

fer to “Wheel And Tire Torque Specifica-

tions” in “Technical Specifications” for

the proper lug bolt torque. If in doubt

about the correct tightness, have them

checked with a torque wrench by your

authorized dealer or service station.5. Lower the jack until it is free. Remove the

wheel blocks. Reassemble the lug wrench

to the jack assembly and stow it in the

spare tire area. Secure the assembly using

the means provided. Release the parking

brake before driving the vehicle.

6. After 25 miles (40 km), check the wheel

bolt torque with a torque wrench to ensure

that all wheel bolts are properly seated

against the wheel.

EC Declaration Of Conformance

1. The undersigned,Jaswant Singh, repre-

senting the Moonlight Tools Pvt. Ltd.,

herewith declares that the machinery de-

scribed below fulfills all the relevant pro-

visions of:

• The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a.Generic Denomination:Pantograph

jack

b.Function:Lifting Motor Vehicle

Model

CodeModel

NameType Working

load

M6 (556) MPV MLF1 1250Kg

3. Manufacturer Detail

Moonlight Tools Pvt. Ltd.

Vill. Jaspalon, G.T. Road Doraha

Distt. Ludhiana (141421) Punjab (India)

Teh. PH. No. 01628 258302

4. Authorized Person to compile the techni-

cal file

Mr. jaswant Singh DGM (QA & Dev.)

Moonlight Tools Pvt. Ltd.

Ludhiana

5. Reference standard : PF-90065

Date Place Signature Seal

29–03–

2017Doraha

Ludhiana

IN CASE OF EMERGENCY

204

Page 255 of 348

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA.......254

Vehicle Identification Number......254

WHEEL AND TIRE TORQUE SPECI-

FICATIONS................255

Torque Specifications...........255

FUEL REQUIREMENTS — GASOLINE

ENGINE..................255

1.4L Turbo Gasoline Engine........255

Ethanol....................256

Materials Added To Fuel.........256

Fuel System Cautions...........256

Carbon Monoxide Warnings.......257FUEL REQUIREMENTS — DIESEL

ENGINE...................257

Diesel Engine................257

FLUID CAPACITIES..........258

FLUIDS AND LUBRICANTS. . . .259

Engine.....................259

Chassis....................259

TECHNICAL SPECIFICATIONS

253

Page 257 of 348

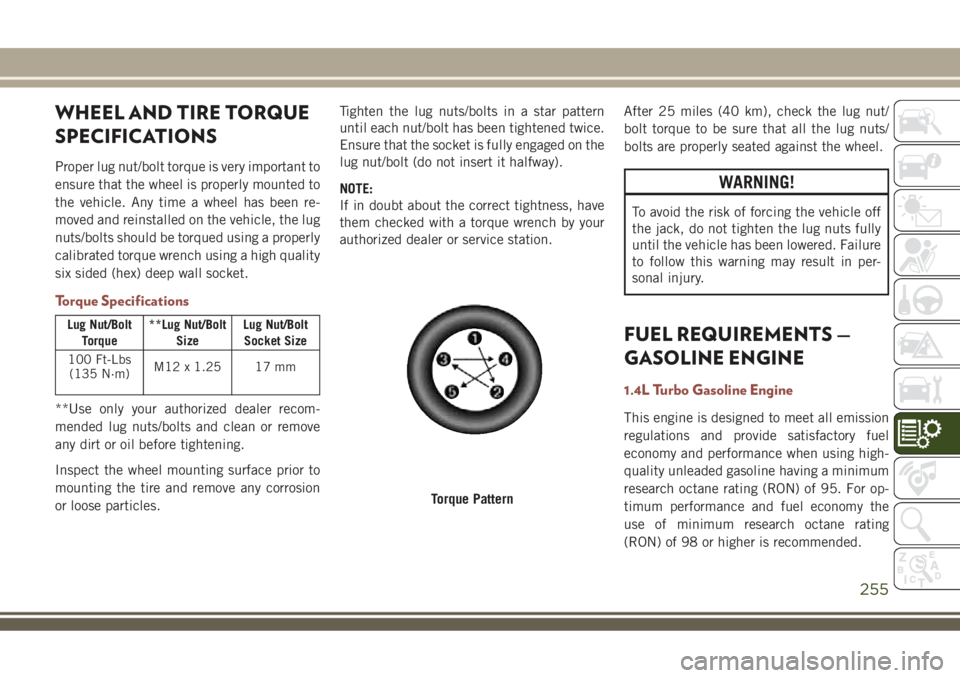

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been re-

moved and reinstalled on the vehicle, the lug

nuts/bolts should be torqued using a properly

calibrated torque wrench using a high quality

six sided (hex) deep wall socket.

Torque Specifications

Lug Nut/Bolt

Torque**Lug Nut/Bolt

SizeLug Nut/Bolt

Socket Size

100 Ft-Lbs

(135 N·m)M12 x 1.25 17 mm

**Use only your authorized dealer recom-

mended lug nuts/bolts and clean or remove

any dirt or oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles.Tighten the lug nuts/bolts in a star pattern

until each nut/bolt has been tightened twice.

Ensure that the socket is fully engaged on the

lug nut/bolt (do not insert it halfway).

NOTE:

If in doubt about the correct tightness, have

them checked with a torque wrench by your

authorized dealer or service station.After 25 miles (40 km), check the lug nut/

bolt torque to be sure that all the lug nuts/

bolts are properly seated against the wheel.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure

to follow this warning may result in per-

sonal injury.

FUEL REQUIREMENTS —

GASOLINE ENGINE

1.4L Turbo Gasoline Engine

This engine is designed to meet all emission

regulations and provide satisfactory fuel

economy and performance when using high-

quality unleaded gasoline having a minimum

research octane rating (RON) of 95. For op-

timum performance and fuel economy the

use of minimum research octane rating

(RON) of 98 or higher is recommended.

Torque Pattern

255

Page 341 of 348

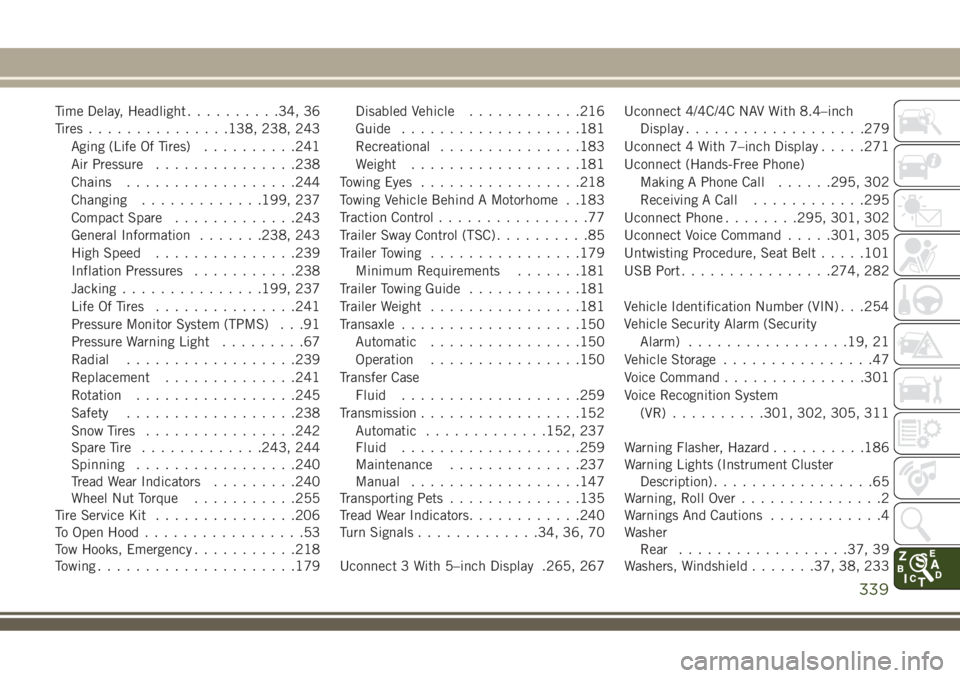

Time Delay, Headlight..........34, 36

Tires...............138, 238, 243

Aging (Life Of Tires)..........241

Air Pressure...............238

Chains..................244

Changing.............199, 237

Compact Spare.............243

General Information.......238, 243

High Speed...............239

Inflation Pressures...........238

Jacking...............199, 237

Life Of Tires...............241

Pressure Monitor System (TPMS) . . .91

Pressure Warning Light.........67

Radial..................239

Replacement..............241

Rotation.................245

Safety..................238

Snow Tires................242

Spare Tire.............243, 244

Spinning.................240

Tread Wear Indicators.........240

Wheel Nut Torque...........255

Tire Service Kit...............206

To Open Hood.................53

Tow Hooks, Emergency...........218

Towing.....................179Disabled Vehicle............216

Guide...................181

Recreational...............183

Weight..................181

Towing Eyes.................218

Towing Vehicle Behind A Motorhome . .183

Traction Control................77

Trailer Sway Control (TSC)..........85

Trailer Towing................179

Minimum Requirements.......181

Trailer Towing Guide............181

T

railer Weight................181

Transaxle...................150

Automatic................150

Operation................150

Transfer Case

Fluid...................259

Transmission.................152

Automatic.............152, 237

Fluid...................259

Maintenance..............237

Manual..................147

Transporting Pets..............135

Tread Wear Indicators............240

Turn Signals.............34, 36, 70

Uconnect 3 With 5–inch Display .265, 267Uconnect 4/4C/4C NAV With 8.4–inch

Display...................279

Uconnect 4 With 7–inch Display.....271

Uconnect (Hands-Free Phone)

Making A Phone Call......295, 302

Receiving A Call............295

Uconnect Phone........295, 301, 302

Uconnect Voice Command.....301, 305

Untwisting Procedure, Seat Belt.....101

USB Port................274, 282

Vehicle Identification Number (VIN) . . .254

Vehicle Security Alarm (Security

Alarm).................19, 21

Vehicle Storage................47

Voice Command...............301

Voice Recognition System

(VR)..........301, 302, 305, 311

Warning Flasher, Hazard..........186

Warning Lights (Instrument Cluster

Description).................65

Warning, Roll Over...............2

Warnings And Cautions............4

Washer

Rear..................37, 39

Washers, Windshield......

.37, 38, 233

339