technical specifications JEEP COMPASS 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2018, Model line: COMPASS, Model: JEEP COMPASS 2018Pages: 348, PDF Size: 6.03 MB

Page 7 of 348

GRAPHICAL TABLE OF CONTENTS

GETTING TO KNOW YOUR VEHICLE

GETTING TO KNOW YOUR INSTRUMENT PANEL

SAFETY

STARTING AND OPERATING

IN CASE OF EMERGENCY

SERVICING AND MAINTENANCE

TECHNICAL SPECIFICATIONS

MULTIMEDIA

CUSTOMER ASSISTANCE

INDEX

Page 205 of 348

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

6. Remove the wheel bolts and tire.

7. Remove the alignment pin from the jack

assembly and thread the pin into the

wheel hub to assist in mounting the spare

tire.

8. Mount the spare tire.

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.NOTE:

• For vehicles equipped, do not attempt

to install a center cap or wheel cover on

the compact spare.

• Refer to “Compact Spare Tire” and to

“Limited-Use Spare” under “Tires—

General Information” in “Servicing And

Maintenance” in the Owner's Manual

for additional warnings, cautions, and

information about the spare tire, its

use, and operation.

9. Install and lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

10. Lower the vehicle to the ground by turn-

ing the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push

down on the wrench while at the end ofthe handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. Refer to “Wheel And Tire Torque

Specifications” in “Technical Specifica-

tions” for the proper lug bolt torque. If in

doubt about the correct tightness, have

them checked with a torque wrench by

your authorized dealer or at a service

station.

12. Place the jack on the foam tray and open

it far enough so that it is secured. Once

placed in position, rotate it clockwise to

lock it in. Replace the alignment pin in

the center hole to lock the jack in place.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

203

Page 206 of 348

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the

threaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel bolts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage. Tighten

the wheel bolts in a star pattern until each

wheel bolt has been tightened twice. Re-

fer to “Wheel And Tire Torque Specifica-

tions” in “Technical Specifications” for

the proper lug bolt torque. If in doubt

about the correct tightness, have them

checked with a torque wrench by your

authorized dealer or service station.5. Lower the jack until it is free. Remove the

wheel blocks. Reassemble the lug wrench

to the jack assembly and stow it in the

spare tire area. Secure the assembly using

the means provided. Release the parking

brake before driving the vehicle.

6. After 25 miles (40 km), check the wheel

bolt torque with a torque wrench to ensure

that all wheel bolts are properly seated

against the wheel.

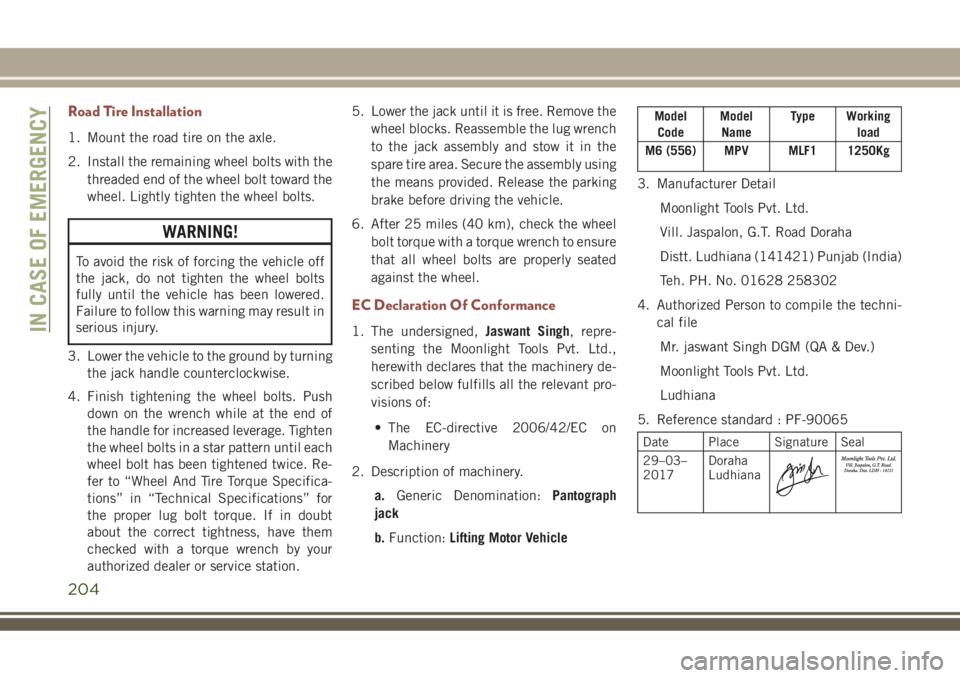

EC Declaration Of Conformance

1. The undersigned,Jaswant Singh, repre-

senting the Moonlight Tools Pvt. Ltd.,

herewith declares that the machinery de-

scribed below fulfills all the relevant pro-

visions of:

• The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a.Generic Denomination:Pantograph

jack

b.Function:Lifting Motor Vehicle

Model

CodeModel

NameType Working

load

M6 (556) MPV MLF1 1250Kg

3. Manufacturer Detail

Moonlight Tools Pvt. Ltd.

Vill. Jaspalon, G.T. Road Doraha

Distt. Ludhiana (141421) Punjab (India)

Teh. PH. No. 01628 258302

4. Authorized Person to compile the techni-

cal file

Mr. jaswant Singh DGM (QA & Dev.)

Moonlight Tools Pvt. Ltd.

Ludhiana

5. Reference standard : PF-90065

Date Place Signature Seal

29–03–

2017Doraha

Ludhiana

IN CASE OF EMERGENCY

204

Page 238 of 348

WARNING!

• When working near the radiator cooling

fan, disconnect the fan motor lead or

turn the ignition to the OFF mode. The

fan is temperature controlled and can

start at any time the ignition is in the ON

mode.

Coolant Checks

Check engine coolant (antifreeze) protection

every 12 months (before the onset of freezing

weather, where applicable). If the engine

coolant (antifreeze) is dirty or rusty in appear-

ance, the system should be drained, flushed

and refilled with fresh engine coolant (anti-

freeze). Check the front of the A/C condenser

for any accumulation of bugs, leaves, etc. If

dirty, clean by gently spraying water from a

garden hose vertically down the face of the

condenser.

Brake System

In order to assure brake system performance,

all brake system components should be in-

spected periodically. Refer to the “Mainte-

nance Plan” in this section for the proper

maintenance intervals.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your

foot resting or riding on the brake pedal

can result in abnormally high brake tem-

peratures, excessive lining wear, and pos-

sible brake damage. You would not have

your full braking capacity in an emergency.

Brake Master Cylinder

The fluid in the master cylinder should be

checked when performing under hood ser-

vices or immediately if the “Brake Warning

Light” is illuminated.

Be sure to clean the top of the master cylin-

der area before removing the cap. If neces-

sary, add fluid to bring the fluid level up to

the requirements described on the brakefluid reservoir. With disc brakes, fluid level

can be expected to fall as the brake pads

wear. Brake fluid level should be checked

when pads are replaced. However, low fluid

level may be caused by a leak and a checkup

may be needed.

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubricants”

in “Technical Specifications” for further

information.

WARNING!

• Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri-

cants” in “Technical Specifications” for

further information. Using the wrong

type of brake fluid can severely damage

your brake system and/or impair its per-

formance. The proper type of brake fluid

for your vehicle is also identified on the

original factory installed hydraulic mas-

ter cylinder reservoir.

• To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

SERVICING AND MAINTENANCE

236

Page 255 of 348

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA.......254

Vehicle Identification Number......254

WHEEL AND TIRE TORQUE SPECI-

FICATIONS................255

Torque Specifications...........255

FUEL REQUIREMENTS — GASOLINE

ENGINE..................255

1.4L Turbo Gasoline Engine........255

Ethanol....................256

Materials Added To Fuel.........256

Fuel System Cautions...........256

Carbon Monoxide Warnings.......257FUEL REQUIREMENTS — DIESEL

ENGINE...................257

Diesel Engine................257

FLUID CAPACITIES..........258

FLUIDS AND LUBRICANTS. . . .259

Engine.....................259

Chassis....................259

TECHNICAL SPECIFICATIONS

253

Page 256 of 348

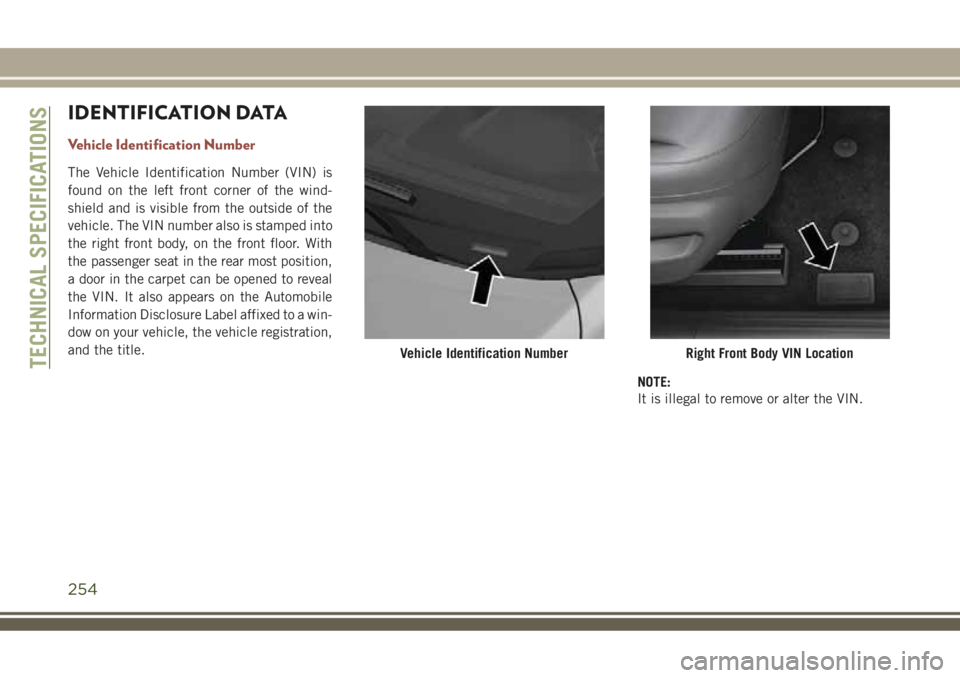

IDENTIFICATION DATA

Vehicle Identification Number

The Vehicle Identification Number (VIN) is

found on the left front corner of the wind-

shield and is visible from the outside of the

vehicle. The VIN number also is stamped into

the right front body, on the front floor. With

the passenger seat in the rear most position,

a door in the carpet can be opened to reveal

the VIN. It also appears on the Automobile

Information Disclosure Label affixed to a win-

dow on your vehicle, the vehicle registration,

and the title.

NOTE:

It is illegal to remove or alter the VIN.

Vehicle Identification NumberRight Front Body VIN LocationTECHNICAL SPECIFICATIONS

254

Page 258 of 348

Light spark knock at low engine speeds is not

harmful to your engine. However, continued

heavy spark knock at high speeds can cause

damage, and immediate service is required.

Poor quality gasoline can cause problems

such as hard starting, stalling, and hesita-

tions. If you experience these symptoms, try

another brand of gasoline before considering

service for the vehicle.

Poor quality gasoline can cause problems

such as hard starting, stalling, and hesita-

tions. If you experience these symptoms, try

another brand of gasoline before considering

service for the vehicle.

Ethanol

The manufacturer recommends that your ve-

hicle be operated on fuel containing no more

than 10% ethanol. Purchasing your fuel from

a reputable supplier may reduce the risk of

exceeding this 10% limit and/or of receiving

fuel with abnormal properties.

CAUTION!

Use of fuel with Ethanol content higher

than 10% may result in engine malfunc-

tion, starting and operating difficulties,

and materials degradation. These adverse

effects could result in permanent damage

to your vehicle.

Materials Added To Fuel

Indiscriminate use of fuel system cleaning

agents should be avoided. Many of these

materials intended for gum and varnish re-

moval may contain active solvents or similar

ingredients. These can harm fuel system gas-

ket and diaphragm materials.

Fuel System Cautions

CAUTION!

Follow these guidelines to maintain your

vehicle’s performance:

• The use of leaded gasoline is prohibited

by law. Using leaded gasoline can impair

CAUTION!

engine performance and damage the

emissions control system.

• An out-of-tune engine or certain fuel or

ignition malfunctions can cause the

catalytic converter to overheat. If you

notice a pungent burning odor or some

light smoke, your engine may be out of

tune or malfunctioning and may require

immediate service. Contact an autho-

rized dealer for service assistance.

• The use of fuel additives, which are now

being sold as octane enhancers, is not

recommended. Most of these products

contain high concentrations of metha-

nol. Fuel system damage or vehicle per-

formance problems resulting from the

use of such fuels or additives is not the

responsibility of the manufacturer and

may void or not be covered under the

New Vehicle Limited Warranty.

NOTE:

Intentional tampering with the emissions

control system can result in civil penalties

being assessed against you.

TECHNICAL SPECIFICATIONS

256

Page 260 of 348

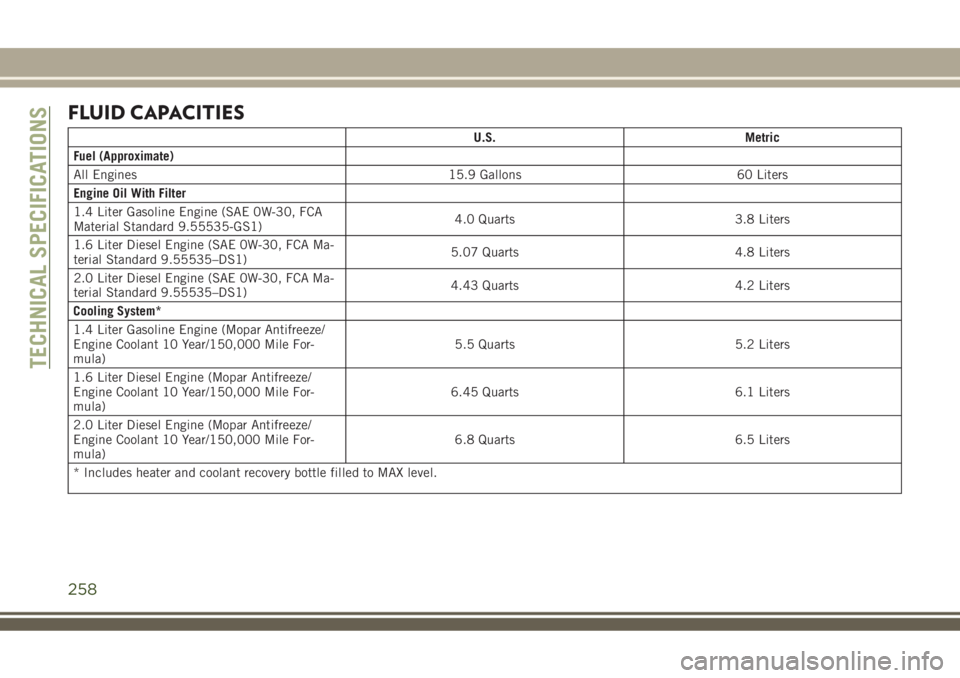

FLUID CAPACITIES

U.S. Metric

Fuel (Approximate)

All Engines 15.9 Gallons 60 Liters

Engine Oil With Filter

1.4 Liter Gasoline Engine (SAE 0W-30, FCA

Material Standard 9.55535-GS1)4.0 Quarts 3.8 Liters

1.6 Liter Diesel Engine (SAE 0W-30, FCA Ma-

terial Standard 9.55535–DS1)5.07 Quarts 4.8 Liters

2.0 Liter Diesel Engine (SAE 0W-30, FCA Ma-

terial Standard 9.55535–DS1)4.43 Quarts 4.2 Liters

Cooling System*

1.4 Liter Gasoline Engine (Mopar Antifreeze/

Engine Coolant 10 Year/150,000 Mile For-

mula)5.5 Quarts 5.2 Liters

1.6 Liter Diesel Engine (Mopar Antifreeze/

Engine Coolant 10 Year/150,000 Mile For-

mula)6.45 Quarts 6.1 Liters

2.0 Liter Diesel Engine (Mopar Antifreeze/

Engine Coolant 10 Year/150,000 Mile For-

mula)6.8 Quarts 6.5 Liters

* Includes heater and coolant recovery bottle filled to MAX level.

TECHNICAL SPECIFICATIONS

258

Page 262 of 348

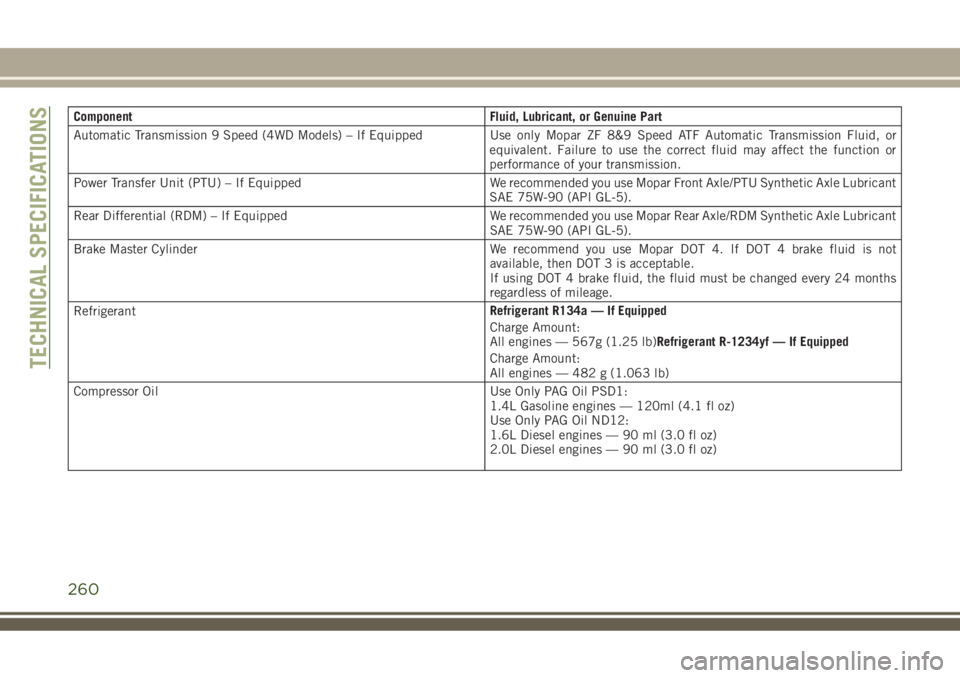

Component Fluid, Lubricant, or Genuine Part

Automatic Transmission 9 Speed (4WD Models) – If Equipped Use only Mopar ZF 8&9 Speed ATF Automatic Transmission Fluid, or

equivalent. Failure to use the correct fluid may affect the function or

performance of your transmission.

Power Transfer Unit (PTU) – If Equipped We recommended you use Mopar Front Axle/PTU Synthetic Axle Lubricant

SAE 75W-90 (API GL-5).

Rear Differential (RDM) – If Equipped We recommended you use Mopar Rear Axle/RDM Synthetic Axle Lubricant

SAE 75W-90 (API GL-5).

Brake Master Cylinder We recommend you use Mopar DOT 4. If DOT 4 brake fluid is not

available, then DOT 3 is acceptable.

If using DOT 4 brake fluid, the fluid must be changed every 24 months

regardless of mileage.

RefrigerantRefrigerant R134a — If Equipped

Charge Amount:

All engines — 567g (1.25 lb)Refrigerant R-1234yf — If Equipped

Charge Amount:

All engines — 482 g (1.063 lb)

Compressor Oil Use Only PAG Oil PSD1:

1.4L Gasoline engines — 120ml (4.1 fl oz)

Use Only PAG Oil ND12:

1.6L Diesel engines — 90 ml (3.0 fl oz)

2.0L Diesel engines — 90 ml (3.0 fl oz)

TECHNICAL SPECIFICATIONS

260