brake fluid JEEP COMPASS 2021 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2021, Model line: COMPASS, Model: JEEP COMPASS 2021Pages: 328, PDF Size: 8.85 MB

Page 220 of 328

SERVICING AND MAINTENANCE

218

Once A Month Or Before A Long Trip

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual

wear or damage. Rotate tires at the first

sign of irregular wear, even if it occurs

before the oil indicator system turns on.

Check the fluid levels of the coolant reser-

voir and brake master cylinder, fill as

needed.

Check function of all interior and exterior

lights.

Control and recovery of additive level for

AdBlue® Diesel emissions (UREA) (if

equipped). At Each Oil Change

Change the engine oil filter.

Inspect the brake hoses and lines.

Inspect for the presence of water in the

fuel filter/water separator unit.

Inspect air cleaner filter if using in dusty

or off-road conditions. Replace air cleaner

filter, if necessary.

Demanding Vehicle Use

Restore additive level for AdBlue® Diesel

emissions (UREA) (if equipped), when the

lamp is illuminated or the message on the

instrument panel.

Maintenance Plan — Diesel Engines

NOTE:

Once you have carried out the last interven -

tion in the table, continue with the sched -

uled servicing, maintaining the frequency

indicated in the plan by marking each oper -

ation with a dot or dedicated note. Simply

restarting the maintenance from the start of

the plan may cause the allowed interval to be

exceeded for some operations.

CAUTION!

Failure to perform the required

maintenance items may result in damage

to the vehicle.

2020_JEEP_M6_UG_UK.book Page 218

Page 221 of 328

219

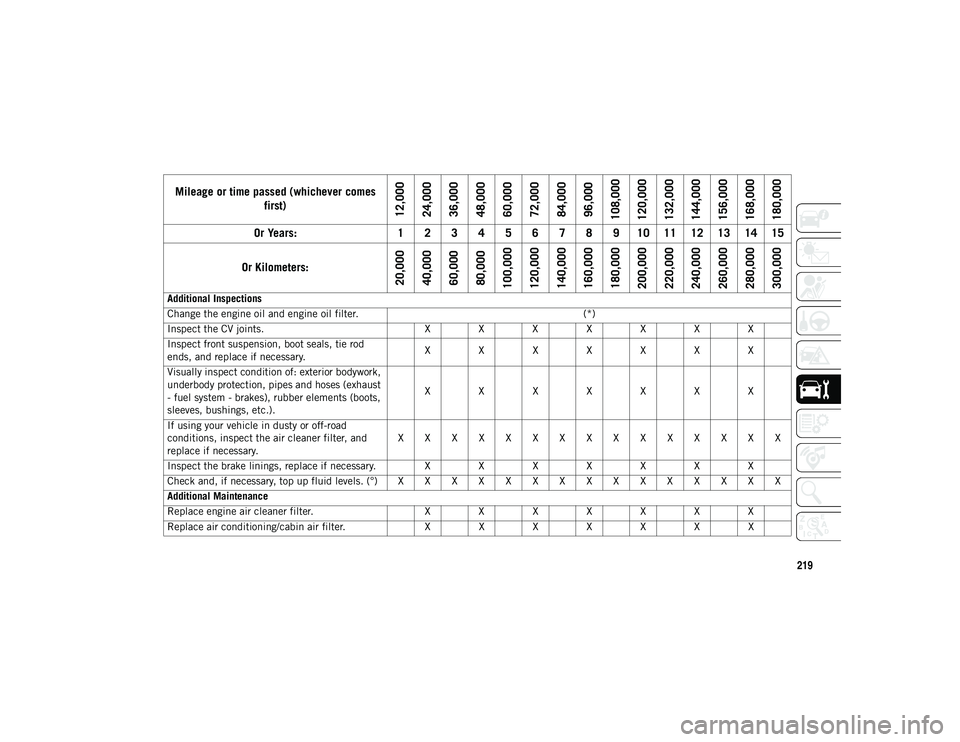

Mileage or time passed (whichever comes

first)

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

168,000

180,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

20,000

40,000

60,000

80,000

100,000

120,000

140,000

160,000

180,000

200,000

220,000

240,000

260,000

280,000

300,000

Additional Inspections

Change the engine oil and engine oil filter. (*)

Inspect the CV joints. X X X X X X X

Inspect front suspension, boot seals, tie rod

ends, and replace if necessary. X X X X X X X

Visually inspect condition of: exterior bodywork,

underbody protection, pipes and hoses (exhaust

- fuel system - brakes), rubber elements (boots,

sleeves, bushings, etc.). X X X X X X X

If using your vehicle in dusty or off-road

conditions, inspect the air cleaner filter, and

replace if necessary. X X X X X X X X X X X X X X X

Inspect the brake linings, replace if necessary. X X X X X X X Check and, if necessary, top up fluid levels. (°) X X X X X X X X X X X X X X X

Additional Maintenance

Replace engine air cleaner filter. X X X X X X X

Replace air conditioning/cabin air filter. X X X X X X X

2020_JEEP_M6_UG_UK.book Page 219

Page 222 of 328

SERVICING AND MAINTENANCE

220

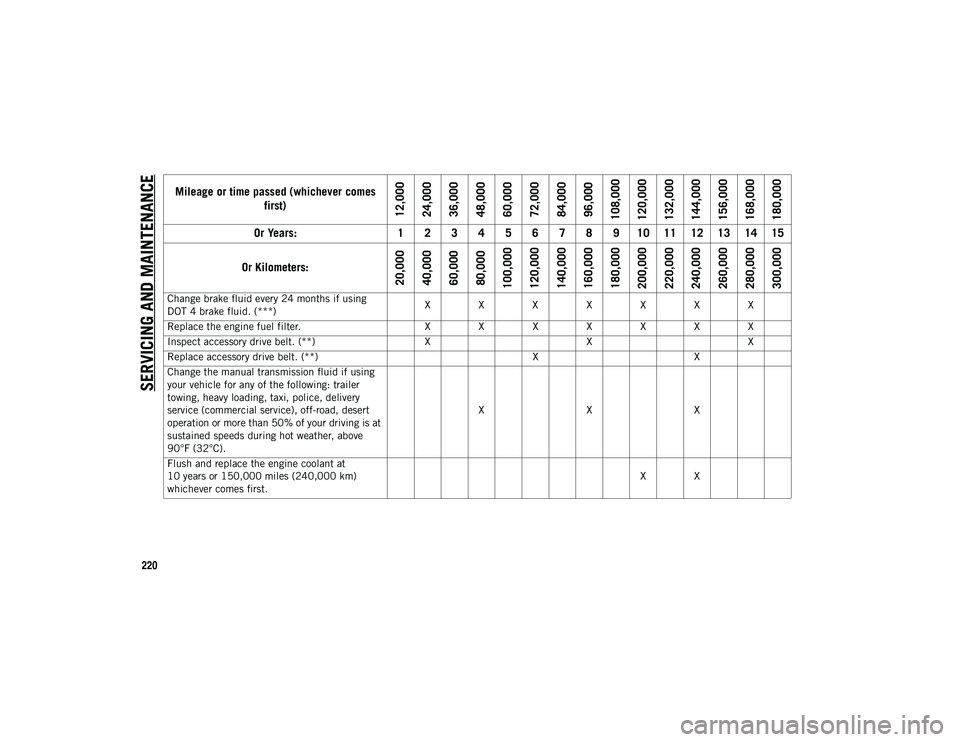

Change brake fluid every 24 months if using

DOT 4 brake fluid. (***)X X X X X X X

Replace the engine fuel filter. X X X X X X X

Inspect accessory drive belt. (**) XXX

Replace accessory drive belt. (**) XX

Change the manual transmission fluid if using

your vehicle for any of the following: trailer

towing, heavy loading, taxi, police, delivery

service (commercial service), off-road, desert

operation or more than 50% of your driving is at

sustained speeds during hot weather, above

90°F (32°C). X

XX

Flush and replace the engine coolant at

10 years or 150,000 miles (240,000 km)

whichever comes first. X X

Mileage or time passed (whichever comes

first)

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

168,000

180,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

20,000

40,000

60,000

80,000

100,000

120,000

140,000

160,000

180,000

200,000

220,000

240,000

260,000

280,000

300,000

2020_JEEP_M6_UG_UK.book Page 220

Page 223 of 328

221

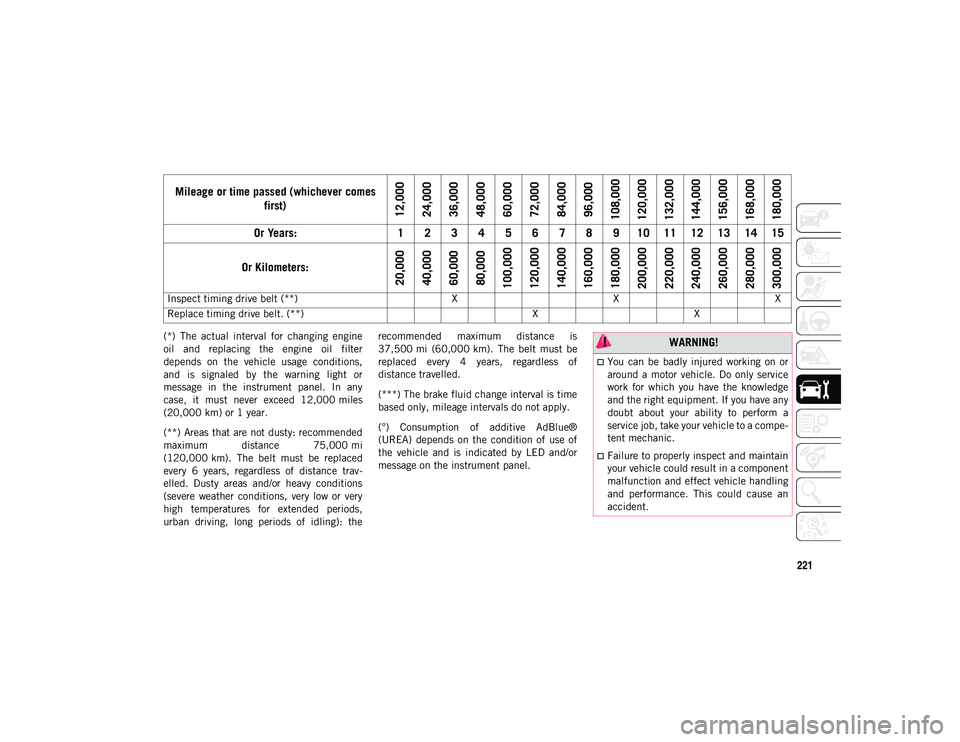

(*) The actual interval for changing engine

oil and replacing the engine oil filter

depends on the vehicle usage conditions,

and is signaled by the warning light or

message in the instrument panel. In any

case, it must never exceed 12,000 miles

(20,000 km) or 1 year.

(**) Areas that are not dusty: recommended

maximum distance 75,000 mi

(120,000 km). The belt must be replaced

every 6 years, regardless of distance trav-

elled. Dusty areas and/or heavy conditions

(severe weather conditions, very low or very

high temperatures for extended periods,

urban driving, long periods of idling): the recommended maximum distance is

37,500 mi (60,000 km). The belt must be

replaced every 4 years, regardless of

distance travelled.

(***) The brake fluid change interval is time

based only, mileage intervals do not apply.

(°) Consumption of additive AdBlue®

(UREA) depends on the condition of use of

the vehicle and is indicated by LED and/or

message on the instrument panel.

Inspect timing drive belt (**)

XXX

Replace timing drive belt. (**) XX

Mileage or time passed (whichever comes

first)

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

168,000

180,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

20,000

40,000

60,000

80,000

100,000

120,000

140,000

160,000

180,000

200,000

220,000

240,000

260,000

280,000

300,000

WARNING!

You can be badly injured working on or

around a motor vehicle. Do only service

work for which you have the knowledge

and the right equipment. If you have any

doubt about your ability to perform a

service job, take your vehicle to a compe-

tent mechanic.

Failure to properly inspect and maintain

your vehicle could result in a component

malfunction and effect vehicle handling

and performance. This could cause an

accident.

2020_JEEP_M6_UG_UK.book Page 221

Page 224 of 328

SERVICING AND MAINTENANCE

222

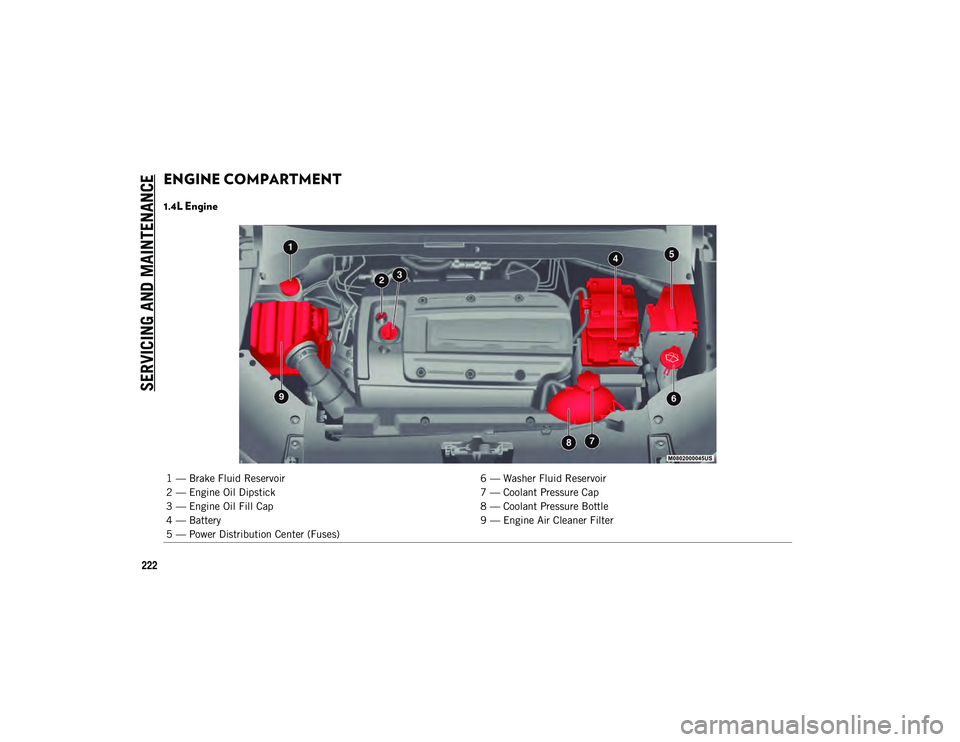

ENGINE COMPARTMENT

1.4L Engine

1 — Brake Fluid Reservoir6 — Washer Fluid Reservoir

2 — Engine Oil Dipstick 7 — Coolant Pressure Cap

3 — Engine Oil Fill Cap 8 — Coolant Pressure Bottle

4 — Battery 9 — Engine Air Cleaner Filter

5 — Power Distribution Center (Fuses)

2020_JEEP_M6_UG_UK.book Page 222

Page 225 of 328

223

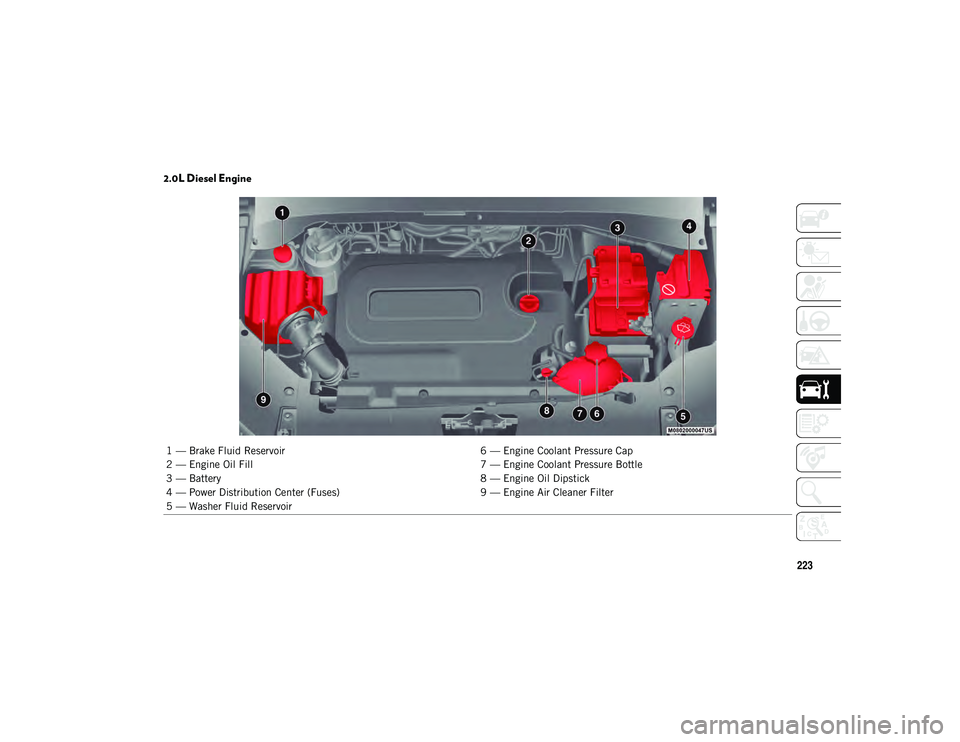

2.0L Diesel Engine

1 — Brake Fluid Reservoir6 — Engine Coolant Pressure Cap

2 — Engine Oil Fill 7 — Engine Coolant Pressure Bottle

3 — Battery 8 — Engine Oil Dipstick

4 — Power Distribution Center (Fuses) 9 — Engine Air Cleaner Filter

5 — Washer Fluid Reservoir

2020_JEEP_M6_UG_UK.book Page 223

Page 226 of 328

SERVICING AND MAINTENANCE

224

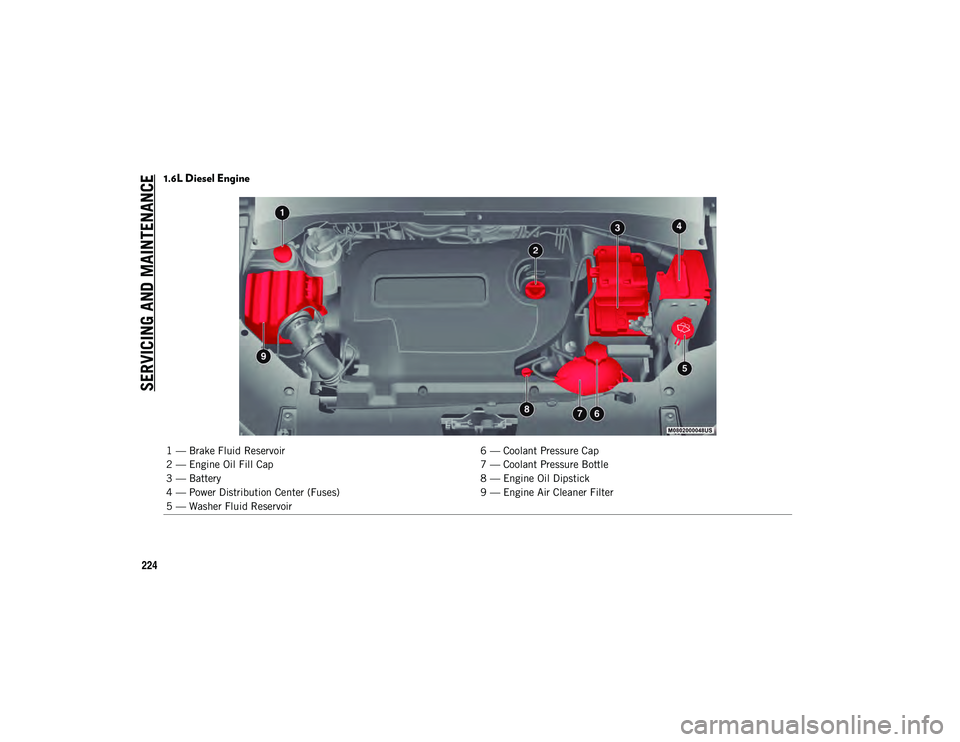

1.6L Diesel Engine

1 — Brake Fluid Reservoir6 — Coolant Pressure Cap

2 — Engine Oil Fill Cap 7 — Coolant Pressure Bottle

3 — Battery 8 — Engine Oil Dipstick

4 — Power Distribution Center (Fuses) 9 — Engine Air Cleaner Filter

5 — Washer Fluid Reservoir

2020_JEEP_M6_UG_UK.book Page 224

Page 232 of 328

SERVICING AND MAINTENANCE

230

(Continued)

Cooling System Pressure Cap

The cap must be fully tightened to prevent

loss of engine coolant (antifreeze), and to

ensure that engine coolant (antifreeze) will

return to the radiator from the coolant expan-

sion bottle/recovery tank if so equipped.

The cap should be inspected and cleaned if

there is any accumulation of foreign material

on the sealing surfaces.

Brake System

In order to assure brake system performance,

all brake system components should be

inspected periodically. Refer to the “Mainte -nance Plan” in this section for the proper

maintenance intervals.

Brake Master Cylinder

The fluid in the master cylinder should be

checked when performing under hood

services or immediately if the “Brake

Warning Light” is illuminated.

Be sure to clean the top of the master

cylinder area before removing the cap. If

necessary, add fluid to bring the fluid level

up to the requirements described on the

brake fluid reservoir. With disc brakes, fluid

level can be expected to fall as the brake

pads wear. Brake fluid level should be

checked when pads are replaced. However,

low fluid level may be caused by a leak and

a checkup may be needed.

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubricants”

in “Technical Specifications” for further

information.

WARNING!

Do not open hot engine cooling system.

Never add engine coolant (antifreeze)

when the engine is overheated. Do not

loosen or remove the cap to cool an over

-

heated engine. Heat causes pressure to

build up in the cooling system. To

prevent scalding or injury, do not remove

the pressure cap while the system is hot

or under pressure.

Do not use a pressure cap other than the

one specified for your vehicle. Personal

injury or engine damage may result.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your

foot resting or riding on the brake pedal

can result in abnormally high brake

temperatures, excessive lining wear, and

possible brake damage. You would not

have your full braking capacity in an

emergency. WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri -

cants” in “Technical Specifications” for

further information. Using the wrong

type of brake fluid can severely damage

your brake system and/or impair its

performance. The proper type of brake

fluid for your vehicle is also identified on

the original factory installed hydraulic

master cylinder reservoir.

To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

closed container. Keep the master

cylinder reservoir cap secured at all

times. Brake fluid in a open container

absorbs moisture from the air resulting

in a lower boiling point. This may cause

it to boil unexpectedly during hard or

prolonged braking, resulting in sudden

brake failure. This could result in a colli -

sion.

2020_JEEP_M6_UG_UK.book Page 230

Page 233 of 328

231

Manual Transmission — If Equipped

Fluid Level Check

Check the fluid level by removing the fill

plug. The fluid level should be between the

bottom of the fill hole and a point not more

than 3/16 inch (4.7 mm) below the bottom

of the hole.

Add fluid, if necessary, to maintain the

proper level.

Please see your authorized dealer for service.

Automatic Transmission

Selection Of Lubricant

It is important to use the proper transmission

fluid to ensure optimum transmission perfor-

mance and life. Use only the manufacturer's

specified transmission fluid. Refer to “Fluids

And Lubricants” in “Technical Specifica -

tions” for fluid specifications. It is important

to maintain the transmission fluid at the

correct level using the recommended fluid.

NOTE:

No chemical flushes should be used in any

transmission; only the approved lubricant

should be used.

Special Additives

The manufacturer strongly recommends

against using any special additives in the transmission. Automatic Transmission Fluid

(ATF) is an engineered product and its

performance may be impaired by supple

-

mental additives. Therefore, do not add any

fluid additives to the transmission. Avoid

using transmission sealers as they may

adversely affect seals.

Fluid Level Check

The fluid level is preset at the factory and

does not require adjustment under normal

operating conditions. Routine fluid level

checks are not required; therefore the trans -

mission has no dipstick. An authorized

dealer can check your transmission fluid

level using special service tools. If you notice

fluid leakage or transmission malfunction,

visit an authorized dealer immediately to

have the transmission fluid level checked.

Operating the vehicle with an improper fluid

level can cause severe transmission damage.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot

engine parts, causing the brake fluid to

catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should

be taken to avoid its contact with these

surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This

could result in a collision.

WARNING! (Continued)

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may

cause deterioration in transmission shift

quality and/or torque converter shudder.

Refer to “Fluids And Lubricants” in

“Technical Specifications” for fluid

specifications.

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage

your transmission components. Such

damage is not covered by the New Vehicle

Limited Warranty.

2020_JEEP_M6_UG_UK.book Page 231

Page 261 of 328

259

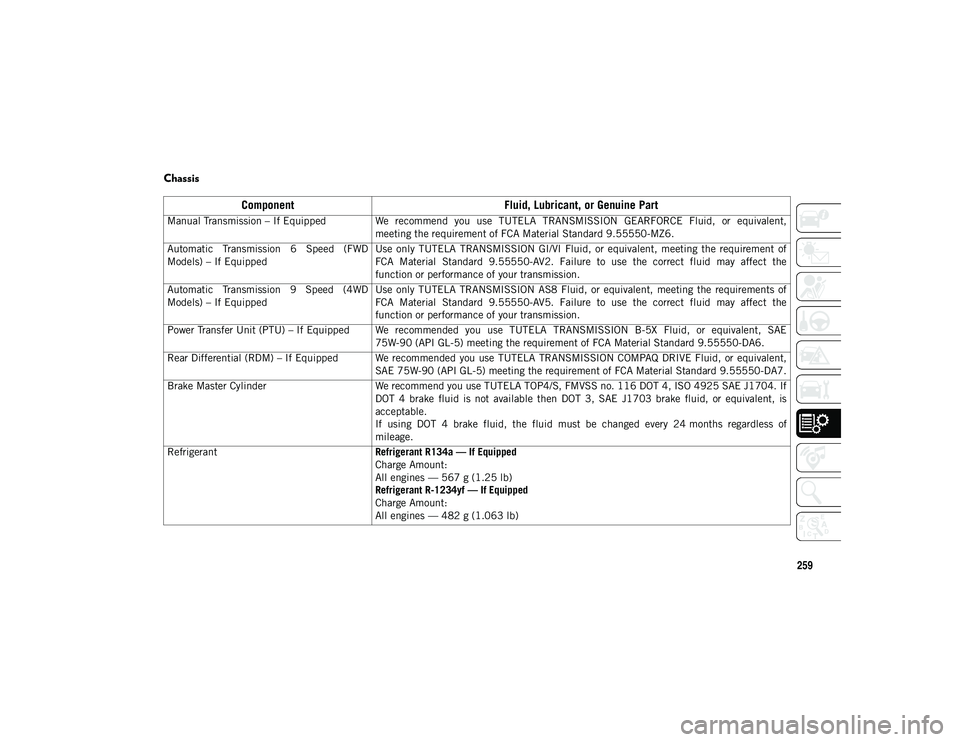

Chassis

ComponentFluid, Lubricant, or Genuine Part

Manual Transmission – If Equipped We recommend you use TUTELA TRANSMISSION GEARFORCE Fluid, or equivalent,

meeting the requirement of FCA Material Standard 9.55550-MZ6.

Automatic Transmission 6 Speed (FWD

Models) – If Equipped Use only TUTELA TRANSMISSION GI/VI Fluid, or equivalent, meeting the requirement of

FCA Material Standard 9.55550-AV2. Failure to use the correct fluid may affect the

function or performance of your transmission.

Automatic Transmission 9 Speed (4WD

Models) – If Equipped Use only TUTELA TRANSMISSION AS8 Fluid, or equivalent, meeting the requirements of

FCA Material Standard 9.55550-AV5. Failure to use the correct fluid may affect the

function or performance of your transmission.

Power Transfer Unit (PTU) – If Equipped We recommended you use TUTELA TRANSMISSION B-5X Fluid, or equivalent, SAE 75W-90 (API GL-5) meeting the requirement of FCA Material Standard 9.55550-DA6.

Rear Differential (RDM) – If Equipped We recommended you use TUTELA TRANSMISSION COMPAQ DRIVE Fluid, or equivalent, SAE 75W-90 (API GL-5) meeting the requirement of FCA Material Standard 9.55550-DA7.

Brake Master Cylinder We recommend you use TUTELA TOP4/S, FMVSS no. 116 DOT 4, ISO 4925 SAE J1704. If

DOT 4 brake fluid is not available then DOT 3, SAE J1703 brake fluid, or equivalent, is

acceptable.

If using DOT 4 brake fluid, the fluid must be changed every 24 months regardless of

mileage.

Refrigerant Refrigerant R134a — If Equipped

Charge Amount:

All engines — 567 g (1.25 lb)

Refrigerant R-1234yf — If Equipped

Charge Amount:

All engines — 482 g (1.063 lb)

2020_JEEP_M6_UG_UK.book Page 259