technical specifications JEEP COMPASS 2021 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2021, Model line: COMPASS, Model: JEEP COMPASS 2021Pages: 328, PDF Size: 8.85 MB

Page 7 of 328

GETTING TO KNOW YOUR VEHICLE

GETTING TO KNOW YOUR INSTRUMENT PANEL SAFETY

STARTING AND OPERATING IN CASE OF EMERGENCY

SERVICING AND MAINTENANCE TECHNICAL SPECIFICATIONS MULTIMEDIA

CUSTOMER ASSISTANCE INDEX

2020_JEEP_M6_UG_UK.book Page 5

Page 12 of 328

10

DEALER SERVICE ................................ 227

Air Conditioner Maintenance.......... 227

Wiper Blades ............................... 228

Exhaust System ........................... 228

Cooling System ............................ 229

Brake System .............................. 230

Manual Transmission — If

Equipped ..................................... 231 Automatic Transmission ................ 231

RAISING THE VEHICLE .......................... 232TIRES ................................................. 232

Tires — General Information ......... 232

Tire Types .................................... 236

Spare Tires — If Equipped ............ 237

Tire Chains (Traction Devices) ....... 239

Tire Rotation Recommendations .... 239

STORING THE VEHICLE ......................... 240

BODYWORK ......................................... 241

Preserving The Bodywork ............... 241

INTERIORS ......................................... 242

Seats And Fabric Parts .................. 242

Plastic And Coated Parts ............... 243

Leather Parts ............................... 243

Glass Surfaces ............................ 243

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA .......................... 244

Vehicle Identification Number ....... 244

WHEEL AND TIRE TORQUE

SPECIFICATIONS ..................................244

Torque Specifications ................... 244

DIMENSIONS .......................................245

WHEELS ..............................................247

WEIGHTS ............................................249

FUEL REQUIREMENTS — GASOLINE

ENGINE ...............................................250

1.4L Turbo Gasoline Engine .......... 250

Ethanol ....................................... 250

Materials Added To Fuel ............... 250

Gasoline/Oxygenate Blends............ 250

Fuel Icon Identification Compliant To

EN16942 .................................... 251 Fuel System Cautions ................... 252

Carbon Monoxide Warnings ........... 252

FUEL REQUIREMENTS — DIESEL

ENGINE ..............................................252

Diesel Engine .............................. 252

Fuel Icon Identification Compliant To

EN16942 .................................... 253

FLUID CAPACITIES ..............................254 FLUIDS AND LUBRICANTS .....................255

Engine ........................................ 255

Chassis ...................................... 259

FUEL CONSUMPTION AND CO2

EMISSIONS ........................................260 MOPAR ACCESSORIES .........................260

Authentic Accessories By Mopar .... 260

MULTIMEDIA

UCONNECT SYSTEMS ...........................262

CYBERSECURITY .................................262

UCONNECT 3 WITH 5–INCH DISPLAY — IF

EQUIPPED............................................263

Uconnect 3 With 5–inch Display At A

Glance .........................................263 Clock Setting ...............................263

Audio Setting ...............................263

Radio Operation ...........................264

USB/Audio Jack (AUX)/Bluetooth®

Operation .....................................265 Voice Text Reply (Not Compatible With

iPhone®) ....................................266 Apps — If Equipped......................267

UCONNECT 4 WITH 7-INCH DISPLAY ....267

Uconnect 4 At A Glance ...............267

Drag & Drop Menu Bar .................268

Radio ..........................................269

Media Hub — USB/Audio Jack (AUX) —

If Equipped ..................................270 Android Auto™ — If Equipped .......271

Apple CarPlay® Integration — If

Equipped .....................................272 Apps — If Equipped......................273

2020_JEEP_M6_UG_UK.book Page 10

Page 171 of 328

169

AdBlue® (UREA) — If Equipped

The vehicle is equipped with an UREA injec -

tion system and Selective Catalytic Reduc -

tion to meet emission standards. These two

systems ensure compliance with the diesel

emissions requirements; at the same time,

they ensure fuel-efficiency, handling, torque

and power. For messages and system warn -

ings, refer to the "Warning Lights And

Messages" in the "Getting To Know Your

Instrument Panel" section. AdBlue® (UREA)

is a very stable product with a long shelf life.

Stored at temperatures LOWER than 90°F

(32°C), it has a shelf life of at least one year.

For more information on the AdBlue® liquid

type, see the “Fluids and lubricants” in the

“Technical specifications” section. The

vehicle is equipped with an automatic

AdBlue® heating system when the engine

starts allowing the system to work correctly

at temperatures lower than 12°F (-11°C).

NOTE:

AdBlue® freezes at temperatures lower than

12 °F (-11 °C).

AdBlue® (UREA) Storage

AdBlue® (UREA) is considered a very stable

product with a long shelf life. If AdBlue®

(UREA) is kept in temperatures between 10°

and 90°F (-12° and 32°C), it will last a

minimum of one year.

AdBlue® (UREA) is subject to freezing at the

lowest temperatures. For example, AdBlue®

(UREA) may freeze at temperatures at or

below 12°F (-11°C). The system has been

designed to operate in this environment.

NOTE:

When working with AdBlue® (UREA), it is

important to know that:

Any containers or parts that come into

contact with AdBlue® (UREA) must be

AdBlue® (UREA) compatible (plastic or

stainless steel). Copper, brass, aluminum,

iron or non-stainless steel should be

avoided as they are subject to corrosion by

AdBlue® (UREA).

If AdBlue® (UREA) is spilled, it should be

wiped up completely.

Adding AdBlue® (UREA)

Preliminary Conditions

AdBlue® (UREA) freezes at temperatures

lower than 12°F (-11°C). If the car stands for

a long time at this temperature refilling

could be difficult. For this reason, it is

advised to park the vehicle in a garage and/

or heated environment and wait for the urea

to return to liquid state before topping up.

Proceed as follows:

Park the car on flat ground and stop the

engine by cycling the ignition to the OFF

position.

Open the fuel door, undo and remove the

cap (blue) from the AdBlue® (UREA) filler.

Fuel Filler

1 — AdBlue® (UREA) Filler Cap

2 — Fuel Filler

2020_JEEP_M6_UG_UK.book Page 169

Page 195 of 328

193

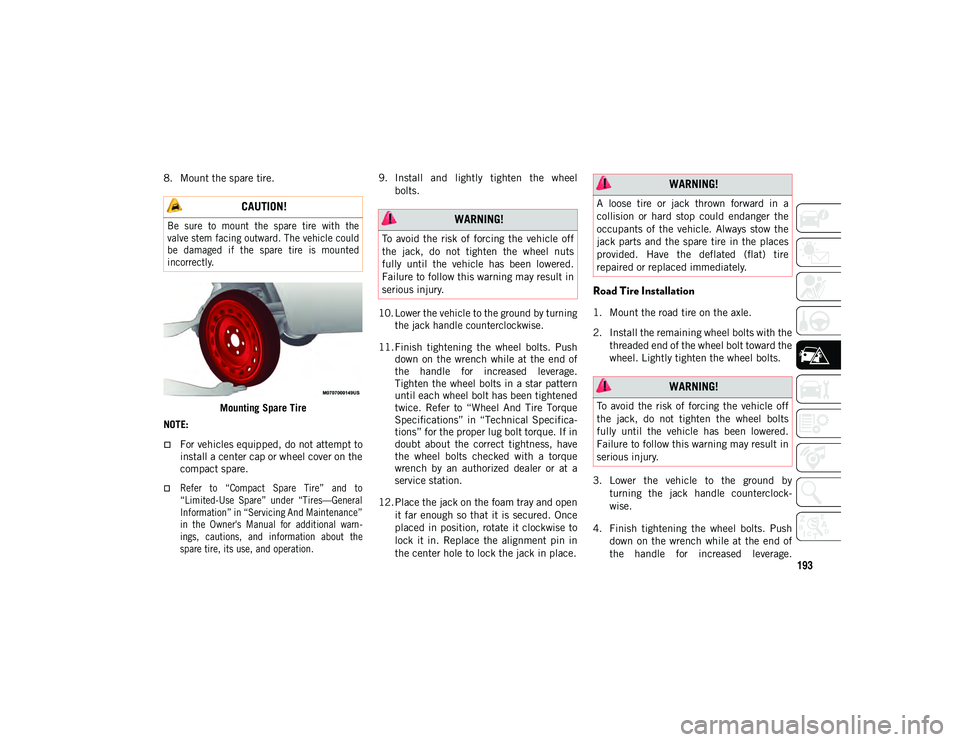

8. Mount the spare tire.Mounting Spare Tire

NOTE:

For vehicles equipped, do not attempt to install a center cap or wheel cover on the

compact spare.

Refer to “Compact Spare Tire” and to

“Limited-Use Spare” under “Tires—General

Information” in “Servicing And Maintenance”

in the Owner's Manual for additional warn- ings, cautions, and information about thespare tire, its use, and operation.

9. Install and lightly tighten the wheel

bolts.

10. Lower the vehicle to the ground by turning the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push down on the wrench while at the end of

the handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. Refer to “Wheel And Tire Torque

Specifications” in “Technical Specifica -

tions” for the proper lug bolt torque. If in

doubt about the correct tightness, have

the wheel bolts checked with a torque

wrench by an authorized dealer or at a

service station.

12. Place the jack on the foam tray and open it far enough so that it is secured. Once

placed in position, rotate it clockwise to

lock it in. Replace the alignment pin in

the center hole to lock the jack in place.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with thethreaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

3. Lower the vehicle to the ground by turning the jack handle counterclock -

wise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end of

the handle for increased leverage.

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle could

be damaged if the spare tire is mounted

incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire

repaired or replaced immediately.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel bolts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

2020_JEEP_M6_UG_UK.book Page 193

Page 196 of 328

IN CASE OF EMERGENCY

194

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. Refer to “Wheel And Tire Torque

Specifications” in “Technical Specifica-

tions” for the proper lug bolt torque. If in

doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station.

5. Lower the jack until it is free. Remove the wheel blocks. Reassemble the lug

wrench to the jack assembly and stow it

in the spare tire area. Secure the

assembly using the means provided.

Release the parking brake before driving

the vehicle.

6. After 25 miles (40 km), check the wheel bolt torque with a torque wrench to

ensure that all wheel bolts are properly

seated against the wheel.

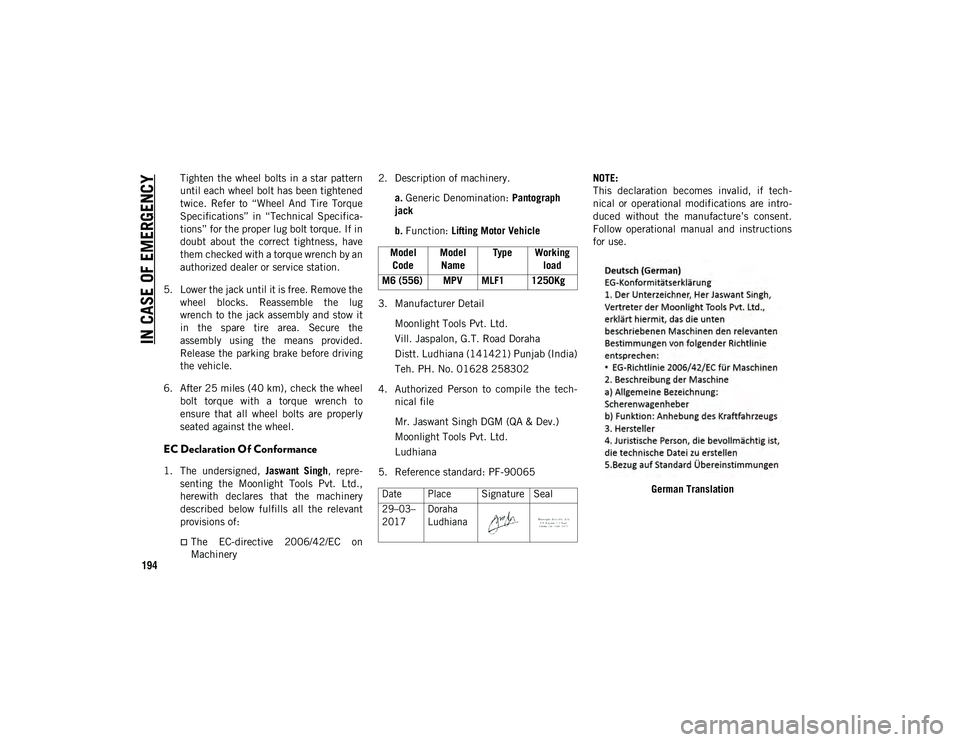

EC Declaration Of Conformance

1. The undersigned, Jaswant Singh, repre-

senting the Moonlight Tools Pvt. Ltd.,

herewith declares that the machinery

described below fulfills all the relevant

provisions of:

The EC-directive 2006/42/EC on Machinery 2. Description of machinery.

a. Generic Denomination: Pantograph

jack

b. Function: Lifting Motor Vehicle

3. Manufacturer Detail Moonlight Tools Pvt. Ltd.

Vill. Jaspalon, G.T. Road Doraha

Distt. Ludhiana (141421) Punjab (India)

Teh. PH. No. 01628 258302

4. Authorized Person to compile the tech -

nical file

Mr. Jaswant Singh DGM (QA & Dev.)

Moonlight Tools Pvt. Ltd.

Ludhiana

5. Reference standard: PF-90065 NOTE:

This declaration becomes invalid, if tech

-

nical or operational modifications are intro -

duced without the manufacture’s consent.

Follow operational manual and instructions

for use.

German Translation

Model

Code Model

Name Type Working

load

M6 (556) MPV MLF1 1250Kg

Date Place

Signature Seal

29–03–

2017 Doraha

Ludhiana

2020_JEEP_M6_UG_UK.book Page 194

Page 232 of 328

SERVICING AND MAINTENANCE

230

(Continued)

Cooling System Pressure Cap

The cap must be fully tightened to prevent

loss of engine coolant (antifreeze), and to

ensure that engine coolant (antifreeze) will

return to the radiator from the coolant expan-

sion bottle/recovery tank if so equipped.

The cap should be inspected and cleaned if

there is any accumulation of foreign material

on the sealing surfaces.

Brake System

In order to assure brake system performance,

all brake system components should be

inspected periodically. Refer to the “Mainte -nance Plan” in this section for the proper

maintenance intervals.

Brake Master Cylinder

The fluid in the master cylinder should be

checked when performing under hood

services or immediately if the “Brake

Warning Light” is illuminated.

Be sure to clean the top of the master

cylinder area before removing the cap. If

necessary, add fluid to bring the fluid level

up to the requirements described on the

brake fluid reservoir. With disc brakes, fluid

level can be expected to fall as the brake

pads wear. Brake fluid level should be

checked when pads are replaced. However,

low fluid level may be caused by a leak and

a checkup may be needed.

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubricants”

in “Technical Specifications” for further

information.

WARNING!

Do not open hot engine cooling system.

Never add engine coolant (antifreeze)

when the engine is overheated. Do not

loosen or remove the cap to cool an over

-

heated engine. Heat causes pressure to

build up in the cooling system. To

prevent scalding or injury, do not remove

the pressure cap while the system is hot

or under pressure.

Do not use a pressure cap other than the

one specified for your vehicle. Personal

injury or engine damage may result.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your

foot resting or riding on the brake pedal

can result in abnormally high brake

temperatures, excessive lining wear, and

possible brake damage. You would not

have your full braking capacity in an

emergency. WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri -

cants” in “Technical Specifications” for

further information. Using the wrong

type of brake fluid can severely damage

your brake system and/or impair its

performance. The proper type of brake

fluid for your vehicle is also identified on

the original factory installed hydraulic

master cylinder reservoir.

To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

closed container. Keep the master

cylinder reservoir cap secured at all

times. Brake fluid in a open container

absorbs moisture from the air resulting

in a lower boiling point. This may cause

it to boil unexpectedly during hard or

prolonged braking, resulting in sudden

brake failure. This could result in a colli -

sion.

2020_JEEP_M6_UG_UK.book Page 230

Page 233 of 328

231

Manual Transmission — If Equipped

Fluid Level Check

Check the fluid level by removing the fill

plug. The fluid level should be between the

bottom of the fill hole and a point not more

than 3/16 inch (4.7 mm) below the bottom

of the hole.

Add fluid, if necessary, to maintain the

proper level.

Please see your authorized dealer for service.

Automatic Transmission

Selection Of Lubricant

It is important to use the proper transmission

fluid to ensure optimum transmission perfor-

mance and life. Use only the manufacturer's

specified transmission fluid. Refer to “Fluids

And Lubricants” in “Technical Specifica -

tions” for fluid specifications. It is important

to maintain the transmission fluid at the

correct level using the recommended fluid.

NOTE:

No chemical flushes should be used in any

transmission; only the approved lubricant

should be used.

Special Additives

The manufacturer strongly recommends

against using any special additives in the transmission. Automatic Transmission Fluid

(ATF) is an engineered product and its

performance may be impaired by supple

-

mental additives. Therefore, do not add any

fluid additives to the transmission. Avoid

using transmission sealers as they may

adversely affect seals.

Fluid Level Check

The fluid level is preset at the factory and

does not require adjustment under normal

operating conditions. Routine fluid level

checks are not required; therefore the trans -

mission has no dipstick. An authorized

dealer can check your transmission fluid

level using special service tools. If you notice

fluid leakage or transmission malfunction,

visit an authorized dealer immediately to

have the transmission fluid level checked.

Operating the vehicle with an improper fluid

level can cause severe transmission damage.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot

engine parts, causing the brake fluid to

catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should

be taken to avoid its contact with these

surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This

could result in a collision.

WARNING! (Continued)

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may

cause deterioration in transmission shift

quality and/or torque converter shudder.

Refer to “Fluids And Lubricants” in

“Technical Specifications” for fluid

specifications.

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage

your transmission components. Such

damage is not covered by the New Vehicle

Limited Warranty.

2020_JEEP_M6_UG_UK.book Page 231

Page 246 of 328

244

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA

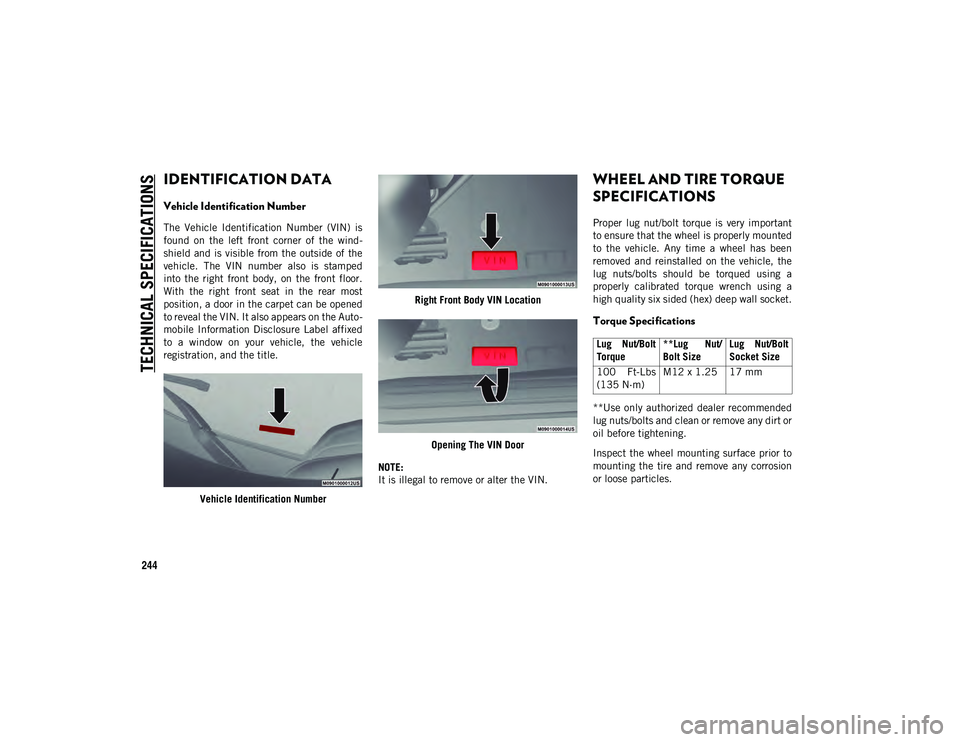

Vehicle Identification Number

The Vehicle Identification Number (VIN) is

found on the left front corner of the wind-

shield and is visible from the outside of the

vehicle. The VIN number also is stamped

into the right front body, on the front floor.

With the right front seat in the rear most

position, a door in the carpet can be opened

to reveal the VIN. It also appears on the Auto -

mobile Information Disclosure Label affixed

to a window on your vehicle, the vehicle

registration, and the title.

Vehicle Identification Number Right Front Body VIN Location

Opening The VIN Door

NOTE:

It is illegal to remove or alter the VIN.

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important

to ensure that the wheel is properly mounted

to the vehicle. Any time a wheel has been

removed and reinstalled on the vehicle, the

lug nuts/bolts should be torqued using a

properly calibrated torque wrench using a

high quality six sided (hex) deep wall socket.

Torque Specifications

**Use only authorized dealer recommended

lug nuts/bolts and clean or remove any dirt or

oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles.

Lug Nut/Bolt

Torque **Lug Nut/

Bolt SizeLug Nut/Bolt

Socket Size

100 Ft-Lbs

(135 N·m) M12 x 1.25 17 mm

2020_JEEP_M6_UG_UK.book Page 244

Page 248 of 328

TECHNICAL SPECIFICATIONS

246

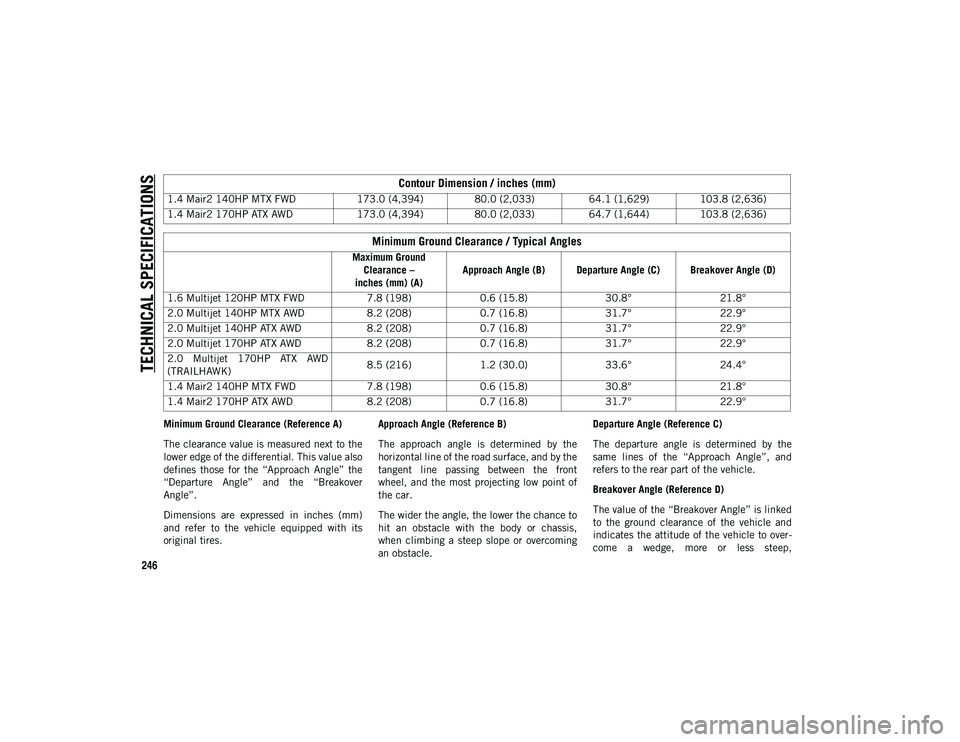

Minimum Ground Clearance (Reference A)

The clearance value is measured next to the

lower edge of the differential. This value also

defines those for the “Approach Angle” the

“Departure Angle” and the “Breakover

Angle”.

Dimensions are expressed in inches (mm)

and refer to the vehicle equipped with its

original tires.Approach Angle (Reference B)

The approach angle is determined by the

horizontal line of the road surface, and by the

tangent line passing between the front

wheel, and the most projecting low point of

the car.

The wider the angle, the lower the chance to

hit an obstacle with the body or chassis,

when climbing a steep slope or overcoming

an obstacle.Departure Angle (Reference C)

The departure angle is determined by the

same lines of the “Approach Angle”, and

refers to the rear part of the vehicle.

Breakover Angle (Reference D)

The value of the “Breakover Angle” is linked

to the ground clearance of the vehicle and

indicates the attitude of the vehicle to over

-

come a wedge, more or less steep,

1.4 Mair2 140HP MTX FWD

173.0 (4,394) 80.0 (2,033) 64.1 (1,629) 103.8 (2,636)

1.4 Mair2 170HP ATX AWD 173.0 (4,394) 80.0 (2,033) 64.7 (1,644) 103.8 (2,636)

Minimum Ground Clearance / Typical Angles

Maximum Ground

Clearance –

inches (mm) (A) Approach Angle (B) Departure Angle (C) Breakover Angle (D)

1.6 Multijet 120HP MTX FWD 7.8 (198)0.6 (15.8) 30.8°21.8°

2.0 Multijet 140HP MTX AWD 8.2 (208)0.7 (16.8) 31.7°22.9°

2.0 Multijet 140HP ATX AWD 8.2 (208)0.7 (16.8) 31.7°22.9°

2.0 Multijet 170HP ATX AWD 8.2 (208)0.7 (16.8) 31.7°22.9°

2.0 Multijet 170HP ATX AWD

(TRAILHAWK) 8.5 (216)

1.2 (30.0) 33.6°24.4°

1.4 Mair2 140HP MTX FWD 7.8 (198)0.6 (15.8) 30.8°21.8°

1.4 Mair2 170HP ATX AWD 8.2 (208)0.7 (16.8) 31.7°22.9°

Contour Dimension / inches (mm)

2020_JEEP_M6_UG_UK.book Page 246

Page 250 of 328

TECHNICAL SPECIFICATIONS

248

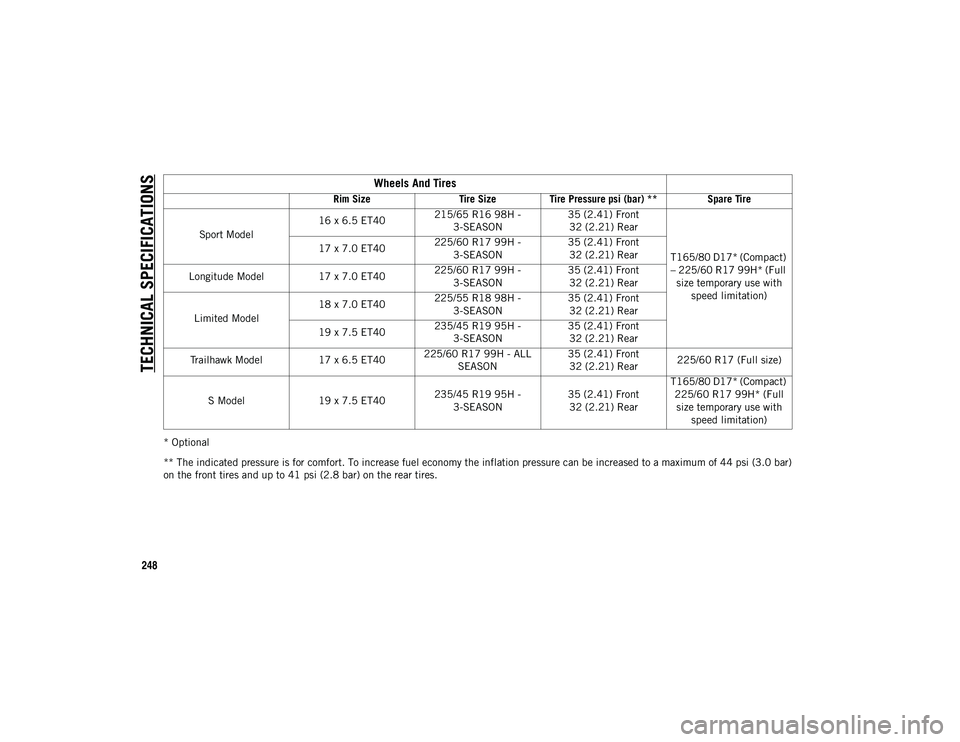

* Optional

** The indicated pressure is for comfort. To increase fuel economy the inflation pressure can be increased to a maximum of 44 psi (3.0 bar)

on the front tires and up to 41 psi (2.8 bar) on the rear tires.

Wheels And Tires

Rim SizeTire SizeTire Pressure psi (bar) ** Spare Tire

Sport Model 16 x 6.5 ET40

215/65 R16 98H -

3-SEASON 35 (2.41) Front

32 (2.21) Rear

T165/80 D17* (Compact)

– 225/60 R17 99H* (Full size temporary use with speed limitation)

17 x 7.0 ET40

225/60 R17 99H -

3-SEASON 35 (2.41) Front

32 (2.21) Rear

Longitude Model 17 x 7.0 ET40225/60 R17 99H -

3-SEASON 35 (2.41) Front

32 (2.21) Rear

Limited Model 18 x 7.0 ET40

225/55 R18 98H -

3-SEASON 35 (2.41) Front

32 (2.21) Rear

19 x 7.5 ET40 235/45 R19 95H -

3-SEASON 35 (2.41) Front

32 (2.21) Rear

Trailhawk Model 17 x 6.5 ET40225/60 R17 99H - ALL

SEASON 35 (2.41) Front

32 (2.21) Rear 225/60 R17 (Full size)

S Model 19 x 7.5 ET40 235/45 R19 95H -

3-SEASON 35 (2.41) Front

32 (2.21) Rear T165/80 D17* (Compact)

225/60 R17 99H* (Full size temporary use with speed limitation)

2020_JEEP_M6_UG_UK.book Page 248