wheel bolts JEEP COMPASS 2021 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2021, Model line: COMPASS, Model: JEEP COMPASS 2021Pages: 328, PDF Size: 8.85 MB

Page 115 of 328

113(Continued)

If a reset procedure step is not completed

within 60 seconds, then the turn signal

lights will blink and the reset procedure must

be performed again in order to be successful.

Maintaining Your Air Bag System Event Data Recorder (EDR)

This vehicle is equipped with an Event Data

Recorder (EDR). The main purpose of an

EDR is to record, in certain crash or near

crash-like situations, such as an air bag

deployment or hitting a road obstacle, data

that will assist in understanding how a

vehicle’s systems performed. The EDR is

designed to record data related to vehicle

dynamics and safety systems for a short

period of time, typically 30 seconds or less.

The EDR in this vehicle is designed to record

such data as:

How various systems in your vehicle were

operating;

Whether or not the driver and passenger

safety belts were buckled/fastened;

11. Turn ignition STOP/OFF/LOCK.

12. Turn ignition MAR/ACC/ON/RUN. (Entire sequence needs to be

completed within one minute or sequence will need to be repeated).

System is now reset and the engine may be started.

Turn hazard flashers OFF (Manually).

Customer Action Customer Will SeeNOTE:

Each step MUST BE held for at least two seconds

WARNING!

Modifications to any part of the air bag

system could cause it to fail when you

need it. You could be injured if the air

bag system is not there to protect you.

Do not modify the components or wiring,

including adding any kind of badges or

stickers to the steering wheel hub trim

cover or the upper passenger side of the

instrument panel. Do not modify the

front bumper, vehicle body structure, or

add aftermarket side steps or running

boards.

It is dangerous to try to repair any part of

the air bag system yourself. Be sure to

tell anyone who works on your vehicle

that it has an air bag system.

Do not attempt to modify any part of your

air bag system. The air bag may inflate

accidentally or may not function properly if

modifications are made. Take your vehicle

to an authorized dealer for any air bag

system service. If your seat, including your

trim cover and cushion, needs to be

serviced in any way (including removal or

loosening/tightening of seat attachment

bolts), take the vehicle to an authorized

dealer. Only manufacturer approved seat

accessories may be used. If it is necessary

to modify the air bag system for persons

with disabilities, contact an authorized

dealer.

WARNING! (Continued)

2020_JEEP_M6_UG_UK.book Page 113

Page 193 of 328

191(Continued)

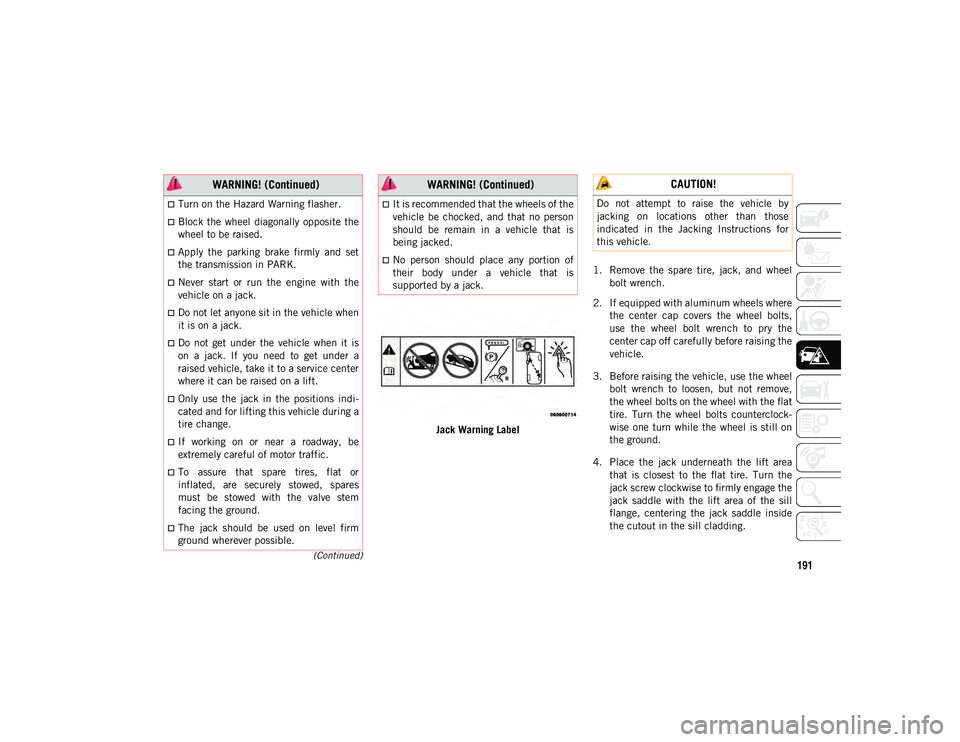

Jack Warning Label1. Remove the spare tire, jack, and wheel

bolt wrench.

2. If equipped with aluminum wheels where the center cap covers the wheel bolts,

use the wheel bolt wrench to pry the

center cap off carefully before raising the

vehicle.

3. Before raising the vehicle, use the wheel bolt wrench to loosen, but not remove,

the wheel bolts on the wheel with the flat

tire. Turn the wheel bolts counterclock -

wise one turn while the wheel is still on

the ground.

4. Place the jack underneath the lift area that is closest to the flat tire. Turn the

jack screw clockwise to firmly engage the

jack saddle with the lift area of the sill

flange, centering the jack saddle inside

the cutout in the sill cladding.

Turn on the Hazard Warning flasher.

Block the wheel diagonally opposite the

wheel to be raised.

Apply the parking brake firmly and set

the transmission in PARK.

Never start or run the engine with the

vehicle on a jack.

Do not let anyone sit in the vehicle when

it is on a jack.

Do not get under the vehicle when it is

on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

Only use the jack in the positions indi -

cated and for lifting this vehicle during a

tire change.

If working on or near a roadway, be

extremely careful of motor traffic.

To assure that spare tires, flat or

inflated, are securely stowed, spares

must be stowed with the valve stem

facing the ground.

The jack should be used on level firm

ground wherever possible.

WARNING! (Continued)

It is recommended that the wheels of the

vehicle be chocked, and that no person

should be remain in a vehicle that is

being jacked.

No person should place any portion of

their body under a vehicle that is

supported by a jack.

WARNING! (Continued) CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those

indicated in the Jacking Instructions for

this vehicle.

2020_JEEP_M6_UG_UK.book Page 191

Page 194 of 328

IN CASE OF EMERGENCY

192

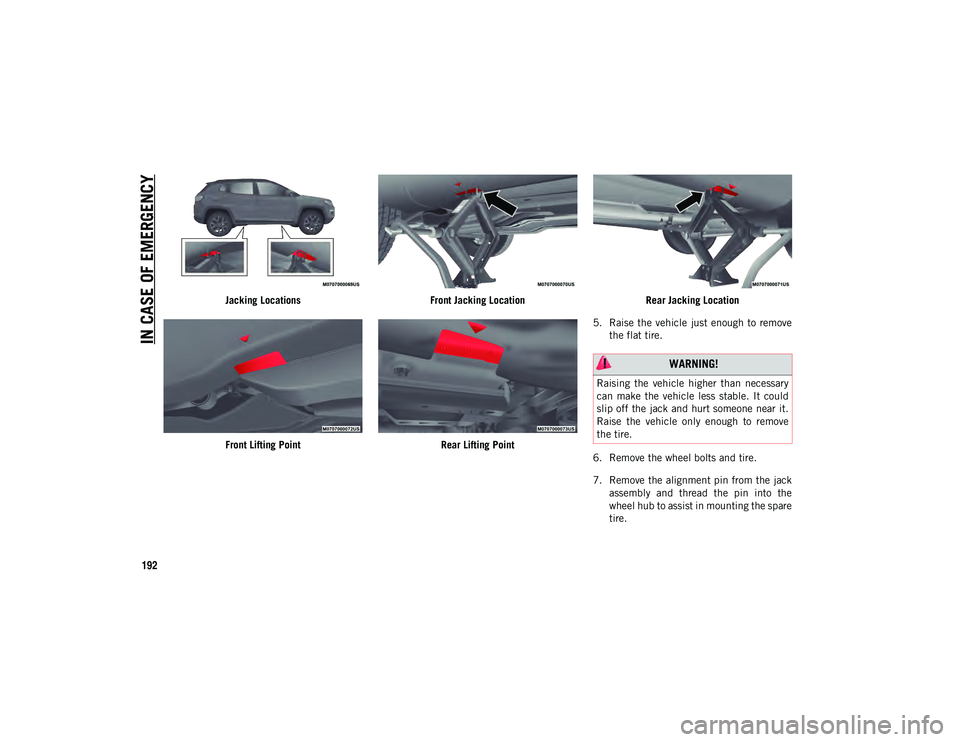

Jacking LocationsFront Lifting Point Front Jacking Location

Rear Lifting Point Rear Jacking Location

5. Raise the vehicle just enough to remove the flat tire.

6. Remove the wheel bolts and tire.

7. Remove the alignment pin from the jack assembly and thread the pin into the

wheel hub to assist in mounting the spare

tire.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

2020_JEEP_M6_UG_UK.book Page 192

Page 195 of 328

193

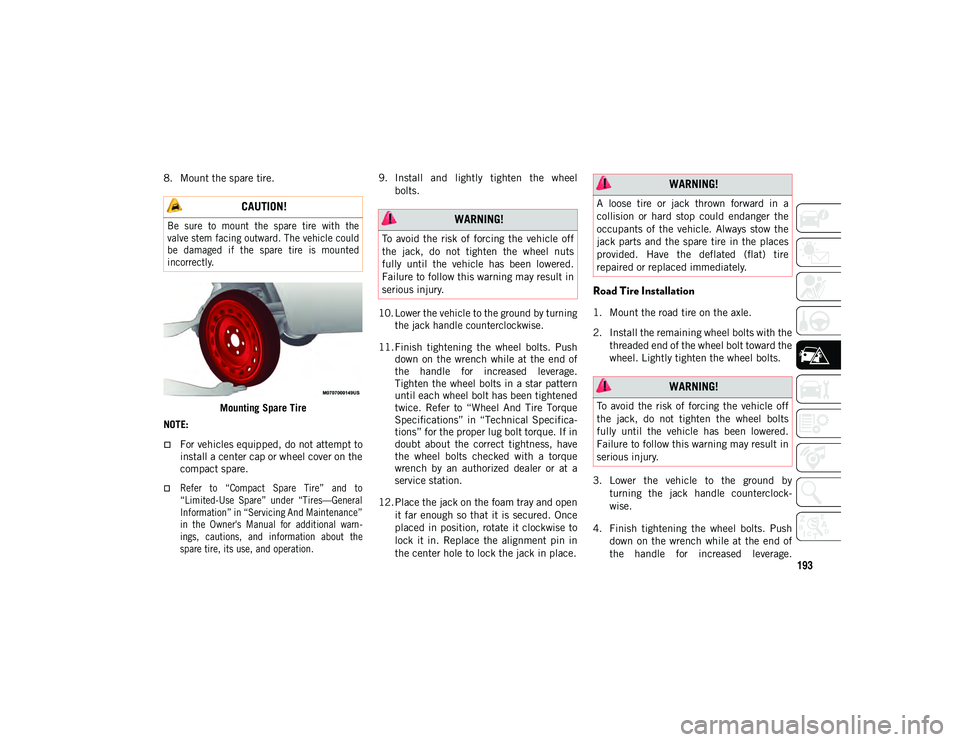

8. Mount the spare tire.Mounting Spare Tire

NOTE:

For vehicles equipped, do not attempt to install a center cap or wheel cover on the

compact spare.

Refer to “Compact Spare Tire” and to

“Limited-Use Spare” under “Tires—General

Information” in “Servicing And Maintenance”

in the Owner's Manual for additional warn- ings, cautions, and information about thespare tire, its use, and operation.

9. Install and lightly tighten the wheel

bolts.

10. Lower the vehicle to the ground by turning the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push down on the wrench while at the end of

the handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. Refer to “Wheel And Tire Torque

Specifications” in “Technical Specifica -

tions” for the proper lug bolt torque. If in

doubt about the correct tightness, have

the wheel bolts checked with a torque

wrench by an authorized dealer or at a

service station.

12. Place the jack on the foam tray and open it far enough so that it is secured. Once

placed in position, rotate it clockwise to

lock it in. Replace the alignment pin in

the center hole to lock the jack in place.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with thethreaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

3. Lower the vehicle to the ground by turning the jack handle counterclock -

wise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end of

the handle for increased leverage.

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle could

be damaged if the spare tire is mounted

incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire

repaired or replaced immediately.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel bolts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

2020_JEEP_M6_UG_UK.book Page 193

Page 196 of 328

IN CASE OF EMERGENCY

194

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. Refer to “Wheel And Tire Torque

Specifications” in “Technical Specifica-

tions” for the proper lug bolt torque. If in

doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station.

5. Lower the jack until it is free. Remove the wheel blocks. Reassemble the lug

wrench to the jack assembly and stow it

in the spare tire area. Secure the

assembly using the means provided.

Release the parking brake before driving

the vehicle.

6. After 25 miles (40 km), check the wheel bolt torque with a torque wrench to

ensure that all wheel bolts are properly

seated against the wheel.

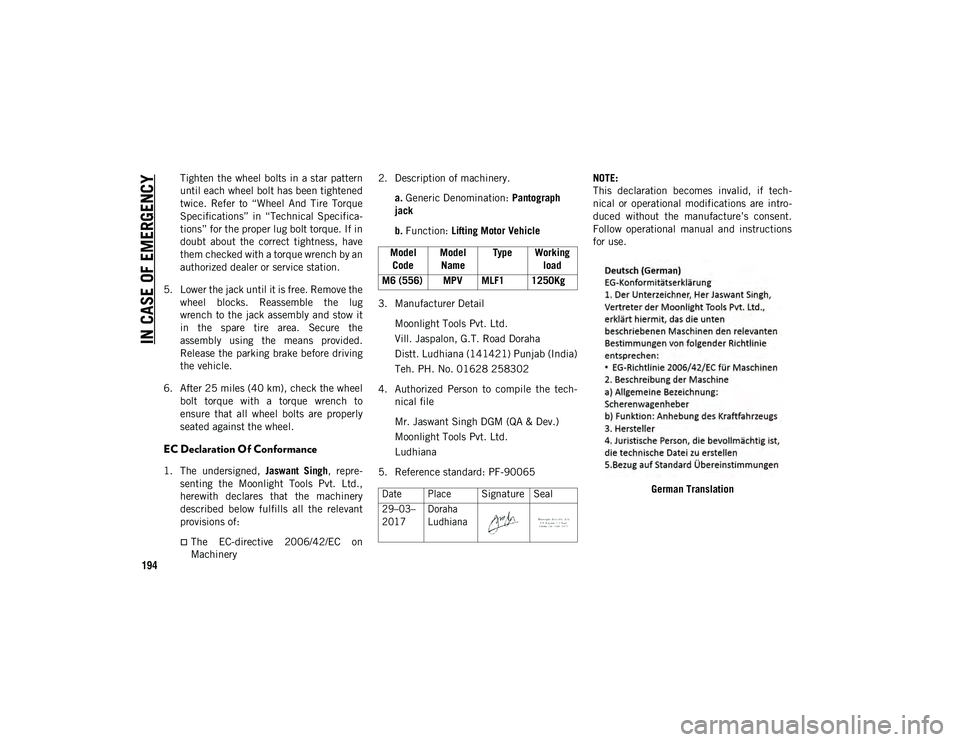

EC Declaration Of Conformance

1. The undersigned, Jaswant Singh, repre-

senting the Moonlight Tools Pvt. Ltd.,

herewith declares that the machinery

described below fulfills all the relevant

provisions of:

The EC-directive 2006/42/EC on Machinery 2. Description of machinery.

a. Generic Denomination: Pantograph

jack

b. Function: Lifting Motor Vehicle

3. Manufacturer Detail Moonlight Tools Pvt. Ltd.

Vill. Jaspalon, G.T. Road Doraha

Distt. Ludhiana (141421) Punjab (India)

Teh. PH. No. 01628 258302

4. Authorized Person to compile the tech -

nical file

Mr. Jaswant Singh DGM (QA & Dev.)

Moonlight Tools Pvt. Ltd.

Ludhiana

5. Reference standard: PF-90065 NOTE:

This declaration becomes invalid, if tech

-

nical or operational modifications are intro -

duced without the manufacture’s consent.

Follow operational manual and instructions

for use.

German Translation

Model

Code Model

Name Type Working

load

M6 (556) MPV MLF1 1250Kg

Date Place

Signature Seal

29–03–

2017 Doraha

Ludhiana

2020_JEEP_M6_UG_UK.book Page 194

Page 246 of 328

244

TECHNICAL SPECIFICATIONS

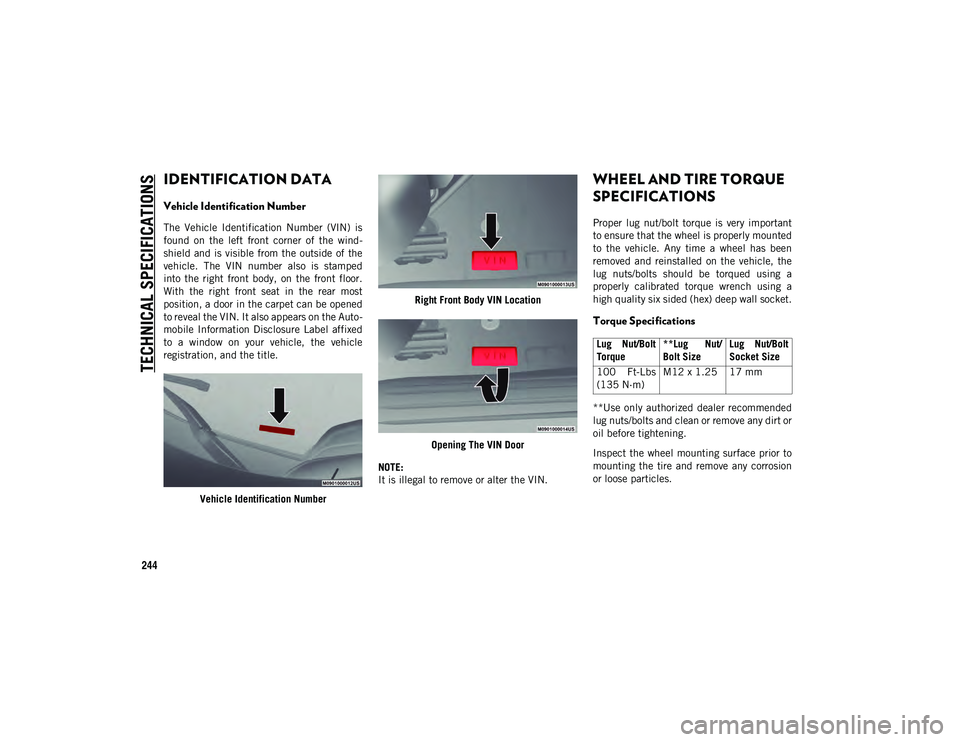

IDENTIFICATION DATA

Vehicle Identification Number

The Vehicle Identification Number (VIN) is

found on the left front corner of the wind-

shield and is visible from the outside of the

vehicle. The VIN number also is stamped

into the right front body, on the front floor.

With the right front seat in the rear most

position, a door in the carpet can be opened

to reveal the VIN. It also appears on the Auto -

mobile Information Disclosure Label affixed

to a window on your vehicle, the vehicle

registration, and the title.

Vehicle Identification Number Right Front Body VIN Location

Opening The VIN Door

NOTE:

It is illegal to remove or alter the VIN.

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important

to ensure that the wheel is properly mounted

to the vehicle. Any time a wheel has been

removed and reinstalled on the vehicle, the

lug nuts/bolts should be torqued using a

properly calibrated torque wrench using a

high quality six sided (hex) deep wall socket.

Torque Specifications

**Use only authorized dealer recommended

lug nuts/bolts and clean or remove any dirt or

oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles.

Lug Nut/Bolt

Torque **Lug Nut/

Bolt SizeLug Nut/Bolt

Socket Size

100 Ft-Lbs

(135 N·m) M12 x 1.25 17 mm

2020_JEEP_M6_UG_UK.book Page 244

Page 247 of 328

245

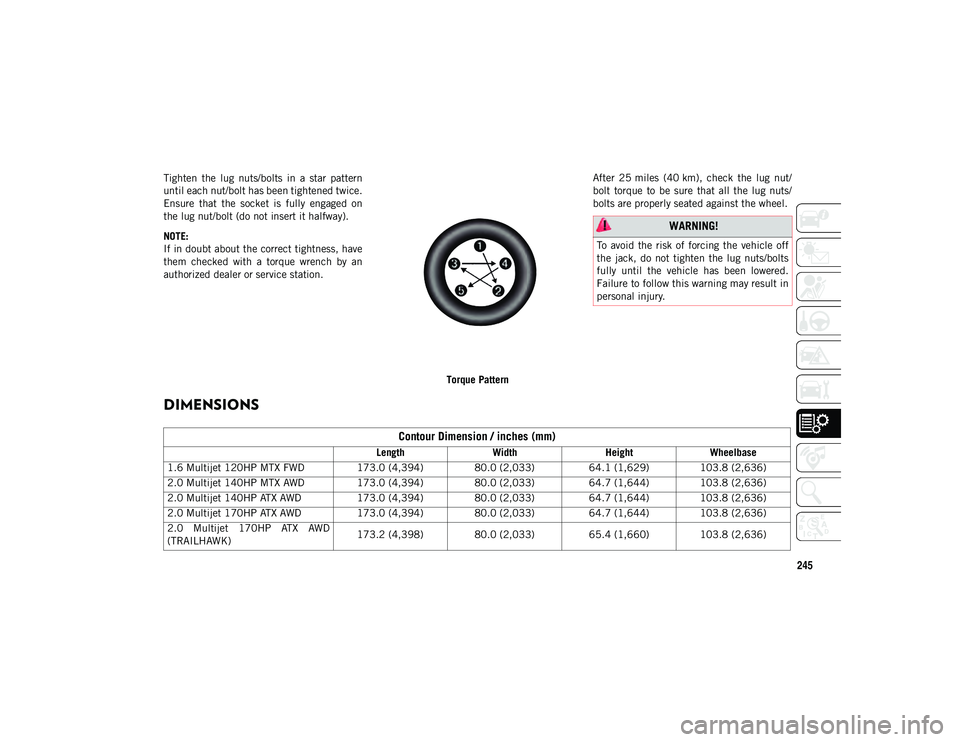

Tighten the lug nuts/bolts in a star pattern

until each nut/bolt has been tightened twice.

Ensure that the socket is fully engaged on

the lug nut/bolt (do not insert it halfway).

NOTE:

If in doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station.Torque PatternAfter 25 miles (40 km), check the lug nut/

bolt torque to be sure that all the lug nuts/

bolts are properly seated against the wheel.

DIMENSIONS

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts/bolts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

personal injury.

Contour Dimension / inches (mm)

Length

WidthHeightWheelbase

1.6 Multijet 120HP MTX FWD 173.0 (4,394) 80.0 (2,033) 64.1 (1,629) 103.8 (2,636)

2.0 Multijet 140HP MTX AWD 173.0 (4,394) 80.0 (2,033) 64.7 (1,644) 103.8 (2,636)

2.0 Multijet 140HP ATX AWD 173.0 (4,394) 80.0 (2,033) 64.7 (1,644) 103.8 (2,636)

2.0 Multijet 170HP ATX AWD 173.0 (4,394) 80.0 (2,033) 64.7 (1,644) 103.8 (2,636)

2.0 Multijet 170HP ATX AWD

(TRAILHAWK) 173.2 (4,398) 80.0 (2,033)

65.4 (1,660) 103.8 (2,636)

2020_JEEP_M6_UG_UK.book Page 245

Page 322 of 328

320

INDEX

J

Jack Location .................................... 189

Jack Operation ...................189, 190 , 232

Jacking Instructions ........................... 190

Jump Starting ................................... 202

K

Key Fob Arm The Alarm................................. 18

Disarm The Alarm ............................ 18Remote Keyless Entry ....................... 13

Keyless Enter-N-Go ........................ 13 , 21

Keys ................................................... 13 Replacement ................................... 14

L

Lane Change And Turn Signals........ 31 , 33

Lane Change Assist .............................. 31

LaneSense ........................................ 162

Lap/Shoulder Belts .............................. 93

Latches............................................. 130 Hood ............................................... 49

Leaks, Fluid ...................................... 130

Life Of Tires ...................................... 235

Liftgate ............................................... 50

Liftgate Window Wiper/Washer .............. 36

Light Bulbs ....................................... 130 Lights............................................... 130

Air Bag .............................. 59 , 98 , 129

Automatic Headlights ....................... 32

Battery Saver ................................... 34

Brake Assist Warning........................ 77

Brake Warning ................................. 59

Bulb Replacement ......................... 177

Cruise .................................. 69 , 70 , 71

Daytime Running ........................31 , 32

Dimmer Switch, Headlight ...........31 , 32

Electronic Stability Program (ESP) Indica- tor............................................... 61

Engine Temperature Warning ............ 61

Exterior ......................................... 130

Fog............................................33 , 68

Headlight Switch ............................. 31

Headlights....................................... 31

Headlights On Reminder................... 33 High Beam ...................................... 32

High Beam/Low Beam Select .......31 , 32

Hill Descent Control Indicator ........... 77

Instrument Cluster ........................... 31

Lights On Reminder ....................31 , 33

Low Fuel ......................................... 63

Malfunction Indicator (Check Engine) ....................................... 64

Park ............................................... 69

Passing ......................................31 , 32 Seat Belt Reminder ..........................62

Security Alarm .................................62

Service ..........................................177

Tire Pressure Monitoring (TPMS) ........86

Traction Control................................77

Turn Signals..................31 , 33 , 69 , 130

Warning Instrument Cluster Descriptions ........................... 61 , 69

Loading Vehicle .................................171

Locks Child Protection ...............................23

Steering Wheel .................................16

Low Tire Pressure System .....................86

Lug Nuts/Bolts ...................................244

Luggage Carrier ....................................54

M

Maintenance........................................48

Maintenance Free Battery ...................226

Maintenance Schedule .......................212

Malfunction Indicator Light (Check

Engine) ...............................................64

Manual Transmission.................. 137 , 231

Fluid Level Check ...........................231

Shift Speeds ..................................137

Memory Feature (Memory Seats)............25

Memory Seat .......................................25

2020_JEEP_M6_UG_UK.book Page 320