torque JEEP COMPASS 2023 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: COMPASS, Model: JEEP COMPASS 2023Pages: 344, PDF Size: 18.8 MB

Page 196 of 344

194SAFETY

Ready Alert Braking (RAB)

RAB may reduce the time required to reach full

braking during emergency braking situations. It

anticipates when an emergency braking situation

may occur by monitoring how fast the throttle is

released by the driver. The Electronic Brake

Controller (EBC) system will prepare the brake

system for a panic stop.

Traction Control System (TCS)

The TCS monitors the amount of wheel spin for

each of the driven wheels. If wheel spin is

detected, the TCS may apply brake pressure to the

spinning wheel(s) and/or reduce vehicle power to

provide enhanced acceleration and stability. A

feature of the TCS, Brake Limited Differential (BLD)

functions similarly to a limited slip differential and

controls the wheel spin across a driven axle. If one

wheel on a driven axle is spinning faster than the

other, the system will apply the brake of the

spinning wheel. This will allow more vehicle torque

to be applied to the wheel that is not spinning.

BLD may remain enabled even if TCS and ESC are

in reduced modes.

Trailer Sway Control (TSC)

TSC uses sensors in the vehicle to recognize an

excessively swaying trailer and will take the

appropriate actions to attempt to stop the sway.

TSC will become active automatically once an

excessively swaying trailer is recognized.

NOTE:TSC cannot stop all trailers from swaying. Always

use caution when towing a trailer and follow the

trailer tongue weight recommendations

Úpage 154.

When TSC is functioning, the ESC Activation/

Malfunction Indicator Light will flash, the engine

power may be reduced and you may feel the

brakes being applied to individual wheels to

attempt to stop the trailer from swaying. TSC is

disabled when the ESC system is in the “Partial

Off” or “Full Off” modes.

AUXILIARY DRIVING SYSTEMS

BLIND SPOT MONITORING (BSM) —

I

F EQUIPPED

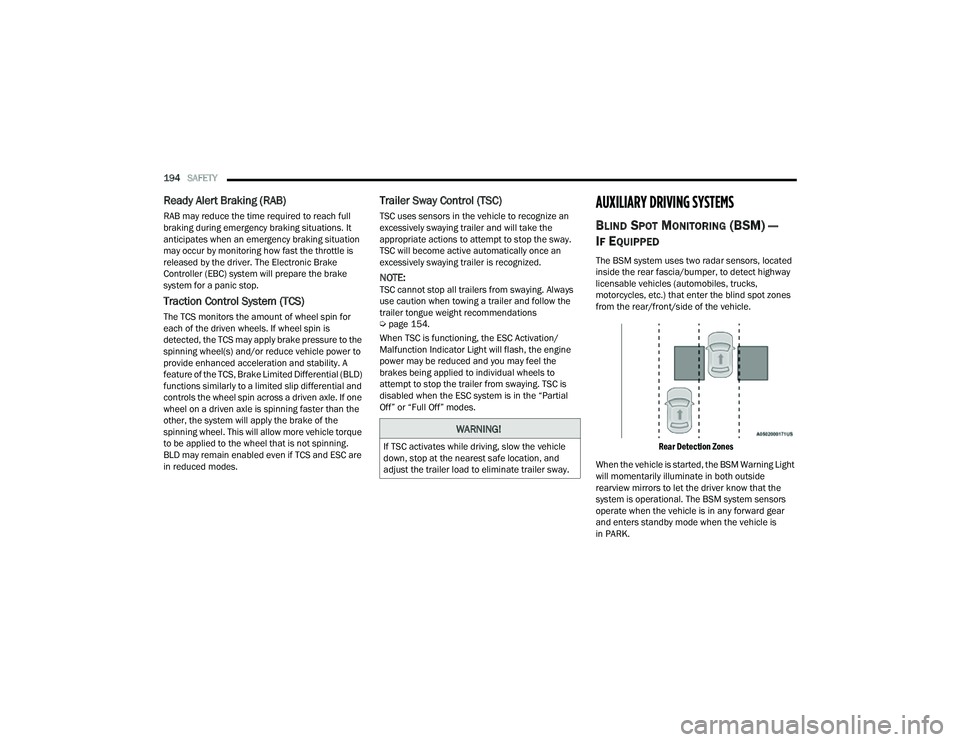

The BSM system uses two radar sensors, located

inside the rear fascia/bumper, to detect highway

licensable vehicles (automobiles, trucks,

motorcycles, etc.) that enter the blind spot zones

from the rear/front/side of the vehicle.

Rear Detection Zones

When the vehicle is started, the BSM Warning Light

will momentarily illuminate in both outside

rearview mirrors to let the driver know that the

system is operational. The BSM system sensors

operate when the vehicle is in any forward gear

and enters standby mode when the vehicle is

in PARK.

WARNING!

If TSC activates while driving, slow the vehicle

down, stop at the nearest safe location, and

adjust the trailer load to eliminate trailer sway.

22_MP_OM_EN_USC_t.book Page 194

Page 197 of 344

SAFETY195

The BSM detection zone covers approximately

one lane width, 12 ft (3.8 m), on both sides of the

vehicle. The zone length starts at the outside

mirror and extends approximately 10 ft (3 m)

beyond the rear fascia/bumper of the vehicle. The

BSM system monitors the detection zones on both

sides of the vehicle when the vehicle speed

reaches approximately 6 mph (10 km/h) or higher

and will alert the driver of vehicles in these areas.

NOTE:

The BSM system DOES NOT alert the driver

about rapidly approaching vehicles that are

outside the detection zones.

The BSM system will automatically disable when

a trailer is detected. If the attached trailer is not

detected, the system detection zone DOES NOT

change. Therefore, visually verify the adjacent

lane is clear for both your vehicle and trailer

before making a lane change. If the trailer or

other object (i.e., bicycle, sports equipment)

extends beyond the side of your vehicle, this

may result in the BSM warning light remaining

illuminated the entire time the vehicle is in a

forward gear. It may be necessary to deactivate

the BSM system manually to avoid misdetection

Ú page 165.

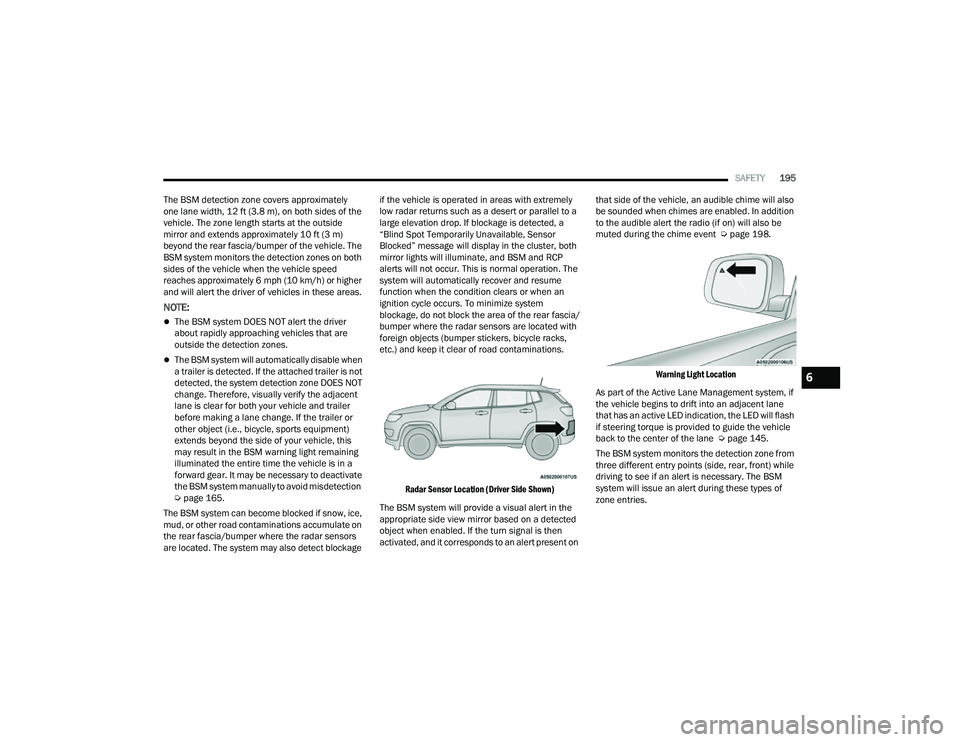

The BSM system can become blocked if snow, ice,

mud, or other road contaminations accumulate on

the rear fascia/bumper where the radar sensors

are located. The system may also detect blockage if the vehicle is operated in areas with extremely

low radar returns such as a desert or parallel to a

large elevation drop. If blockage is detected, a

“Blind Spot Temporarily Unavailable, Sensor

Blocked” message will display in the cluster, both

mirror lights will illuminate, and BSM and RCP

alerts will not occur. This is normal operation. The

system will automatically recover and resume

function when the condition clears or when an

ignition cycle occurs. To minimize system

blockage, do not block the area of the rear fascia/

bumper where the radar sensors are located with

foreign objects (bumper stickers, bicycle racks,

etc.) and keep it clear of road contaminations.

Radar Sensor Location (Driver Side Shown)

The BSM system will provide a visual alert in the

appropriate side view mirror based on a detected

object when enabled. If the turn signal is then

activated, and it corresponds to an alert present on that side of the vehicle, an audible chime will also

be sounded when chimes are enabled. In addition

to the audible alert the radio (if on) will also be

muted during the chime event Ú

page 198.

Warning Light Location

As part of the Active Lane Management system, if

the vehicle begins to drift into an adjacent lane

that has an active LED indication, the LED will flash

if steering torque is provided to guide the vehicle

back to the center of the lane Ú page 145.

The BSM system monitors the detection zone from

three different entry points (side, rear, front) while

driving to see if an alert is necessary. The BSM

system will issue an alert during these types of

zone entries.

6

22_MP_OM_EN_USC_t.book Page 195

Page 244 of 344

242SAFETY

(Continued)

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven

wear patterns. Check for stones, nails, glass, or

other objects lodged in the tread or sidewall.

Inspect the tread for cuts and cracks. Inspect

sidewalls for cuts, cracks, and bulges. Check the

lug nut/bolt torque for tightness. Check the tires

(including spare) for proper cold inflation pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam

indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid leaks.

Also, if gasoline fumes are detected or if fuel or

brake fluid leaks are suspected, the cause should

be located and corrected immediately.

ONLY use the driver’s side floor mat on the

driver’s side floor area. To check for interfer -

ence, with the vehicle properly parked with the

engine off, fully depress the accelerator, the

brake, and the clutch pedal (if present) to

check for interference. If your floor mat inter -

feres with the operation of any pedal, or is not

secure to the floor, remove the floor mat from

the vehicle and place the floor mat in your

trunk.

ONLY use the passenger’s side floor mat on

the passenger’s side floor area.

ALWAYS make sure objects cannot fall or slide

into the driver’s side floor area when the

vehicle is moving. Objects can become

trapped under accelerator, brake, or clutch

pedals and could cause a loss of vehicle

control.

WARNING!

NEVER place any objects under the floor mat

(e.g., towels, keys, etc.). These objects could

change the position of the floor mat and may

cause interference with the accelerator,

brake, or clutch pedals.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to

the floor and check the floor mat fasteners are

secure to the vehicle carpet. Fully depress

each pedal to check for interference with the

accelerator, brake, or clutch pedals then

re-install the floor mats.

It is recommended to only use mild soap and

water to clean your floor mats. After cleaning,

always check your floor mat has been properly

installed and is secured to your vehicle using

the floor mat fasteners by lightly pulling mat.

WARNING!

22_MP_OM_EN_USC_t.book Page 242

Page 254 of 344

252IN CASE OF EMERGENCY

NOTE:

For vehicles equipped, do not attempt to

install a center cap or wheel cover on the

compact spare.

For additional warnings, cautions, and infor -

mation about the spare tire, its use, and

operation Ú page 298.

9. Install and lightly tighten the wheel bolts.

10. Lower the vehicle to the ground by turning the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle

for increased leverage. Tighten the wheel bolts

in a star pattern until each wheel bolt has been

tightened twice Úpage 319. If in doubt about

the correct tightness, have them checked with

a torque wrench by an authorized dealer or at

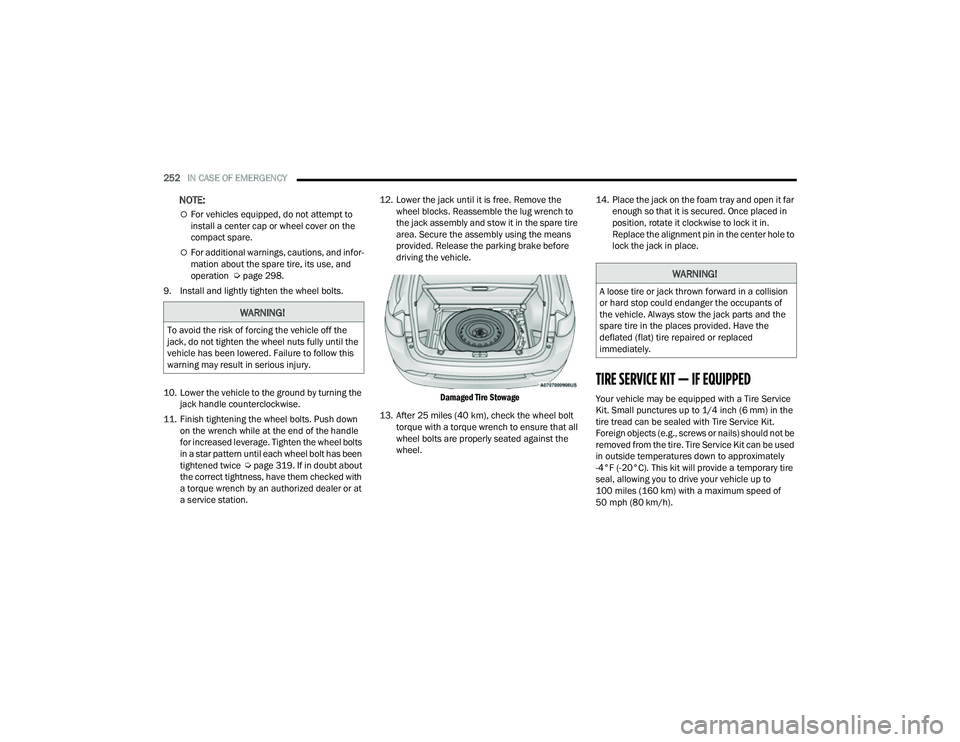

a service station. 12. Lower the jack until it is free. Remove the

wheel blocks. Reassemble the lug wrench to

the jack assembly and stow it in the spare tire

area. Secure the assembly using the means

provided. Release the parking brake before

driving the vehicle.

Damaged Tire Stowage

13. After 25 miles (40 km), check the wheel bolt torque with a torque wrench to ensure that all

wheel bolts are properly seated against the

wheel. 14. Place the jack on the foam tray and open it far

enough so that it is secured. Once placed in

position, rotate it clockwise to lock it in.

Replace the alignment pin in the center hole to

lock the jack in place.

TIRE SERVICE KIT — IF EQUIPPED

Your vehicle may be equipped with a Tire Service

Kit. Small punctures up to 1/4 inch (6 mm) in the

tire tread can be sealed with Tire Service Kit.

Foreign objects (e.g., screws or nails) should not be

removed from the tire. Tire Service Kit can be used

in outside temperatures down to approximately

-4°F (-20°C). This kit will provide a temporary tire

seal, allowing you to drive your vehicle up to

100 miles (160 km) with a maximum speed of

50 mph (80 km/h).

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided. Have the

deflated (flat) tire repaired or replaced

immediately.

22_MP_OM_EN_USC_t.book Page 252

Page 285 of 344

SERVICING AND MAINTENANCE283

AUTOMATIC TRANSMISSION —

I

F EQUIPPED

Special Additives

It is strongly recommended against using any

special additives in the transmission. Automatic

Transmission Fluid (ATF) is an engineered product

and its performance may be impaired by

supplemental additives. Therefore, do not add any

fluid additives to the transmission. The only

exception to this policy is the use of special dyes

for diagnosing fluid leaks in 6-speed

transmissions. Avoid using transmission sealers as

they may adversely affect seals.

Fluid Level Check

The fluid level is preset at the factory and does not

require adjustment under normal operating

conditions. Routine fluid level checks are not

required; therefore the transmission has no

dipstick. An authorized dealer can check your

transmission fluid level using special service tools.

If you notice fluid leakage or transmission

malfunction, visit an authorized dealer

immediately to have the transmission fluid level

checked. Operating the vehicle with an improper

fluid level can cause severe transmission damage.

Fluid And Filter Changes

Under normal operating conditions, the fluid

installed at the factory will provide satisfactory

lubrication for the life of the vehicle.

Routine fluid and filter changes are not required.

However, change the fluid and filter if the fluid

becomes contaminated (with water, etc.), or if the

transmission is disassembled for any reason.

Selection Of Lubricant

It is important to use the proper transmission fluid

to ensure optimum transmission performance and

life. Use only the manufacturer specified

transmission fluid Ú page 324. It is important to

maintain the transmission fluid at the correct level

using the recommended fluid.

NOTE:No chemical flushes should be used in any trans -

mission; only the approved lubricant should be

used.

Do not allow petroleum-based fluid to contam -

inate the brake fluid. Brake seal components

could be damaged, causing partial or

complete brake failure. This could result in a

collision.

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage your

transmission components. Such damage is not

covered by the New Vehicle Limited Warranty.

WARNING!

CAUTION!

If a transmission fluid leak occurs, visit an

authorized dealer immediately. Severe

transmission damage may occur. An authorized

dealer has the proper tools to adjust the fluid

level accurately.

CAUTION!

Using a transmission fluid other than the

manufacturer recommended fluid may cause

deterioration in transmission shift quality and/or

torque converter shudder. For fluid

specifications Ú page 324.

8

22_MP_OM_EN_USC_t.book Page 283

Page 321 of 344

319

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is found on the left front corner of the

windshield and is visible from the outside of the

vehicle.

Vehicle Identification Number

NOTE:It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with power assisted

brakes as standard equipment. In the event power

assist is lost for any reason (for example, repeated

brake applications with the engine off), the brakes will still function. However, the effort required to

brake the vehicle will be much greater than that

required with the power system operating.

If either of the two hydraulic systems lose normal

capability, the remaining system will still function

with some loss of overall braking effectiveness.

This will be evident by increased pedal travel

during application and greater pedal force

required to slow or stop. In addition, if the

malfunction is caused by an internal leak, as

the brake fluid in the master cylinder drops, the

Brake Warning Light will light.

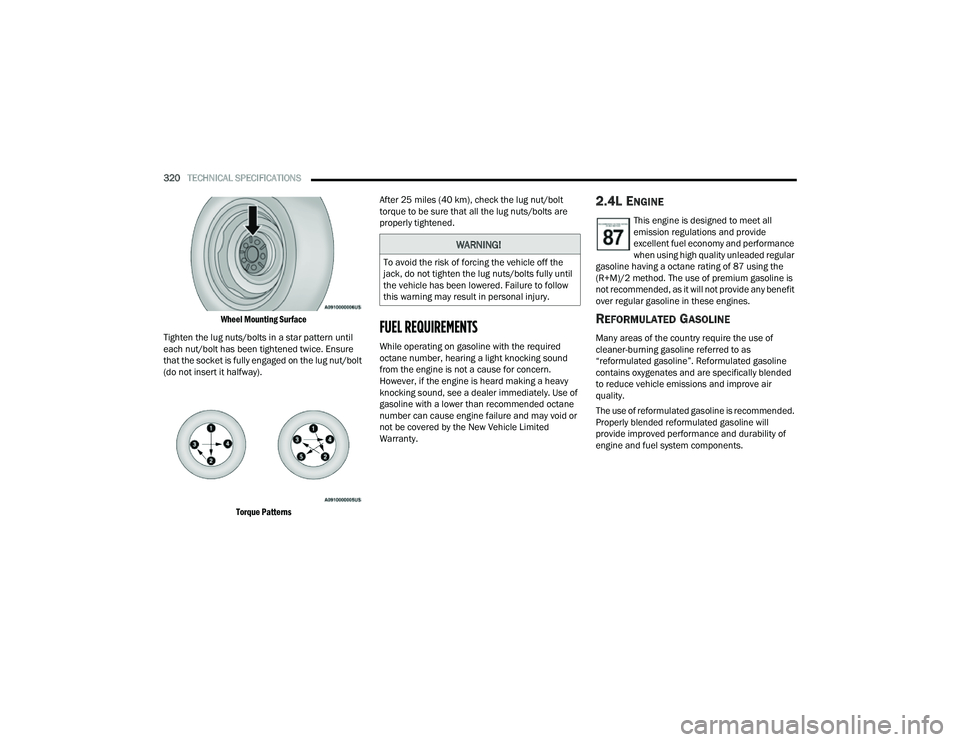

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to the

vehicle. Any time a wheel has been removed and

reinstalled on the vehicle, the lug nuts/bolts

should be torqued using a properly calibrated

torque wrench using a six-sided (hex) deep wall

socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug

nuts/bolts and clean or remove any dirt or oil

before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

WARNING!

Driving a vehicle with the Brake Warning Light on

is dangerous. A significant decrease in braking

performance or vehicle stability during braking

may occur. It will take you longer to stop the

vehicle or will make your vehicle harder to

control. You could have a collision. Have the

vehicle checked immediately.

Lug Nut/Bolt

Torque

**Lug Nut/

Bolt SizeLug Nut/Bolt

Socket Size

100 Ft-Lb

(135 N·m) M12 x 1.25 19 mm

9

22_MP_OM_EN_USC_t.book Page 319

Page 322 of 344

320TECHNICAL SPECIFICATIONS

Wheel Mounting Surface

Tighten the lug nuts/bolts in a star pattern until

each nut/bolt has been tightened twice. Ensure

that the socket is fully engaged on the lug nut/bolt

(do not insert it halfway).

Torque Patterns

After 25 miles (40 km), check the lug nut/bolt

torque to be sure that all the lug nuts/bolts are

properly tightened.

FUEL REQUIREMENTS

While operating on gasoline with the required

octane number, hearing a light knocking sound

from the engine is not a cause for concern.

However, if the engine is heard making a heavy

knocking sound, see a dealer immediately. Use of

gasoline with a lower than recommended octane

number can cause engine failure and may void or

not be covered by the New Vehicle Limited

Warranty.

2.4L ENGINE

This engine is designed to meet all

emission regulations and provide

excellent fuel economy and performance

when using high quality unleaded regular

gasoline having a octane rating of 87 using the

(R+M)/2 method. The use of premium gasoline is

not recommended, as it will not provide any benefit

over regular gasoline in these engines.

REFORMULATED GASOLINE

Many areas of the country require the use of

cleaner-burning gasoline referred to as

“reformulated gasoline”. Reformulated gasoline

contains oxygenates and are specifically blended

to reduce vehicle emissions and improve air

quality.

The use of reformulated gasoline is recommended.

Properly blended reformulated gasoline will

provide improved performance and durability of

engine and fuel system components.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts/bolts fully until

the vehicle has been lowered. Failure to follow

this warning may result in personal injury.

22_MP_OM_EN_USC_t.book Page 320

Page 338 of 344

336 Snow Chains (Tire Chains)

............................. 311Snow Tires..................................................... 310Spare Tires.......................................... 310, 311Specifications Fuel (Gasoline).......................................... 323Oil.............................................................. 323Starting................................................... 19, 100Automatic Transmission............................ 100Button......................................................... 17Cold Weather............................................ 101Engine Fails To Start................................. 101Remote....................................................... 19Starting And Operating.................................. 100Starting Procedures....................................... 100SteeringColumn Controls.......................................... 43Tilt Column.................................................. 26Wheel, Heated...................................... 26, 27Wheel, Tilt................................................... 26Storage............................................................ 58Storage, Vehicle............................................... 56Stuck, Freeing............................................... 262Sun Roof................................................... 63, 65Sun Visor......................................................... 38Supplemental Restraint System – Air Bag..... 214Sway Control, Trailer...................................... 194Synthetic Engine Oil....................................... 273System, Remote Starting................................. 19

T

Telescoping Steering Column.......................... 26Temperature Control, Automatic (ATC)............. 56Tie Down Hooks, Cargo............................. 70, 71Tilt Steering Column........................................ 26Time DelayHeadlight.............................................. 43, 45Tire And Loading Information Placard........... 303Tire Markings................................................ 298Tire Safety Information................................. 298Tire Service Kit.............................................. 252Tires...................................242, 306, 310, 314Aging (Life Of Tires).................................. 308Air Pressure.............................................. 306Chains...................................................... 311Changing.................................................. 247Compact Spare......................................... 310General Information........................ 306, 310High Speed............................................... 307Inflation Pressure..................................... 306Jacking..................................................... 247Life Of Tires.............................................. 308Load Capacity........................................... 303Pressure Monitoring System (TPMS)...............................94, 201Quality Grading......................................... 314Radial....................................................... 307Replacement............................................ 309Rotation.................................................... 313Safety.............................................. 298, 306

Sizes......................................................... 299Snow Tires................................................ 310Spare Tires...................................... 310, 311Spinning................................................... 308Trailer Towing........................................... 157Tread Wear Indicators.............................. 308Wheel Nut Torque..................................... 319To Open Hood..................................................66Tongue Weight/Trailer Weight...................... 156Tow HooksEmergency................................................ 266Towing........................................................... 154Disabled Vehicle....................................... 264Guide........................................................ 155Recreational............................................. 160Weight...................................................... 155Towing Behind A Motorhome........................ 160Traction Control................................... 191, 194Traffic Sign Assist System............................. 127Trailer Sway Control (TSC)............................. 194Trailer Towing................................................ 154Minimum Requirements........................... 156Tips........................................................... 159Trailer And Tongue Weight........................ 156Wiring....................................................... 158Trailer Towing Guide..................................... 155Trailer Weight................................................ 155TransaxleAutomatic................................................. 106Operation.................................................. 106

22_MP_OM_EN_USC_t.book Page 336