oil change JEEP DJ 1953 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: DJ, Model: JEEP DJ 1953Pages: 376, PDF Size: 19.96 MB

Page 49 of 376

'Jeep'

UNIVERSAL SERIES

SERVICE

MANUAL

D

FIG.

D-ll—CHECKING PISTON

AND

CONNECTING

ROD

ALIGNMENT 1—

Feeler

Gauge

2—

Fixture

the

opposite

side from the oil spray

hole

in the

bearing

end of the connecting rod. See Fig. D-10.

Install

the piston pin lock screw and torque 35 to

41 lb-ft. [4,8 a 5,7 kg-m.].

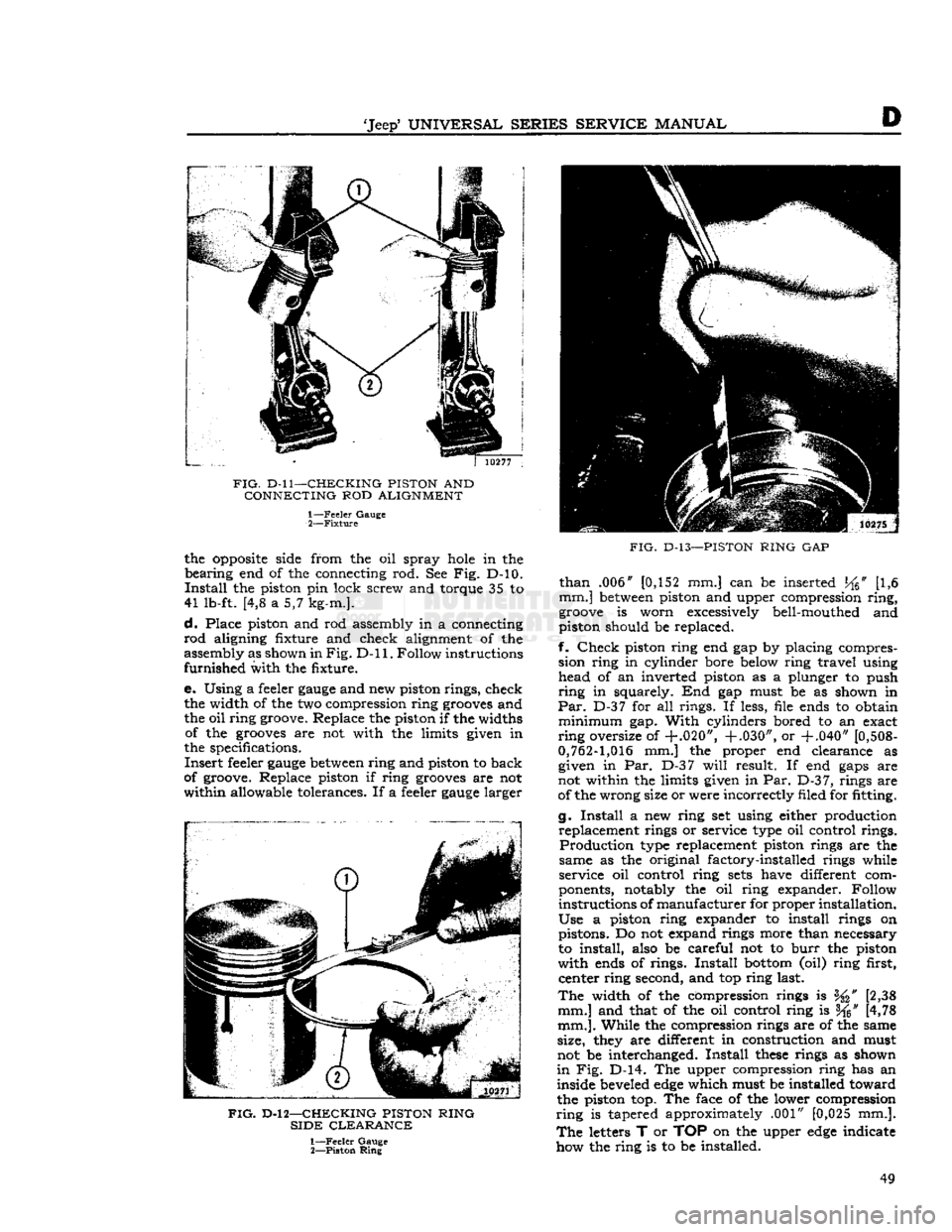

d.

Place piston and rod assembly in a connecting

rod

aligning fixture and check alignment of the

assembly as shown in

Fig. D-ll.

Follow instructions

furnished

with the fixture.

e. Using a feeler

gauge

and new piston rings, check the width of the two compression ring

grooves

and

the oil ring groove. Replace the piston if the widths of the

grooves

are not with the limits given in

the specifications.

Insert

feeler

gauge

between

ring and piston to back

of groove. Replace piston if ring

grooves

are not

within

allowable tolerances. If a feeler

gauge

larger

FIG.

D-l 2—CHECKING PISTON RING

SIDE

CLEARANCE

1—

Feeler

Gauge

2—

Piston

Ring

FIG.

D-13—PISTON

RING

GAP

than

.006" [0,152 mm.] can be inserted

J^6"

[1,6

mm.]

between

piston and upper compression

ring,

groove

is worn excessively bell-mouthed and

piston should be replaced.

f.

Check

piston ring end gap by placing compres sion ring in cylinder bore below ring travel using head of an inverted piston as a plunger to push

ring

in squarely. End gap must be as shown in

Par.

D-37 for all rings. If less, file ends to obtain

minimum

gap.

With

cylinders bored to an exact

ring

oversize of

+.020", +.030",

or

+.040"

[0,508-

0,762-1,016

mm.] the proper end clearance as given in Par. D-37

will

result. If end

gaps

are

not within the limits given in Par.

D-3

7, rings are

of the wrong size or were incorrectly filed for fitting.

g.

Install

a new ring set using either production replacement rings or service type oil control rings.

Production

type replacement piston rings are the

same as the original factory-installed rings while

service oil control ring

sets

have different com

ponents, notably the oil ring expander. Follow

instructions of

manufacturer

for proper installation.

Use

a piston ring expander to install rings on pistons. Do not expand rings more than necessary

to install, also be careful not to

burr

the piston

with

ends of rings.

Install

bottom

(oil) ring first, center ring second, and top ring last.

The

width of the compression rings is [2,38

mm.] and that of the oil control ring is f^" [4,78

mm.].

While the compression rings are of the same

size, they are different in construction and must

not be interchanged.

Install

these

rings as shown

in

Fig. D-14. The upper compression ring has an

inside beveled

edge

which must be installed toward

the piston top. The face of the lower compression

ring

is tapered approximately .001" [0,025 mm.].

The

letters T or TOP on the upper

edge

indicate

how the ring is to be installed. 49

Page 52 of 376

D

HURRICANE

F4

ENGINE

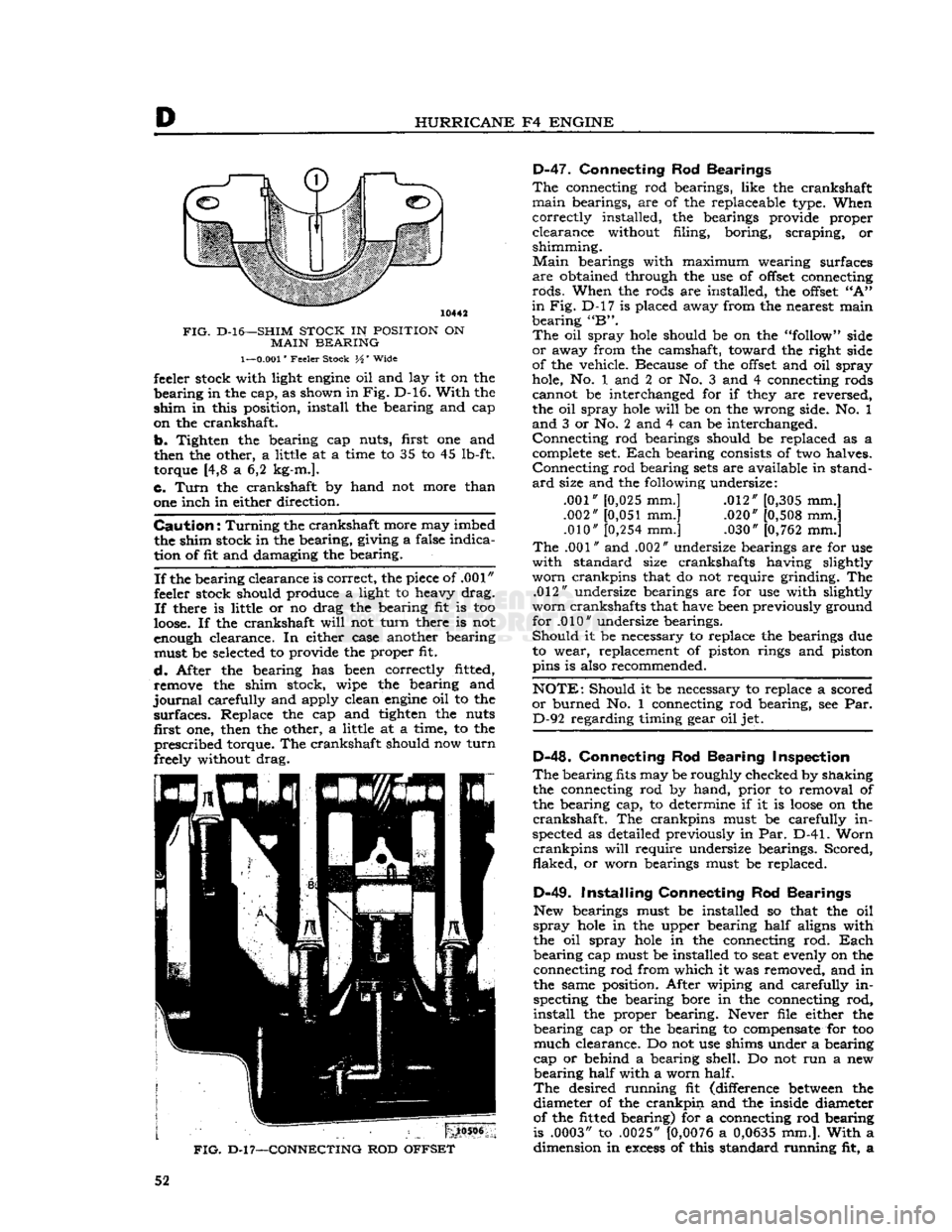

10442

FIG.

D-l6—SHIM

STOCK

IN

POSITION

ON

MAIN

BEARING

1—0.001"

Feeler Stock H' Wide feeler stock with light

engine

oil and lay it on the

bearing

in the cap, as shown in

Fig.

D-16.

With

the

shim

in this position, install the bearing and cap

on the crankshaft.

b.

Tighten the bearing cap nuts, first one and

then the other, a little at a time to 35 to 45 lb-ft. torque [4,8 a 6,2 kg-m.].

c.

Turn

the crankshaft by hand not more than

one inch in either direction.

Caution:

Turning

the crankshaft more may imbed the shim stock in the bearing, giving a false indica

tion of fit and damaging the bearing.

If

the bearing clearance is correct, the piece of .001"

feeler stock should produce a light to heavy drag.

If

there is little or no drag the bearing fit is too

loose.

If the crankshaft

will

not

turn

there is not

enough clearance. In either case another bearing must be selected to provide the proper fit.

d.

After the bearing has been correctly fitted, remove the shim stock, wipe the bearing and

journal

carefully and apply clean

engine

oil to the

surfaces.

Replace the cap and tighten the nuts first one, then the other, a little at a time, to the

prescribed

torque. The crankshaft should now

turn

freely without drag.

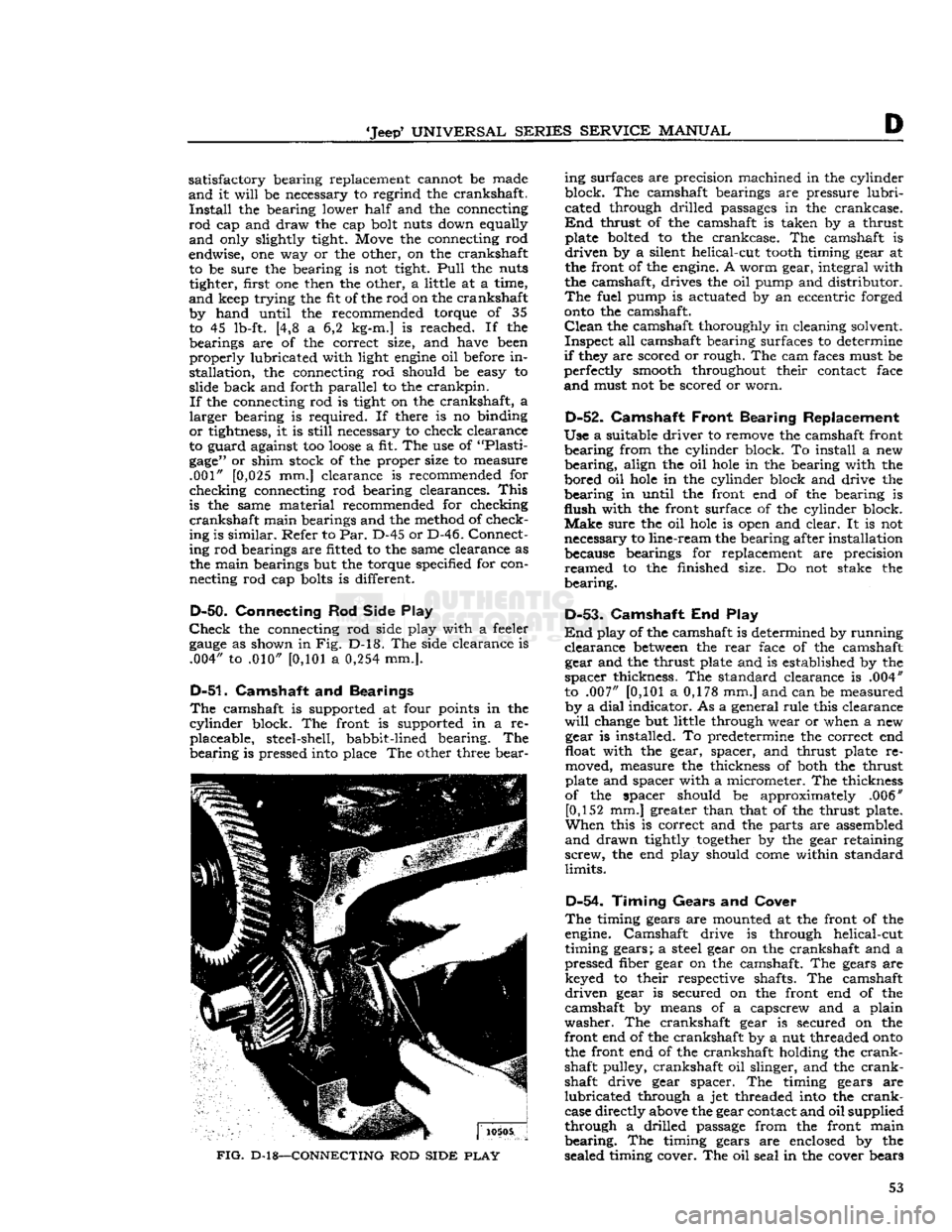

FIG.

D-l

7—CONNECTING

ROD

OFFSET

D-47.

Connecting Rod Bearings

The

connecting rod bearings, like the crankshaft

main

bearings, are of the replaceable type. When

correctly

installed, the bearings provide proper

clearance

without filing, boring, scraping, or

shimming.

Main

bearings with maximum wearing surfaces

are

obtained through the use of

offset

connecting

rods.

When the rods are installed, the

offset

"A"

in

Fig. D-l7 is placed away from the nearest main

bearing

"B".

The

oil spray

hole

should be on the "follow" side

or

away from the camshaft, toward the right side

of the vehicle. Because of the

offset

and oil spray

hole, No. 1 and 2 or No. 3 and 4 connecting rods cannot be interchanged for if they are reversed,

the oil spray

hole

will

be on the wrong side. No. 1

and

3 or No. 2 and 4 can be interchanged.

Connecting

rod bearings should be replaced as a complete set.

Each

bearing consists of two halves.

Connecting

rod bearing

sets

are available in stand

ard

size and the following undersize:

.001" [0,025 mm.] .012" [0,305 mm.]

.002"

[0,051

mm.] .020" [0,508 mm.] .010"

[0,254

mm.] .030" [0,762 mm.]

The

.001" and .002" undersize bearings are for use

with

standard size crankshafts having slightly

worn

crankpins that do not require grinding. The .012" undersize bearings are for use with slightly

worn

crankshafts that have been previously ground for .010" undersize bearings.

Should

it be necessary to replace the bearings due to wear, replacement of piston rings and piston

pins is also recommended.

NOTE:

Should it be necessary to replace a scored

or

burned No. 1 connecting rod bearing, see Par. D-92 regarding timing gear oil jet.

D-48.

Connecting Rod Bearing Inspection

The

bearing fits may be roughly checked by shaking the connecting rod by hand,

prior

to removal of

the bearing cap, to determine if it is

loose

on the

crankshaft.

The crankpins must be carefully in

spected as detailed previously in Par. D-41.

Worn

crankpins

will

require undersize bearings. Scored,

flaked,

or

worn bearings must be replaced.

D-49.

Installing Connecting Rod Bearings

New bearings must be installed so that the oil

spray

hole

in the upper bearing

half

aligns with

the oil spray

hole

in the connecting rod.

Each

bearing

cap must be installed to seat evenly on the connecting rod from which it was removed, and in

the same position. After wiping and carefully in specting the bearing bore in the connecting rod,

install

the proper bearing. Never file either the

bearing

cap or the bearing to compensate for too

much

clearance. Do not use shims under a bearing

cap or behind a bearing shell. Do not run a new

bearing

half

with a worn half.

The

desired running fit (difference

between

the diameter of the

crankpin

and the inside diameter

of the fitted bearing) for a connecting rod bearing

is .0003" to .0025"

[0,0076

a

0,0635

mm.].

With

a dimension in

excess

of this standard running fit, a 52

Page 53 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

D

satisfactory bearing replacement cannot be made

and

it

will

be necessary to regrind the crankshaft.

Install

the bearing lower

half

and the connecting

rod

cap and draw the cap bolt nuts down equally

and

only slightly tight. Move the connecting rod

endwise, one way or the other, on the crankshaft to be sure the bearing is not tight.

Pull

the nuts tighter, first one then the other, a little at a time,

and

keep trying the fit of the rod on the crankshaft by hand until the recommended torque of 35 to 45 lb-ft. [4,8 a 6,2 kg-m.] is reached. If the

bearings are of the correct size, and have been

properly

lubricated with light

engine

oil before in

stallation,

the connecting rod should be easy to

slide back and forth parallel to the

crankpin.

If

the connecting rod is tight on the crankshaft, a

larger

bearing is required. If there is no binding

or

tightness, it is

still

necessary to check clearance

to guard against too

loose

a fit. The use of "Plasti

gage"

or shim stock of the proper size to measure .001" [0,025 mm.] clearance is recommended for

checking

connecting rod bearing clearances.

This

is the same material recommended for checking

crankshaft

main bearings and the method of check

ing is

similar.

Refer to

Par.

D-45 or D-46. Connect

ing rod bearings are fitted to the same clearance as the main bearings but the torque specified for con

necting rod cap

bolts

is different.

D-50.

Connecting

Rod

Side Play

Check

the connecting rod side play with a feeler

gauge

as shown in Fig. D-l8. The side clearance is .004" to .010"

[0,101

a

0,254

mm.].

D-51.

Camshaft and Bearings

The

camshaft is supported at four points in the

cylinder

block. The front is supported in a re placeable, steel-shell, babbit-lined bearing. The

bearing

is pressed into place The other three bear-

FIG.

D-18—CONNECTING

ROD

SIDE

PLAY

ing surfaces are precision machined in the cylinder

block. The camshaft bearings are pressure

lubri

cated through drilled passages in the crankcase.

End

thrust of the camshaft is taken by a thrust plate bolted to the crankcase. The camshaft is

driven

by a silent helical-cut

tooth

timing gear at

the front of the engine. A worm gear, integral with

the camshaft, drives the oil pump and distributor.

The

fuel pump is actuated by an eccentric forged

onto

the camshaft.

Clean

the camshaft thoroughly in cleaning solvent.

Inspect

all camshaft bearing surfaces to determine

if

they are scored or rough. The cam faces must be

perfectly smooth throughout their contact face

and

must not be scored or worn.

D-52.

Camshaft

Front Bearing Replacement

Use

a suitable driver to remove the camshaft front

bearing

from the cylinder block. To install a new

bearing,

align the oil

hole

in the bearing with the

bored oil

hole

in the cylinder block and drive the

bearing

in until the front end of the bearing is

flush

with the front surface of the cylinder block.

Make

sure the oil

hole

is open and clear. It is not

necessary to line-ream the bearing after installation because bearings for replacement are precision

reamed

to the finished size. Do not stake the

bearing.

D-53-

Camshaft End Play

End

play of the camshaft is determined by running

clearance

between

the

rear

face of the camshaft gear and the thrust plate and is established by the

spacer

thickness. The standard clearance is .004"

to .007"

[0,101

a 0,178 mm.] and can be measured by a

dial

indicator. As a general rule this clearance

will

change but little through wear or when a new gear is installed. To predetermine the correct end

float with the gear, spacer, and thrust plate re

moved, measure the thickness of both the thrust

plate and spacer with a micrometer. The thickness

of the spacer should be approximately .006" [0,152 mm.] greater than that of the thrust plate.

When

this is correct and the parts are assembled

and

drawn tightly

together

by the gear retaining

screw,

the end play should

come

within standard

limits.

D-54.

Timing Gears

and

Cover

The

timing gears are mounted at the front of the

engine. Camshaft drive is through helical-cut

timing gears; a steel gear on the crankshaft and a

pressed fiber gear on the camshaft. The gears are keyed to their respective shafts. The camshaft

driven

gear is secured on the front end of the

camshaft by means of a capscrew and a plain

washer.

The crankshaft gear is secured on the

front end of the crankshaft by a nut threaded

onto

the front end of the crankshaft holding the

crank

shaft pulley, crankshaft oil slinger, and the

crank

shaft drive gear spacer. The timing gears are

lubricated

through a jet threaded into the

crank

case directly above the gear contact and oil supplied

through a drilled passage from the front main

bearing.

The timing gears are enclosed by the

sealed timing cover. The oil seal in the cover bears 53

Page 54 of 376

D

HURRICANE

F4

ENGINE

against the hub of the crankshaft pulley.

Timing

gears are accessible for inspection or replacement

with

the

engine

installed in the vehicle after re moving the radiator, belt drive pulley, and timing

cover.

Should

it be necessary to replace the timing gears, attention must be given to the end float of both

the camshaft and crankshaft and to the running

clearance

of both gears. It is also advisable to

check

both the oil jet and oil passage to the

crank

shaft front bearing to be sure that they are clear.

D-55.

Inspection and

Repair

Check

the general condition of both gears and

inspect for evidence of excessive wear. Replace

excessively worn or damaged gears. Inspect the

cover and replace if bent or damaged. It is recom mended that the crankshaft oil seal in the cover

be replaced when the cover is removed to ensure a

good

seal around the crankshaft. To replace this

seal

with the

engine

in the vehicle

requires

removing

the radiator and water pump.

D-56.

Valves, Springs, and Guides

The

exhaust valves seat on the top of the cylinder

block

with the

stems

extending down through

replaceable valve guides. The exhaust valves are actuated by the camshaft through exhaust valve

tappets. The exhaust valve springs are assembled

and

locked on the lower end of the exhaust valve

stems. The retaining locks are the split type, which

fit in a recess on the valve

stems

and into the taper

in

the valve spring retainers.

Adjustment

of exhaust valves is by means of the

adjusting

screw threaded into the upper end of the

exhaust valve tappets. An exhaust valve rotator used as a valve spring retainer is installed on the

lower end of the exhaust valve.

This

valve rotator,

known

as "Roto Cap", is a spring-loaded

ball

bearing

device. On each lift, or opening stroke of

a

valve, the rotator

gives

the valve a slight positive

clockwise rotation.

The

intake valves operate in valve

guides

in the

cylinder

head and are actuated by rocker arms.

The

rocker arms are actuated by valve push rods

and

the intake valve tappets. The intake valve

springs,

the intake valve spring retainers, and the

intake

valve spring retainer locks make up the

remainder

of the valve operating parts. An intake

valve spring retainer oil seal which encircles the

upper

end of the intake valve

between

the valve

locks and the upper end of the valve spring re

tainer,

controls the passage of oil along the valve

stem and guide.

Note:

When

engine

trouble indicates defective

valves as a possible source of trouble, also check

all

vacuum line connections for possible leaks.

D-57.

Inspection of Valves, Springs,

and

Guides

Clean

the valves on a wire wheel, making sure that

all

carbon is removed from the top and the under

side of the heads and that all gum and varnish

deposits

are removed from the stems.

Polish

the valve

stems

with steel wool or crocus

cloth.

Visually

inspect all valves for warpage,

cracks,

or excessive burning and discard if one of

these

conditions exists. Replace any worn, pitted,

or

corroded valves that cannot be cleaned with a

wire

brush.

Replace any valves when

seats

are pitted, burned, or corroded so badly that they

cannot be cleaned up with a light refacing on a valve refacing machine.

Replace

valves with marks of scoring or abrasion visible on the stem. Replace any valves with bent

stems

which

will

be apparent when the valve is

mounted in the valve refacing machine.

Note:

Use only hard-face exhaust valves for

replacement.

Examine

the

stems

of valves which employ the

ball

bearing rotators.

Wear

marks around the

cir

cumference of the

stems

indicates that the valve is

rotating satisfactorily.

Vertical

heavy pressure

areas

indicate that the valve is not rotating and the valve spring retainer (Roto

Cap)

should be replaced

if

at fault.

Check

the diameter of the valve stem at two or three places along the length of the stem

with

a micrometer. The intake valve stem diameter is .3733" to .3738" [9,482 a

9,495

mm.]. The

exhaust valve stem diameter is .371" to .372"

[9,423

a

9,449

mm.].

Note:

Exhaust

and intake valve springs are

similar

in appearance. They must not be inter

changed as they have different spring

charac

teristics.

Wash

the valve springs thoroughly in solvent.

Visually

examine the springs and replace any that

are

deformed or obviously damaged. Examine for

corrosion

from moisture or acid etching which might

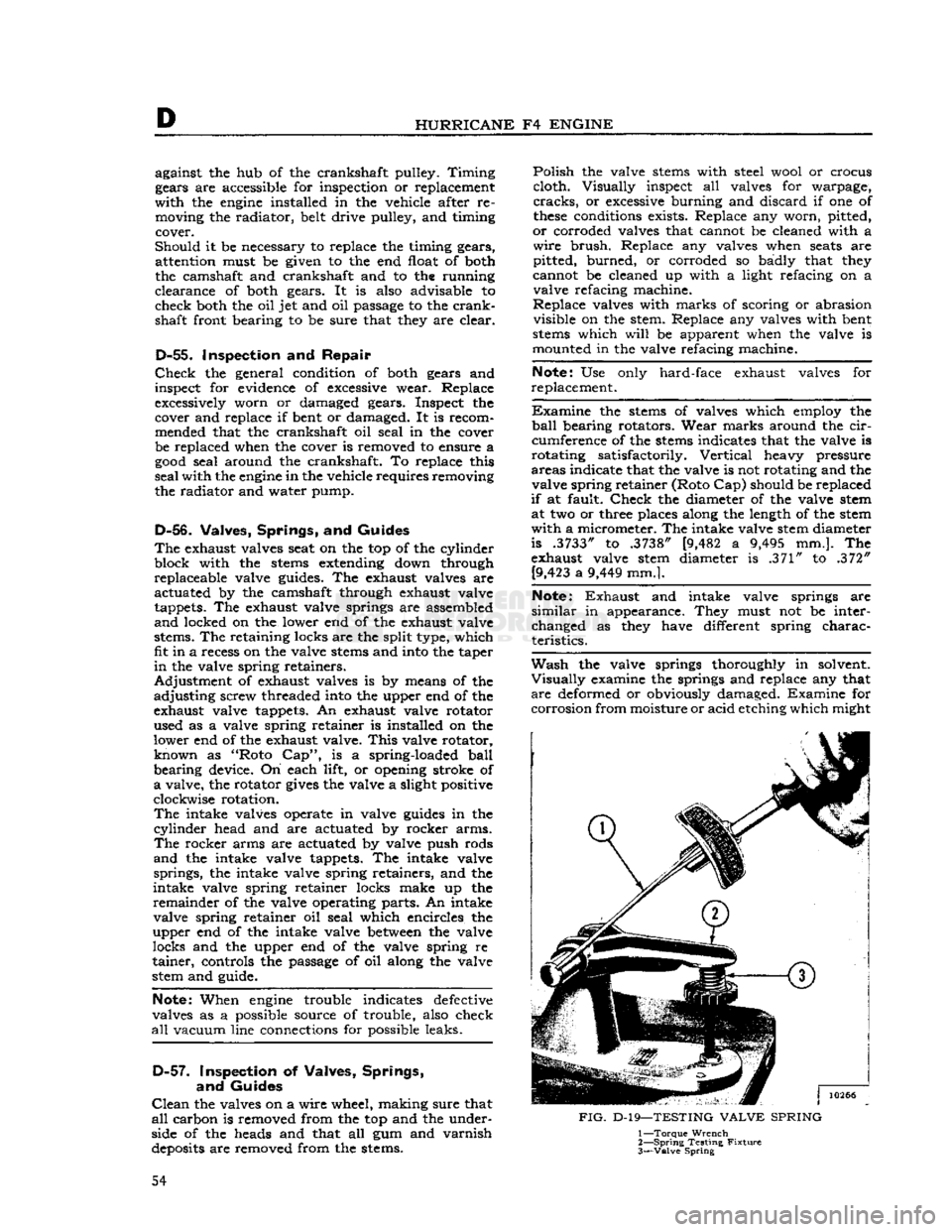

FIG.

D-19—TESTING

VALVE

SPRING

1—

Torque

Wrench

2—

Spring

Testing

Fixture

3—

Valve

Spring

54

Page 59 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

D

10262

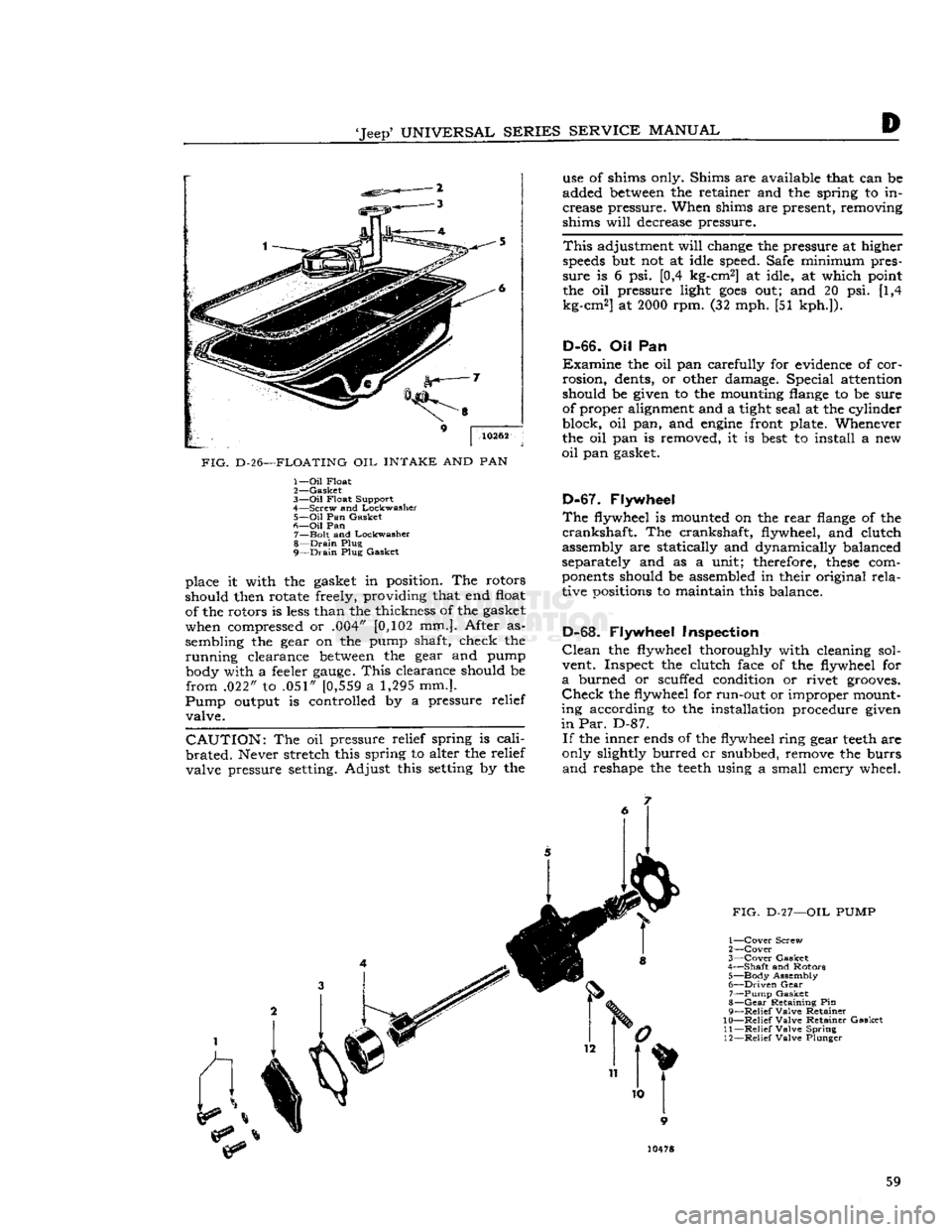

FIG.

D-26—FLOATING OIL INTAKE AND PAN 1—

Oil

Float

2—

Gasket

3—

Oil

Float Support

4—

Screw and Lockwasher 5—

Oil

Pan Gasket

6—

Oil

Pan 7—

Bolt

and Lockwasher

8—

Drain

Plug

9—

Drain

Plug Gasket

place it with the gasket in position. The rotors

should then rotate freely, providing that end float of the rotors is

less

than the thickness of the gasket

when compressed or .004" [0,102 mm.]. After as

sembling the gear on the pump shaft, check the

running

clearance

between

the gear and pump body with a feeler

gauge.

This

clearance should be

from

.022" to .051" [0,559 a 1,295 mm.].

Pump

output is controlled by a pressure relief valve.

CAUTION:

The oil pressure relief spring is

cali

brated.

Never stretch this spring to alter the relief valve pressure setting. Adjust this setting by the use of shims only. Shims are available that can be

added

between

the retainer and the spring to in

crease pressure. When shims are present, removing

shims

will

decrease pressure.

This

adjustment

will

change the pressure at higher

speeds

but not at idle speed. Safe minimum pres

sure

is 6 psi. [0,4 kg-cm2] at idle, at which point

the oil pressure light

goes

out; and 20 psi. [1,4

kg-cm2] at

2000

rpm. (32 mph. [51 kph.]).

D-66.

Oil Pan

Examine

the oil pan carefully for evidence of cor

rosion,

dents, or other damage. Special attention

should be given to the mounting flange to be sure of proper alignment and a tight seal at the cylinder

block, oil pan, and

engine

front plate. Whenever

the oil pan is removed, it is

best

to install a new

oil

pan gasket.

D-67.

Flywheel

The

flywheel is mounted on the

rear

flange of the

crankshaft.

The crankshaft, flywheel, and clutch

assembly are statically and dynamically balanced

separately and as a unit; therefore,

these

com

ponents

should be assembled in their original

rela

tive positions to maintain this balance.

D-68.

Flywheel Inspection

Clean

the flywheel thoroughly with cleaning sol vent. Inspect the clutch face of the flywheel for

a

burned or scuffed condition or rivet grooves.

Check

the flywheel for run-out or improper mount

ing according to the installation procedure given

in Par.

D-87.

If

the inner ends of the flywheel ring gear

teeth

are

only slightly burred cr snubbed, remove the burrs

and

reshape the

teeth

using a small emery wheel. 59

Page 76 of 376

Dl

DAUNTLESS

V-6

ENGINE

DM.

GENERAL

This

section describes service and repair of the

Dauntless V-6 engine. The

engine

code

number shown in

Fig.

A-4 is provided to identify the Daunt

less

V6-225 engine. The meaning of the coded letters and numbers that are stamped on the right front face of the crankcase, just below the rocker

arm

cover,

between

exhaust manifold ports, is given

below.

Letter

to

Designate

Market

M

—

Military

E

—

Export

D

— Domestic

Letter

to

Designate

Year

Built

N

— 1967

P

— 1968

R

— 1969

S

— 1970

T

— 1971

Letter

to Designate

Engine

and Compression

Ratio

H—V6-225

9.0 to 1

C.R.

(2 Bbl.

Carb.)

Y—V6-225

9.0 to 1

C.R.

Marine

(Low

Profile)

(2

Bbl.Carb.)

Z—V6-225

9.0 to 1

C.R.

Marine

(High

Profile)

(2 Bbl.

Carb.)

K—V6-225

7.6 to 1

C.R.

(2 Bbl.

Carb.)

L—V6-225

7.4 to 1

C.R.

(2 Bbl.

Carb.)

Market

Domestic

—

Year

"1967"

Engine

J

Day

Plus Chg. If

Any-

Service Engine "S"

Short

Block

"R" -Oversize Bores "B"

Undersize Crank

&

"A"

Rod

Bearings

The

identifying letter or letters follow the

engine

letters are decoded as follows:

A—.010"

Undersize

Main

and Connecting Rod

Bearings

B—.010"

Oversize Pistons

AB—Combination

of A and B

S—Service

Engine

R—Short

Block

All

disassembly and assembly procedures are pre sented in logical order, assuming a complete

engine

overhaul

with

engine

removed from the vehicle.

However,

many of

these

procedures can also be

performed as on-vehicle services if vehicle or

engine

components are removed to gain access to parts

involved.

Note:

Some

engines

are equipped with an exhaust

emission control system. Service information on

the components of this system is given in sec tion F2.

Dl-2.

ENGINE

DESCRIPTION

The

Dauntless V-6

engine

has a displacement of

225 cubic inches. It has a compression ratio of

9.0 to 1, which permits use of regular-grade

gaso

line.

See

Figs.

Dl-1 and Dl-2.

The

cylinder block is made of cast

iron.

Two banks

of cylinders (three cylinders per bank) are cast at a

90-degree

angle. The lower part of the cylinder-

block

extends

below the centerline of the

crank

shaft, forming a continuous flat surface with the

rear

crankshaft main bearing cap and the timing

chain

cover.

This

design allows installation of an

oil

pan with a

one-piece

gasket. The cylinders in

the left bank (as viewed from the driver's seat) are

numbered

1-3-5,

from front to

rear.

The cylinders

in

the right bank are numbered

2-4-6,

from front

to

rear.

The

crankshaft is supported in the cylinder block

by four steel-backed full-precision bearings, all of

which

have an identical diameter.

Crankshaft

main bearings are numbered 1 to 4, front to

rear.

The

thrust

bearing is flanged to maintain crankshaft position and to compensate against crankshaft end

thrust

The No. 2 bearing is the thrust bearing.

The

crankshaft is counterbalanced by weights,

which

are cast integral with the

crank

cheeks. The

weights

are shaped to a contour which

gives

mini

mum

clearance with cylinder barrels and piston

skirts

to conserve space.

Connecting

rods have I-beam sections with

bosses

on each side. Metal is removed, as required, to secure correct weight and balance. The lower end

of each connecting rod has a steel-backed preci

sion bearing. The piston pin is a press fit into the upper end. The outer ends of the piston pin

are

a slide fit in the piston

bosses.

The

full-skirted, aluminum alloy pistons are cam ground and tin plated. Two compression rings and

one oil control ring are installed above the piston

pin.

The cast iron compression rings in the two

upper

grooves

of the piston have a

groove

or bevel cut around the inner

edge

on one side. The

top compression ring is installed with this

groove

or

bevel up. The lower compression ring is installed

with

bevel down. The oil

ring,

in the lower groove,

consists of two thin steel

rails

separated by a

spacer.

It is backed by a hump-type spring-steel

expander.

V-6

engine

cylinder heads are made of cast

iron.

Their

valve

guides

are cast integrally. Right and left cylinder heads are identical and interchange

able. In service, however, it is

good

practice to

install

the cylinder heads on the side from which

they were removed.

The

valves are in line in each head, at an angle

10°

above the centerline of the cylinder bores.

Each

valve has a spring strong enough to ensure

positive valve seating throughout the operating speed range of the engine. The valve rocker arm

mechanism is protected by a

sheet

metal cover.

This

cover is seated on a raised surface of the

cylinder

head. It is gasketed to prevent oil leaks.

The

rocker arms for each bank of cylinders are mounted on a tubular steel shaft, supported on

the cylinder head by brackets. The rocker arms

are

made of aluminum. They have inserts at the

push

rod socket and the valve stem contact face.

The

camshaft is located above the crankshaft be

tween the two cylinder banks; it is supported in

four steel-backed babbitt-metal bearings. The cam shaft is driven at one-half crankshaft speed by

sprockets and a single outside-guide type chain.

Hydraulic

valve lifters and

one-piece

push rods operate overhead rocker arms and valves of both

banks

of cylinders from a single camshaft.

This

system requires no lash adjustment during assem

bly

or in service.

In

addition to its normal function of a cam follower,

each hydraulic valve lifter also serves as an auto- 76

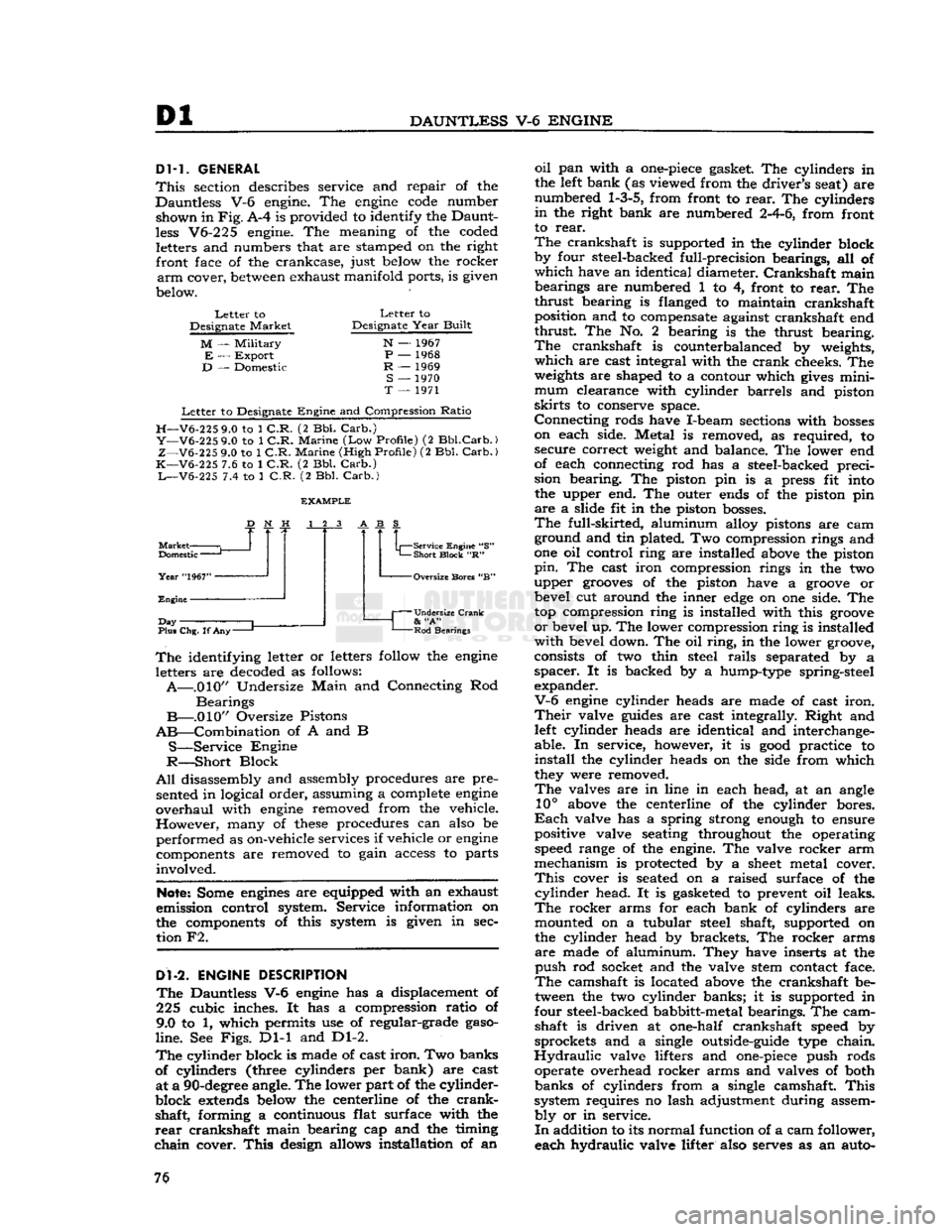

Page 77 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

Dl

©©©©©©©©©

12697

FIG.

Dl-1—DAUNTLESS

V-6

ENGINE, SIDE SECTIONAL VIEW

1—

Fan

Blade

2—

Fan

Spacer

3—Fan

Pulley

4—

Water

Pump 5—

Timing

Chain

Cover

6—

Camshaft

Sprocket

7—

Thermostat

Bypass Hose

8—

Thermostat

Housing

9—

Thermostat

10—

Carburetor

11—

Intake

Manifold

12—

Rocker

Arm Cover 13—

Cylinder

Block 14—

Push

Rod

15—

Camshaft

16—

Flywheel

17—

Clutch

Pressure Plate

18—

Clutch

Driven Plate

19—

Clutch

Pilot Bearing

20—

Oil

Seal Packing

21—

Rear

Main

Bearing Shell

22— Connecting Rods

23—

Rear

Center

Main

Bearing Shell

24—

Oil

Screen

25—

Oil

Screen Pipe and Housing

26—

Oil

Pan 27—

Front

Center

Main

Bearing Shell

28—

Crankshaft

29—

Front

Main

Bearing Shell

30—

Timing

Chain

31—

Crankshaft

Sprocket

32—

Oil

Slinger

33—

Oil

Shedder 34 Oil Shedder Packing

35—

-Woodruff

Key

36—

"Vibration

Damper

37—

Crankshaft

Pulley

38—

Fan

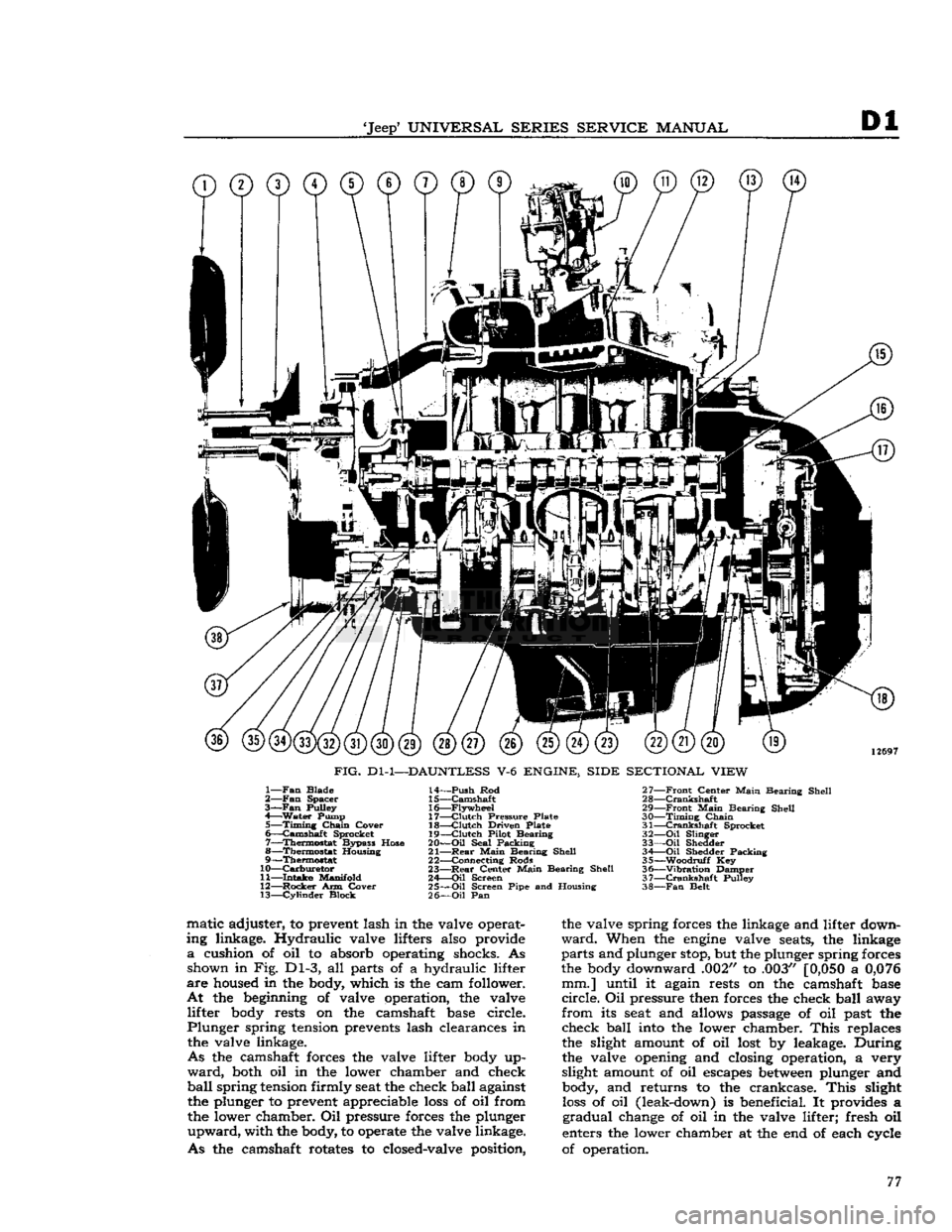

Belt matic adjuster, to prevent lash in the valve operat

ing linkage. Hydraulic valve lifters also provide

a

cushion of oil to absorb operating shocks. As shown in Fig. Dl-3, all parts of a hydraulic lifter

are

housed in the body, which is the cam follower.

At

the beginning of valve operation, the valve lifter body rests on the camshaft base circle.

Plunger

spring tension prevents lash clearances in the valve linkage.

As

the camshaft forces the valve lifter body up

ward,

both oil in the lower chamber and check

ball

spring

tension firmly seat the check ball against the plunger to prevent appreciable

loss

of oil from

the lower chamber. Oil pressure forces the plunger

upward,

with the body, to operate the valve linkage.

As

the camshaft rotates to closed-valve position, the valve spring forces the linkage and lifter down

ward.

When the

engine

valve seats, the linkage

parts

and plunger stop, but the plunger spring forces

the body downward .002" to .003"

[0,050

a

0,076

mm.] until it again rests on the camshaft base

circle.

Oil pressure then forces the check ball away

from

its seat and allows passage of oil past the check ball into the lower chamber.

This

replaces

the slight amount of oil lost by leakage. During

the valve opening and closing operation, a very

slight amount of oil escapes

between

plunger and body, and returns to the crankcase.

This

slight

loss

of oil (leak-down) is beneficial. It provides a

gradual

change of oil in the valve lifter; fresh oil

enters the lower chamber at the end of each cycle

of operation. 77

Page 79 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

Dl

12710

FIG.

D1

-3—HYDRAULIC VALVE

LIFTER

ASSEMBLY, CROSS-SECTIONAL VIEW

1—

Snap

Ring

6—Ball Retainer

2— Rod

Seat

7—Plunger Spring

3—

Oil

Inlets

8—Lifter

Body

4—

Plunger

9—Bronzed

Cap

5— Feed

Hole

sages

in the block and cylinder head.

The

water cooled system is pressurized to provide efficient

engine

cooling. It consists of a centrifugal-

type water pump, mounted on the timing chain cover, and is driven by the

engine

fan pulley. The

pump provides coolant flow equally to both

cylin

der banks under control of a thermostat. Coolant

flow is around the cylinders and through the

cylinder

head to dispel the heat of combustion in

the engine.

Dl-3.

Engine Mounts

The

engine-transmission unit is mounted to the chassis at three points by rubber pads. The two

front mounts are bolted to the

engine

cylinder

block and the frame members. These mounts sup port most of the

engine

weight, and absorb

vibra

tion which would otherwise be caused by changes

in

engine

output torque. The single

rear

mount is

placed

between

the transmission and the trans mission support. It supports part of the engine'

and

transmission weight, and locates the

rear

of

the

engine

with respect to the centerline of the

vehicle.

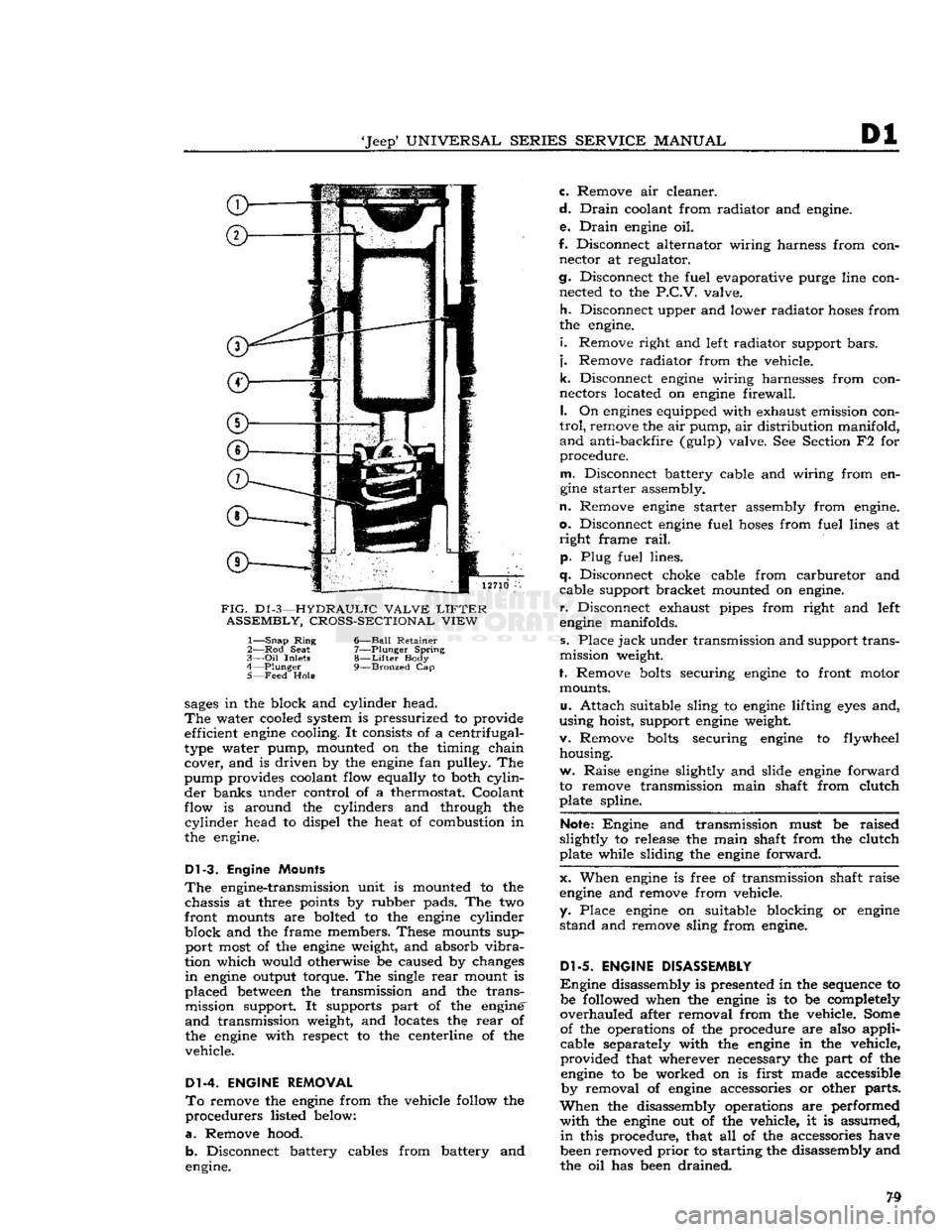

Dl-4. ENGINE REMOVAL

To

remove the

engine

from the vehicle follow the

procedurers listed below:

a.

Remove hood. b. Disconnect battery cables from battery and

engine. c. Remove air cleaner.

d.

Drain

coolant from radiator and engine.

e.

Drain

engine

oil.

f. Disconnect alternator wiring harness from con nector at regulator.

cj.

Disconnect the fuel evaporative purge line con nected to the

P.C.V.

valve.

h.

Disconnect upper and lower radiator

hoses

from

the engine.

i.

Remove right and left radiator support

bars,

j.

Remove radiator from the vehicle.

k.

Disconnect

engine

wiring harnesses from con

nectors located on

engine

firewall.

I.

On

engines

equipped with exhaust emission con

trol,

remove the air pump, air distribution manifold,

and

anti-backfire (gulp) valve. See Section F2 for

procedure.

m.

Disconnect battery cable and wiring from en

gine

starter assembly.

n.

Remove

engine

starter assembly from engine,

o.

Disconnect

engine

fuel

hoses

from fuel lines at

right

frame

rail,

p. Plug fuel lines.

q.

Disconnect choke cable from carburetor and cable support bracket mounted on engine,

r.

Disconnect exhaust pipes from right and left

engine

manifolds.

s. Place

jack

under transmission and support trans

mission weight.

f. Remove

bolts

securing

engine

to front motor mounts.

u.

Attach suitable sling to

engine

lifting

eyes

and,

using hoist, support

engine

weight.

v. Remove

bolts

securing

engine

to flywheel housing.

w. Raise

engine

slightly and slide

engine

forward

to remove transmission main shaft from clutch plate spline.

Note:

Engine and transmission must be raised

slightly to release the main shaft from the clutch

plate while sliding the

engine

forward.

x. When

engine

is free of transmission shaft raise

engine

and remove from vehicle,

y. Place

engine

on suitable blocking or

engine

stand and remove sling from engine.

Dl-5.

ENGINE DISASSEMBLY

Engine

disassembly is presented in the sequence to be followed when the

engine

is to be completely

overhauled after removal from the vehicle. Some of the operations of the procedure are also applicable separately with the

engine

in the vehicle,

provided that wherever necessary the part of the

engine

to be worked on is first made accessible by removal of

engine

accessories or other parts.

When

the disassembly operations are performed

with

the

engine

out of the vehicle, it is assumed,

in

this procedure, that all of the accessories have

been removed

prior

to starting the disassembly and

the oil has been drained.

Page 86 of 376

Dl

DAUNTLESS

V-6

ENGINE

Dl-38.

Crankshaft

Cleaning

Clean

the crankshaft thoroughly with a suitable

cleaning solvent.

Clean

drilled oil

passages

in its

journals

with a small rifle brush to remove all

sludge

or gum deposits; dry

passages

with com

pressed air.

Dl-39.

Crankshaft

Inspection

and

Repair

If

the crankshaft has not

been

removed from the

cylinder

block for inspection, disconnect two con necting rods at a time from crankshaft. Inspect

the bearings and crankpin journals. While turning

crankshaft,

it is necessary to temporarily reconnect

the rods to crankshaft to avoid possibility of dam aging the journals through contact with uncon

nected rods.

Inspect the crankpins visually for excessive or ir

regular

wear, and for scoring. Use an

outside

micrometer to check crankpins for out-of-round.

Standard

crankpin

diameter is

2.0000"

[5,080

cm.].

If

crankpins are more than .0015"

[0,0381

mm.]

out-of-round, new bearings cannot be

expected

to

have satisfactory life.

If

the crankshaft has

been

removed from the

cyl

inder

block for inspection support it on V-blocks

at its main bearing journals 1 and 4. Inspect the

main

bearing journals visually for excessive or ir

regular

wear, and for scoring. Standard main bear

ing

journal

diameter is 2.4995"

[6,349

cm.].

Total

indicator readings at each

journal

should not ex

ceed .003"

[0,076

mm.].

Check

run out at all four journals and

note

high

spot

(maximum eccentricity) of each

journal.

High

spot

of each

journal

should

come

at the same

angular

location. If high

spots

do not coincide,

crankshaft

is misaligned and unsatisfactory for

service.

If

crankpin or main bearing journals are scored,

ridged, or out-of-round, the crankshaft must be replaced or reground to a standard undersize bear

ing diameter to ensure satisfactory life of bearings. Slight roughness can be removed with a fine grit

polishing cloth thoroughly

wetted

with

engine

oil.

Burrs

can

be

honed with a fine oil

stone,

so long as

bearing clearances

will

remain within specified

limits.

Dl-40.

Crankshaft

Main

Bearings

A

crankshaft bearing consists of two halves which

are

neither alike nor interchangeable. One half is

carried

in the corresponding main bearing cap; the

other half is located

between

the crankshaft and

cylinder

block. The upper (cylinder block) half

of the bearing is grooved to supply oil to the con necting rod bearings, while the lower (bearing cap)

half

of the bearing is not grooved. The two bearing

halves must not be interchanged. All crankshaft

bearings

except

the thrust bearing and the

rear

main

bearing are identical. The thrust bearing (No. 2) is longer and it is flanged to take

crank

shaft end thrust. When the bearing halves are

placed in cylinder block and bearing cap, the

ends

extend slightly beyond the parting surfaces. When

cap

bolts

are tightened, the halves are clamped

tightly in place to ensure positive seating and to

prevent turning. The

ends

of bearing halves must never be filed flush with parting surface of

crank

case or bearing cap.

Crankshaft

bearings are the precision type which

do not require reaming to size or other fitting.

Shims

are not provided for adjustment since worn

bearings are readily replaced with new bearings of proper size. Bearings for service replacement are

furnished

in standard size and undersizes. Under no circumstances should crankshaft bearing caps

be filed to adjust for wear in old bearings.

Dl-41.

Crankshaft

Main

Bearing

Cleaning

and

Inspection

Clean

main bearing surfaces. Inspect the bearings

visually

for excessive or uneven wear, scoring, and

flaking.

Visibly worn or damaged bearings must

be replaced. It is necessary to check

radial

clear ance of each new or used crankshaft main bearing

before installation.

This

can be

done

by either of two methods, which are described in

Pars.

Dl-42

and

Dl-43.

a.

The desired

radial

clearance of a new bearing

is .0005" to .0021"

[0,0127

a

0,0534

mm.].

b. Replacement bearings are furnished in standard

size, and in several undersizes, including undersizes

for reground journals. If a new bearing is to be installed, try a standard size; then try each under

size in turn until one is found that

meets

the

specified clearance limits.

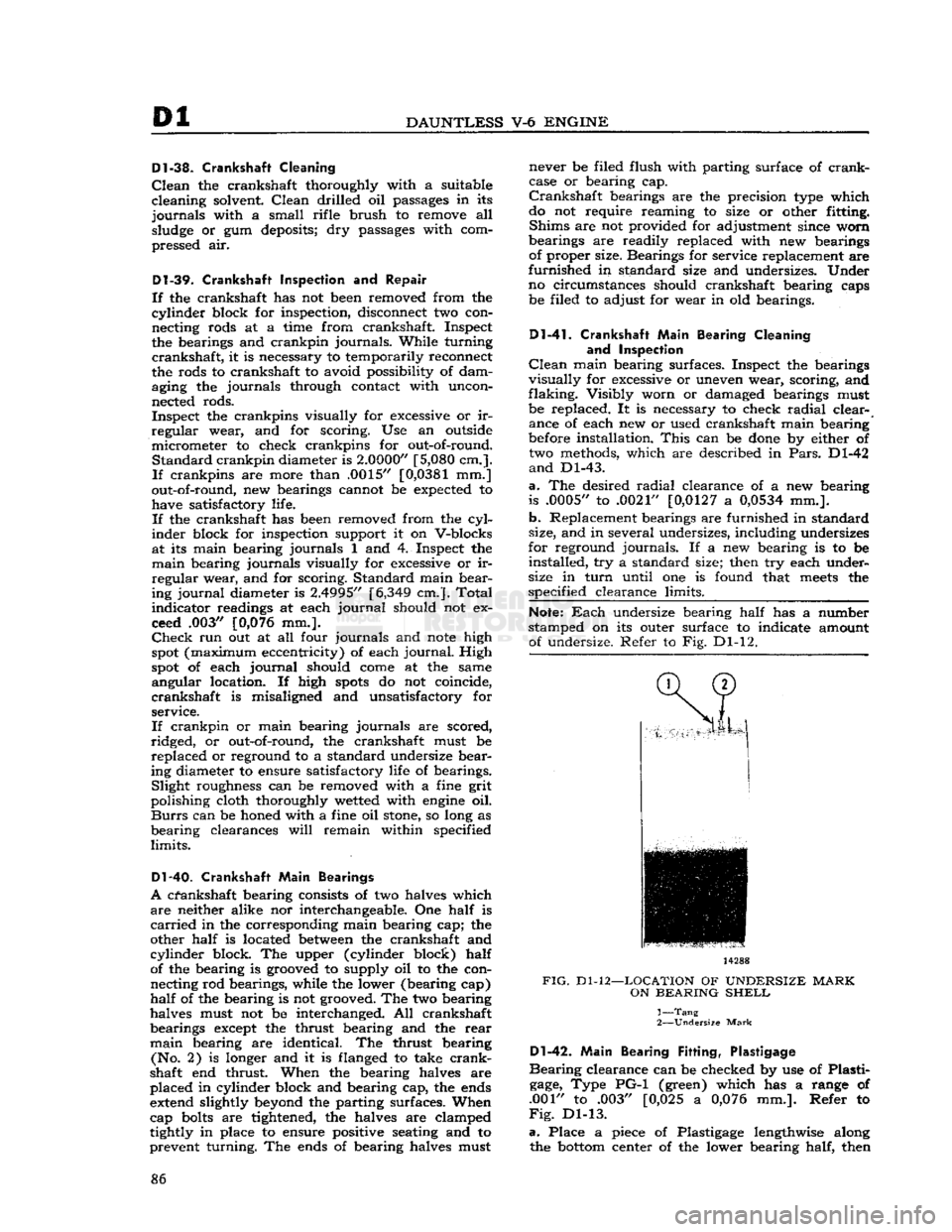

Note:

Each

undersize bearing half has a number

stamped on its outer surface to indicate amount of undersize. Refer to Fig. Dl-12. 14288

FIG.

Dl-12—LOCATION

OF

UNDERSIZE

MARK

ON

BEARING

SHELL

1—

Tang

2—

Undersize

Mark

Dl-42.

Main

Bearing

Fitting,

Plastigage

Bearing

clearance can be checked by use of Plasti

gage,

Type PG-1 (green) which has a range of

.001" to .003" [0,025 a

0,076

mm.]. Refer to

Fig.

Dl-13.

a.

Place a piece of Plastigage lengthwise along the

bottom

center of the lower bearing half, then 86

Page 90 of 376

DAUNTLESS

V-6

ENGINE

Note:

The rib on

edge

of cap and the conical

boss

on web of connecting rod must be toward

rear

of

engine

in all connecting rod assemblies of left

cyl

inder

bank and toward front of

engine

in all connecting rod assemblies of right cylinder bank.

Dl-50.

Oil

Pump Intake

and

Screen Cleaning

a.

Pry screen from housing and examine for clog

ging due to deposit of sludge or other foreign

material.

b.

Clean

the screen and housing thoroughly in sol

vent; dry with compressed air.

c.

Install

screen in housing.

Dl-51.

Oil Pan Cleaning and Inspection

Inspect

the oil pan for corrosion, dents, leaks, and

other damage. Inspect its mounting flange carefully

for damage or distortion to be certain that it

will

give

a

good

seal.

Dl-52.

Flywheel Cleaning

and

Inspection

Clean

the flywheel with suitable cleaning solvent;

dry

with compressed air. Inspect clutch face for

burned

or scuffed condition and for rivet grooves.

Inspection

for run out or improper mounting is de

scribed

in installation procedure.

Inspect

teeth

of the flywheel

ring

gear for

burrs,

nicks,

and minor distortion. If necessary and pos

sible, use a small emery wheel to remove

burrs

and

reshape teeth. If gear

teeth

are broken,

cracked,

seriously

burred

or deformed, the

ring

gear must be replaced.

Dl-53.

Ring Gear Replacement

a.

Drill

a

hole

between

two

ring

gear teeth; then

split

the gear with a cold chisel. Be careful not to

damage

ring

gear shoulder or seat surfaces of fly

wheel.

b.

Polish several

spots

on the new

ring

gear to be

installed.

With

a hot plate or slowly moving torch,

heat the new

ring

gear until polished

spots

become

blue, about

600°F.

[312°C.].

Caution:

Do not heat the

ring

gear to a temperature

greater than

800°F.

[424°C.].

Excessive heat

will

destroy heat treatment given to

ring

gear during

manufacture.

c.

Quickly

install

ring

gear on flywheel. Chamfered

edge

of

ring

gear must be toward

ring

gear shoulder

of flywheel. Be certain that

ring

gear is seated prop

erly.

Allow

ring

gear to cool slowly, so that it

will

be held tightly in place.

Dl-54.

Flywheel Housing Cleaning and Inspection

Both

flywheel and clutch are enclosed by a fly

wheel housing. Its front surface is bolted to the

engine

cylinder block, and its

rear

surface acts as

front

support to the transmission.

Clean

the fly wheel housing with a suitable cleaning solvent; dry

with

compressed air. Inspect front and

rear

surfaces

for distortion and improper alignment with each

other;

these

planes must be

parallel

to assure

proper

alignment

between

engine

and transmission.

Dl-55.

Camshaft Cleaning

and

Inspection

Clean

both camshaft and camshaft bearing surfaces

with

a suitable cleaning solvent; dry with com

pressed air.

Note:

The steel-backed babbitt-lined camshaft

bearings are pressed into the crankcase.

From

front

to

rear,

each bearing is .030" [0,76 mm.] smaller

in

diameter than the preceding bearing.

From

front

to

rear,

each camshaft

journal

is correspondingly

smaller

in diameter.

The

camshaft bearings must be line reamed to

proper

diameter after being pressed into crankcase.

Since

this operation requires special reaming equip

ment, the original bearings should be retained un

less

they are severly damaged. Slightly scored cam

shaft bearings are satisfactory if the surfaces of camshaft journals are polished, bearings are

polished to remove

burrs,

and

radial

clearance

between

camshaft and bearings is within .0015"

to .004" [0,038 a 0,102 mm.].

Dl-56.

Valve Lifter

and

Push

Rod

Cleaning and Inspection

a.

Examine the cam contact surface at lower end of each valve lifter body. If surface is excessively

worn,

galled, or otherwise damaged, discard the

valve lifter. Also examine the mating camshaft

lobe

for excessive wear or damage.

b.

Disassemble one or two valve lifters, as de

scribed

below, and inspect them for

dirt

or

varnish.

If

they are dirty or have a varnish deposit, clean

and

inspect all twelve valve lifters. Otherwise,

service

only

those

valve lifters which do not operate

properly.

c.

To disassemble each valve lifter, depress the

push

rod seat with a push rod, and remove the

plunger retainer from the valve lifter body with

a

retainer remover. Remove push rod seat and

plunger from valve lifter body. If plunger sticks

in

valve lifter body, place body in large end of

a

plunger remover tool, with plunger downward.

While

holding lifter with thumb, rap the open end

of remover against a block of wood with just enough force to jar the plunger from body. Refer to

Figs.

Dl-20, Dl-22 and Dl-23.

d.

Drain

oil from valve lifter and remove the check

valve retainer,

ball,

valve spring, and plunger

spring.

e. Keep all parts of each valve lifter separated

during

part cleaning and inspection. The valve

lifter

body and plunger are selectively fitted to each other and must not be interchanged with parts

of other valve lifters.

f. Rinse all valve lifter parts in kerosene to remove as much oil as possible.

This

will

reduce contamina

tion of the cleaning solvent. Immerse all parts in cleaning solvent for approximately one hour. The

time required

will

depend on varnish

deposits

and

effectiveness

of the solvent. After the varnish has

dissolved or has

softened

sufficiently to permit re

moval

by wiping, allow parts to

drain.

Varnish

can

then be cleaned from the valve lifter body

with

a

brush.

Rinse the parts in kerosene to dissolve 90