clutch JEEP DJ 1953 Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: DJ, Model: JEEP DJ 1953Pages: 376, PDF Size: 19.96 MB

Page 271 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

K

the

bottom.

Remove

rear

bearing

cone

and roller

assembly from the shaft by striking the end of the

shaft lightly against a

wooden

block,

j.

Remove the set screw in sliding gear shift fork.

Remove shift rod.

See the following paragraphs for disassembly of

the front and

rear

bearing caps.

K-4.

Front

Bearing Cap Disassembly

•

Refer to Fig. K-1, K-2.

The

front bearing cap is a separate assembly which

may

be removed for service. Should difficulty be

experienced in this section of the transfer case,

follow

the

sequence

below

for removal and dis assembly.

a.

Remove the output shaft yoke as outlined in

Par. K-3.

Remove the

poppet

balls and

move

the

front wheel drive shift rod forward as outlined in

Par.

K-3f.

b.

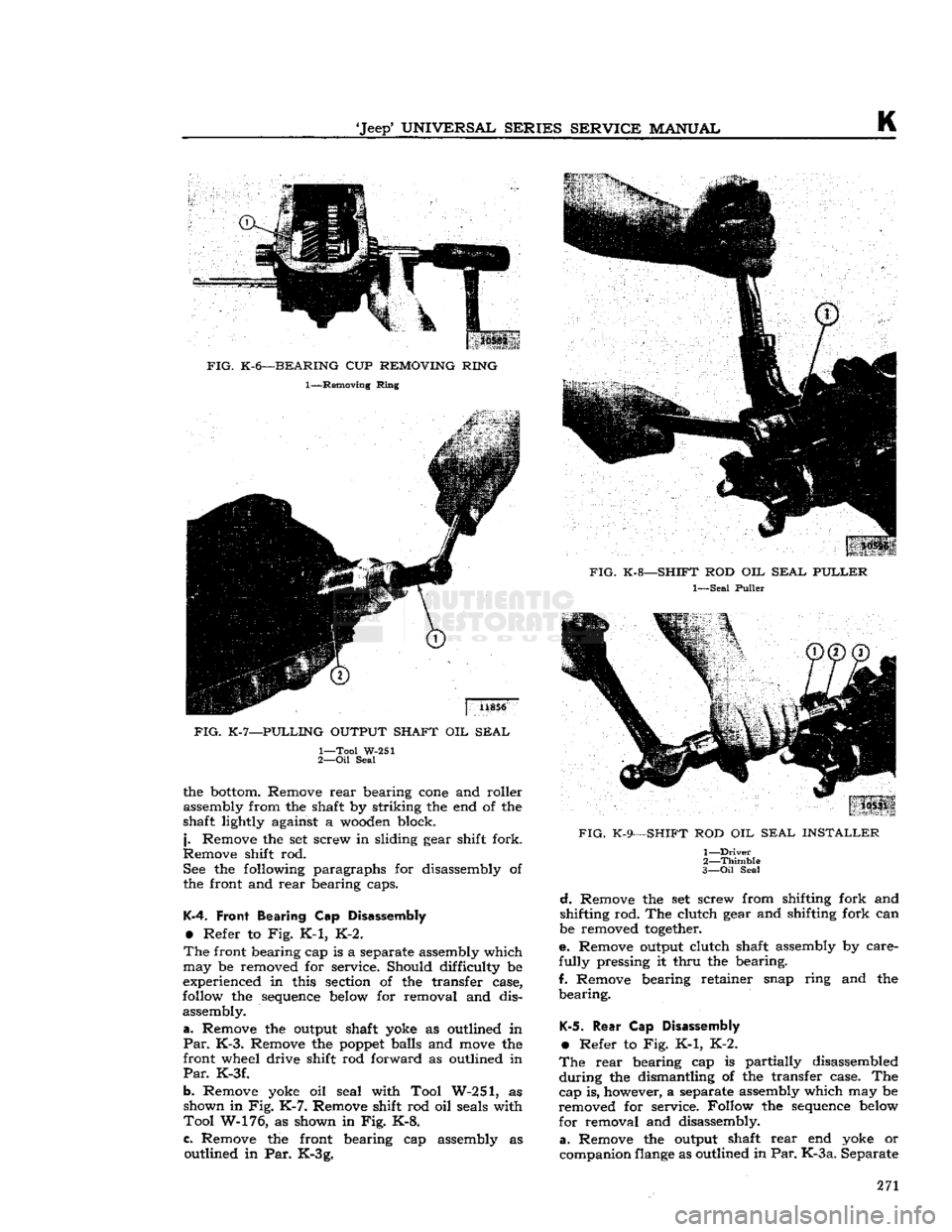

Remove yoke oil seal with Tool W-251, as shown in Fig.

K-7.

Remove shift rod oil seals with

Tool

W-176, as shown in Fig. K-8.

c.

Remove the front bearing cap assembly as outlined in Par. K-3g.

FIG.

K-9—SHIFT

ROD OIL

SEAL INSTALLER

1—

Driver

2—

Thimble

3— Oil

Seal

d.

Remove the set screw from shifting fork and

shifting rod. The clutch gear and shifting fork can

be removed

together.

e. Remove output clutch shaft assembly by care

fully

pressing it

thru

the bearing.

f. Remove bearing retainer snap ring and the

bearing.

K-5.

Rear

Cap Disassembly

•

Refer to Fig. K-1, K-2.

The

rear

bearing cap is partially disassembled

during

the dismantling of the transfer case. The

cap is, however, a separate assembly which may be

removed for service. Follow the

sequence

below

for removal and disassembly,

a.

Remove the output shaft

rear

end yoke or

companion

flange

as outlined in

Par. K-3 a.

Separate 271

Page 273 of 376

![JEEP DJ 1953 Repair Manual

Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

K

ment, the shaft should have .004" to .008"

[0,102

a

0,203

mm.] end play. Adjustment is made by

selective

shim installation

between

the cap an JEEP DJ 1953 Repair Manual

Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

K

ment, the shaft should have .004" to .008"

[0,102

a

0,203

mm.] end play. Adjustment is made by

selective

shim installation

between

the cap an](/img/16/57041/w960_57041-272.png)

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

K

ment, the shaft should have .004" to .008"

[0,102

a

0,203

mm.] end play. Adjustment is made by

selective

shim installation

between

the cap and the

case. Shims .003", .010" and .031" [0,076,

0,254,

0,787

mm.] in thickness are available for this ad

justment. Do not install the rear cap oil seal until

the bearings are correctly adjusted. Both the front

and

rear oil seals may be installed with oil seal

driver

Tool W-143, shown in Fig. K-12.

When

installing the end yokes on the output shafts,

inspect for the presence of

felt

seals in each oil

seal guard. (The oil seal guard is a part of each

yoke assembly.) Felt seals should be installed in the oil seal guards if

they

are not present. When

installing the shift

rail

oil seals in the front bear

ing cap, it is necessary to protect the seals against

damage when passing over the shift

rail

notches.

Protect them with the thimble, and install them with the driver, Tool W-130, shown in Fig. K-9.

K-7.

Transfer Case Installation

The

installation of the assembly in the vehicle is

the reverse of the removal operation covered in

Par.

K-2.

If

the transmission was removed from the vehicle,

lubricate the pilot bearing and also lubricate the

transmission and transfer case as outlined in the

"Lubrication

Section". Be sure that the clutch pedal has %"

[19,05

mm.] free travel as outlined

in

the

"Clutch

Section".

K-8.

Transfer Case Linkage Adjustment

Adjust

the link to provide

xh"

[12,7 mm.] clear

ance

between

the floor pan and the shift lever

bend when operating in four wheel drive low

position. Refer to Fig. K-4.

K-3.

TRENSFER

CESE

SERVICE

DIAGNOSIS

SYMPTOMS PROBABLE REMEDY

Slips

Out of

Gear (High-Low)

Shifting

Lock

Spring Weak Replace Spring

Bearing

Broken or Worn Replace

Shifting

Fork

Bent Replace

Slips

Out of

Front Wheel Drive

Shifting

Lock

Spring Weak. Replace

Bearing

Worn or Broken Replace

End

Play in Shaft. . . ..... Adjust Shifting

Fork

Bent.. Replace

Hard Shifting

Lack

of

Lubricant

Drain

and

Refill

Shift

Lever

Stuck on Shaft Remove, Clean and Lubricate

Shifting

Lock

Ball

Scored Replace

Ball

Shifting

Fork

Bent Replace

Fork

Low

Tire

Pressure Inflate

Grease Leak

at

Front

or

Rear Drive

Grease

Leak

at Covers. Install New Gaskets

Grease

Leak

between

Transmission and Transfer Cases Install New Gaskets

Grease

Leak

at Output Shaft Install New Oil Seal

K-10.

TRANSFER

CESE

SPECIFICATIONS

Transfer

Case:

All

Models

Spicer

18

On

Floor

Gear

Ratio: 1.00 to 1

2.46 to 1 273

Page 302 of 376

N

REAR

AXLE a.

Place the transmission in neutral.

b.

Raise one wheel off the floor and place a block

in

front and at the

rear

of the

opposite

wheel.

c.

Apply a torque wrench to the axle shaft nut of

the elevated wheel.

d.

Turn

wheel with torque wrench. Disregard

breakaway

torque and observe torque required to

continuously

turn

wheel smoothly. Torque should

read

40 lb-ft [5,53 kg-m.] or more.

N-23. Powr-Lok

Differential Disassembly

/

and Reassembly

Refer

to

Figs.

N-38 and N-39.

The

procedure for overhauling disc type

Powr-Lok

differentials is as follows:

a.

Remove axle shafts following procedure de

scribed

in Par. N-2.

b.

Remove housing cover and gasket.

c.

Remove the

Powr-Lok

differential from the axle.

Do not remove the ring gear or bearing

cone

and

rollers

unless replacement is to be made.

Mark

the hearing cups so they may later be reassembled

with

the same bearing cones.

Mark

the differential

case halves for correct alignment at reassembly.

Each

pinion mate cross shaft should also be marked

so that each pin cam surface

will

match with the

same

V-ramp

in the case when reassembled.

d.

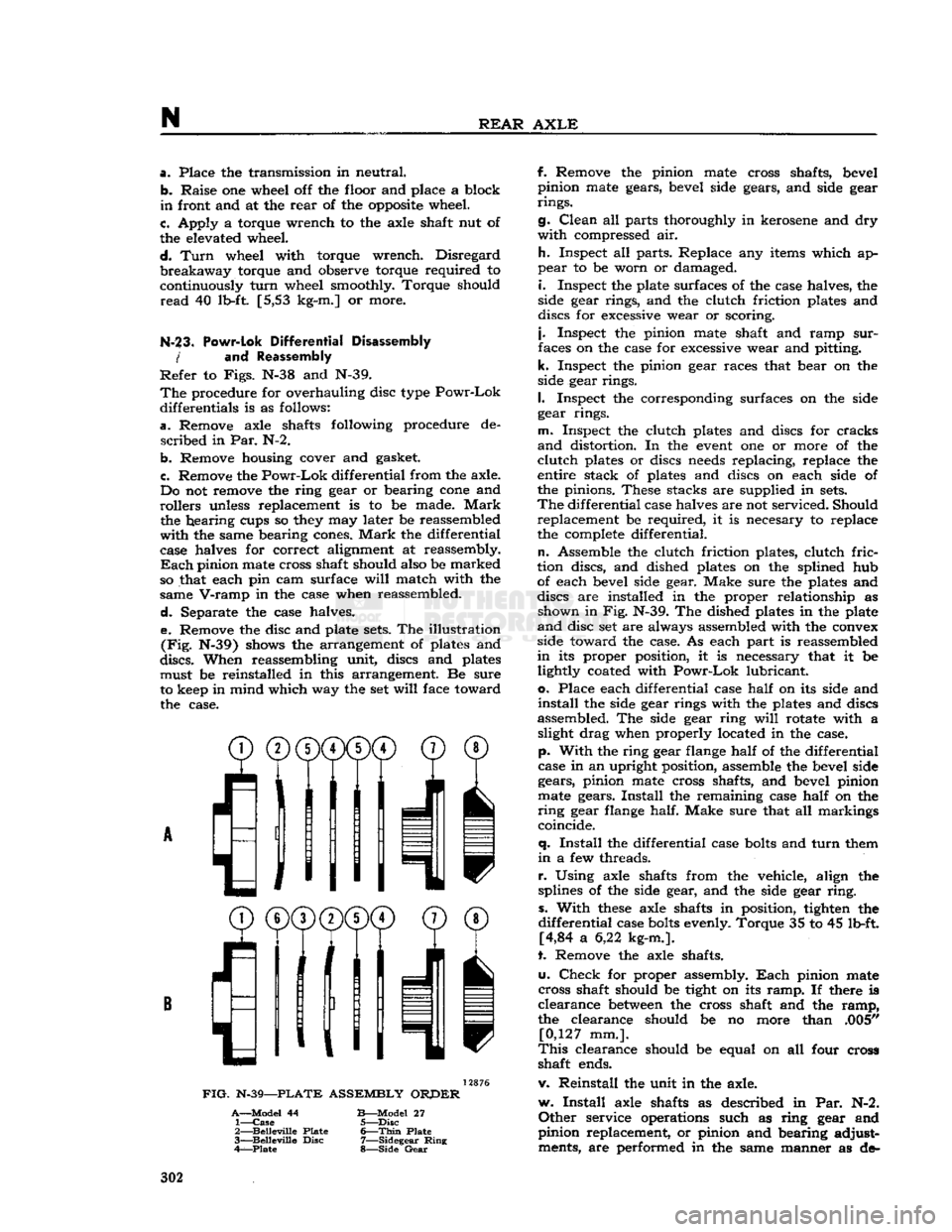

Separate the case halves. e. Remove the disc and plate

sets.

The illustration

(Fig.

N-39) shows the arrangement of plates and

discs.

When reassembling unit, discs and plates must be reinstalled in this arrangement. Be sure

to keep in mind which way the set

will

face toward the case.

^®(j)(j)CD©

® /'Ml

I

11

11 v

FIG.

N-39—PLATE

ASSEMBLY

ORPER

A—Model

44

B—Model

27 1—

Case

5—Disc

2—

Belleville

Plate

6—Thin

Plate

3—

Belleville

Disc

7—Sidegear

Ring

4—Plate

8—Side

Gear

f. Remove the pinion mate cross shafts, bevel

pinion mate gears, bevel side gears, and side gear

rings.

g.

Clean

all parts thoroughly in kerosene and dry

with

compressed air.

h.

Inspect all parts. Replace any items which ap

pear

to be worn or damaged.

i.

Inspect the plate surfaces of the case halves, the

side gear rings, and the clutch friction plates and

discs for excessive wear or scoring.

j.

Inspect the pinion mate shaft and ramp

sur

faces on the case for excessive wear and pitting,

k.

Inspect the pinion gear races that bear on the

side gear rings.

I.

Inspect the corresponding surfaces on the side

gear rings.

m.

Inspect the clutch plates and discs for cracks

and

distortion. In the

event

one or more of the

clutch

plates or discs

needs

replacing, replace the

entire stack of plates and discs on each side of

the pinions. These stacks are supplied in

sets.

The

differential case halves are not serviced. Should replacement be required, it is necesary to replace

the complete differential.

n.

Assemble the clutch friction plates, clutch

fric

tion discs, and dished plates on the splined hub of each bevel side gear. Make sure the plates and

discs are installed in the proper relationship as shown in Fig. N-39. The dished plates in the plate

and

disc set are always assembled with the convex

side toward the case. As each part is reassembled

in

its proper position, it is necessary that it be lightly coated with

Powr-Lok

lubricant,

o.

Place each differential case

half

on its side and

install

the side gear rings with the plates and discs

assembled. The side gear ring

will

rotate with a slight drag when properly located in the case,

p.

With

the ring gear flange

half

of the differential

case in an upright position, assemble the bevel side gears, pinion mate cross shafts, and bevel pinion

mate gears.

Install

the remaining case

half

on the

ring

gear flange half. Make sure that all markings

coincide.

q.

Install

the differential case

bolts

and

turn

them

in

a few threads.

r.

Using axle shafts from the vehicle, align the

splines of the side gear, and the side gear

ring,

s.

With

these

axle shafts in position, tighten the

differential

case

bolts

evenly. Torque 35 to 45 lb-ft. [4,84 a 6,22 kg-m.].

t. Remove the axle shafts.

u.

Check

for proper assembly.

Each

pinion mate

cross shaft should be tight on its

ramp.

If there is

clearance

between

the cross shaft and the

ramp,

the clearance should be no more than .005" [0,127 mm.].

This

clearance should be equal on all four cross

shaft ends.

v. Reinstall the unit in the axle.

w.

Install

axle shafts as described in Par. N-2.

Other

service operations such as ring gear and

pinion replacement, or pinion and bearing adjust ments, are performed in the same manner as de- 302

Page 303 of 376

'Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

N

scribed

in

Pars.

N-ll through N-l9 for standard

axles, with the exception of the following torque

recommendations. Torque the differential case

bearing

cap screws 70 to 90 lb-ft. [9,7 a 12,4 kg-m.]

and

the cover screws 15 to 25 lb-ft. [2,1 a 3,4

kg-m.].

The ring gear screws on axles with Powr-

Lok

differentials should be torqued as follows:

Model

30 and 44 axles 35 to 55 lb-ft. [4,84 a 7,60 kg-m.].

N-24. TRAC-LOK DIFFERENTIAL

As

optional equipment

Trac-Lok

Model 44 differen

tial

is available on all Jeep Universal vehicles equipped with semi-float flanged axle shafts.

A

conventional differential transmits all of the

ring

gear torque through the differential gears to the axle shafts. Torque is at all

times

equal on the axle shafts, and if one wheel slips, the other wheel

can

only put out as much torque as the slipping

wheel.

The

Trac-Lok

differential is similar,

except

that

part

of the torque from the ring gear is trans mitted through clutch packs

between

the side gears

and

differential case. The multiple disc clutches

with

radial

grooves

on the plates and concentric

grooves

on the discs are

engaged

by a preload

from

Belleville springs, plus separating forces from

the side gears as torque is applied through the

ring

gear.

The

Trac-Lok

construction permits differential action when required for turning corners and transmits equal torque to both

wheels

when driving

straight

ahead. However, when one wheel tries to spin due to leaving the ground, a patch of ice,

etc., the clutch packs automatically provide more

torque to the wheel which is not trying to spin.

It

can be

seen

then that the

Trac-Lok

differential

resists wheel spin on bumpy roads and provides

more pulling power when one wheel tries to slip.

In

many cases of differences in traction, pulling

power

will

be automatically provided until both

wheels

start to slip.

In

diagnosis of vehicle operators' complaints, it

is important to recognize two things:

a.

If, with unequal traction, both

wheels

slip, the

Trac-Lok

has

done

all it can possibly do.

b.

In extreme cases of differences in traction, the

wheel with least traction may spin after the

Trac-

Lok

has transferred as much torque as possible

to the non-slipping wheel.

N-25.

Lubrication

The

Trac-Lok

differential requires a special

lubri

cant

and ordinary multipurpose gear lubricants

MUST

NOT be used. Use only 'Jeep* Differential

Oil,

Part

No. 94557.

Trac-Lok

differential may be cleaned only by disassembling the unit and wiping with clean rags. Do not flush the

Trac-Lok

unit.

Note:

The

Trac-Lok

differential is serviced at the

same time intervals as the standard differential.

N-26.

Trouble

Symptoms

If

noises

or roughness, such as chatter, are present

in

turning corners, the probable cause is incorrect

or

contaminated lubricant.

Before any differential is removed and disassem

bled for chatter complaints, the correctness of

lubri

cant

can and should be determined.

A

complete

lubricant

drain,

and

refill

with specified

Limited

Slip Differential lubricant

will

usually

correct

chatter.

The

following procedure is recommended to ensure

complete

removal of old lubricant.

a.

Warm

the lubricant by vehicle road operation,

or

5 minutes of operation in gear at 30 mph with

both

wheels

off the ground on a hoist.

Caution:

Never place the transmission in gear with

the

engine

running when only one wheel of a

Limited

Slip Differential equipped vehicle is raised.

The

vehicle might drive itself off the

jack

and produce damage or

injury.

b.

Drain

lubricant while

warm.

Remove

drain

plug

or

cover to

drain

completely. If cover is removed,

it

may be necessary to replace gasket at this time.

c.

Refill

axle with specified

Limited

Slip Differen

tial

lubricant.

d.

Operate the vehicle for approximately ten miles

[16,09

km.], making at least ten figure 8 turns

to flush the old lubricant out of the clutch packs.

e.

Repeat

steps

b, c, and d, making sure to replace

the cover gasket if required in

step

c.

f. It is possible that slight chatter, requiring ad

ditional

vehicle operation, may remain after

step

e. If chatter persists after 100 miles

[160,9

km.]

of vehicle operation, or remains severe after

step

e above, disassembly and repair

will

be necessary.

N-27.

Unit

Inoperative

Proper

performance and capabilities of

Limited

Slip

Differentials are

often

misunderstood. No

precise

methods

of measuring

Limited

Slip Dif

ferential

performance are generally available in the field. A functioning unit can be determined by

relatively

simple vehicle operational

tests,

as

follows:

a.

Place one wheel on

good

dry pavement, and the

other on ice, mud, grease, etc.

b.

Gradually

increase

engine

rpm to obtain maxi

mum

traction

prior

to "break-a-way." The ability

to

move

the vehicle

effectively

will

demonstrate

proper

performance.

c.

If extremely slick surfaces, such as ice or grease,

are

used

some

question may exist as to proper per

formance at

step

b. In

these

extreme cases a prop

erly

performing

Limited

Slip Differential

will

pro

vide greater "pulling" power by lightly applying

the parking brake.

N-23.

Trac-Lok

Differential Disassembly

and

Reassembly

It

is recommended that the

complete

axle assembly

be removed from the vehicle, when it

becomes

necessary to remove the

Trac-Lok

from the hous

ing.

Refer to Par. N-3 and N-12 for removal of axle shafts and differential case from axle housing. 303

Page 306 of 376

N

REAR

AXLE

FIG.

N-49—REMOVING

PINION

MATE

WASHERS

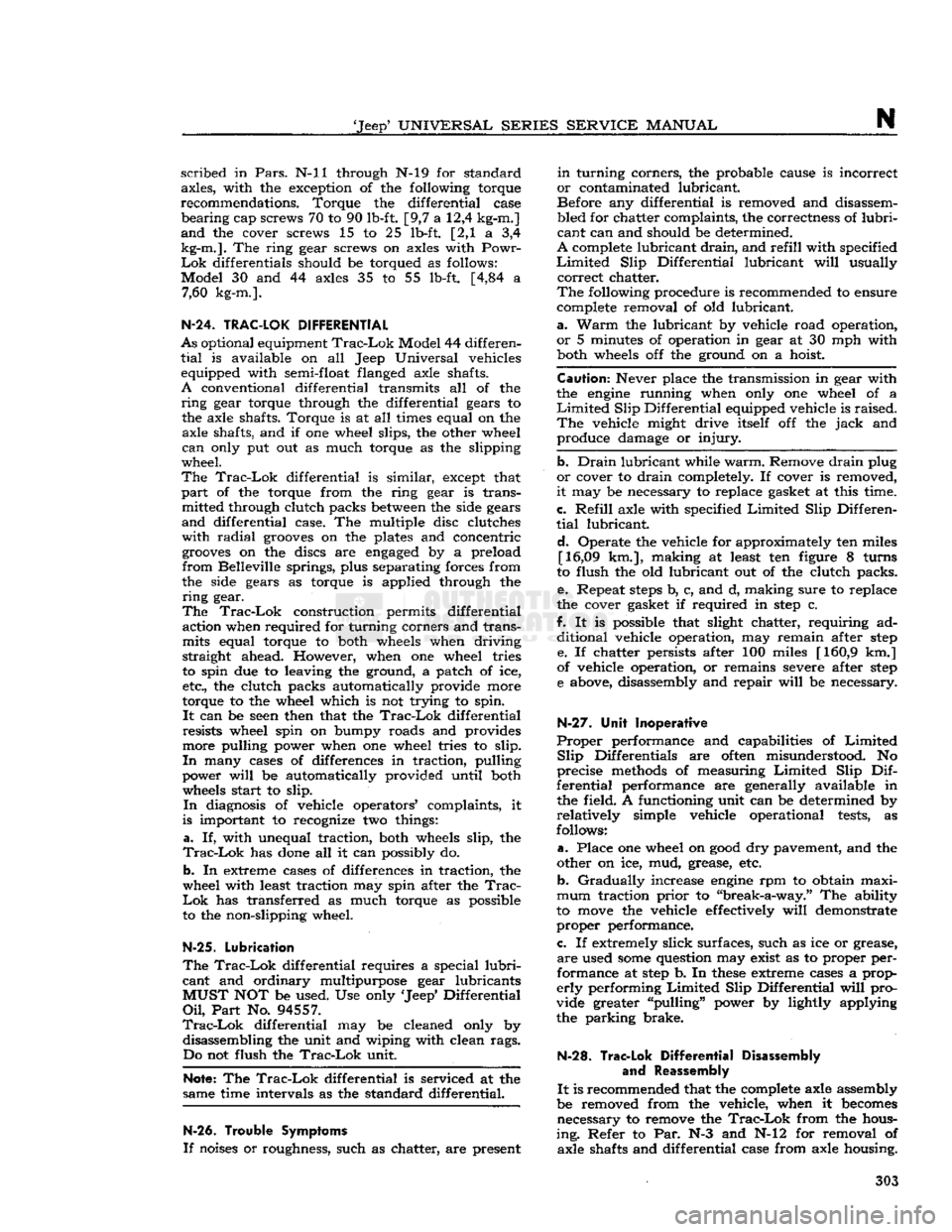

m.

Thread

forcing screw so that it becomes cen

tered into the

step

plate. Torque forcing screw

tight.

This

will

move the side gears away from

the pinion mate gears, and relieve the load between

the gears, allowing only the pinion mate gears to

be

loose.

n.

Remove both pinion mate spherical washers. Use

a

shim stock of .030" [0,762 mm.] thickness or an

equivalent tool to push out the spherical washers.

Relieve

the tension of the Belleville spring by

loose

ning

the forcing screw. Refer to Fig. N-49.

o.

Retighten forcing screw until a very slight move ment of the pinion mate gears is detected.

FIG.

N-50—-REMOVING

PINION

MATE

GEARS

p.

Insert the pawl rotating tool between one of

the side gear

teeth

as shown.

Pull

on handle so

the top side gear

will

rotate and also allow the

pinion mate gears to rotate. Also continue pulling

on tool until the gear hits the handle,

q.

Remove pawl from between the gear

teeth

and

repeat the above until the pinion mate gears can

be removed through the large opening of the case.

Note:

When attempting to rotate the side gear, it

will

probably be necessary to adjust the forcing

screw

by very slightly tightening or loosening until the required load is applied to the Belleville springs

to allow the side gear and pinion mate gears to

rotate. Refer to Fig. N-50.

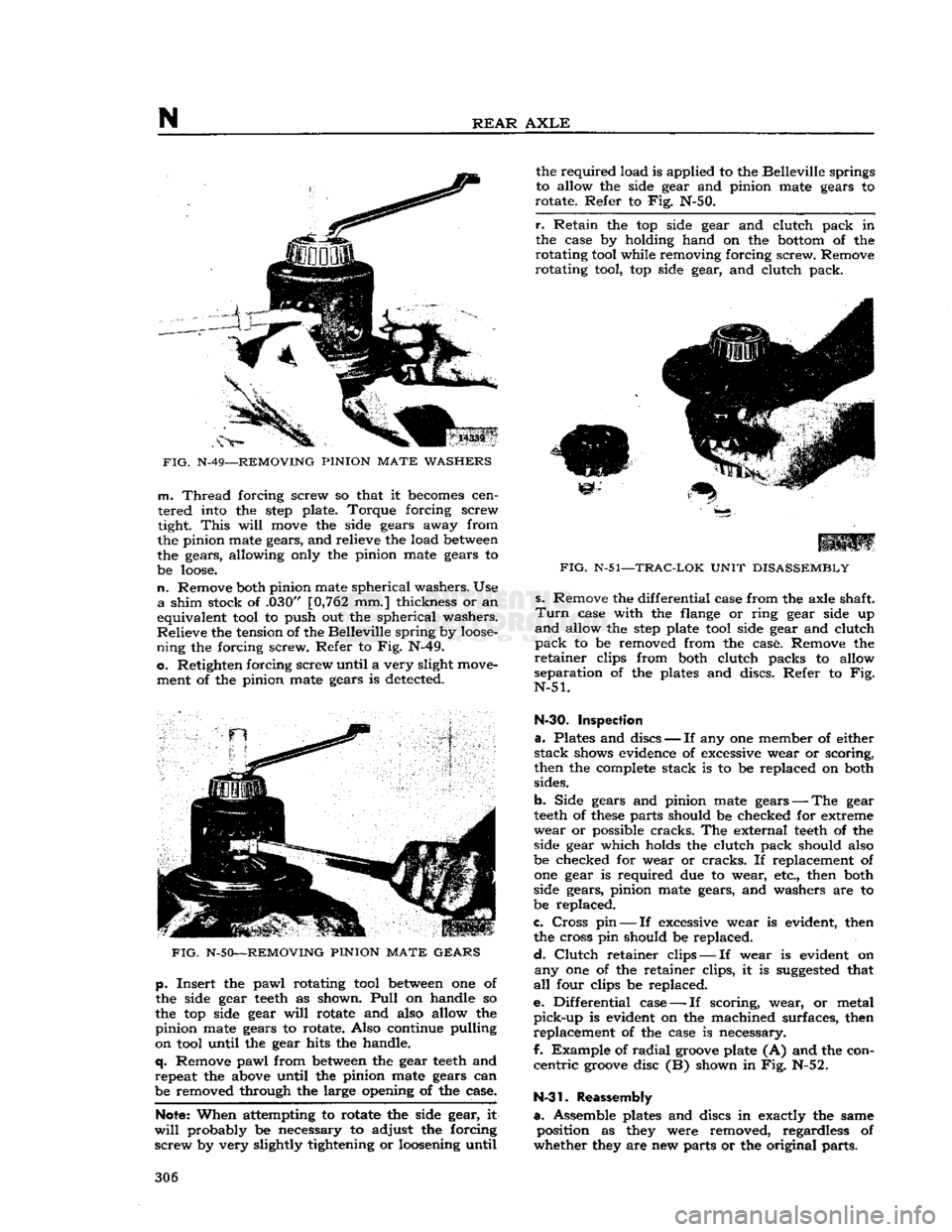

r.

Retain the top side gear and clutch pack in

the case by holding hand on the bottom of the

rotating tool while removing forcing screw. Remove

rotating tool, top side gear, and clutch pack.

FIG.

N-51—-TRAC-LOK

UNIT

DISASSEMBLY

s. Remove the differential case from the axle shaft.

Turn

case with the flange or ring gear side up

and

allow the

step

plate tool side gear and clutch

pack

to be removed from the case. Remove the

retainer

clips from both clutch packs to allow

separation of the plates and discs. Refer to Fig.

N-51.

N-30.

Inspection

a.

Plates and discs —

If

any one member of either

stack

shows evidence of excessive wear or scoring,

then the complete stack is to be replaced on both

sides.

b.

Side gears and pinion mate gears —

The

gear

teeth

of

these

parts should be checked for extreme

wear

or possible

cracks.

The external

teeth

of the side gear which holds the clutch pack should also

be checked for wear or

cracks.

If replacement of one gear is required due to wear, etc., then both

side gears, pinion mate gears, and washers are to

be replaced.

c.

Cross

pin

— If excessive wear is evident, then

the cross pin should be replaced.

d.

Clutch

retainer clips — If wear is evident on

any

one of the retainer clips, it is

suggested

that

all

four clips be replaced.

e. Differential case — If scoring, wear, or metal

pick-up

is evident on the machined surfaces, then replacement of the case is necessary.

I.

Example of

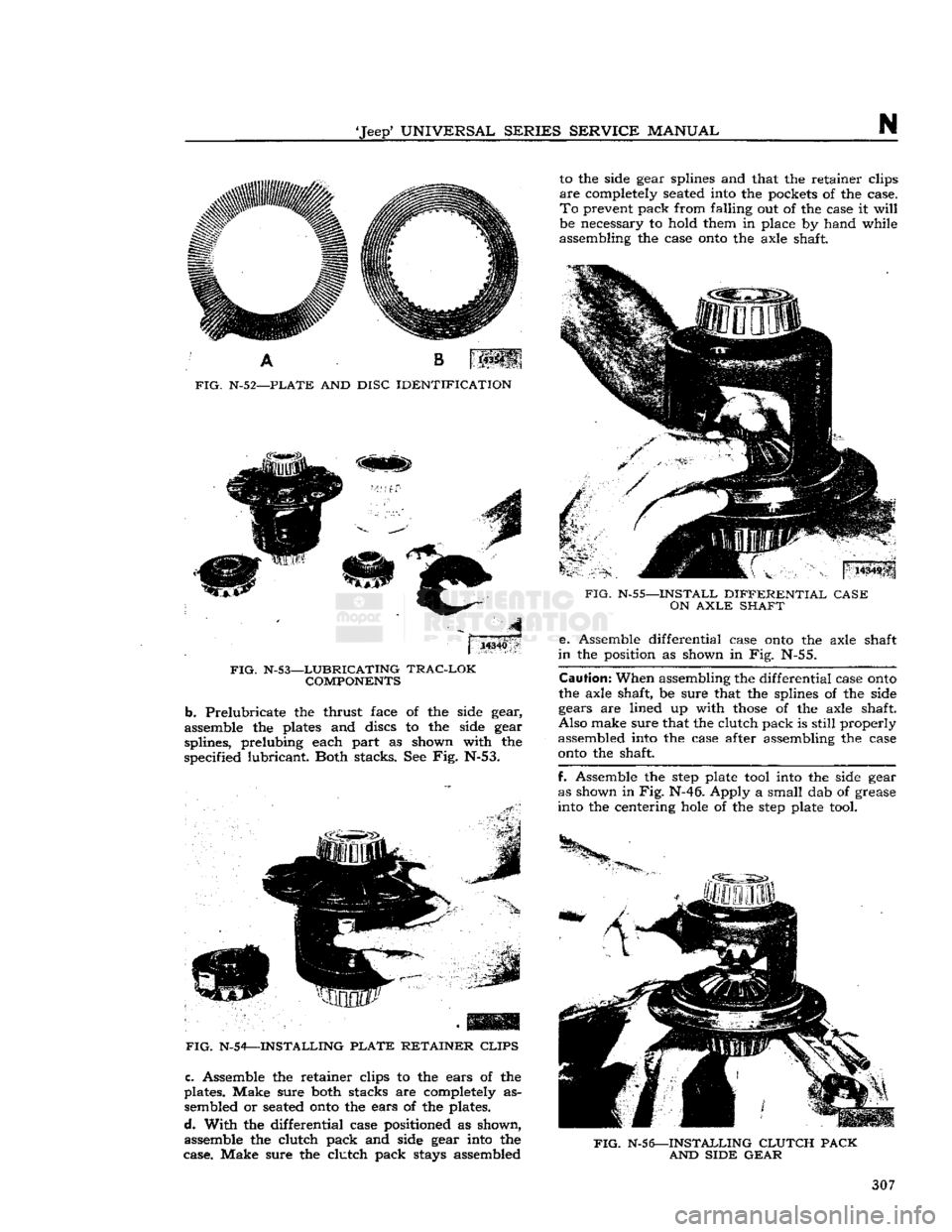

radial

groove plate (A) and the con

centric

groove disc (B) shown in Fig. N-52.

N-31.

Reassembly

a.

Assemble plates and discs in exactly the same position as they were removed, regardless of

whether they are new parts or the original parts. 306

Page 307 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

N

FIG.

N-52—PLATE

AND

DISC

IDENTIFICATION

I 14340

FIG.

N-S3—LUBRICATING

TRAC-LOK

COMPONENTS

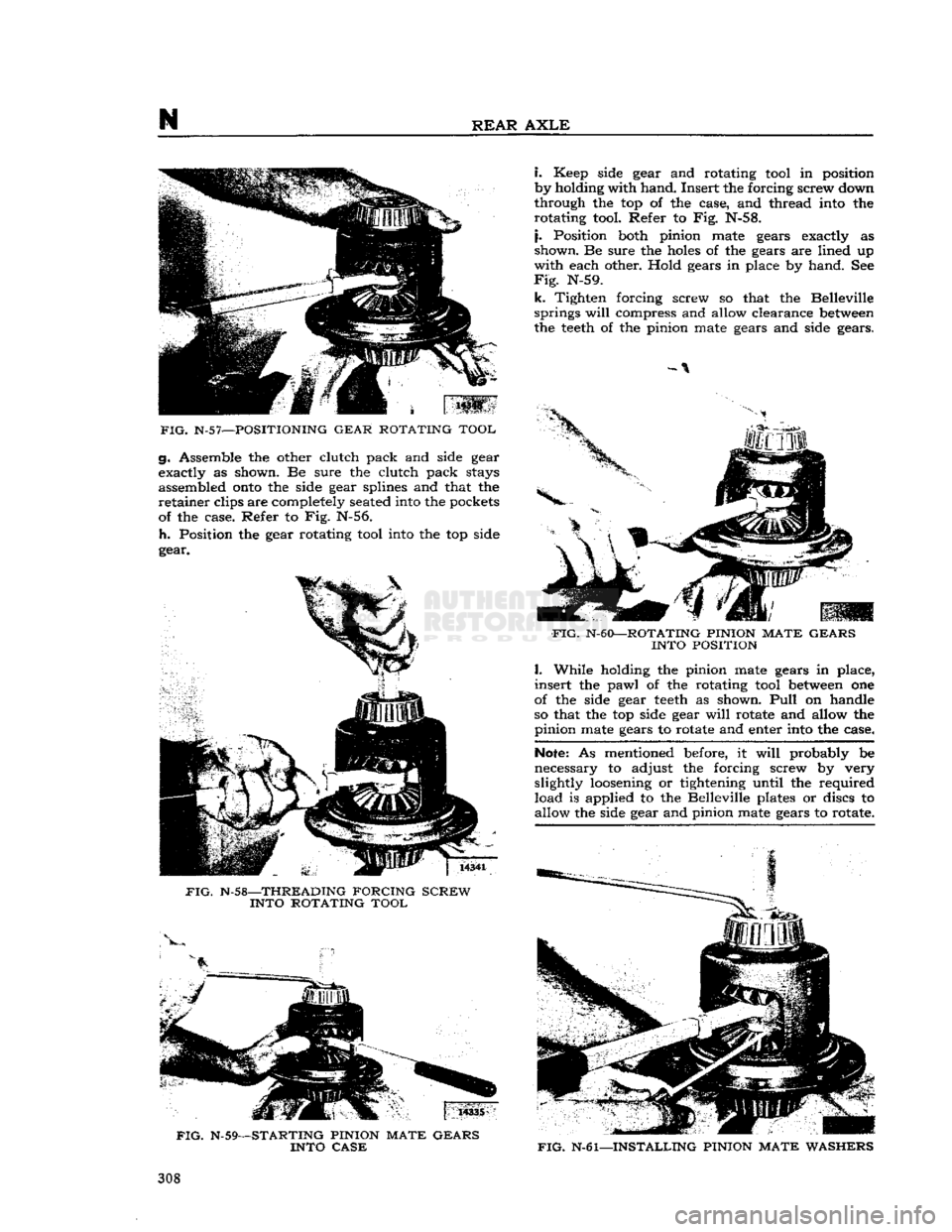

b.

Prelubricate the thrust face of the side

gear,

assemble

the plates and discs to the side

gear

splines, prelubing each part as shown

with

the

specified

lubricant.

Both

stacks. See Fig. N-53.

FIG.

N-54—INSTALLING

PLATE

RETAINER

CLIPS

c. Assemble the retainer clips to the

ears

of the

plates. Make

sure

both

stacks

are completely as sembled or

seated

onto the

ears

of the plates.

d.

With

the

differential

case

positioned as shown,

assemble

the

clutch

pack and side

gear

into

the

case.

Make

sure

the

clutch

pack

stays

assembled

to

the side

gear

splines and that the retainer clips

are completely

seated

into

the pockets of the

case.

To

prevent pack

from

falling

out of the

case

it

will

be

necessary

to

hold

them in place by hand

while

assembling the

case

onto the axle shaft.

FIG.

N-55—INSTALL

DIFFERENTIAL

CASE

ON

AXLE

SHAFT

e. Assemble

differential

case

onto the axle shaft

in

the position as shown in Fig. N-55.

Caution:

When assembling the

differential

case

onto

the axle shaft, be

sure

that the splines of the side

gears

are

lined

up

with

those

of the axle shaft.

Also

make

sure

that the

clutch

pack is

still

properly

assembled

into

the

case

after assembling the

case

onto the shaft.

f. Assemble the

step

plate

tool

into

the side

gear

as shown in Fig. N-4 6.

Apply

a small dab of

grease

into

the centering hole of the

step

plate

tool.

FIG.

N-56—INSTALLING

CLUTCH

PACK

AND

SIDE

GEAR

307

Page 308 of 376

N

REAR

AXLE

FIG.

N-57—POSITIONING GEAR ROTATING TOOL

g. Assemble the other clutch pack and side gear

exactly as shown. Be sure the clutch pack stays

assembled

onto

the side gear splines and that the

retainer

clips are completely seated into the pockets

of the case. Refer to Fig. N-56.

h.

Position the gear rotating tool into the top side

gear.

FIG.

N-58—THREADING FORCING SCREW

INTO ROTATING TOOL

FIG.

N-59—STARTING PINION MATE GEARS INTO CASE

i.

Keep side gear and rotating tool in position

by holding with hand. Insert the forcing screw down

through the top of the case, and thread into the

rotating tool. Refer to Fig. N-58.

j.

Position both pinion mate gears exactly as

shown. Be sure the holes of the gears are lined up

with

each other. Hold gears in place by hand. See

Fig.

N-59.

k.

Tighten forcing screw so that the Belleville

springs

will

compress and allow clearance between

the

teeth

of the pinion mate gears and side gears.

FIG.

N-60—ROTATING PINION MATE GEARS

INTO POSITION

I.

While holding the pinion mate gears in place,

insert

the pawl of the rotating tool between one

of the side gear

teeth

as shown.

Pull

on handle

so that the top side gear

will

rotate and allow the pinion mate gears to rotate and enter into the case.

Note:

As mentioned before, it

will

probably be

necessary to adjust the forcing screw by very

slightly loosening or tightening until the required load is applied to the Belleville plates or discs to allow the side gear and pinion mate gears to rotate.

FIG.

N-61—INSTALLING PINION MATE WASHERS

308

Page 327 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

P

lengthening of the brake master cylinder eye bolt.

This

is

done

so the primary cup

will

clear the by

pass port when the piston is in the off position,

otherwise the compensating action of the master

cylinder

for expansion and contraction of the fluid

in

the system, due to temperature changes,

will

be destroyed and cause the brakes to drag.

Note:

Some older 'Jeep' vehicles may

develop

side

movement

of the clutch and brake pedals resulting

from wear of the pedals, shafts, and bushings. One

way to

compensate

for this wear is to install a pedal

slack

adjuster kit,

Part

No.

921936.

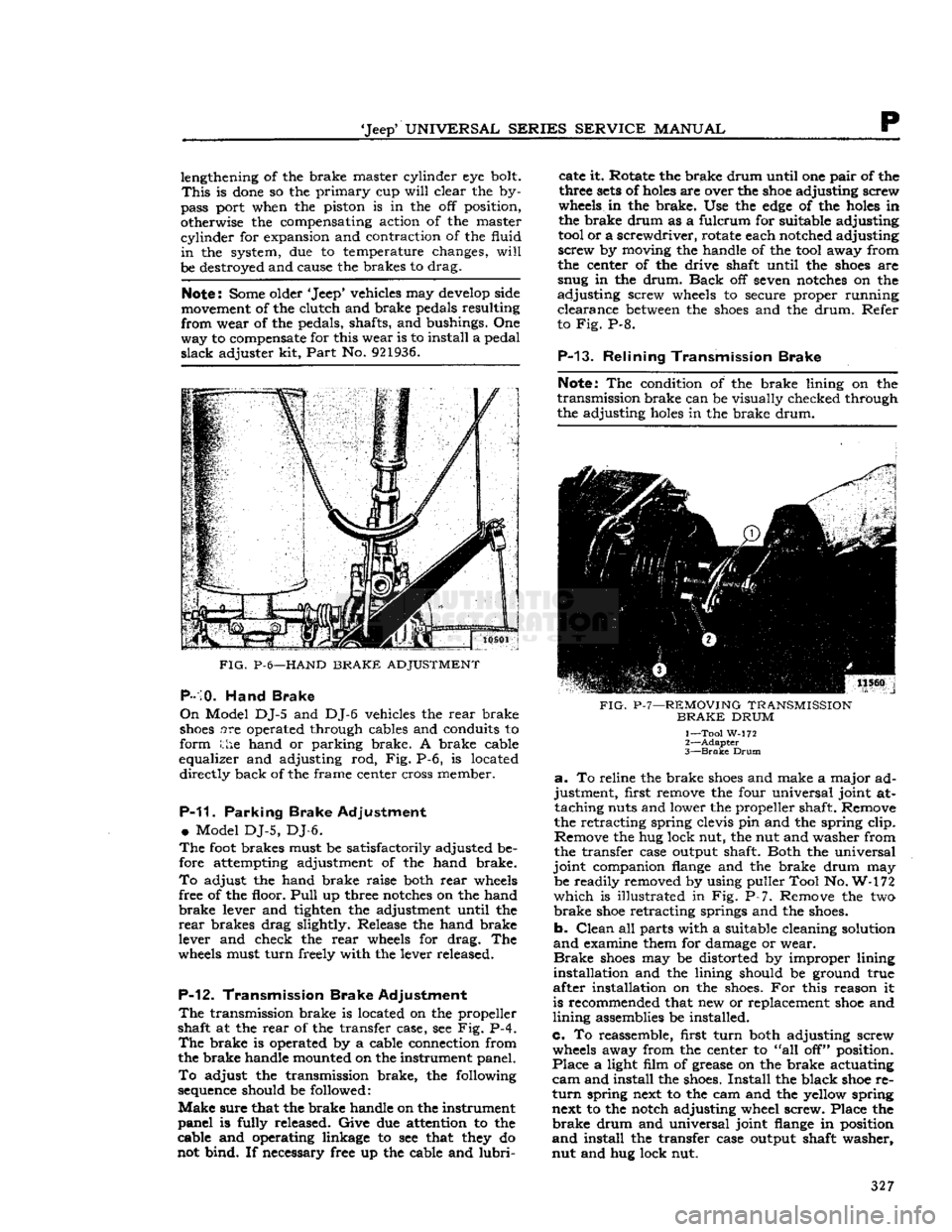

FIG.

P-6—HAND

BRAKE

ADJUSTMENT

P-10.

Hand Brake

On

Model DJ-5 and DJ-6 vehicles the rear brake

shoes

are operated through cables and conduits to

form the hand or parking brake. A brake cable

equalizer and adjusting rod, Fig. P-6, is located directly back of the frame center cross member.

P-11.

Parking Brake Adjustment

•

Model DJ-5, DJ-6.

The

foot

brakes must be satisfactorily adjusted be

fore attempting adjustment of the hand brake.

To

adjust the hand brake raise both rear

wheels

free of the floor.

Pull

up three

notches

on the hand

brake

lever and tighten the adjustment until the

rear

brakes drag slightly. Release the hand brake

lever and check the rear

wheels

for drag. The

wheels

must turn freely with the lever released.

P-12.

Transmission Brake Adjustment

The

transmission brake is located on the propeller

shaft at the rear of the transfer case, see Fig. P-4.

The

brake is operated by a cable connection from

the brake handle mounted on the instrument panel.

To

adjust the transmission brake, the following

sequence

should be followed:

Make

sure that the brake handle on the instrument

panel is fully released. Give due attention to the

cable and operating linkage to see that

they

do

not bind. If necessary free up the cable and

lubri

cate it. Rotate the brake drum until one pair of the

three

sets

of

holes

are over the

shoe

adjusting screw

wheels

in the brake. Use the

edge

of the

holes

in

the brake drum as a fulcrum for suitable adjusting

tool

or a screwdriver, rotate each notched adjusting

screw by moving the handle of the

tool

away from

the center of the drive shaft until the

shoes

are

snug in the drum.

Back

off seven

notches

on the

adjusting screw

wheels

to secure proper running clearance

between

the

shoes

and the drum. Refer

to Fig. P-8.

P-13.

Relining Transmission Brake

Note:

The condition of the brake lining on the

transmission brake can be visually checked through

the adjusting

holes

in the brake drum.

FIG.

P-7—REMOVING

TRANSMISSION

BRAKE

DRUM

1— Tool W-172

2—

Adapter

3—

Brake

Drum

a.

To reline the brake

shoes

and make a major ad

justment, first remove the four universal joint at taching nuts and lower the propeller shaft. Remove

the retracting spring clevis pin and the spring clip.

Remove the hug lock nut, the nut and washer from

the transfer case output shaft. Both the universal

joint companion

flange

and the brake drum may be readily removed by using puller Tool No. W-172

which

is illustrated in Fig. P-7. Remove the two

brake

shoe

retracting springs and the

shoes.

b. Clean all parts with a suitable cleaning solution

and

examine them for damage or wear.

Brake

shoes

may be distorted by improper lining

installation and the lining should be ground true

after installation on the

shoes.

For this reason it

is recommended that new or replacement

shoe

and

lining assemblies be installed.

c. To reassemble, first turn both adjusting screw

wheels

away from the center to "all off" position.

Place a light film of grease on the brake actuating

cam

and install the

shoes.

Install the black

shoe

re

turn

spring next to the cam and the yellow spring next to the notch adjusting wheel screw. Place the

brake

drum and universal joint

flange

in position

and

install the transfer case output shaft washer,

nut and hug lock nut. 327

Page 351 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

T

BODY

Contents

SUBJECT

PAR.

Brake

and

Clutch

Pedal Pads T-7

Canvas

Tops T-5

Care

of

Fabric

Tops. : T-6

Front

Seat Adjustment. . . T-8

Passenger Seat Safety

Catch

. .T-9

Windshield

T-2, T-3

Windshield

Glass and Weatherstrip T-4

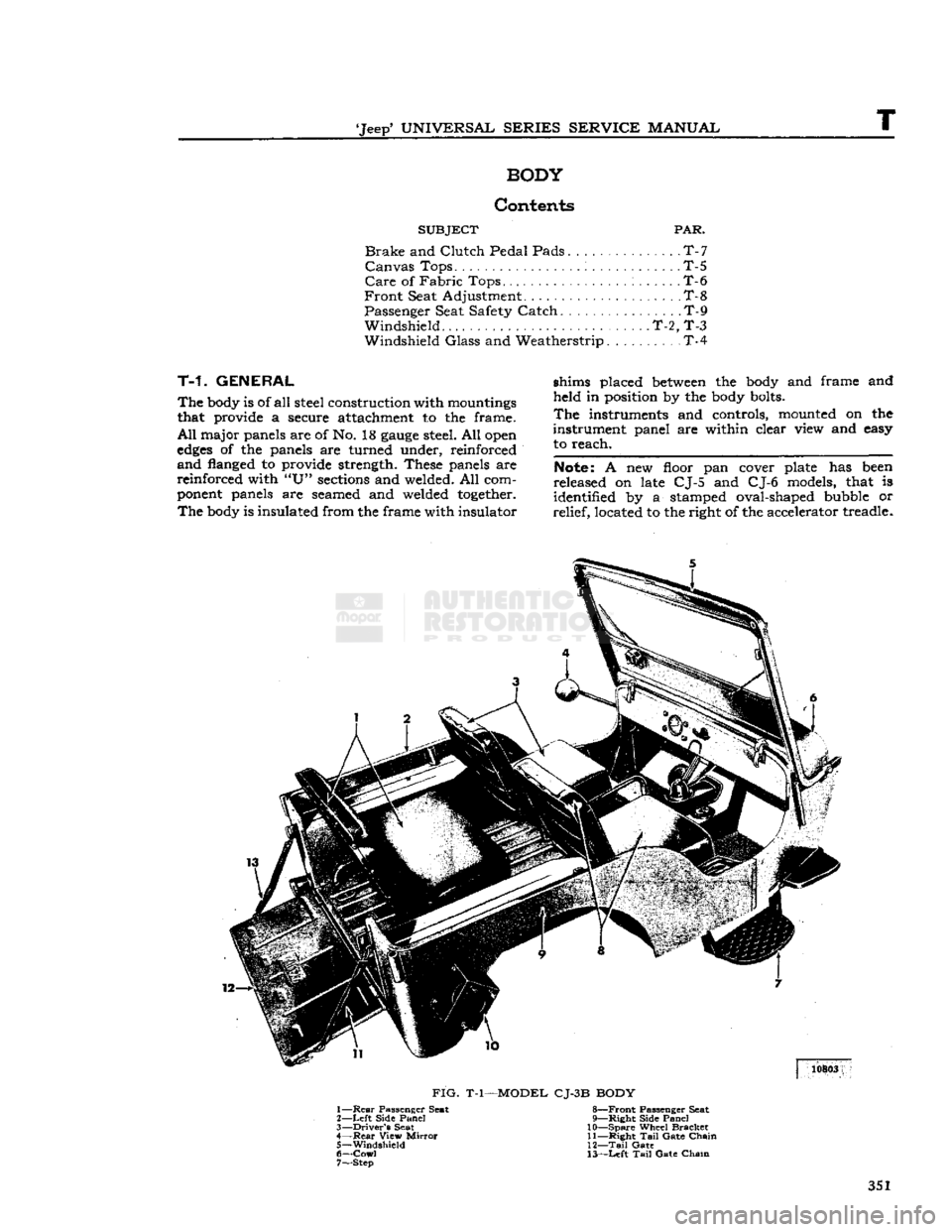

T-1.

GENERAL

The

body

is of

all

steel construction with mountings

that provide a secure attachment to the frame.

All

major panels are of No. 18

gauge

steel. All

open

edges

of the panels are turned under, reinforced

and

flanged to provide strength. These panels are reinforced with

"U"

sections

and welded. All com

ponent

panels are seamed and welded

together.

The

body

is insulated from the frame with insulator shims placed

between

the

body

and frame and

held in position by the

body

bolts.

The

instruments and controls, mounted on the

instrument panel are within clear view and easy

to reach.

Note:

A new floor pan cover plate has

been

released on late CJ-5 and CJ-6 models, that is

identified by a stamped oval-shaped bubble or

relief, located to the right of the accelerator treadle.

FIG.

T-l—MODEL CJ-3B BODY

1—

Rear

Passenger Seat 8—Front Passenger Seat

2—

Left

Side

Panel

9—Right Side

Panel

3—

Driver's

Seat 10—Spare Wheel

Bracket

4—

Rear

View

Mirror

11—Right

Tail

Gate

Chain

5—

Windshield

12—Tail

Gate

6—

Cowl

13—Left

Tail

Gate

Chain

7— Step

351

Page 354 of 376

T

BODY

from the windshield wiper vacuum fitting. On

late

models

disconnect electrical wires from wiper

motor. Unlatch the two windshield clamps on each

side

of the windshield.

Fold

the windshield forward

until

the

slot

in the windshield

hinges

aligns with the flat

side

of the pin in the

body

hinges.

Slip wind

shield off the pins and remove from

body.

T-4.

Windshield Glass

The

windshield

glass

is mounted in a rubber

weatherstrip which in turn

mounts

in the frame. A

rubber

locking strip, which

holds

the

glass

firmly in

the frame, is inserted in a moulded

groove

around

the rear

face

of the weatherstrip as shown in Fig.

T-2.

To remove the

glass

it is necessary to first

remove the locking strip which may be pried out

with a screwdriver or similar

tool.

Installation is,

obvious.

T-5.

Canvas Tops

Canvas

tops

are available in

Half

Tops and

Full

Tops.

Installation instructions are provided with

each canvas top kit for each model vehicle.

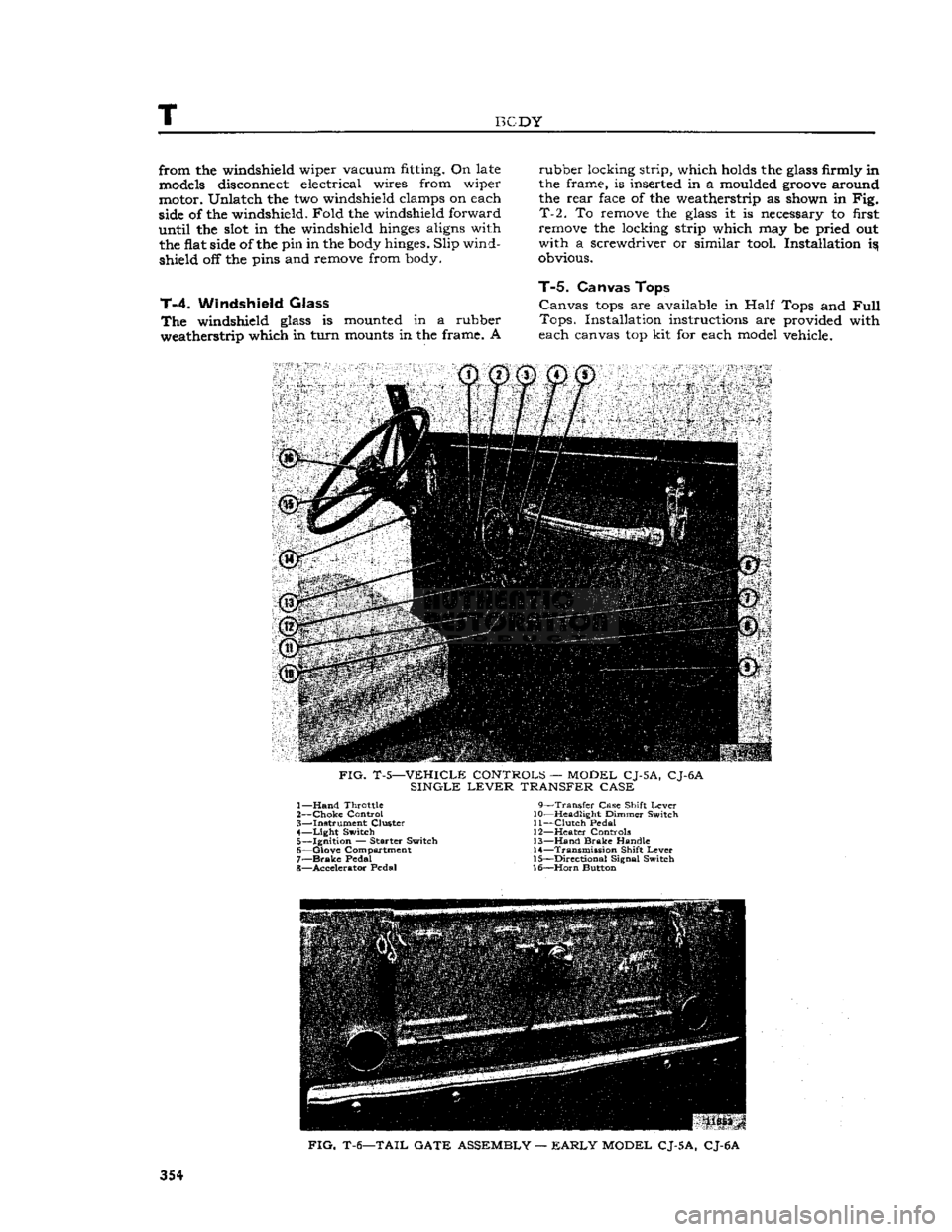

FIG.

T-5—VEHICLE CONTROLS — MODEL CJ-5A, CJ-6A

SINGLE

LEVER

TRANSFER CASE 1—

Hand

Throttle 9—Transfer Case Shift

Lever

2—

Choke

Control 10—Headlight Dimmer Switch

3— Instrument Cluster 11—Clutch Pedal 4—

Light

Switch 12—Heater Controls 5— Ignition — Starter Switch 13—Hand

Brake

Handle

6— Glove Compartment 14—Transmission Shift

Lever

7—

Brake

Pedal 15—Directional Signal Switch

8— Accelerator Pedal 16—Horn Button

FIG.

T-6—TAIL GATE ASSEMBLY —

EARLY

MODEL CJ-5A, CJ-6A

354