clutch JEEP GRAND CHEROKEE 2001 Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2001, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2001Pages: 993, PDF Size: 50.98 MB

Page 52 of 993

Fig. 40 Clutch Pack and Upper Side Gear

Page 582 of 993

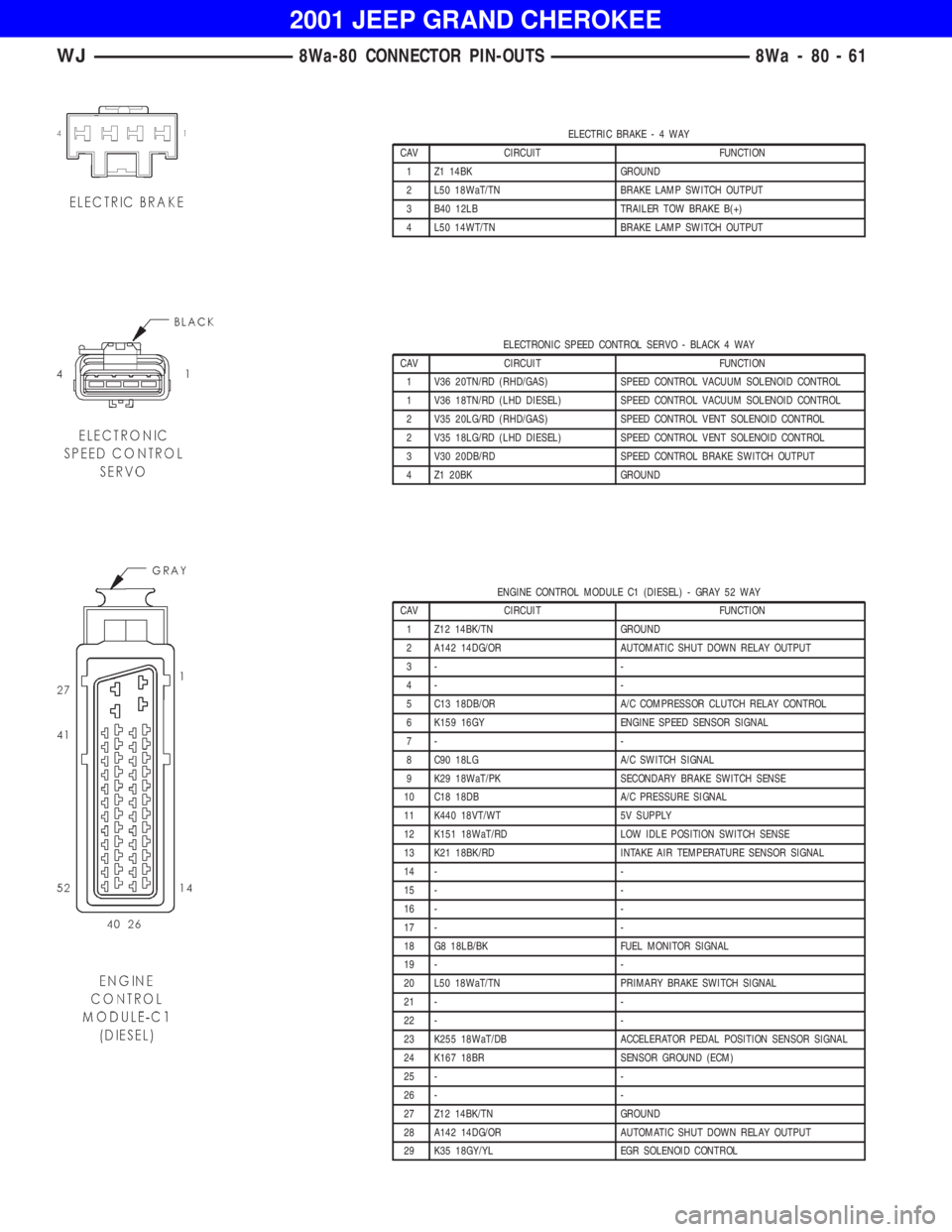

ELECTRONIC SPEED CONTROL SERVO - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 V36 20TN/RD (RHD/GAS) SPEED CONTROL VACUUM SOLENOID CONTROL

1 V36 18TN/RD (LHD DIESEL) SPEED CONTROL VACUUM SOLENOID CONTROL

2 V35 20LG/RD (RHD/GAS) SPEED CONTROL VENT SOLENOID CONTROL

2 V35 18LG/RD (LHD DIESEL) SPEED CONTROL VENT SOLENOID CONTROL

3 V30 20DB/RD SPEED CONTROL BRAKE SWITCH OUTPUT

4 Z1 20BK GROUND

ENGINE CONTROL MODULE C1 (DIESEL) - GRAY 52 WAY

CAV CIRCUIT FUNCTION

1 Z12 14BK/TN GROUND

2 A142 14DG/OR AUTOMATIC SHUT DOWN RELAY OUTPUT

3- -

4- -

5 C13 18DB/OR A/C COMPRESSOR CLUTCH RELAY CONTROL

6 K159 16GY ENGINE SPEED SENSOR SIGNAL

7- -

8 C90 18LG A/C SWITCH SIGNAL

9 K29 18WaT/PK SECONDARY BRAKE SWITCH SENSE

10 C18 18DB A/C PRESSURE SIGNAL

11 K440 18VT/WT 5V SUPPLY

12 K151 18WaT/RD LOW IDLE POSITION SWITCH SENSE

13 K21 18BK/RD INTAKE AIR TEMPERATURE SENSOR SIGNAL

14 - -

15 - -

16 - -

17 - -

18 G8 18LB/BK FUEL MONITOR SIGNAL

19 - -

20 L50 18WaT/TN PRIMARY BRAKE SWITCH SIGNAL

21 - -

22 - -

23 K255 18WaT/DB ACCELERATOR PEDAL POSITION SENSOR SIGNAL

24 K167 18BR SENSOR GROUND (ECM)

25 - -

26 - -

27 Z12 14BK/TN GROUND

28 A142 14DG/OR AUTOMATIC SHUT DOWN RELAY OUTPUT

29 K35 18GY/YL EGR SOLENOID CONTROL

WJ8Wa-80 CONNECTOR PIN-OUTS 8Wa - 80 - 61

Page 616 of 993

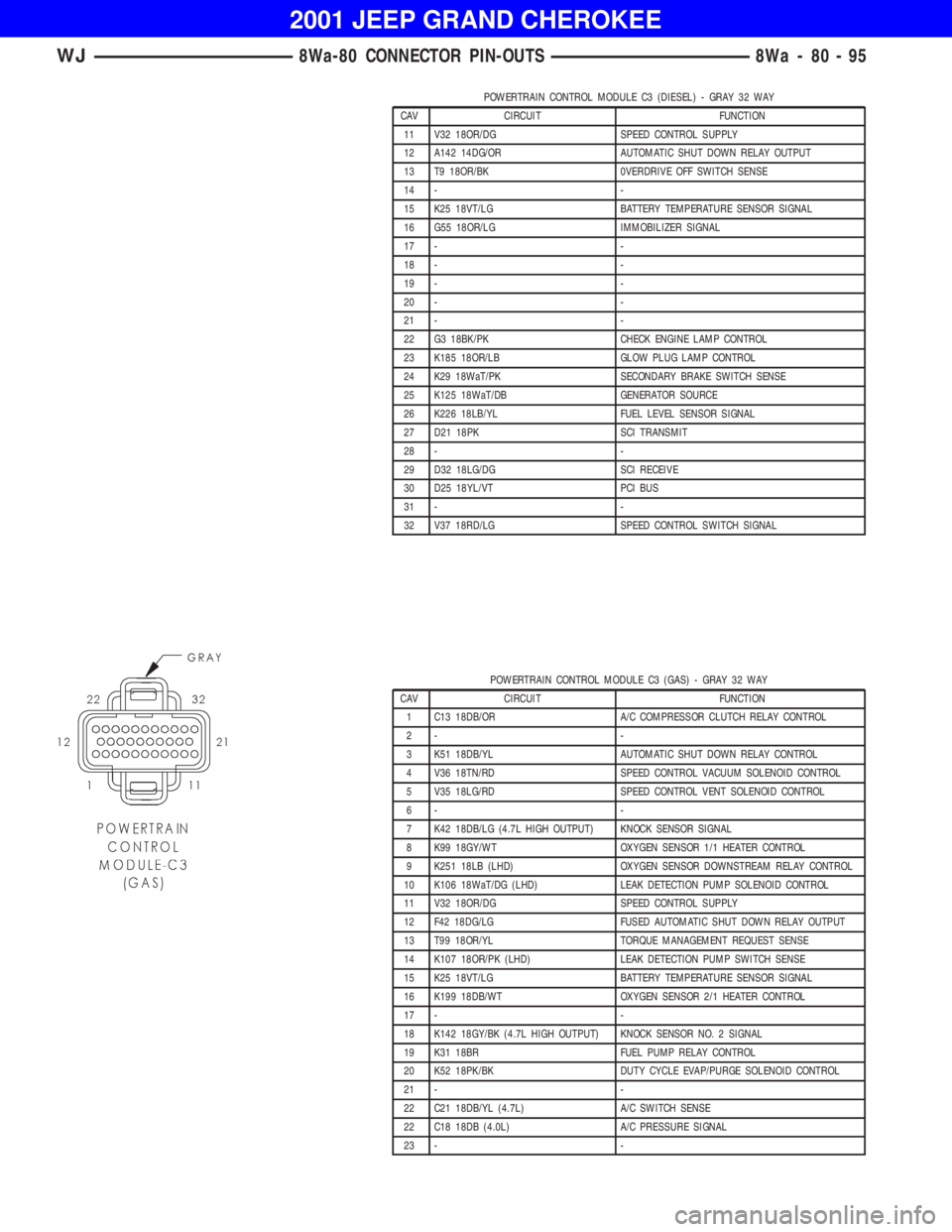

POWERTRAIN CONTROL MODULE C3 (GAS) - GRAY 32 WAY

CAV CIRCUIT FUNCTION

1 C13 18DB/OR A/C COMPRESSOR CLUTCH RELAY CONTROL

2- -

3 K51 18DB/YL AUTOMATIC SHUT DOWN RELAY CONTROL

4 V36 18TN/RD SPEED CONTROL VACUUM SOLENOID CONTROL

5 V35 18LG/RD SPEED CONTROL VENT SOLENOID CONTROL

6- -

7 K42 18DB/LG (4.7L HIGH OUTPUT) KNOCK SENSOR SIGNAL

8 K99 18GY/WT OXYGEN SENSOR 1/1 HEATER CONTROL

9 K251 18LB (LHD) OXYGEN SENSOR DOWNSTREAM RELAY CONTROL

10 K106 18WaT/DG (LHD) LEAK DETECTION PUMP SOLENOID CONTROL

11 V32 18OR/DG SPEED CONTROL SUPPLY

12 F42 18DG/LG FUSED AUTOMATIC SHUT DOWN RELAY OUTPUT

13 T99 18OR/YL TORQUE MANAGEMENT REQUEST SENSE

14 K107 18OR/PK (LHD) LEAK DETECTION PUMP SWITCH SENSE

15 K25 18VT/LG BATTERY TEMPERATURE SENSOR SIGNAL

16 K199 18DB/WT OXYGEN SENSOR 2/1 HEATER CONTROL

17 - -

18 K142 18GY/BK (4.7L HIGH OUTPUT) KNOCK SENSOR NO. 2 SIGNAL

19 K31 18BR FUEL PUMP RELAY CONTROL

20 K52 18PK/BK DUTY CYCLE EVAP/PURGE SOLENOID CONTROL

21 - -

22 C21 18DB/YL (4.7L) A/C SWITCH SENSE

22 C18 18DB (4.0L) A/C PRESSURE SIGNAL

23 - -

WJ8Wa-80 CONNECTOR PIN-OUTS 8Wa - 80 - 95

Page 631 of 993

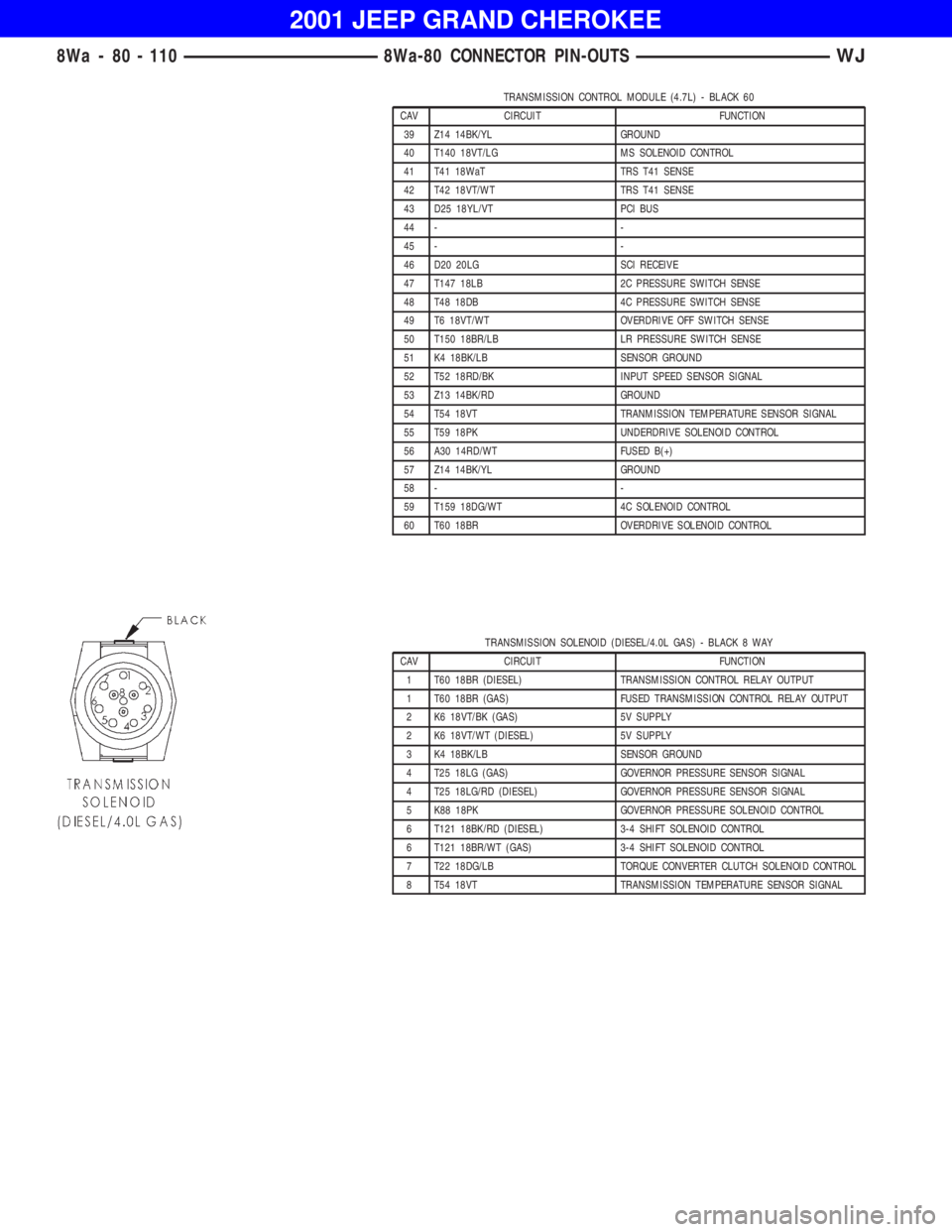

TRANSMISSION SOLENOID (DIESEL/4.0L GAS) - BLACK 8 WAY

CAV CIRCUIT FUNCTION

1 T60 18BR (DIESEL) TRANSMISSION CONTROL RELAY OUTPUT

1 T60 18BR (GAS) FUSED TRANSMISSION CONTROL RELAY OUTPUT

2 K6 18VT/BK (GAS) 5V SUPPLY

2 K6 18VT/WT (DIESEL) 5V SUPPLY

3 K4 18BK/LB SENSOR GROUND

4 T25 18LG (GAS) GOVERNOR PRESSURE SENSOR SIGNAL

4 T25 18LG/RD (DIESEL) GOVERNOR PRESSURE SENSOR SIGNAL

5 K88 18PK GOVERNOR PRESSURE SOLENOID CONTROL

6 T121 18BK/RD (DIESEL) 3-4 SHIFT SOLENOID CONTROL

6 T121 18BR/WT (GAS) 3-4 SHIFT SOLENOID CONTROL

7 T22 18DG/LB TORQUE CONVERTER CLUTCH SOLENOID CONTROL

8 T54 18VT TRANSMISSION TEMPERATURE SENSOR SIGNAL

8Wa - 80 - 110 8Wa-80 CONNECTOR PIN-OUTSWJ

Page 742 of 993

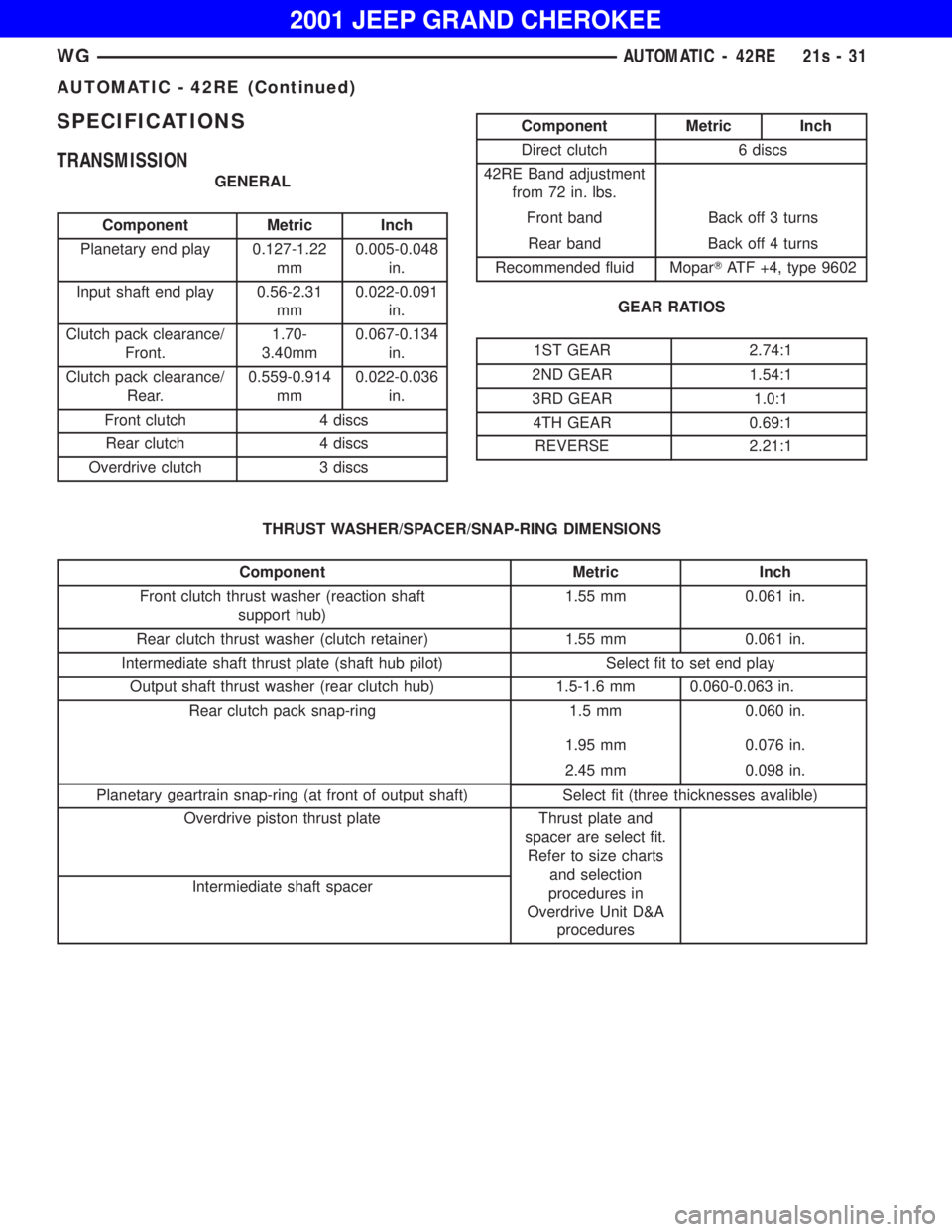

Component Metric Inch

Planetary end play 0.127-1.22

mm0.005-0.048

in.

Input shaft end play 0.56-2.31

mm0.022-0.091

in.

Clutch pack clearance/

Front.1.70-

3.40mm0.067-0.134

in.

Clutch pack clearance/

Rear.0.559-0.914

mm0.022-0.036

in.

Front clutch 4 discs

Rear clutch 4 discs

Overdrive clutch 3 discs

Component Metric Inch

Front clutch thrust washer (reaction shaft

support hub)1.55 mm 0.061 in.

Rear clutch thrust washer (clutch retainer) 1.55 mm 0.061 in.

Intermediate shaft thrust plate (shaft hub pilot) Select fit to set end play

Output shaft thrust washer (rear clutch hub) 1.5-1.6 mm 0.060-0.063 in.

Rear clutch pack snap-ring 1.5 mm 0.060 in.

1.95 mm 0.076 in.

2.45 mm 0.098 in.

Planetary geartrain snap-ring (at front of output shaft) Select fit (three thicknesses avalible)

Overdrive piston thrust plate Thrust plate and

spacer are select fit.

Refer to size charts

and selection

procedures in

Overdrive Unit D&A

procedures Intermiediate shaft spacer

WGAUTOMATIC - 42RE 21s - 31

Page 758 of 993

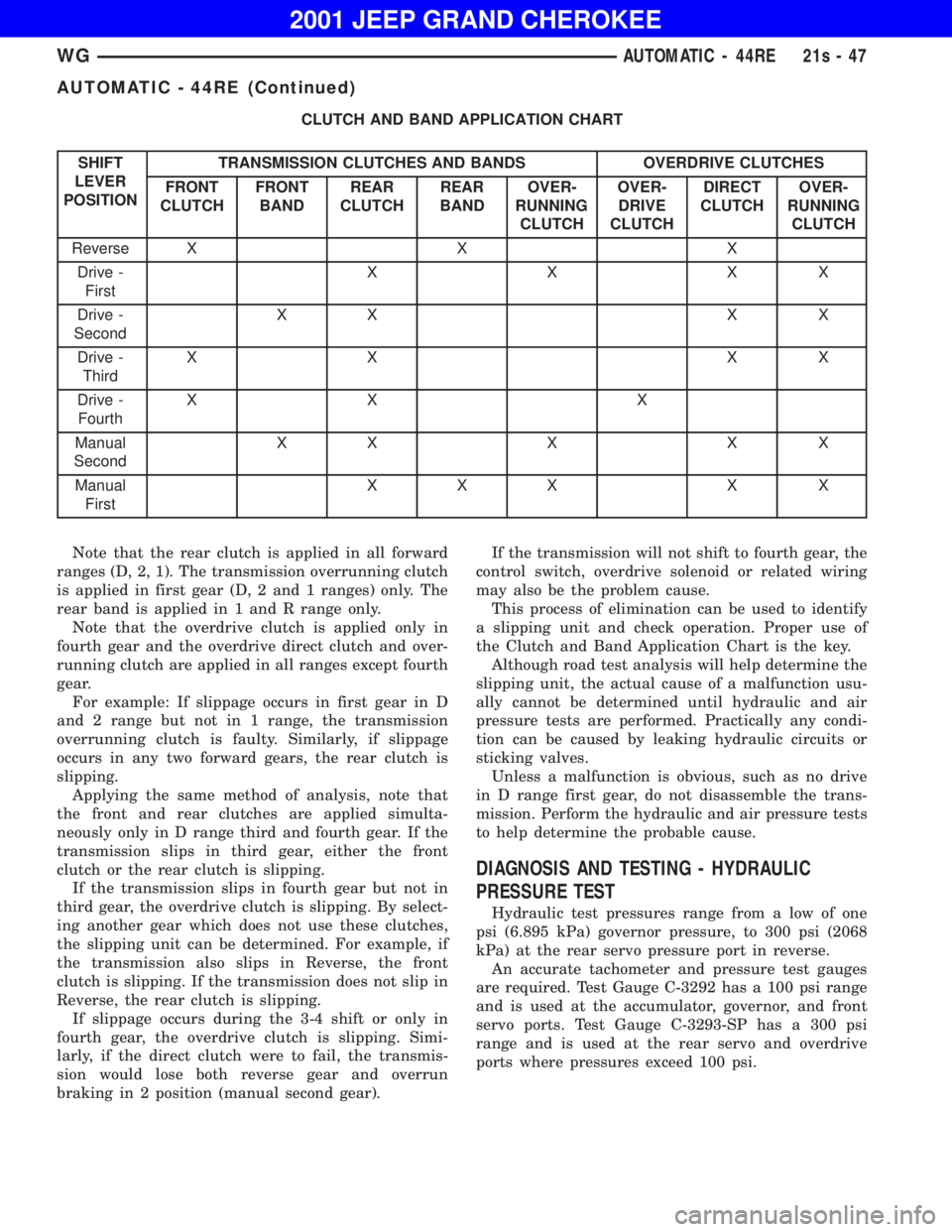

SHIFT

LEVER

POSITIONTRANSMISSION CLUTCHES AND BANDS OVERDRIVE CLUTCHES

FRONT

CLUTCHFRONT

BANDREAR

CLUTCHREAR

BANDOVER-

RUNNING

CLUTCHOVER-

DRIVE

CLUTCHDIRECT

CLUTCHOVER-

RUNNING

CLUTCH

Reverse X X X

Drive -

FirstXXXX

Drive -

SecondXX X X

Drive -

ThirdXX XX

Drive -

FourthXX X

Manual

SecondXXXXX

Manual

FirstXXX X X

Note that the rear clutch is applied in all forward

ranges (D, 2, 1). The transmission overrunning clutch

is applied in first gear (D, 2 and 1 ranges) only. The

rear band is applied in 1 and R range only.

Note that the overdrive clutch is applied only in

fourth gear and the overdrive direct clutch and over-

running clutch are applied in all ranges except fourth

gear.

For example: If slippage occurs in first gear in D

and 2 range but not in 1 range, the transmission

overrunning clutch is faulty. Similarly, if slippage

occurs in any two forward gears, the rear clutch is

slipping.

Applying the same method of analysis, note that

the front and rear clutches are applied simulta-

neously only in D range third and fourth gear. If the

transmission slips in third gear, either the front

clutch or the rear clutch is slipping.

If the transmission slips in fourth gear but not in

third gear, the overdrive clutch is slipping. By select-

ing another gear which does not use these clutches,

the slipping unit can be determined. For example, if

the transmission also slips in Reverse, the front

clutch is slipping. If the transmission does not slip in

Reverse, the rear clutch is slipping.

If slippage occurs during the 3-4 shift or only in

fourth gear, the overdrive clutch is slipping. Simi-

larly, if the direct clutch were to fail, the transmis-

sion would lose both reverse gear and overrun

braking in 2 position (manual second gear).If the transmission will not shift to fourth gear, the

control switch, overdrive solenoid or related wiring

may also be the problem cause.

This process of elimination can be used to identify

a slipping unit and check operation. Proper use of

the Clutch and Band Application Chart is the key.

Although road test analysis will help determine the

slipping unit, the actual cause of a malfunction usu-

ally cannot be determined until hydraulic and air

pressure tests are performed. Practically any condi-

tion can be caused by leaking hydraulic circuits or

sticking valves.

Unless a malfunction is obvious, such as no drive

in D range first gear, do not disassemble the trans-

mission. Perform the hydraulic and air pressure tests

to help determine the probable cause.

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST

Hydraulic test pressures range from a low of one

psi (6.895 kPa) governor pressure, to 300 psi (2068

kPa) at the rear servo pressure port in reverse.

An accurate tachometer and pressure test gauges

are required. Test Gauge C-3292 has a 100 psi range

and is used at the accumulator, governor, and front

servo ports. Test Gauge C-3293-SP has a 300 psi

range and is used at the rear servo and overdrive

ports where pressures exceed 100 psi.

WGAUTOMATIC - 44RE 21s - 47

Page 763 of 993

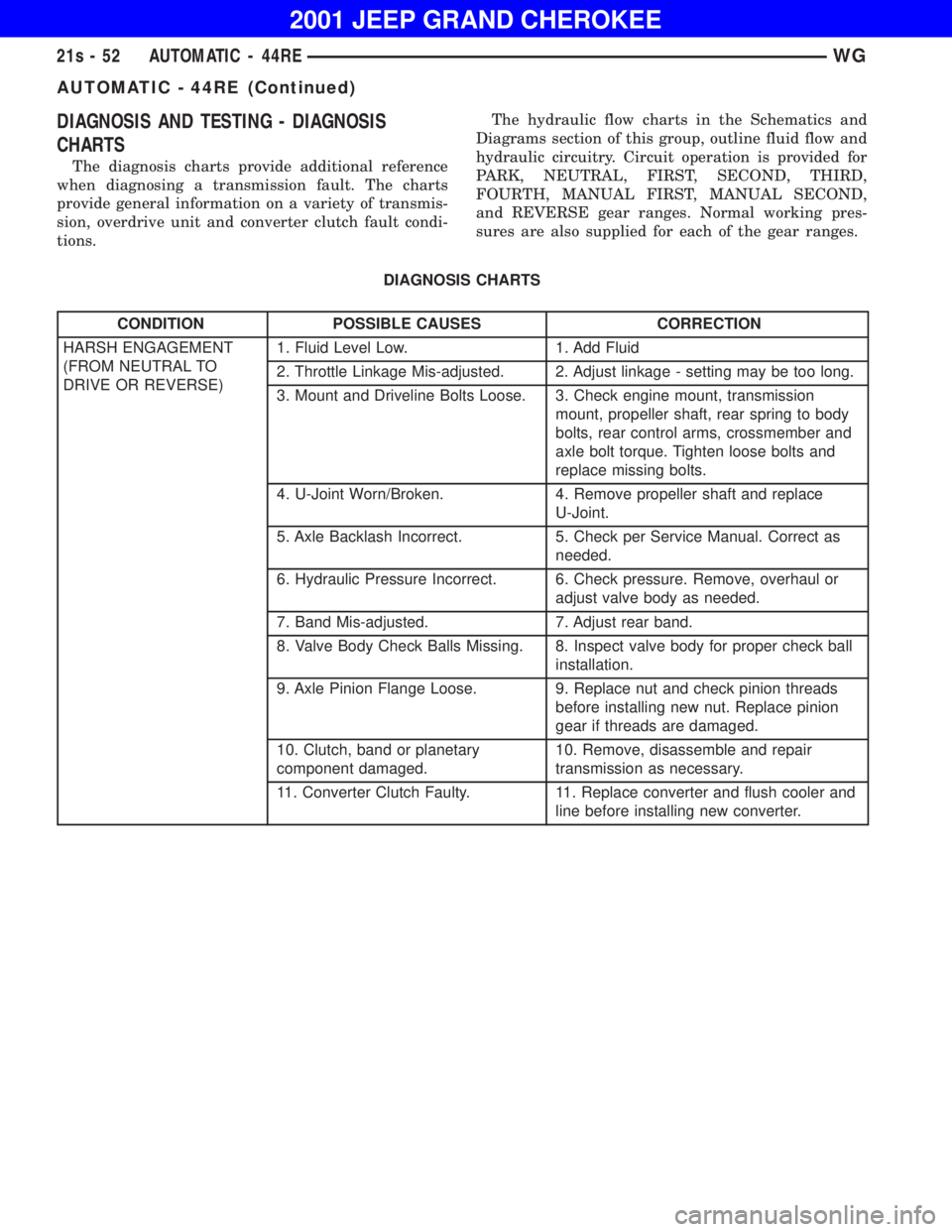

CONDITION POSSIBLE CAUSES CORRECTION

HARSH ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low. 1. Add Fluid

2. Throttle Linkage Mis-adjusted. 2. Adjust linkage - setting may be too long.

3. Mount and Driveline Bolts Loose. 3. Check engine mount, transmission

mount, propeller shaft, rear spring to body

bolts, rear control arms, crossmember and

axle bolt torque. Tighten loose bolts and

replace missing bolts.

4. U-Joint Worn/Broken. 4. Remove propeller shaft and replace

U-Joint.

5. Axle Backlash Incorrect. 5. Check per Service Manual. Correct as

needed.

6. Hydraulic Pressure Incorrect. 6. Check pressure. Remove, overhaul or

adjust valve body as needed.

7. Band Mis-adjusted. 7. Adjust rear band.

8. Valve Body Check Balls Missing. 8. Inspect valve body for proper check ball

installation.

9. Axle Pinion Flange Loose. 9. Replace nut and check pinion threads

before installing new nut. Replace pinion

gear if threads are damaged.

10. Clutch, band or planetary

component damaged.10. Remove, disassemble and repair

transmission as necessary.

11. Converter Clutch Faulty. 11. Replace converter and flush cooler and

line before installing new converter.

21s - 52 AUTOMATIC - 44REWG

AUTOMATIC - 44RE (Continued)

Page 805 of 993

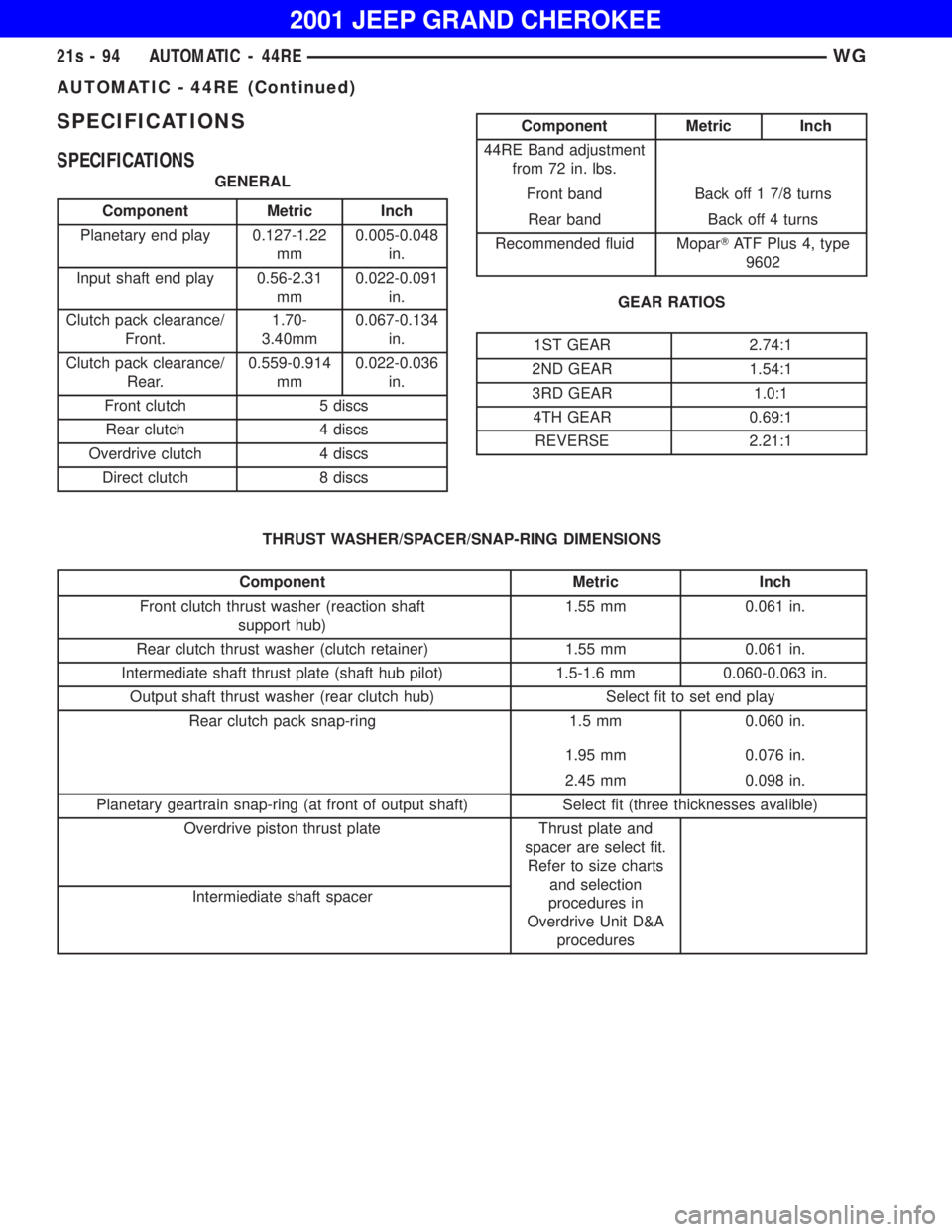

Component Metric Inch

Planetary end play 0.127-1.22

mm0.005-0.048

in.

Input shaft end play 0.56-2.31

mm0.022-0.091

in.

Clutch pack clearance/

Front.1.70-

3.40mm0.067-0.134

in.

Clutch pack clearance/

Rear.0.559-0.914

mm0.022-0.036

in.

Front clutch 5 discs

Rear clutch 4 discs

Overdrive clutch 4 discs

Direct clutch 8 discs

Component Metric Inch

Front clutch thrust washer (reaction shaft

support hub)1.55 mm 0.061 in.

Rear clutch thrust washer (clutch retainer) 1.55 mm 0.061 in.

Intermediate shaft thrust plate (shaft hub pilot) 1.5-1.6 mm 0.060-0.063 in.

Output shaft thrust washer (rear clutch hub) Select fit to set end play

Rear clutch pack snap-ring 1.5 mm 0.060 in.

1.95 mm 0.076 in.

2.45 mm 0.098 in.

Planetary geartrain snap-ring (at front of output shaft) Select fit (three thicknesses avalible)

Overdrive piston thrust plate Thrust plate and

spacer are select fit.

Refer to size charts

and selection

procedures in

Overdrive Unit D&A

procedures Intermiediate shaft spacer

21s - 94 AUTOMATIC - 44REWG

AUTOMATIC - 44RE (Continued)

Page 827 of 993

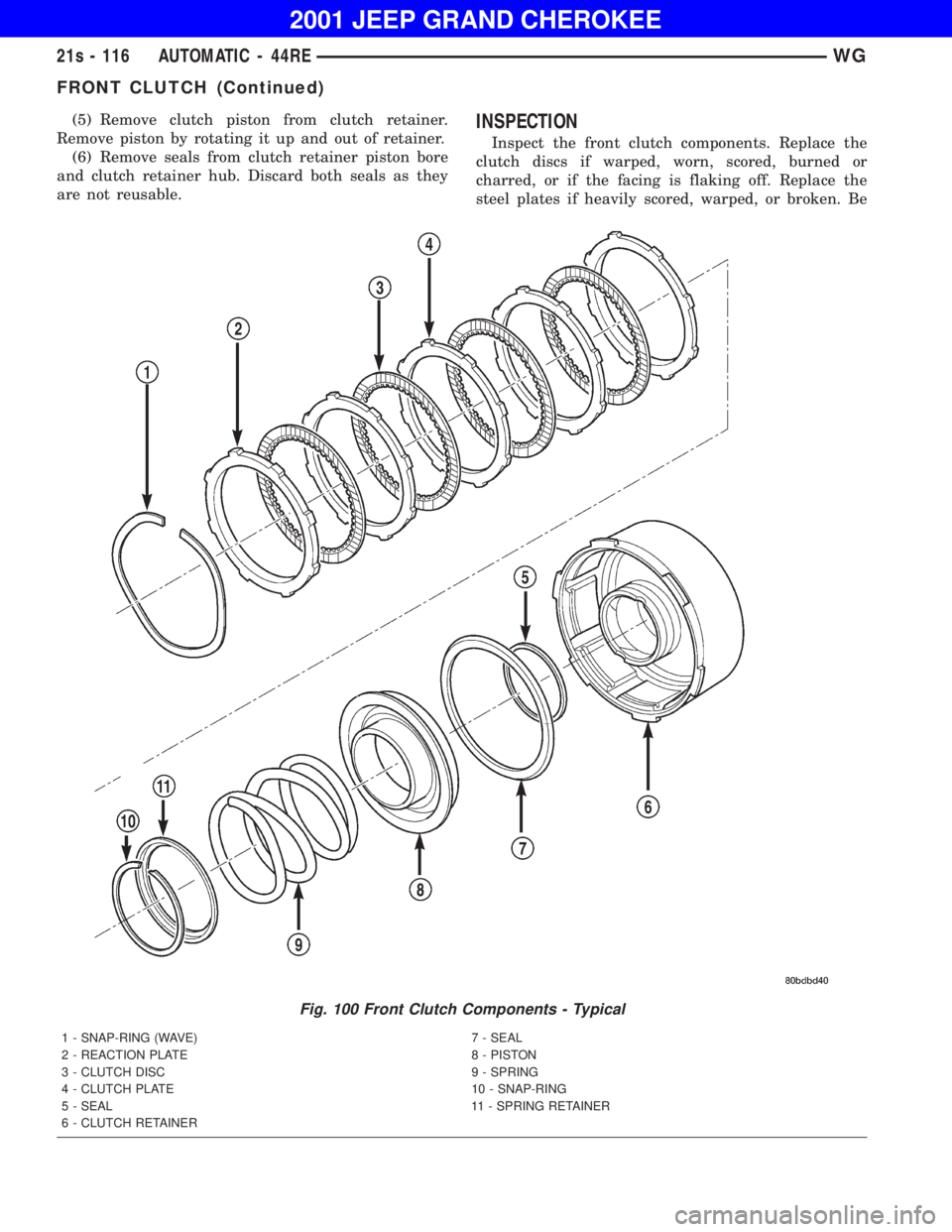

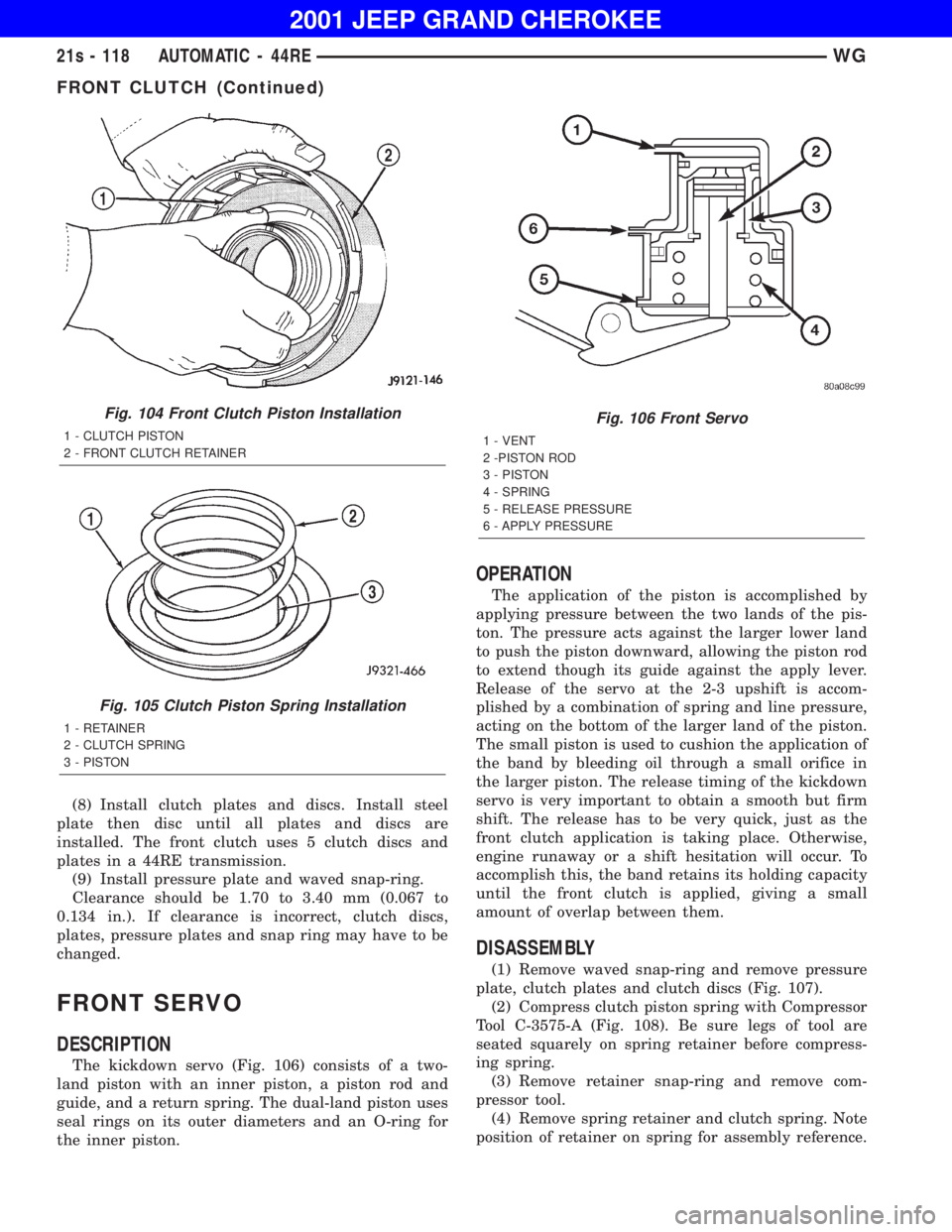

FRONT CLUTCH (Continued)

Page 829 of 993

FRONT CLUTCH (Continued)