JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 111 of 2199

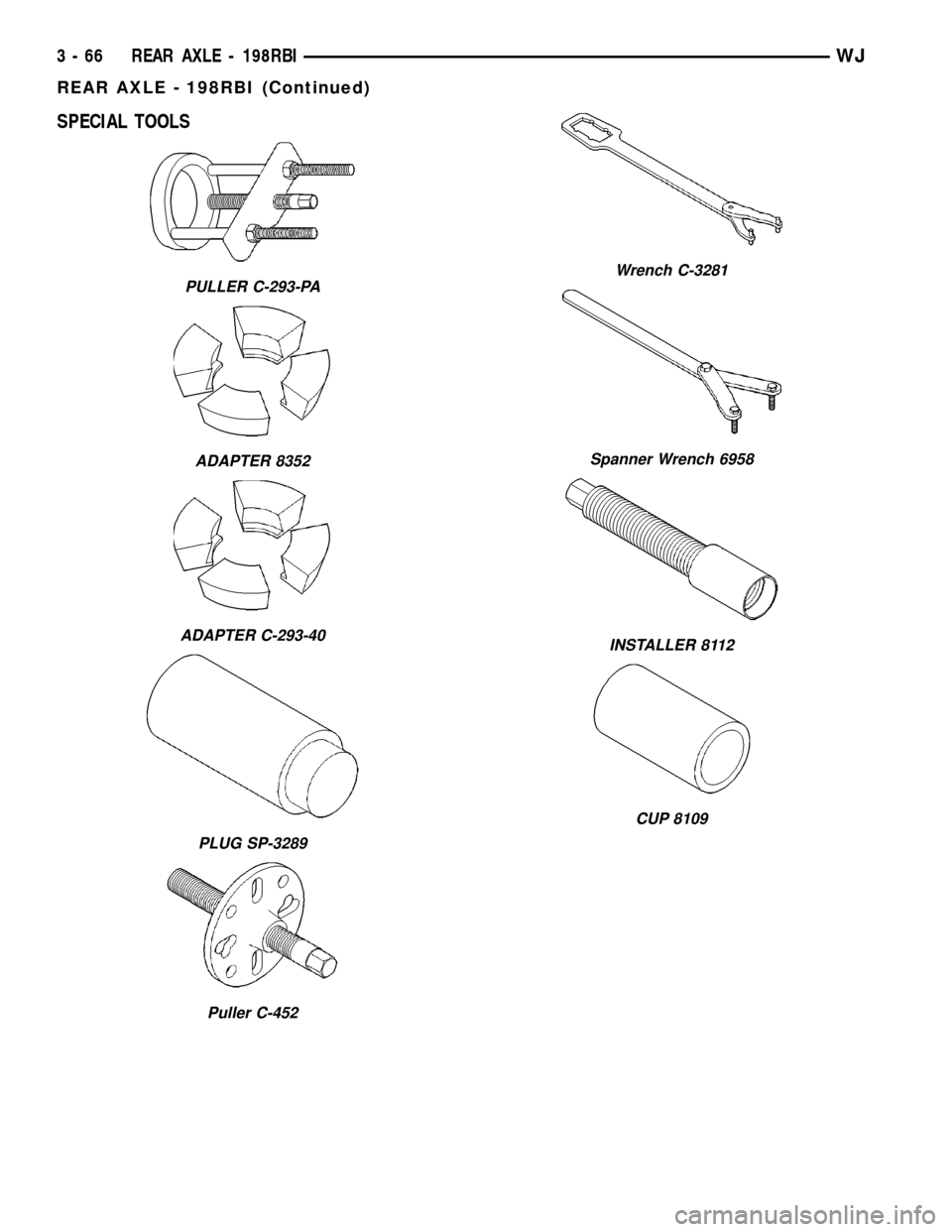

SPECIAL TOOLS

PULLER C-293-PA

ADAPTER 8352

ADAPTER C-293-40

PLUG SP-3289

Puller C-452

Wrench C-3281

Spanner Wrench 6958

INSTALLER 8112

CUP 8109

3 - 66 REAR AXLE - 198RBIWJ

REAR AXLE - 198RBI (Continued)

Page 112 of 2199

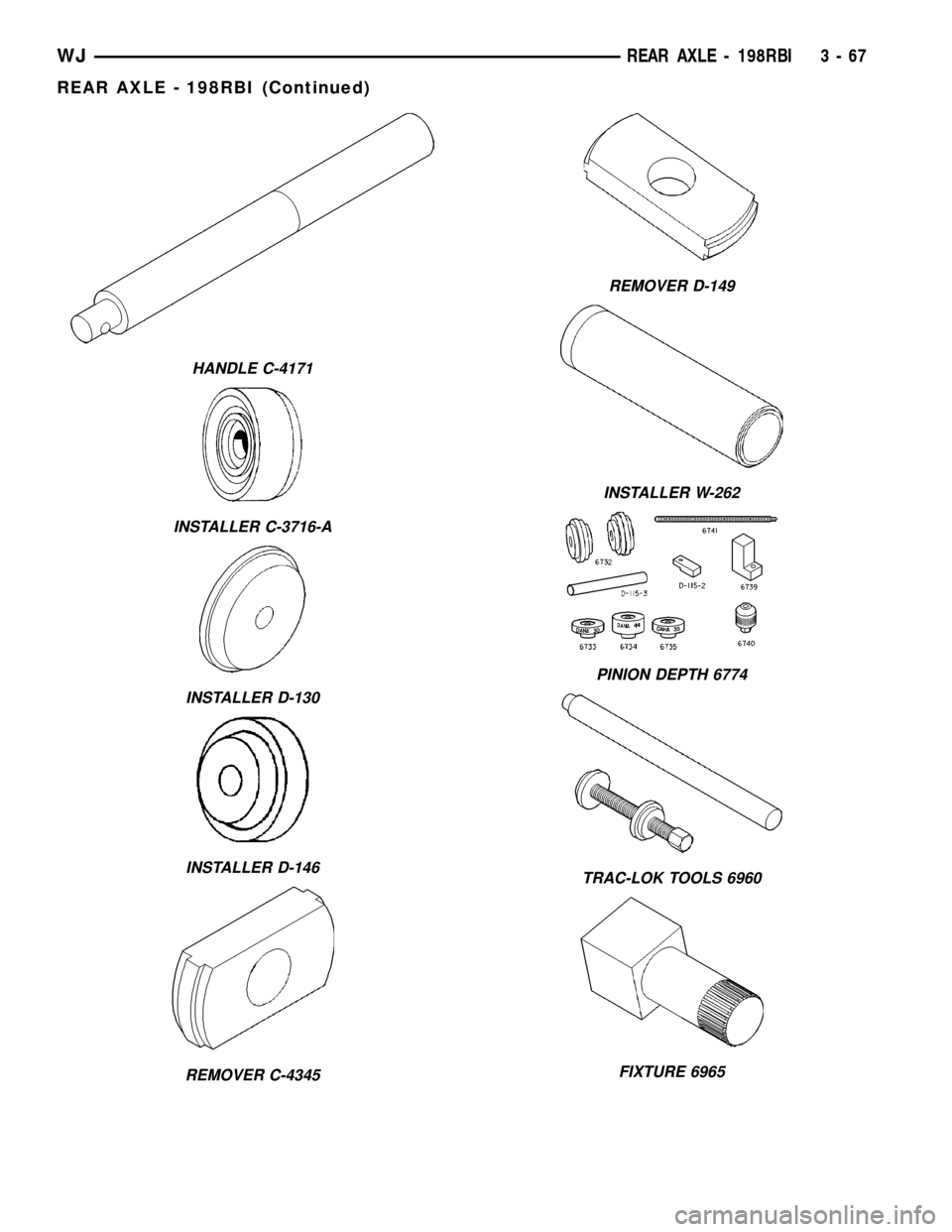

HANDLE C-4171

INSTALLER C-3716-A

INSTALLER D-130

INSTALLER D-146

REMOVER C-4345

REMOVER D-149

INSTALLER W-262

PINION DEPTH 6774

TRAC-LOK TOOLS 6960

FIXTURE 6965

WJREAR AXLE - 198RBI 3 - 67

REAR AXLE - 198RBI (Continued)

Page 113 of 2199

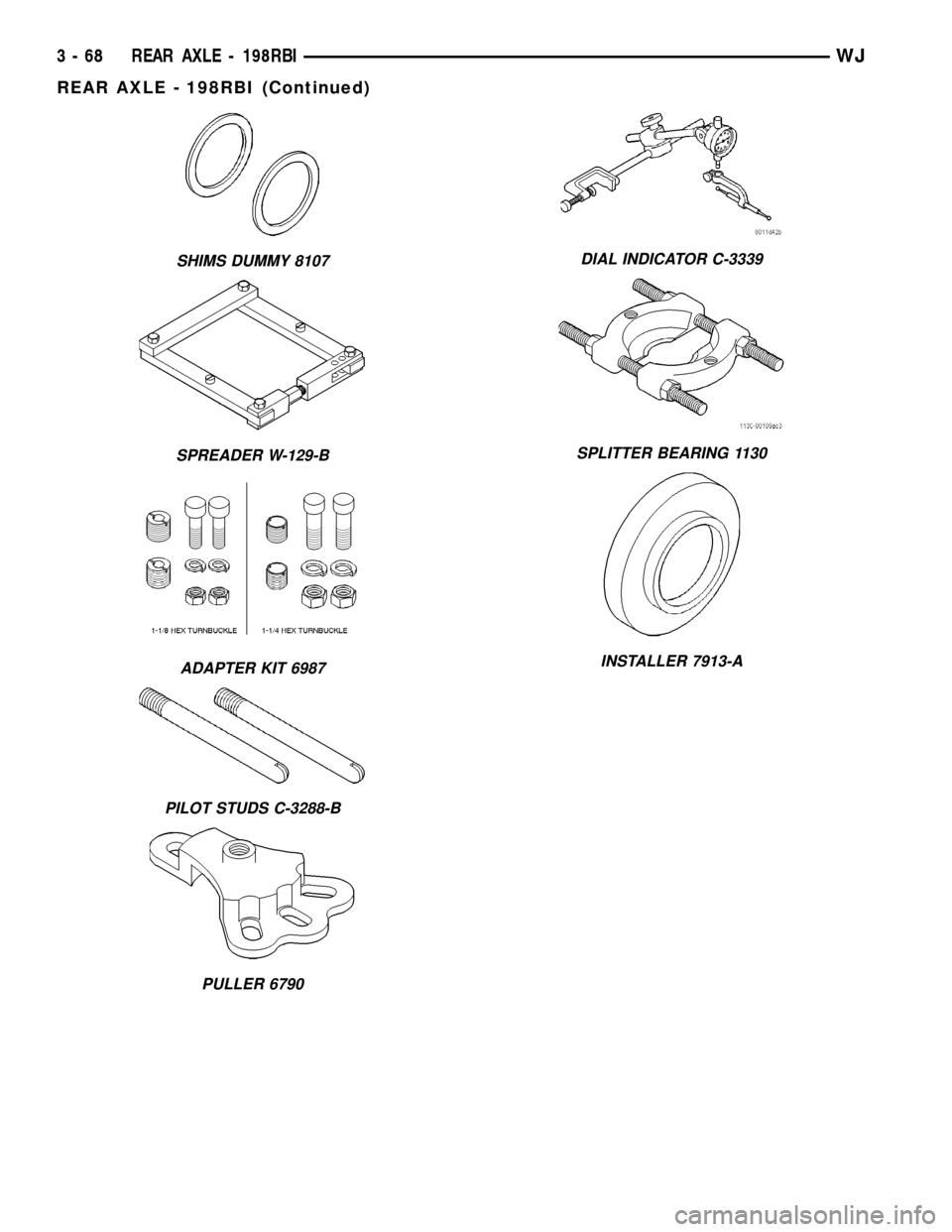

SHIMS DUMMY 8107

SPREADER W-129-B

ADAPTER KIT 6987

PILOT STUDS C-3288-B

PULLER 6790

DIAL INDICATOR C-3339

SPLITTER BEARING 1130

INSTALLER 7913-A

3 - 68 REAR AXLE - 198RBIWJ

REAR AXLE - 198RBI (Continued)

Page 114 of 2199

AXLE SHAFTS

REMOVAL

(1) Place transmission in neutral.

(2) Raise and support vehicle.

(3) Remove wheel and tire assembly.

(4) Remove brake caliper and rotor.

(5) Remove nuts holding axle retainer plate to axle

tube from the rear of the axle flange.

(6) Pull axle shaft from the axle with Slide Ham-

mer 7420 and Adapter 6790. Mount the adapter to

the axle with lug nuts.

NOTE: The axle bearing race is normally loose in

the axle tube.

INSTALLATION

(1) Insall axle into the axle tube with the flat area

of the retainer plate upward.

(2) Insert retaining plate studs into the brake

backing plate and axle tube flange.

(3) Install retainer nuts and tighten nuts to 61

N´m (45 ft. lbs.).

(4) Install the brake rotor and caliper.

(5) Install wheel and tire.

(6) Check and fill the differential with gear lubri-

cant.

(7) Lower vehicle.

AXLE BEARINGS/SEALS

REMOVAL

(1) Remove axle shaft from vehicle.

NOTE: The axle bearing race is normally loose in

the axle tube.

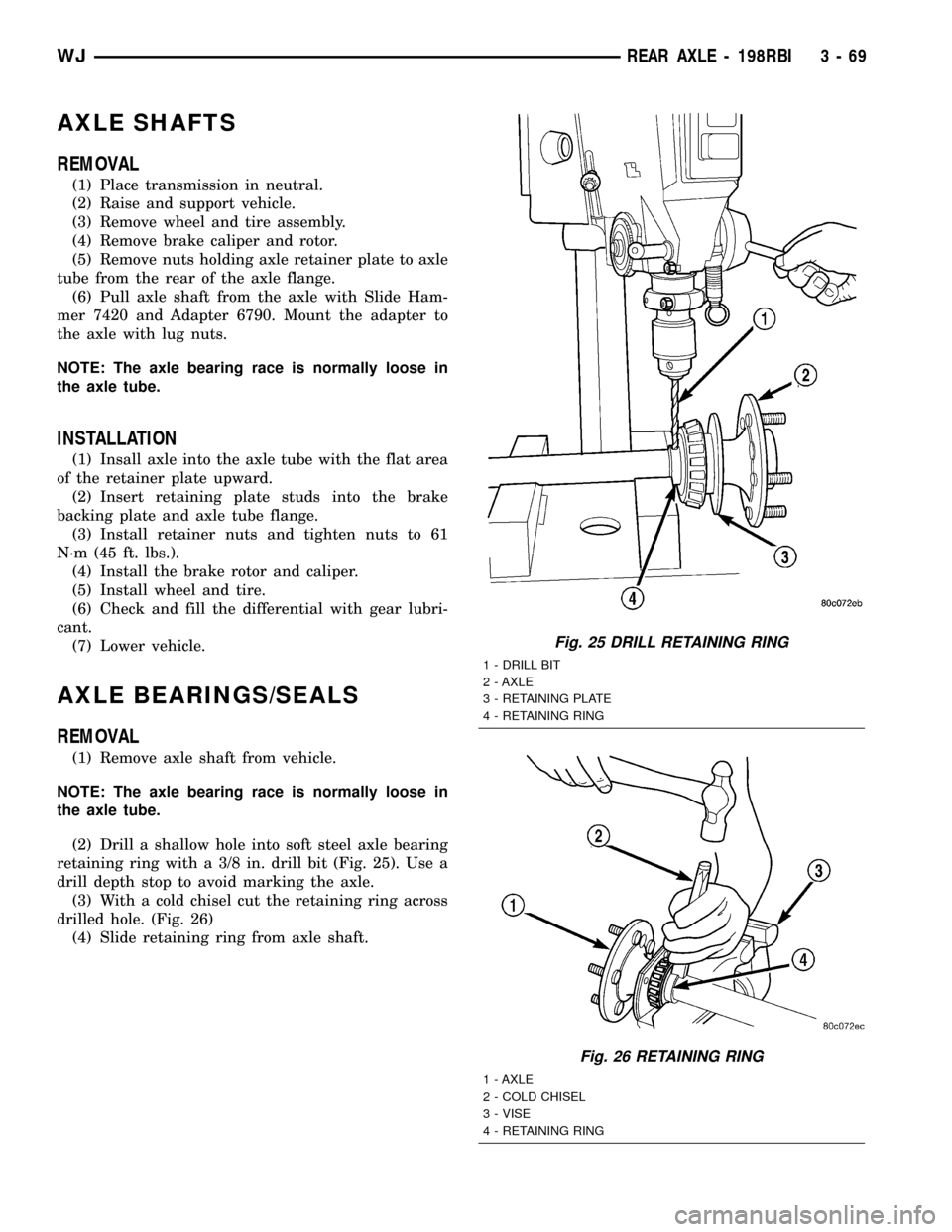

(2) Drill a shallow hole into soft steel axle bearing

retaining ring with a 3/8 in. drill bit (Fig. 25). Use a

drill depth stop to avoid marking the axle.

(3) With a cold chisel cut the retaining ring across

drilled hole. (Fig. 26)

(4) Slide retaining ring from axle shaft.

Fig. 25 DRILL RETAINING RING

1 - DRILL BIT

2 - AXLE

3 - RETAINING PLATE

4 - RETAINING RING

Fig. 26 RETAINING RING

1 - AXLE

2 - COLD CHISEL

3 - VISE

4 - RETAINING RING

WJREAR AXLE - 198RBI 3 - 69

Page 115 of 2199

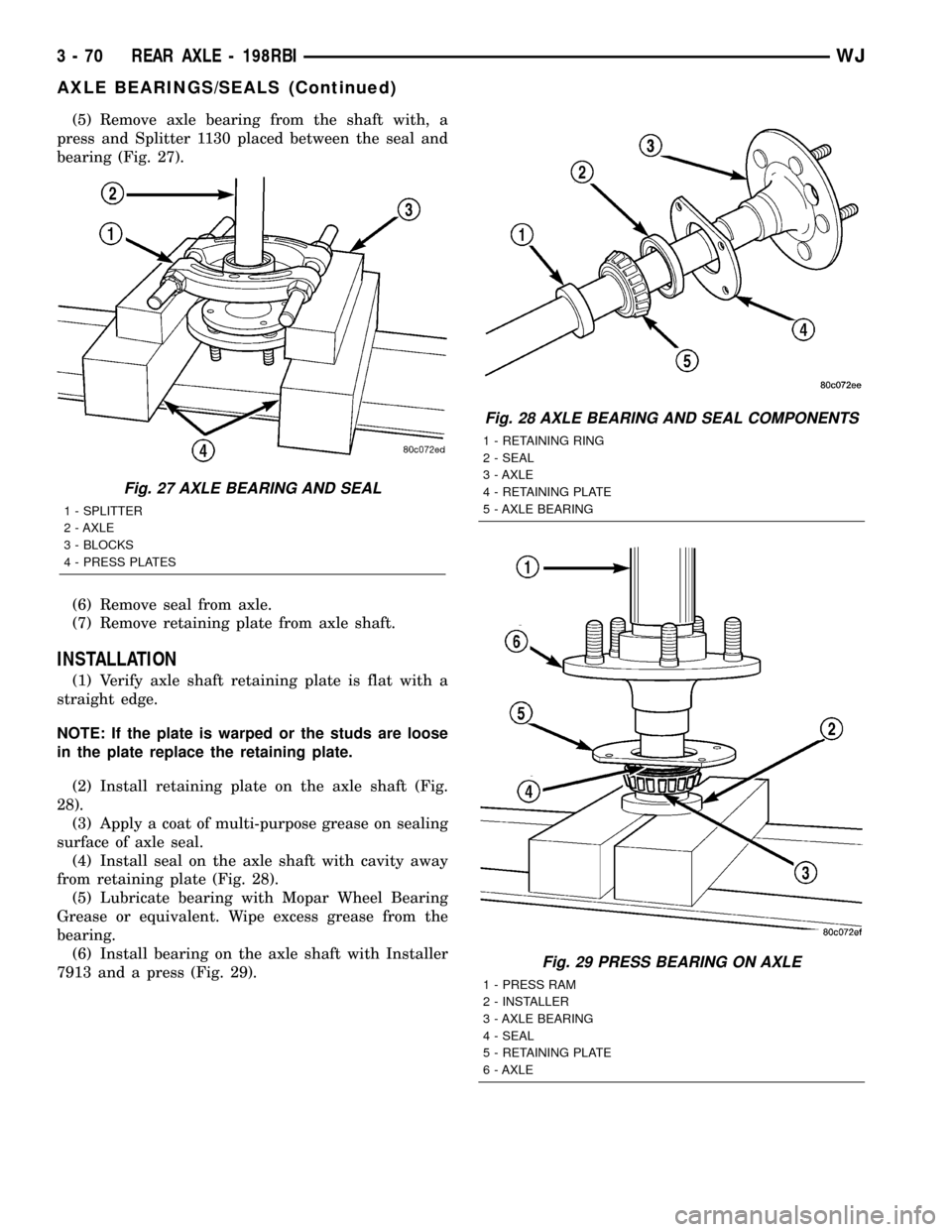

(5) Remove axle bearing from the shaft with, a

press and Splitter 1130 placed between the seal and

bearing (Fig. 27).

(6) Remove seal from axle.

(7) Remove retaining plate from axle shaft.

INSTALLATION

(1) Verify axle shaft retaining plate is flat with a

straight edge.

NOTE: If the plate is warped or the studs are loose

in the plate replace the retaining plate.

(2) Install retaining plate on the axle shaft (Fig.

28).

(3) Apply a coat of multi-purpose grease on sealing

surface of axle seal.

(4) Install seal on the axle shaft with cavity away

from retaining plate (Fig. 28).

(5) Lubricate bearing with Mopar Wheel Bearing

Grease or equivalent. Wipe excess grease from the

bearing.

(6) Install bearing on the axle shaft with Installer

7913 and a press (Fig. 29).

Fig. 27 AXLE BEARING AND SEAL

1 - SPLITTER

2 - AXLE

3 - BLOCKS

4 - PRESS PLATES

Fig. 28 AXLE BEARING AND SEAL COMPONENTS

1 - RETAINING RING

2 - SEAL

3 - AXLE

4 - RETAINING PLATE

5 - AXLE BEARING

Fig. 29 PRESS BEARING ON AXLE

1 - PRESS RAM

2 - INSTALLER

3 - AXLE BEARING

4 - SEAL

5 - RETAINING PLATE

6 - AXLE

3 - 70 REAR AXLE - 198RBIWJ

AXLE BEARINGS/SEALS (Continued)

Page 116 of 2199

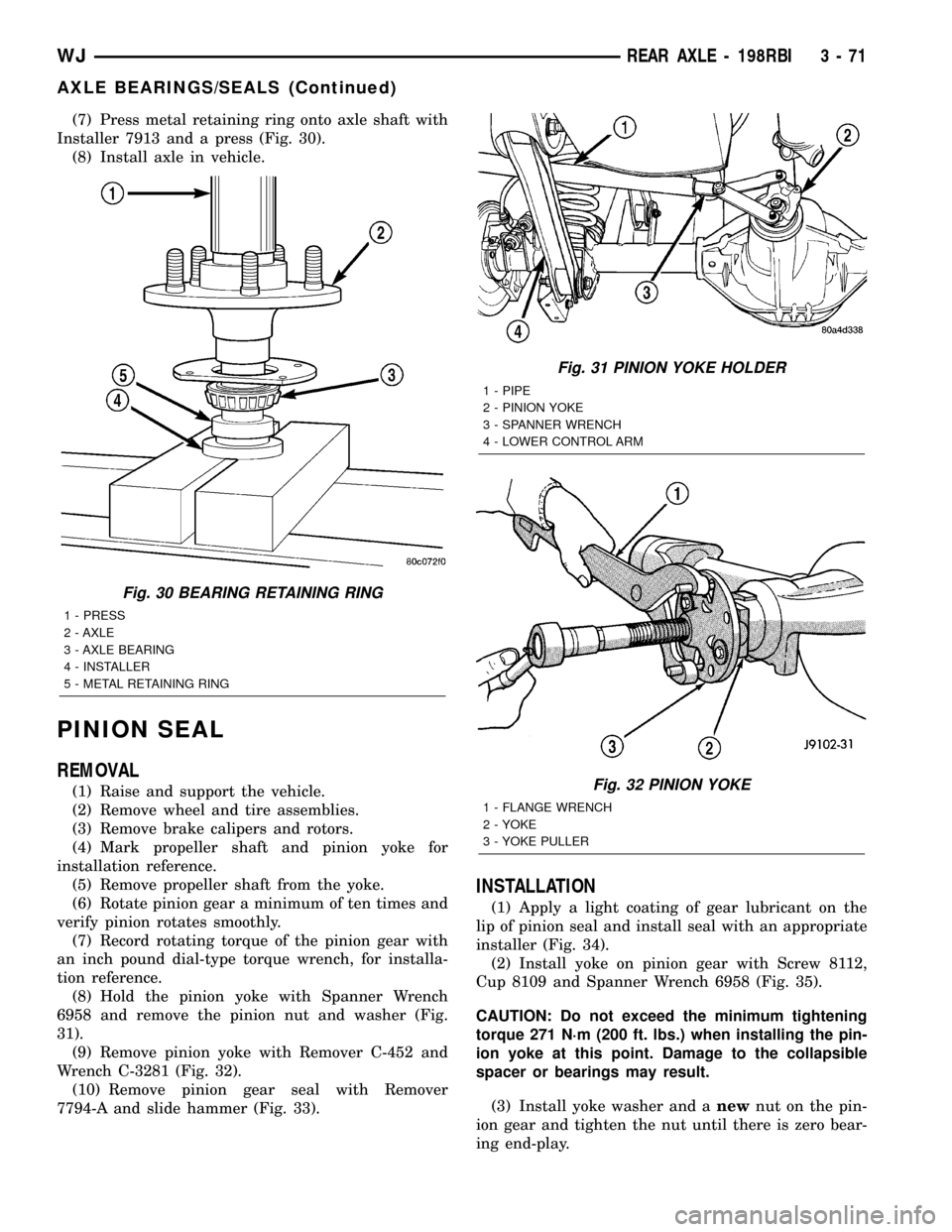

(7) Press metal retaining ring onto axle shaft with

Installer 7913 and a press (Fig. 30).

(8) Install axle in vehicle.

PINION SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove brake calipers and rotors.

(4) Mark propeller shaft and pinion yoke for

installation reference.

(5) Remove propeller shaft from the yoke.

(6) Rotate pinion gear a minimum of ten times and

verify pinion rotates smoothly.

(7) Record rotating torque of the pinion gear with

an inch pound dial-type torque wrench, for installa-

tion reference.

(8) Hold the pinion yoke with Spanner Wrench

6958 and remove the pinion nut and washer (Fig.

31).

(9) Remove pinion yoke with Remover C-452 and

Wrench C-3281 (Fig. 32).

(10) Remove pinion gear seal with Remover

7794-A and slide hammer (Fig. 33).

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal and install seal with an appropriate

installer (Fig. 34).

(2) Install yoke on pinion gear with Screw 8112,

Cup 8109 and Spanner Wrench 6958 (Fig. 35).

CAUTION: Do not exceed the minimum tightening

torque 271 N´m (200 ft. lbs.) when installing the pin-

ion yoke at this point. Damage to the collapsible

spacer or bearings may result.

(3) Install yoke washer and anewnut on the pin-

ion gear and tighten the nut until there is zero bear-

ing end-play.

Fig. 30 BEARING RETAINING RING

1 - PRESS

2 - AXLE

3 - AXLE BEARING

4 - INSTALLER

5 - METAL RETAINING RING

Fig. 31 PINION YOKE HOLDER

1 - PIPE

2 - PINION YOKE

3 - SPANNER WRENCH

4 - LOWER CONTROL ARM

Fig. 32 PINION YOKE

1 - FLANGE WRENCH

2 - YOKE

3 - YOKE PULLER

WJREAR AXLE - 198RBI 3 - 71

AXLE BEARINGS/SEALS (Continued)

Page 117 of 2199

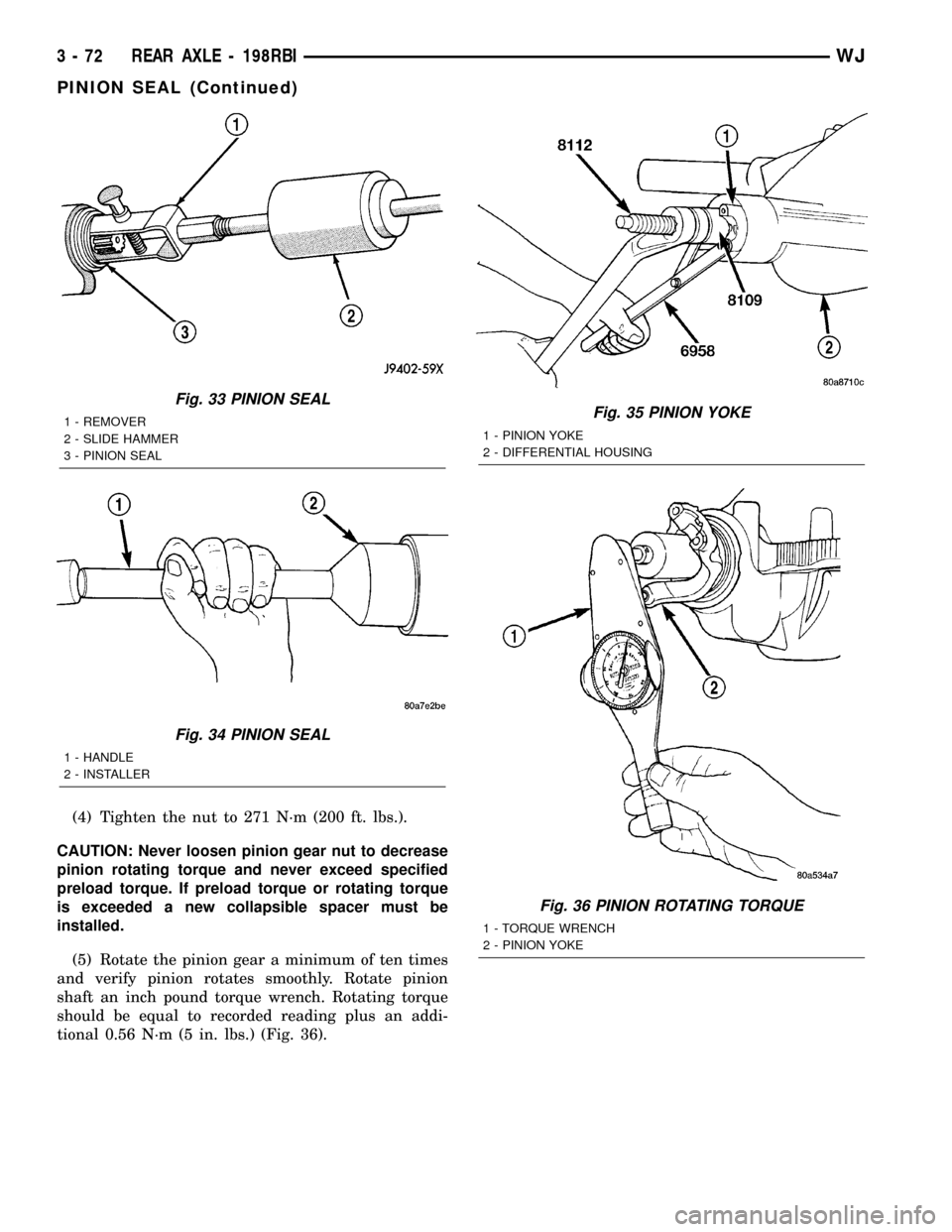

(4) Tighten the nut to 271 N´m (200 ft. lbs.).

CAUTION: Never loosen pinion gear nut to decrease

pinion rotating torque and never exceed specified

preload torque. If preload torque or rotating torque

is exceeded a new collapsible spacer must be

installed.

(5) Rotate the pinion gear a minimum of ten times

and verify pinion rotates smoothly. Rotate pinion

shaft an inch pound torque wrench. Rotating torque

should be equal to recorded reading plus an addi-

tional 0.56 N´m (5 in. lbs.) (Fig. 36).

Fig. 33 PINION SEAL

1 - REMOVER

2 - SLIDE HAMMER

3 - PINION SEAL

Fig. 34 PINION SEAL

1 - HANDLE

2 - INSTALLER

Fig. 35 PINION YOKE

1 - PINION YOKE

2 - DIFFERENTIAL HOUSING

Fig. 36 PINION ROTATING TORQUE

1 - TORQUE WRENCH

2 - PINION YOKE

3 - 72 REAR AXLE - 198RBIWJ

PINION SEAL (Continued)

Page 118 of 2199

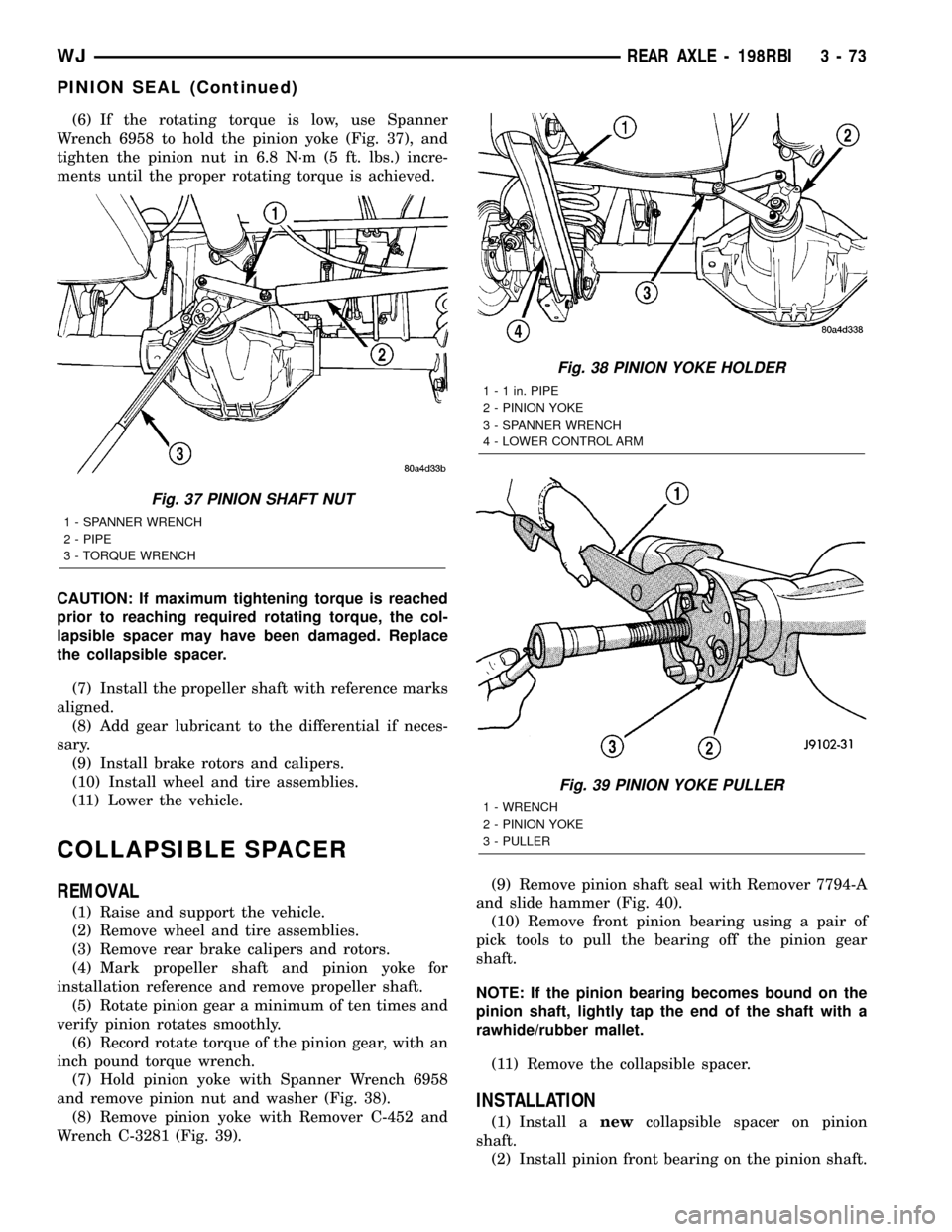

(6) If the rotating torque is low, use Spanner

Wrench 6958 to hold the pinion yoke (Fig. 37), and

tighten the pinion nut in 6.8 N´m (5 ft. lbs.) incre-

ments until the proper rotating torque is achieved.

CAUTION: If maximum tightening torque is reached

prior to reaching required rotating torque, the col-

lapsible spacer may have been damaged. Replace

the collapsible spacer.

(7) Install the propeller shaft with reference marks

aligned.

(8) Add gear lubricant to the differential if neces-

sary.

(9) Install brake rotors and calipers.

(10) Install wheel and tire assemblies.

(11) Lower the vehicle.

COLLAPSIBLE SPACER

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove rear brake calipers and rotors.

(4) Mark propeller shaft and pinion yoke for

installation reference and remove propeller shaft.

(5) Rotate pinion gear a minimum of ten times and

verify pinion rotates smoothly.

(6) Record rotate torque of the pinion gear, with an

inch pound torque wrench.

(7) Hold pinion yoke with Spanner Wrench 6958

and remove pinion nut and washer (Fig. 38).

(8) Remove pinion yoke with Remover C-452 and

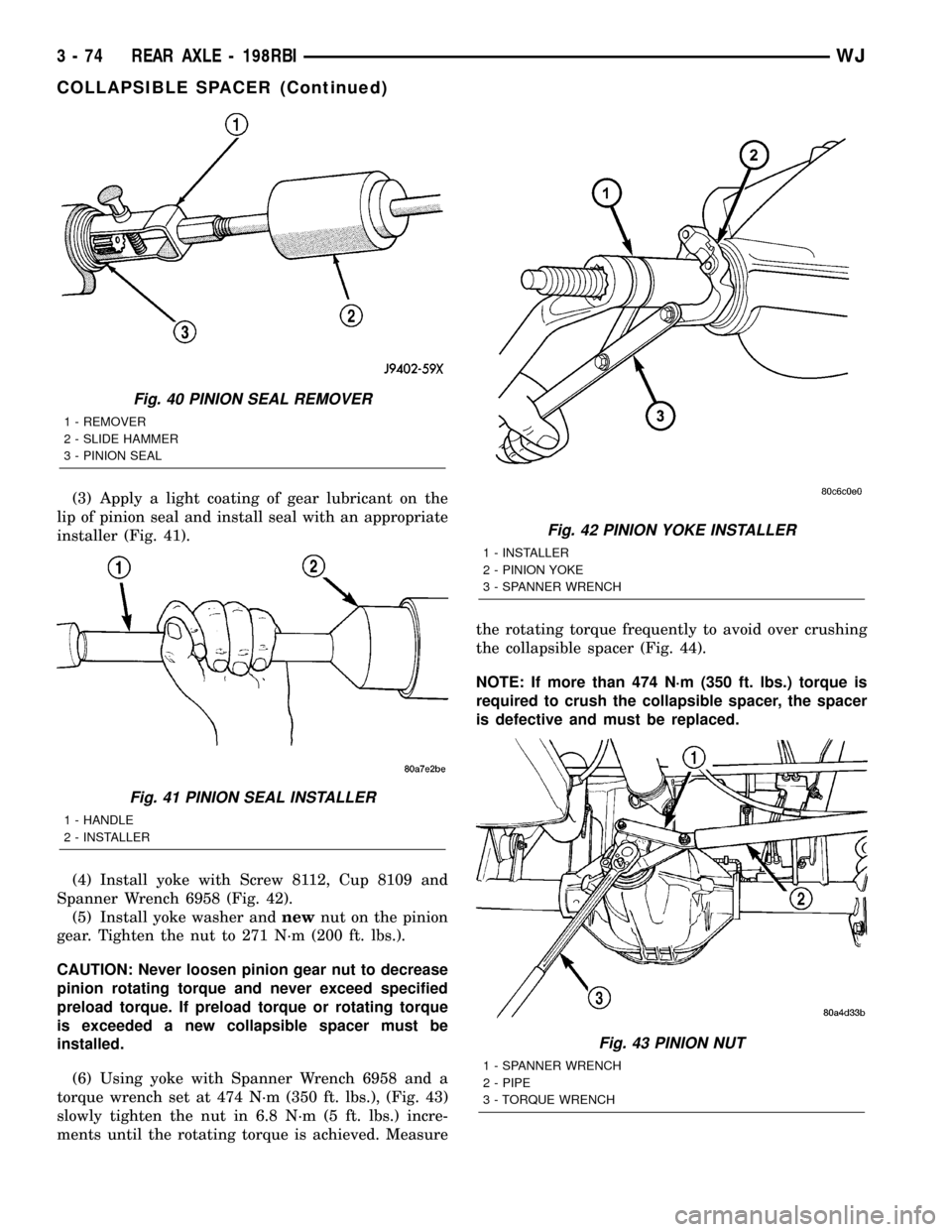

Wrench C-3281 (Fig. 39).(9) Remove pinion shaft seal with Remover 7794-A

and slide hammer (Fig. 40).

(10) Remove front pinion bearing using a pair of

pick tools to pull the bearing off the pinion gear

shaft.

NOTE: If the pinion bearing becomes bound on the

pinion shaft, lightly tap the end of the shaft with a

rawhide/rubber mallet.

(11) Remove the collapsible spacer.

INSTALLATION

(1) Install anewcollapsible spacer on pinion

shaft.

(2) Install pinion front bearing on the pinion shaft.

Fig. 37 PINION SHAFT NUT

1 - SPANNER WRENCH

2 - PIPE

3 - TORQUE WRENCH

Fig. 38 PINION YOKE HOLDER

1 - 1 in. PIPE

2 - PINION YOKE

3 - SPANNER WRENCH

4 - LOWER CONTROL ARM

Fig. 39 PINION YOKE PULLER

1 - WRENCH

2 - PINION YOKE

3 - PULLER

WJREAR AXLE - 198RBI 3 - 73

PINION SEAL (Continued)

Page 119 of 2199

(3) Apply a light coating of gear lubricant on the

lip of pinion seal and install seal with an appropriate

installer (Fig. 41).

(4) Install yoke with Screw 8112, Cup 8109 and

Spanner Wrench 6958 (Fig. 42).

(5) Install yoke washer andnewnut on the pinion

gear. Tighten the nut to 271 N´m (200 ft. lbs.).

CAUTION: Never loosen pinion gear nut to decrease

pinion rotating torque and never exceed specified

preload torque. If preload torque or rotating torque

is exceeded a new collapsible spacer must be

installed.

(6) Using yoke with Spanner Wrench 6958 and a

torque wrench set at 474 N´m (350 ft. lbs.), (Fig. 43)

slowly tighten the nut in 6.8 N´m (5 ft. lbs.) incre-

ments until the rotating torque is achieved. Measurethe rotating torque frequently to avoid over crushing

the collapsible spacer (Fig. 44).

NOTE: If more than 474 N´m (350 ft. lbs.) torque is

required to crush the collapsible spacer, the spacer

is defective and must be replaced.

Fig. 40 PINION SEAL REMOVER

1 - REMOVER

2 - SLIDE HAMMER

3 - PINION SEAL

Fig. 41 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

Fig. 42 PINION YOKE INSTALLER

1 - INSTALLER

2 - PINION YOKE

3 - SPANNER WRENCH

Fig. 43 PINION NUT

1 - SPANNER WRENCH

2 - PIPE

3 - TORQUE WRENCH

3 - 74 REAR AXLE - 198RBIWJ

COLLAPSIBLE SPACER (Continued)

Page 120 of 2199

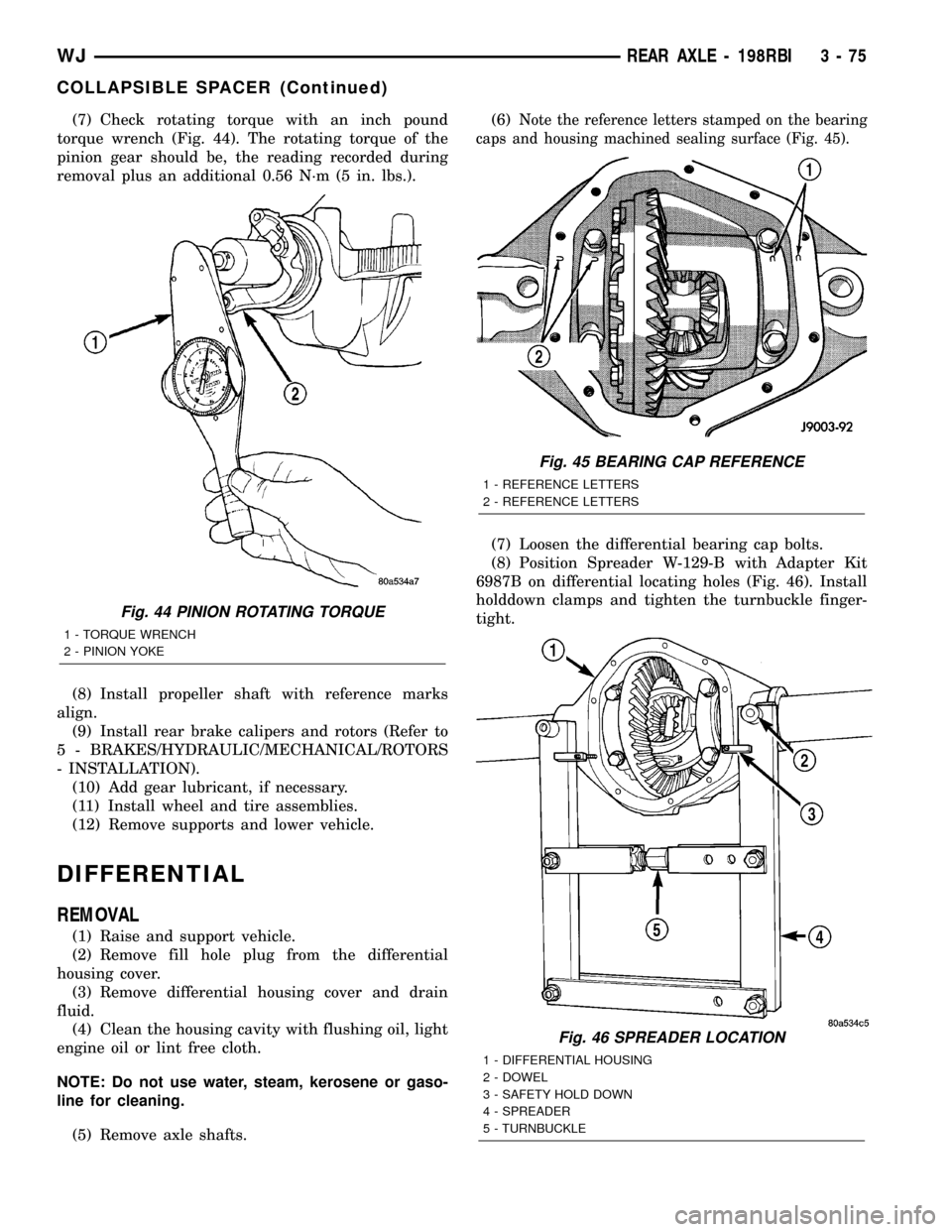

(7) Check rotating torque with an inch pound

torque wrench (Fig. 44). The rotating torque of the

pinion gear should be, the reading recorded during

removal plus an additional 0.56 N´m (5 in. lbs.).

(8) Install propeller shaft with reference marks

align.

(9) Install rear brake calipers and rotors (Refer to

5 - BRAKES/HYDRAULIC/MECHANICAL/ROTORS

- INSTALLATION).

(10) Add gear lubricant, if necessary.

(11) Install wheel and tire assemblies.

(12) Remove supports and lower vehicle.

DIFFERENTIAL

REMOVAL

(1) Raise and support vehicle.

(2) Remove fill hole plug from the differential

housing cover.

(3) Remove differential housing cover and drain

fluid.

(4) Clean the housing cavity with flushing oil, light

engine oil or lint free cloth.

NOTE: Do not use water, steam, kerosene or gaso-

line for cleaning.

(5) Remove axle shafts.(6)

Note the reference letters stamped on the bearing

caps and housing machined sealing surface (Fig. 45).

(7) Loosen the differential bearing cap bolts.

(8) Position Spreader W-129-B with Adapter Kit

6987B on differential locating holes (Fig. 46). Install

holddown clamps and tighten the turnbuckle finger-

tight.

Fig. 44 PINION ROTATING TORQUE

1 - TORQUE WRENCH

2 - PINION YOKE

Fig. 45 BEARING CAP REFERENCE

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 46 SPREADER LOCATION

1 - DIFFERENTIAL HOUSING

2 - DOWEL

3 - SAFETY HOLD DOWN

4 - SPREADER

5 - TURNBUCKLE

WJREAR AXLE - 198RBI 3 - 75

COLLAPSIBLE SPACER (Continued)