can bus JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1111 of 2199

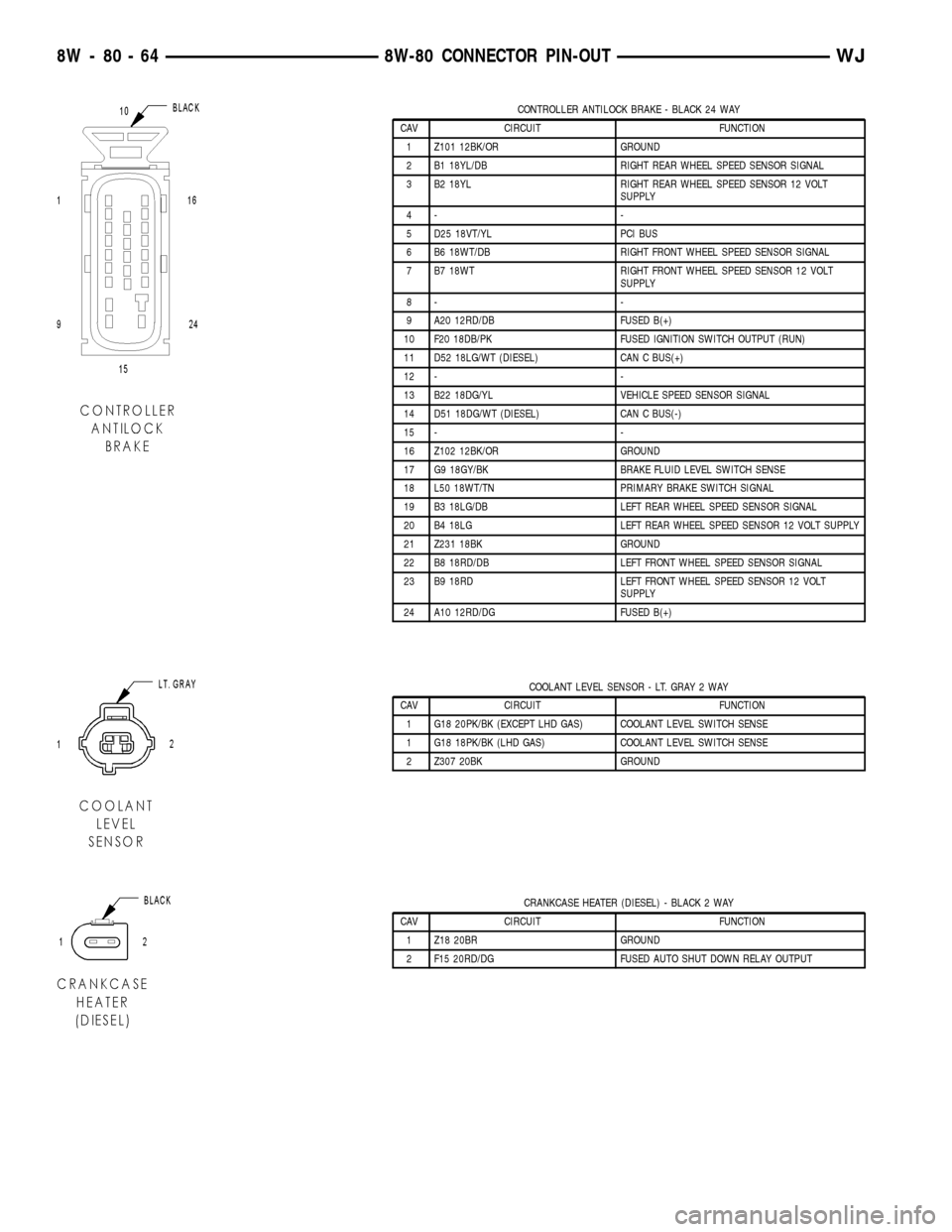

CONTROLLER ANTILOCK BRAKE - BLACK 24 WAY

CAV CIRCUIT FUNCTION

1 Z101 12BK/OR GROUND

2 B1 18YL/DB RIGHT REAR WHEEL SPEED SENSOR SIGNAL

3 B2 18YL RIGHT REAR WHEEL SPEED SENSOR 12 VOLT

SUPPLY

4- -

5 D25 18VT/YL PCI BUS

6 B6 18WT/DB RIGHT FRONT WHEEL SPEED SENSOR SIGNAL

7 B7 18WT RIGHT FRONT WHEEL SPEED SENSOR 12 VOLT

SUPPLY

8- -

9 A20 12RD/DB FUSED B(+)

10 F20 18DB/PK FUSED IGNITION SWITCH OUTPUT (RUN)

11 D52 18LG/WT (DIESEL) CAN C BUS(+)

12 - -

13 B22 18DG/YL VEHICLE SPEED SENSOR SIGNAL

14 D51 18DG/WT (DIESEL) CAN C BUS(-)

15 - -

16 Z102 12BK/OR GROUND

17 G9 18GY/BK BRAKE FLUID LEVEL SWITCH SENSE

18 L50 18WT/TN PRIMARY BRAKE SWITCH SIGNAL

19 B3 18LG/DB LEFT REAR WHEEL SPEED SENSOR SIGNAL

20 B4 18LG LEFT REAR WHEEL SPEED SENSOR 12 VOLT SUPPLY

21 Z231 18BK GROUND

22 B8 18RD/DB LEFT FRONT WHEEL SPEED SENSOR SIGNAL

23 B9 18RD LEFT FRONT WHEEL SPEED SENSOR 12 VOLT

SUPPLY

24 A10 12RD/DG FUSED B(+)

COOLANT LEVEL SENSOR - LT. GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 G18 20PK/BK (EXCEPT LHD GAS) COOLANT LEVEL SWITCH SENSE

1 G18 18PK/BK (LHD GAS) COOLANT LEVEL SWITCH SENSE

2 Z307 20BK GROUND

CRANKCASE HEATER (DIESEL) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Z18 20BR GROUND

2 F15 20RD/DG FUSED AUTO SHUT DOWN RELAY OUTPUT

8W - 80 - 64 8W-80 CONNECTOR PIN-OUTWJ

Page 1122 of 2199

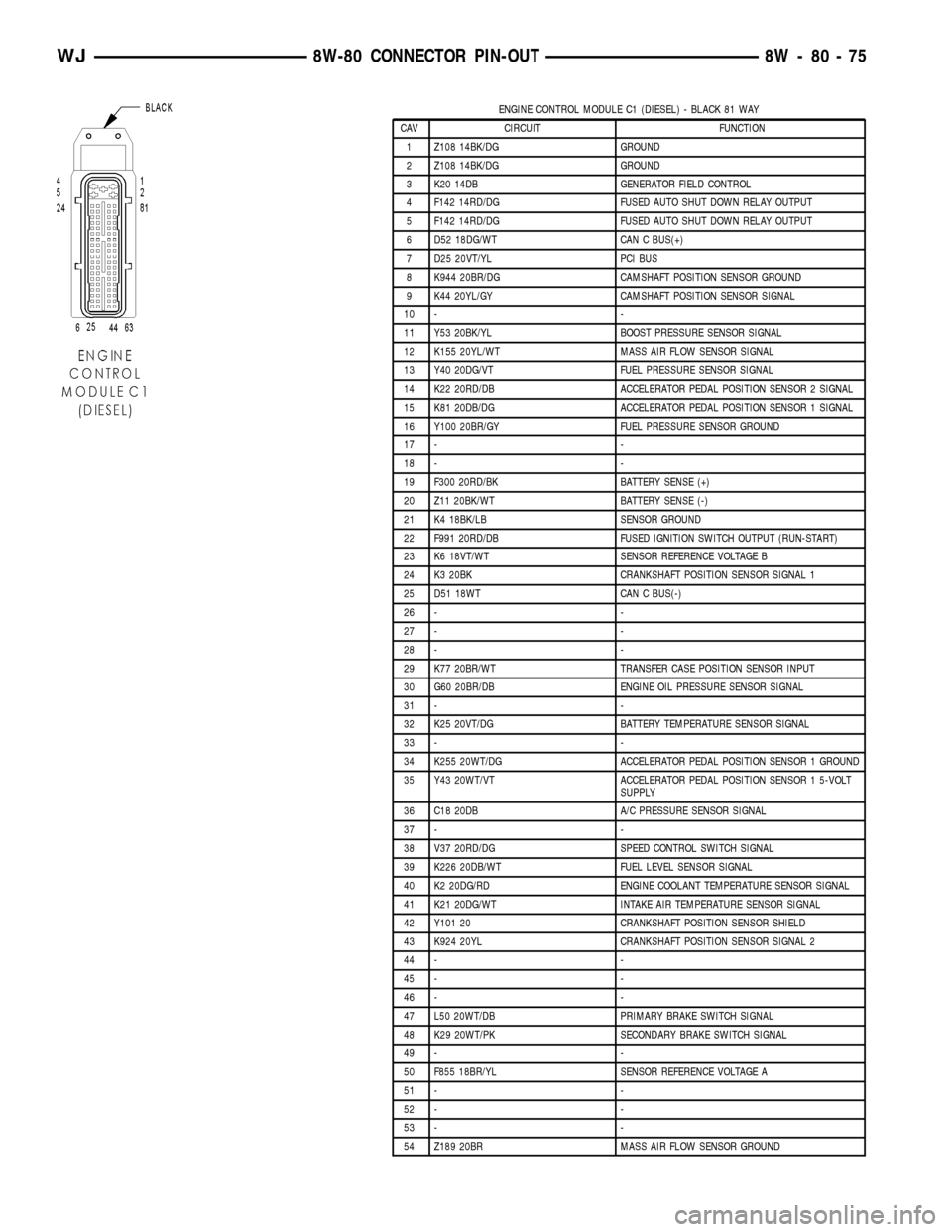

ENGINE CONTROL MODULE C1 (DIESEL) - BLACK 81 WAY

CAV CIRCUIT FUNCTION

1 Z108 14BK/DG GROUND

2 Z108 14BK/DG GROUND

3 K20 14DB GENERATOR FIELD CONTROL

4 F142 14RD/DG FUSED AUTO SHUT DOWN RELAY OUTPUT

5 F142 14RD/DG FUSED AUTO SHUT DOWN RELAY OUTPUT

6 D52 18DG/WT CAN C BUS(+)

7 D25 20VT/YL PCI BUS

8 K944 20BR/DG CAMSHAFT POSITION SENSOR GROUND

9 K44 20YL/GY CAMSHAFT POSITION SENSOR SIGNAL

10 - -

11 Y53 20BK/YL BOOST PRESSURE SENSOR SIGNAL

12 K155 20YL/WT MASS AIR FLOW SENSOR SIGNAL

13 Y40 20DG/VT FUEL PRESSURE SENSOR SIGNAL

14 K22 20RD/DB ACCELERATOR PEDAL POSITION SENSOR 2 SIGNAL

15 K81 20DB/DG ACCELERATOR PEDAL POSITION SENSOR 1 SIGNAL

16 Y100 20BR/GY FUEL PRESSURE SENSOR GROUND

17 - -

18 - -

19 F300 20RD/BK BATTERY SENSE (+)

20 Z11 20BK/WT BATTERY SENSE (-)

21 K4 18BK/LB SENSOR GROUND

22 F991 20RD/DB FUSED IGNITION SWITCH OUTPUT (RUN-START)

23 K6 18VT/WT SENSOR REFERENCE VOLTAGE B

24 K3 20BK CRANKSHAFT POSITION SENSOR SIGNAL 1

25 D51 18WT CAN C BUS(-)

26 - -

27 - -

28 - -

29 K77 20BR/WT TRANSFER CASE POSITION SENSOR INPUT

30 G60 20BR/DB ENGINE OIL PRESSURE SENSOR SIGNAL

31 - -

32 K25 20VT/DG BATTERY TEMPERATURE SENSOR SIGNAL

33 - -

34 K255 20WT/DG ACCELERATOR PEDAL POSITION SENSOR 1 GROUND

35 Y43 20WT/VT ACCELERATOR PEDAL POSITION SENSOR 1 5-VOLT

SUPPLY

36 C18 20DB A/C PRESSURE SENSOR SIGNAL

37 - -

38 V37 20RD/DG SPEED CONTROL SWITCH SIGNAL

39 K226 20DB/WT FUEL LEVEL SENSOR SIGNAL

40 K2 20DG/RD ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

41 K21 20DG/WT INTAKE AIR TEMPERATURE SENSOR SIGNAL

42 Y101 20 CRANKSHAFT POSITION SENSOR SHIELD

43 K924 20YL CRANKSHAFT POSITION SENSOR SIGNAL 2

44 - -

45 - -

46 - -

47 L50 20WT/DB PRIMARY BRAKE SWITCH SIGNAL

48 K29 20WT/PK SECONDARY BRAKE SWITCH SIGNAL

49 - -

50 F855 18BR/YL SENSOR REFERENCE VOLTAGE A

51 - -

52 - -

53 - -

54 Z189 20BR MASS AIR FLOW SENSOR GROUND

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 75

Page 1172 of 2199

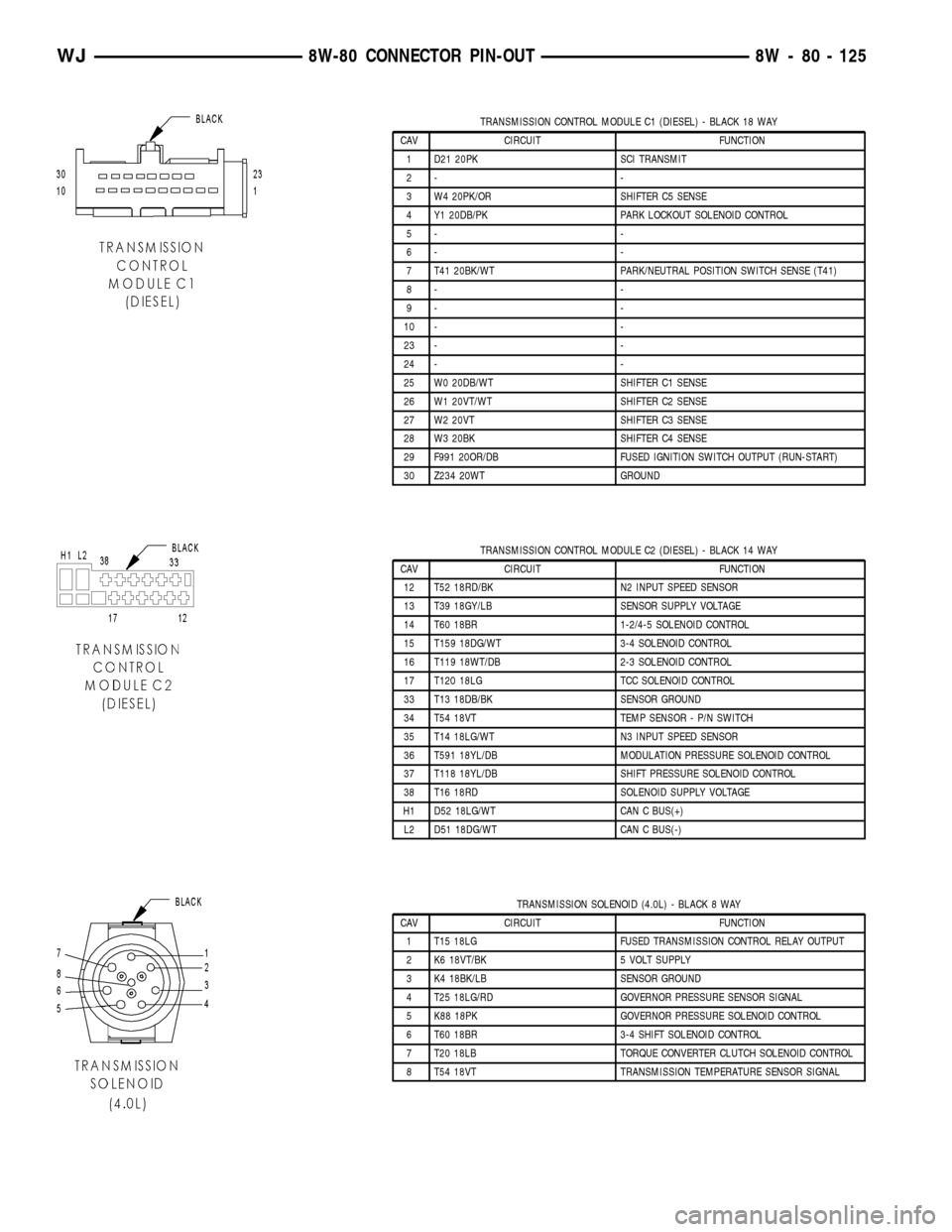

TRANSMISSION CONTROL MODULE C1 (DIESEL) - BLACK 18 WAY

CAV CIRCUIT FUNCTION

1 D21 20PK SCI TRANSMIT

2- -

3 W4 20PK/OR SHIFTER C5 SENSE

4 Y1 20DB/PK PARK LOCKOUT SOLENOID CONTROL

5- -

6- -

7 T41 20BK/WT PARK/NEUTRAL POSITION SWITCH SENSE (T41)

8- -

9- -

10 - -

23 - -

24 - -

25 W0 20DB/WT SHIFTER C1 SENSE

26 W1 20VT/WT SHIFTER C2 SENSE

27 W2 20VT SHIFTER C3 SENSE

28 W3 20BK SHIFTER C4 SENSE

29 F991 20OR/DB FUSED IGNITION SWITCH OUTPUT (RUN-START)

30 Z234 20WT GROUND

TRANSMISSION CONTROL MODULE C2 (DIESEL) - BLACK 14 WAY

CAV CIRCUIT FUNCTION

12 T52 18RD/BK N2 INPUT SPEED SENSOR

13 T39 18GY/LB SENSOR SUPPLY VOLTAGE

14 T60 18BR 1-2/4-5 SOLENOID CONTROL

15 T159 18DG/WT 3-4 SOLENOID CONTROL

16 T119 18WT/DB 2-3 SOLENOID CONTROL

17 T120 18LG TCC SOLENOID CONTROL

33 T13 18DB/BK SENSOR GROUND

34 T54 18VT TEMP SENSOR - P/N SWITCH

35 T14 18LG/WT N3 INPUT SPEED SENSOR

36 T591 18YL/DB MODULATION PRESSURE SOLENOID CONTROL

37 T118 18YL/DB SHIFT PRESSURE SOLENOID CONTROL

38 T16 18RD SOLENOID SUPPLY VOLTAGE

H1 D52 18LG/WT CAN C BUS(+)

L2 D51 18DG/WT CAN C BUS(-)

TRANSMISSION SOLENOID (4.0L) - BLACK 8 WAY

CAV CIRCUIT FUNCTION

1 T15 18LG FUSED TRANSMISSION CONTROL RELAY OUTPUT

2 K6 18VT/BK 5 VOLT SUPPLY

3 K4 18BK/LB SENSOR GROUND

4 T25 18LG/RD GOVERNOR PRESSURE SENSOR SIGNAL

5 K88 18PK GOVERNOR PRESSURE SOLENOID CONTROL

6 T60 18BR 3-4 SHIFT SOLENOID CONTROL

7 T20 18LB TORQUE CONVERTER CLUTCH SOLENOID CONTROL

8 T54 18VT TRANSMISSION TEMPERATURE SENSOR SIGNAL

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 125

Page 1232 of 2199

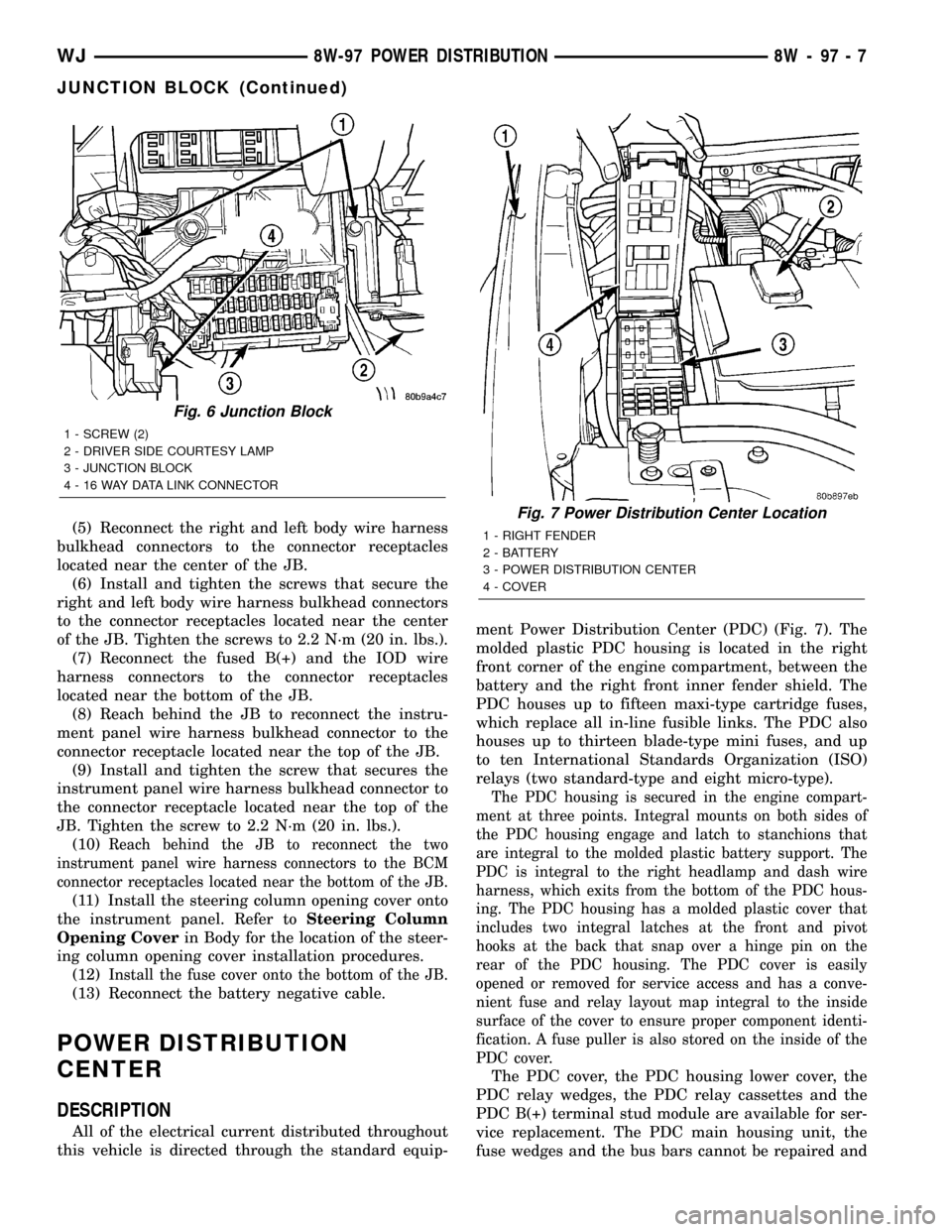

(5) Reconnect the right and left body wire harness

bulkhead connectors to the connector receptacles

located near the center of the JB.

(6) Install and tighten the screws that secure the

right and left body wire harness bulkhead connectors

to the connector receptacles located near the center

of the JB. Tighten the screws to 2.2 N´m (20 in. lbs.).

(7) Reconnect the fused B(+) and the IOD wire

harness connectors to the connector receptacles

located near the bottom of the JB.

(8) Reach behind the JB to reconnect the instru-

ment panel wire harness bulkhead connector to the

connector receptacle located near the top of the JB.

(9) Install and tighten the screw that secures the

instrument panel wire harness bulkhead connector to

the connector receptacle located near the top of the

JB. Tighten the screw to 2.2 N´m (20 in. lbs.).

(10)

Reach behind the JB to reconnect the two

instrument panel wire harness connectors to the BCM

connector receptacles located near the bottom of the JB.

(11) Install the steering column opening cover onto

the instrument panel. Refer toSteering Column

Opening Coverin Body for the location of the steer-

ing column opening cover installation procedures.

(12)

Install the fuse cover onto the bottom of the JB.

(13) Reconnect the battery negative cable.

POWER DISTRIBUTION

CENTER

DESCRIPTION

All of the electrical current distributed throughout

this vehicle is directed through the standard equip-ment Power Distribution Center (PDC) (Fig. 7). The

molded plastic PDC housing is located in the right

front corner of the engine compartment, between the

battery and the right front inner fender shield. The

PDC houses up to fifteen maxi-type cartridge fuses,

which replace all in-line fusible links. The PDC also

houses up to thirteen blade-type mini fuses, and up

to ten International Standards Organization (ISO)

relays (two standard-type and eight micro-type).

The PDC housing is secured in the engine compart-

ment at three points. Integral mounts on both sides of

the PDC housing engage and latch to stanchions that

are integral to the molded plastic battery support. The

PDC is integral to the right headlamp and dash wire

harness, which exits from the bottom of the PDC hous-

ing. The PDC housing has a molded plastic cover that

includes two integral latches at the front and pivot

hooks at the back that snap over a hinge pin on the

rear of the PDC housing. The PDC cover is easily

opened or removed for service access and has a conve-

nient fuse and relay layout map integral to the inside

surface of the cover to ensure proper component identi-

fication. A fuse puller is also stored on the inside of the

PDC cover.

The PDC cover, the PDC housing lower cover, the

PDC relay wedges, the PDC relay cassettes and the

PDC B(+) terminal stud module are available for ser-

vice replacement. The PDC main housing unit, the

fuse wedges and the bus bars cannot be repaired and

Fig. 6 Junction Block

1 - SCREW (2)

2 - DRIVER SIDE COURTESY LAMP

3 - JUNCTION BLOCK

4 - 16 WAY DATA LINK CONNECTOR

Fig. 7 Power Distribution Center Location

1 - RIGHT FENDER

2 - BATTERY

3 - POWER DISTRIBUTION CENTER

4 - COVER

WJ8W-97 POWER DISTRIBUTION 8W - 97 - 7

JUNCTION BLOCK (Continued)

Page 1233 of 2199

are only serviced as a unit with the right headlamp

and dash wire harness. If the PDC main housing

unit, fuse wedges or the bus bars are faulty or dam-

aged, the right headlamp and dash wire harness unit

must be replaced.

OPERATION

All of the current from the battery and the generator

output enters the PDC through two cables and a single

two-holed eyelet that is secured with nuts to the two

PDC B(+) terminal studs just inside the front end of the

PDC housing. The PDC cover is unlatched and opened

to access the battery and generator output connection

B(+) terminal studs, the fuses or the relays. Internal

connection of all of the PDC circuits is accomplished by

an intricate combination of hard wiring and bus bars.

Refer toPower Distribution

in Wiring Diagrams for

the location of complete PDC circuit diagrams.

REMOVAL

The Power Distribution Center (PDC) main housing

unit, the PDC fuse wedges and the PDC bus bars can-

not be repaired and are only serviced as a unit with the

right headlamp and dash wire harness. If the PDC

main housing unit, the fuse wedges or the bus bars are

faulty or damaged, the entire PDC and right headlamp

and dash wire harness unit must be replaced.

(1)Disconnect and isolate the battery negative cable.

(2) Disconnect each of the right headlamp and

dash wire harness connectors. Refer toConnector

Locationsin Wiring Diagrams for the location of

more information on the right headlamp and dash

wire harness connector locations.

(3) Remove all of the fasteners that secure each of

the right headlamp and dash wire harness ground

eyelets to the vehicle body and chassis components.

Refer toConnector Locationsin Wiring Diagrams

for the location of more information on the ground

eyelet locations.

(4) Disengage each of the retainers that secure the

right headlamp and dash wire harness to the vehicle

body and chassis components. Refer toConnector

Locationsin Wiring Diagrams for the location of

more information on the right headlamp and dash

wire harness retainer locations.

(5) Unlatch and open the PDC cover.

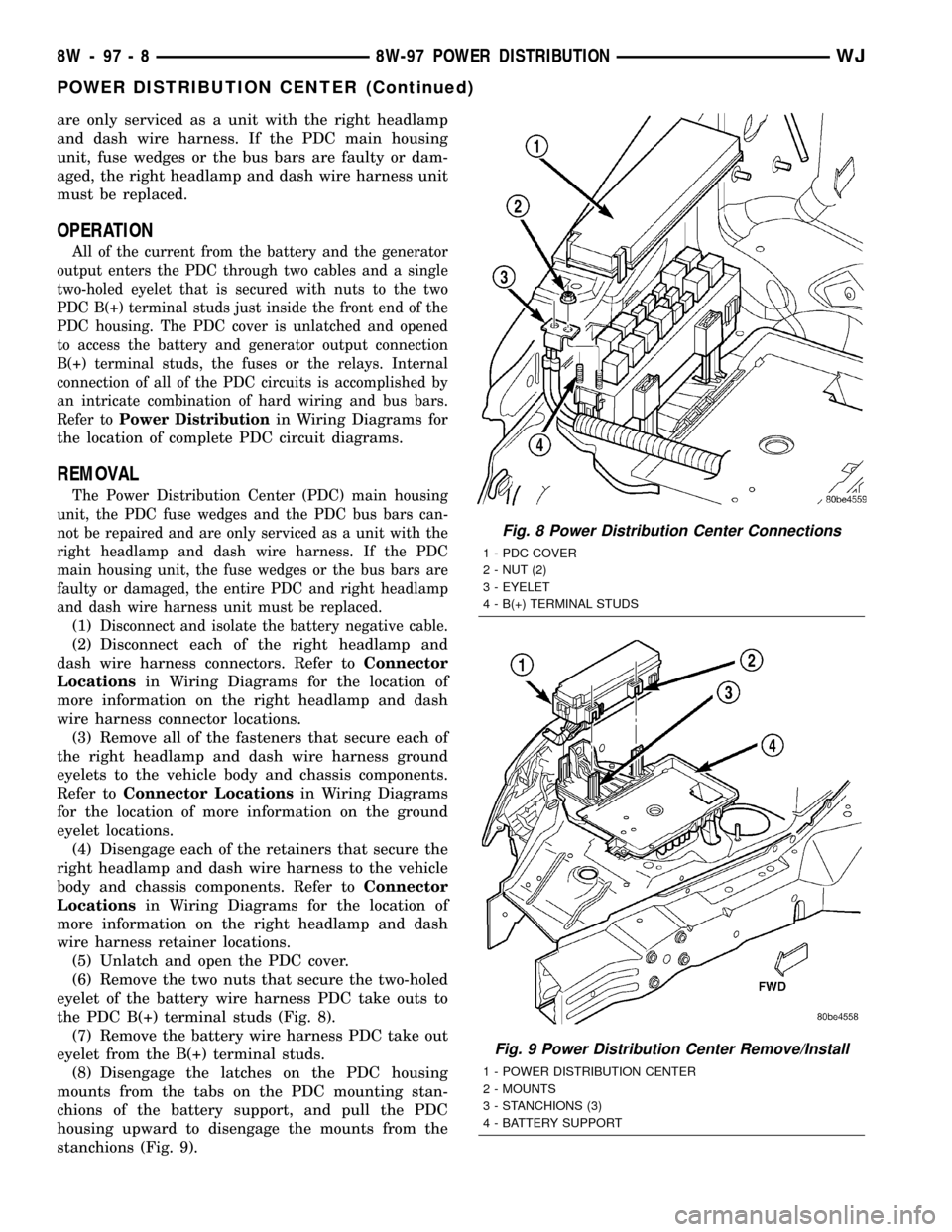

(6) Remove the two nuts that secure the two-holed

eyelet of the battery wire harness PDC take outs to

the PDC B(+) terminal studs (Fig. 8).

(7) Remove the battery wire harness PDC take out

eyelet from the B(+) terminal studs.

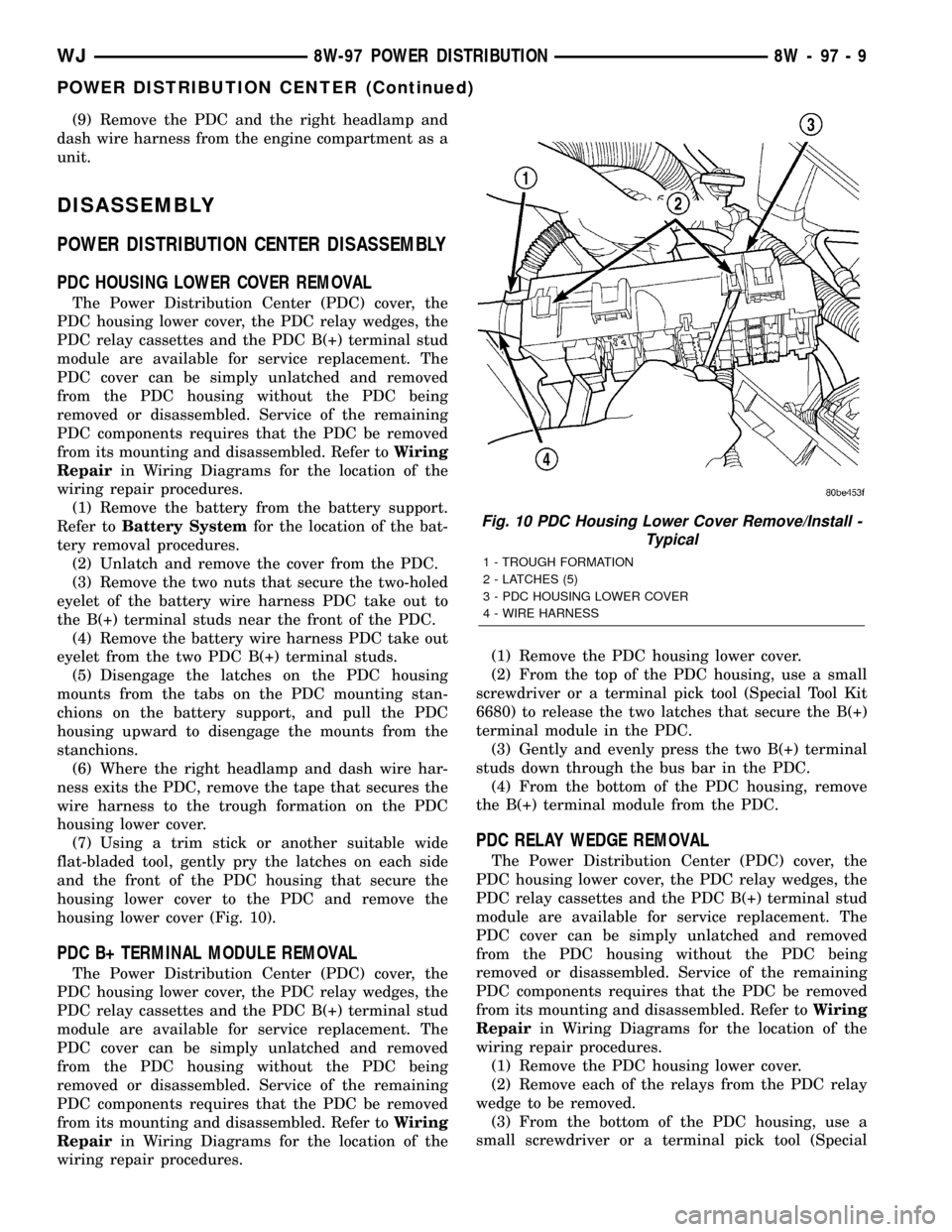

(8) Disengage the latches on the PDC housing

mounts from the tabs on the PDC mounting stan-

chions of the battery support, and pull the PDC

housing upward to disengage the mounts from the

stanchions (Fig. 9).

Fig. 8 Power Distribution Center Connections

1 - PDC COVER

2 - NUT (2)

3 - EYELET

4 - B(+) TERMINAL STUDS

Fig. 9 Power Distribution Center Remove/Install

1 - POWER DISTRIBUTION CENTER

2 - MOUNTS

3 - STANCHIONS (3)

4 - BATTERY SUPPORT

8W - 97 - 8 8W-97 POWER DISTRIBUTIONWJ

POWER DISTRIBUTION CENTER (Continued)

Page 1234 of 2199

(9) Remove the PDC and the right headlamp and

dash wire harness from the engine compartment as a

unit.

DISASSEMBLY

POWER DISTRIBUTION CENTER DISASSEMBLY

PDC HOUSING LOWER COVER REMOVAL

The Power Distribution Center (PDC) cover, the

PDC housing lower cover, the PDC relay wedges, the

PDC relay cassettes and the PDC B(+) terminal stud

module are available for service replacement. The

PDC cover can be simply unlatched and removed

from the PDC housing without the PDC being

removed or disassembled. Service of the remaining

PDC components requires that the PDC be removed

from its mounting and disassembled. Refer toWiring

Repairin Wiring Diagrams for the location of the

wiring repair procedures.

(1) Remove the battery from the battery support.

Refer toBattery Systemfor the location of the bat-

tery removal procedures.

(2) Unlatch and remove the cover from the PDC.

(3) Remove the two nuts that secure the two-holed

eyelet of the battery wire harness PDC take out to

the B(+) terminal studs near the front of the PDC.

(4) Remove the battery wire harness PDC take out

eyelet from the two PDC B(+) terminal studs.

(5) Disengage the latches on the PDC housing

mounts from the tabs on the PDC mounting stan-

chions on the battery support, and pull the PDC

housing upward to disengage the mounts from the

stanchions.

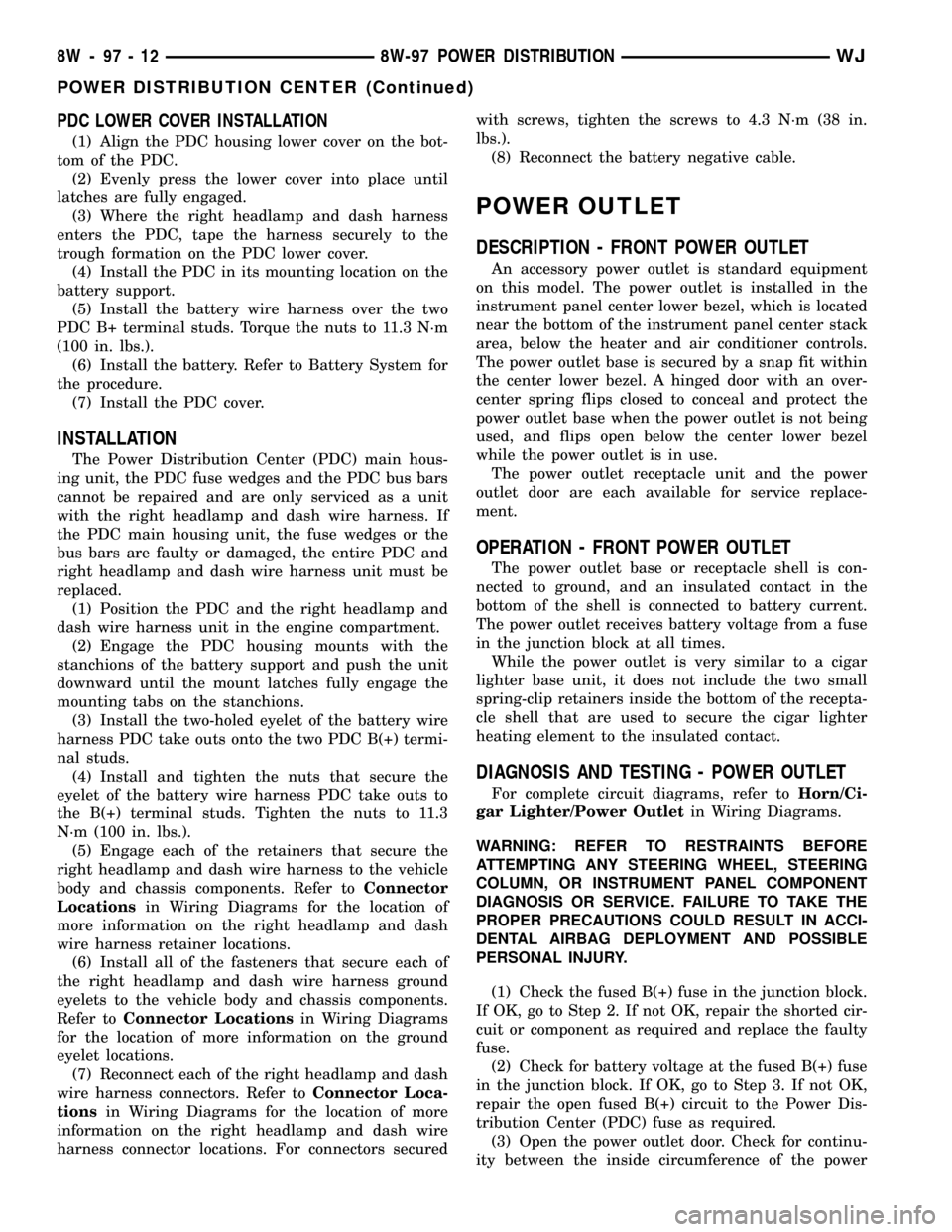

(6) Where the right headlamp and dash wire har-

ness exits the PDC, remove the tape that secures the

wire harness to the trough formation on the PDC

housing lower cover.

(7) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the latches on each side

and the front of the PDC housing that secure the

housing lower cover to the PDC and remove the

housing lower cover (Fig. 10).

PDC B+ TERMINAL MODULE REMOVAL

The Power Distribution Center (PDC) cover, the

PDC housing lower cover, the PDC relay wedges, the

PDC relay cassettes and the PDC B(+) terminal stud

module are available for service replacement. The

PDC cover can be simply unlatched and removed

from the PDC housing without the PDC being

removed or disassembled. Service of the remaining

PDC components requires that the PDC be removed

from its mounting and disassembled. Refer toWiring

Repairin Wiring Diagrams for the location of the

wiring repair procedures.(1) Remove the PDC housing lower cover.

(2) From the top of the PDC housing, use a small

screwdriver or a terminal pick tool (Special Tool Kit

6680) to release the two latches that secure the B(+)

terminal module in the PDC.

(3) Gently and evenly press the two B(+) terminal

studs down through the bus bar in the PDC.

(4) From the bottom of the PDC housing, remove

the B(+) terminal module from the PDC.

PDC RELAY WEDGE REMOVAL

The Power Distribution Center (PDC) cover, the

PDC housing lower cover, the PDC relay wedges, the

PDC relay cassettes and the PDC B(+) terminal stud

module are available for service replacement. The

PDC cover can be simply unlatched and removed

from the PDC housing without the PDC being

removed or disassembled. Service of the remaining

PDC components requires that the PDC be removed

from its mounting and disassembled. Refer toWiring

Repairin Wiring Diagrams for the location of the

wiring repair procedures.

(1) Remove the PDC housing lower cover.

(2) Remove each of the relays from the PDC relay

wedge to be removed.

(3) From the bottom of the PDC housing, use a

small screwdriver or a terminal pick tool (Special

Fig. 10 PDC Housing Lower Cover Remove/Install -

Typical

1 - TROUGH FORMATION

2 - LATCHES (5)

3 - PDC HOUSING LOWER COVER

4 - WIRE HARNESS

WJ8W-97 POWER DISTRIBUTION 8W - 97 - 9

POWER DISTRIBUTION CENTER (Continued)

Page 1237 of 2199

PDC LOWER COVER INSTALLATION

(1) Align the PDC housing lower cover on the bot-

tom of the PDC.

(2) Evenly press the lower cover into place until

latches are fully engaged.

(3) Where the right headlamp and dash harness

enters the PDC, tape the harness securely to the

trough formation on the PDC lower cover.

(4) Install the PDC in its mounting location on the

battery support.

(5) Install the battery wire harness over the two

PDC B+ terminal studs. Torque the nuts to 11.3 N´m

(100 in. lbs.).

(6) Install the battery. Refer to Battery System for

the procedure.

(7) Install the PDC cover.

INSTALLATION

The Power Distribution Center (PDC) main hous-

ing unit, the PDC fuse wedges and the PDC bus bars

cannot be repaired and are only serviced as a unit

with the right headlamp and dash wire harness. If

the PDC main housing unit, the fuse wedges or the

bus bars are faulty or damaged, the entire PDC and

right headlamp and dash wire harness unit must be

replaced.

(1) Position the PDC and the right headlamp and

dash wire harness unit in the engine compartment.

(2) Engage the PDC housing mounts with the

stanchions of the battery support and push the unit

downward until the mount latches fully engage the

mounting tabs on the stanchions.

(3) Install the two-holed eyelet of the battery wire

harness PDC take outs onto the two PDC B(+) termi-

nal studs.

(4) Install and tighten the nuts that secure the

eyelet of the battery wire harness PDC take outs to

the B(+) terminal studs. Tighten the nuts to 11.3

N´m (100 in. lbs.).

(5) Engage each of the retainers that secure the

right headlamp and dash wire harness to the vehicle

body and chassis components. Refer toConnector

Locationsin Wiring Diagrams for the location of

more information on the right headlamp and dash

wire harness retainer locations.

(6) Install all of the fasteners that secure each of

the right headlamp and dash wire harness ground

eyelets to the vehicle body and chassis components.

Refer toConnector Locationsin Wiring Diagrams

for the location of more information on the ground

eyelet locations.

(7) Reconnect each of the right headlamp and dash

wire harness connectors. Refer toConnector Loca-

tionsin Wiring Diagrams for the location of more

information on the right headlamp and dash wire

harness connector locations. For connectors securedwith screws, tighten the screws to 4.3 N´m (38 in.

lbs.).

(8) Reconnect the battery negative cable.

POWER OUTLET

DESCRIPTION - FRONT POWER OUTLET

An accessory power outlet is standard equipment

on this model. The power outlet is installed in the

instrument panel center lower bezel, which is located

near the bottom of the instrument panel center stack

area, below the heater and air conditioner controls.

The power outlet base is secured by a snap fit within

the center lower bezel. A hinged door with an over-

center spring flips closed to conceal and protect the

power outlet base when the power outlet is not being

used, and flips open below the center lower bezel

while the power outlet is in use.

The power outlet receptacle unit and the power

outlet door are each available for service replace-

ment.

OPERATION - FRONT POWER OUTLET

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet receives battery voltage from a fuse

in the junction block at all times.

While the power outlet is very similar to a cigar

lighter base unit, it does not include the two small

spring-clip retainers inside the bottom of the recepta-

cle shell that are used to secure the cigar lighter

heating element to the insulated contact.

DIAGNOSIS AND TESTING - POWER OUTLET

For complete circuit diagrams, refer toHorn/Ci-

gar Lighter/Power Outletin Wiring Diagrams.

WARNING: REFER TO RESTRAINTS BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the junction block. If OK, go to Step 3. If not OK,

repair the open fused B(+) circuit to the Power Dis-

tribution Center (PDC) fuse as required.

(3) Open the power outlet door. Check for continu-

ity between the inside circumference of the power

8W - 97 - 12 8W-97 POWER DISTRIBUTIONWJ

POWER DISTRIBUTION CENTER (Continued)

Page 1246 of 2199

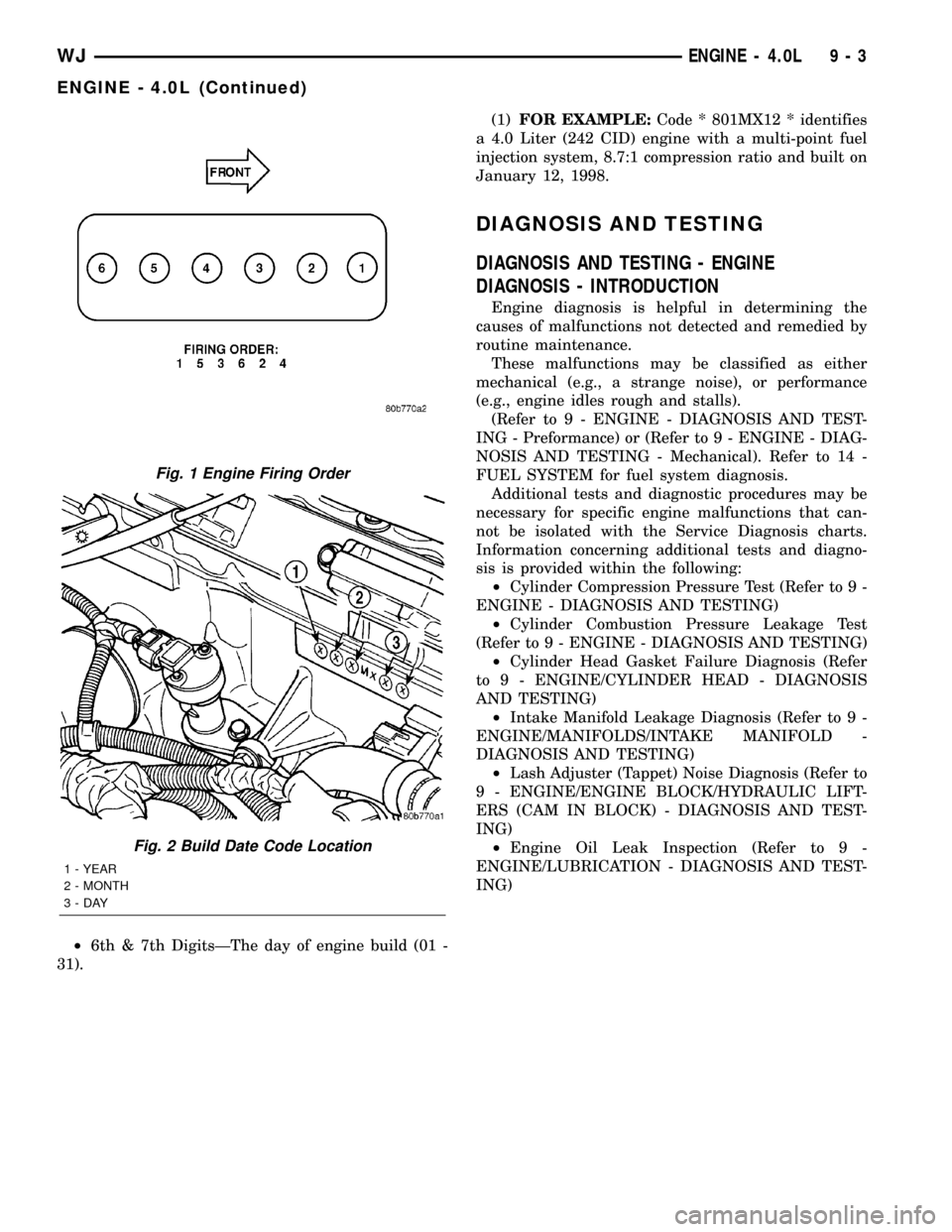

²6th & 7th DigitsÐThe day of engine build (01 -

31).(1)FOR EXAMPLE:Code * 801MX12 * identifies

a 4.0 Liter (242 CID) engine with a multi-point fuel

injection system, 8.7:1 compression ratio and built on

January 12, 1998.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING - Preformance) or (Refer to 9 - ENGINE - DIAG-

NOSIS AND TESTING - Mechanical). Refer to 14 -

FUEL SYSTEM for fuel system diagnosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING)

²Cylinder Combustion Pressure Leakage Test

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING)

²Cylinder Head Gasket Failure Diagnosis (Refer

to 9 - ENGINE/CYLINDER HEAD - DIAGNOSIS

AND TESTING)

²Intake Manifold Leakage Diagnosis (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

DIAGNOSIS AND TESTING)

²Lash Adjuster (Tappet) Noise Diagnosis (Refer to

9 - ENGINE/ENGINE BLOCK/HYDRAULIC LIFT-

ERS (CAM IN BLOCK) - DIAGNOSIS AND TEST-

ING)

²Engine Oil Leak Inspection (Refer to 9 -

ENGINE/LUBRICATION - DIAGNOSIS AND TEST-

ING)

Fig. 1 Engine Firing Order

Fig. 2 Build Date Code Location

1 - YEAR

2 - MONTH

3-DAY

WJENGINE - 4.0L 9 - 3

ENGINE - 4.0L (Continued)

Page 1251 of 2199

DIAGNOSIS AND TESTINGÐCYLINDER

COMPRESSION PRESSURE

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise, the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Clean the spark plug recesses with compressed

air.

(2) Remove the spark plugs (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/SPARK PLUG -

REMOVAL).

(3) Secure the throttle in the wide-open position.

(4) Disconnect the ignition coil.

(5) Insert a compression pressure gauge and rotate

the engine with the engine starter motor for three

revolutions.

(6) Record the compression pressure on the third

revolution. Continue the test for the remaining cylin-

ders.

(Refer to 9 - ENGINE - SPECIFICATIONS) for the

correct engine compression pressures.

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing)

²Leaks between adjacent cylinders or into water

jacket²Any causes for combustion/compression pressure

loss

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM HOT COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn OFF the

engine.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.

Perform the test procedure on each cylinder accord-

ing to the tester manufacturer's instructions. While

testing, listen for pressurized air escaping through

the throttle body, tailpipe or oil filler cap opening.

Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder CYLINDER COMBUSTION

PRESSURE LEAKAGE DIAGNOSIS CHART .

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODYIntake valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary

AIR ESCAPES THROUGH

TAILPIPEExhaust valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary

AIR ESCAPES THROUGH

RADIATORHead gasket leaking or cracked

cylinder head or blockRemove cylinder head and inspect.

Replace defective part

MORE THAN 50% LEAKAGE

FROM ADJACENT CYLINDERSHead gasket leaking or crack in

cylinder head or block between

adjacent cylindersRemove cylinder head and inspect.

Replace gasket, head, or block as

necessary

MORE THAN 25% LEAKAGE AND

AIR ESCAPES THROUGH OIL

FILLER CAP OPENING ONLYStuck or broken piston rings;

cracked piston; worn rings and/or

cylinder wallInspect for broken rings or piston.

Measure ring gap and cylinder

diameter, taper and out-of-round.

Replace defective part as necessary

9 - 8 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)

Page 1262 of 2199

(2) Lift cover up and position to the side.

(3) Remove air cleaner element.

INSTALLATION - 4.0L

(1) Clean inside of air cleaner housing before

installing new element.

(2) Install air cleaner element into housing.

(3) Latch clips and clamp cover down to secure. Be

sure air cleaner cover is properly seated to air

cleaner housing.

AIR CLEANER HOUSING

REMOVAL - 4.0L

(1) Disconnect air cleaner cover-to-air duct clamp

(Fig. 6).

(2) Disconnect air duct at housing.

(3)Each of the 3 air cleaner housing mount-

ing bolts is attached with 2 nuts (an upper nut

and lower nut). DO NOT REMOVE BOLTS. To

prevent stripping bolts, only remove lower

nuts. The lower housing nuts are located under

left front inner fender (Fig. 6).

(a) To gain access to lower nuts, raise vehicle.

(b) Remove clips retaining rubber inner fender

shield.

(c) Pry back shield enough to gain access to

lower nuts.

(d) Remove 3 nuts.

(e) Remove air cleaner assembly from vehicle.

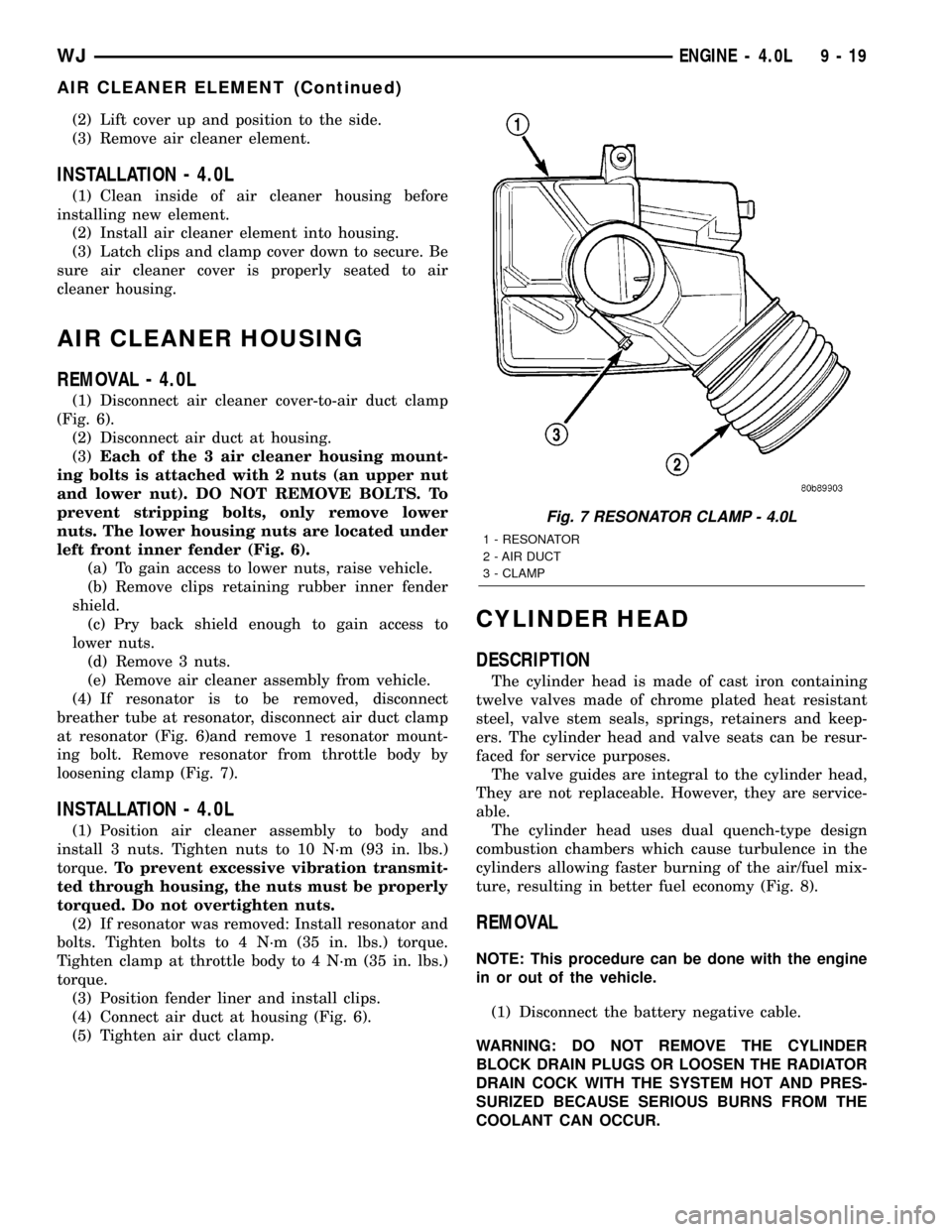

(4) If resonator is to be removed, disconnect

breather tube at resonator, disconnect air duct clamp

at resonator (Fig. 6)and remove 1 resonator mount-

ing bolt. Remove resonator from throttle body by

loosening clamp (Fig. 7).

INSTALLATION - 4.0L

(1) Position air cleaner assembly to body and

install 3 nuts. Tighten nuts to 10 N´m (93 in. lbs.)

torque.To prevent excessive vibration transmit-

ted through housing, the nuts must be properly

torqued. Do not overtighten nuts.

(2) If resonator was removed: Install resonator and

bolts. Tighten bolts to 4 N´m (35 in. lbs.) torque.

Tighten clamp at throttle body to 4 N´m (35 in. lbs.)

torque.

(3) Position fender liner and install clips.

(4) Connect air duct at housing (Fig. 6).

(5) Tighten air duct clamp.

CYLINDER HEAD

DESCRIPTION

The cylinder head is made of cast iron containing

twelve valves made of chrome plated heat resistant

steel, valve stem seals, springs, retainers and keep-

ers. The cylinder head and valve seats can be resur-

faced for service purposes.

The valve guides are integral to the cylinder head,

They are not replaceable. However, they are service-

able.

The cylinder head uses dual quench-type design

combustion chambers which cause turbulence in the

cylinders allowing faster burning of the air/fuel mix-

ture, resulting in better fuel economy (Fig. 8).

REMOVAL

NOTE: This procedure can be done with the engine

in or out of the vehicle.

(1) Disconnect the battery negative cable.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM THE

COOLANT CAN OCCUR.

Fig. 7 RESONATOR CLAMP - 4.0L

1 - RESONATOR

2 - AIR DUCT

3 - CLAMP

WJENGINE - 4.0L 9 - 19

AIR CLEANER ELEMENT (Continued)