Automatic switch JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1928 of 2199

(6) Reach through the front bin opening of the

floor console to access and tighten the two nuts that

secure the center floor tunnel bracket to the studs on

the floor panel transmission tunnel. Tighten the nuts

to 11.8 N´m (105 in. lbs.).

(7) Reinstall the front bin into the floor console.

(Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE -

INSTALLATION).

(8) Install and tighten all of the screws that secure

the perimeter of the top pad to the instrument panel

structural duct. Tighten the screws to 2.2 N´m (20 in.

lbs.).

(9) Install and tighten the four screws that secure

the heater-A/C control to the instrument panel struc-

tural duct. Tighten the screws to 2.2 N´m (20 in.

lbs.).

(10) Install and tighten the four screws that secure

the radio to the instrument panel structural duct.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(11) Reinstall the center lower bezel onto the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP CENTER BEZEL - LOWER -

INSTALLATION).

(12) Reinstall the center upper bezel onto the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP CENTER BEZEL - UPPER -

INSTALLATION).

(13) Install and tighten the two large screws on

the glove box opening upper reinforcement that

secure the top pad to the instrument panel structural

duct (Fig. 24). Tighten the screws to 11.8 N´m (105

in. lbs.).

(14) Install and tighten the two small screws on

the glove box opening upper reinforcement that

secure the panel outlets to the instrument panel

structural duct. Tighten the screws to 2.2 N´m (20 in.

lbs.).

(15) Reinstall the glove box lamp and switch into

the instrument panel. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - INTERIOR/GLOVE BOX

LAMP/SWITCH - INSTALLATION).

(16) Reinstall the lower right center bezel onto the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP LOWER RIGHT CENTER BEZEL

- INSTALLATION).(17) Reinstall the end cap onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL END CAP - INSTALLA-

TION).

(18) Roll the glove box back up into the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - STANDARD PROCEDURE - GLOVE

BOX ROLL DOWN).

(19) Reinstall the steering column opening cover

onto the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(20) Reinstall the instrument cluster into the

instrument panel. (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - INSTALLATION).

(21) Reinstall the cluster bezel onto the instru-

ment panel. (Refer to 23 - BODY/INSTRUMENT

PANEL/CLUSTER BEZEL - INSTALLATION).

(22) If the vehicle is so equipped, position the

automatic headlamp light sensor/vehicle theft secu-

rity system indicator unit to the instrument panel

top pad just outboard of the driver side defroster out-

let. Install and tighten the two screws that secure

the sensor/indicator unit. Tighten the screws to 2.2

N´m (20 in. lbs.).

(23) Engage the retainer that secures each of the

two instrument panel wire harness speaker take outs

to the mounting hole in the instrument panel top

pad.

(24) Reinstall the speakers onto the instrument

panel top pad. (Refer to 8 - ELECTRICAL/AUDIO/

SPEAKER - INSTALLATION - INSTRUMENT

PANEL SPEAKER).

(25) Install and tighten the four nuts that secure

the instrument panel top pad to the studs on the

dash panel near the windshield fence line (Fig. 23).

Tighten the nuts to 11.8 N´m (105 in. lbs.).

(26) Reinstall the top cover onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL TOP COVER - INSTALLA-

TION).

(27) Reinstall the trim onto the right and left

A-pillars. (Refer to 23 - BODY/INTERIOR/A-PILLAR

TRIM - INSTALLATION).

(28) Reconnect the battery negative cable.

WJINSTRUMENT PANEL SYSTEM 23 - 55

INSTRUMENT PANEL TOP PAD (Continued)

Page 1969 of 2199

SUNROOF

TABLE OF CONTENTS

page page

SUNROOF

DESCRIPTION.........................96

DIAGNOSIS AND TESTING - SUNROOF......96

DRAIN TUBE

REMOVAL............................100

INSTALLATION........................100

CONTROL MODULE

REMOVAL............................101

INSTALLATION........................101

DRIVE MOTOR

REMOVAL............................101

INSTALLATION........................101

WIND DEFLECTOR

REMOVAL............................102INSTALLATION........................102

GLASS PANEL

REMOVAL............................102

INSTALLATION........................103

ADJUSTMENTS

ADJUSTMENTS - FIT.................103

ADJUSTMENT - TIMING...............103

SUNSHADE

REMOVAL............................103

INSTALLATION........................103

HOUSING ASSEMBLY

REMOVAL............................104

INSTALLATION........................104

SUNROOF

DESCRIPTION

WARNING: Keep fingers and other body parts out

of sunroof opening at all times.

The sunroof features a power sliding glass panel

and a sunshade which can be manually positioned

anywhere along its travel, rearward of glass panel

front edge.

The sunroof is electrically operated from a switch

located on the mini overhead console. To operate the

sunroof the ignition switch must be in the On/Run

position. The sunroof has both manual and Express

Open modes of operation when opening. To open the

sunroof in the Express Open mode, the switch is

pressed rearward for less than1 second.This causes

the sunroof glass to automatically retract and stop at

a position slightly forward of full open that reduces

low speed wind buffeting. The sunroof can also be

opened manually by pressing and holding the switch

rearward. Once the switch is held reward for more

than1 second,the glass will retract in the manual

mode. Releasing the switch at any time during travel

will cause the sunroof to stop at the current position.

To close the sunroof from an open position, the

switch must be pushed forward and held until the

sunroof glass comes to a complete stop. Releasing the

switch at any time in this mode will cause the sun-

roof to stop at the current position.

To vent the sunroof from the closed position, the

switch is pushed forward and held. Releasing theswitch at any time during travel will cause the sun-

roof to stop at the current vent position. To reach the

fully vented position, continue to hold the switch for-

ward until vent motion stops. To close the sunroof

from the vent position, push and hold the switch

rearward until the glass comes to a complete stop.

DIAGNOSIS AND TESTING - SUNROOF

CAUTION: The sunroof motor is only to be powered

through the vehicle battery and vehicle wire har-

ness. Applying power to the sunroof motor leads

will cause failure of the sunroof control unit.

Before beginning sunroof diagnostics verify that all

other power accessories are in proper operating con-

dition. Refer to Sunroof Diagnostic Chart for possible

causes. If not, a common electrical problem may

exist. Refer to Group 8W, Wiring Diagrams, of this

publication for circuit, splice and component descrip-

tions. Check the condition of the circuit protection

(20 amp high current fuse (battery feed) located in

the Power Distribution Center (PDC). Check the

cover of the PDC for location of the fuse. Check for

correct operation of the sunroof delay relay. Inspect

all wiring connector pins for proper engagement and

continuity. Check for battery voltage at battery and

ignition pins of the power sunroof express module

wiring connector. Refer to Group 8W, Wiring Dia-

grams, for circuit information. The controller will not

operate at less than 10 volts. Check the ground at

the sunroof express module.

Before beginning diagnosis for wind noise or water

leaks, verify that the problem was not caused by

23 - 96 SUNROOFWJ

Page 1970 of 2199

releasing the control switch before the sunroof was

fully closed. The sunroof module has a water-man-

agement system. During washing high-pressure

water may be forced between the glass panel seal

and the roof opening. Normally this water will drain.

However, when some type of drying blower system is

used, like those found in automatic car washes, thewater may not have a chance to drain before the

blower forces air between the seal and the roof open-

ing. This causes the water to blow over the edge of

the module and onto the headlining.

Refer to (Fig. 1) Sunroof Assembly for exploded

view of the sunroof.

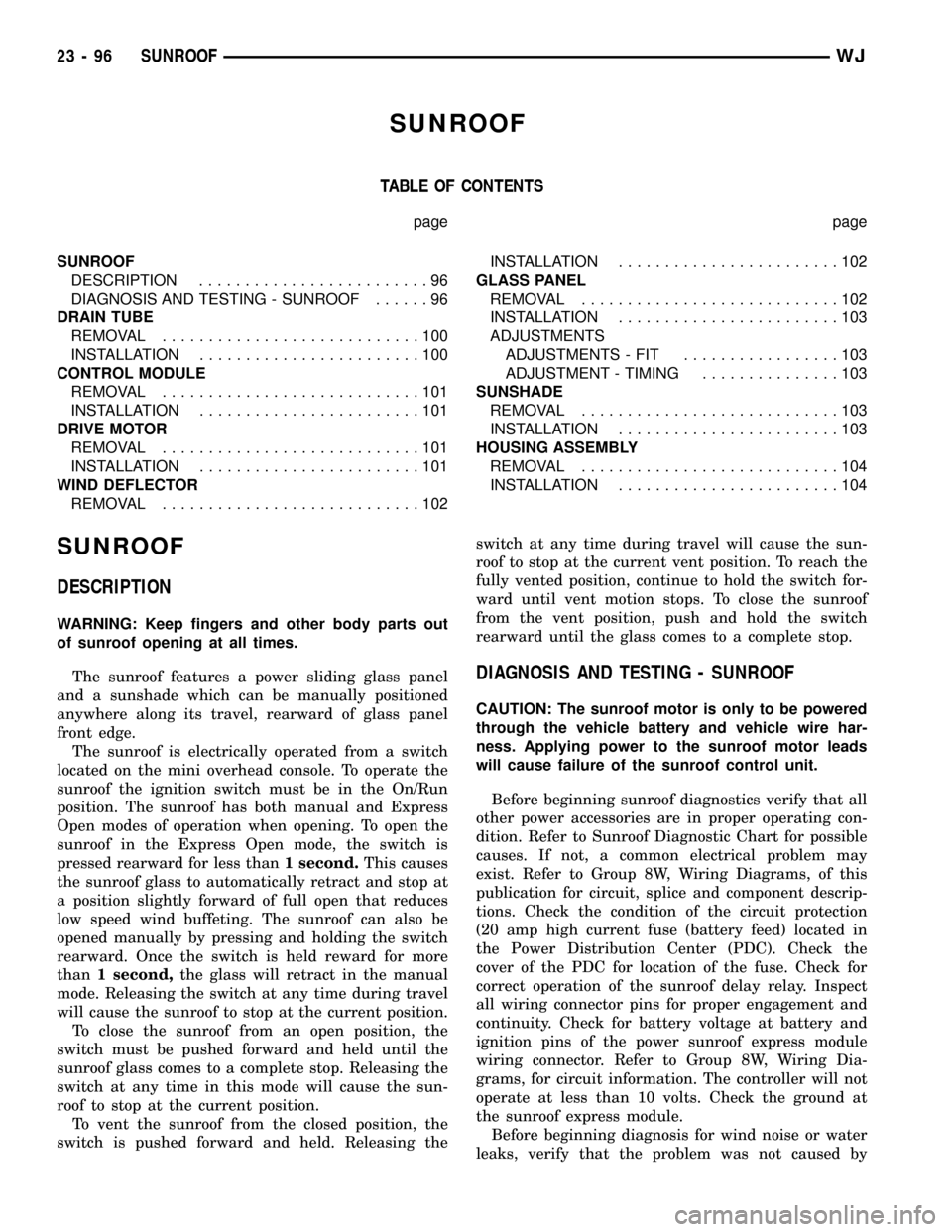

SYMPTOM STEP POSSIBLE CAUSE

Sunroof squeaks when

opening/closing.1 Identify if the cause is a seal squeak. If seal is worn, replace the

seal.

2 Check seal compression for uniformity in opening, If not uniform,

glass is not centered in opening.

3 Re-center glass by repositioning module in opening.

4 Identify if mechanism squeaks.

5 Check for lubrication, re-lube if necessary.

6 Check for dirt/debris in tracks, clean and re-lube.

7 Identify if motor squeaks, replace the motor.

Water leaks into the vehicle. 1 Check for a good connection at the drain tubes, re-connect where

needed.

2 Check for plugged/pinched hoses throughout.

3 Adjust the glass panel. Refer to glass panel adjustments in this

section.

4 Check seal for wear/damage, replace glass as necessary.

Motor inoperative. 1 Check connectors at the motor, switch, control module and power

source.

2 Check for defective control module, replace if necessary.

3 Replace the motor.

Motor noise when opening/

closing.1 Identify if motor noise, replace motor.

2 Insure noise is from the motor and not cables, (cable ratcheting).

Grinding noise when opening/

closing.1 Identify if the motor is grinding, replace motor.

(Mechanism noise, scraping.) 2 Check for lubrication in tracks and mechanism, re-lube if

necessary.

3 Check for dirt/debris in tracks, clean and re-lube.

(Cable ratcheting.) 4 Cables ratchet at the motor pinion; mechanism jammed, fix

mechanism and replace cables and motor bracket.

Wind noise when sunroof fully

closed.1 Check seal compression for uniformity in opening, If not uniform,

glass is not centered in opening.

2 Glass not adjusted flush to roof. Refer to glass panel adjustments

in this section.

3 Mechanism not fully closed.

A) Motor out of time, re-time motor/mechanism. Refer to glass

panel adjustments in this section.

B) Cable ratcheting, replace cables and motor bracket.

4 Seal worn, replace glass.

Sunroof will not open/close. 1 Check switch and switch connection.

WJSUNROOF 23 - 97

SUNROOF (Continued)

Page 1974 of 2199

CONTROL MODULE

REMOVAL

(1) Move the glass panel to the fully closed posi-

tion.

(2) Remove the A-pillar trim. (Refer to 23 - BODY/

INTERIOR/A-PILLAR TRIM - REMOVAL)

(3) Remove the sun visors. (Refer to 23 - BODY/

INTERIOR/SUN VISOR - REMOVAL)

(4) Remove the overhead console. (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - REMOVAL)

(5) Lower headliner as necessary to gain access to

the sunroof express module.

(6) Disconnect the express module wire harness

connectors.

(7) Remove express module screw.

(8) Remove express module from the keyway by

sliding module towards the center of the vehicle.

INSTALLATION

(1) Insert sunroof express module in the keyway

located in the sunroof module and slide the module

outward to lock it into position.

(2) Install the sunroof express module screw.

(3) Connect the wire connectors to the sunroof

express module.

(4) Install the headliner into position.

(5) Install the overhead console. (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - INSTALLA-

TION)

(6) Install the sun visors. (Refer to 23 - BODY/IN-

TERIOR/SUN VISOR - INSTALLATION)

(7) Install the A-pillar trim. (Refer to 23 - BODY/

INTERIOR/A-PILLAR TRIM - INSTALLATION)

(8) Test sunroof operation, adjust if necessary.

(Refer to 23 - BODY/SUNROOF/GLASS PANEL -

ADJUSTMENTS)

DRIVE MOTOR

REMOVAL

CAUTION: The sunroof system is timed from the

factory so that the motor shuts off automatically

when the sunroof window reaches a certain posi-

tion. Extreme care must be taken when removing

the motor, timing may be thrown off causing possi-

ble damage to the sunroof system. Anytime the

motor is removed from the sunroof assembly the

sunroof glass panel must be in the FULLY CLOSED

POSITION or the unit will be out of timing. The drive

motor cannot be reset to the park position after

being removed.CAUTION: The sunroof motor should only be pow-

ered through the vehicle battery and sunroof wire

harness. Applying power to the sunroof motor leads

will cause failure of the control module.

(1) Move glass panel to the fully closed position.

(2) Remove the A-pillar trim. (Refer to 23 - BODY/

INTERIOR/A-PILLAR TRIM - REMOVAL)

(3) Remove the B-pillar upper trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

REMOVAL)

(4) Remove the C-pillar trim. (Refer to 23 - BODY/

INTERIOR/C-PILLAR TRIM - REMOVAL)

(5) Remove the D-pillar trim. (Refer to 23 - BODY/

INTERIOR/D-PILLAR TRIM - REMOVAL)

(6) Remove the sunvisors. (Refer to 23 - BODY/IN-

TERIOR/SUN VISOR - REMOVAL)

(7) Remove the overhead console. (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - REMOVAL)

(8) Disconnect the control switch wire connector.

(9) Remove headliner as necessary to gain access

to sunroof drive motor. Refer to Headliner Removal

and Installation for proper procedures.

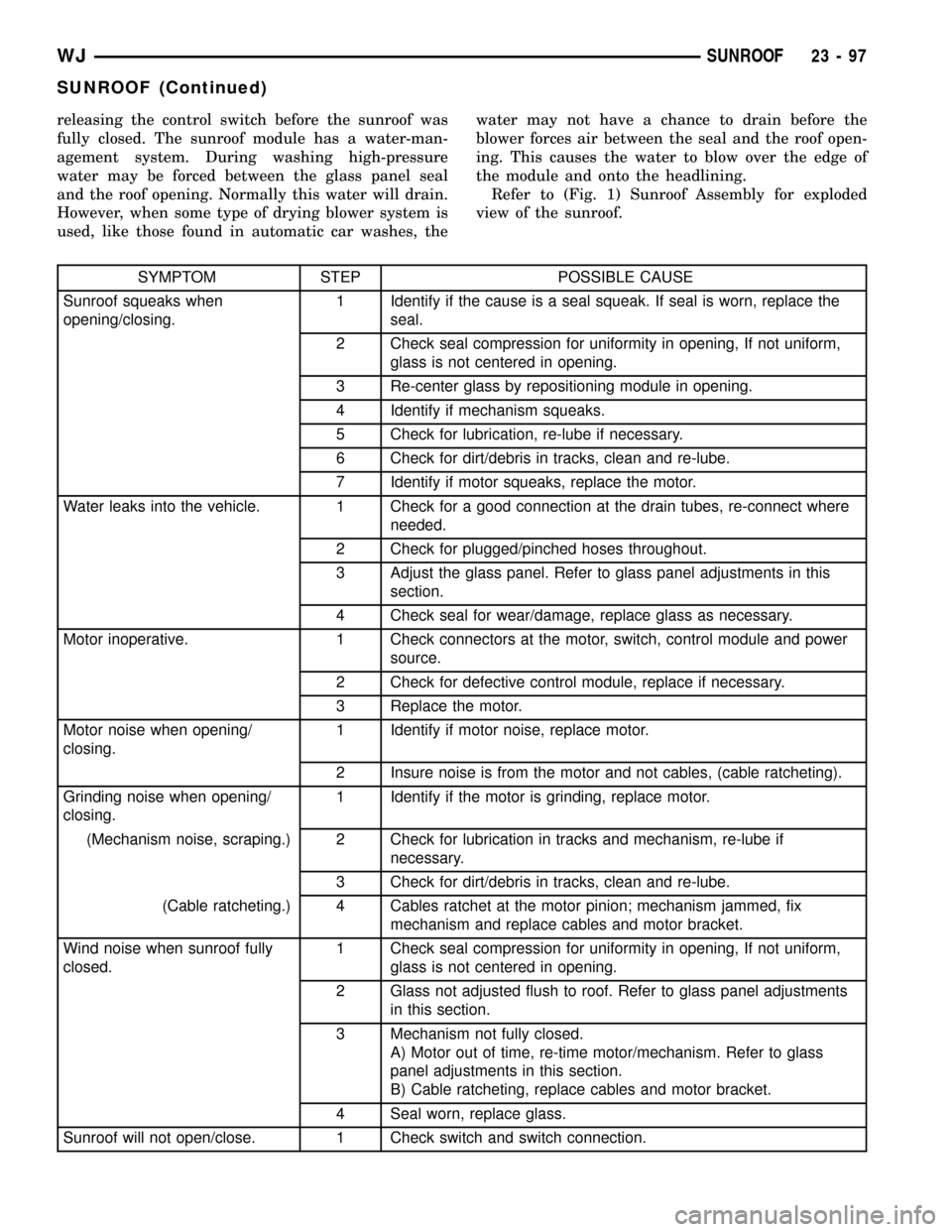

(10) Disconnect the drive motor wire harness con-

nectors (Fig. 3).

(11) Remove drive motor fasteners and remove

motor from the sunroof housing.

INSTALLATION

(1) Ensure that the window is in the fully closed

position before mounting the motor. If motor fails

with the window in the open position the sunroof

glass panel timing will have to be timed. The new

motor comes in the fully closed position and with a

gage for setting cable timing. (Refer to 23 - BODY/

SUNROOF/GLASS PANEL - ADJUSTMENTS - TIM-

ING)

(2) Place drive motor into position on the sunroof

housing and install fasteners.

Fig. 3 Sunroof Drive Motor and Express Module

1 - EXPRESS MODULE

2 - SCREW

WJSUNROOF 23 - 101

Page 2079 of 2199

OPERATION

OPERATION - HEATER AND AIR CONDITIONER

Outside fresh air enters the vehicle through the

cowl top opening at the base of the windshield, and

passes through a plenum chamber to the HVAC sys-

tem blower housing. Air flow velocity can then be

adjusted with the blower motor speed selector switch

on the a/c heater control panel. The air intake open-

ings must be kept free of snow, ice, leaves, and other

obstructions for the HVAC system to receive a suffi-

cient volume of outside air.

It is also important to keep the air intake openings

clear of debris because leaf particles and other debris

that is small enough to pass through the cowl ple-

num screen can accumulate within the HVAC hous-

ing. The closed, warm, damp and dark environment

created within the HVAC housing is ideal for the

growth of certain molds, mildews and other fungi.

Any accumulation of decaying plant matter provides

an additional food source for fungal spores, which

enter the housing with the fresh air. Excess debris,

as well as objectionable odors created by decaying

plant matter and growing fungi can be discharged

into the passenger compartment during HVAC sys-

tem operation.

Both the manual and AZC heater and air condi-

tioner are blend-air type systems. In a blend-air sys-

tem, a blend door controls the amount of

unconditioned air (or cooled air from the evaporator)

that is allowed to flow through, or around, the heater

core. A temperature control knob on the a/c heater

control panel determines the discharge air tempera-

ture by energizing the blend door actuator, which

operates the blend door. This allows an almost imme-

diate control of the output air temperature of the sys-

tem. The AZC system will have separate blend doors

and temperature controls for each front seat occu-

pant.

The mode control knob on the a/c heater control

panel is used to direct the conditioned air to the

selected system outlets. On manual temperature con-

trol systems, the mode control knob switches engine

vacuum to control the mode doors, which are oper-

ated by vacuum actuators. On AZC systems, the

mode control knob switches electrical current to con-

trol the mode doors, which are operated by electronic

actuators.

The outside air intake can be shut off on manual

temperature control systems by selecting the Recircu-

lation Mode with the mode control knob. The outside

air intake can be shut off on Automatic Zone Control

(AZC) type system by pushing the Recirculation

Mode button. This will operate the recirculation door

that closes off the outside fresh air intake and recir-

culates the air that is already inside the vehicle.The air conditioner for all models is designed for

the use of non-CFC, R-134a refrigerant. The air con-

ditioning system has an evaporator to cool and dehu-

midify the incoming air prior to blending it with the

heated air. This air conditioning system uses a ther-

mal expansion valve to meter refrigerant flow to the

evaporator coil. To maintain minimum evaporator

temperature and prevent evaporator freezing, the

system utilizes an evaporator thermister probe with

the appropriate operating logic located in the body

control module (BCM).

OPERATION - REFRIGERANT SYSTEM SERVICE

PORT

The high pressure service port is located on the liq-

uid line near the receiver/drier. The low pressure ser-

vice port is located on the suction line near the

evaporator at the rear of the engine compartment.

Each of the service ports has a threaded plastic

protective cap installed over it from the factory. After

servicing the refrigerant system, always reinstall

both of the service port caps.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to provide

the passenger compartment with low temperature

and low specific humidity air. The evaporator, located

in the HVAC housing on the dash panel below the

instrument panel, is cooled to temperatures near the

freezing point. As warm damp air passes through the

cooled evaporator, the air transfers its heat to the

refrigerant in the evaporator and the moisture in the

air condenses on the evaporator fins. During periods

of high heat and humidity, an air conditioning sys-

tem will be more effective in the Recirculation Mode.

With the system in the Recirculation Mode, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, the air conditioning system performance

levels improve.

Humidity has an important bearing on the tempera-

ture of the air delivered to the interior of the vehicle. It

is important to understand the effect that humidity has

on the performance of the air conditioning system.

When humidity is high, the evaporator has to perform a

double duty. It must lower the air temperature, and it

must lower the temperature of the moisture in the air

that condenses on the evaporator fins. Condensing the

moisture in the air transfers heat energy into the evap-

orator fins and tubing. This reduces the amount of heat

the evaporator can absorb from the air. High humidity

greatly reduces the ability of the evaporator to lower

the temperature of the air.

24 - 2 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)

Page 2080 of 2199

However, evaporator capacity used to reduce the

amount of moisture in the air is not wasted. Wring-

ing some of the moisture out of the air entering the

vehicle adds to the comfort of the passengers.

Although, an owner may expect too much from their

air conditioning system on humid days. A perfor-

mance test is the best way to determine whether the

system is performing up to standard. This test also

provides valuable clues as to the possible cause of

trouble with the air conditioning system.

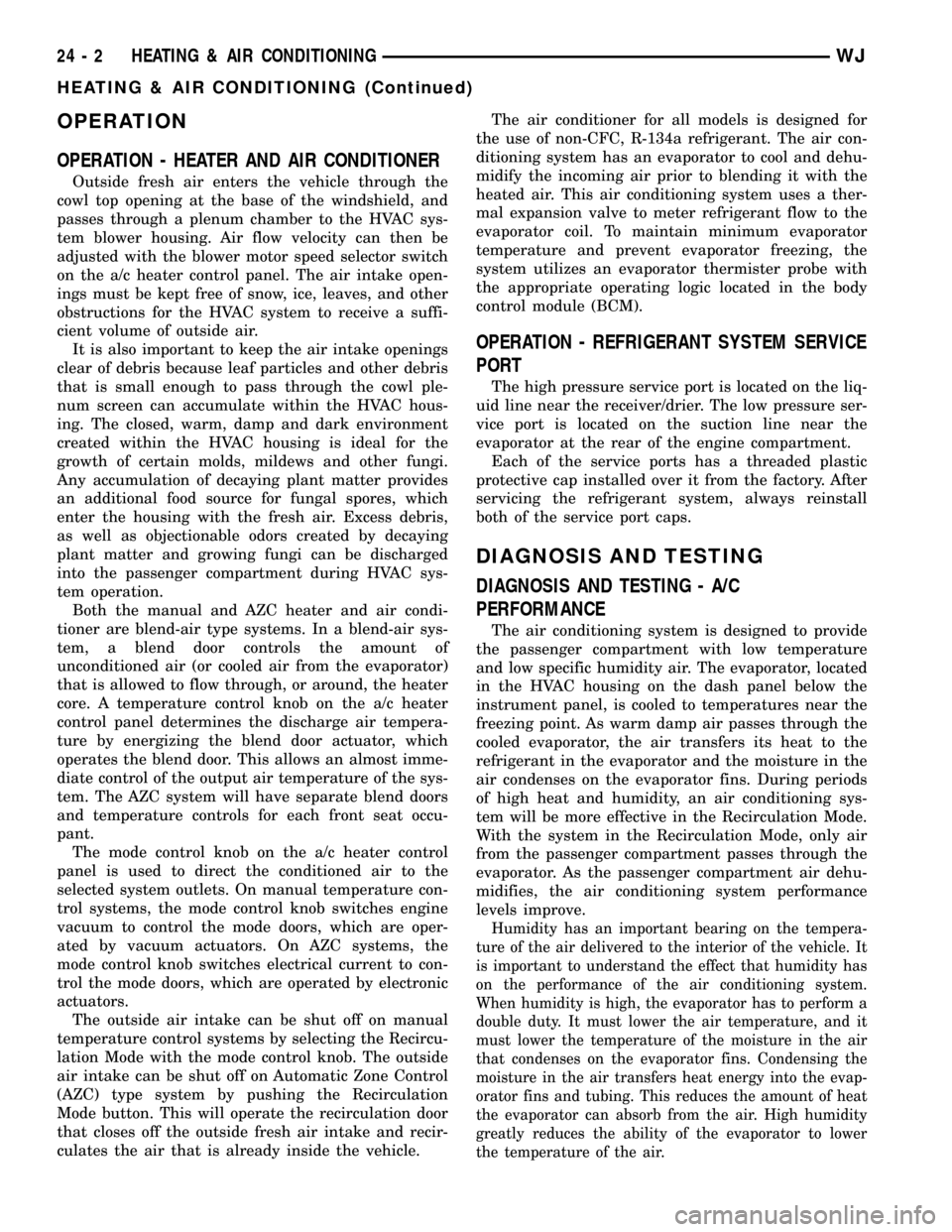

If the vehicle has the optional Automatic Zone Control

(AZC) system, and has intermittent operational prob-

lems or fault codes, be certain that the wire harness

connectors on the HVAC housing are properly seated

(Fig. 2). To check this condition, unplug the two wire

harness connector halves, then plug them in again.

Before performing the following procedure, (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - CAUTION) (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNING). The air

temperature in the test room and in the vehicle must

be a minimum of 21É C (70É F) for this test.

(1)

Connect a tachometer and a manifold gauge set.

(2) If the vehicle has the standard manual temper-

ature control, set the A/C Heater mode control switch

knob in the Panel position, the temperature control

knob in the full cool (Fresh Air Mode) position, the

A/C button in the On position, and the blower motor

switch knob in the highest speed position. If the vehi-

cle has the optional AZC, set the A/C Heater mode

control switch knob in the Panel position, the tem-

perature control knob in the full cool position, the

A/C button in the On position, and the blower motor

switch knob in the highest (manual) speed position.

(3) Start the engine and hold the idle at 1,300 rpm

with the compressor clutch engaged.

(4) The engine should be at operating temperature.

The doors and windows must be open.

(5)

Insert a thermometer in the driver side center

A/C (panel) outlet. Operate the engine for five minutes.

(6) The compressor clutch may cycle, depending

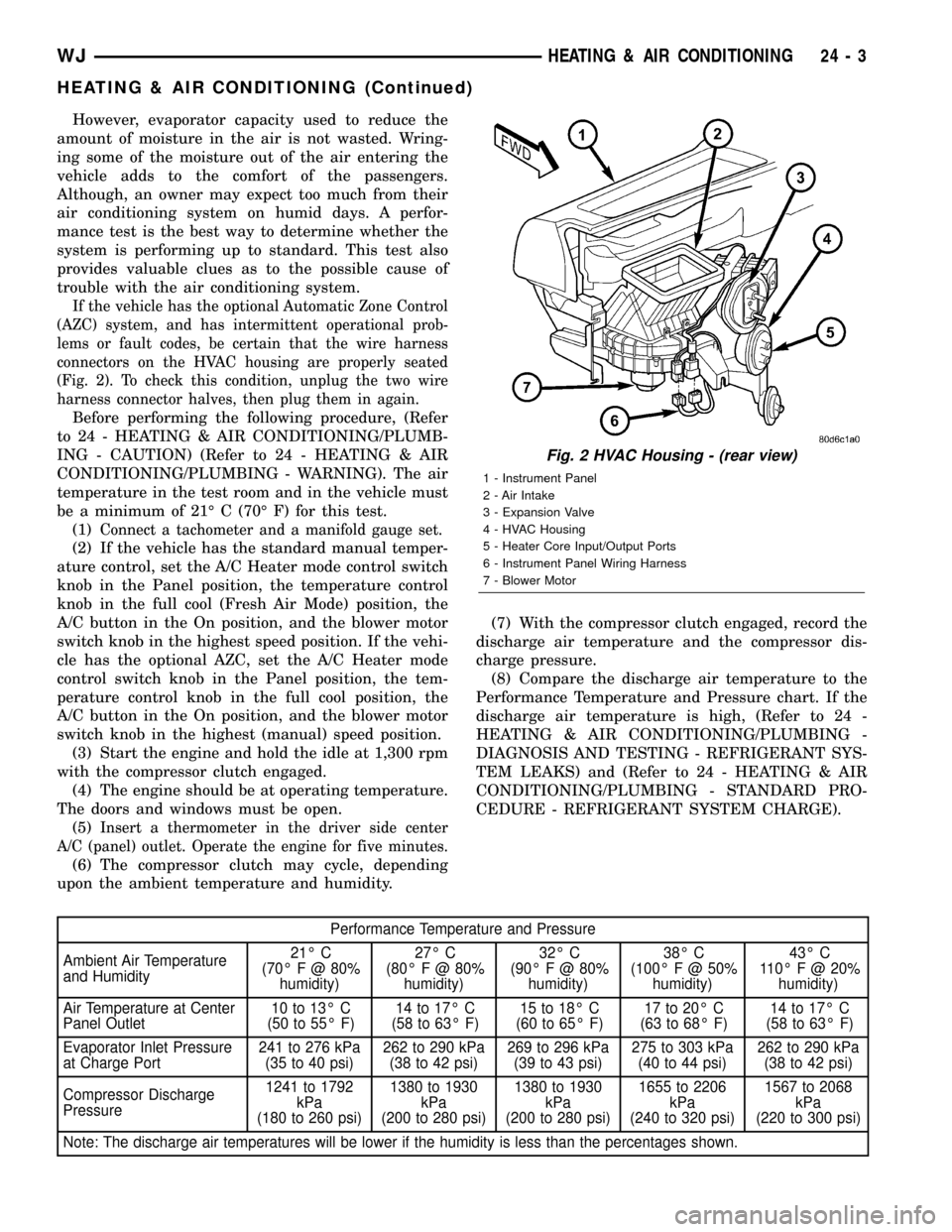

upon the ambient temperature and humidity.(7) With the compressor clutch engaged, record the

discharge air temperature and the compressor dis-

charge pressure.

(8) Compare the discharge air temperature to the

Performance Temperature and Pressure chart. If the

discharge air temperature is high, (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

DIAGNOSIS AND TESTING - REFRIGERANT SYS-

TEM LEAKS) and (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

Performance Temperature and Pressure

Ambient Air Temperature

and Humidity21É C

(70É F @ 80%

humidity)27É C

(80É F @ 80%

humidity)32É C

(90É F @ 80%

humidity)38É C

(100ÉF@50%

humidity)43É C

110É F @ 20%

humidity)

Air Temperature at Center

Panel Outlet10 to 13É C

(50 to 55É F)14 to 17É C

(58 to 63É F)15 to 18É C

(60 to 65É F)17 to 20É C

(63 to 68É F)14 to 17É C

(58 to 63É F)

Evaporator Inlet Pressure

at Charge Port241 to 276 kPa

(35 to 40 psi)262 to 290 kPa

(38 to 42 psi)269 to 296 kPa

(39 to 43 psi)275 to 303 kPa

(40 to 44 psi)262 to 290 kPa

(38 to 42 psi)

Compressor Discharge

Pressure1241 to 1792

kPa

(180 to 260 psi)1380 to 1930

kPa

(200 to 280 psi)1380 to 1930

kPa

(200 to 280 psi)1655 to 2206

kPa

(240 to 320 psi)1567 to 2068

kPa

(220 to 300 psi)

Note: The discharge air temperatures will be lower if the humidity is less than the percentages shown.

Fig. 2 HVAC Housing - (rear view)

1 - Instrument Panel

2 - Air Intake

3 - Expansion Valve

4 - HVAC Housing

5 - Heater Core Input/Output Ports

6 - Instrument Panel Wiring Harness

7 - Blower Motor

WJHEATING & AIR CONDITIONING 24 - 3

HEATING & AIR CONDITIONING (Continued)

Page 2084 of 2199

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary refer to the

appropriate wiring diagram for current flow.

(6) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape making, sure the diode is completely sealed

from the elements.

(8) Re-connect the battery, and test affected sys-

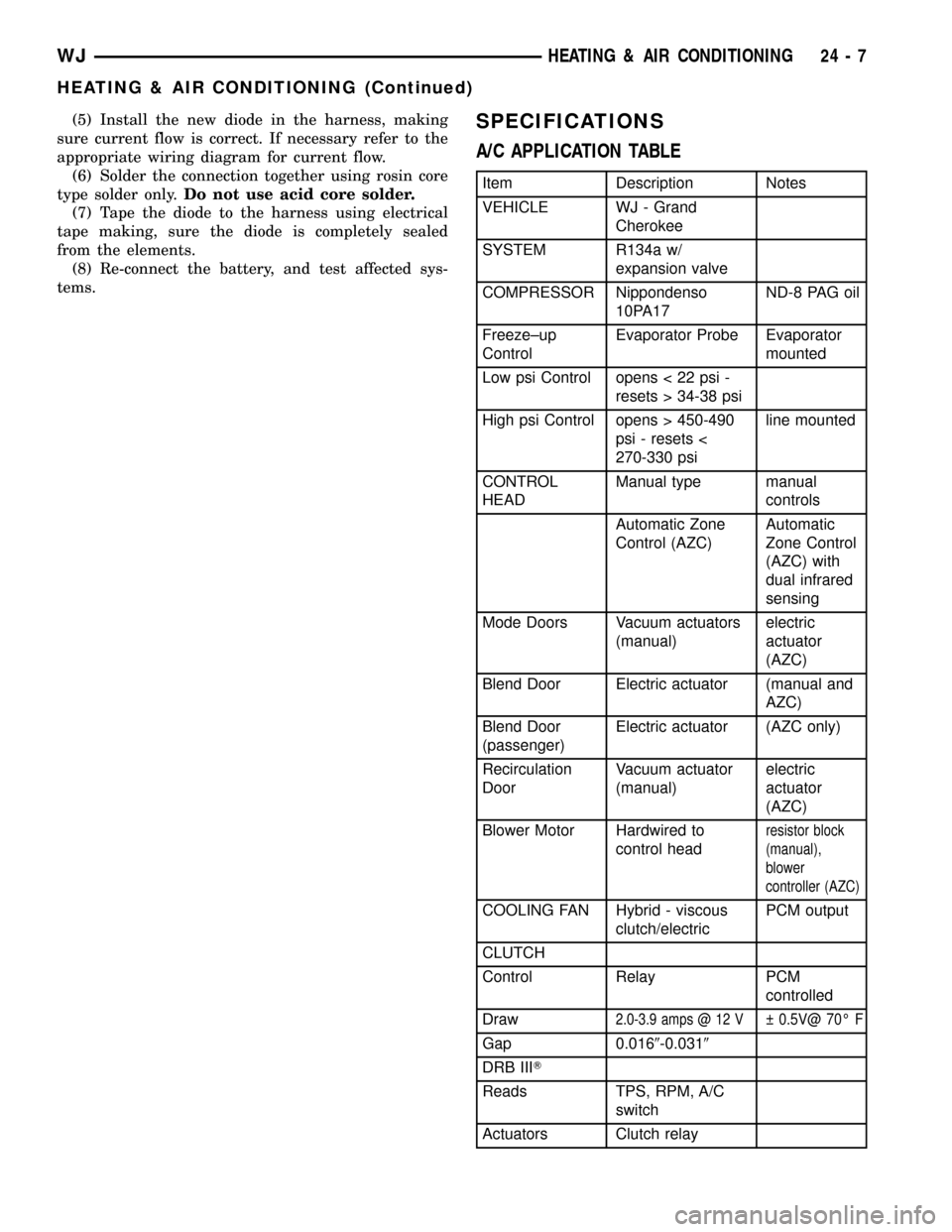

tems.SPECIFICATIONS

A/C APPLICATION TABLE

Item Description Notes

VEHICLE WJ - Grand

Cherokee

SYSTEM R134a w/

expansion valve

COMPRESSOR Nippondenso

10PA17ND-8 PAG oil

Freeze±up

ControlEvaporator Probe Evaporator

mounted

Low psi Control opens < 22 psi -

resets > 34-38 psi

High psi Control opens > 450-490

psi - resets <

270-330 psiline mounted

CONTROL

HEADManual type manual

controls

Automatic Zone

Control (AZC)Automatic

Zone Control

(AZC) with

dual infrared

sensing

Mode Doors Vacuum actuators

(manual)electric

actuator

(AZC)

Blend Door Electric actuator (manual and

AZC)

Blend Door

(passenger)Electric actuator (AZC only)

Recirculation

DoorVacuum actuator

(manual)electric

actuator

(AZC)

Blower Motor Hardwired to

control head

resistor block

(manual),

blower

controller (AZC)

COOLING FAN Hybrid - viscous

clutch/electricPCM output

CLUTCH

Control Relay PCM

controlled

Draw

2.0-3.9 amps @ 12 V 0.5V@ 70É F

Gap 0.0169-0.0319

DRB IIIT

Reads TPS, RPM, A/C

switch

Actuators Clutch relay

WJHEATING & AIR CONDITIONING 24 - 7

HEATING & AIR CONDITIONING (Continued)

Page 2086 of 2199

CONTROLS

TABLE OF CONTENTS

page page

CONTROLS

DIAGNOSIS AND TESTING - VACUUM

SYSTEM............................10

A/C COMPRESSOR CLUTCH

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH COIL........................13

STANDARD PROCEDURE - COMPRESSOR

CLUTCH BREAK-IN....................14

REMOVAL.............................14

INSPECTION..........................15

INSTALLATION.........................15

A/C COMPRESSOR CLUTCH RELAY

DESCRIPTION.........................16

OPERATION...........................16

DIAGNOSIS AND TESTING - A/C

COMPRESSOR CLUTCH RELAY..........16

REMOVAL.............................17

INSTALLATION.........................17

A/C HEATER CONTROL

DESCRIPTION.........................17

OPERATION...........................17

DIAGNOSIS AND TESTING - AUTOMATIC

ZONE CONTROL SYSTEM..............18

REMOVAL.............................24

INSTALLATION.........................25

A/C PRESSURE TRANSDUCER

DESCRIPTION.........................25

OPERATION...........................25

DIAGNOSIS AND TESTING - A/C PRESSURE

TRANSDUCER.......................26

REMOVAL.............................26

INSTALLATION.........................26

BLOWER MOTOR CONTROLLER

DESCRIPTION.........................26

OPERATION...........................26

REMOVAL.............................27

INSTALLATION.........................27

BLOWER MOTOR RESISTOR BLOCK

DESCRIPTION.........................27

OPERATION...........................27

DIAGNOSIS AND TESTING - BLOWER

MOTOR RESISTOR BLOCK..............27

REMOVAL.............................28

INSTALLATION.........................28BLOWER MOTOR SWITCH

DESCRIPTION.........................28

OPERATION...........................28

DIAGNOSIS AND TESTING - BLOWER

MOTOR SWITCH-MANUAL TEMPERATURE

CONTROL SYSTEM....................28

REMOVAL.............................29

IN-CAR TEMPERATURE SENSOR

DESCRIPTION.........................29

OPERATION...........................29

REMOVAL.............................29

BLEND DOOR ACTUATOR

DESCRIPTION.........................30

REMOVAL.............................30

INSTALLATION.........................30

MODE DOOR ACTUATOR

DESCRIPTION.........................30

REMOVAL

REMOVAL - HEAT/DEFROST - PANEL/

DEFROST DOOR ELECTRIC ACTUATOR . . . 31

REMOVAL - HEAT/DEFROST DOOR

VACUUM ACTUATOR..................31

REMOVAL - PANEL/DEFROST DOOR

VACUUM ACTUATOR..................32

INSTALLATION

INSTALLATION - HEAT/DEFROST -

PANEL/DEFROST DOOR ELECTRIC

ACTUATOR..........................32

INSTALLATION - HEAT/DEFROST DOOR

VACUUM ACTUATOR..................33

INSTALLATION - PANEL/DEFROST DOOR

VACUUM ACTUATOR..................33

RECIRCULATION DOOR ACTUATOR

DESCRIPTION.........................33

REMOVAL

REMOVAL - RECIRCULATION DOOR

VACUUM ACTUATOR..................33

REMOVAL - RECIRCULATION DOOR

ELECTRIC ACTUATOR.................33

INSTALLATION

INSTALLATION - RECIRCULATION DOOR

VACUUM ACTUATOR..................34

INSTALLATION - RECIRCULATION DOOR

ELECTRIC ACTUATOR.................34

VACUUM CHECK VALVE

DESCRIPTION.........................34

OPERATION...........................34

REMOVAL.............................34

INSTALLATION.........................34

WJCONTROLS 24 - 9

Page 2090 of 2199

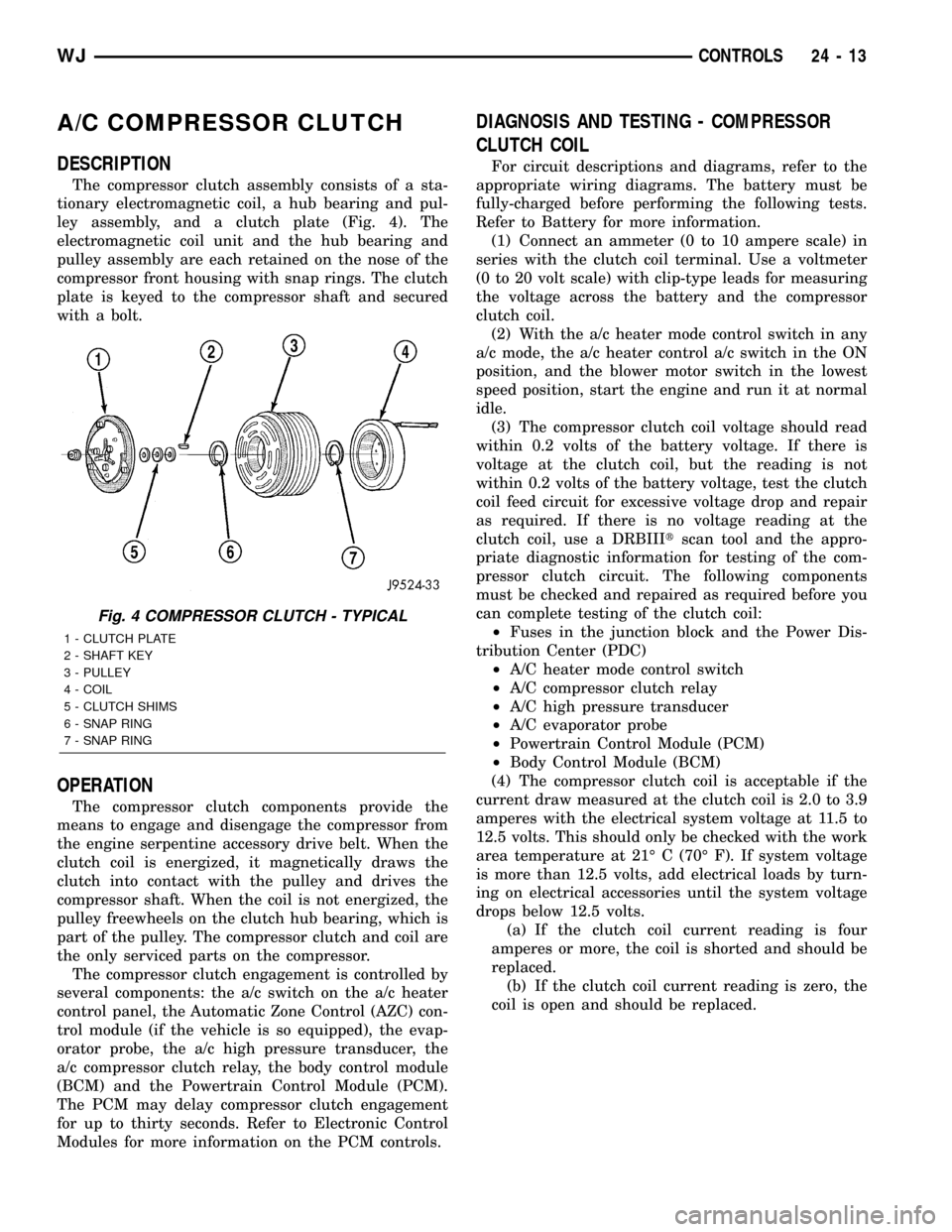

A/C COMPRESSOR CLUTCH

DESCRIPTION

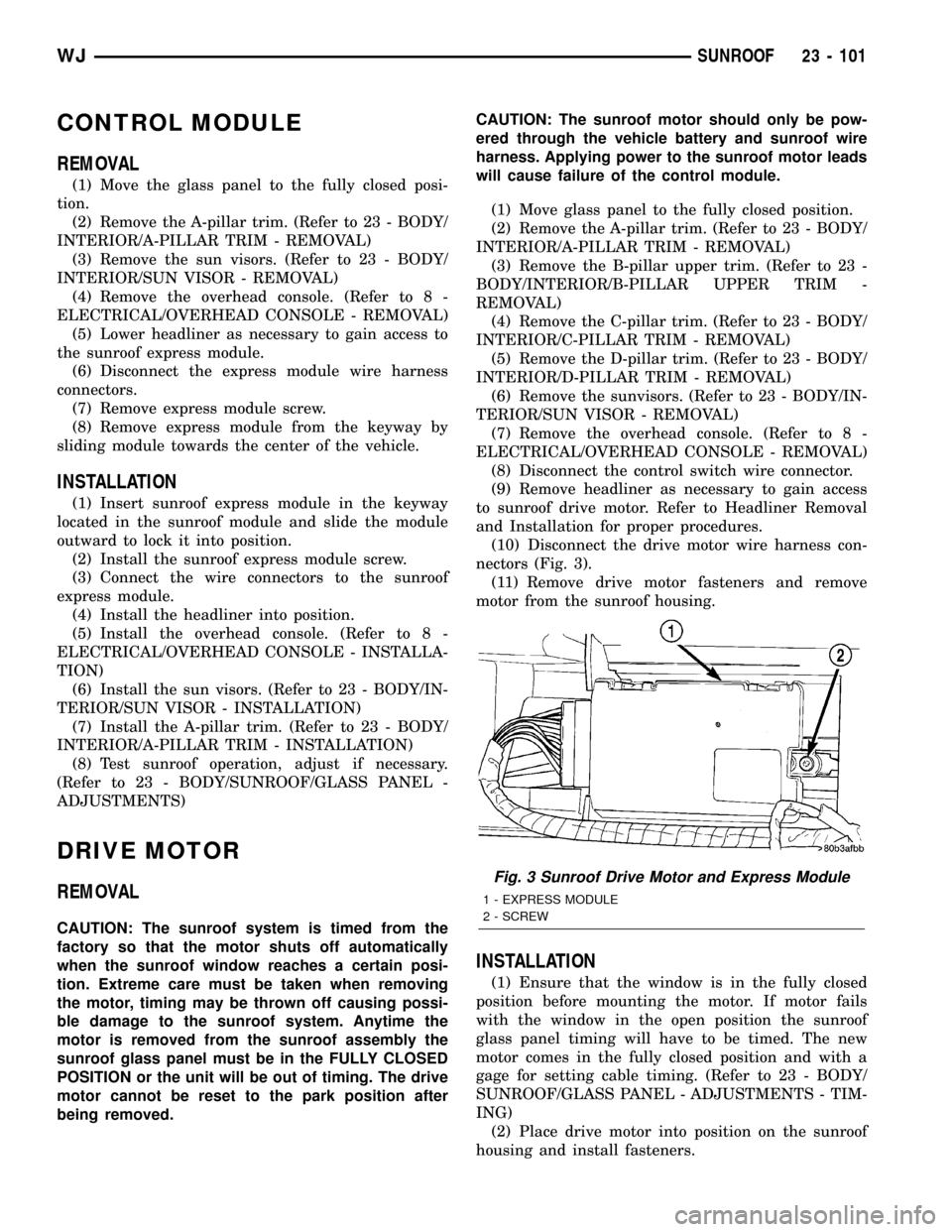

The compressor clutch assembly consists of a sta-

tionary electromagnetic coil, a hub bearing and pul-

ley assembly, and a clutch plate (Fig. 4). The

electromagnetic coil unit and the hub bearing and

pulley assembly are each retained on the nose of the

compressor front housing with snap rings. The clutch

plate is keyed to the compressor shaft and secured

with a bolt.

OPERATION

The compressor clutch components provide the

means to engage and disengage the compressor from

the engine serpentine accessory drive belt. When the

clutch coil is energized, it magnetically draws the

clutch into contact with the pulley and drives the

compressor shaft. When the coil is not energized, the

pulley freewheels on the clutch hub bearing, which is

part of the pulley. The compressor clutch and coil are

the only serviced parts on the compressor.

The compressor clutch engagement is controlled by

several components: the a/c switch on the a/c heater

control panel, the Automatic Zone Control (AZC) con-

trol module (if the vehicle is so equipped), the evap-

orator probe, the a/c high pressure transducer, the

a/c compressor clutch relay, the body control module

(BCM) and the Powertrain Control Module (PCM).

The PCM may delay compressor clutch engagement

for up to thirty seconds. Refer to Electronic Control

Modules for more information on the PCM controls.

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH COIL

For circuit descriptions and diagrams, refer to the

appropriate wiring diagrams. The battery must be

fully-charged before performing the following tests.

Refer to Battery for more information.

(1) Connect an ammeter (0 to 10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0 to 20 volt scale) with clip-type leads for measuring

the voltage across the battery and the compressor

clutch coil.

(2) With the a/c heater mode control switch in any

a/c mode, the a/c heater control a/c switch in the ON

position, and the blower motor switch in the lowest

speed position, start the engine and run it at normal

idle.

(3) The compressor clutch coil voltage should read

within 0.2 volts of the battery voltage. If there is

voltage at the clutch coil, but the reading is not

within 0.2 volts of the battery voltage, test the clutch

coil feed circuit for excessive voltage drop and repair

as required. If there is no voltage reading at the

clutch coil, use a DRBIIItscan tool and the appro-

priate diagnostic information for testing of the com-

pressor clutch circuit. The following components

must be checked and repaired as required before you

can complete testing of the clutch coil:

²Fuses in the junction block and the Power Dis-

tribution Center (PDC)

²A/C heater mode control switch

²A/C compressor clutch relay

²A/C high pressure transducer

²A/C evaporator probe

²Powertrain Control Module (PCM)

²Body Control Module (BCM)

(4) The compressor clutch coil is acceptable if the

current draw measured at the clutch coil is 2.0 to 3.9

amperes with the electrical system voltage at 11.5 to

12.5 volts. This should only be checked with the work

area temperature at 21É C (70É F). If system voltage

is more than 12.5 volts, add electrical loads by turn-

ing on electrical accessories until the system voltage

drops below 12.5 volts.

(a) If the clutch coil current reading is four

amperes or more, the coil is shorted and should be

replaced.

(b) If the clutch coil current reading is zero, the

coil is open and should be replaced.

Fig. 4 COMPRESSOR CLUTCH - TYPICAL

1 - CLUTCH PLATE

2 - SHAFT KEY

3 - PULLEY

4 - COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

WJCONTROLS 24 - 13

Page 2093 of 2199

gap should be between 0.35 to 0.65 millimeter (0.014

to 0.026 inch). If the proper air gap is not obtained,

add or subtract shims as needed until the desired air

gap is obtained.

(9) Install the compressor shaft bolt. Tighten the

bolt to 13 N´m (115 in. lbs.).

NOTE: The shims may compress after tightening

the shaft bolt. Check the air gap in four or more

places to verify the air gap is still correct. Spin the

pulley before performing a final check of the air

gap.

(10) To complete the installation, (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION)

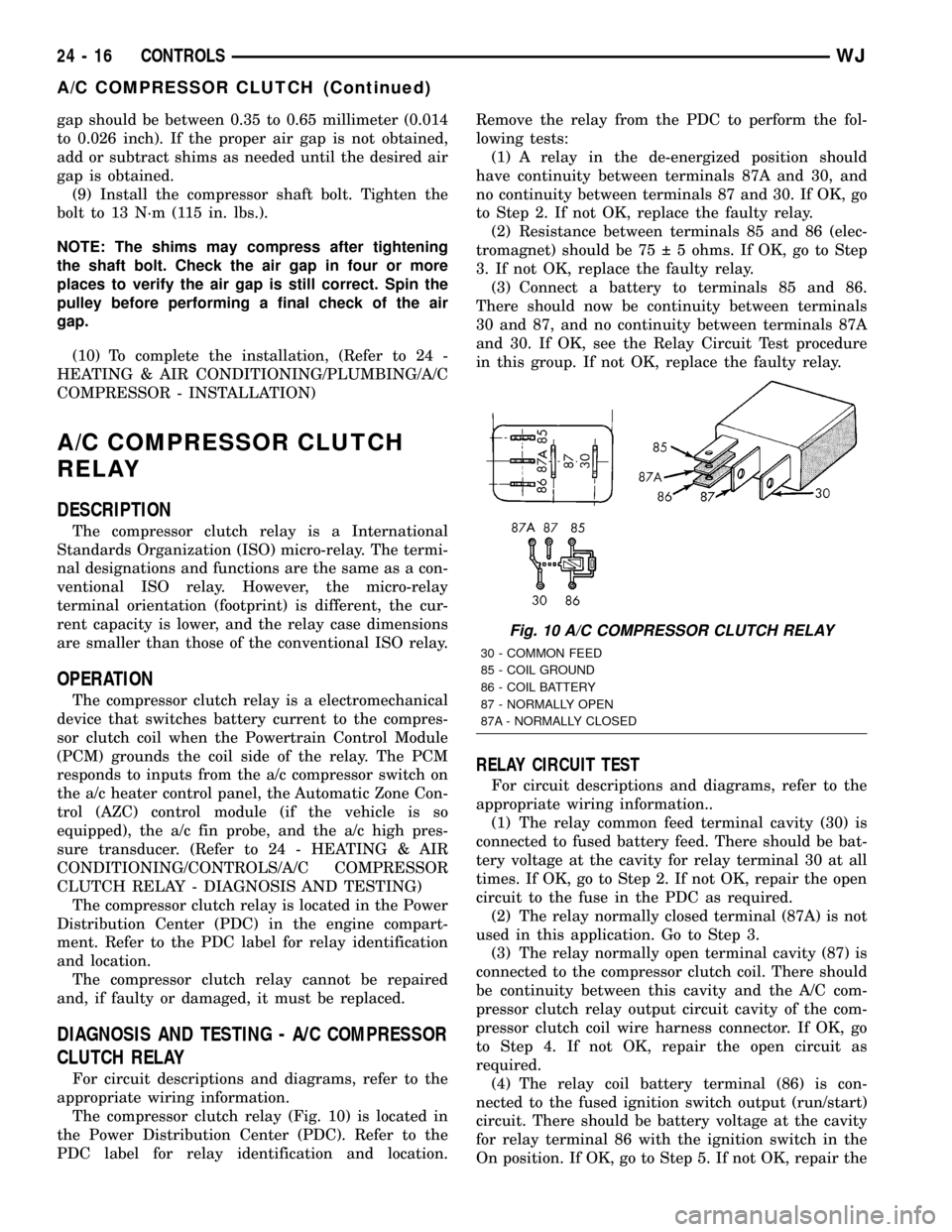

A/C COMPRESSOR CLUTCH

RELAY

DESCRIPTION

The compressor clutch relay is a International

Standards Organization (ISO) micro-relay. The termi-

nal designations and functions are the same as a con-

ventional ISO relay. However, the micro-relay

terminal orientation (footprint) is different, the cur-

rent capacity is lower, and the relay case dimensions

are smaller than those of the conventional ISO relay.

OPERATION

The compressor clutch relay is a electromechanical

device that switches battery current to the compres-

sor clutch coil when the Powertrain Control Module

(PCM) grounds the coil side of the relay. The PCM

responds to inputs from the a/c compressor switch on

the a/c heater control panel, the Automatic Zone Con-

trol (AZC) control module (if the vehicle is so

equipped), the a/c fin probe, and the a/c high pres-

sure transducer. (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/A/C COMPRESSOR

CLUTCH RELAY - DIAGNOSIS AND TESTING)

The compressor clutch relay is located in the Power

Distribution Center (PDC) in the engine compart-

ment. Refer to the PDC label for relay identification

and location.

The compressor clutch relay cannot be repaired

and, if faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - A/C COMPRESSOR

CLUTCH RELAY

For circuit descriptions and diagrams, refer to the

appropriate wiring information.

The compressor clutch relay (Fig. 10) is located in

the Power Distribution Center (PDC). Refer to the

PDC label for relay identification and location.Remove the relay from the PDC to perform the fol-

lowing tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, see the Relay Circuit Test procedure

in this group. If not OK, replace the faulty relay.

RELAY CIRCUIT TEST

For circuit descriptions and diagrams, refer to the

appropriate wiring information..

(1) The relay common feed terminal cavity (30) is

connected to fused battery feed. There should be bat-

tery voltage at the cavity for relay terminal 30 at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is not

used in this application. Go to Step 3.

(3) The relay normally open terminal cavity (87) is

connected to the compressor clutch coil. There should

be continuity between this cavity and the A/C com-

pressor clutch relay output circuit cavity of the com-

pressor clutch coil wire harness connector. If OK, go

to Step 4. If not OK, repair the open circuit as

required.

(4) The relay coil battery terminal (86) is con-

nected to the fused ignition switch output (run/start)

circuit. There should be battery voltage at the cavity

for relay terminal 86 with the ignition switch in the

On position. If OK, go to Step 5. If not OK, repair the

Fig. 10 A/C COMPRESSOR CLUTCH RELAY

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

24 - 16 CONTROLSWJ

A/C COMPRESSOR CLUTCH (Continued)