air JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 447 of 2199

Control Module (PCM) over the Programmable Com-

munications Interface (PCI) data bus. The tachome-

ter is an air core magnetic unit that receives battery

current on the instrument cluster electronic circuit

board through the fused ignition switch output (run-

start) circuit whenever the ignition switch is in the

On or Start positions. The cluster is programmed to

move the gauge needle back to the low end of the

scale after the ignition switch is turned to the Off

position. The instrument cluster circuitry controls

the gauge needle position and provides the following

features:

²Engine Speed Message- Each time the cluster

receives an engine speed message from the PCM it

will calculate the correct engine speed reading and

position the gauge needle at that speed position on

the gauge scale. The cluster will receive a new

engine speed message and reposition the gauge

pointer accordingly about every 86 milliseconds. The

gauge needle will continue to be positioned at the

actual engine speed position on the gauge scale until

the ignition switch is turned to the Off position.

²Communication Error- If the cluster fails to

receive an engine speed message, it will hold the

gauge needle at the last indication for about six sec-

onds, or until the ignition switch is turned to the Off

position, whichever occurs first. If a new engine

speed message is not received after about six sec-

onds, the gauge needle will return to the far left

(low) end of the scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept across the entire gauge scale and back in order

to confirm the functionality of the gauge and the

cluster control circuitry.

The PCM continually monitors the crankshaft posi-

tion sensor to determine the engine speed, then

sends the proper engine speed messages to the

instrument cluster. For further diagnosis of the

tachometer or the instrument cluster circuitry that

controls the gauge, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the crankshaft position

sensor, the PCM, the PCI data bus, or the electronic

message inputs to the instrument cluster that control

the tachometer, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

TRANS TEMP INDICATOR

DESCRIPTION

A transmission over-temperature indicator is stan-

dard equipment on all gasoline engine instrument

clusters. The transmission over-temperature indica-

tor is located near the lower right corner of theinstrument cluster, to the right of the speedometer.

The transmission over-temperature indicator consists

of the words ªTRANS OVER TEMPº imprinted on an

amber lens. The lens is located behind a cutout in

the opaque layer of the instrument cluster overlay.

The dark outer layer of the overlay prevents the indi-

cator from being clearly visible when it is not illumi-

nated. The words ªTRANS OVER TEMPº appear

silhouetted against an amber field through the trans-

lucent outer layer of the overlay when the indicator

is illuminated from behind by a replaceable incandes-

cent bulb and bulb holder unit located on the instru-

ment cluster electronic circuit board. The

transmission over-temperature indicator lens is ser-

viced as a unit with the instrument cluster lens, hood

and mask unit.

OPERATION

The transmission over-temperature indicator gives

an indication to the vehicle operator when the trans-

mission fluid temperature is excessive, which may

lead to accelerated transmission component wear or

failure. This indicator is controlled by a transistor on

the instrument cluster electronic circuit board based

upon cluster programming and electronic messages

received by the cluster over the Programmable Com-

munications Interface (PCI) data bus. These mes-

sages are sent by the Powertrain Control Module

(PCM) or by the Transmission Control Module

(TCM), depending on the model of the automatic

transmission. The transmission over-temperature

indicator bulb is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster receives a battery current input on the fused

ignition switch output (run-start) circuit. Therefore,

the indicator will always be off when the ignition

switch is in any position except On or Start. The bulb

only illuminates when it is provided a path to ground

by the instrument cluster transistor. The instrument

cluster will turn on the transmission over-tempera-

ture indicator for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the transmission over-tem-

perature indicator is illuminated for about three sec-

onds as a bulb test.

²Trans Over-Temp Indicator Lamp-On Mes-

sage- Each time the cluster receives a trans over-

temp indicator lamp-on message from the PCM or

TCM indicating that the transmission fluid tempera-

ture is 135É C (275É F) or higher, the transmission

over-temperature indicator will be illuminated. The

indicator remains illuminated until the cluster

receives a trans over-temp indicator lamp-off mes-

sage from the PCM or TCM, or until the ignition

8J - 32 INSTRUMENT CLUSTERWJ

TACHOMETER (Continued)

Page 448 of 2199

switch is turned to the Off position, whichever occurs

first.

²Actuator Test- Each time the cluster is put

through the actuator test, the transmission over-tem-

perature indicator will be turned on for the duration

of the test to confirm the functionality of the bulb

and the cluster control circuitry.

The PCM or TCM continually monitors the trans-

mission temperature sensor to determine the trans-

mission operating condition. The PCM or TCM then

sends the proper trans over-temp indicator lamp-on

or lamp-off messages to the instrument cluster. If the

transmission over-temperature indicator fails to light

during the bulb test, replace the bulb with a known

good unit. If the instrument cluster turns on the

transmission over-temperature indicator due to a

high transmission oil temperature condition, it may

indicate that the transmission or the transmission

cooling system are being overloaded or that they

require service. For further diagnosis of the trans-

mission over-temperature indicator or the instrument

cluster circuitry that controls the indicator, (Refer to

8 - ELECTRICAL/INSTRUMENT CLUSTER - DIAG-

NOSIS AND TESTING). For proper diagnosis of the

transmission temperature sensor, the PCM, the

TCM, the PCI data bus, or the electronic message

inputs to the instrument cluster that control the

transmission over-temperature indicator, a DRBIIIt

scan tool is required. Refer to the appropriate diag-

nostic information.

TURN SIGNAL INDICATOR

DESCRIPTION

Two turn signal indicators, one right and one left,

are standard equipment on all instrument clusters.

The turn signal indicators are located near the upper

edge of the instrument cluster, the left one is left of

the tachometer, and the right one is right of the

speedometer. Each turn signal indicator consists of

an International Control and Display Symbol icon for

ªTurn Warningº imprinted on a green lens. Each lens

is located behind a dedicated cutout in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents these icons from

being clearly visible when they are not illuminated.

The icons appear silhouetted against a green field

through the translucent outer layer of the overlay

when the indicator is illuminated from behind by a

replaceable incandescent bulb and bulb holder unit

located on the instrument cluster electronic circuit

board. The turn signal indicator lenses are serviced

as a unit with the instrument cluster lens, hood and

mask unit.

OPERATION

The turn signal indicators give an indication to the

vehicle operator that the turn signal (left or right

indicator flashing) or hazard warning (both left and

right indicators flashing) have been selected and are

operating. These indicators are controlled by two

individual hard wired inputs from the combination

flasher circuitry to the instrument cluster electronic

circuit board. Each turn signal indicator bulb is

grounded on the instrument cluster electronic circuit

board at all times; therefore, these indicators remain

functional regardless of the ignition switch position.

Each indicator bulb will only illuminate when it is

provided with battery current by the combination

flasher in the Junction Block (JB).

The turn signal indicators are connected in parallel

with the other turn signal circuits. This arrangement

allows the turn signal indicators to remain func-

tional, regardless of the condition of the other cir-

cuits in the turn signal and hazard warning systems.

The combination flasher outputs to the instrument

cluster turn signal indicator inputs can be diagnosed

using conventional diagnostic tools and methods. For

more information on the turn signal and hazard

warning system, (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR - OPERATION - TURN

SIGNAL & HAZARD WARNING SYSTEM).

DIAGNOSIS AND TESTING - TURN SIGNAL

INDICATOR

The diagnosis found here addresses an inoperative

turn signal indicator condition. If the problem being

diagnosed is related to inoperative turn signal or

hazard warning lamps, be certain to repair the turn

signal and hazard warning system before attempting

to diagnose or repair the turn signal indicators.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR - DIAGNOSIS AND TESTING - TURN

SIGNAL & HAZARD WARNING SYSTEM). If no

turn signal and hazard warning system problem is

found, the following procedure will help locate an

open in the turn signal indicator circuit. Refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

WJINSTRUMENT CLUSTER 8J - 33

TRANS TEMP INDICATOR (Continued)

Page 449 of 2199

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SIDE CURTAIN AIRBAG,

FRONT IMPACT SENSOR, SIDE IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable. Remove the instrument cluster from the

instrument panel and disconnect the instrument

panel wire harness for the instrument cluster from

the cluster connector receptacle.

(2) Reconnect the battery negative cable. Activate

the hazard warning system by moving the hazard

warning switch button to the On position. Check for

battery voltage at the inoperative (right or left) turn

signal circuit cavity of the instrument panel wire

harness connector for the instrument cluster. There

should be a switching (on and off) battery voltage sig-

nal present. If OK, replace the faulty (right or left)

turn signal indicator bulb. If not OK, repair the open

(right or left) turn signal circuit between the instru-

ment cluster and the combination flasher in the

Junction Block (JB) as required.

VOLTAGE GAUGE

DESCRIPTION

A voltage gauge is standard equipment on all

instrument clusters. The voltage gauge is located in

the upper left corner of the instrument cluster, to the

left of the tachometer. The voltage gauge consists of a

movable gauge needle or pointer controlled by the

instrument cluster circuitry and a fixed 90 degree

scale on the gauge dial face that reads left-to-right

from 9 volts to 19 volts. An International Control and

Display Symbol icon for ªBattery Charging Condi-

tionº is located on the gauge dial face.

The voltage gauge graphics are either white, gray

and orange against a black gauge dial face (base

cluster) or black, gray and red against a taupe gauge

dial face (premium cluster), making them clearly vis-

ible within the instrument cluster in daylight. When

illuminated from behind by the panel lamps dimmer

controlled cluster illumination lighting with the exte-rior lamps turned On, the base cluster white gauge

graphics appear blue-green and the orange graphics

still appear orange, while the premium cluster taupe

gauge dial face appears blue-green with the black

graphics silhouetted against the illuminated back-

ground and the red graphics still appear red. The

gray gauge graphics for both versions of the cluster

are not illuminated. The orange gauge needle in the

base cluster gauge is internally illuminated, while

the black gauge needle in the premium cluster gauge

is not.

Base cluster gauge illumination is provided by

replaceable incandescent bulb and bulb holder units

located on the instrument cluster electronic circuit

board. Premium cluster gauge illumination is pro-

vided by an integral electro-luminescent lamp that is

serviced as a unit with the instrument cluster. The

voltage gauge is serviced as a unit with the instru-

ment cluster.

OPERATION

The voltage gauge gives an indication to the vehi-

cle operator of the electrical system voltage. This

gauge is controlled by the instrument cluster circuit

board based upon cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Program-

mable Communications Interface (PCI) data bus. The

voltage gauge is an air core magnetic unit that

receives battery current on the instrument cluster

electronic circuit board through the fused ignition

switch output (run-start) circuit whenever the igni-

tion switch is in the On or Start positions. The clus-

ter is programmed to move the gauge needle back to

the low end of the scale after the ignition switch is

turned to the Off position. The instrument cluster

circuitry controls the gauge needle position and pro-

vides the following features:

²System Voltage Message- Each time the clus-

ter receives a message from the PCM indicating the

system voltage, the cluster moves the gauge needle to

the relative voltage level position on the gauge scale.

²System Voltage Low Message- Each time the

cluster receives a message from the PCM indicating

the system voltage is low (system voltage is about

eleven volts or lower), the gauge needle is moved to

the relative voltage position in the red zone of the

gauge scale and the check gauges indicator is illumi-

nated. The gauge needle remains in the red zone and

the check gauges indicator remains illuminated until

the cluster receives a message from the PCM indicat-

ing there is no low system voltage condition (system

voltage is above about eleven volts, but lower than

about sixteen volts).

²System Voltage High Message- Each time

the cluster receives a message from the PCM indicat-

8J - 34 INSTRUMENT CLUSTERWJ

TURN SIGNAL INDICATOR (Continued)

Page 454 of 2199

ergize the combination flasher in response to mes-

sage inputs received over the Programmable

Communications Interface (PCI) data bus network.

The BCM can energize the combination flasher when

the VTSS is requested.

Vehicles equipped with the optional Electronic

Vehicle Information Center (EVIC) use turn signal

status messages received from the Electro-Mechani-

cal Instrument Cluster (EMIC) and distance mes-

sages received from the Powertrain Control Module

(PCM) over the PCI data bus to determine when the

Turn Signal On warning should be activated. The

EMIC receives hard wired inputs from the combina-

tion flasher to operate the turn signal indicators,

then sends the proper turn signal status message to

the EVIC. If a turn signal is left on for more than

about 1.6 kilometers (1 mile) of driving distance, the

EVIC will display a visual ªTurn Signal Onº message

and will send a request to the BCM over the PCI

data bus to notify the vehicle operator.

During both the turn signal and the hazard warn-

ing operation, if the exterior lamps are turned Off,

the front park/turn signal lamps and the front side

marker lamps will flash in unison. If the exterior

lamps are turned On, the front park/turn signal

lamps and the front side marker lamps will flash

alternately. Refer to the owner's manual.

DIAGNOSIS AND TESTING - TURN SIGNAL &

HAZARD WARNING SYSTEMS

When diagnosing the turn signal and hazard warn-

ing circuits, remember that high generator output

can burn out bulbs rapidly and repeatedly. If this is a

concern on the vehicle being diagnosed, test the

charging system as required.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Turn the ignition switch to the On position.

Actuate the turn signal switch or the hazard warning

switch. Observe the turn signal indicator lamp(s) in

the instrument cluster. If the flash rate is very high,

check for a turn signal bulb that is not lit or is verydimly lit. Repair the circuits to that lamp or replace

the faulty bulb, as required. If the turn signal indi-

cator(s) fail to light, go to Step 2.

(2) Turn the ignition switch to the Off position.

Check the ignition run fuse and the flasher fuse in

the Junction Block (JB). If OK, go to Step 3. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).

(3) Check for battery voltage at the flasher fuse in

the JB. If OK, go to Step 4. If not OK, repair the

open fused B(+) circuit between the JB and the

Power Distribution Center (PDC).

(4) Turn the ignition switch to the On position.

Check for battery voltage at the ignition run fuse in

the JB. If OK, go to Step 5. If not OK, repair the

open fused ignition switch output (run) circuit

between the JB and the ignition switch.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the combination flasher from the JB and

replace it with a known good unit. Reconnect the bat-

tery negative cable. Test the operation of the turn

signal and hazard warning systems. If OK, discard

the faulty combination flasher. If not OK, remove the

test flasher and go to Step 6.

(6) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) circuit cavity in the JB for the combina-

tion flasher. If OK, go to Step 7. If not OK, repair the

open fused ignition switch output (run) circuit

between the combination flasher and the ignition run

fuse in the JB.

(7) Turn the ignition switch to the Off position.

Check for battery voltage at the B(+) circuit of the JB

for the combination flasher. If OK, go to Step 8. If

not OK, repair the open B(+) circuit between the

combination flasher and the flasher fuse in the JB.

(8) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector for the turn signal and hazard warning

switches from the multi-function switch connector.

Check for continuity between the ground circuit of

the instrument panel wire harness connector for the

left multi-function switch and a good ground. There

should be continuity. If OK, go to Step 9. If not OK,

repair the open ground circuit.

(9) Check for continuity between the hazard switch

sense circuit of the instrument panel wire harness

connector for the multi-function switch and a good

ground. There should be no continuity. If OK, go to

Step 10. If not OK, repair the shorted hazard switch

sense circuit between the multi-function switch and

the combination flasher.

(10) Check for continuity between the hazard

switch sense circuit of the JB for the combination

flasher and the instrument panel wire harness con-

WJLAMPS/LIGHTING - EXTERIOR 8L - 3

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 455 of 2199

nector for the multi-function switch. There should be

continuity. If OK, go to Step 11. If not OK, repair the

open hazard switch sense circuit between the multi-

function switch and the combination flasher.

(11) Check for continuity between the turn switch

sense circuit of the instrument panel wire harness

connector for the multi-function switch and a good

ground. There should be no continuity. If OK, go to

Step 12. If not OK, repair the shorted left turn

switch sense circuit between the multi-function

switch and the combination flasher.

(12) Check for continuity between the left turn

switch sense circuit of the JB for the combination

flasher and the instrument panel wire harness con-

nector for the multi-function switch. There should be

continuity. If OK, go to Step 13. If not OK, repair the

open left turn switch sense circuit between the multi-

function switch and the combination flasher.

(13) Check for continuity between the right turn

switch sense circuit of the instrument panel wire

harness connector for the left multi-function switch

and a good ground. There should be no continuity. If

OK, go to Step 14. If not OK, repair the shorted right

turn switch sense circuit between the left multi-func-

tion switch and the combination flasher.

(14) Check for continuity between the right turn

switch sense circuit of the JB for the combination

flasher and the instrument panel wire harness con-

nector for the multi-function switch. There should be

continuity. If OK, test the left multi-function switch.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/LEFT MULTI-FUNCTION SWITCH -

DIAGNOSIS AND TESTING). If not OK, repair the

open right turn switch sense circuit between the

multi-function switch and the combination flasher as

required.

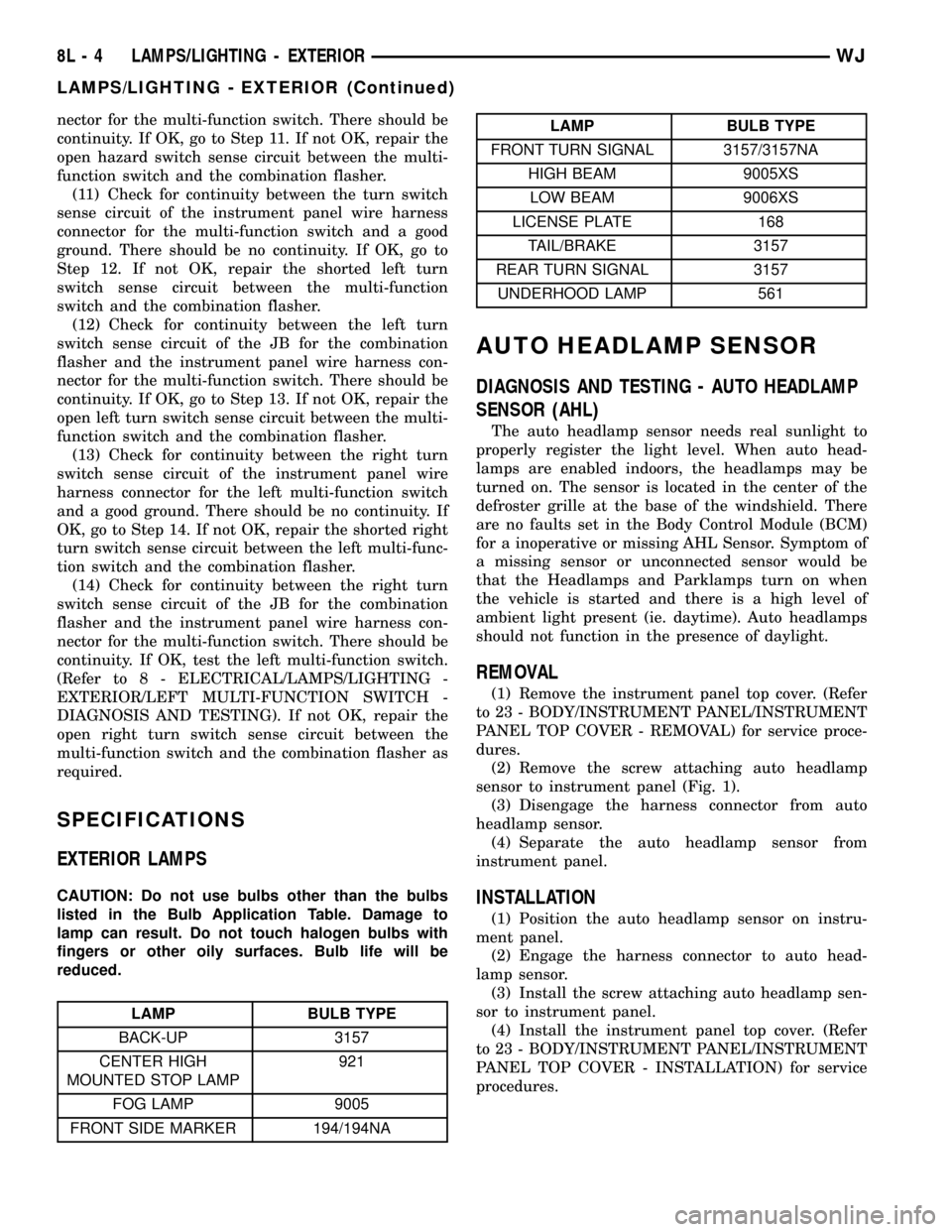

SPECIFICATIONS

EXTERIOR LAMPS

CAUTION: Do not use bulbs other than the bulbs

listed in the Bulb Application Table. Damage to

lamp can result. Do not touch halogen bulbs with

fingers or other oily surfaces. Bulb life will be

reduced.

LAMP BULB TYPE

BACK-UP 3157

CENTER HIGH

MOUNTED STOP LAMP921

FOG LAMP 9005

FRONT SIDE MARKER 194/194NA

LAMP BULB TYPE

FRONT TURN SIGNAL 3157/3157NA

HIGH BEAM 9005XS

LOW BEAM 9006XS

LICENSE PLATE 168

TAIL/BRAKE 3157

REAR TURN SIGNAL 3157

UNDERHOOD LAMP 561

AUTO HEADLAMP SENSOR

DIAGNOSIS AND TESTING - AUTO HEADLAMP

SENSOR (AHL)

The auto headlamp sensor needs real sunlight to

properly register the light level. When auto head-

lamps are enabled indoors, the headlamps may be

turned on. The sensor is located in the center of the

defroster grille at the base of the windshield. There

are no faults set in the Body Control Module (BCM)

for a inoperative or missing AHL Sensor. Symptom of

a missing sensor or unconnected sensor would be

that the Headlamps and Parklamps turn on when

the vehicle is started and there is a high level of

ambient light present (ie. daytime). Auto headlamps

should not function in the presence of daylight.

REMOVAL

(1) Remove the instrument panel top cover. (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - REMOVAL) for service proce-

dures.

(2) Remove the screw attaching auto headlamp

sensor to instrument panel (Fig. 1).

(3) Disengage the harness connector from auto

headlamp sensor.

(4) Separate the auto headlamp sensor from

instrument panel.

INSTALLATION

(1) Position the auto headlamp sensor on instru-

ment panel.

(2) Engage the harness connector to auto head-

lamp sensor.

(3) Install the screw attaching auto headlamp sen-

sor to instrument panel.

(4) Install the instrument panel top cover. (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - INSTALLATION) for service

procedures.

8L - 4 LAMPS/LIGHTING - EXTERIORWJ

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 458 of 2199

INSTALLATION - CHMSL

(1) Connect the wire harness connector.

(2) Position the CHMSL on liftgate.

(3) Install the screws attaching the CHMSL to the

liftgate.

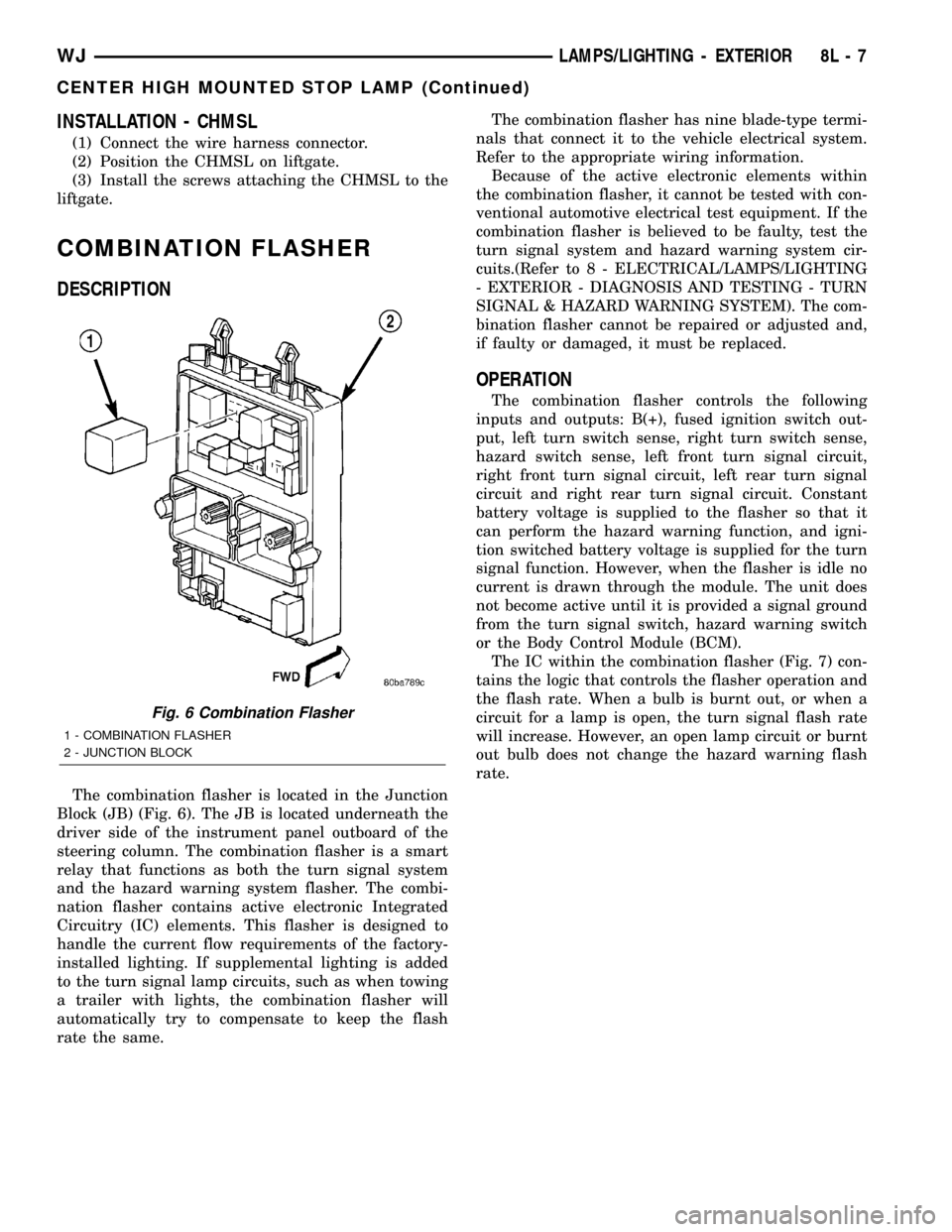

COMBINATION FLASHER

DESCRIPTION

The combination flasher is located in the Junction

Block (JB) (Fig. 6). The JB is located underneath the

driver side of the instrument panel outboard of the

steering column. The combination flasher is a smart

relay that functions as both the turn signal system

and the hazard warning system flasher. The combi-

nation flasher contains active electronic Integrated

Circuitry (IC) elements. This flasher is designed to

handle the current flow requirements of the factory-

installed lighting. If supplemental lighting is added

to the turn signal lamp circuits, such as when towing

a trailer with lights, the combination flasher will

automatically try to compensate to keep the flash

rate the same.The combination flasher has nine blade-type termi-

nals that connect it to the vehicle electrical system.

Refer to the appropriate wiring information.

Because of the active electronic elements within

the combination flasher, it cannot be tested with con-

ventional automotive electrical test equipment. If the

combination flasher is believed to be faulty, test the

turn signal system and hazard warning system cir-

cuits.(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING

- EXTERIOR - DIAGNOSIS AND TESTING - TURN

SIGNAL & HAZARD WARNING SYSTEM). The com-

bination flasher cannot be repaired or adjusted and,

if faulty or damaged, it must be replaced.

OPERATION

The combination flasher controls the following

inputs and outputs: B(+), fused ignition switch out-

put, left turn switch sense, right turn switch sense,

hazard switch sense, left front turn signal circuit,

right front turn signal circuit, left rear turn signal

circuit and right rear turn signal circuit. Constant

battery voltage is supplied to the flasher so that it

can perform the hazard warning function, and igni-

tion switched battery voltage is supplied for the turn

signal function. However, when the flasher is idle no

current is drawn through the module. The unit does

not become active until it is provided a signal ground

from the turn signal switch, hazard warning switch

or the Body Control Module (BCM).

The IC within the combination flasher (Fig. 7) con-

tains the logic that controls the flasher operation and

the flash rate. When a bulb is burnt out, or when a

circuit for a lamp is open, the turn signal flash rate

will increase. However, an open lamp circuit or burnt

out bulb does not change the hazard warning flash

rate.

Fig. 6 Combination Flasher

1 - COMBINATION FLASHER

2 - JUNCTION BLOCK

WJLAMPS/LIGHTING - EXTERIOR 8L - 7

CENTER HIGH MOUNTED STOP LAMP (Continued)

Page 460 of 2199

Turn signal inputs that actuate the combination

flasher are low current grounds, each drawing a

maximum of 300 milliamperes.The hazard warning

signal input is a low current ground drawing a max-

imum of 600 milliamperes.

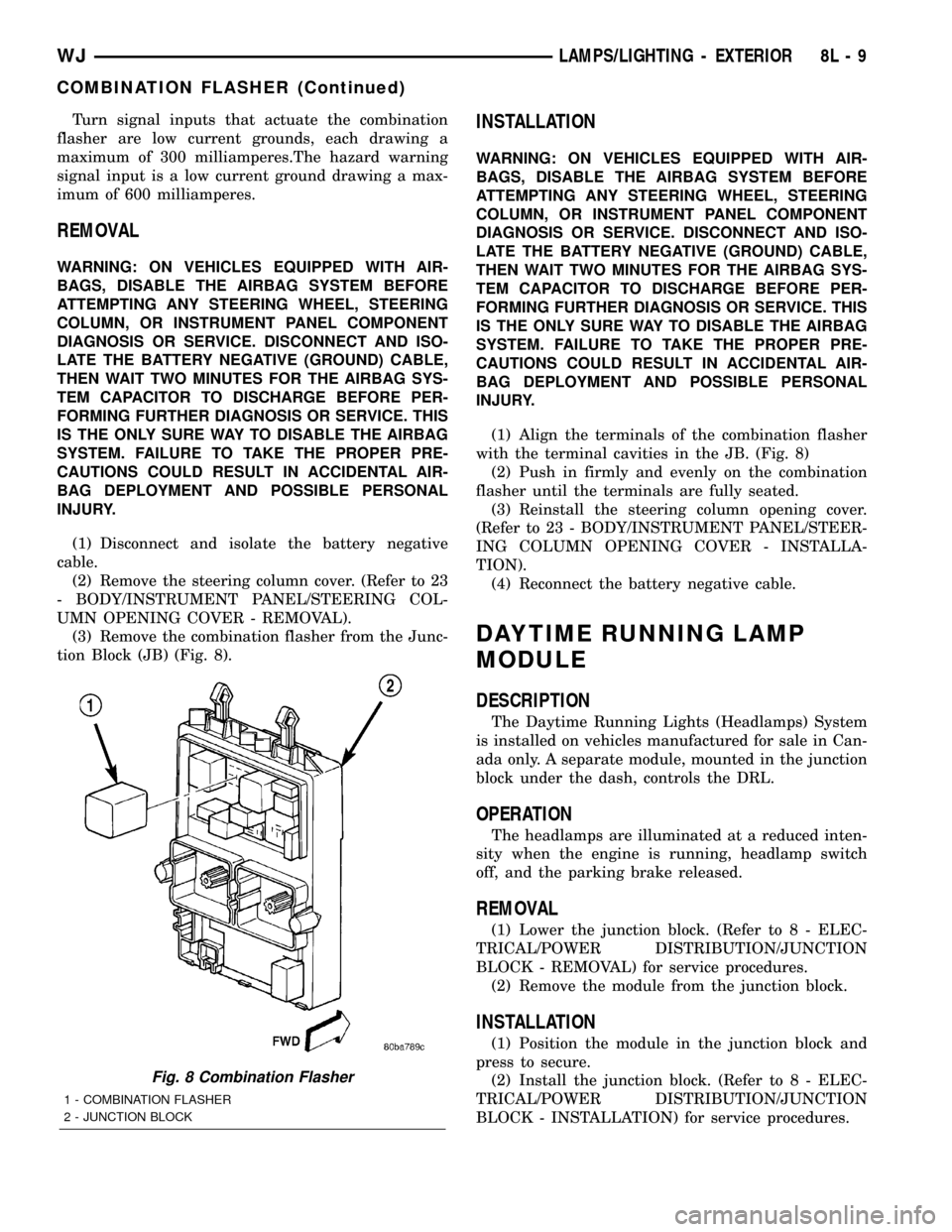

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the steering column cover. (Refer to 23

- BODY/INSTRUMENT PANEL/STEERING COL-

UMN OPENING COVER - REMOVAL).

(3) Remove the combination flasher from the Junc-

tion Block (JB) (Fig. 8).

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Align the terminals of the combination flasher

with the terminal cavities in the JB. (Fig. 8)

(2) Push in firmly and evenly on the combination

flasher until the terminals are fully seated.

(3) Reinstall the steering column opening cover.

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(4) Reconnect the battery negative cable.

DAYTIME RUNNING LAMP

MODULE

DESCRIPTION

The Daytime Running Lights (Headlamps) System

is installed on vehicles manufactured for sale in Can-

ada only. A separate module, mounted in the junction

block under the dash, controls the DRL.

OPERATION

The headlamps are illuminated at a reduced inten-

sity when the engine is running, headlamp switch

off, and the parking brake released.

REMOVAL

(1) Lower the junction block. (Refer to 8 - ELEC-

TRICAL/POWER DISTRIBUTION/JUNCTION

BLOCK - REMOVAL) for service procedures.

(2) Remove the module from the junction block.

INSTALLATION

(1) Position the module in the junction block and

press to secure.

(2) Install the junction block. (Refer to 8 - ELEC-

TRICAL/POWER DISTRIBUTION/JUNCTION

BLOCK - INSTALLATION) for service procedures.

Fig. 8 Combination Flasher

1 - COMBINATION FLASHER

2 - JUNCTION BLOCK

WJLAMPS/LIGHTING - EXTERIOR 8L - 9

COMBINATION FLASHER (Continued)

Page 463 of 2199

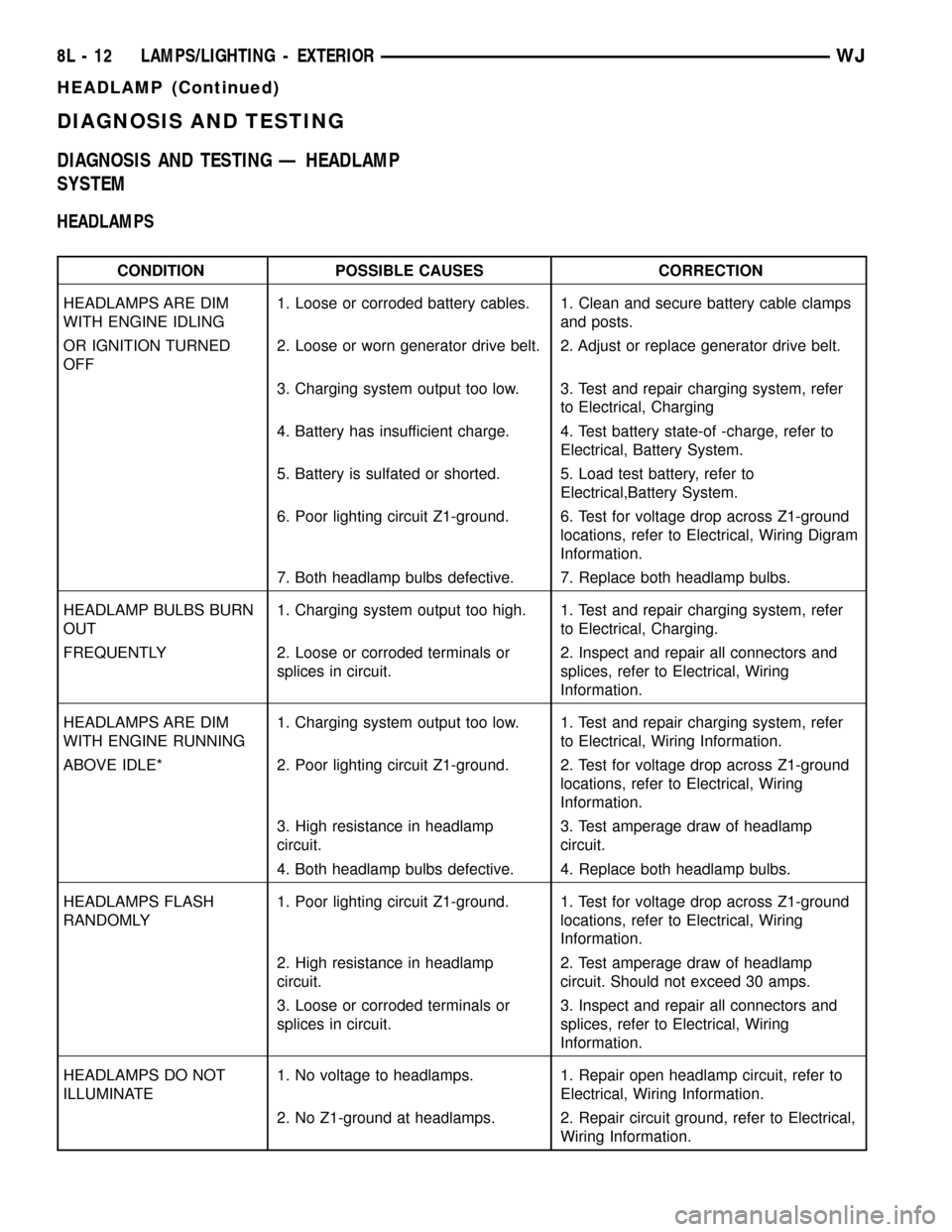

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING Ð HEADLAMP

SYSTEM

HEADLAMPS

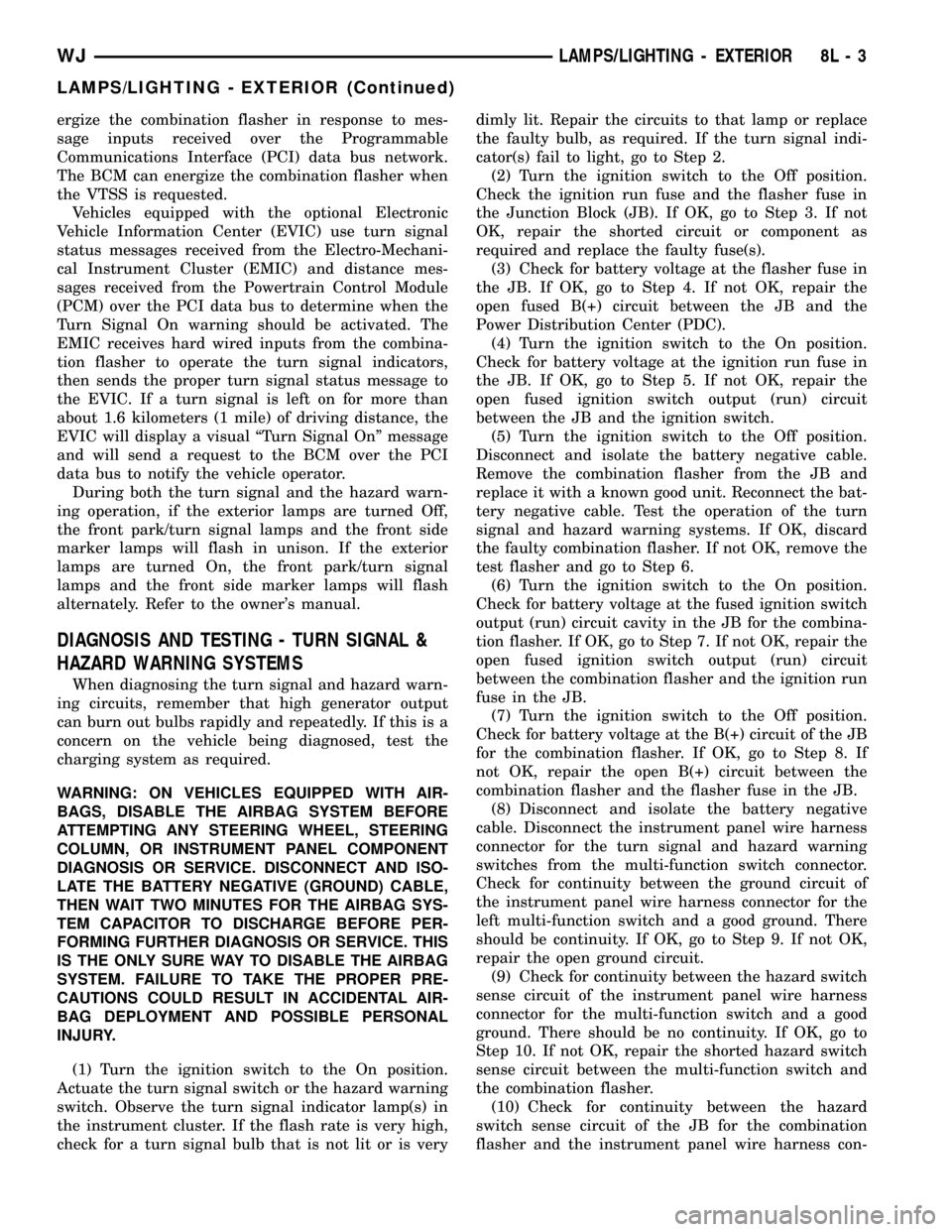

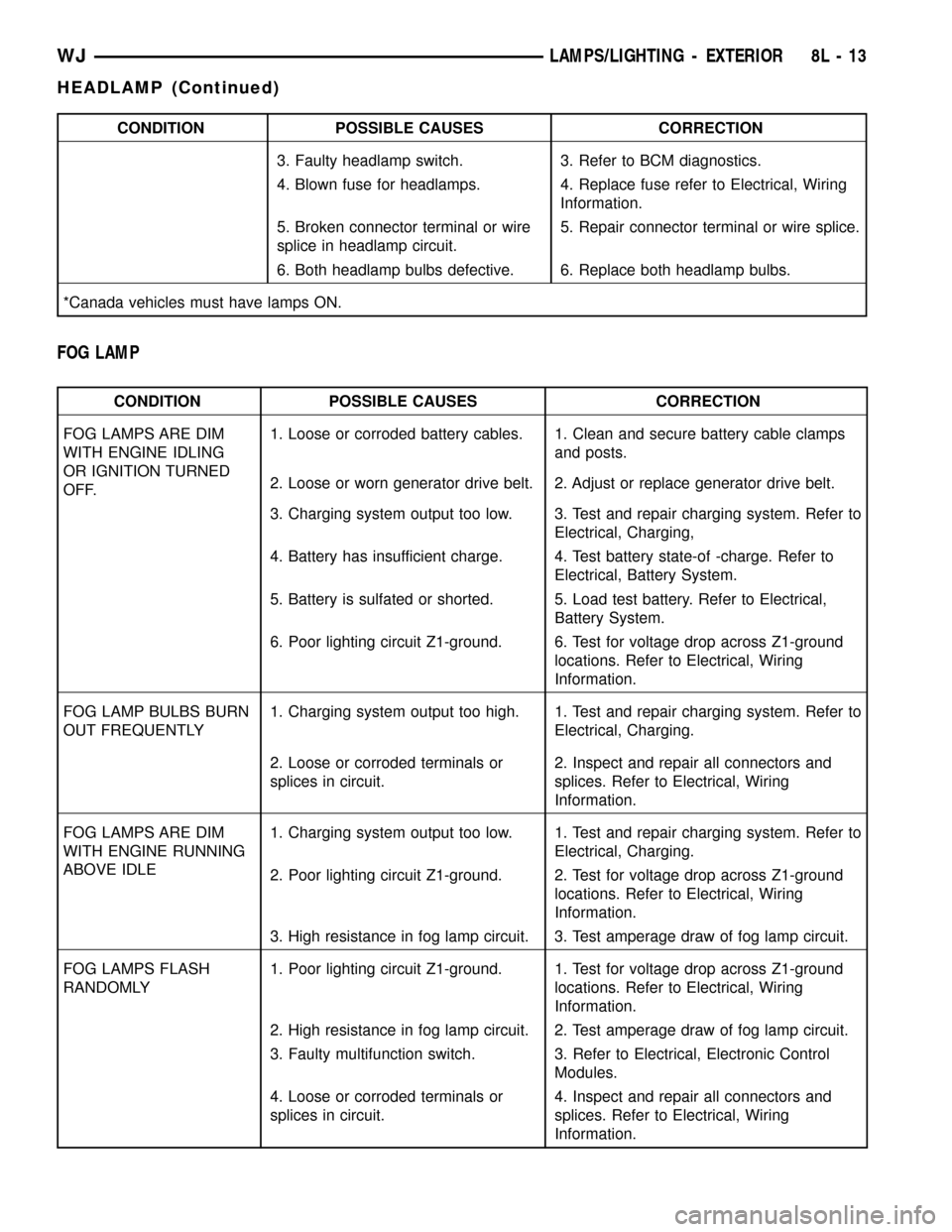

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMPS ARE DIM

WITH ENGINE IDLING1. Loose or corroded battery cables. 1. Clean and secure battery cable clamps

and posts.

OR IGNITION TURNED

OFF2. Loose or worn generator drive belt. 2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system, refer

to Electrical, Charging

4. Battery has insufficient charge. 4. Test battery state-of -charge, refer to

Electrical, Battery System.

5. Battery is sulfated or shorted. 5. Load test battery, refer to

Electrical,Battery System.

6. Poor lighting circuit Z1-ground. 6. Test for voltage drop across Z1-ground

locations, refer to Electrical, Wiring Digram

Information.

7. Both headlamp bulbs defective. 7. Replace both headlamp bulbs.

HEADLAMP BULBS BURN

OUT1. Charging system output too high. 1. Test and repair charging system, refer

to Electrical, Charging.

FREQUENTLY 2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and

splices, refer to Electrical, Wiring

Information.

HEADLAMPS ARE DIM

WITH ENGINE RUNNING1. Charging system output too low. 1. Test and repair charging system, refer

to Electrical, Wiring Information.

ABOVE IDLE* 2. Poor lighting circuit Z1-ground. 2. Test for voltage drop across Z1-ground

locations, refer to Electrical, Wiring

Information.

3. High resistance in headlamp

circuit.3. Test amperage draw of headlamp

circuit.

4. Both headlamp bulbs defective. 4. Replace both headlamp bulbs.

HEADLAMPS FLASH

RANDOMLY1. Poor lighting circuit Z1-ground. 1. Test for voltage drop across Z1-ground

locations, refer to Electrical, Wiring

Information.

2. High resistance in headlamp

circuit.2. Test amperage draw of headlamp

circuit. Should not exceed 30 amps.

3. Loose or corroded terminals or

splices in circuit.3. Inspect and repair all connectors and

splices, refer to Electrical, Wiring

Information.

HEADLAMPS DO NOT

ILLUMINATE1. No voltage to headlamps. 1. Repair open headlamp circuit, refer to

Electrical, Wiring Information.

2. No Z1-ground at headlamps. 2. Repair circuit ground, refer to Electrical,

Wiring Information.

8L - 12 LAMPS/LIGHTING - EXTERIORWJ

HEADLAMP (Continued)

Page 464 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

3. Faulty headlamp switch. 3. Refer to BCM diagnostics.

4. Blown fuse for headlamps. 4. Replace fuse refer to Electrical, Wiring

Information.

5. Broken connector terminal or wire

splice in headlamp circuit.5. Repair connector terminal or wire splice.

6. Both headlamp bulbs defective. 6. Replace both headlamp bulbs.

*Canada vehicles must have lamps ON.

FOG LAMP

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE DIM

WITH ENGINE IDLING

OR IGNITION TURNED

OFF.1. Loose or corroded battery cables. 1. Clean and secure battery cable clamps

and posts.

2. Loose or worn generator drive belt. 2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system. Refer to

Electrical, Charging,

4. Battery has insufficient charge. 4. Test battery state-of -charge. Refer to

Electrical, Battery System.

5. Battery is sulfated or shorted. 5. Load test battery. Refer to Electrical,

Battery System.

6. Poor lighting circuit Z1-ground. 6. Test for voltage drop across Z1-ground

locations. Refer to Electrical, Wiring

Information.

FOG LAMP BULBS BURN

OUT FREQUENTLY1. Charging system output too high. 1. Test and repair charging system. Refer to

Electrical, Charging.

2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and

splices. Refer to Electrical, Wiring

Information.

FOG LAMPS ARE DIM

WITH ENGINE RUNNING

ABOVE IDLE1. Charging system output too low. 1. Test and repair charging system. Refer to

Electrical, Charging.

2. Poor lighting circuit Z1-ground. 2. Test for voltage drop across Z1-ground

locations. Refer to Electrical, Wiring

Information.

3. High resistance in fog lamp circuit. 3. Test amperage draw of fog lamp circuit.

FOG LAMPS FLASH

RANDOMLY1. Poor lighting circuit Z1-ground. 1. Test for voltage drop across Z1-ground

locations. Refer to Electrical, Wiring

Information.

2. High resistance in fog lamp circuit. 2. Test amperage draw of fog lamp circuit.

3. Faulty multifunction switch. 3. Refer to Electrical, Electronic Control

Modules.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and

splices. Refer to Electrical, Wiring

Information.

WJLAMPS/LIGHTING - EXTERIOR 8L - 13

HEADLAMP (Continued)

Page 465 of 2199

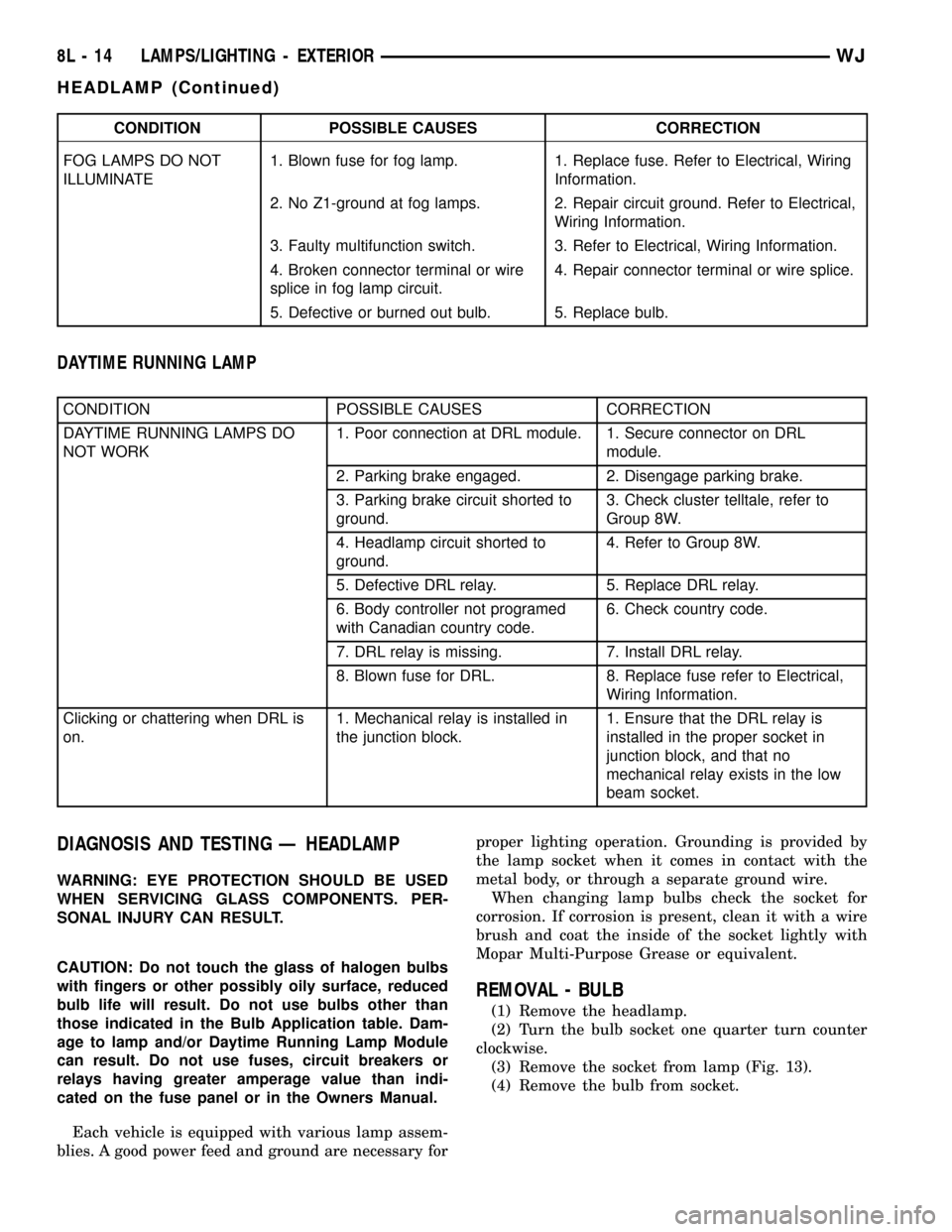

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS DO NOT

ILLUMINATE1. Blown fuse for fog lamp. 1. Replace fuse. Refer to Electrical, Wiring

Information.

2. No Z1-ground at fog lamps. 2. Repair circuit ground. Refer to Electrical,

Wiring Information.

3. Faulty multifunction switch. 3. Refer to Electrical, Wiring Information.

4. Broken connector terminal or wire

splice in fog lamp circuit.4. Repair connector terminal or wire splice.

5. Defective or burned out bulb. 5. Replace bulb.

DAYTIME RUNNING LAMP

CONDITION POSSIBLE CAUSES CORRECTION

DAYTIME RUNNING LAMPS DO

NOT WORK1. Poor connection at DRL module. 1. Secure connector on DRL

module.

2. Parking brake engaged. 2. Disengage parking brake.

3. Parking brake circuit shorted to

ground.3. Check cluster telltale, refer to

Group 8W.

4. Headlamp circuit shorted to

ground.4. Refer to Group 8W.

5. Defective DRL relay. 5. Replace DRL relay.

6. Body controller not programed

with Canadian country code.6. Check country code.

7. DRL relay is missing. 7. Install DRL relay.

8. Blown fuse for DRL. 8. Replace fuse refer to Electrical,

Wiring Information.

Clicking or chattering when DRL is

on.1. Mechanical relay is installed in

the junction block.1. Ensure that the DRL relay is

installed in the proper socket in

junction block, and that no

mechanical relay exists in the low

beam socket.

DIAGNOSIS AND TESTING Ð HEADLAMP

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result. Do not use bulbs other than

those indicated in the Bulb Application table. Dam-

age to lamp and/or Daytime Running Lamp Module

can result. Do not use fuses, circuit breakers or

relays having greater amperage value than indi-

cated on the fuse panel or in the Owners Manual.

Each vehicle is equipped with various lamp assem-

blies. A good power feed and ground are necessary forproper lighting operation. Grounding is provided by

the lamp socket when it comes in contact with the

metal body, or through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush and coat the inside of the socket lightly with

Mopar Multi-Purpose Grease or equivalent.

REMOVAL - BULB

(1) Remove the headlamp.

(2) Turn the bulb socket one quarter turn counter

clockwise.

(3) Remove the socket from lamp (Fig. 13).

(4) Remove the bulb from socket.

8L - 14 LAMPS/LIGHTING - EXTERIORWJ

HEADLAMP (Continued)