Engine oil drain plug JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1263 of 2199

(2) Drain the coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE) and disconnect the hoses

at the engine thermostat housing and the water

pump inlet. DO NOT waste reusable coolant. If the

solution is clean and is being drained only to service

the engine or cooling system, drain the coolant into a

clean container for reuse.

(3) Remove the air cleaner assembly (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - REMOVAL).

(4) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(5) Remove the capscrews, bridge and pivot assem-

blies and rocker arms (Refer to 9 - ENGINE/CYLIN-

DER HEAD/ROCKER ARM / ADJUSTER ASSY -

REMOVAL).

(6) Remove the push rods.Retain the push rods,

bridges, pivots and rocker arms in the same

order as removed.

(7) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(8) Remove the A/C compressor mounting bolts

and secure the compressor to the side.

(9) Remove the power steering pump and bracket

from the intake manifold and water pump. Set the

pump and bracket aside. DO NOT disconnect the

hoses.

(10) Perform the Fuel System Pressure Release

procedure. (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE).

(11) Disconnect the fuel supply line at the fuel rail.(12) Remove the intake and exhaust manifolds

from the engine cylinder head (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

(13) Remove the coil rail (Refer to 8 - ELECTRI-

CAL/IGNITION CONTROL/COIL RAIL - REMOV-

AL).

(14) Remove spark plugs (Refer to 8 - ELECTRI-

CAL/IGNITION CONTROL/SPARK PLUG - REMOV-

AL).

(15) Disconnect the temperature sending unit wire

connector.

(16) Remove the engine cylinder head bolts. Bolt

No.14 cannot be removed until the head is moved for-

ward (Fig. 9). Pull bolt No.14 out as far as it will go

and then suspend the bolt in this position (tape

around the bolt).

(17) Remove the engine cylinder head and gasket

(Fig. 9).

(18) If this was the first time the bolts were

removed, put a paint dab on the top of the bolt. If the

bolts have a paint dab on the top of the bolt or it

isn't known if they were used before, discard the

bolts.

(19) Stuff clean lint free shop towels into the cyl-

inder bores.

NOTE: If the valves, springs, or seals are to be

inspected/replaced at this time, (Refer to 9 -

ENGINE/CYLINDER HEAD/INTAKE/EXHAUST

VALVES & SEATS - STANDARD PROCEDURE) for

proper inspection procedures.

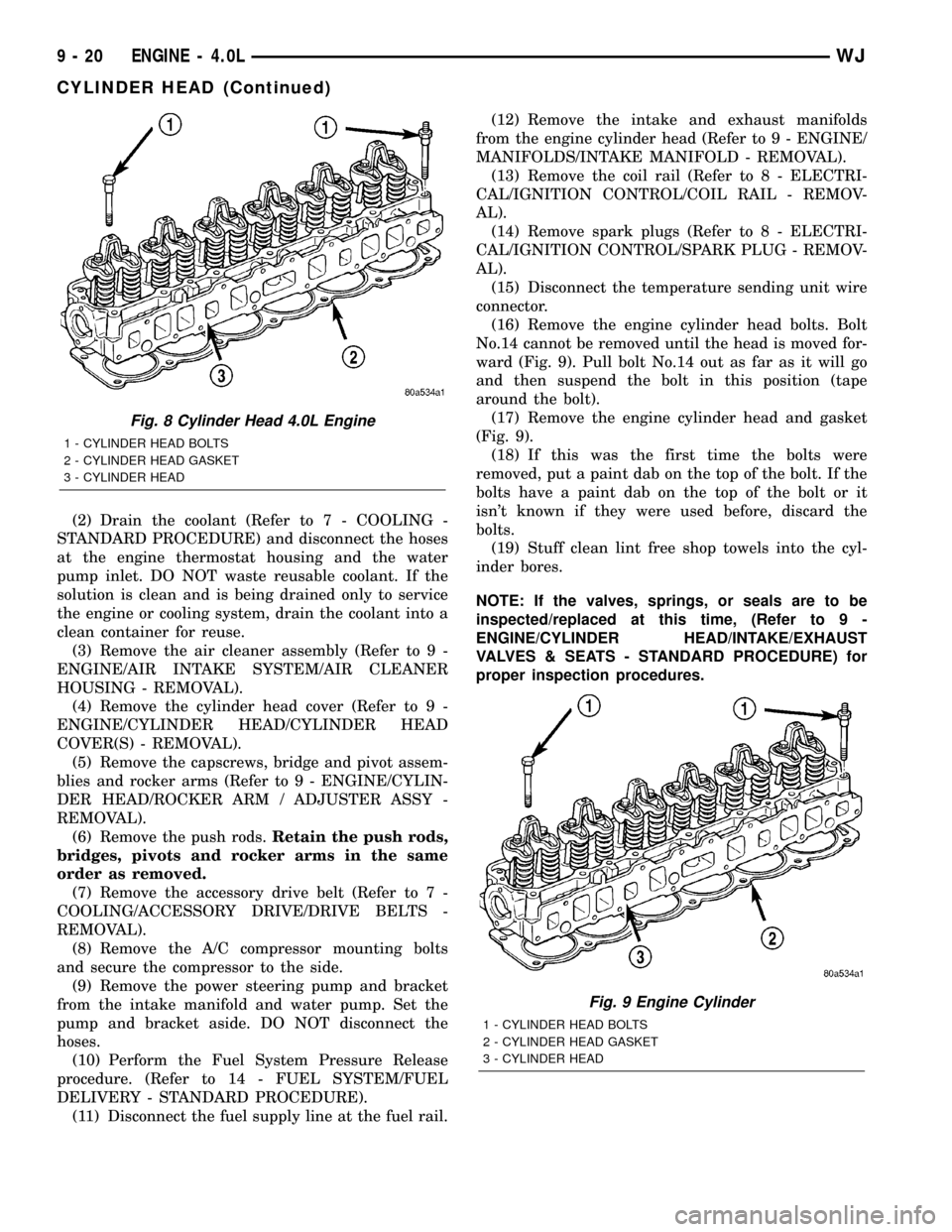

Fig. 8 Cylinder Head 4.0L Engine

1 - CYLINDER HEAD BOLTS

2 - CYLINDER HEAD GASKET

3 - CYLINDER HEAD

Fig. 9 Engine Cylinder

1 - CYLINDER HEAD BOLTS

2 - CYLINDER HEAD GASKET

3 - CYLINDER HEAD

9 - 20 ENGINE - 4.0LWJ

CYLINDER HEAD (Continued)

Page 1274 of 2199

REMOVAL

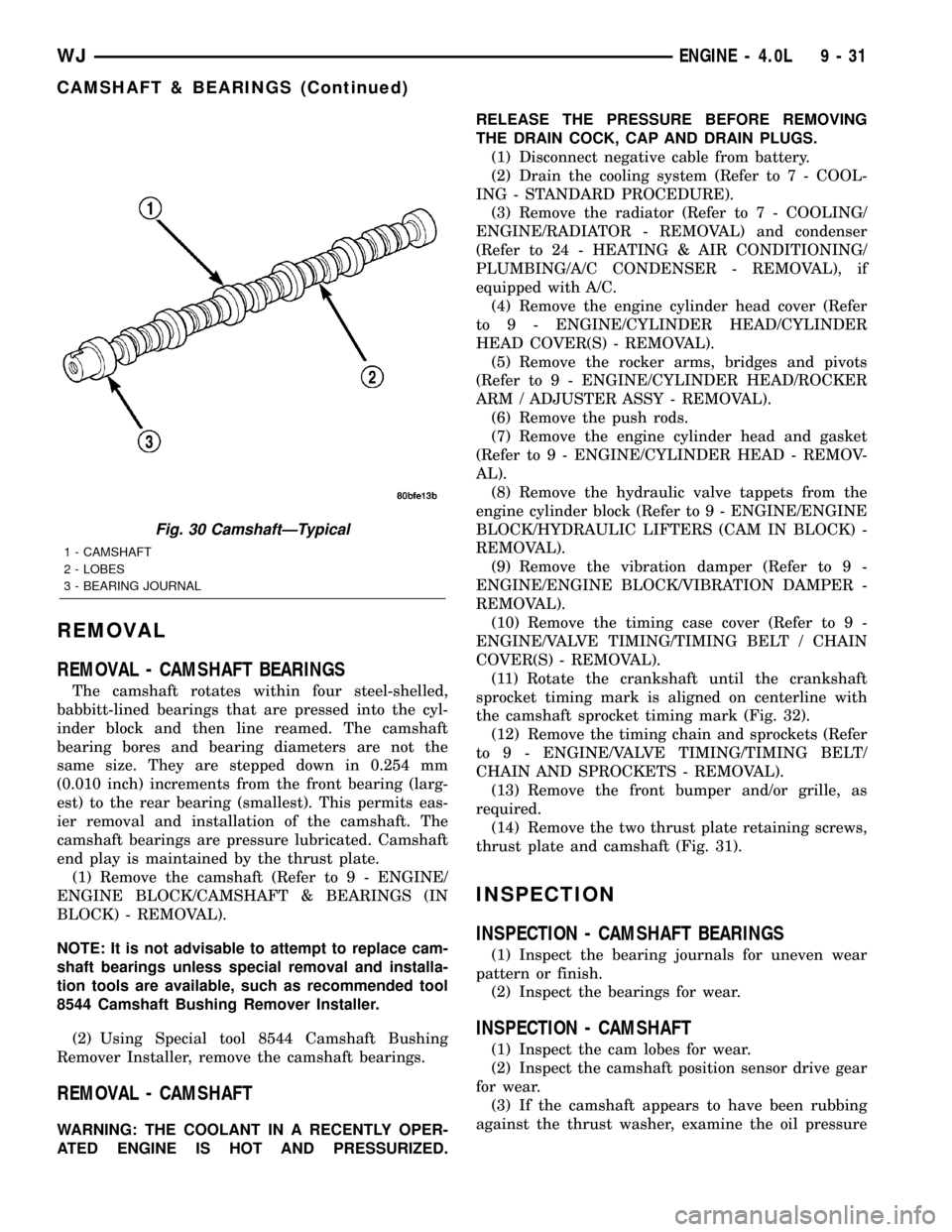

REMOVAL - CAMSHAFT BEARINGS

The camshaft rotates within four steel-shelled,

babbitt-lined bearings that are pressed into the cyl-

inder block and then line reamed. The camshaft

bearing bores and bearing diameters are not the

same size. They are stepped down in 0.254 mm

(0.010 inch) increments from the front bearing (larg-

est) to the rear bearing (smallest). This permits eas-

ier removal and installation of the camshaft. The

camshaft bearings are pressure lubricated. Camshaft

end play is maintained by the thrust plate.

(1) Remove the camshaft (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - REMOVAL).

NOTE: It is not advisable to attempt to replace cam-

shaft bearings unless special removal and installa-

tion tools are available, such as recommended tool

8544 Camshaft Bushing Remover Installer.

(2) Using Special tool 8544 Camshaft Bushing

Remover Installer, remove the camshaft bearings.

REMOVAL - CAMSHAFT

WARNING: THE COOLANT IN A RECENTLY OPER-

ATED ENGINE IS HOT AND PRESSURIZED.RELEASE THE PRESSURE BEFORE REMOVING

THE DRAIN COCK, CAP AND DRAIN PLUGS.

(1) Disconnect negative cable from battery.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(3) Remove the radiator (Refer to 7 - COOLING/

ENGINE/RADIATOR - REMOVAL) and condenser

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - REMOVAL), if

equipped with A/C.

(4) Remove the engine cylinder head cover (Refer

to 9 - ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - REMOVAL).

(5) Remove the rocker arms, bridges and pivots

(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARM / ADJUSTER ASSY - REMOVAL).

(6) Remove the push rods.

(7) Remove the engine cylinder head and gasket

(Refer to 9 - ENGINE/CYLINDER HEAD - REMOV-

AL).

(8) Remove the hydraulic valve tappets from the

engine cylinder block (Refer to 9 - ENGINE/ENGINE

BLOCK/HYDRAULIC LIFTERS (CAM IN BLOCK) -

REMOVAL).

(9) Remove the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(10) Remove the timing case cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(11) Rotate the crankshaft until the crankshaft

sprocket timing mark is aligned on centerline with

the camshaft sprocket timing mark (Fig. 32).

(12) Remove the timing chain and sprockets (Refer

to 9 - ENGINE/VALVE TIMING/TIMING BELT/

CHAIN AND SPROCKETS - REMOVAL).

(13) Remove the front bumper and/or grille, as

required.

(14) Remove the two thrust plate retaining screws,

thrust plate and camshaft (Fig. 31).

INSPECTION

INSPECTION - CAMSHAFT BEARINGS

(1) Inspect the bearing journals for uneven wear

pattern or finish.

(2) Inspect the bearings for wear.

INSPECTION - CAMSHAFT

(1) Inspect the cam lobes for wear.

(2) Inspect the camshaft position sensor drive gear

for wear.

(3) If the camshaft appears to have been rubbing

against the thrust washer, examine the oil pressure

Fig. 30 CamshaftÐTypical

1 - CAMSHAFT

2 - LOBES

3 - BEARING JOURNAL

WJENGINE - 4.0L 9 - 31

CAMSHAFT & BEARINGS (Continued)

Page 1284 of 2199

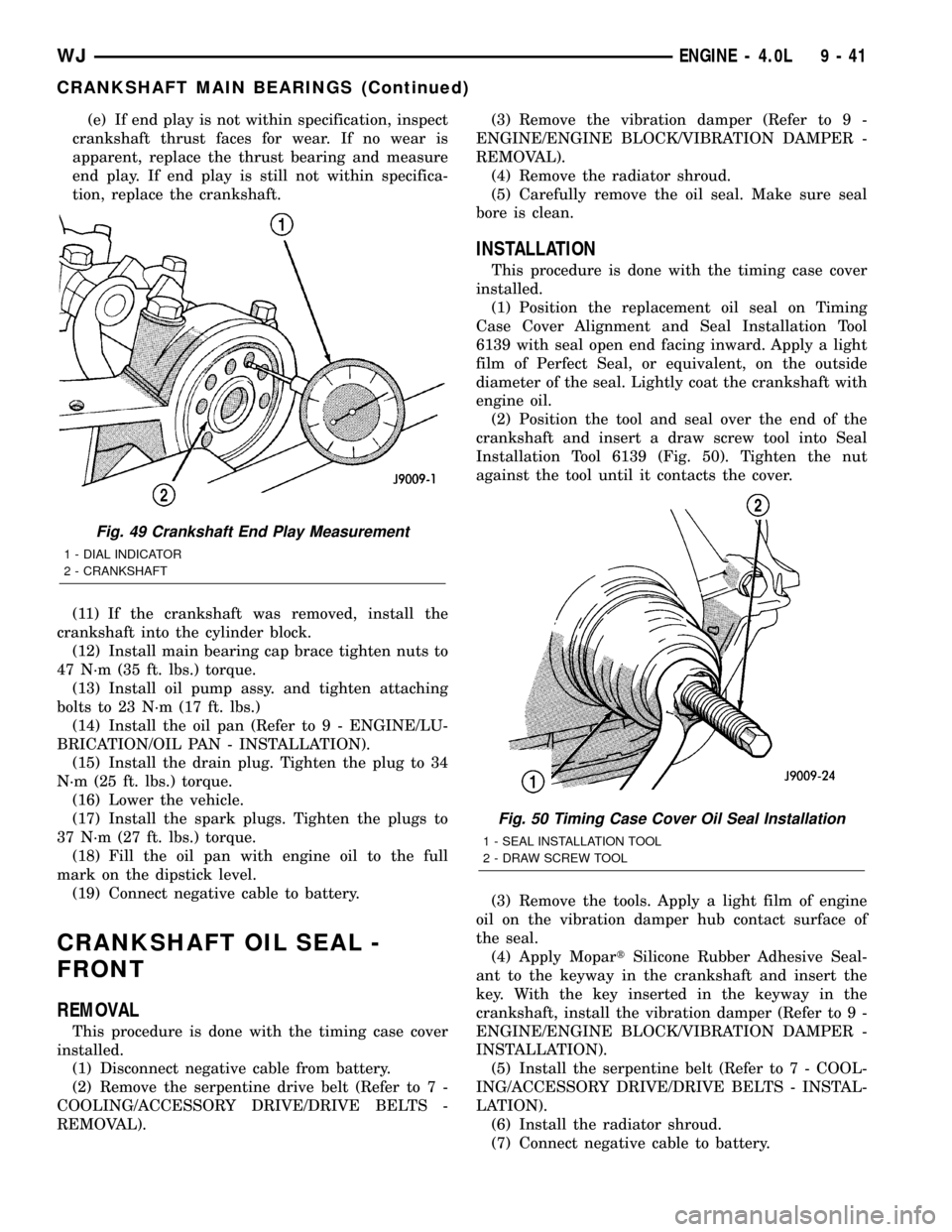

(e) If end play is not within specification, inspect

crankshaft thrust faces for wear. If no wear is

apparent, replace the thrust bearing and measure

end play. If end play is still not within specifica-

tion, replace the crankshaft.

(11) If the crankshaft was removed, install the

crankshaft into the cylinder block.

(12) Install main bearing cap brace tighten nuts to

47 N´m (35 ft. lbs.) torque.

(13) Install oil pump assy. and tighten attaching

bolts to 23 N´m (17 ft. lbs.)

(14) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(15) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(16) Lower the vehicle.

(17) Install the spark plugs. Tighten the plugs to

37 N´m (27 ft. lbs.) torque.

(18) Fill the oil pan with engine oil to the full

mark on the dipstick level.

(19) Connect negative cable to battery.

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

This procedure is done with the timing case cover

installed.

(1) Disconnect negative cable from battery.

(2) Remove the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).(3) Remove the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(4) Remove the radiator shroud.

(5) Carefully remove the oil seal. Make sure seal

bore is clean.

INSTALLATION

This procedure is done with the timing case cover

installed.

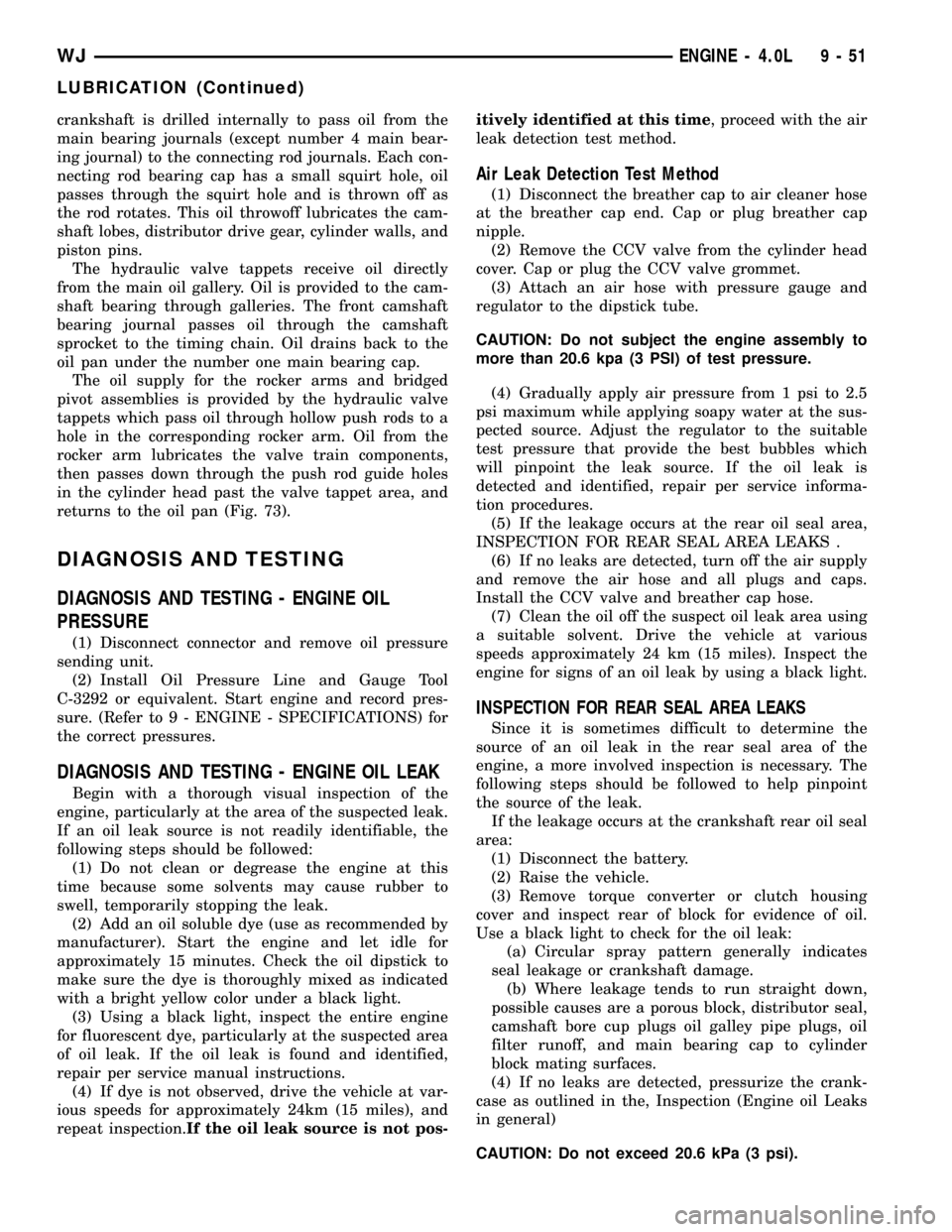

(1) Position the replacement oil seal on Timing

Case Cover Alignment and Seal Installation Tool

6139 with seal open end facing inward. Apply a light

film of Perfect Seal, or equivalent, on the outside

diameter of the seal. Lightly coat the crankshaft with

engine oil.

(2) Position the tool and seal over the end of the

crankshaft and insert a draw screw tool into Seal

Installation Tool 6139 (Fig. 50). Tighten the nut

against the tool until it contacts the cover.

(3) Remove the tools. Apply a light film of engine

oil on the vibration damper hub contact surface of

the seal.

(4) Apply MopartSilicone Rubber Adhesive Seal-

ant to the keyway in the crankshaft and insert the

key. With the key inserted in the keyway in the

crankshaft, install the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(5) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(6) Install the radiator shroud.

(7) Connect negative cable to battery.

Fig. 49 Crankshaft End Play Measurement

1 - DIAL INDICATOR

2 - CRANKSHAFT

Fig. 50 Timing Case Cover Oil Seal Installation

1 - SEAL INSTALLATION TOOL

2 - DRAW SCREW TOOL

WJENGINE - 4.0L 9 - 41

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1294 of 2199

crankshaft is drilled internally to pass oil from the

main bearing journals (except number 4 main bear-

ing journal) to the connecting rod journals. Each con-

necting rod bearing cap has a small squirt hole, oil

passes through the squirt hole and is thrown off as

the rod rotates. This oil throwoff lubricates the cam-

shaft lobes, distributor drive gear, cylinder walls, and

piston pins.

The hydraulic valve tappets receive oil directly

from the main oil gallery. Oil is provided to the cam-

shaft bearing through galleries. The front camshaft

bearing journal passes oil through the camshaft

sprocket to the timing chain. Oil drains back to the

oil pan under the number one main bearing cap.

The oil supply for the rocker arms and bridged

pivot assemblies is provided by the hydraulic valve

tappets which pass oil through hollow push rods to a

hole in the corresponding rocker arm. Oil from the

rocker arm lubricates the valve train components,

then passes down through the push rod guide holes

in the cylinder head past the valve tappet area, and

returns to the oil pan (Fig. 73).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE OIL

PRESSURE

(1) Disconnect connector and remove oil pressure

sending unit.

(2) Install Oil Pressure Line and Gauge Tool

C-3292 or equivalent. Start engine and record pres-

sure. (Refer to 9 - ENGINE - SPECIFICATIONS) for

the correct pressures.

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat inspection.If the oil leak source is not pos-itively identified at this time, proceed with the air

leak detection test method.

Air Leak Detection Test Method

(1) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(2) Remove the CCV valve from the cylinder head

cover. Cap or plug the CCV valve grommet.

(3) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(4) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service informa-

tion procedures.

(5) If the leakage occurs at the rear oil seal area,

INSPECTION FOR REAR SEAL AREA LEAKS .

(6) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps.

Install the CCV valve and breather cap hose.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

WJENGINE - 4.0L 9 - 51

LUBRICATION (Continued)

Page 1296 of 2199

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

OIL

STANDARD PROCEDURE - ENGINE OIL

SERVICE

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in Maintenance Schedules.

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug if

damaged.

(6) Install drain plug in crankcase.

(7) Replace engine oil filter. (Refer to 9 - ENGINE/

LUBRICATION/OIL FILTER - REMOVAL).

(8) Lower vehicle and fill crankcase with specified

type of engine oil (Refer to LUBRICATION & MAIN-

TENANCE/FLUID TYPES - DESCRIPTION) and

amount of engine oil (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(9) Install oil fill cap.

(10) Start engine and inspect for leaks.

(11) Stop engine and inspect oil level. Refer to

CRANKCASE OIL LEVEL INSPECTION .

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing used

engine oil after it has been drained from a vehicle

engine.

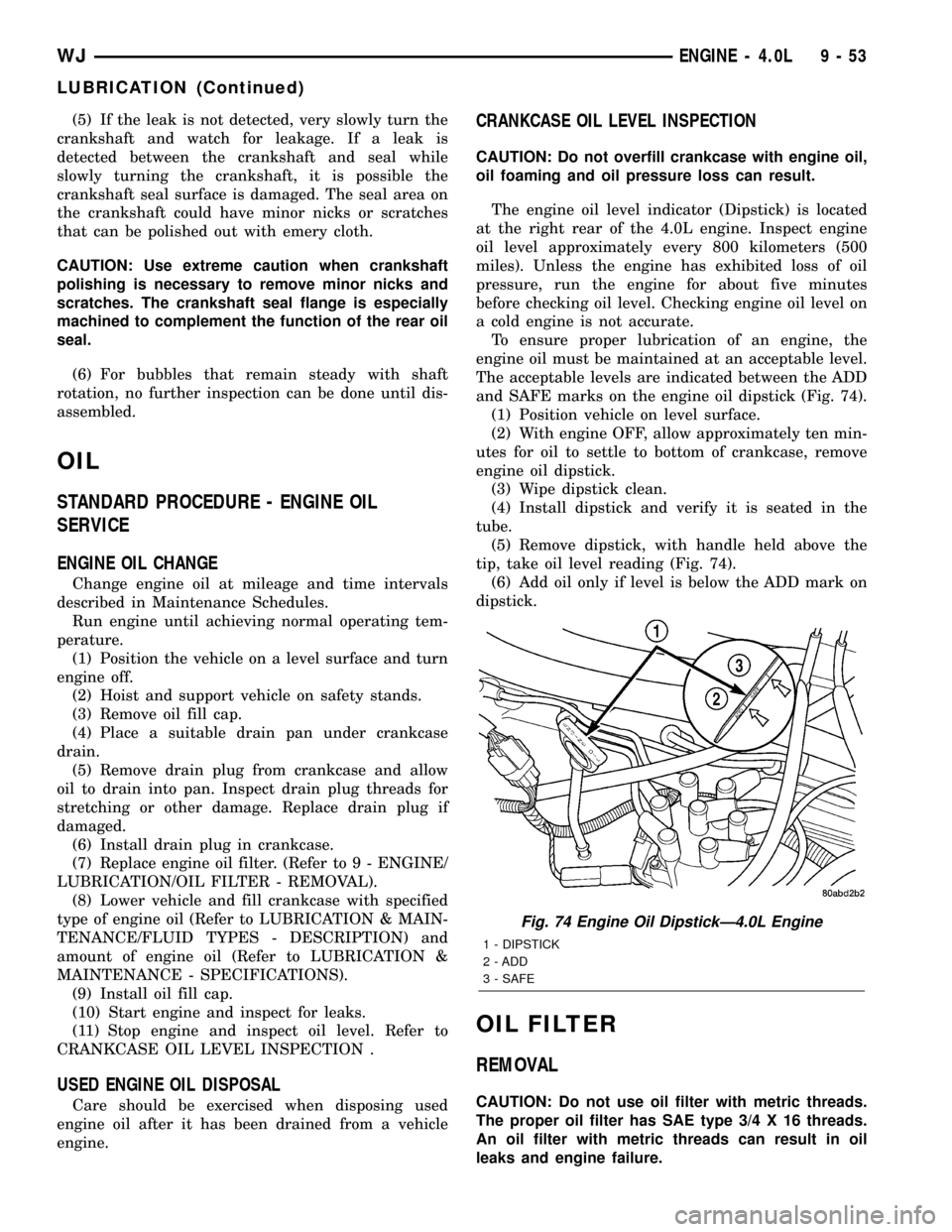

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

oil foaming and oil pressure loss can result.

The engine oil level indicator (Dipstick) is located

at the right rear of the 4.0L engine. Inspect engine

oil level approximately every 800 kilometers (500

miles). Unless the engine has exhibited loss of oil

pressure, run the engine for about five minutes

before checking oil level. Checking engine oil level on

a cold engine is not accurate.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick (Fig. 74).

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading (Fig. 74).

(6) Add oil only if level is below the ADD mark on

dipstick.

OIL FILTER

REMOVAL

CAUTION: Do not use oil filter with metric threads.

The proper oil filter has SAE type 3/4 X 16 threads.

An oil filter with metric threads can result in oil

leaks and engine failure.

Fig. 74 Engine Oil DipstickÐ4.0L Engine

1 - DIPSTICK

2 - ADD

3 - SAFE

WJENGINE - 4.0L 9 - 53

LUBRICATION (Continued)

Page 1297 of 2199

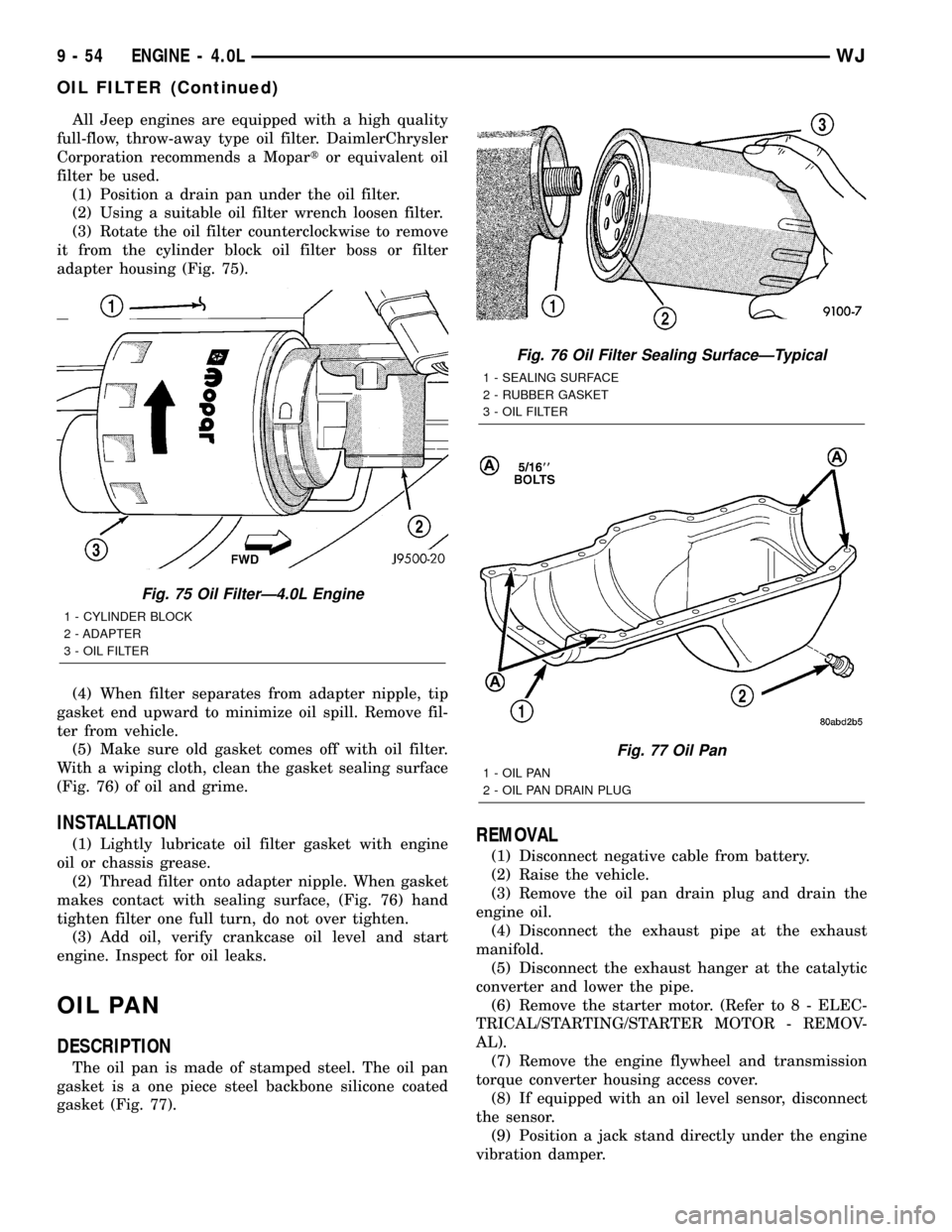

All Jeep engines are equipped with a high quality

full-flow, throw-away type oil filter. DaimlerChrysler

Corporation recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss or filter

adapter housing (Fig. 75).

(4) When filter separates from adapter nipple, tip

gasket end upward to minimize oil spill. Remove fil-

ter from vehicle.

(5) Make sure old gasket comes off with oil filter.

With a wiping cloth, clean the gasket sealing surface

(Fig. 76) of oil and grime.

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil or chassis grease.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 76) hand

tighten filter one full turn, do not over tighten.

(3) Add oil, verify crankcase oil level and start

engine. Inspect for oil leaks.

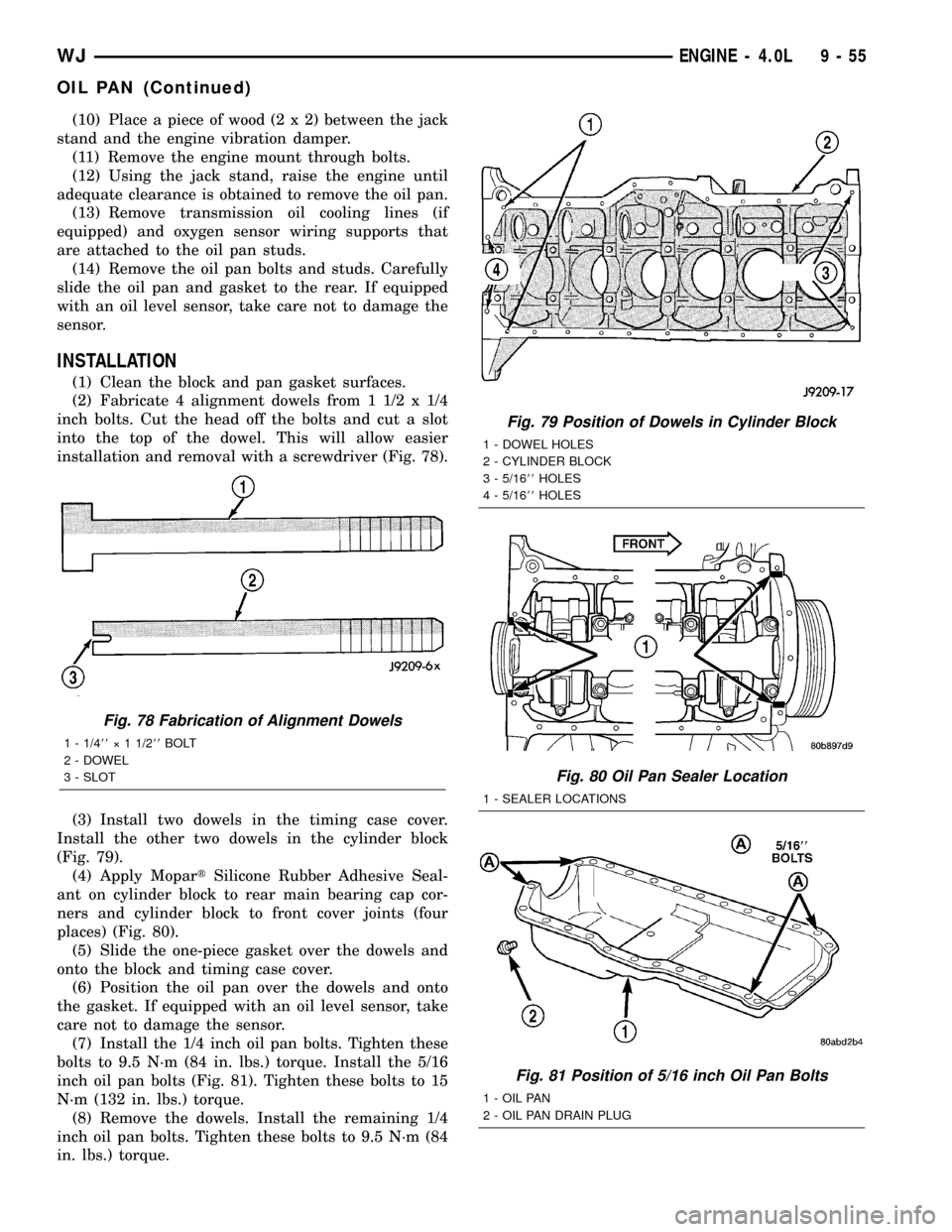

OIL PAN

DESCRIPTION

The oil pan is made of stamped steel. The oil pan

gasket is a one piece steel backbone silicone coated

gasket (Fig. 77).

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise the vehicle.

(3) Remove the oil pan drain plug and drain the

engine oil.

(4) Disconnect the exhaust pipe at the exhaust

manifold.

(5) Disconnect the exhaust hanger at the catalytic

converter and lower the pipe.

(6) Remove the starter motor. (Refer to 8 - ELEC-

TRICAL/STARTING/STARTER MOTOR - REMOV-

AL).

(7) Remove the engine flywheel and transmission

torque converter housing access cover.

(8) If equipped with an oil level sensor, disconnect

the sensor.

(9) Position a jack stand directly under the engine

vibration damper.

Fig. 75 Oil FilterÐ4.0L Engine

1 - CYLINDER BLOCK

2 - ADAPTER

3 - OIL FILTER

Fig. 76 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

Fig. 77 Oil Pan

1 - OIL PAN

2 - OIL PAN DRAIN PLUG

9 - 54 ENGINE - 4.0LWJ

OIL FILTER (Continued)

Page 1298 of 2199

(10) Place a piece of wood (2 x 2) between the jack

stand and the engine vibration damper.

(11) Remove the engine mount through bolts.

(12) Using the jack stand, raise the engine until

adequate clearance is obtained to remove the oil pan.

(13) Remove transmission oil cooling lines (if

equipped) and oxygen sensor wiring supports that

are attached to the oil pan studs.

(14) Remove the oil pan bolts and studs. Carefully

slide the oil pan and gasket to the rear. If equipped

with an oil level sensor, take care not to damage the

sensor.

INSTALLATION

(1) Clean the block and pan gasket surfaces.

(2) Fabricate 4 alignment dowels from 1 1/2 x 1/4

inch bolts. Cut the head off the bolts and cut a slot

into the top of the dowel. This will allow easier

installation and removal with a screwdriver (Fig. 78).

(3) Install two dowels in the timing case cover.

Install the other two dowels in the cylinder block

(Fig. 79).

(4) Apply MopartSilicone Rubber Adhesive Seal-

ant on cylinder block to rear main bearing cap cor-

ners and cylinder block to front cover joints (four

places) (Fig. 80).

(5) Slide the one-piece gasket over the dowels and

onto the block and timing case cover.

(6) Position the oil pan over the dowels and onto

the gasket. If equipped with an oil level sensor, take

care not to damage the sensor.

(7) Install the 1/4 inch oil pan bolts. Tighten these

bolts to 9.5 N´m (84 in. lbs.) torque. Install the 5/16

inch oil pan bolts (Fig. 81). Tighten these bolts to 15

N´m (132 in. lbs.) torque.

(8) Remove the dowels. Install the remaining 1/4

inch oil pan bolts. Tighten these bolts to 9.5 N´m (84

in. lbs.) torque.

Fig. 78 Fabrication of Alignment Dowels

1 - 1/488ý 1 1/288BOLT

2 - DOWEL

3 - SLOT

Fig. 79 Position of Dowels in Cylinder Block

1 - DOWEL HOLES

2 - CYLINDER BLOCK

3 - 5/1688HOLES

4 - 5/1688HOLES

Fig. 80 Oil Pan Sealer Location

1 - SEALER LOCATIONS

Fig. 81 Position of 5/16 inch Oil Pan Bolts

1 - OIL PAN

2 - OIL PAN DRAIN PLUG

WJENGINE - 4.0L 9 - 55

OIL PAN (Continued)

Page 1299 of 2199

(9) Lower the engine until it is properly located on

the engine mounts.

(10) Install the through bolts and tighten the nuts.

(11) Lower the jack stand and remove the piece of

wood.

(12) Install the engine flywheel and transmission

torque converter housing access cover.

(13) Install the engine starter motor. (Refer to 8 -

ELECTRICAL/STARTING/STARTER MOTOR -

INSTALLATION).

(14) Connect the exhaust pipe to the hanger and to

the engine exhaust manifold.

(15) Install transmission oil cooling lines (if

equipped) and oxygen sensor wiring supports that

attach to the oil pan studs.

(16) Install the oil pan drain plug (Fig. 81).

Tighten the plug to 34 N´m (25 ft. lbs.) torque.

(17) Lower the vehicle.

(18) Connect negative cable to battery.

(19) Fill the oil pan with engine oil to the specified

level.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(20) Start the engine and inspect for leaks.

ENGINE OIL PRESSURE

SENSOR

DESCRIPTION

The 3±wire, solid-state engine oil pressure sensor

(sending unit) is located in an engine oil pressure

gallery.

OPERATION

The oil pressure sensor uses three circuits. They

are:

²A 5±volt power supply from the Powertrain Con-

trol Module (PCM)

²A sensor ground through the PCM's sensor

return

²A signal to the PCM relating to engine oil pres-

sure

The oil pressure sensor has a 3±wire electrical

function very much like the Manifold Absolute Pres-

sure (MAP) sensor. Meaning different pressures

relate to different output voltages.

A 5±volt supply is sent to the sensor from the PCM

to power up the sensor. The sensor returns a voltage

signal back to the PCM relating to engine oil pres-

sure. This signal is then transferred (bussed) to theinstrument panel on either a CCD or PCI bus circuit

(depending on vehicle line) to operate the oil pressure

gauge and the check gauges lamp. Ground for the

sensor is provided by the PCM through a low-noise

sensor return.

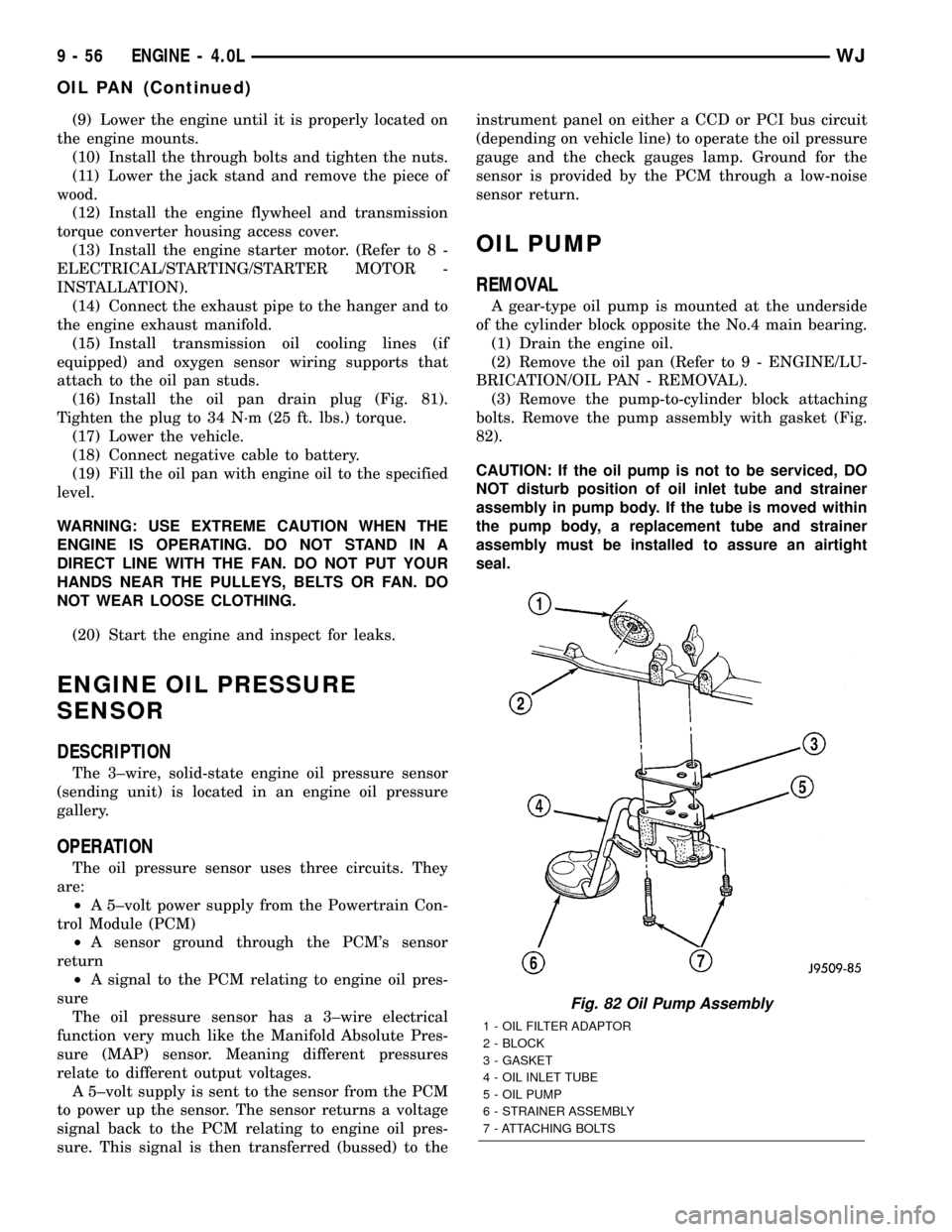

OIL PUMP

REMOVAL

A gear-type oil pump is mounted at the underside

of the cylinder block opposite the No.4 main bearing.

(1) Drain the engine oil.

(2) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(3) Remove the pump-to-cylinder block attaching

bolts. Remove the pump assembly with gasket (Fig.

82).

CAUTION: If the oil pump is not to be serviced, DO

NOT disturb position of oil inlet tube and strainer

assembly in pump body. If the tube is moved within

the pump body, a replacement tube and strainer

assembly must be installed to assure an airtight

seal.

Fig. 82 Oil Pump Assembly

1 - OIL FILTER ADAPTOR

2 - BLOCK

3 - GASKET

4 - OIL INLET TUBE

5 - OIL PUMP

6 - STRAINER ASSEMBLY

7 - ATTACHING BOLTS

9 - 56 ENGINE - 4.0LWJ

OIL PAN (Continued)

Page 1314 of 2199

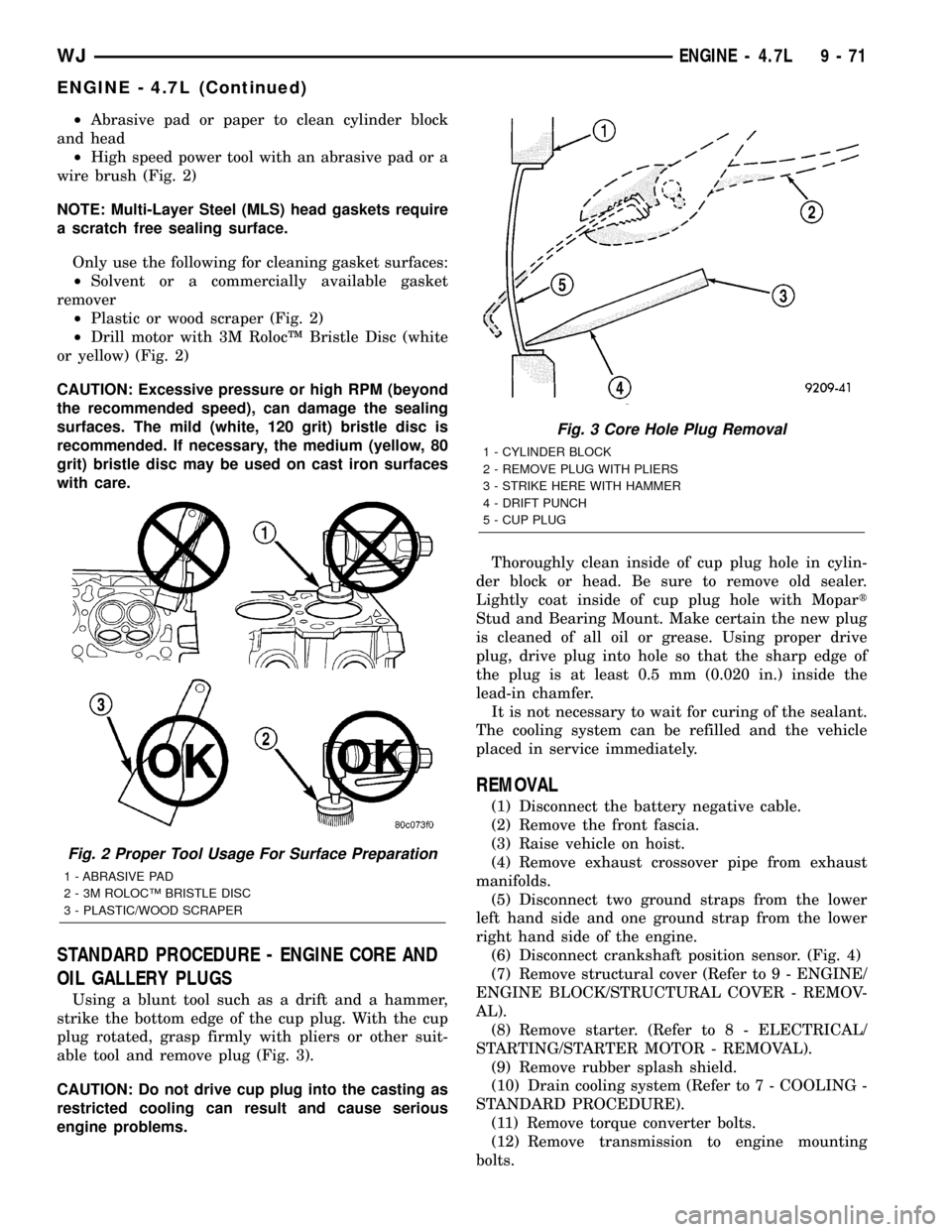

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 2)

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 2)

²Drill motor with 3M RolocŸ Bristle Disc (white

or yellow) (Fig. 2)

CAUTION: Excessive pressure or high RPM (beyond

the recommended speed), can damage the sealing

surfaces. The mild (white, 120 grit) bristle disc is

recommended. If necessary, the medium (yellow, 80

grit) bristle disc may be used on cast iron surfaces

with care.

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 3).

CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plug

is cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the front fascia.

(3) Raise vehicle on hoist.

(4) Remove exhaust crossover pipe from exhaust

manifolds.

(5) Disconnect two ground straps from the lower

left hand side and one ground strap from the lower

right hand side of the engine.

(6) Disconnect crankshaft position sensor. (Fig. 4)

(7) Remove structural cover (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - REMOV-

AL).

(8) Remove starter. (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - REMOVAL).

(9) Remove rubber splash shield.

(10) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(11) Remove torque converter bolts.

(12) Remove transmission to engine mounting

bolts.

Fig. 2 Proper Tool Usage For Surface Preparation

1 - ABRASIVE PAD

2 - 3M ROLOCŸ BRISTLE DISC

3 - PLASTIC/WOOD SCRAPER

Fig. 3 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

WJENGINE - 4.7L 9 - 71

ENGINE - 4.7L (Continued)

Page 1323 of 2199

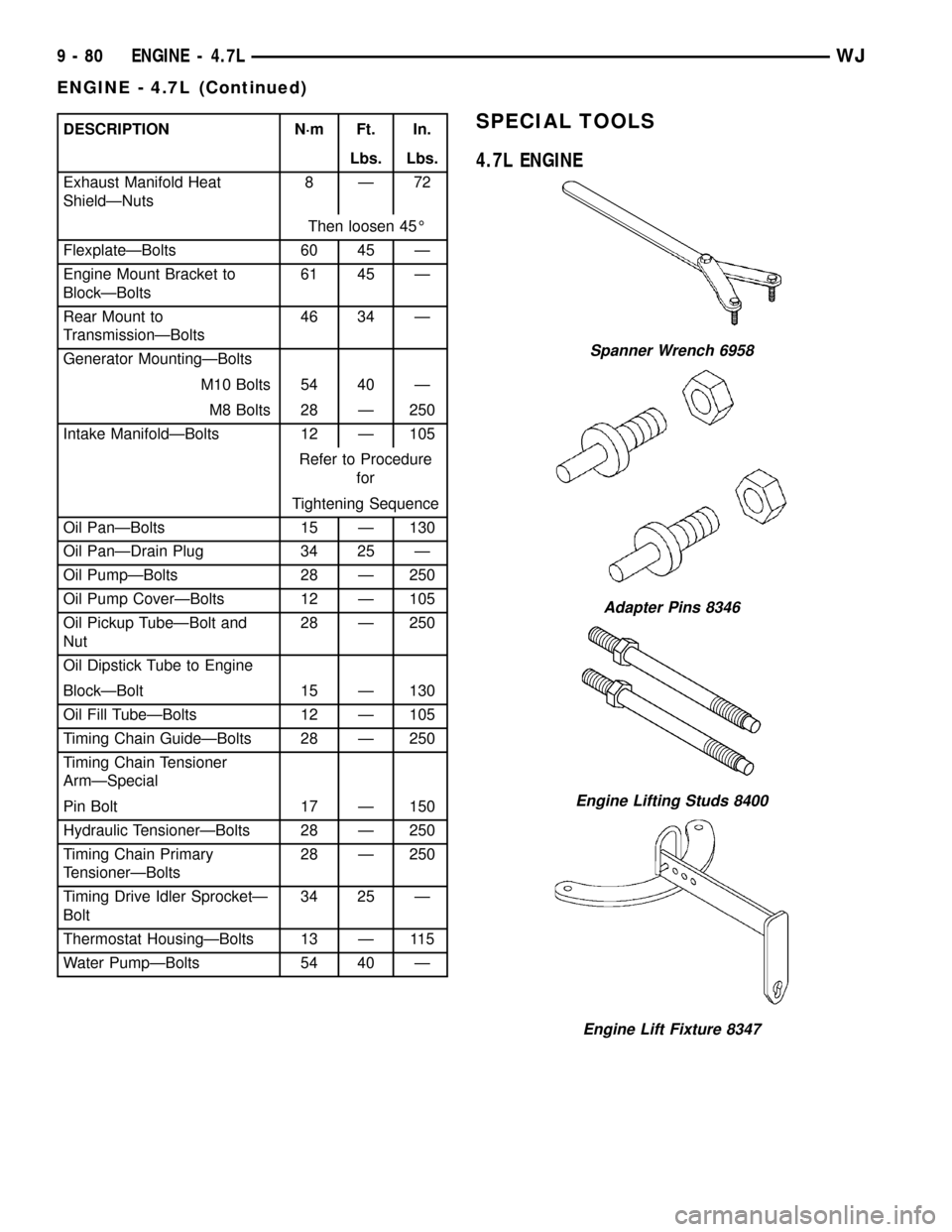

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Exhaust Manifold Heat

ShieldÐNuts8Ð72

Then loosen 45É

FlexplateÐBolts 60 45 Ð

Engine Mount Bracket to

BlockÐBolts61 45 Ð

Rear Mount to

TransmissionÐBolts46 34 Ð

Generator MountingÐBolts

M10 Bolts 54 40 Ð

M8 Bolts 28 Ð 250

Intake ManifoldÐBolts 12 Ð 105

Refer to Procedure

for

Tightening Sequence

Oil PanÐBolts 15 Ð 130

Oil PanÐDrain Plug 34 25 Ð

Oil PumpÐBolts 28 Ð 250

Oil Pump CoverÐBolts 12 Ð 105

Oil Pickup TubeÐBolt and

Nut28 Ð 250

Oil Dipstick Tube to Engine

BlockÐBolt 15 Ð 130

Oil Fill TubeÐBolts 12 Ð 105

Timing Chain GuideÐBolts 28 Ð 250

Timing Chain Tensioner

ArmÐSpecial

Pin Bolt 17 Ð 150

Hydraulic TensionerÐBolts 28 Ð 250

Timing Chain Primary

TensionerÐBolts28 Ð 250

Timing Drive Idler SprocketÐ

Bolt34 25 Ð

Thermostat HousingÐBolts 13 Ð 115

Water PumpÐBolts 54 40 ÐSPECIAL TOOLS

4.7L ENGINE

Spanner Wrench 6958

Adapter Pins 8346

Engine Lifting Studs 8400

Engine Lift Fixture 8347

9 - 80 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)