Vacuum lines JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1457 of 2199

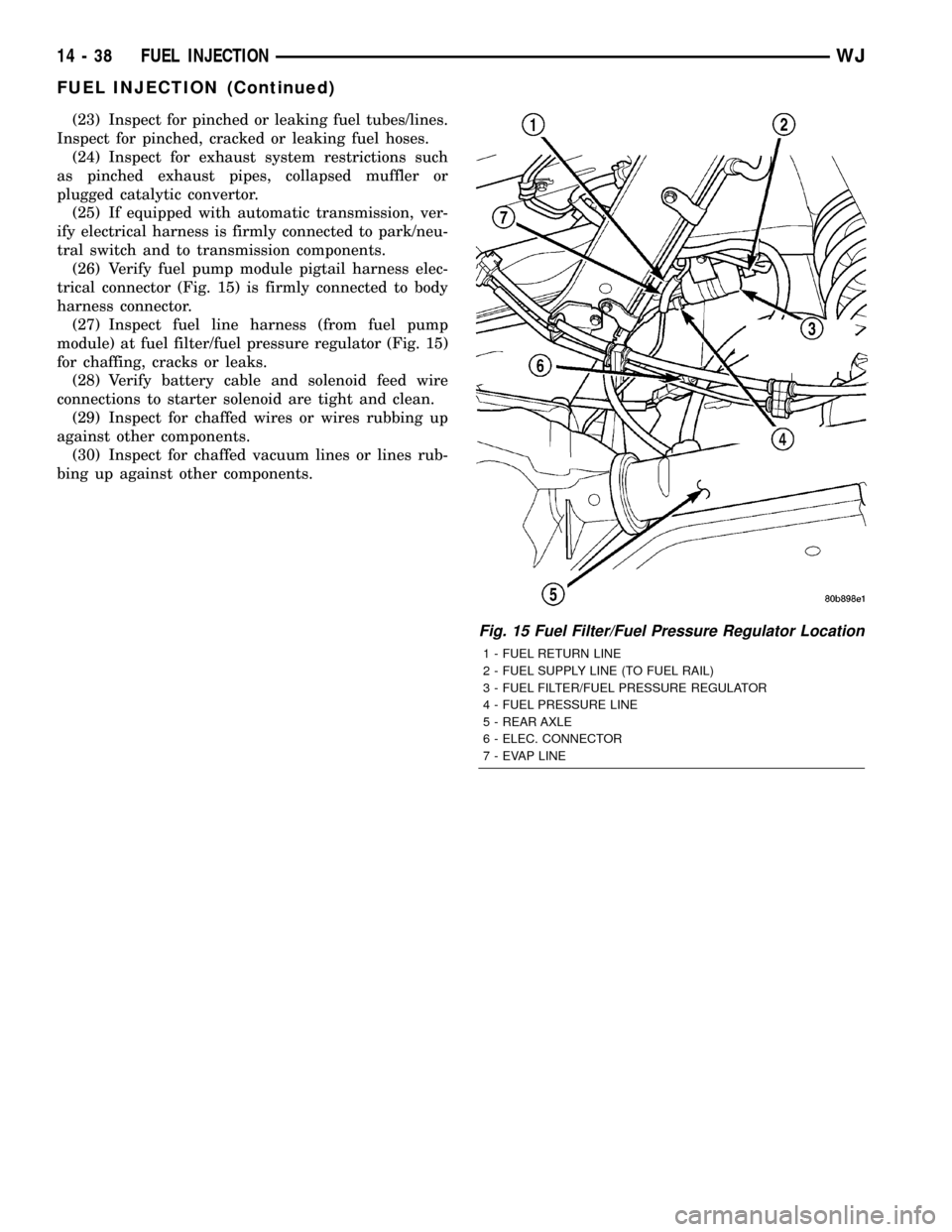

(23) Inspect for pinched or leaking fuel tubes/lines.

Inspect for pinched, cracked or leaking fuel hoses.

(24) Inspect for exhaust system restrictions such

as pinched exhaust pipes, collapsed muffler or

plugged catalytic convertor.

(25) If equipped with automatic transmission, ver-

ify electrical harness is firmly connected to park/neu-

tral switch and to transmission components.

(26) Verify fuel pump module pigtail harness elec-

trical connector (Fig. 15) is firmly connected to body

harness connector.

(27) Inspect fuel line harness (from fuel pump

module) at fuel filter/fuel pressure regulator (Fig. 15)

for chaffing, cracks or leaks.

(28) Verify battery cable and solenoid feed wire

connections to starter solenoid are tight and clean.

(29) Inspect for chaffed wires or wires rubbing up

against other components.

(30) Inspect for chaffed vacuum lines or lines rub-

bing up against other components.

Fig. 15 Fuel Filter/Fuel Pressure Regulator Location

1 - FUEL RETURN LINE

2 - FUEL SUPPLY LINE (TO FUEL RAIL)

3 - FUEL FILTER/FUEL PRESSURE REGULATOR

4 - FUEL PRESSURE LINE

5 - REAR AXLE

6 - ELEC. CONNECTOR

7 - EVAP LINE

14 - 38 FUEL INJECTIONWJ

FUEL INJECTION (Continued)

Page 2109 of 2199

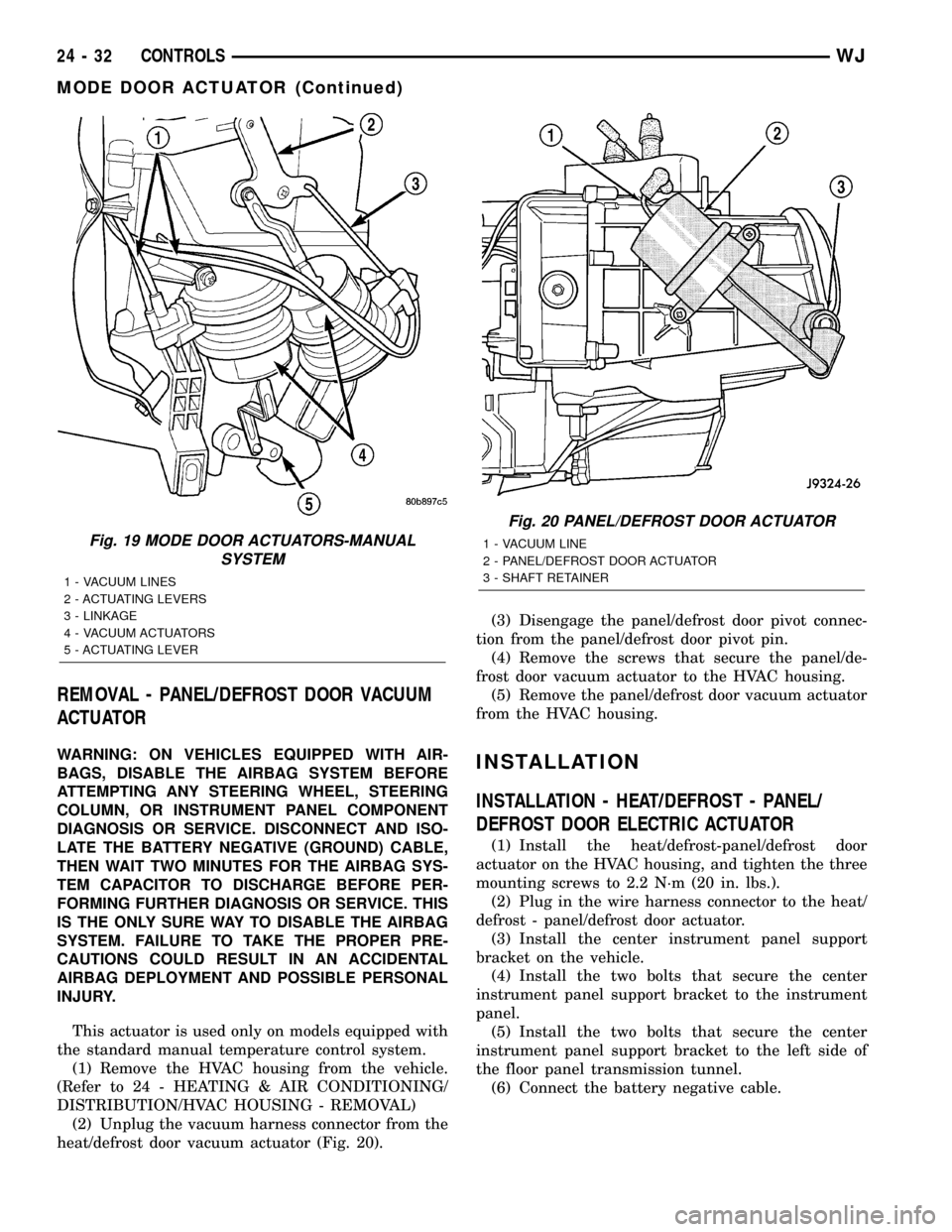

REMOVAL - PANEL/DEFROST DOOR VACUUM

ACTUATOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

This actuator is used only on models equipped with

the standard manual temperature control system.

(1) Remove the HVAC housing from the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(2) Unplug the vacuum harness connector from the

heat/defrost door vacuum actuator (Fig. 20).(3) Disengage the panel/defrost door pivot connec-

tion from the panel/defrost door pivot pin.

(4) Remove the screws that secure the panel/de-

frost door vacuum actuator to the HVAC housing.

(5) Remove the panel/defrost door vacuum actuator

from the HVAC housing.INSTALLATION

INSTALLATION - HEAT/DEFROST - PANEL/

DEFROST DOOR ELECTRIC ACTUATOR

(1) Install the heat/defrost-panel/defrost door

actuator on the HVAC housing, and tighten the three

mounting screws to 2.2 N´m (20 in. lbs.).

(2) Plug in the wire harness connector to the heat/

defrost - panel/defrost door actuator.

(3) Install the center instrument panel support

bracket on the vehicle.

(4) Install the two bolts that secure the center

instrument panel support bracket to the instrument

panel.

(5) Install the two bolts that secure the center

instrument panel support bracket to the left side of

the floor panel transmission tunnel.

(6) Connect the battery negative cable.

Fig. 19 MODE DOOR ACTUATORS-MANUAL

SYSTEM

1 - VACUUM LINES

2 - ACTUATING LEVERS

3 - LINKAGE

4 - VACUUM ACTUATORS

5 - ACTUATING LEVER

Fig. 20 PANEL/DEFROST DOOR ACTUATOR

1 - VACUUM LINE

2 - PANEL/DEFROST DOOR ACTUATOR

3 - SHAFT RETAINER

24 - 32 CONTROLSWJ

MODE DOOR ACTUATOR (Continued)

Page 2120 of 2199

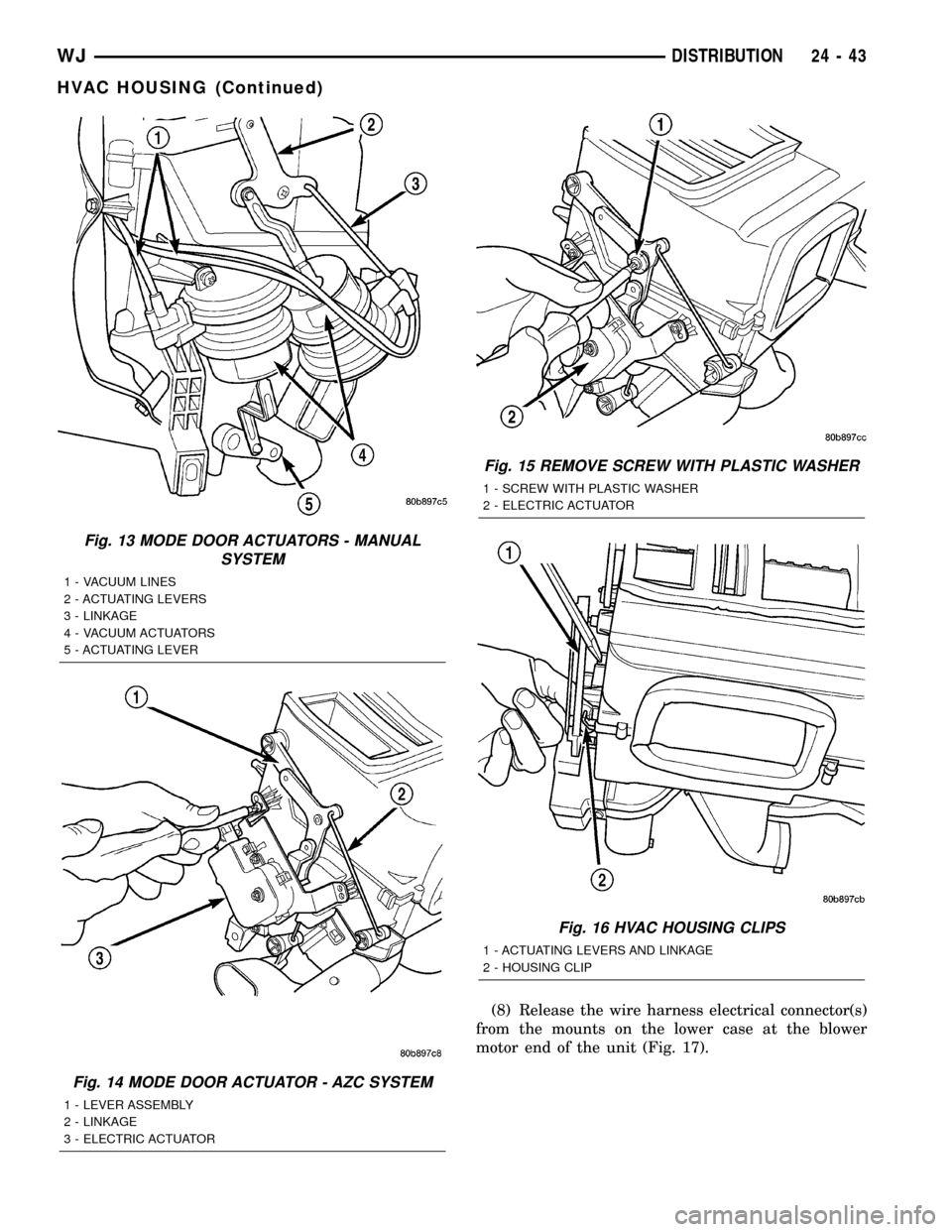

(8) Release the wire harness electrical connector(s)

from the mounts on the lower case at the blower

motor end of the unit (Fig. 17).

Fig. 13 MODE DOOR ACTUATORS - MANUAL

SYSTEM

1 - VACUUM LINES

2 - ACTUATING LEVERS

3 - LINKAGE

4 - VACUUM ACTUATORS

5 - ACTUATING LEVER

Fig. 14 MODE DOOR ACTUATOR - AZC SYSTEM

1 - LEVER ASSEMBLY

2 - LINKAGE

3 - ELECTRIC ACTUATOR

Fig. 15 REMOVE SCREW WITH PLASTIC WASHER

1 - SCREW WITH PLASTIC WASHER

2 - ELECTRIC ACTUATOR

Fig. 16 HVAC HOUSING CLIPS

1 - ACTUATING LEVERS AND LINKAGE

2 - HOUSING CLIP

WJDISTRIBUTION 24 - 43

HVAC HOUSING (Continued)

Page 2122 of 2199

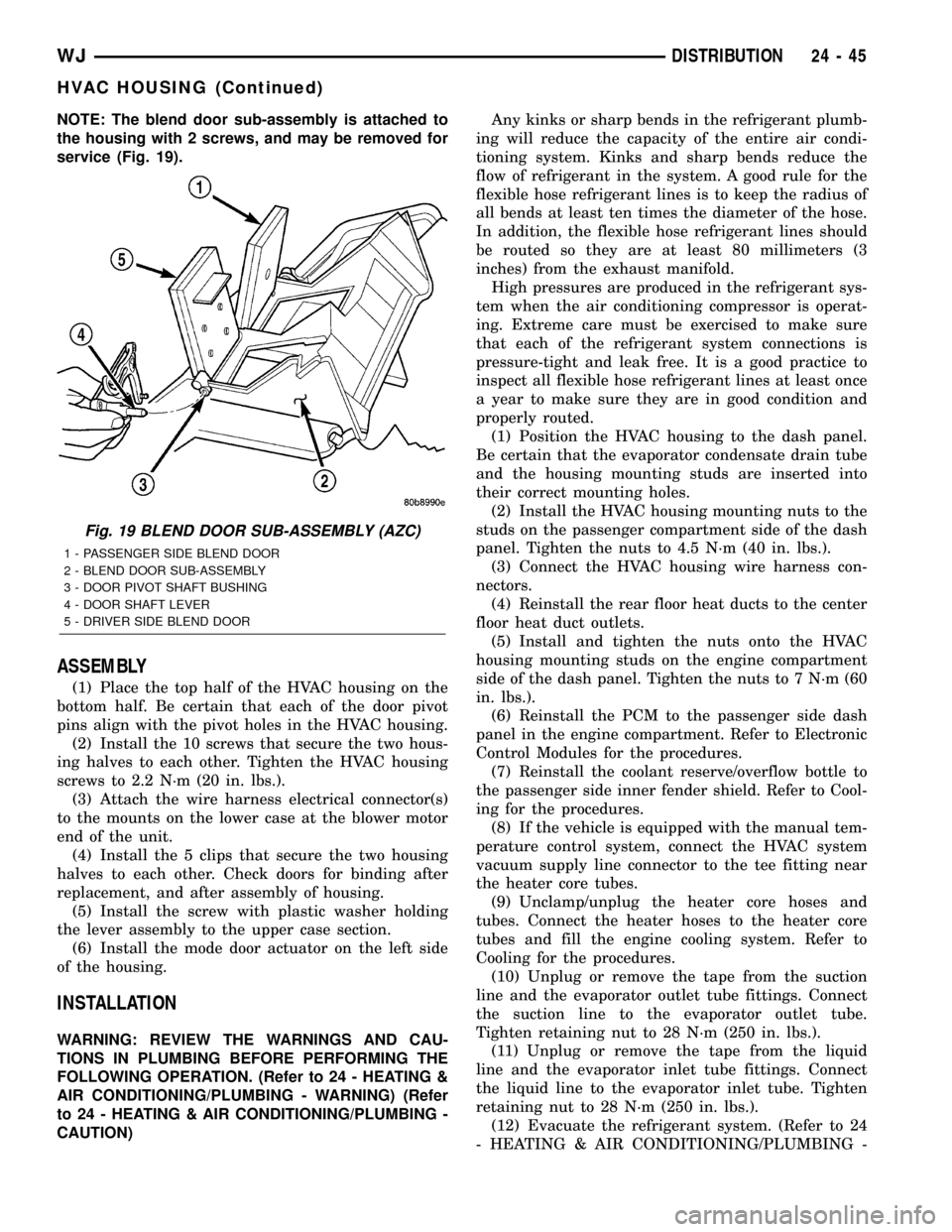

NOTE: The blend door sub-assembly is attached to

the housing with 2 screws, and may be removed for

service (Fig. 19).

ASSEMBLY

(1) Place the top half of the HVAC housing on the

bottom half. Be certain that each of the door pivot

pins align with the pivot holes in the HVAC housing.

(2) Install the 10 screws that secure the two hous-

ing halves to each other. Tighten the HVAC housing

screws to 2.2 N´m (20 in. lbs.).

(3) Attach the wire harness electrical connector(s)

to the mounts on the lower case at the blower motor

end of the unit.

(4) Install the 5 clips that secure the two housing

halves to each other. Check doors for binding after

replacement, and after assembly of housing.

(5) Install the screw with plastic washer holding

the lever assembly to the upper case section.

(6) Install the mode door actuator on the left side

of the housing.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN PLUMBING BEFORE PERFORMING THE

FOLLOWING OPERATION. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - WARNING) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION)Any kinks or sharp bends in the refrigerant plumb-

ing will reduce the capacity of the entire air condi-

tioning system. Kinks and sharp bends reduce the

flow of refrigerant in the system. A good rule for the

flexible hose refrigerant lines is to keep the radius of

all bends at least ten times the diameter of the hose.

In addition, the flexible hose refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) from the exhaust manifold.

High pressures are produced in the refrigerant sys-

tem when the air conditioning compressor is operat-

ing. Extreme care must be exercised to make sure

that each of the refrigerant system connections is

pressure-tight and leak free. It is a good practice to

inspect all flexible hose refrigerant lines at least once

a year to make sure they are in good condition and

properly routed.

(1) Position the HVAC housing to the dash panel.

Be certain that the evaporator condensate drain tube

and the housing mounting studs are inserted into

their correct mounting holes.

(2) Install the HVAC housing mounting nuts to the

studs on the passenger compartment side of the dash

panel. Tighten the nuts to 4.5 N´m (40 in. lbs.).

(3) Connect the HVAC housing wire harness con-

nectors.

(4) Reinstall the rear floor heat ducts to the center

floor heat duct outlets.

(5) Install and tighten the nuts onto the HVAC

housing mounting studs on the engine compartment

side of the dash panel. Tighten the nuts to 7 N´m (60

in. lbs.).

(6) Reinstall the PCM to the passenger side dash

panel in the engine compartment. Refer to Electronic

Control Modules for the procedures.

(7) Reinstall the coolant reserve/overflow bottle to

the passenger side inner fender shield. Refer to Cool-

ing for the procedures.

(8) If the vehicle is equipped with the manual tem-

perature control system, connect the HVAC system

vacuum supply line connector to the tee fitting near

the heater core tubes.

(9) Unclamp/unplug the heater core hoses and

tubes. Connect the heater hoses to the heater core

tubes and fill the engine cooling system. Refer to

Cooling for the procedures.

(10) Unplug or remove the tape from the suction

line and the evaporator outlet tube fittings. Connect

the suction line to the evaporator outlet tube.

Tighten retaining nut to 28 N´m (250 in. lbs.).

(11) Unplug or remove the tape from the liquid

line and the evaporator inlet tube fittings. Connect

the liquid line to the evaporator inlet tube. Tighten

retaining nut to 28 N´m (250 in. lbs.).

(12) Evacuate the refrigerant system. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

Fig. 19 BLEND DOOR SUB-ASSEMBLY (AZC)

1 - PASSENGER SIDE BLEND DOOR

2 - BLEND DOOR SUB-ASSEMBLY

3 - DOOR PIVOT SHAFT BUSHING

4 - DOOR SHAFT LEVER

5 - DRIVER SIDE BLEND DOOR

WJDISTRIBUTION 24 - 45

HVAC HOUSING (Continued)

Page 2147 of 2199

INSTALLATION

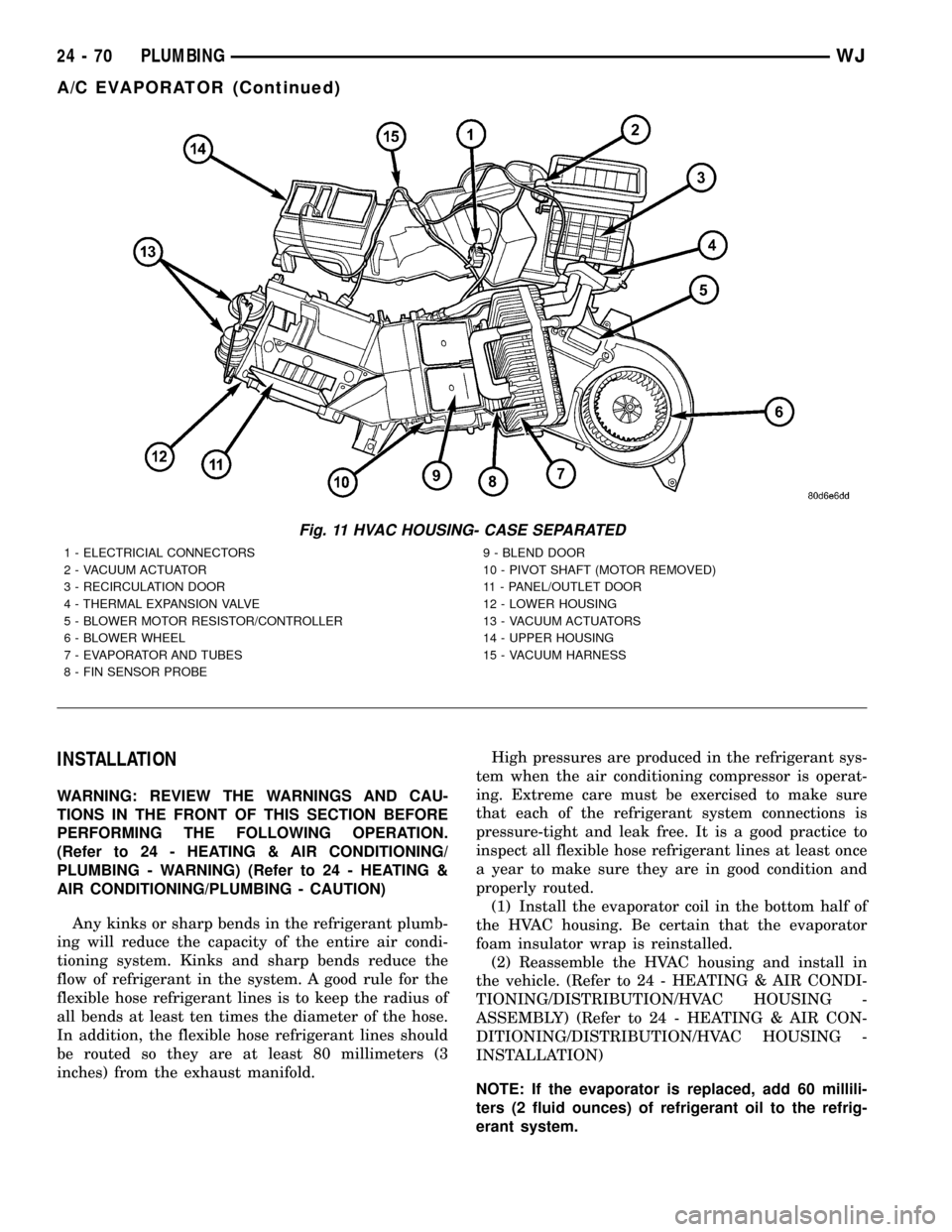

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

Any kinks or sharp bends in the refrigerant plumb-

ing will reduce the capacity of the entire air condi-

tioning system. Kinks and sharp bends reduce the

flow of refrigerant in the system. A good rule for the

flexible hose refrigerant lines is to keep the radius of

all bends at least ten times the diameter of the hose.

In addition, the flexible hose refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) from the exhaust manifold.High pressures are produced in the refrigerant sys-

tem when the air conditioning compressor is operat-

ing. Extreme care must be exercised to make sure

that each of the refrigerant system connections is

pressure-tight and leak free. It is a good practice to

inspect all flexible hose refrigerant lines at least once

a year to make sure they are in good condition and

properly routed.

(1) Install the evaporator coil in the bottom half of

the HVAC housing. Be certain that the evaporator

foam insulator wrap is reinstalled.

(2) Reassemble the HVAC housing and install in

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HVAC HOUSING -

ASSEMBLY) (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/HVAC HOUSING -

INSTALLATION)

NOTE: If the evaporator is replaced, add 60 millili-

ters (2 fluid ounces) of refrigerant oil to the refrig-

erant system.

Fig. 11 HVAC HOUSING- CASE SEPARATED

1 - ELECTRICIAL CONNECTORS

2 - VACUUM ACTUATOR

3 - RECIRCULATION DOOR

4 - THERMAL EXPANSION VALVE

5 - BLOWER MOTOR RESISTOR/CONTROLLER

6 - BLOWER WHEEL

7 - EVAPORATOR AND TUBES

8 - FIN SENSOR PROBE9 - BLEND DOOR

10 - PIVOT SHAFT (MOTOR REMOVED)

11 - PANEL/OUTLET DOOR

12 - LOWER HOUSING

13 - VACUUM ACTUATORS

14 - UPPER HOUSING

15 - VACUUM HARNESS

24 - 70 PLUMBINGWJ

A/C EVAPORATOR (Continued)

Page 2179 of 2199

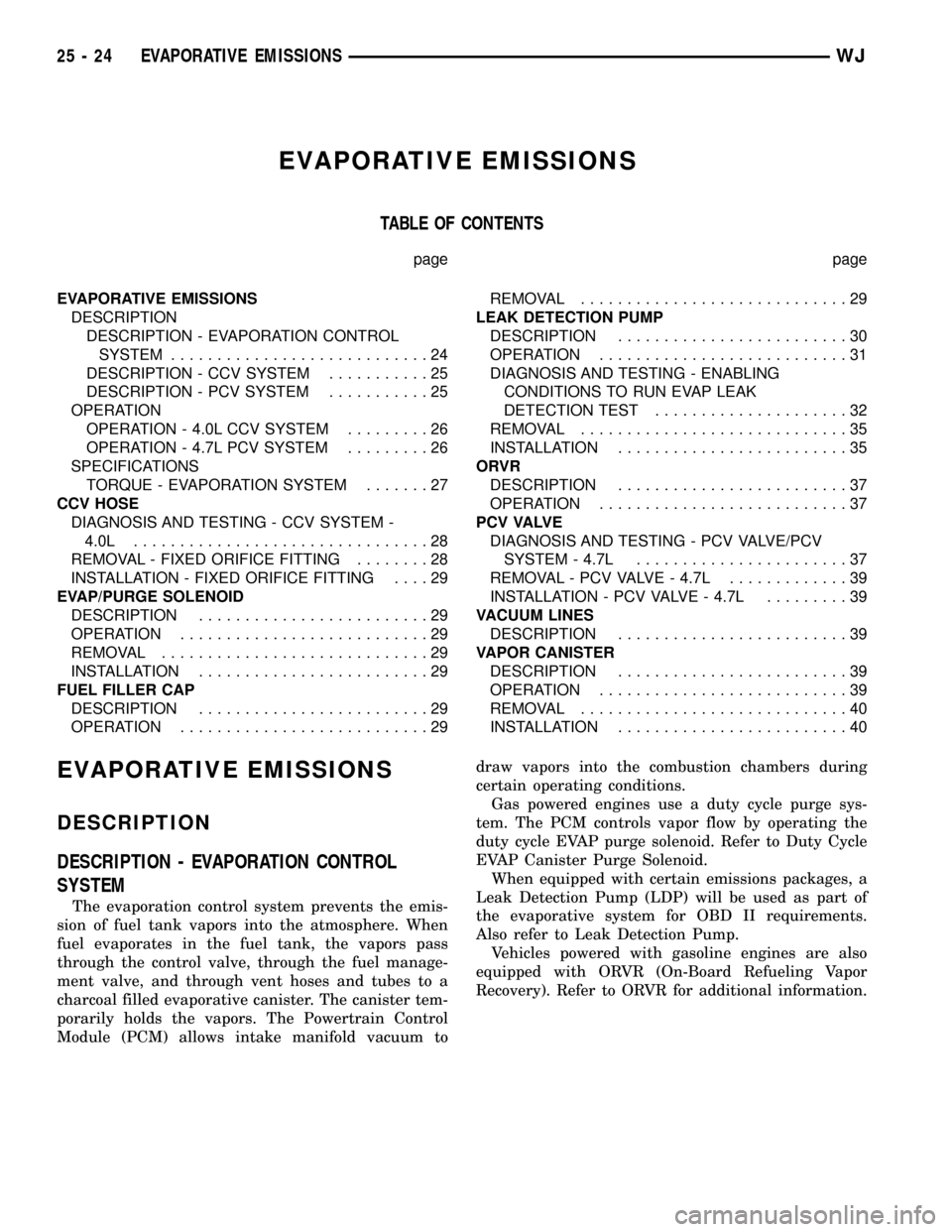

EVAPORATIVE EMISSIONS

TABLE OF CONTENTS

page page

EVAPORATIVE EMISSIONS

DESCRIPTION

DESCRIPTION - EVAPORATION CONTROL

SYSTEM............................24

DESCRIPTION - CCV SYSTEM...........25

DESCRIPTION - PCV SYSTEM...........25

OPERATION

OPERATION - 4.0L CCV SYSTEM.........26

OPERATION - 4.7L PCV SYSTEM.........26

SPECIFICATIONS

TORQUE - EVAPORATION SYSTEM.......27

CCV HOSE

DIAGNOSIS AND TESTING - CCV SYSTEM -

4.0L................................28

REMOVAL - FIXED ORIFICE FITTING........28

INSTALLATION - FIXED ORIFICE FITTING....29

EVAP/PURGE SOLENOID

DESCRIPTION.........................29

OPERATION...........................29

REMOVAL.............................29

INSTALLATION.........................29

FUEL FILLER CAP

DESCRIPTION.........................29

OPERATION...........................29REMOVAL.............................29

LEAK DETECTION PUMP

DESCRIPTION.........................30

OPERATION...........................31

DIAGNOSIS AND TESTING - ENABLING

CONDITIONS TO RUN EVAP LEAK

DETECTION TEST.....................32

REMOVAL.............................35

INSTALLATION.........................35

ORVR

DESCRIPTION.........................37

OPERATION...........................37

P C V VA LV E

DIAGNOSIS AND TESTING - PCV VALVE/PCV

SYSTEM - 4.7L.......................37

REMOVAL - PCV VALVE - 4.7L.............39

INSTALLATION - PCV VALVE - 4.7L.........39

VACUUM LINES

DESCRIPTION.........................39

VAPOR CANISTER

DESCRIPTION.........................39

OPERATION...........................39

REMOVAL.............................40

INSTALLATION.........................40

EVAPORATIVE EMISSIONS

DESCRIPTION

DESCRIPTION - EVAPORATION CONTROL

SYSTEM

The evaporation control system prevents the emis-

sion of fuel tank vapors into the atmosphere. When

fuel evaporates in the fuel tank, the vapors pass

through the control valve, through the fuel manage-

ment valve, and through vent hoses and tubes to a

charcoal filled evaporative canister. The canister tem-

porarily holds the vapors. The Powertrain Control

Module (PCM) allows intake manifold vacuum todraw vapors into the combustion chambers during

certain operating conditions.

Gas powered engines use a duty cycle purge sys-

tem. The PCM controls vapor flow by operating the

duty cycle EVAP purge solenoid. Refer to Duty Cycle

EVAP Canister Purge Solenoid.

When equipped with certain emissions packages, a

Leak Detection Pump (LDP) will be used as part of

the evaporative system for OBD II requirements.

Also refer to Leak Detection Pump.

Vehicles powered with gasoline engines are also

equipped with ORVR (On-Board Refueling Vapor

Recovery). Refer to ORVR for additional information.

25 - 24 EVAPORATIVE EMISSIONSWJ

Page 2183 of 2199

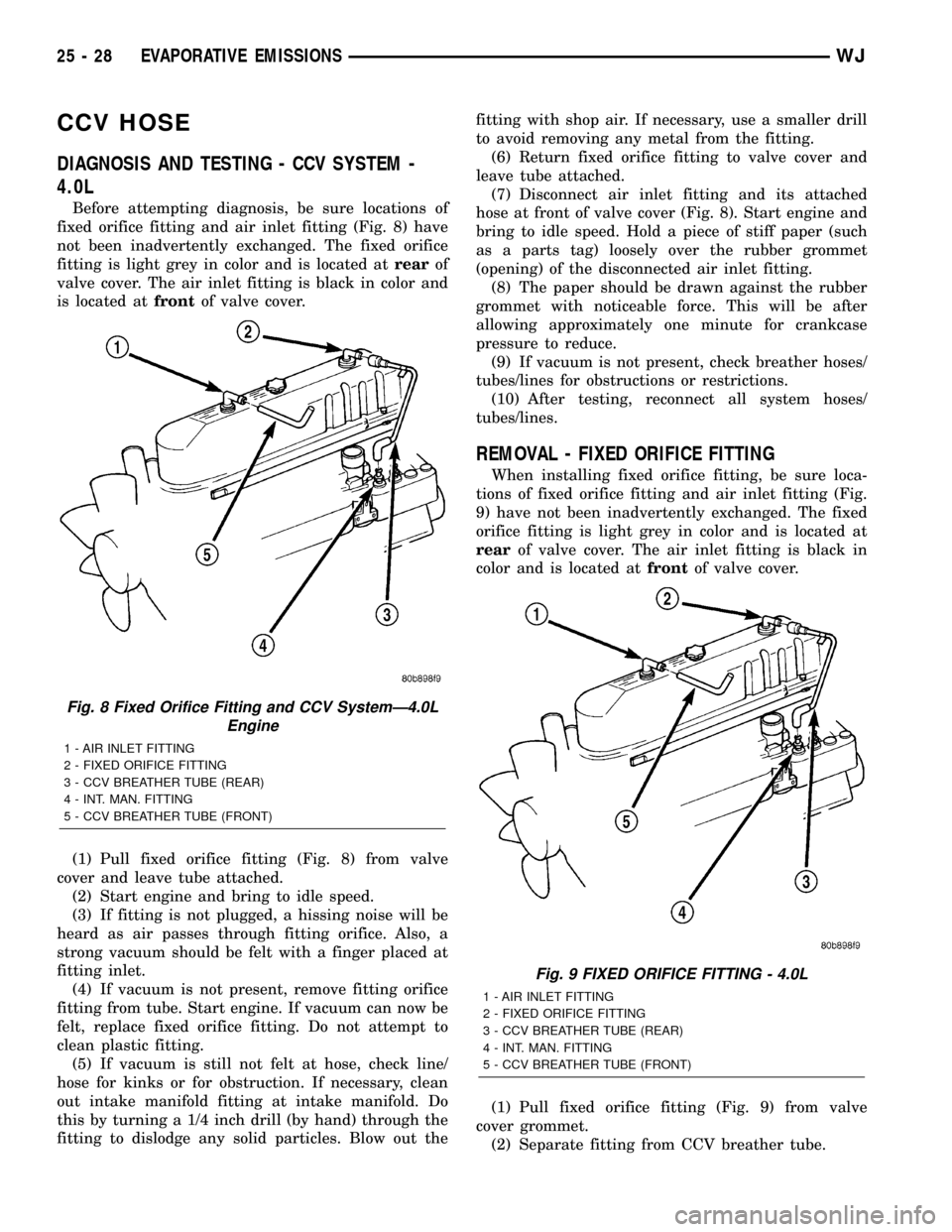

CCV HOSE

DIAGNOSIS AND TESTING - CCV SYSTEM -

4.0L

Before attempting diagnosis, be sure locations of

fixed orifice fitting and air inlet fitting (Fig. 8) have

not been inadvertently exchanged. The fixed orifice

fitting is light grey in color and is located atrearof

valve cover. The air inlet fitting is black in color and

is located atfrontof valve cover.

(1) Pull fixed orifice fitting (Fig. 8) from valve

cover and leave tube attached.

(2) Start engine and bring to idle speed.

(3) If fitting is not plugged, a hissing noise will be

heard as air passes through fitting orifice. Also, a

strong vacuum should be felt with a finger placed at

fitting inlet.

(4) If vacuum is not present, remove fitting orifice

fitting from tube. Start engine. If vacuum can now be

felt, replace fixed orifice fitting. Do not attempt to

clean plastic fitting.

(5) If vacuum is still not felt at hose, check line/

hose for kinks or for obstruction. If necessary, clean

out intake manifold fitting at intake manifold. Do

this by turning a 1/4 inch drill (by hand) through the

fitting to dislodge any solid particles. Blow out thefitting with shop air. If necessary, use a smaller drill

to avoid removing any metal from the fitting.

(6) Return fixed orifice fitting to valve cover and

leave tube attached.

(7) Disconnect air inlet fitting and its attached

hose at front of valve cover (Fig. 8). Start engine and

bring to idle speed. Hold a piece of stiff paper (such

as a parts tag) loosely over the rubber grommet

(opening) of the disconnected air inlet fitting.

(8) The paper should be drawn against the rubber

grommet with noticeable force. This will be after

allowing approximately one minute for crankcase

pressure to reduce.

(9) If vacuum is not present, check breather hoses/

tubes/lines for obstructions or restrictions.

(10) After testing, reconnect all system hoses/

tubes/lines.

REMOVAL - FIXED ORIFICE FITTING

When installing fixed orifice fitting, be sure loca-

tions of fixed orifice fitting and air inlet fitting (Fig.

9) have not been inadvertently exchanged. The fixed

orifice fitting is light grey in color and is located at

rearof valve cover. The air inlet fitting is black in

color and is located atfrontof valve cover.

(1) Pull fixed orifice fitting (Fig. 9) from valve

cover grommet.

(2) Separate fitting from CCV breather tube.

Fig. 8 Fixed Orifice Fitting and CCV SystemÐ4.0L

Engine

1 - AIR INLET FITTING

2 - FIXED ORIFICE FITTING

3 - CCV BREATHER TUBE (REAR)

4 - INT. MAN. FITTING

5 - CCV BREATHER TUBE (FRONT)

Fig. 9 FIXED ORIFICE FITTING - 4.0L

1 - AIR INLET FITTING

2 - FIXED ORIFICE FITTING

3 - CCV BREATHER TUBE (REAR)

4 - INT. MAN. FITTING

5 - CCV BREATHER TUBE (FRONT)

25 - 28 EVAPORATIVE EMISSIONSWJ

Page 2184 of 2199

INSTALLATION - FIXED ORIFICE FITTING

When installing fixed orifice fitting, be sure loca-

tions of fixed orifice fitting and air inlet fitting (Fig.

9) have not been inadvertently exchanged. The fixed

orifice fitting is light grey in color and is located at

rearof valve cover. The air inlet fitting is black in

color and is located atfrontof valve cover.

(1) Connect fitting to CCV breather tube.

(2) Return fixed orifice fitting to valve cover grom-

met.

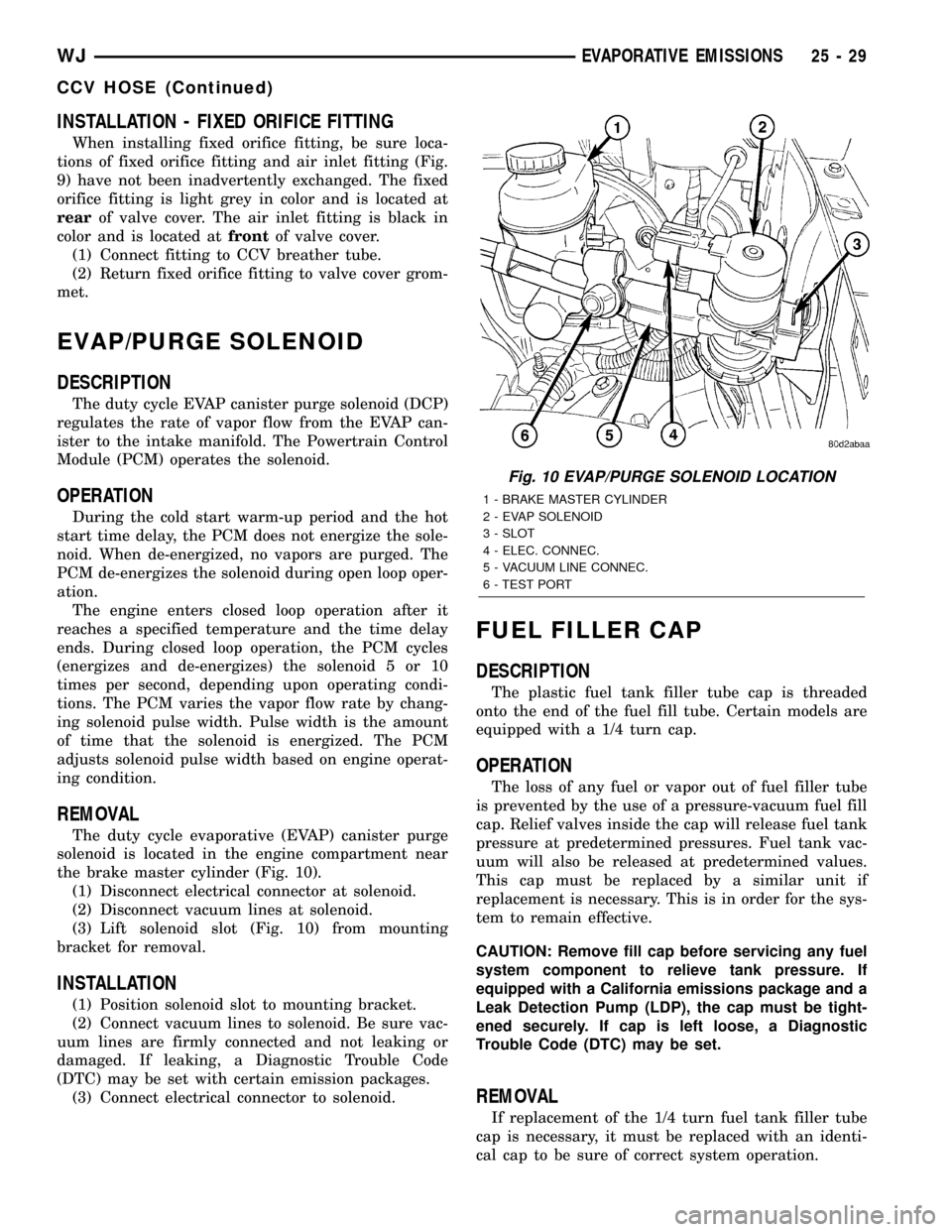

EVAP/PURGE SOLENOID

DESCRIPTION

The duty cycle EVAP canister purge solenoid (DCP)

regulates the rate of vapor flow from the EVAP can-

ister to the intake manifold. The Powertrain Control

Module (PCM) operates the solenoid.

OPERATION

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged. The

PCM de-energizes the solenoid during open loop oper-

ation.

The engine enters closed loop operation after it

reaches a specified temperature and the time delay

ends. During closed loop operation, the PCM cycles

(energizes and de-energizes) the solenoid 5 or 10

times per second, depending upon operating condi-

tions. The PCM varies the vapor flow rate by chang-

ing solenoid pulse width. Pulse width is the amount

of time that the solenoid is energized. The PCM

adjusts solenoid pulse width based on engine operat-

ing condition.

REMOVAL

The duty cycle evaporative (EVAP) canister purge

solenoid is located in the engine compartment near

the brake master cylinder (Fig. 10).

(1) Disconnect electrical connector at solenoid.

(2) Disconnect vacuum lines at solenoid.

(3) Lift solenoid slot (Fig. 10) from mounting

bracket for removal.

INSTALLATION

(1) Position solenoid slot to mounting bracket.

(2) Connect vacuum lines to solenoid. Be sure vac-

uum lines are firmly connected and not leaking or

damaged. If leaking, a Diagnostic Trouble Code

(DTC) may be set with certain emission packages.

(3) Connect electrical connector to solenoid.

FUEL FILLER CAP

DESCRIPTION

The plastic fuel tank filler tube cap is threaded

onto the end of the fuel fill tube. Certain models are

equipped with a 1/4 turn cap.

OPERATION

The loss of any fuel or vapor out of fuel filler tube

is prevented by the use of a pressure-vacuum fuel fill

cap. Relief valves inside the cap will release fuel tank

pressure at predetermined pressures. Fuel tank vac-

uum will also be released at predetermined values.

This cap must be replaced by a similar unit if

replacement is necessary. This is in order for the sys-

tem to remain effective.

CAUTION: Remove fill cap before servicing any fuel

system component to relieve tank pressure. If

equipped with a California emissions package and a

Leak Detection Pump (LDP), the cap must be tight-

ened securely. If cap is left loose, a Diagnostic

Trouble Code (DTC) may be set.

REMOVAL

If replacement of the 1/4 turn fuel tank filler tube

cap is necessary, it must be replaced with an identi-

cal cap to be sure of correct system operation.

Fig. 10 EVAP/PURGE SOLENOID LOCATION

1 - BRAKE MASTER CYLINDER

2 - EVAP SOLENOID

3 - SLOT

4 - ELEC. CONNEC.

5 - VACUUM LINE CONNEC.

6 - TEST PORT

WJEVAPORATIVE EMISSIONS 25 - 29

CCV HOSE (Continued)

Page 2190 of 2199

set a temporary fault without turning on the MIL

and continue the leak portion of the test. However,

the PCM will assume that the system is already

pressurized and skip the rapid pump cycles.

Always diagnose leaks, if possible, before discon-

necting connections. Disconnecting connections may

mask a leak condition.

Keep in mind that if the purge solenoid seat is

leaking, it could go undetected since the leak would

end up in the intake manifold. Disconnect the purge

solenoid at the manifold when leak checking. In addi-

tion, a pinched hose fault (P1486) could set if the

purge solenoid does not purge the fuel system prop-

erly (blocked seat). The purge solenoid must vent the

fuel system prior to the LDP system test. If the

purge solenoid cannot properly vent the system the

LDP cannot properly complete the test for P1486 and

this fault can set due to pressure being in the EVAP

system during the test sequence.

Multiple actuation's of the DRB IIItLeak Detec-

tion Pump (LDP) Monitor Test can hide a 0.020 leak

because of excess vapor generation. Additionally, any

source for additional vapor generation can hide a

small leak in the EVAP system. Excess vapor gener-

ation can delay the fall of the LDP diaphragm thus

hiding the small leak. An example of this condition

could be bringing a cold vehicle into a warm shop for

testing or high ambient temperatures.

Fully plugged and partially plugged underhood

vacuum lines have been known to set MIL condi-

tions. P1494 and P0456 can be set for this reason.

Always, thoroughly, check plumbing for pinches or

blockage before condemning components.

TEST EQUIPMENT The Evaporative Emission

Leak Detector (EELD) Miller Special Tool 8404 is

capable of visually detecting leaks in the evaporative

system and will take the place of the ultrasonic leak

detector 6917A. The EELD utilizes shop air and a

smoke generator to visually detect leaks down to

0.020 or smaller. The food grade oil used to make the

smoke includes an UV trace dye that will leave tell-

tale signs of the leak under a black light. This is

helpful when components have to be removed to

determine the exact leak location. For detailed test

instructions, follow the operators manual packaged

with the EELD.

NOTE: Be sure that the PCM has the latest software

update. Reprogram as indicated by any applicable

Technical Service Bulletin. After LDP repairs are

completed, verify the repair by running the DRB IIIT

Leak Detection Pump (LDP) Monitor Test as

described in Technical Service Bulletin 18-12-99.REMOVAL

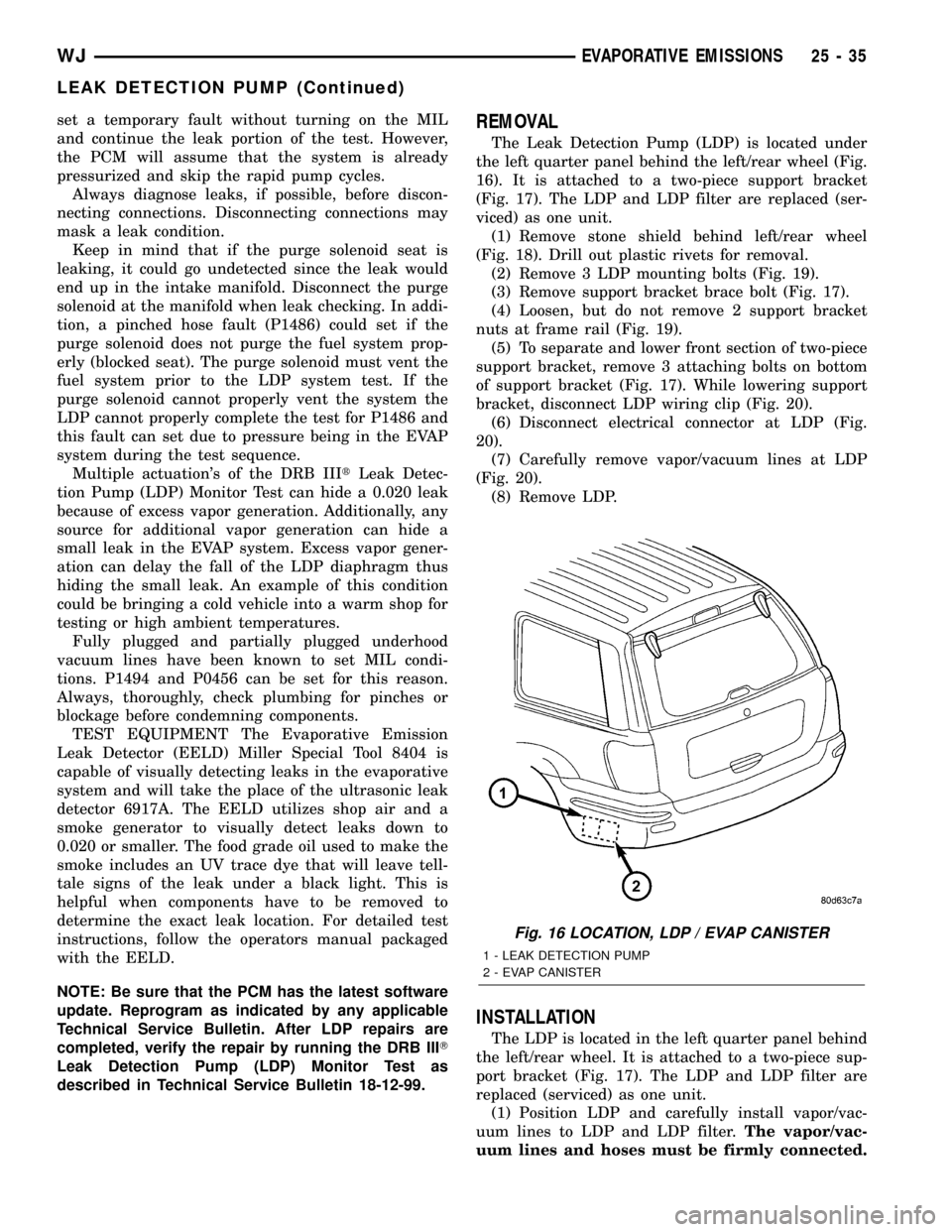

The Leak Detection Pump (LDP) is located under

the left quarter panel behind the left/rear wheel (Fig.

16). It is attached to a two-piece support bracket

(Fig. 17). The LDP and LDP filter are replaced (ser-

viced) as one unit.

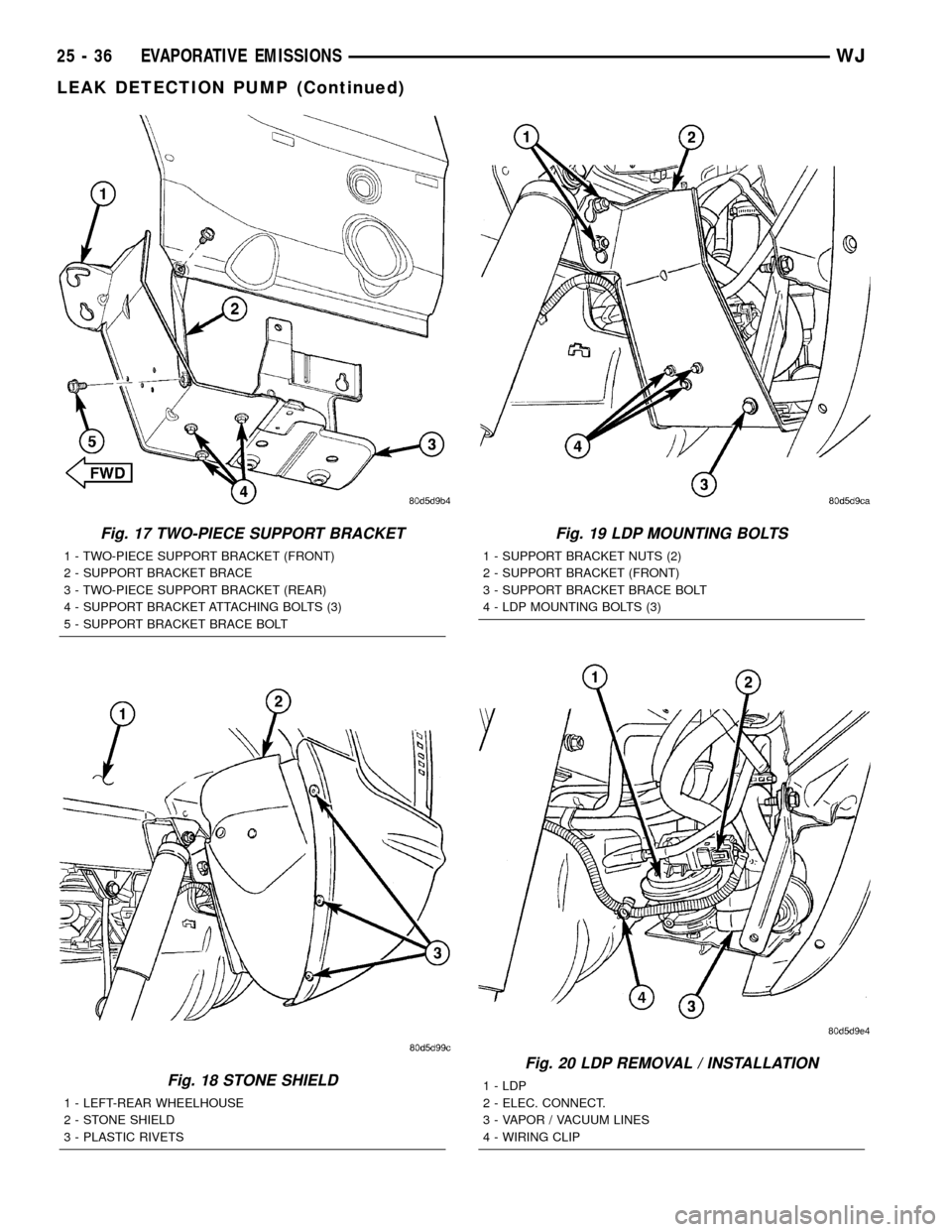

(1) Remove stone shield behind left/rear wheel

(Fig. 18). Drill out plastic rivets for removal.

(2) Remove 3 LDP mounting bolts (Fig. 19).

(3) Remove support bracket brace bolt (Fig. 17).

(4) Loosen, but do not remove 2 support bracket

nuts at frame rail (Fig. 19).

(5) To separate and lower front section of two-piece

support bracket, remove 3 attaching bolts on bottom

of support bracket (Fig. 17). While lowering support

bracket, disconnect LDP wiring clip (Fig. 20).

(6) Disconnect electrical connector at LDP (Fig.

20).

(7) Carefully remove vapor/vacuum lines at LDP

(Fig. 20).

(8) Remove LDP.

INSTALLATION

The LDP is located in the left quarter panel behind

the left/rear wheel. It is attached to a two-piece sup-

port bracket (Fig. 17). The LDP and LDP filter are

replaced (serviced) as one unit.

(1) Position LDP and carefully install vapor/vac-

uum lines to LDP and LDP filter.The vapor/vac-

uum lines and hoses must be firmly connected.

Fig. 16 LOCATION, LDP / EVAP CANISTER

1 - LEAK DETECTION PUMP

2 - EVAP CANISTER

WJEVAPORATIVE EMISSIONS 25 - 35

LEAK DETECTION PUMP (Continued)

Page 2191 of 2199

Fig. 17 TWO-PIECE SUPPORT BRACKET

1 - TWO-PIECE SUPPORT BRACKET (FRONT)

2 - SUPPORT BRACKET BRACE

3 - TWO-PIECE SUPPORT BRACKET (REAR)

4 - SUPPORT BRACKET ATTACHING BOLTS (3)

5 - SUPPORT BRACKET BRACE BOLT

Fig. 18 STONE SHIELD

1 - LEFT-REAR WHEELHOUSE

2 - STONE SHIELD

3 - PLASTIC RIVETS

Fig. 19 LDP MOUNTING BOLTS

1 - SUPPORT BRACKET NUTS (2)

2 - SUPPORT BRACKET (FRONT)

3 - SUPPORT BRACKET BRACE BOLT

4 - LDP MOUNTING BOLTS (3)

Fig. 20 LDP REMOVAL / INSTALLATION

1 - LDP

2 - ELEC. CONNECT.

3 - VAPOR / VACUUM LINES

4 - WIRING CLIP

25 - 36 EVAPORATIVE EMISSIONSWJ

LEAK DETECTION PUMP (Continued)