ad blue JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 449 of 2199

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SIDE CURTAIN AIRBAG,

FRONT IMPACT SENSOR, SIDE IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable. Remove the instrument cluster from the

instrument panel and disconnect the instrument

panel wire harness for the instrument cluster from

the cluster connector receptacle.

(2) Reconnect the battery negative cable. Activate

the hazard warning system by moving the hazard

warning switch button to the On position. Check for

battery voltage at the inoperative (right or left) turn

signal circuit cavity of the instrument panel wire

harness connector for the instrument cluster. There

should be a switching (on and off) battery voltage sig-

nal present. If OK, replace the faulty (right or left)

turn signal indicator bulb. If not OK, repair the open

(right or left) turn signal circuit between the instru-

ment cluster and the combination flasher in the

Junction Block (JB) as required.

VOLTAGE GAUGE

DESCRIPTION

A voltage gauge is standard equipment on all

instrument clusters. The voltage gauge is located in

the upper left corner of the instrument cluster, to the

left of the tachometer. The voltage gauge consists of a

movable gauge needle or pointer controlled by the

instrument cluster circuitry and a fixed 90 degree

scale on the gauge dial face that reads left-to-right

from 9 volts to 19 volts. An International Control and

Display Symbol icon for ªBattery Charging Condi-

tionº is located on the gauge dial face.

The voltage gauge graphics are either white, gray

and orange against a black gauge dial face (base

cluster) or black, gray and red against a taupe gauge

dial face (premium cluster), making them clearly vis-

ible within the instrument cluster in daylight. When

illuminated from behind by the panel lamps dimmer

controlled cluster illumination lighting with the exte-rior lamps turned On, the base cluster white gauge

graphics appear blue-green and the orange graphics

still appear orange, while the premium cluster taupe

gauge dial face appears blue-green with the black

graphics silhouetted against the illuminated back-

ground and the red graphics still appear red. The

gray gauge graphics for both versions of the cluster

are not illuminated. The orange gauge needle in the

base cluster gauge is internally illuminated, while

the black gauge needle in the premium cluster gauge

is not.

Base cluster gauge illumination is provided by

replaceable incandescent bulb and bulb holder units

located on the instrument cluster electronic circuit

board. Premium cluster gauge illumination is pro-

vided by an integral electro-luminescent lamp that is

serviced as a unit with the instrument cluster. The

voltage gauge is serviced as a unit with the instru-

ment cluster.

OPERATION

The voltage gauge gives an indication to the vehi-

cle operator of the electrical system voltage. This

gauge is controlled by the instrument cluster circuit

board based upon cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Program-

mable Communications Interface (PCI) data bus. The

voltage gauge is an air core magnetic unit that

receives battery current on the instrument cluster

electronic circuit board through the fused ignition

switch output (run-start) circuit whenever the igni-

tion switch is in the On or Start positions. The clus-

ter is programmed to move the gauge needle back to

the low end of the scale after the ignition switch is

turned to the Off position. The instrument cluster

circuitry controls the gauge needle position and pro-

vides the following features:

²System Voltage Message- Each time the clus-

ter receives a message from the PCM indicating the

system voltage, the cluster moves the gauge needle to

the relative voltage level position on the gauge scale.

²System Voltage Low Message- Each time the

cluster receives a message from the PCM indicating

the system voltage is low (system voltage is about

eleven volts or lower), the gauge needle is moved to

the relative voltage position in the red zone of the

gauge scale and the check gauges indicator is illumi-

nated. The gauge needle remains in the red zone and

the check gauges indicator remains illuminated until

the cluster receives a message from the PCM indicat-

ing there is no low system voltage condition (system

voltage is above about eleven volts, but lower than

about sixteen volts).

²System Voltage High Message- Each time

the cluster receives a message from the PCM indicat-

8J - 34 INSTRUMENT CLUSTERWJ

TURN SIGNAL INDICATOR (Continued)

Page 660 of 2199

TERMINOLOGY

This is a list of terms and definitions used in the

wiring diagrams.

LHD .................Left Hand Drive Vehicles

RHD................Right Hand Drive Vehicles

ATX . . Automatic Transmissions-Front Wheel Drive

MTX....Manual Transmissions-Front Wheel Drive

AT ....Automatic Transmissions-Rear Wheel Drive

MT .....Manual Transmissions-Rear Wheel Drive

SOHC...........Single Over Head Cam Engine

DOHC..........Double Over Head Cam Engine

Built-Up-Export........ Vehicles Built For Sale In

Markets Other Than North America

Except Built-Up-Export . . Vehicles Built For Sale In

North America

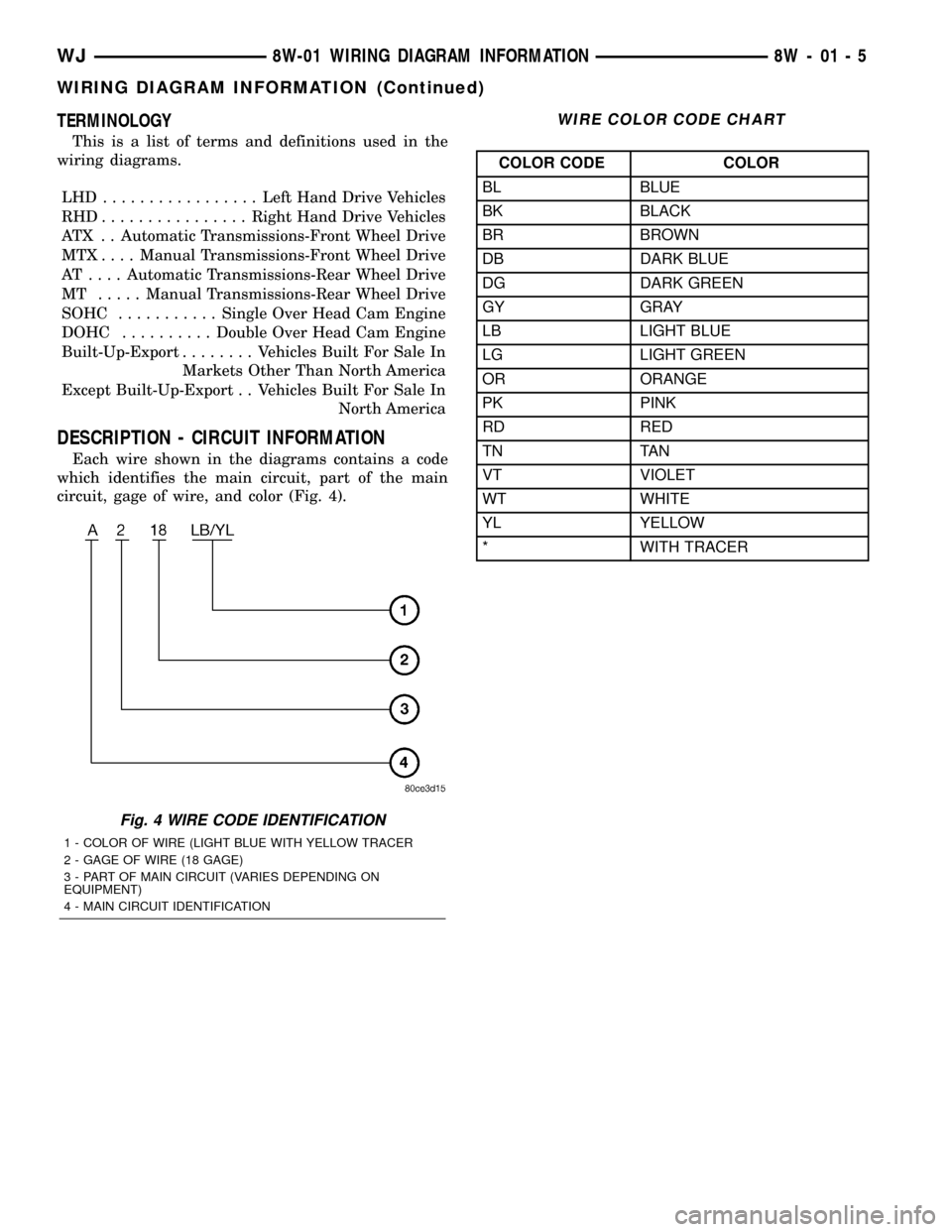

DESCRIPTION - CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies the main circuit, part of the main

circuit, gage of wire, and color (Fig. 4).

WIRE COLOR CODE CHART

COLOR CODE COLOR

BL BLUE

BK BLACK

BR BROWN

DB DARK BLUE

DG DARK GREEN

GY GRAY

LB LIGHT BLUE

LG LIGHT GREEN

OR ORANGE

PK PINK

RD RED

TN TAN

VT VIOLET

WT WHITE

YL YELLOW

* WITH TRACER

Fig. 4 WIRE CODE IDENTIFICATION

1 - COLOR OF WIRE (LIGHT BLUE WITH YELLOW TRACER

2 - GAGE OF WIRE (18 GAGE)

3 - PART OF MAIN CIRCUIT (VARIES DEPENDING ON

EQUIPMENT)

4 - MAIN CIRCUIT IDENTIFICATION

WJ8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 5

WIRING DIAGRAM INFORMATION (Continued)

Page 1120 of 2199

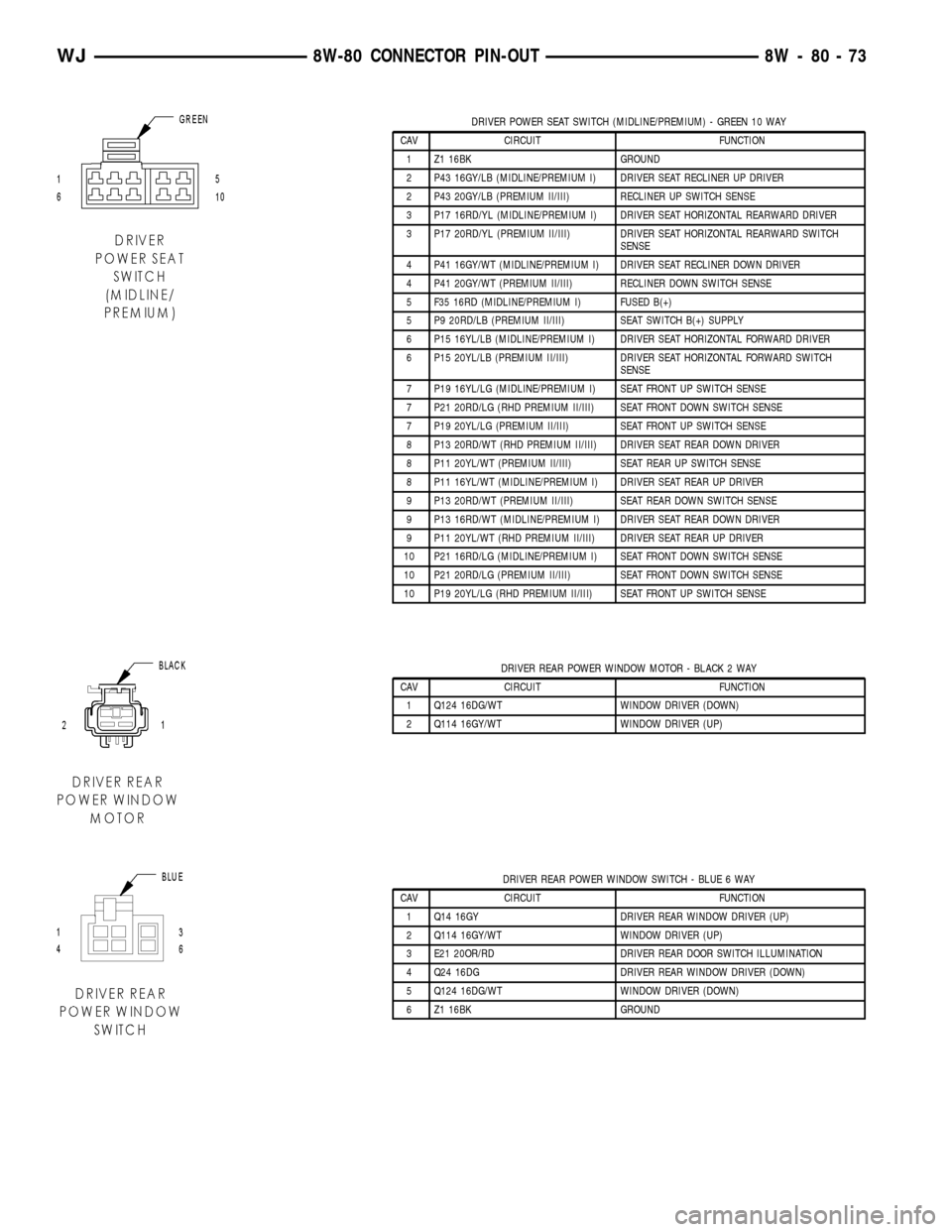

DRIVER POWER SEAT SWITCH (MIDLINE/PREMIUM) - GREEN 10 WAY

CAV CIRCUIT FUNCTION

1 Z1 16BK GROUND

2 P43 16GY/LB (MIDLINE/PREMIUM I) DRIVER SEAT RECLINER UP DRIVER

2 P43 20GY/LB (PREMIUM II/III) RECLINER UP SWITCH SENSE

3 P17 16RD/YL (MIDLINE/PREMIUM I) DRIVER SEAT HORIZONTAL REARWARD DRIVER

3 P17 20RD/YL (PREMIUM II/III) DRIVER SEAT HORIZONTAL REARWARD SWITCH

SENSE

4 P41 16GY/WT (MIDLINE/PREMIUM I) DRIVER SEAT RECLINER DOWN DRIVER

4 P41 20GY/WT (PREMIUM II/III) RECLINER DOWN SWITCH SENSE

5 F35 16RD (MIDLINE/PREMIUM I) FUSED B(+)

5 P9 20RD/LB (PREMIUM II/III) SEAT SWITCH B(+) SUPPLY

6 P15 16YL/LB (MIDLINE/PREMIUM I) DRIVER SEAT HORIZONTAL FORWARD DRIVER

6 P15 20YL/LB (PREMIUM II/III) DRIVER SEAT HORIZONTAL FORWARD SWITCH

SENSE

7 P19 16YL/LG (MIDLINE/PREMIUM I) SEAT FRONT UP SWITCH SENSE

7 P21 20RD/LG (RHD PREMIUM II/III) SEAT FRONT DOWN SWITCH SENSE

7 P19 20YL/LG (PREMIUM II/III) SEAT FRONT UP SWITCH SENSE

8 P13 20RD/WT (RHD PREMIUM II/III) DRIVER SEAT REAR DOWN DRIVER

8 P11 20YL/WT (PREMIUM II/III) SEAT REAR UP SWITCH SENSE

8 P11 16YL/WT (MIDLINE/PREMIUM I) DRIVER SEAT REAR UP DRIVER

9 P13 20RD/WT (PREMIUM II/III) SEAT REAR DOWN SWITCH SENSE

9 P13 16RD/WT (MIDLINE/PREMIUM I) DRIVER SEAT REAR DOWN DRIVER

9 P11 20YL/WT (RHD PREMIUM II/III) DRIVER SEAT REAR UP DRIVER

10 P21 16RD/LG (MIDLINE/PREMIUM I) SEAT FRONT DOWN SWITCH SENSE

10 P21 20RD/LG (PREMIUM II/III) SEAT FRONT DOWN SWITCH SENSE

10 P19 20YL/LG (RHD PREMIUM II/III) SEAT FRONT UP SWITCH SENSE

DRIVER REAR POWER WINDOW MOTOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Q124 16DG/WT WINDOW DRIVER (DOWN)

2 Q114 16GY/WT WINDOW DRIVER (UP)

DRIVER REAR POWER WINDOW SWITCH - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 Q14 16GY DRIVER REAR WINDOW DRIVER (UP)

2 Q114 16GY/WT WINDOW DRIVER (UP)

3 E21 20OR/RD DRIVER REAR DOOR SWITCH ILLUMINATION

4 Q24 16DG DRIVER REAR WINDOW DRIVER (DOWN)

5 Q124 16DG/WT WINDOW DRIVER (DOWN)

6 Z1 16BK GROUND

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 73

Page 1121 of 2199

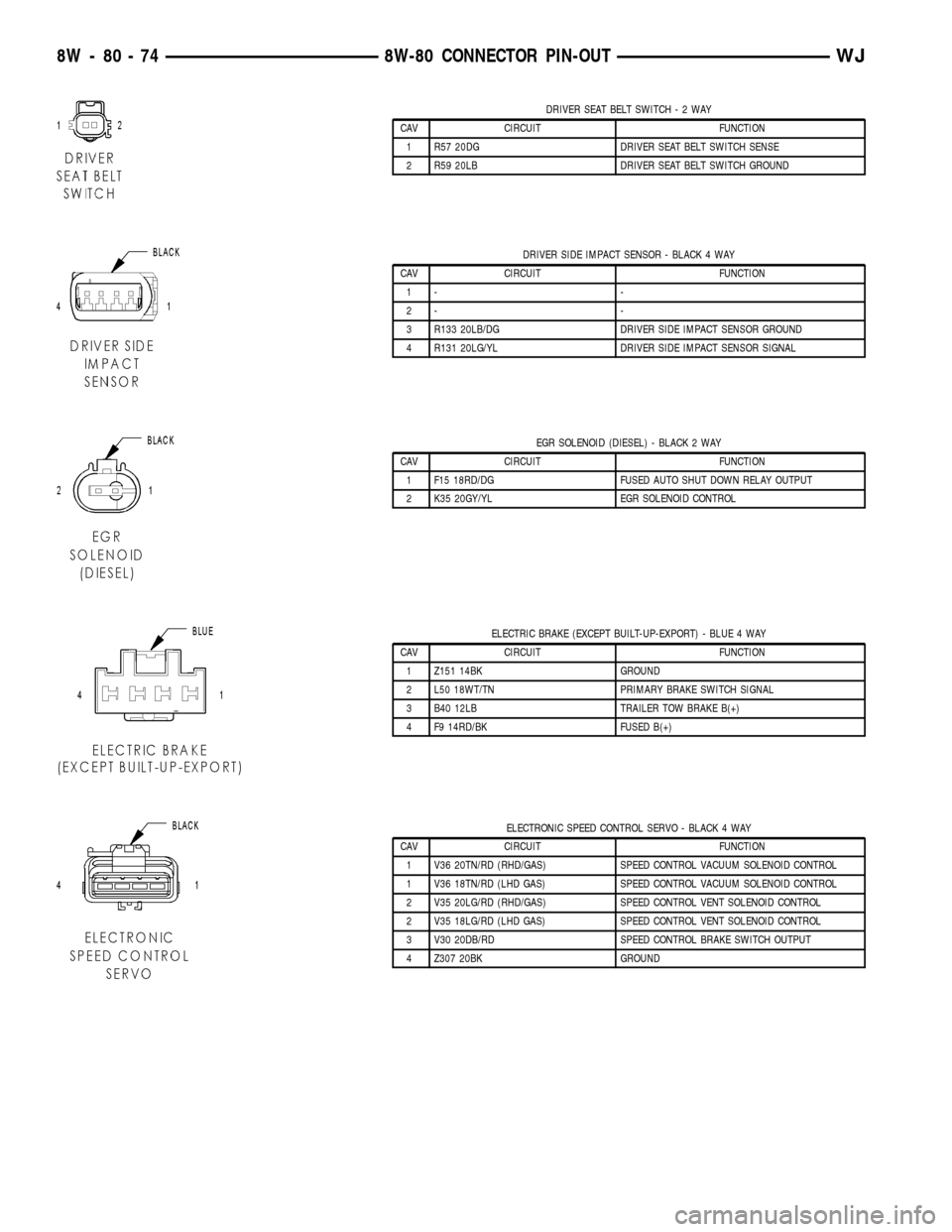

DRIVER SEAT BELT SWITCH-2WAY

CAV CIRCUIT FUNCTION

1 R57 20DG DRIVER SEAT BELT SWITCH SENSE

2 R59 20LB DRIVER SEAT BELT SWITCH GROUND

DRIVER SIDE IMPACT SENSOR - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1- -

2- -

3 R133 20LB/DG DRIVER SIDE IMPACT SENSOR GROUND

4 R131 20LG/YL DRIVER SIDE IMPACT SENSOR SIGNAL

EGR SOLENOID (DIESEL) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 F15 18RD/DG FUSED AUTO SHUT DOWN RELAY OUTPUT

2 K35 20GY/YL EGR SOLENOID CONTROL

ELECTRIC BRAKE (EXCEPT BUILT-UP-EXPORT) - BLUE 4 WAY

CAV CIRCUIT FUNCTION

1 Z151 14BK GROUND

2 L50 18WT/TN PRIMARY BRAKE SWITCH SIGNAL

3 B40 12LB TRAILER TOW BRAKE B(+)

4 F9 14RD/BK FUSED B(+)

ELECTRONIC SPEED CONTROL SERVO - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 V36 20TN/RD (RHD/GAS) SPEED CONTROL VACUUM SOLENOID CONTROL

1 V36 18TN/RD (LHD GAS) SPEED CONTROL VACUUM SOLENOID CONTROL

2 V35 20LG/RD (RHD/GAS) SPEED CONTROL VENT SOLENOID CONTROL

2 V35 18LG/RD (LHD GAS) SPEED CONTROL VENT SOLENOID CONTROL

3 V30 20DB/RD SPEED CONTROL BRAKE SWITCH OUTPUT

4 Z307 20BK GROUND

8W - 80 - 74 8W-80 CONNECTOR PIN-OUTWJ

Page 1153 of 2199

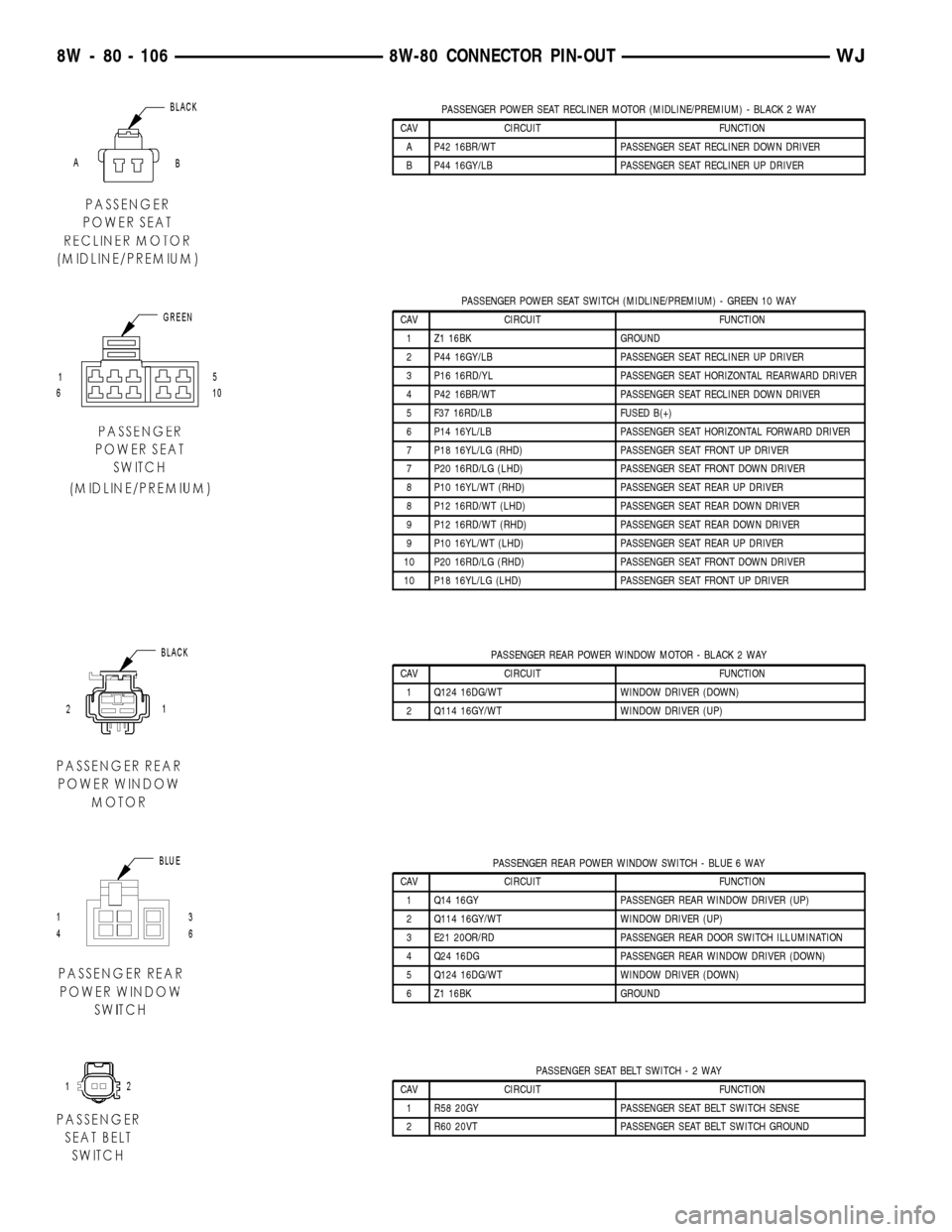

PASSENGER POWER SEAT RECLINER MOTOR (MIDLINE/PREMIUM) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

A P42 16BR/WT PASSENGER SEAT RECLINER DOWN DRIVER

B P44 16GY/LB PASSENGER SEAT RECLINER UP DRIVER

PASSENGER POWER SEAT SWITCH (MIDLINE/PREMIUM) - GREEN 10 WAY

CAV CIRCUIT FUNCTION

1 Z1 16BK GROUND

2 P44 16GY/LB PASSENGER SEAT RECLINER UP DRIVER

3 P16 16RD/YL PASSENGER SEAT HORIZONTAL REARWARD DRIVER

4 P42 16BR/WT PASSENGER SEAT RECLINER DOWN DRIVER

5 F37 16RD/LB FUSED B(+)

6 P14 16YL/LB PASSENGER SEAT HORIZONTAL FORWARD DRIVER

7 P18 16YL/LG (RHD) PASSENGER SEAT FRONT UP DRIVER

7 P20 16RD/LG (LHD) PASSENGER SEAT FRONT DOWN DRIVER

8 P10 16YL/WT (RHD) PASSENGER SEAT REAR UP DRIVER

8 P12 16RD/WT (LHD) PASSENGER SEAT REAR DOWN DRIVER

9 P12 16RD/WT (RHD) PASSENGER SEAT REAR DOWN DRIVER

9 P10 16YL/WT (LHD) PASSENGER SEAT REAR UP DRIVER

10 P20 16RD/LG (RHD) PASSENGER SEAT FRONT DOWN DRIVER

10 P18 16YL/LG (LHD) PASSENGER SEAT FRONT UP DRIVER

PASSENGER REAR POWER WINDOW MOTOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Q124 16DG/WT WINDOW DRIVER (DOWN)

2 Q114 16GY/WT WINDOW DRIVER (UP)

PASSENGER REAR POWER WINDOW SWITCH - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 Q14 16GY PASSENGER REAR WINDOW DRIVER (UP)

2 Q114 16GY/WT WINDOW DRIVER (UP)

3 E21 20OR/RD PASSENGER REAR DOOR SWITCH ILLUMINATION

4 Q24 16DG PASSENGER REAR WINDOW DRIVER (DOWN)

5 Q124 16DG/WT WINDOW DRIVER (DOWN)

6 Z1 16BK GROUND

PASSENGER SEAT BELT SWITCH-2WAY

CAV CIRCUIT FUNCTION

1 R58 20GY PASSENGER SEAT BELT SWITCH SENSE

2 R60 20VT PASSENGER SEAT BELT SWITCH GROUND

8W - 80 - 106 8W-80 CONNECTOR PIN-OUTWJ

Page 1160 of 2199

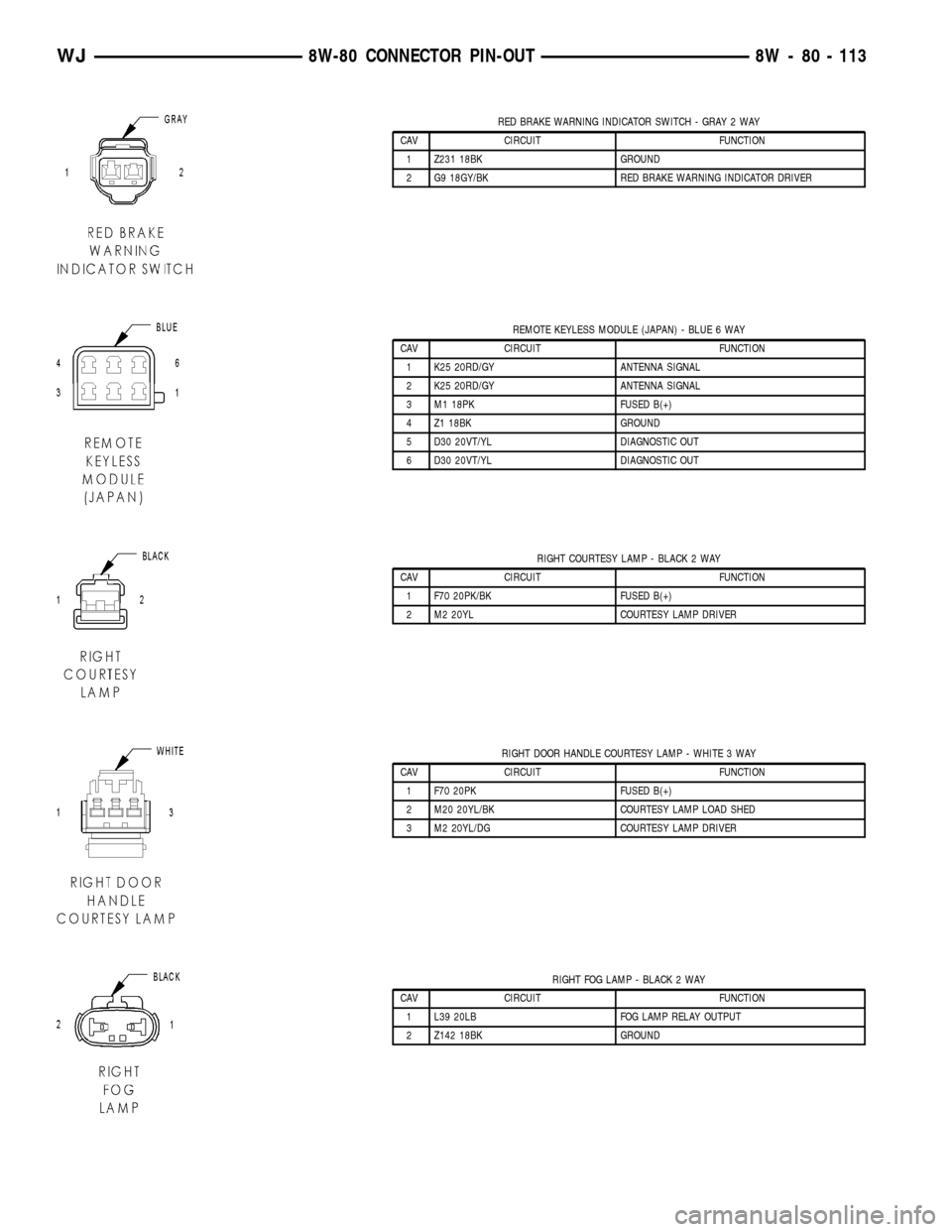

RED BRAKE WARNING INDICATOR SWITCH - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 Z231 18BK GROUND

2 G9 18GY/BK RED BRAKE WARNING INDICATOR DRIVER

REMOTE KEYLESS MODULE (JAPAN) - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 K25 20RD/GY ANTENNA SIGNAL

2 K25 20RD/GY ANTENNA SIGNAL

3 M1 18PK FUSED B(+)

4 Z1 18BK GROUND

5 D30 20VT/YL DIAGNOSTIC OUT

6 D30 20VT/YL DIAGNOSTIC OUT

RIGHT COURTESY LAMP - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 F70 20PK/BK FUSED B(+)

2 M2 20YL COURTESY LAMP DRIVER

RIGHT DOOR HANDLE COURTESY LAMP - WHITE 3 WAY

CAV CIRCUIT FUNCTION

1 F70 20PK FUSED B(+)

2 M20 20YL/BK COURTESY LAMP LOAD SHED

3 M2 20YL/DG COURTESY LAMP DRIVER

RIGHT FOG LAMP - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 L39 20LB FOG LAMP RELAY OUTPUT

2 Z142 18BK GROUND

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 113

Page 1278 of 2199

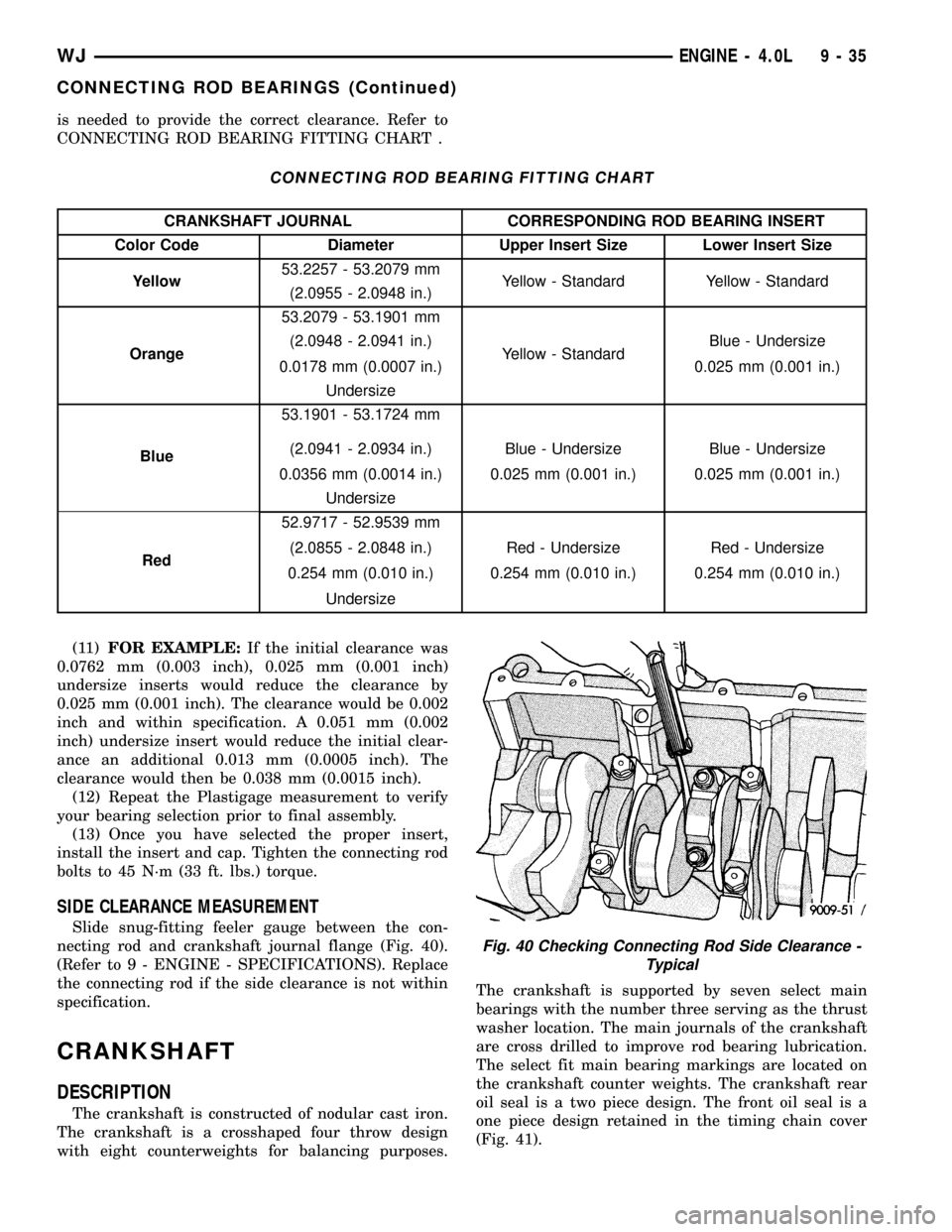

is needed to provide the correct clearance. Refer to

CONNECTING ROD BEARING FITTING CHART .

CONNECTING ROD BEARING FITTING CHART

CRANKSHAFT JOURNAL CORRESPONDING ROD BEARING INSERT

Color Code Diameter Upper Insert Size Lower Insert Size

Yellow53.2257 - 53.2079 mm

Yellow - Standard Yellow - Standard

(2.0955 - 2.0948 in.)

Orange53.2079 - 53.1901 mm

Yellow - StandardBlue - Undersize (2.0948 - 2.0941 in.)

0.0178 mm (0.0007 in.) 0.025 mm (0.001 in.)

Undersize

Blue53.1901 - 53.1724 mm

Blue - Undersize Blue - Undersize (2.0941 - 2.0934 in.)

0.0356 mm (0.0014 in.) 0.025 mm (0.001 in.) 0.025 mm (0.001 in.)

Undersize

Red52.9717 - 52.9539 mm

Red - Undersize Red - Undersize (2.0855 - 2.0848 in.)

0.254 mm (0.010 in.) 0.254 mm (0.010 in.) 0.254 mm (0.010 in.)

Undersize

(11)FOR EXAMPLE:If the initial clearance was

0.0762 mm (0.003 inch), 0.025 mm (0.001 inch)

undersize inserts would reduce the clearance by

0.025 mm (0.001 inch). The clearance would be 0.002

inch and within specification. A 0.051 mm (0.002

inch) undersize insert would reduce the initial clear-

ance an additional 0.013 mm (0.0005 inch). The

clearance would then be 0.038 mm (0.0015 inch).

(12) Repeat the Plastigage measurement to verify

your bearing selection prior to final assembly.

(13) Once you have selected the proper insert,

install the insert and cap. Tighten the connecting rod

bolts to 45 N´m (33 ft. lbs.) torque.

SIDE CLEARANCE MEASUREMENT

Slide snug-fitting feeler gauge between the con-

necting rod and crankshaft journal flange (Fig. 40).

(Refer to 9 - ENGINE - SPECIFICATIONS). Replace

the connecting rod if the side clearance is not within

specification.

CRANKSHAFT

DESCRIPTION

The crankshaft is constructed of nodular cast iron.

The crankshaft is a crosshaped four throw design

with eight counterweights for balancing purposes.The crankshaft is supported by seven select main

bearings with the number three serving as the thrust

washer location. The main journals of the crankshaft

are cross drilled to improve rod bearing lubrication.

The select fit main bearing markings are located on

the crankshaft counter weights. The crankshaft rear

oil seal is a two piece design. The front oil seal is a

one piece design retained in the timing chain cover

(Fig. 41).

Fig. 40 Checking Connecting Rod Side Clearance -

Typical

WJENGINE - 4.0L 9 - 35

CONNECTING ROD BEARINGS (Continued)

Page 1281 of 2199

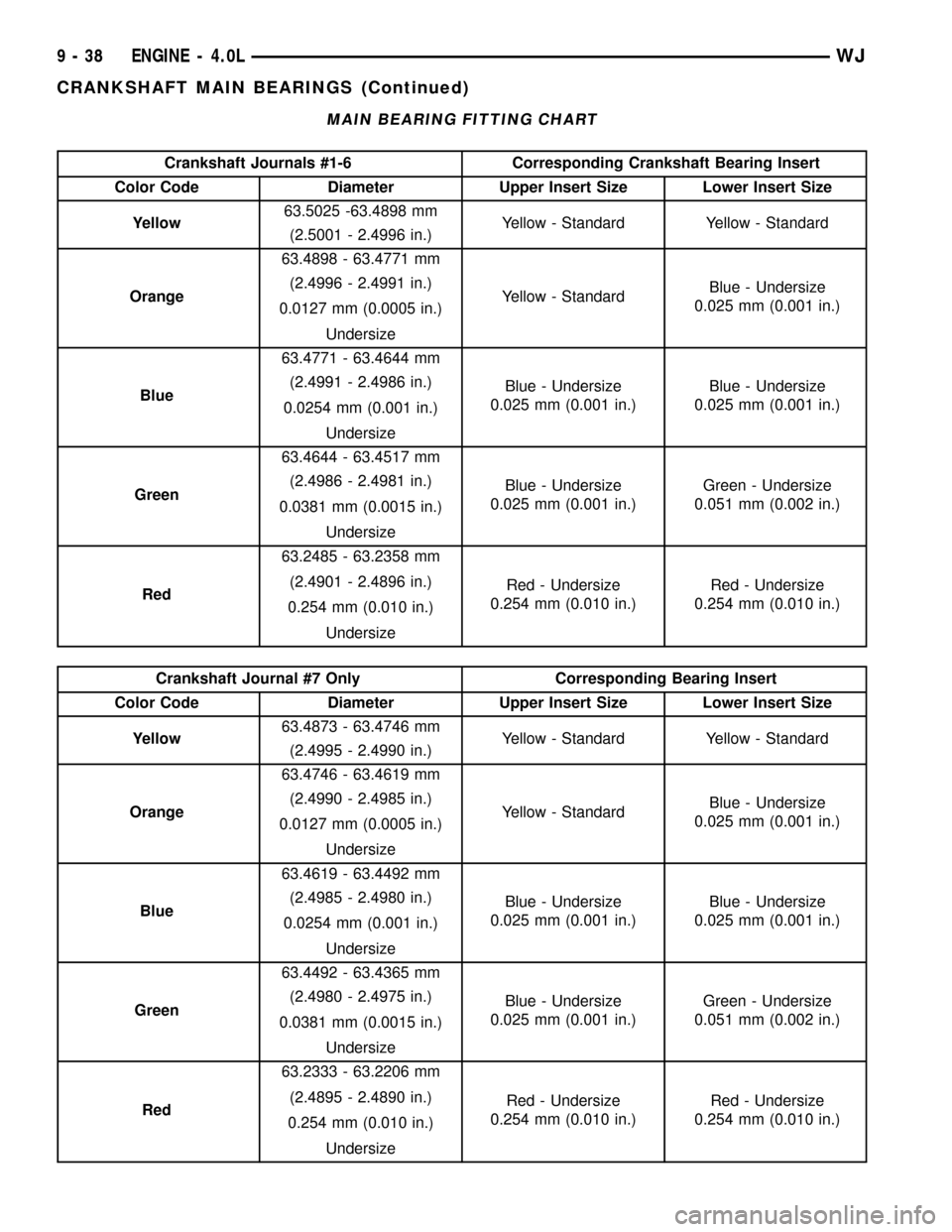

MAIN BEARING FITTING CHART

Crankshaft Journals #1-6 Corresponding Crankshaft Bearing Insert

Color Code Diameter Upper Insert Size Lower Insert Size

Yellow63.5025 -63.4898 mm

Yellow - Standard Yellow - Standard

(2.5001 - 2.4996 in.)

Orange63.4898 - 63.4771 mm

Yellow - StandardBlue - Undersize

0.025 mm (0.001 in.) (2.4996 - 2.4991 in.)

0.0127 mm (0.0005 in.)

Undersize

Blue63.4771 - 63.4644 mm

Blue - Undersize

0.025 mm (0.001 in.)Blue - Undersize

0.025 mm (0.001 in.) (2.4991 - 2.4986 in.)

0.0254 mm (0.001 in.)

Undersize

Green63.4644 - 63.4517 mm

Blue - Undersize

0.025 mm (0.001 in.)Green - Undersize

0.051 mm (0.002 in.) (2.4986 - 2.4981 in.)

0.0381 mm (0.0015 in.)

Undersize

Red63.2485 - 63.2358 mm

Red - Undersize

0.254 mm (0.010 in.)Red - Undersize

0.254 mm (0.010 in.) (2.4901 - 2.4896 in.)

0.254 mm (0.010 in.)

Undersize

Crankshaft Journal #7 Only Corresponding Bearing Insert

Color Code Diameter Upper Insert Size Lower Insert Size

Yellow63.4873 - 63.4746 mm

Yellow - Standard Yellow - Standard

(2.4995 - 2.4990 in.)

Orange63.4746 - 63.4619 mm

Yellow - StandardBlue - Undersize

0.025 mm (0.001 in.) (2.4990 - 2.4985 in.)

0.0127 mm (0.0005 in.)

Undersize

Blue63.4619 - 63.4492 mm

Blue - Undersize

0.025 mm (0.001 in.)Blue - Undersize

0.025 mm (0.001 in.) (2.4985 - 2.4980 in.)

0.0254 mm (0.001 in.)

Undersize

Green63.4492 - 63.4365 mm

Blue - Undersize

0.025 mm (0.001 in.)Green - Undersize

0.051 mm (0.002 in.) (2.4980 - 2.4975 in.)

0.0381 mm (0.0015 in.)

Undersize

Red63.2333 - 63.2206 mm

Red - Undersize

0.254 mm (0.010 in.)Red - Undersize

0.254 mm (0.010 in.) (2.4895 - 2.4890 in.)

0.254 mm (0.010 in.)

Undersize

9 - 38 ENGINE - 4.0LWJ

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1337 of 2199

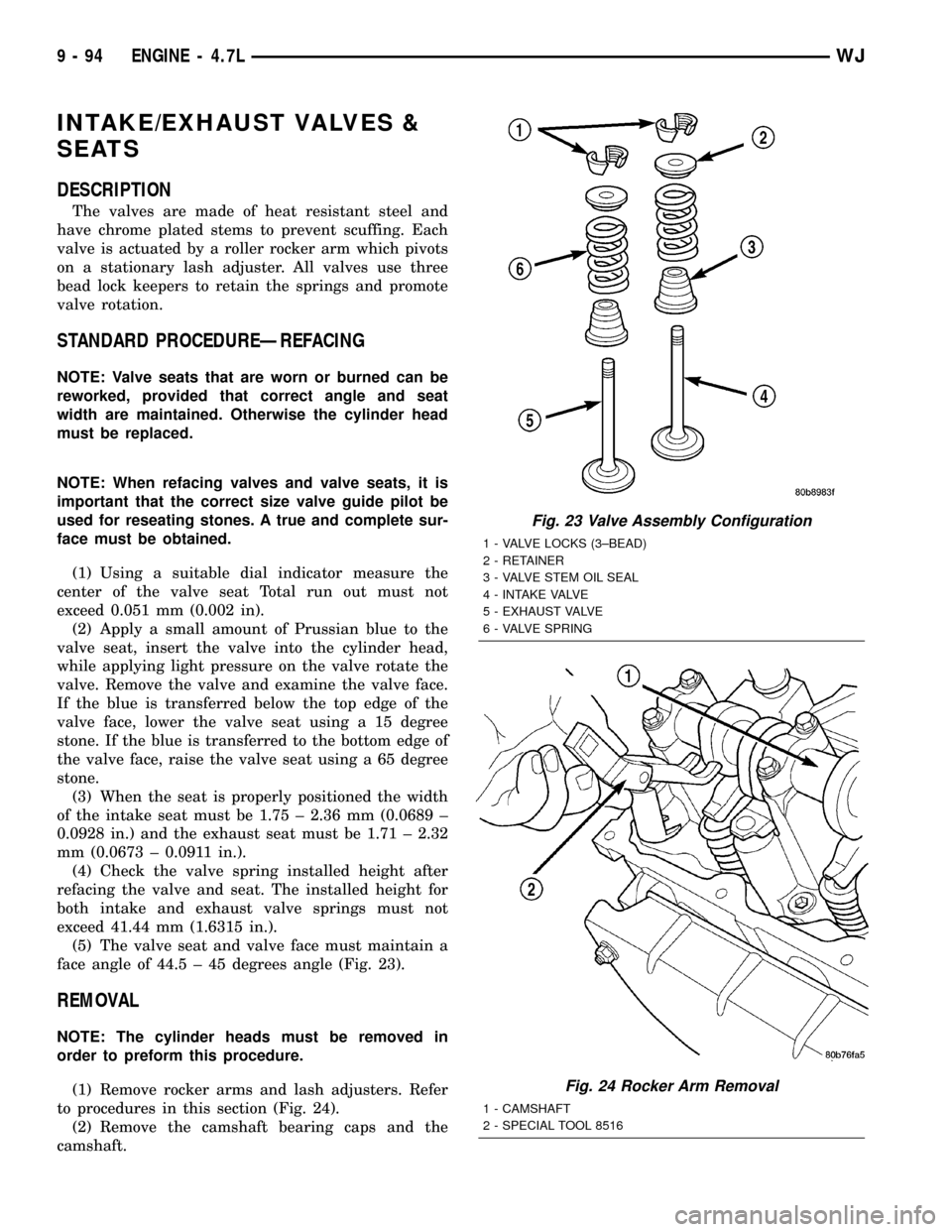

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves are made of heat resistant steel and

have chrome plated stems to prevent scuffing. Each

valve is actuated by a roller rocker arm which pivots

on a stationary lash adjuster. All valves use three

bead lock keepers to retain the springs and promote

valve rotation.

STANDARD PROCEDUREÐREFACING

NOTE: Valve seats that are worn or burned can be

reworked, provided that correct angle and seat

width are maintained. Otherwise the cylinder head

must be replaced.

NOTE: When refacing valves and valve seats, it is

important that the correct size valve guide pilot be

used for reseating stones. A true and complete sur-

face must be obtained.

(1) Using a suitable dial indicator measure the

center of the valve seat Total run out must not

exceed 0.051 mm (0.002 in).

(2) Apply a small amount of Prussian blue to the

valve seat, insert the valve into the cylinder head,

while applying light pressure on the valve rotate the

valve. Remove the valve and examine the valve face.

If the blue is transferred below the top edge of the

valve face, lower the valve seat using a 15 degree

stone. If the blue is transferred to the bottom edge of

the valve face, raise the valve seat using a 65 degree

stone.

(3) When the seat is properly positioned the width

of the intake seat must be 1.75 ± 2.36 mm (0.0689 ±

0.0928 in.) and the exhaust seat must be 1.71 ± 2.32

mm (0.0673 ± 0.0911 in.).

(4) Check the valve spring installed height after

refacing the valve and seat. The installed height for

both intake and exhaust valve springs must not

exceed 41.44 mm (1.6315 in.).

(5) The valve seat and valve face must maintain a

face angle of 44.5 ± 45 degrees angle (Fig. 23).

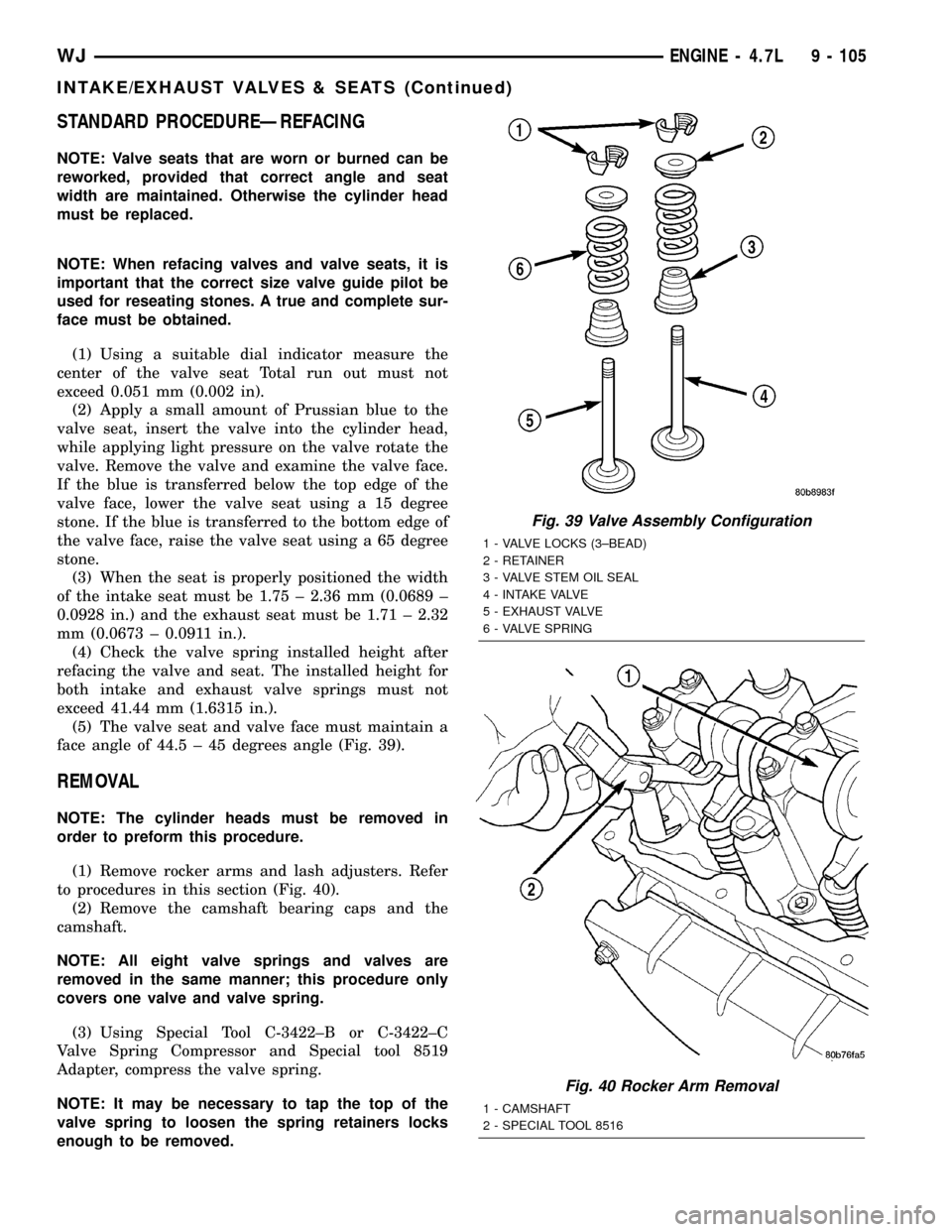

REMOVAL

NOTE: The cylinder heads must be removed in

order to preform this procedure.

(1) Remove rocker arms and lash adjusters. Refer

to procedures in this section (Fig. 24).

(2) Remove the camshaft bearing caps and the

camshaft.

Fig. 23 Valve Assembly Configuration

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

Fig. 24 Rocker Arm Removal

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

9 - 94 ENGINE - 4.7LWJ

Page 1348 of 2199

STANDARD PROCEDUREÐREFACING

NOTE: Valve seats that are worn or burned can be

reworked, provided that correct angle and seat

width are maintained. Otherwise the cylinder head

must be replaced.

NOTE: When refacing valves and valve seats, it is

important that the correct size valve guide pilot be

used for reseating stones. A true and complete sur-

face must be obtained.

(1) Using a suitable dial indicator measure the

center of the valve seat Total run out must not

exceed 0.051 mm (0.002 in).

(2) Apply a small amount of Prussian blue to the

valve seat, insert the valve into the cylinder head,

while applying light pressure on the valve rotate the

valve. Remove the valve and examine the valve face.

If the blue is transferred below the top edge of the

valve face, lower the valve seat using a 15 degree

stone. If the blue is transferred to the bottom edge of

the valve face, raise the valve seat using a 65 degree

stone.

(3) When the seat is properly positioned the width

of the intake seat must be 1.75 ± 2.36 mm (0.0689 ±

0.0928 in.) and the exhaust seat must be 1.71 ± 2.32

mm (0.0673 ± 0.0911 in.).

(4) Check the valve spring installed height after

refacing the valve and seat. The installed height for

both intake and exhaust valve springs must not

exceed 41.44 mm (1.6315 in.).

(5) The valve seat and valve face must maintain a

face angle of 44.5 ± 45 degrees angle (Fig. 39).

REMOVAL

NOTE: The cylinder heads must be removed in

order to preform this procedure.

(1) Remove rocker arms and lash adjusters. Refer

to procedures in this section (Fig. 40).

(2) Remove the camshaft bearing caps and the

camshaft.

NOTE: All eight valve springs and valves are

removed in the same manner; this procedure only

covers one valve and valve spring.

(3) Using Special Tool C-3422±B or C-3422±C

Valve Spring Compressor and Special tool 8519

Adapter, compress the valve spring.

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

Fig. 39 Valve Assembly Configuration

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

Fig. 40 Rocker Arm Removal

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

WJENGINE - 4.7L 9 - 105

INTAKE/EXHAUST VALVES & SEATS (Continued)