front lower control arm JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 623 of 2199

(3) Insert the hook formation on the tip of the

wiper arm through the opening in the wiper blade

superstructure ahead of the wiper blade pivot block/

latch unit far enough to engage the pivot block with

the hook (Fig. 10).

(4) Slide the wiper blade pivot block/latch up into

the hook formation on the tip of the wiper arm until

the latch release tab snaps into its locked position.

Latch engagement will be accompanied by an audible

click.

(5) Gently lower the wiper blade onto the glass.

FRONT WIPER MODULE

DESCRIPTION

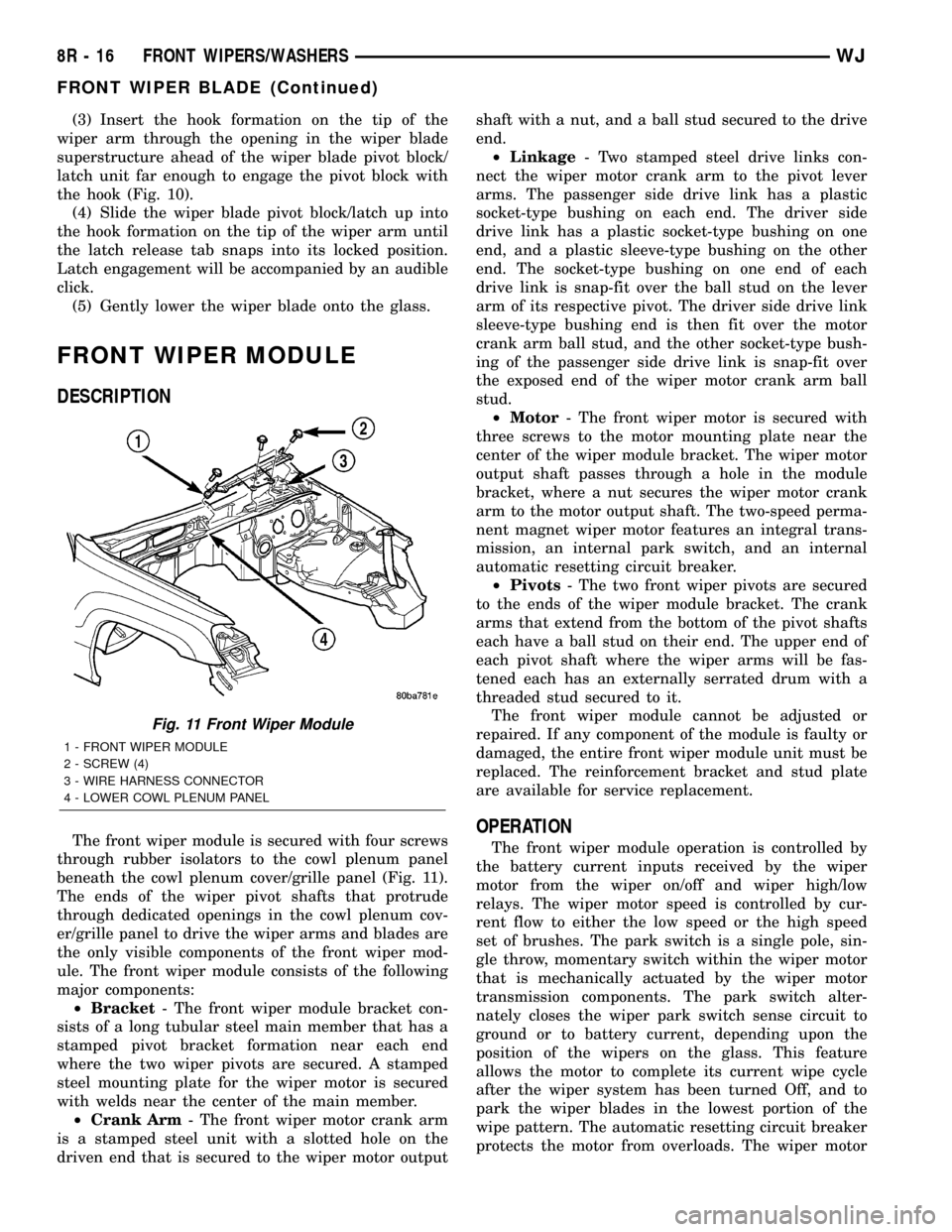

The front wiper module is secured with four screws

through rubber isolators to the cowl plenum panel

beneath the cowl plenum cover/grille panel (Fig. 11).

The ends of the wiper pivot shafts that protrude

through dedicated openings in the cowl plenum cov-

er/grille panel to drive the wiper arms and blades are

the only visible components of the front wiper mod-

ule. The front wiper module consists of the following

major components:

²Bracket- The front wiper module bracket con-

sists of a long tubular steel main member that has a

stamped pivot bracket formation near each end

where the two wiper pivots are secured. A stamped

steel mounting plate for the wiper motor is secured

with welds near the center of the main member.

²Crank Arm- The front wiper motor crank arm

is a stamped steel unit with a slotted hole on the

driven end that is secured to the wiper motor outputshaft with a nut, and a ball stud secured to the drive

end.

²Linkage- Two stamped steel drive links con-

nect the wiper motor crank arm to the pivot lever

arms. The passenger side drive link has a plastic

socket-type bushing on each end. The driver side

drive link has a plastic socket-type bushing on one

end, and a plastic sleeve-type bushing on the other

end. The socket-type bushing on one end of each

drive link is snap-fit over the ball stud on the lever

arm of its respective pivot. The driver side drive link

sleeve-type bushing end is then fit over the motor

crank arm ball stud, and the other socket-type bush-

ing of the passenger side drive link is snap-fit over

the exposed end of the wiper motor crank arm ball

stud.

²Motor- The front wiper motor is secured with

three screws to the motor mounting plate near the

center of the wiper module bracket. The wiper motor

output shaft passes through a hole in the module

bracket, where a nut secures the wiper motor crank

arm to the motor output shaft. The two-speed perma-

nent magnet wiper motor features an integral trans-

mission, an internal park switch, and an internal

automatic resetting circuit breaker.

²Pivots- The two front wiper pivots are secured

to the ends of the wiper module bracket. The crank

arms that extend from the bottom of the pivot shafts

each have a ball stud on their end. The upper end of

each pivot shaft where the wiper arms will be fas-

tened each has an externally serrated drum with a

threaded stud secured to it.

The front wiper module cannot be adjusted or

repaired. If any component of the module is faulty or

damaged, the entire front wiper module unit must be

replaced. The reinforcement bracket and stud plate

are available for service replacement.OPERATION

The front wiper module operation is controlled by

the battery current inputs received by the wiper

motor from the wiper on/off and wiper high/low

relays. The wiper motor speed is controlled by cur-

rent flow to either the low speed or the high speed

set of brushes. The park switch is a single pole, sin-

gle throw, momentary switch within the wiper motor

that is mechanically actuated by the wiper motor

transmission components. The park switch alter-

nately closes the wiper park switch sense circuit to

ground or to battery current, depending upon the

position of the wipers on the glass. This feature

allows the motor to complete its current wipe cycle

after the wiper system has been turned Off, and to

park the wiper blades in the lowest portion of the

wipe pattern. The automatic resetting circuit breaker

protects the motor from overloads. The wiper motor

Fig. 11 Front Wiper Module

1 - FRONT WIPER MODULE

2 - SCREW (4)

3 - WIRE HARNESS CONNECTOR

4 - LOWER COWL PLENUM PANEL

8R - 16 FRONT WIPERS/WASHERSWJ

FRONT WIPER BLADE (Continued)

Page 640 of 2199

REAR WIPERS/WASHERS

TABLE OF CONTENTS

page page

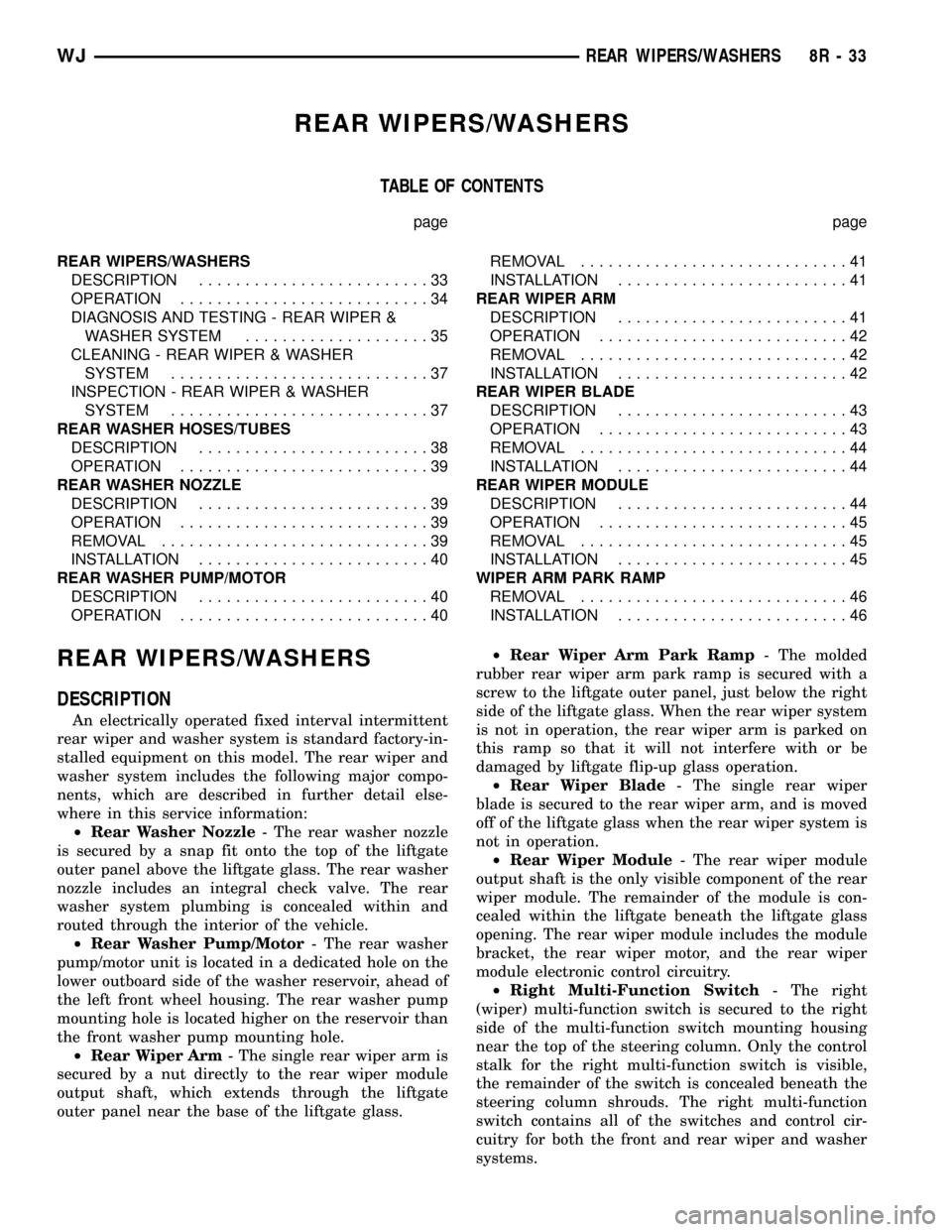

REAR WIPERS/WASHERS

DESCRIPTION.........................33

OPERATION...........................34

DIAGNOSIS AND TESTING - REAR WIPER &

WASHER SYSTEM....................35

CLEANING - REAR WIPER & WASHER

SYSTEM............................37

INSPECTION - REAR WIPER & WASHER

SYSTEM............................37

REAR WASHER HOSES/TUBES

DESCRIPTION.........................38

OPERATION...........................39

REAR WASHER NOZZLE

DESCRIPTION.........................39

OPERATION...........................39

REMOVAL.............................39

INSTALLATION.........................40

REAR WASHER PUMP/MOTOR

DESCRIPTION.........................40

OPERATION...........................40REMOVAL.............................41

INSTALLATION.........................41

REAR WIPER ARM

DESCRIPTION.........................41

OPERATION...........................42

REMOVAL.............................42

INSTALLATION.........................42

REAR WIPER BLADE

DESCRIPTION.........................43

OPERATION...........................43

REMOVAL.............................44

INSTALLATION.........................44

REAR WIPER MODULE

DESCRIPTION.........................44

OPERATION...........................45

REMOVAL.............................45

INSTALLATION.........................45

WIPER ARM PARK RAMP

REMOVAL.............................46

INSTALLATION.........................46

REAR WIPERS/WASHERS

DESCRIPTION

An electrically operated fixed interval intermittent

rear wiper and washer system is standard factory-in-

stalled equipment on this model. The rear wiper and

washer system includes the following major compo-

nents, which are described in further detail else-

where in this service information:

²Rear Washer Nozzle- The rear washer nozzle

is secured by a snap fit onto the top of the liftgate

outer panel above the liftgate glass. The rear washer

nozzle includes an integral check valve. The rear

washer system plumbing is concealed within and

routed through the interior of the vehicle.

²Rear Washer Pump/Motor- The rear washer

pump/motor unit is located in a dedicated hole on the

lower outboard side of the washer reservoir, ahead of

the left front wheel housing. The rear washer pump

mounting hole is located higher on the reservoir than

the front washer pump mounting hole.

²Rear Wiper Arm- The single rear wiper arm is

secured by a nut directly to the rear wiper module

output shaft, which extends through the liftgate

outer panel near the base of the liftgate glass.²Rear Wiper Arm Park Ramp- The molded

rubber rear wiper arm park ramp is secured with a

screw to the liftgate outer panel, just below the right

side of the liftgate glass. When the rear wiper system

is not in operation, the rear wiper arm is parked on

this ramp so that it will not interfere with or be

damaged by liftgate flip-up glass operation.

²Rear Wiper Blade- The single rear wiper

blade is secured to the rear wiper arm, and is moved

off of the liftgate glass when the rear wiper system is

not in operation.

²Rear Wiper Module- The rear wiper module

output shaft is the only visible component of the rear

wiper module. The remainder of the module is con-

cealed within the liftgate beneath the liftgate glass

opening. The rear wiper module includes the module

bracket, the rear wiper motor, and the rear wiper

module electronic control circuitry.

²Right Multi-Function Switch- The right

(wiper) multi-function switch is secured to the right

side of the multi-function switch mounting housing

near the top of the steering column. Only the control

stalk for the right multi-function switch is visible,

the remainder of the switch is concealed beneath the

steering column shrouds. The right multi-function

switch contains all of the switches and control cir-

cuitry for both the front and rear wiper and washer

systems.

WJREAR WIPERS/WASHERS 8R - 33

Page 1177 of 2199

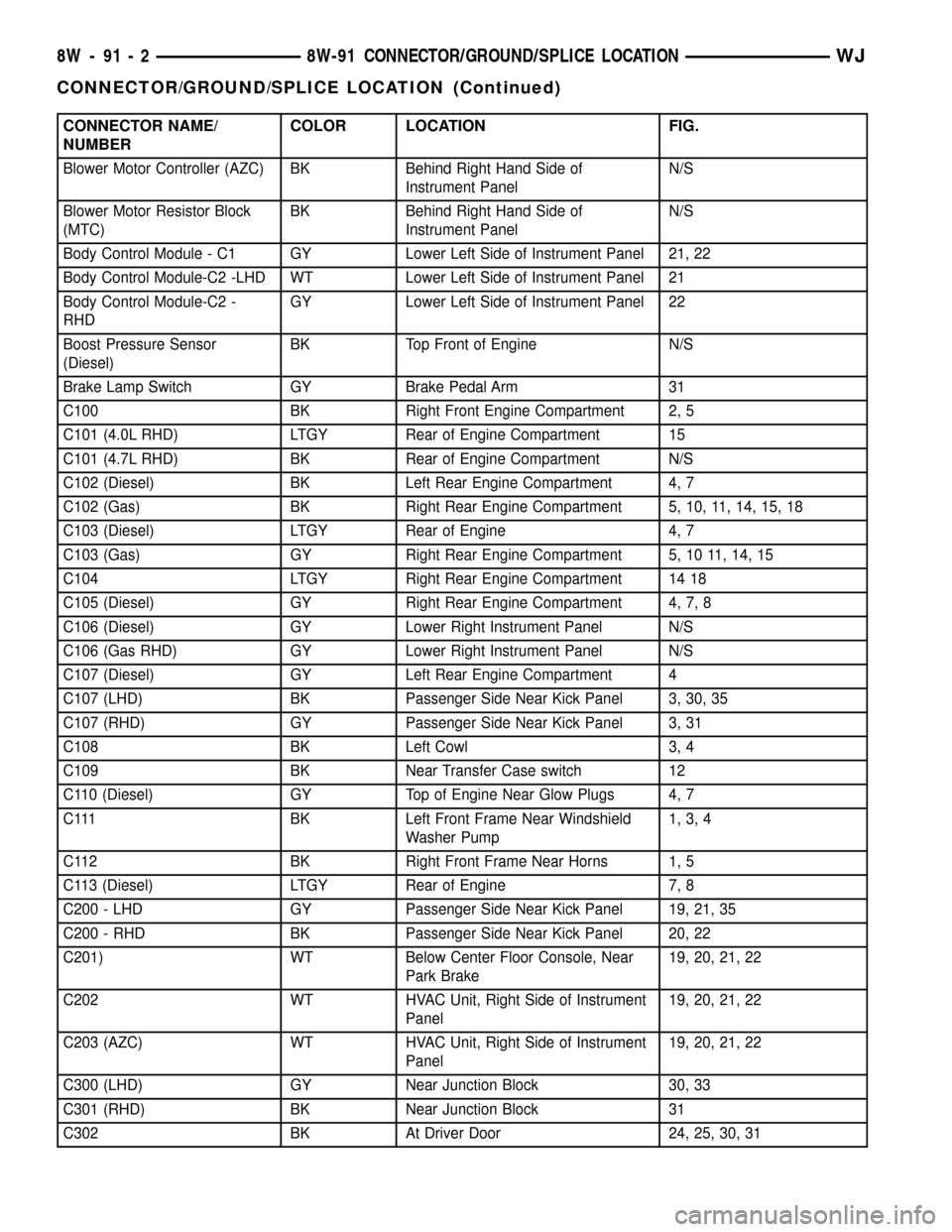

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Blower Motor Controller (AZC) BK Behind Right Hand Side of

Instrument PanelN/S

Blower Motor Resistor Block

(MTC)BK Behind Right Hand Side of

Instrument PanelN/S

Body Control Module - C1 GY Lower Left Side of Instrument Panel 21, 22

Body Control Module-C2 -LHD WT Lower Left Side of Instrument Panel 21

Body Control Module-C2 -

RHDGY Lower Left Side of Instrument Panel 22

Boost Pressure Sensor

(Diesel)BK Top Front of Engine N/S

Brake Lamp Switch GY Brake Pedal Arm 31

C100 BK Right Front Engine Compartment 2, 5

C101 (4.0L RHD) LTGY Rear of Engine Compartment 15

C101 (4.7L RHD) BK Rear of Engine Compartment N/S

C102 (Diesel) BK Left Rear Engine Compartment 4, 7

C102 (Gas) BK Right Rear Engine Compartment 5, 10, 11, 14, 15, 18

C103 (Diesel) LTGY Rear of Engine 4, 7

C103 (Gas) GY Right Rear Engine Compartment 5, 10 11, 14, 15

C104 LTGY Right Rear Engine Compartment 14 18

C105 (Diesel) GY Right Rear Engine Compartment 4, 7, 8

C106 (Diesel) GY Lower Right Instrument Panel N/S

C106 (Gas RHD) GY Lower Right Instrument Panel N/S

C107 (Diesel) GY Left Rear Engine Compartment 4

C107 (LHD) BK Passenger Side Near Kick Panel 3, 30, 35

C107 (RHD) GY Passenger Side Near Kick Panel 3, 31

C108 BK Left Cowl 3, 4

C109 BK Near Transfer Case switch 12

C110 (Diesel) GY Top of Engine Near Glow Plugs 4, 7

C111 BK Left Front Frame Near Windshield

Washer Pump1, 3, 4

C112 BK Right Front Frame Near Horns 1, 5

C113 (Diesel) LTGY Rear of Engine 7, 8

C200 - LHD GY Passenger Side Near Kick Panel 19, 21, 35

C200 - RHD BK Passenger Side Near Kick Panel 20, 22

C201) WT Below Center Floor Console, Near

Park Brake19, 20, 21, 22

C202 WT HVAC Unit, Right Side of Instrument

Panel19, 20, 21, 22

C203 (AZC) WT HVAC Unit, Right Side of Instrument

Panel19, 20, 21, 22

C300 (LHD) GY Near Junction Block 30, 33

C301 (RHD) BK Near Junction Block 31

C302 BK At Driver Door 24, 25, 30, 31

8W - 91 - 2 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1315 of 2199

(13) Disconnect the engine block heater power

cable from the block heater.

(14) Lower vehicle.

(15) Remove throttle body resonator assembly and

inlet hose.

(16) Disconnect throttle and speed control cables.

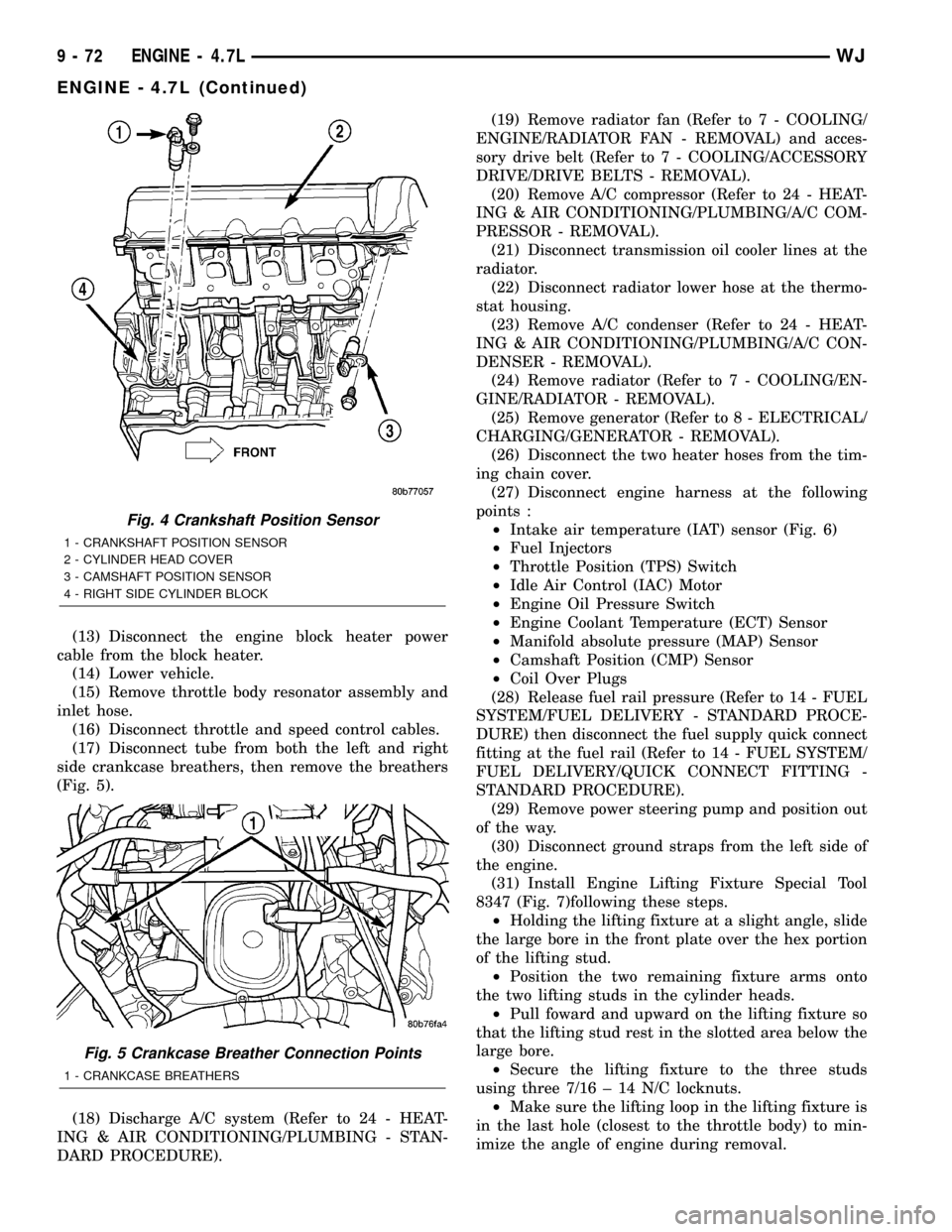

(17) Disconnect tube from both the left and right

side crankcase breathers, then remove the breathers

(Fig. 5).

(18) Discharge A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE).(19) Remove radiator fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL) and acces-

sory drive belt (Refer to 7 - COOLING/ACCESSORY

DRIVE/DRIVE BELTS - REMOVAL).

(20) Remove A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - REMOVAL).

(21) Disconnect transmission oil cooler lines at the

radiator.

(22) Disconnect radiator lower hose at the thermo-

stat housing.

(23) Remove A/C condenser (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C CON-

DENSER - REMOVAL).

(24) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(25) Remove generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - REMOVAL).

(26) Disconnect the two heater hoses from the tim-

ing chain cover.

(27) Disconnect engine harness at the following

points :

²Intake air temperature (IAT) sensor (Fig. 6)

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold absolute pressure (MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

(28) Release fuel rail pressure (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - STANDARD PROCE-

DURE) then disconnect the fuel supply quick connect

fitting at the fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/QUICK CONNECT FITTING -

STANDARD PROCEDURE).

(29) Remove power steering pump and position out

of the way.

(30) Disconnect ground straps from the left side of

the engine.

(31) Install Engine Lifting Fixture Special Tool

8347 (Fig. 7)following these steps.

²Holding the lifting fixture at a slight angle, slide

the large bore in the front plate over the hex portion

of the lifting stud.

²Position the two remaining fixture arms onto

the two lifting studs in the cylinder heads.

²Pull foward and upward on the lifting fixture so

that the lifting stud rest in the slotted area below the

large bore.

²Secure the lifting fixture to the three studs

using three 7/16 ± 14 N/C locknuts.

²Make sure the lifting loop in the lifting fixture is

in the last hole (closest to the throttle body) to min-

imize the angle of engine during removal.

Fig. 4 Crankshaft Position Sensor

1 - CRANKSHAFT POSITION SENSOR

2 - CYLINDER HEAD COVER

3 - CAMSHAFT POSITION SENSOR

4 - RIGHT SIDE CYLINDER BLOCK

Fig. 5 Crankcase Breather Connection Points

1 - CRANKCASE BREATHERS

9 - 72 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)

Page 1421 of 2199

FUEL DELIVERY

DESCRIPTION

The fuel delivery system consists of:

²the fuel pump module containing the electric

fuel pump, fuel gauge sending unit (fuel level sensor)

and a separate fuel filter located at bottom of pump

module

²a separate combination fuel filter/fuel pressure

regulator

²fuel tubes/lines/hoses

²quick-connect fittings

²fuel injector rail

²fuel injectors

²fuel tank

²fuel tank filler/vent tube assembly

²fuel tank filler tube cap

²accelerator pedal

²throttle cable

OPERATION

The fuel tank assembly consists of: the fuel tank,

fuel tank shield, fuel tank straps, fuel pump module

assembly, fuel pump module locknut/gasket, and fuel

tank check valve (refer to Emission Control System

for fuel tank check valve information).

A fuel filler/vent tube assembly using a pressure/

vacuum, 1/4 turn fuel filler cap is used. The fuel

filler tube contains a flap door located below the fuel

fill cap.

Also to be considered part of the fuel system is the

evaporation control system. This is designed to

reduce the emission of fuel vapors into the atmo-

sphere. The description and function of the Evapora-

tive Control System is found in Emission Control

Systems.

Both fuel filters (at bottom of fuel pump module

and within fuel pressure regulator) are designed for

extended service. They do not require normal sched-

uled maintenance. Filters should only be replaced if

a diagnostic procedure indicates to do so.

DIAGNOSIS AND TESTING

FUEL PRESSURE LEAK DOWN TEST

Use this test in conjunction with the Fuel Pump

Pressure Test and Fuel Pump Capacity Test.

Check Valve Operation:The electric fuel pump

outlet contains a one-way check valve to prevent fuel

flow back into the tank and to maintain fuel supply

line pressure (engine warm) when pump is not oper-

ational. It is also used to keep the fuel supply line

full of gasoline when pump is not operational. After

the vehicle has cooled down, fuel pressure may drop

to 0 psi (cold fluid contracts), but liquid gasoline willremain in fuel supply line between the check valve

and fuel injectors.Fuel pressure that has

dropped to 0 psi on a cooled down vehicle

(engine off) is a normal condition.When the elec-

tric fuel pump is activated, fuel pressure should

immediately(1±2 seconds) rise to specification.

Abnormally long periods of cranking to restart a

hotengine that has been shut down for a short

period of time may be caused by:

²Fuel pressure bleeding past a fuel injector(s).

²Fuel pressure bleeding past the check valve in

the fuel pump module.

²A defective fuel filter/pressure regulator.

Two #6539, 5/16º, Fuel Line Pressure Test Adapter

Hose Tools are required for the following tests.

(1) Release fuel system pressure. Refer to Fuel

Pressure Release Procedure.

(2) Raise vehicle.

Fuel Line Identification:The fuel filter/pressure

regulator is located in front of the fuel tank and

above the rear axle. It is transversely mounted to a

chassis crossmember (left-to-right). The filter/regula-

tor is equipped with 3 fuel line fittings (2 at one end

and 1 at the other end). The single fitting facing the

left side of the vehicle is the supply line to the fuel

rail (Fig. 1) . The 2 fittings facing the right side of

the vehicle are connected to the fuel tank. Of these 2

fittings, the fitting towards thefrontis used for fuel

return to the fuel tank. The fitting towards therear

is a pressure line. Thisrearfitting must be discon-

nected for the following step.

(3) See previous step. Disconnect fuel pressure line

atrearof filter/regulator. This is a 5/169quick-con-

nect fitting (Fig. 1) . Refer to Quick-Connect Fittings

for procedures.

(4) Obtain correct Fuel Line Pressure Test Adapter

Hose Tool # 6539 for 5/16º fuel lines. Connect one

end of this Special Tool into the disconnected fuel

pressure line. Connect the other end of the Tool into

fitting on filter/regulator.

(5) Lower vehicle.

(6) Disconnect the fuel inlet line at fuel rail. Refer

to Quick-Connect Fittings for procedures. On some

engines, air cleaner housing removal may be neces-

sary before fuel line disconnection.

(7) Obtain a second Fuel Line Pressure Test

Adapter Hose Tool # 6539 for 5/16º fuel lines. Con-

nect this tool between disconnected fuel line and fuel

rail (Fig. 2) .

(8) Connect the 0-414 kPa (0-60 psi) fuel pressure

test gauge (from Gauge Set 5069) to the test port on

the appropriate Adaptor Tool.NOTE: The DRB III

Scan Tool along with the PEP module, the 500

psi pressure transducer, and the transducer-to-

test port adapter may also be used in place of

the fuel pressure gauge.

14 - 2 FUEL DELIVERYWJ

Page 2026 of 2199

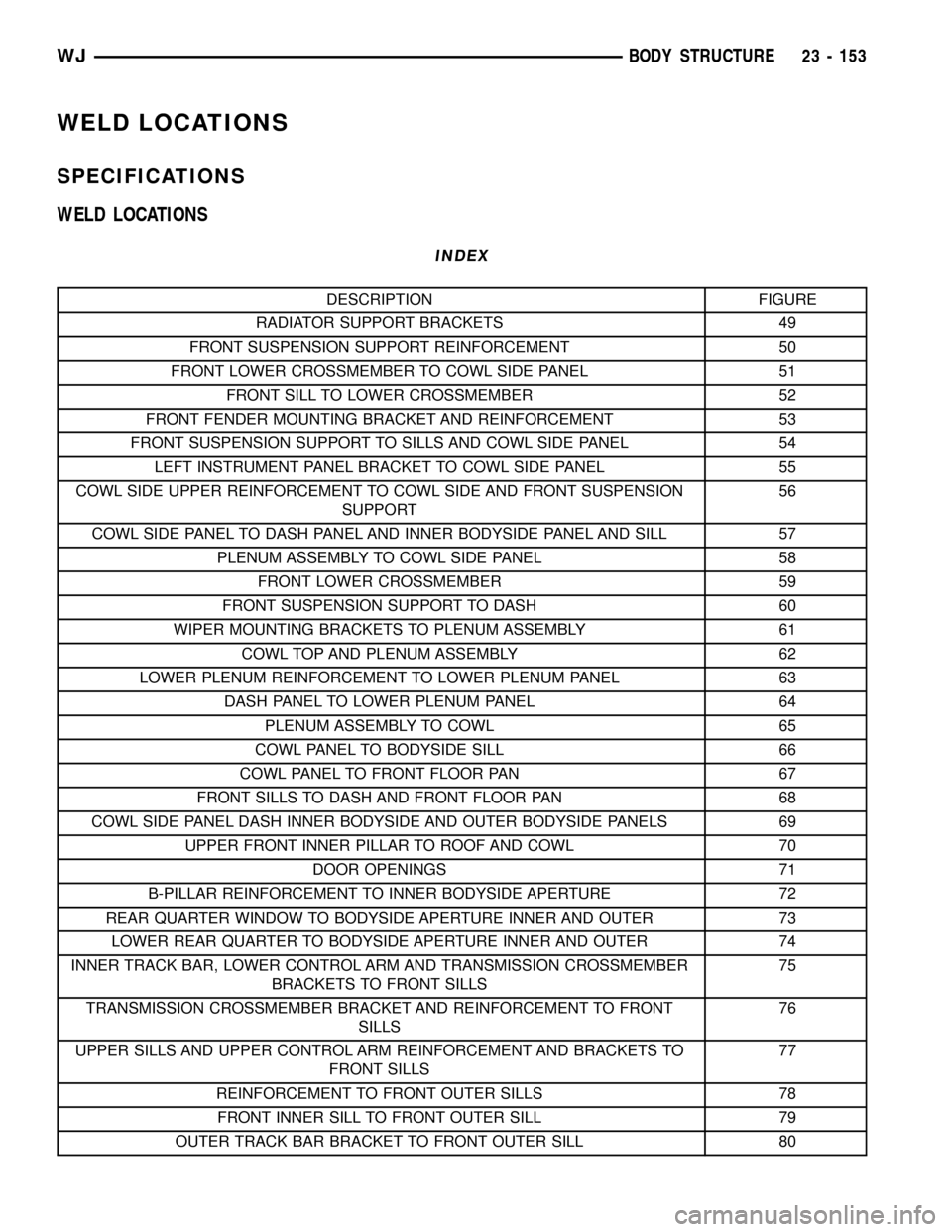

WELD LOCATIONS

SPECIFICATIONS

WELD LOCATIONS

INDEX

DESCRIPTION FIGURE

RADIATOR SUPPORT BRACKETS 49

FRONT SUSPENSION SUPPORT REINFORCEMENT 50

FRONT LOWER CROSSMEMBER TO COWL SIDE PANEL 51

FRONT SILL TO LOWER CROSSMEMBER 52

FRONT FENDER MOUNTING BRACKET AND REINFORCEMENT 53

FRONT SUSPENSION SUPPORT TO SILLS AND COWL SIDE PANEL 54

LEFT INSTRUMENT PANEL BRACKET TO COWL SIDE PANEL 55

COWL SIDE UPPER REINFORCEMENT TO COWL SIDE AND FRONT SUSPENSION

SUPPORT56

COWL SIDE PANEL TO DASH PANEL AND INNER BODYSIDE PANEL AND SILL 57

PLENUM ASSEMBLY TO COWL SIDE PANEL 58

FRONT LOWER CROSSMEMBER 59

FRONT SUSPENSION SUPPORT TO DASH 60

WIPER MOUNTING BRACKETS TO PLENUM ASSEMBLY 61

COWL TOP AND PLENUM ASSEMBLY 62

LOWER PLENUM REINFORCEMENT TO LOWER PLENUM PANEL 63

DASH PANEL TO LOWER PLENUM PANEL 64

PLENUM ASSEMBLY TO COWL 65

COWL PANEL TO BODYSIDE SILL 66

COWL PANEL TO FRONT FLOOR PAN 67

FRONT SILLS TO DASH AND FRONT FLOOR PAN 68

COWL SIDE PANEL DASH INNER BODYSIDE AND OUTER BODYSIDE PANELS 69

UPPER FRONT INNER PILLAR TO ROOF AND COWL 70

DOOR OPENINGS 71

B-PILLAR REINFORCEMENT TO INNER BODYSIDE APERTURE 72

REAR QUARTER WINDOW TO BODYSIDE APERTURE INNER AND OUTER 73

LOWER REAR QUARTER TO BODYSIDE APERTURE INNER AND OUTER 74

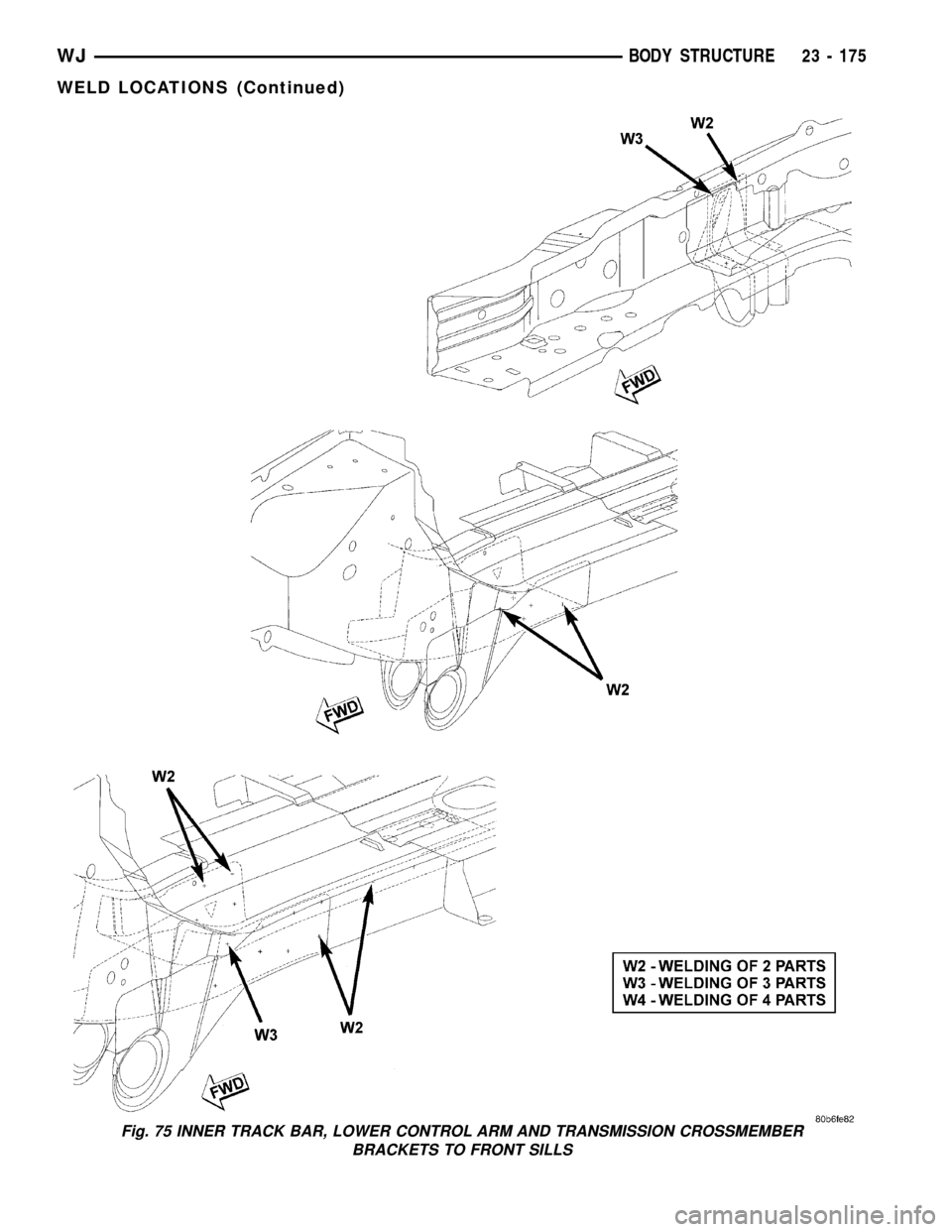

INNER TRACK BAR, LOWER CONTROL ARM AND TRANSMISSION CROSSMEMBER

BRACKETS TO FRONT SILLS75

TRANSMISSION CROSSMEMBER BRACKET AND REINFORCEMENT TO FRONT

SILLS76

UPPER SILLS AND UPPER CONTROL ARM REINFORCEMENT AND BRACKETS TO

FRONT SILLS77

REINFORCEMENT TO FRONT OUTER SILLS 78

FRONT INNER SILL TO FRONT OUTER SILL 79

OUTER TRACK BAR BRACKET TO FRONT OUTER SILL 80

WJBODY STRUCTURE 23 - 153

Page 2027 of 2199

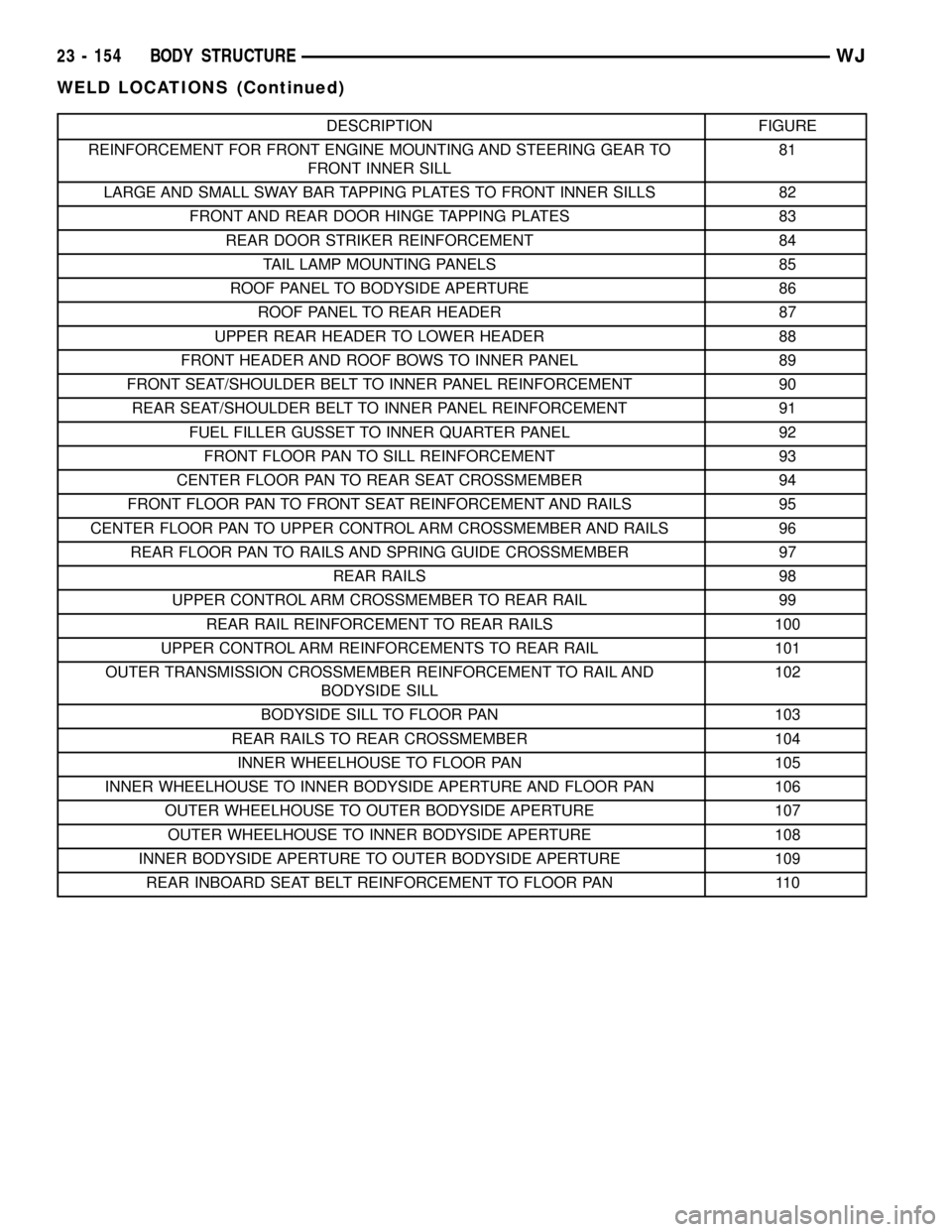

DESCRIPTION FIGURE

REINFORCEMENT FOR FRONT ENGINE MOUNTING AND STEERING GEAR TO

FRONT INNER SILL81

LARGE AND SMALL SWAY BAR TAPPING PLATES TO FRONT INNER SILLS 82

FRONT AND REAR DOOR HINGE TAPPING PLATES 83

REAR DOOR STRIKER REINFORCEMENT 84

TAIL LAMP MOUNTING PANELS 85

ROOF PANEL TO BODYSIDE APERTURE 86

ROOF PANEL TO REAR HEADER 87

UPPER REAR HEADER TO LOWER HEADER 88

FRONT HEADER AND ROOF BOWS TO INNER PANEL 89

FRONT SEAT/SHOULDER BELT TO INNER PANEL REINFORCEMENT 90

REAR SEAT/SHOULDER BELT TO INNER PANEL REINFORCEMENT 91

FUEL FILLER GUSSET TO INNER QUARTER PANEL 92

FRONT FLOOR PAN TO SILL REINFORCEMENT 93

CENTER FLOOR PAN TO REAR SEAT CROSSMEMBER 94

FRONT FLOOR PAN TO FRONT SEAT REINFORCEMENT AND RAILS 95

CENTER FLOOR PAN TO UPPER CONTROL ARM CROSSMEMBER AND RAILS 96

REAR FLOOR PAN TO RAILS AND SPRING GUIDE CROSSMEMBER 97

REAR RAILS 98

UPPER CONTROL ARM CROSSMEMBER TO REAR RAIL 99

REAR RAIL REINFORCEMENT TO REAR RAILS 100

UPPER CONTROL ARM REINFORCEMENTS TO REAR RAIL 101

OUTER TRANSMISSION CROSSMEMBER REINFORCEMENT TO RAIL AND

BODYSIDE SILL102

BODYSIDE SILL TO FLOOR PAN 103

REAR RAILS TO REAR CROSSMEMBER 104

INNER WHEELHOUSE TO FLOOR PAN 105

INNER WHEELHOUSE TO INNER BODYSIDE APERTURE AND FLOOR PAN 106

OUTER WHEELHOUSE TO OUTER BODYSIDE APERTURE 107

OUTER WHEELHOUSE TO INNER BODYSIDE APERTURE 108

INNER BODYSIDE APERTURE TO OUTER BODYSIDE APERTURE 109

REAR INBOARD SEAT BELT REINFORCEMENT TO FLOOR PAN 110

23 - 154 BODY STRUCTUREWJ

WELD LOCATIONS (Continued)

Page 2048 of 2199

Fig. 75 INNER TRACK BAR, LOWER CONTROL ARM AND TRANSMISSION CROSSMEMBER

BRACKETS TO FRONT SILLS

WJBODY STRUCTURE 23 - 175

WELD LOCATIONS (Continued)

Page 2079 of 2199

OPERATION

OPERATION - HEATER AND AIR CONDITIONER

Outside fresh air enters the vehicle through the

cowl top opening at the base of the windshield, and

passes through a plenum chamber to the HVAC sys-

tem blower housing. Air flow velocity can then be

adjusted with the blower motor speed selector switch

on the a/c heater control panel. The air intake open-

ings must be kept free of snow, ice, leaves, and other

obstructions for the HVAC system to receive a suffi-

cient volume of outside air.

It is also important to keep the air intake openings

clear of debris because leaf particles and other debris

that is small enough to pass through the cowl ple-

num screen can accumulate within the HVAC hous-

ing. The closed, warm, damp and dark environment

created within the HVAC housing is ideal for the

growth of certain molds, mildews and other fungi.

Any accumulation of decaying plant matter provides

an additional food source for fungal spores, which

enter the housing with the fresh air. Excess debris,

as well as objectionable odors created by decaying

plant matter and growing fungi can be discharged

into the passenger compartment during HVAC sys-

tem operation.

Both the manual and AZC heater and air condi-

tioner are blend-air type systems. In a blend-air sys-

tem, a blend door controls the amount of

unconditioned air (or cooled air from the evaporator)

that is allowed to flow through, or around, the heater

core. A temperature control knob on the a/c heater

control panel determines the discharge air tempera-

ture by energizing the blend door actuator, which

operates the blend door. This allows an almost imme-

diate control of the output air temperature of the sys-

tem. The AZC system will have separate blend doors

and temperature controls for each front seat occu-

pant.

The mode control knob on the a/c heater control

panel is used to direct the conditioned air to the

selected system outlets. On manual temperature con-

trol systems, the mode control knob switches engine

vacuum to control the mode doors, which are oper-

ated by vacuum actuators. On AZC systems, the

mode control knob switches electrical current to con-

trol the mode doors, which are operated by electronic

actuators.

The outside air intake can be shut off on manual

temperature control systems by selecting the Recircu-

lation Mode with the mode control knob. The outside

air intake can be shut off on Automatic Zone Control

(AZC) type system by pushing the Recirculation

Mode button. This will operate the recirculation door

that closes off the outside fresh air intake and recir-

culates the air that is already inside the vehicle.The air conditioner for all models is designed for

the use of non-CFC, R-134a refrigerant. The air con-

ditioning system has an evaporator to cool and dehu-

midify the incoming air prior to blending it with the

heated air. This air conditioning system uses a ther-

mal expansion valve to meter refrigerant flow to the

evaporator coil. To maintain minimum evaporator

temperature and prevent evaporator freezing, the

system utilizes an evaporator thermister probe with

the appropriate operating logic located in the body

control module (BCM).

OPERATION - REFRIGERANT SYSTEM SERVICE

PORT

The high pressure service port is located on the liq-

uid line near the receiver/drier. The low pressure ser-

vice port is located on the suction line near the

evaporator at the rear of the engine compartment.

Each of the service ports has a threaded plastic

protective cap installed over it from the factory. After

servicing the refrigerant system, always reinstall

both of the service port caps.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to provide

the passenger compartment with low temperature

and low specific humidity air. The evaporator, located

in the HVAC housing on the dash panel below the

instrument panel, is cooled to temperatures near the

freezing point. As warm damp air passes through the

cooled evaporator, the air transfers its heat to the

refrigerant in the evaporator and the moisture in the

air condenses on the evaporator fins. During periods

of high heat and humidity, an air conditioning sys-

tem will be more effective in the Recirculation Mode.

With the system in the Recirculation Mode, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, the air conditioning system performance

levels improve.

Humidity has an important bearing on the tempera-

ture of the air delivered to the interior of the vehicle. It

is important to understand the effect that humidity has

on the performance of the air conditioning system.

When humidity is high, the evaporator has to perform a

double duty. It must lower the air temperature, and it

must lower the temperature of the moisture in the air

that condenses on the evaporator fins. Condensing the

moisture in the air transfers heat energy into the evap-

orator fins and tubing. This reduces the amount of heat

the evaporator can absorb from the air. High humidity

greatly reduces the ability of the evaporator to lower

the temperature of the air.

24 - 2 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)

Page 2133 of 2199

(a) If the refrigerant system fails to reach the

specified vacuum, the system has a leak that must

be corrected. (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - DIAGNOSIS AND

TESTING - REFRIGERANT SYSTEM LEAKS)

(b) If the refrigerant system maintains the spec-

ified vacuum for five minutes, restart the vacuum

pump, open the suction and discharge valves and

evacuate the system for an additional ten minutes.

(3) Close all of the valves, and turn off the charg-

ing station vacuum pump.

(4) The refrigerant system is now ready to be

charged with R-134a refrigerant. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

STANDARD PROCEDURE - REFRIGERANT

SYSTEM CHARGE

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

After the refrigerant system has been tested for

leaks and evacuated, a refrigerant charge can be

injected into the system. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - SPECIFICA-

TIONS - CHARGE CAPACITY)

A R-134a refrigerant recovery/recycling/charging

station that meets SAE Standard J2210 must be

used to charge the refrigerant system with R-134a

refrigerant. Refer to the operating instructions sup-

plied by the equipment manufacturer for proper care

and use of this equipment.

PARTIAL CHARGE METHOD

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

The partial charge method is used to add a partial

charge to a refrigerant system that is low on refrig-

erant. To perform this procedure the evaporator inlet

and outlet tube temperatures are measured. The

temperature difference is measured with a tempera-

ture meter with one or two clamp-on thermocouple

probes. The difference between the evaporator inlet

and outlet tube temperatures will determine the

amount of refrigerant needed.Before adding a partial refrigerant charge, check

for refrigerant system leaks. (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING - DIAGNOSIS

AND TESTING - REFRIGERANT SYSTEM LEAKS)

If a leak is found, make the necessary repairs before

attempting a full or partial refrigerant charge.

(1) Attach a manifold gauge set to the refrigerant

system service ports.

(2) Attach the two clamp-on thermocouple probes

to the inlet and outlet tubes of the evaporator coil.

²If a single thermocouple probe is used, attach

the probe to the evaporator inlet tube just before the

collar of the refrigerant line connector fitting. The

probe must make contact with the bottom surface of

the evaporator inlet tube.

²If dual thermocouple probes are used, attach

probe 1 to the evaporator inlet tube, and probe 2 to

the evaporator outlet tube. Attach both probes to the

evaporator tubes just before the collar of the refrig-

erant line connector fittings. The probes must make

contact with the bottom surfaces of the evaporator

inlet and outlet tubes.

(3) Open all of the windows or doors of the passen-

ger compartment.

(4) Set the A/C button on the A/C Heater controls

to the on position, the temperature control knob in

the full cool position, select Recirculation Mode, and

place the blower motor switch in the highest speed

position.

(5) Start the engine and hold the engine idle speed

at 1,000 rpm. Allow the engine to warm up to normal

operating temperature.

(6) The compressor clutch may cycle, depending

upon ambient temperature, humidity, and the refrig-

erant system charge level.

(7) Hold the engine idle speed at 1,000 rpm.

(8) Allow three to five minutes for the refrigerant

system to stabilize, then record the temperatures of

the evaporator inlet and outlet tubes.

²If a single probe is used, record the temperature

of the evaporator inlet tube. Then remove the probe

from the inlet tube and attach it to the evaporator

outlet tube just before the collar of the refrigerant

line connector fitting. The probe must make contact

with the bottom surface of the evaporator outlet tube.

Allow the thermocouple and meter time to stabilize,

then record the temperature of the evaporator outlet

tube. Subtract the inlet tube temperature reading

from the outlet tube temperature reading.

²If dual probes are used, record the temperatures

of both the evaporator inlet and outlet tubes. Then

subtract the inlet tube temperature reading from the

outlet tube temperature reading.

(9) If the measured temperature differential is

higher than 22É C to 26É C (40É F to 47É F), add 0.4

kilograms (14 ounces) of refrigerant.

24 - 56 PLUMBINGWJ

PLUMBING (Continued)