cli JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1958 of 2199

INSTALLATION

(1) Position seat on floor pan.

(2) If equipped, connect power seat wire harness

connector.

(3) Install rear bolts attaching seat to floor pan.

Tighten bolts to 40 N´m (30 ft. lbs.) torque.

(4) If equipped, install cover on seat track.

(5) Move seat to full rearward position.

(6) Install front bolts attaching seat to floor pan.

Tighten bolts to 40 N´m (30 ft. lbs.) torque.

FRONT SEAT BACK

REMOVAL

(1) Move seat to full rearward position.

(2) Remove inboard bolt attaching seat back frame

to seat cushion frame.

(3) Move seat to full forward position.

(4) Move seat back to full recline position.

(5) Remove screws attaching seat side shield to

seat frame.

(6) Disconnect wire harness connector from

recliner motor, if equipped.

(7) From the underside of the seat, disconnect the

wire harness connector for the power lumber and/or

heated seat, if equipped.

(8) Remove outboard bolts attaching recliner to

seat cushion frame.

(9) Route the power lumber and/or heated seat

harness through the seat cushion cover, if equipped.

(10) Separate seat back from seat cushion.

INSTALLATION

(1) Position seat back on seat cushion.

(2) Route the power lumber and heater harness

through the seat cushion cover, if equipped.

(3) Install recliner bolts attaching seat back frame

to seat cushion frame. Tighten bolts to 28 N´m (20 ft.

lbs.) torque.

(4) Install the inboard bolt attaching seat back

frame to seat cushion frame. Tighten bolt to 47N´m

(35 ft.lbs.).

(5) Connect wire harness connector to recliner

motor and/or heated seat, if equipped.

(6) From the underside of the seat, connect the

power lumber and/or heated seat wire harness con-

nector to the seat harness, if equipped.

(7) Install screws attaching seat side shield to seat

frame.

FRONT SEAT BACK COVER

REMOVAL

(1) Remove head restraint (Refer to 23 - BODY/

SEATS/FRONT HEADREST - REMOVAL).

(2) Using a trim stick, carefully pry head restraint

release button caps from the top of seat back.

(3) Remove seat back (Refer to 23 - BODY/SEATS/

FRONT SEAT BACK - REMOVAL).

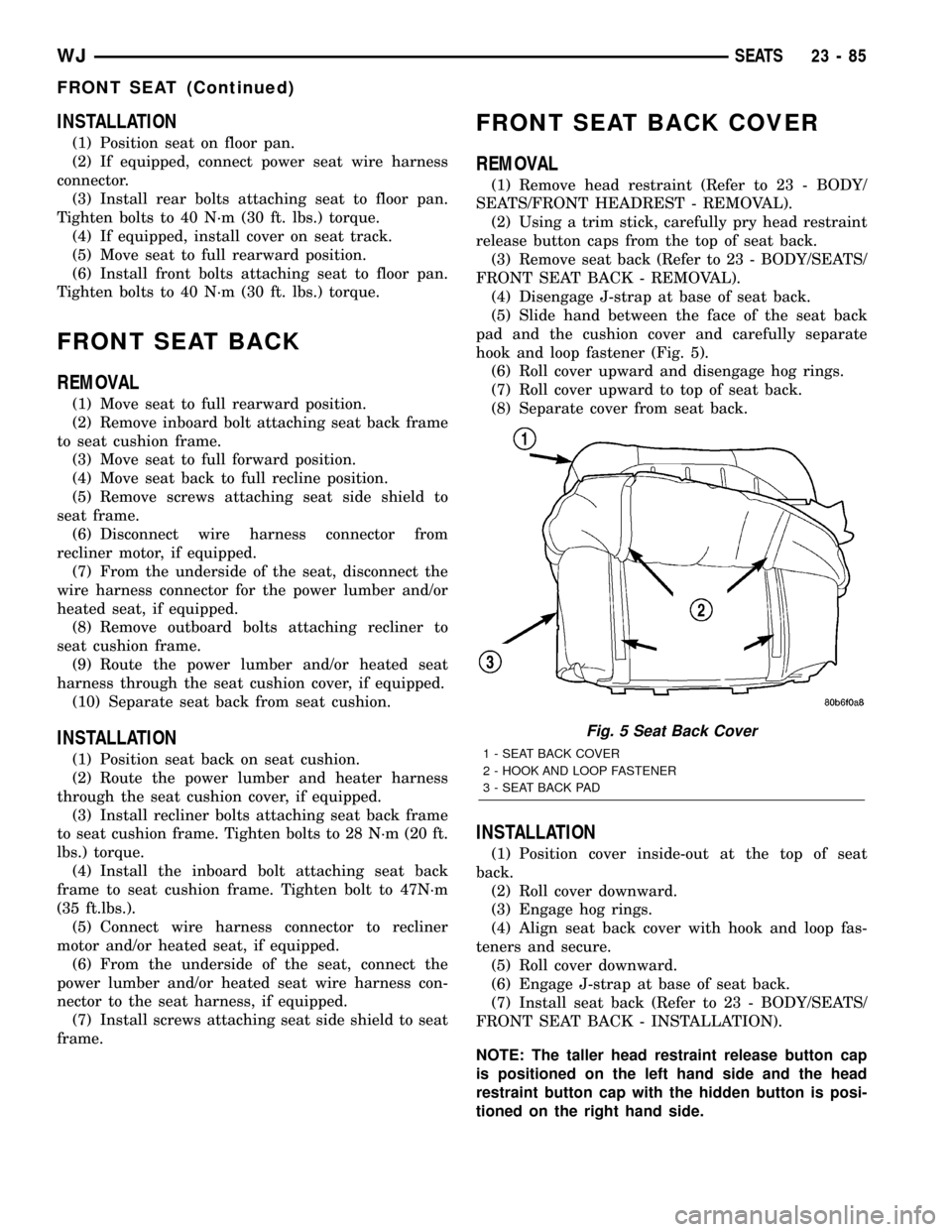

(4) Disengage J-strap at base of seat back.

(5) Slide hand between the face of the seat back

pad and the cushion cover and carefully separate

hook and loop fastener (Fig. 5).

(6) Roll cover upward and disengage hog rings.

(7) Roll cover upward to top of seat back.

(8) Separate cover from seat back.

INSTALLATION

(1) Position cover inside-out at the top of seat

back.

(2) Roll cover downward.

(3) Engage hog rings.

(4) Align seat back cover with hook and loop fas-

teners and secure.

(5) Roll cover downward.

(6) Engage J-strap at base of seat back.

(7) Install seat back (Refer to 23 - BODY/SEATS/

FRONT SEAT BACK - INSTALLATION).

NOTE: The taller head restraint release button cap

is positioned on the left hand side and the head

restraint button cap with the hidden button is posi-

tioned on the right hand side.

Fig. 5 Seat Back Cover

1 - SEAT BACK COVER

2 - HOOK AND LOOP FASTENER

3 - SEAT BACK PAD

WJSEATS 23 - 85

FRONT SEAT (Continued)

Page 1959 of 2199

(8) Position head restraint release button caps on

head restraint sleeves and press to secure.

(9) Install head restraint (Refer to 23 - BODY/

SEATS/FRONT HEADREST - INSTALLATION).

FRONT SEAT CUSHION/COVER

REMOVAL

(1) Remove seat from vehicle (Refer to 23 - BODY/

SEATS/FRONT SEAT - REMOVAL).

(2) Remove seat back (Refer to 23 - BODY/SEATS/

FRONT SEAT BACK - REMOVAL).

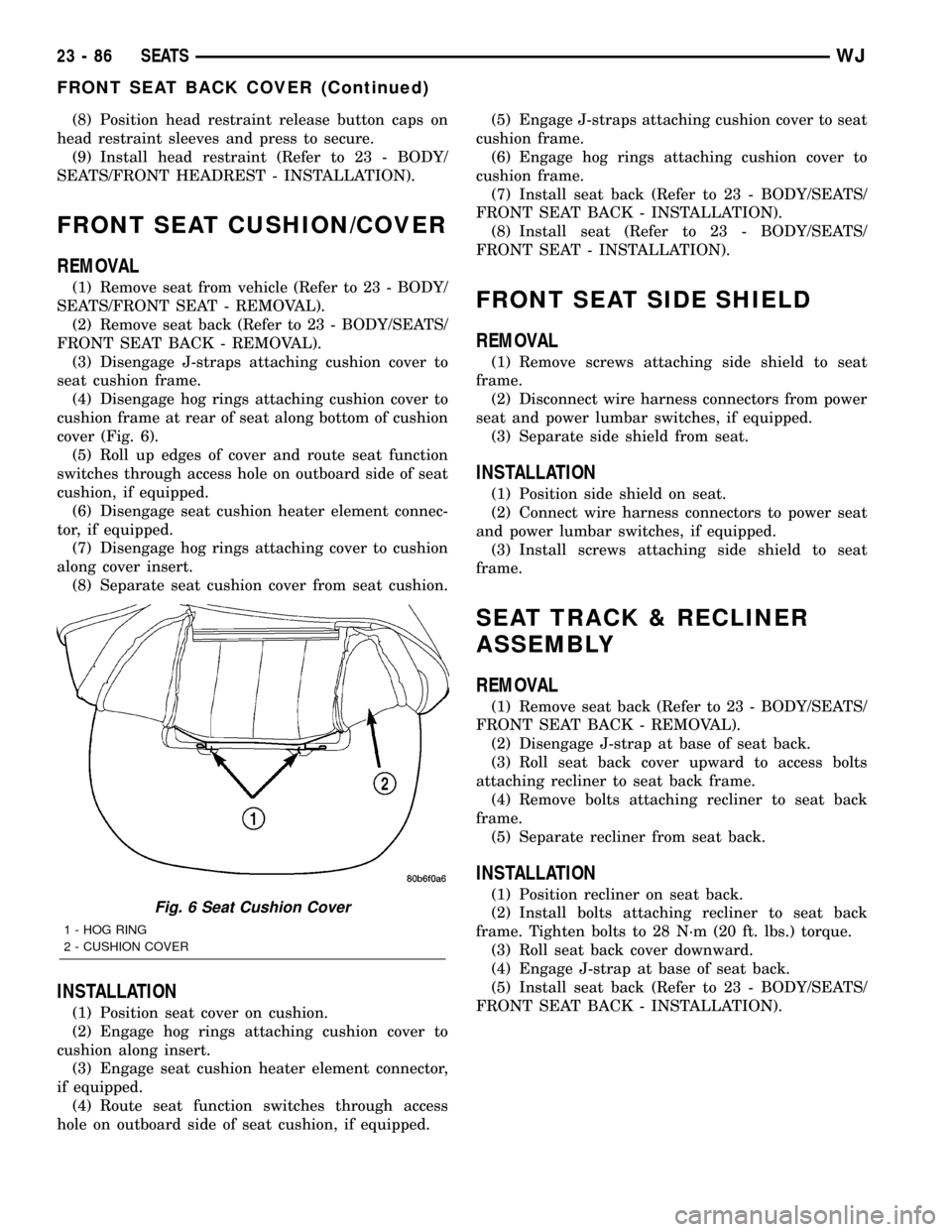

(3) Disengage J-straps attaching cushion cover to

seat cushion frame.

(4) Disengage hog rings attaching cushion cover to

cushion frame at rear of seat along bottom of cushion

cover (Fig. 6).

(5) Roll up edges of cover and route seat function

switches through access hole on outboard side of seat

cushion, if equipped.

(6) Disengage seat cushion heater element connec-

tor, if equipped.

(7) Disengage hog rings attaching cover to cushion

along cover insert.

(8) Separate seat cushion cover from seat cushion.

INSTALLATION

(1) Position seat cover on cushion.

(2) Engage hog rings attaching cushion cover to

cushion along insert.

(3) Engage seat cushion heater element connector,

if equipped.

(4) Route seat function switches through access

hole on outboard side of seat cushion, if equipped.(5) Engage J-straps attaching cushion cover to seat

cushion frame.

(6) Engage hog rings attaching cushion cover to

cushion frame.

(7) Install seat back (Refer to 23 - BODY/SEATS/

FRONT SEAT BACK - INSTALLATION).

(8) Install seat (Refer to 23 - BODY/SEATS/

FRONT SEAT - INSTALLATION).

FRONT SEAT SIDE SHIELD

REMOVAL

(1) Remove screws attaching side shield to seat

frame.

(2) Disconnect wire harness connectors from power

seat and power lumbar switches, if equipped.

(3) Separate side shield from seat.

INSTALLATION

(1) Position side shield on seat.

(2) Connect wire harness connectors to power seat

and power lumbar switches, if equipped.

(3) Install screws attaching side shield to seat

frame.

SEAT TRACK & RECLINER

ASSEMBLY

REMOVAL

(1) Remove seat back (Refer to 23 - BODY/SEATS/

FRONT SEAT BACK - REMOVAL).

(2) Disengage J-strap at base of seat back.

(3) Roll seat back cover upward to access bolts

attaching recliner to seat back frame.

(4) Remove bolts attaching recliner to seat back

frame.

(5) Separate recliner from seat back.

INSTALLATION

(1) Position recliner on seat back.

(2) Install bolts attaching recliner to seat back

frame. Tighten bolts to 28 N´m (20 ft. lbs.) torque.

(3) Roll seat back cover downward.

(4) Engage J-strap at base of seat back.

(5) Install seat back (Refer to 23 - BODY/SEATS/

FRONT SEAT BACK - INSTALLATION).Fig. 6 Seat Cushion Cover

1 - HOG RING

2 - CUSHION COVER

23 - 86 SEATSWJ

FRONT SEAT BACK COVER (Continued)

Page 1960 of 2199

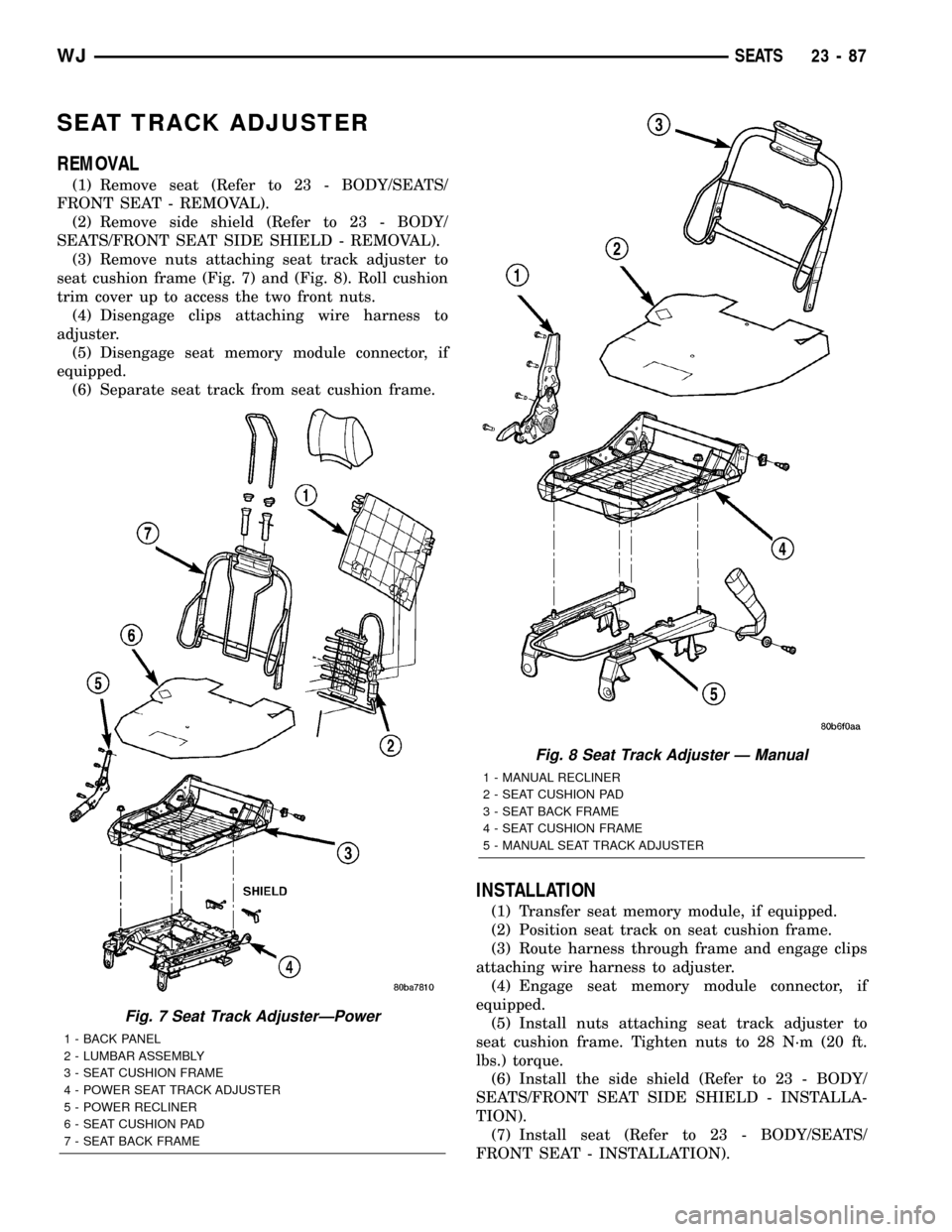

SEAT TRACK ADJUSTER

REMOVAL

(1) Remove seat (Refer to 23 - BODY/SEATS/

FRONT SEAT - REMOVAL).

(2) Remove side shield (Refer to 23 - BODY/

SEATS/FRONT SEAT SIDE SHIELD - REMOVAL).

(3) Remove nuts attaching seat track adjuster to

seat cushion frame (Fig. 7) and (Fig. 8). Roll cushion

trim cover up to access the two front nuts.

(4) Disengage clips attaching wire harness to

adjuster.

(5) Disengage seat memory module connector, if

equipped.

(6) Separate seat track from seat cushion frame.

INSTALLATION

(1) Transfer seat memory module, if equipped.

(2) Position seat track on seat cushion frame.

(3) Route harness through frame and engage clips

attaching wire harness to adjuster.

(4) Engage seat memory module connector, if

equipped.

(5) Install nuts attaching seat track adjuster to

seat cushion frame. Tighten nuts to 28 N´m (20 ft.

lbs.) torque.

(6) Install the side shield (Refer to 23 - BODY/

SEATS/FRONT SEAT SIDE SHIELD - INSTALLA-

TION).

(7) Install seat (Refer to 23 - BODY/SEATS/

FRONT SEAT - INSTALLATION).

Fig. 7 Seat Track AdjusterÐPower

1 - BACK PANEL

2 - LUMBAR ASSEMBLY

3 - SEAT CUSHION FRAME

4 - POWER SEAT TRACK ADJUSTER

5 - POWER RECLINER

6 - SEAT CUSHION PAD

7 - SEAT BACK FRAME

Fig. 8 Seat Track Adjuster Ð Manual

1 - MANUAL RECLINER

2 - SEAT CUSHION PAD

3 - SEAT BACK FRAME

4 - SEAT CUSHION FRAME

5 - MANUAL SEAT TRACK ADJUSTER

WJSEATS 23 - 87

Page 1967 of 2199

(3) Apply fence primer around edge of fence. Allow

at least eighteen minutes drying time.

(4) Apply a 10 mm (0.4 in.) bead of urethane

around window vinyl border location.

(5)

Position glass into window opening and lock clips

into place (Fig. 3).

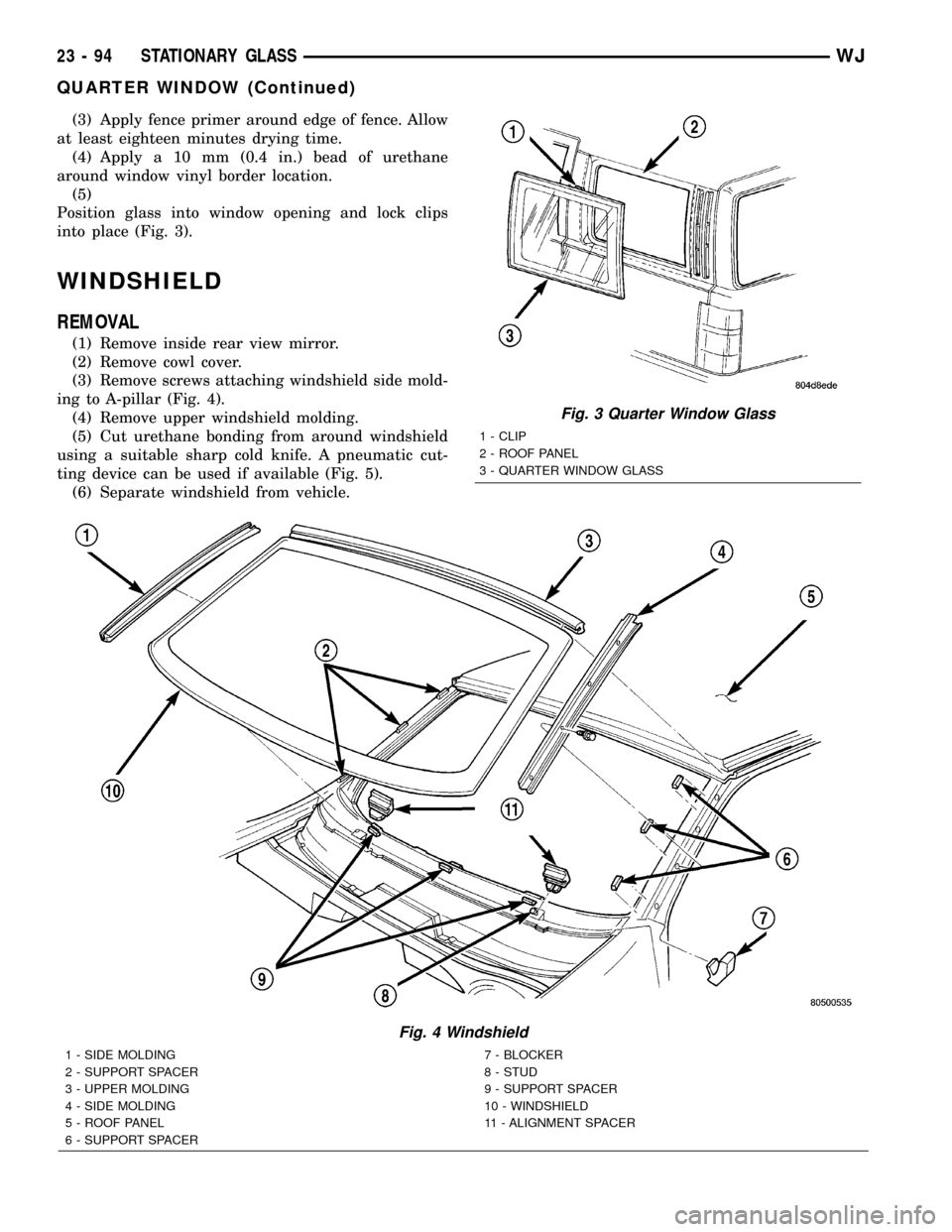

WINDSHIELD

REMOVAL

(1) Remove inside rear view mirror.

(2) Remove cowl cover.

(3) Remove screws attaching windshield side mold-

ing to A-pillar (Fig. 4).

(4) Remove upper windshield molding.

(5) Cut urethane bonding from around windshield

using a suitable sharp cold knife. A pneumatic cut-

ting device can be used if available (Fig. 5).

(6) Separate windshield from vehicle.

Fig. 3 Quarter Window Glass

1 - CLIP

2 - ROOF PANEL

3 - QUARTER WINDOW GLASS

Fig. 4 Windshield

1 - SIDE MOLDING

2 - SUPPORT SPACER

3 - UPPER MOLDING

4 - SIDE MOLDING

5 - ROOF PANEL

6 - SUPPORT SPACER7 - BLOCKER

8 - STUD

9 - SUPPORT SPACER

10 - WINDSHIELD

11 - ALIGNMENT SPACER

23 - 94 STATIONARY GLASSWJ

QUARTER WINDOW (Continued)

Page 1977 of 2199

(6) Push sunshade down until the sunshade clears

the glass then move sunshade rearward behind the

glass panel.

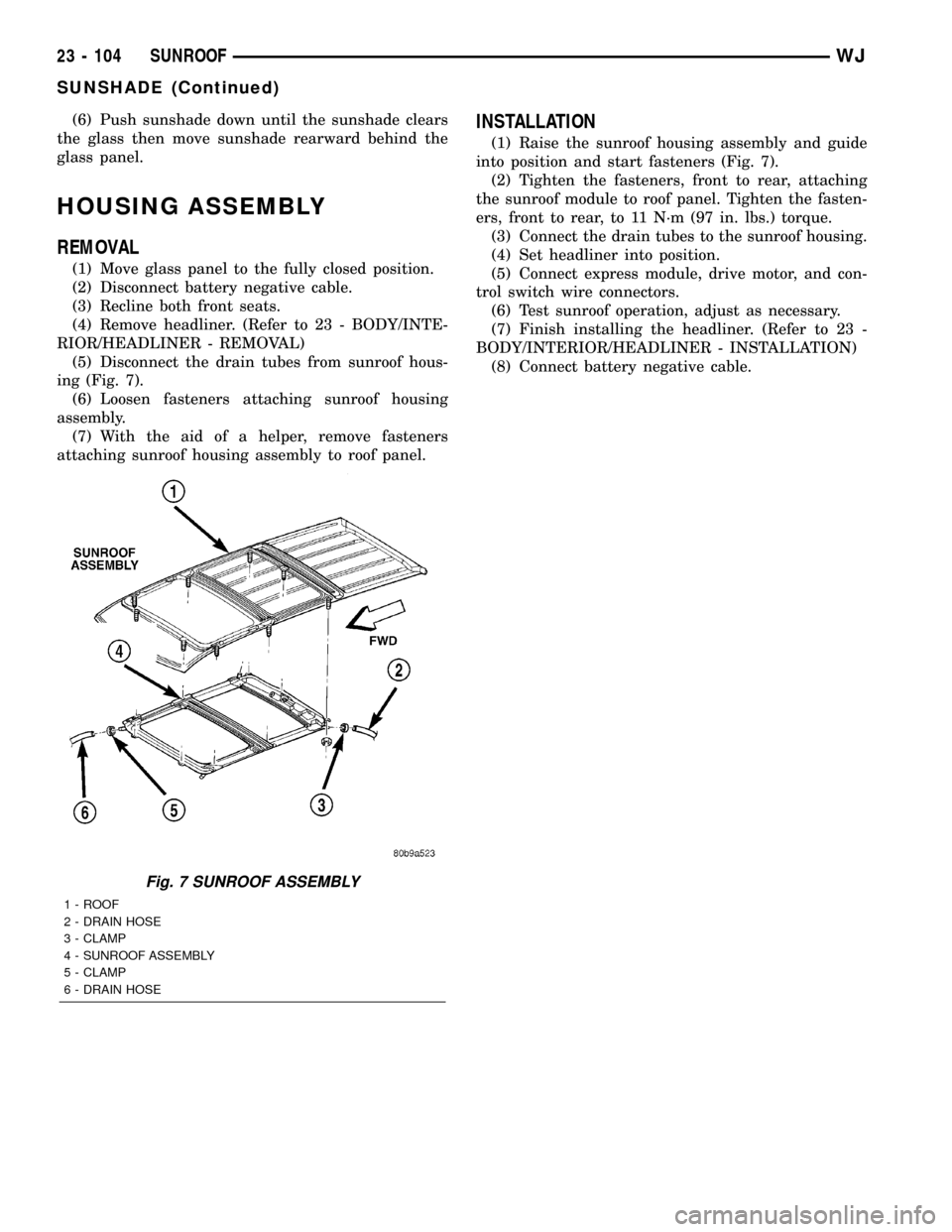

HOUSING ASSEMBLY

REMOVAL

(1) Move glass panel to the fully closed position.

(2) Disconnect battery negative cable.

(3) Recline both front seats.

(4) Remove headliner. (Refer to 23 - BODY/INTE-

RIOR/HEADLINER - REMOVAL)

(5) Disconnect the drain tubes from sunroof hous-

ing (Fig. 7).

(6) Loosen fasteners attaching sunroof housing

assembly.

(7) With the aid of a helper, remove fasteners

attaching sunroof housing assembly to roof panel.

INSTALLATION

(1) Raise the sunroof housing assembly and guide

into position and start fasteners (Fig. 7).

(2) Tighten the fasteners, front to rear, attaching

the sunroof module to roof panel. Tighten the fasten-

ers, front to rear, to 11 N´m (97 in. lbs.) torque.

(3) Connect the drain tubes to the sunroof housing.

(4) Set headliner into position.

(5) Connect express module, drive motor, and con-

trol switch wire connectors.

(6) Test sunroof operation, adjust as necessary.

(7) Finish installing the headliner. (Refer to 23 -

BODY/INTERIOR/HEADLINER - INSTALLATION)

(8) Connect battery negative cable.

Fig. 7 SUNROOF ASSEMBLY

1 - ROOF

2 - DRAIN HOSE

3 - CLAMP

4 - SUNROOF ASSEMBLY

5 - CLAMP

6 - DRAIN HOSE

23 - 104 SUNROOFWJ

SUNSHADE (Continued)

Page 2081 of 2199

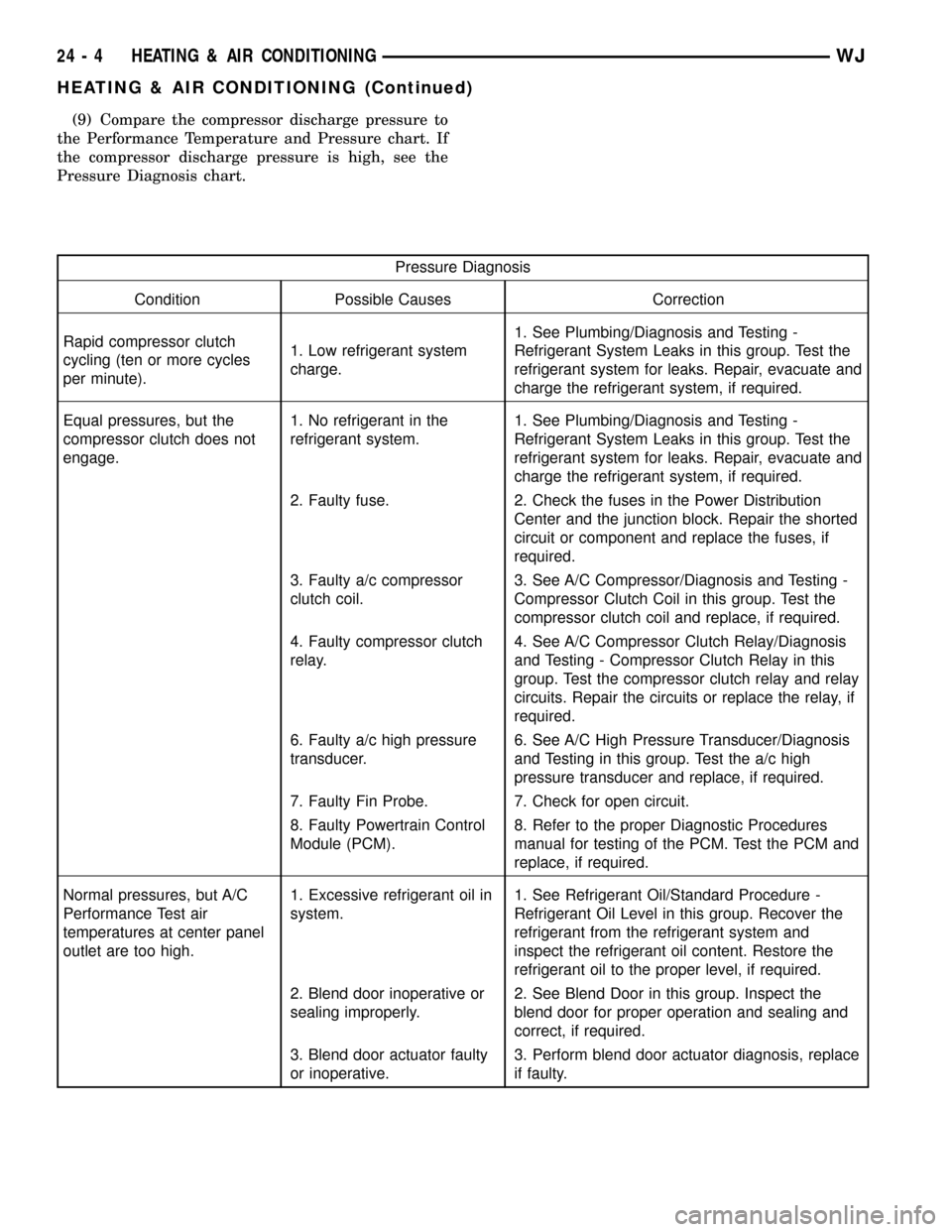

(9) Compare the compressor discharge pressure to

the Performance Temperature and Pressure chart. If

the compressor discharge pressure is high, see the

Pressure Diagnosis chart.

Pressure Diagnosis

Condition Possible Causes Correction

Rapid compressor clutch

cycling (ten or more cycles

per minute).1. Low refrigerant system

charge.1. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

Equal pressures, but the

compressor clutch does not

engage.1. No refrigerant in the

refrigerant system.1. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

2. Faulty fuse. 2. Check the fuses in the Power Distribution

Center and the junction block. Repair the shorted

circuit or component and replace the fuses, if

required.

3. Faulty a/c compressor

clutch coil.3. See A/C Compressor/Diagnosis and Testing -

Compressor Clutch Coil in this group. Test the

compressor clutch coil and replace, if required.

4. Faulty compressor clutch

relay.4. See A/C Compressor Clutch Relay/Diagnosis

and Testing - Compressor Clutch Relay in this

group. Test the compressor clutch relay and relay

circuits. Repair the circuits or replace the relay, if

required.

6. Faulty a/c high pressure

transducer.6. See A/C High Pressure Transducer/Diagnosis

and Testing in this group. Test the a/c high

pressure transducer and replace, if required.

7. Faulty Fin Probe. 7. Check for open circuit.

8. Faulty Powertrain Control

Module (PCM).8. Refer to the proper Diagnostic Procedures

manual for testing of the PCM. Test the PCM and

replace, if required.

Normal pressures, but A/C

Performance Test air

temperatures at center panel

outlet are too high.1. Excessive refrigerant oil in

system.1. See Refrigerant Oil/Standard Procedure -

Refrigerant Oil Level in this group. Recover the

refrigerant from the refrigerant system and

inspect the refrigerant oil content. Restore the

refrigerant oil to the proper level, if required.

2. Blend door inoperative or

sealing improperly.2. See Blend Door in this group. Inspect the

blend door for proper operation and sealing and

correct, if required.

3. Blend door actuator faulty

or inoperative.3. Perform blend door actuator diagnosis, replace

if faulty.

24 - 4 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)

Page 2090 of 2199

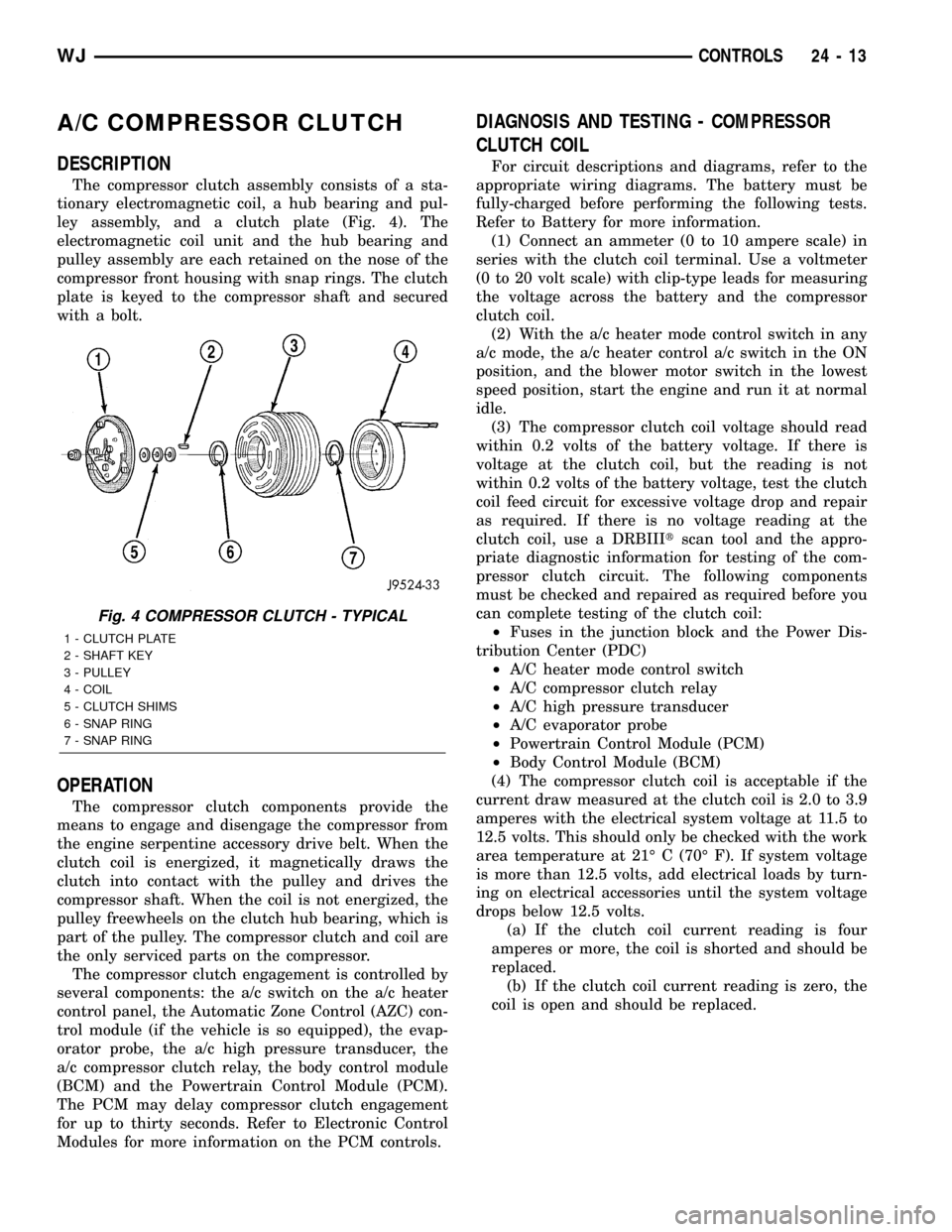

A/C COMPRESSOR CLUTCH

DESCRIPTION

The compressor clutch assembly consists of a sta-

tionary electromagnetic coil, a hub bearing and pul-

ley assembly, and a clutch plate (Fig. 4). The

electromagnetic coil unit and the hub bearing and

pulley assembly are each retained on the nose of the

compressor front housing with snap rings. The clutch

plate is keyed to the compressor shaft and secured

with a bolt.

OPERATION

The compressor clutch components provide the

means to engage and disengage the compressor from

the engine serpentine accessory drive belt. When the

clutch coil is energized, it magnetically draws the

clutch into contact with the pulley and drives the

compressor shaft. When the coil is not energized, the

pulley freewheels on the clutch hub bearing, which is

part of the pulley. The compressor clutch and coil are

the only serviced parts on the compressor.

The compressor clutch engagement is controlled by

several components: the a/c switch on the a/c heater

control panel, the Automatic Zone Control (AZC) con-

trol module (if the vehicle is so equipped), the evap-

orator probe, the a/c high pressure transducer, the

a/c compressor clutch relay, the body control module

(BCM) and the Powertrain Control Module (PCM).

The PCM may delay compressor clutch engagement

for up to thirty seconds. Refer to Electronic Control

Modules for more information on the PCM controls.

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH COIL

For circuit descriptions and diagrams, refer to the

appropriate wiring diagrams. The battery must be

fully-charged before performing the following tests.

Refer to Battery for more information.

(1) Connect an ammeter (0 to 10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0 to 20 volt scale) with clip-type leads for measuring

the voltage across the battery and the compressor

clutch coil.

(2) With the a/c heater mode control switch in any

a/c mode, the a/c heater control a/c switch in the ON

position, and the blower motor switch in the lowest

speed position, start the engine and run it at normal

idle.

(3) The compressor clutch coil voltage should read

within 0.2 volts of the battery voltage. If there is

voltage at the clutch coil, but the reading is not

within 0.2 volts of the battery voltage, test the clutch

coil feed circuit for excessive voltage drop and repair

as required. If there is no voltage reading at the

clutch coil, use a DRBIIItscan tool and the appro-

priate diagnostic information for testing of the com-

pressor clutch circuit. The following components

must be checked and repaired as required before you

can complete testing of the clutch coil:

²Fuses in the junction block and the Power Dis-

tribution Center (PDC)

²A/C heater mode control switch

²A/C compressor clutch relay

²A/C high pressure transducer

²A/C evaporator probe

²Powertrain Control Module (PCM)

²Body Control Module (BCM)

(4) The compressor clutch coil is acceptable if the

current draw measured at the clutch coil is 2.0 to 3.9

amperes with the electrical system voltage at 11.5 to

12.5 volts. This should only be checked with the work

area temperature at 21É C (70É F). If system voltage

is more than 12.5 volts, add electrical loads by turn-

ing on electrical accessories until the system voltage

drops below 12.5 volts.

(a) If the clutch coil current reading is four

amperes or more, the coil is shorted and should be

replaced.

(b) If the clutch coil current reading is zero, the

coil is open and should be replaced.

Fig. 4 COMPRESSOR CLUTCH - TYPICAL

1 - CLUTCH PLATE

2 - SHAFT KEY

3 - PULLEY

4 - COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

WJCONTROLS 24 - 13

Page 2092 of 2199

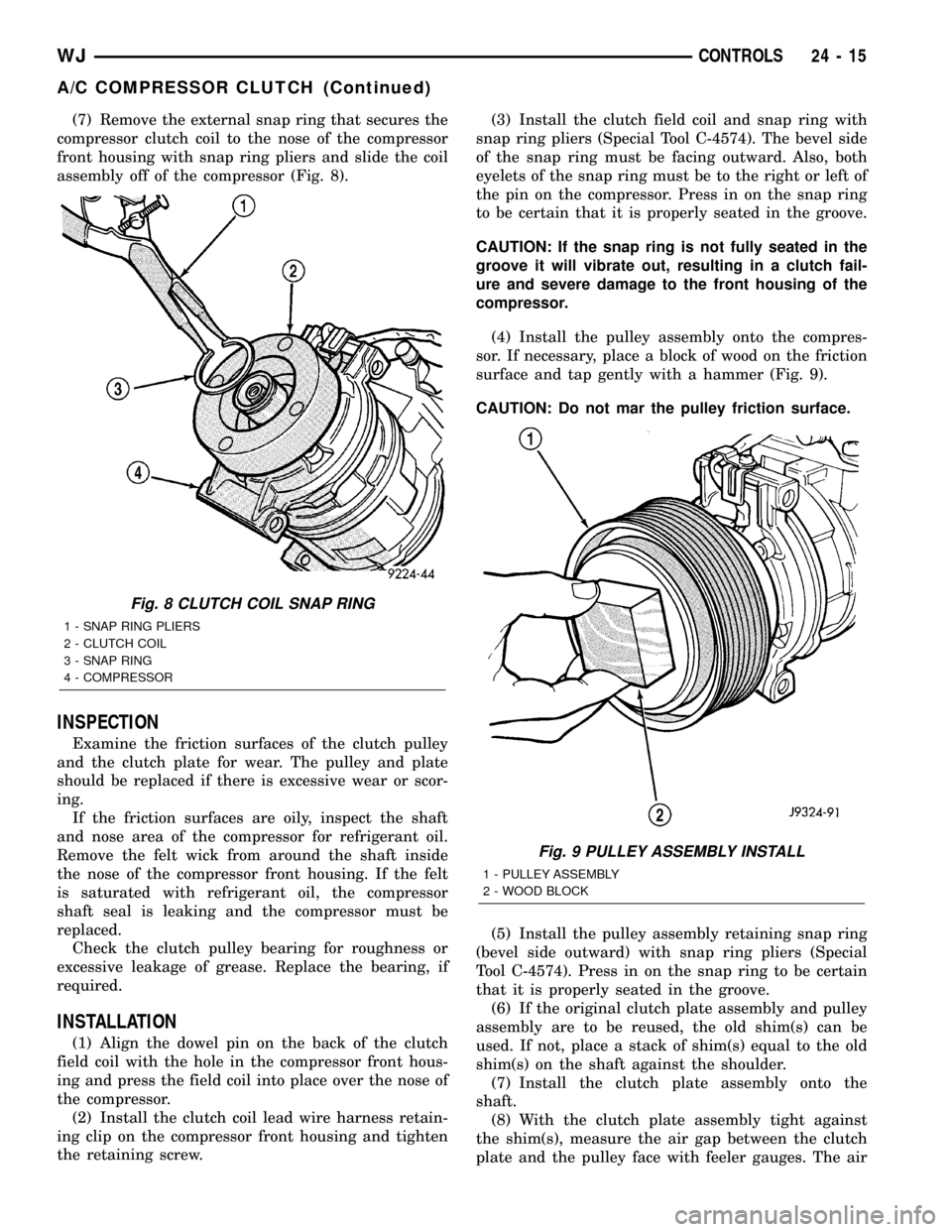

(7) Remove the external snap ring that secures the

compressor clutch coil to the nose of the compressor

front housing with snap ring pliers and slide the coil

assembly off of the compressor (Fig. 8).

INSPECTION

Examine the friction surfaces of the clutch pulley

and the clutch plate for wear. The pulley and plate

should be replaced if there is excessive wear or scor-

ing.

If the friction surfaces are oily, inspect the shaft

and nose area of the compressor for refrigerant oil.

Remove the felt wick from around the shaft inside

the nose of the compressor front housing. If the felt

is saturated with refrigerant oil, the compressor

shaft seal is leaking and the compressor must be

replaced.

Check the clutch pulley bearing for roughness or

excessive leakage of grease. Replace the bearing, if

required.

INSTALLATION

(1) Align the dowel pin on the back of the clutch

field coil with the hole in the compressor front hous-

ing and press the field coil into place over the nose of

the compressor.

(2) Install the clutch coil lead wire harness retain-

ing clip on the compressor front housing and tighten

the retaining screw.(3) Install the clutch field coil and snap ring with

snap ring pliers (Special Tool C-4574). The bevel side

of the snap ring must be facing outward. Also, both

eyelets of the snap ring must be to the right or left of

the pin on the compressor. Press in on the snap ring

to be certain that it is properly seated in the groove.

CAUTION: If the snap ring is not fully seated in the

groove it will vibrate out, resulting in a clutch fail-

ure and severe damage to the front housing of the

compressor.

(4) Install the pulley assembly onto the compres-

sor. If necessary, place a block of wood on the friction

surface and tap gently with a hammer (Fig. 9).

CAUTION: Do not mar the pulley friction surface.

(5) Install the pulley assembly retaining snap ring

(bevel side outward) with snap ring pliers (Special

Tool C-4574). Press in on the snap ring to be certain

that it is properly seated in the groove.

(6) If the original clutch plate assembly and pulley

assembly are to be reused, the old shim(s) can be

used. If not, place a stack of shim(s) equal to the old

shim(s) on the shaft against the shoulder.

(7) Install the clutch plate assembly onto the

shaft.

(8) With the clutch plate assembly tight against

the shim(s), measure the air gap between the clutch

plate and the pulley face with feeler gauges. The air

Fig. 8 CLUTCH COIL SNAP RING

1 - SNAP RING PLIERS

2 - CLUTCH COIL

3 - SNAP RING

4 - COMPRESSOR

Fig. 9 PULLEY ASSEMBLY INSTALL

1 - PULLEY ASSEMBLY

2 - WOOD BLOCK

WJCONTROLS 24 - 15

A/C COMPRESSOR CLUTCH (Continued)

Page 2094 of 2199

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

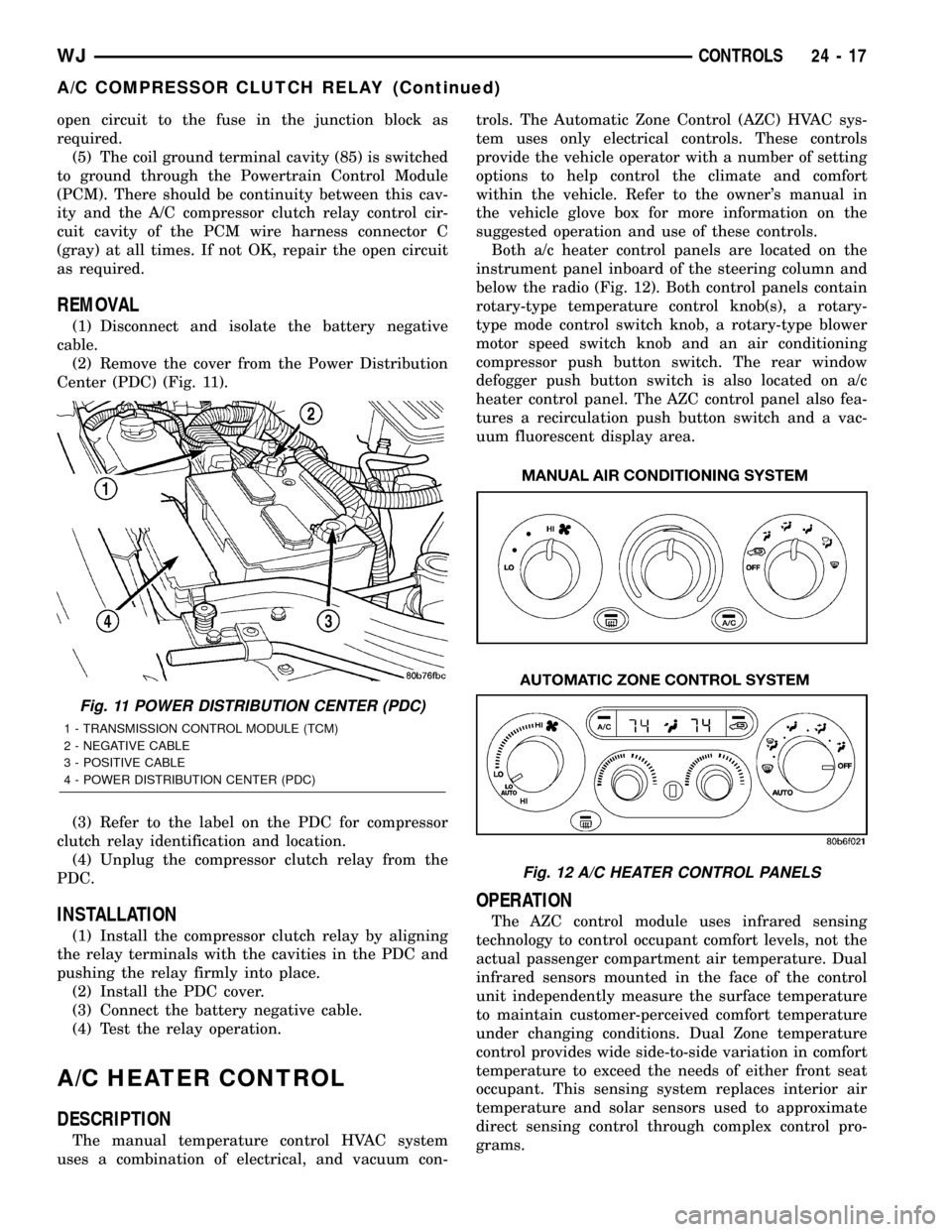

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 11).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

A/C HEATER CONTROL

DESCRIPTION

The manual temperature control HVAC system

uses a combination of electrical, and vacuum con-trols. The Automatic Zone Control (AZC) HVAC sys-

tem uses only electrical controls. These controls

provide the vehicle operator with a number of setting

options to help control the climate and comfort

within the vehicle. Refer to the owner's manual in

the vehicle glove box for more information on the

suggested operation and use of these controls.

Both a/c heater control panels are located on the

instrument panel inboard of the steering column and

below the radio (Fig. 12). Both control panels contain

rotary-type temperature control knob(s), a rotary-

type mode control switch knob, a rotary-type blower

motor speed switch knob and an air conditioning

compressor push button switch. The rear window

defogger push button switch is also located on a/c

heater control panel. The AZC control panel also fea-

tures a recirculation push button switch and a vac-

uum fluorescent display area.

OPERATION

The AZC control module uses infrared sensing

technology to control occupant comfort levels, not the

actual passenger compartment air temperature. Dual

infrared sensors mounted in the face of the control

unit independently measure the surface temperature

to maintain customer-perceived comfort temperature

under changing conditions. Dual Zone temperature

control provides wide side-to-side variation in comfort

temperature to exceed the needs of either front seat

occupant. This sensing system replaces interior air

temperature and solar sensors used to approximate

direct sensing control through complex control pro-

grams.

Fig. 11 POWER DISTRIBUTION CENTER (PDC)

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - NEGATIVE CABLE

3 - POSITIVE CABLE

4 - POWER DISTRIBUTION CENTER (PDC)

Fig. 12 A/C HEATER CONTROL PANELS

WJCONTROLS 24 - 17

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 2112 of 2199

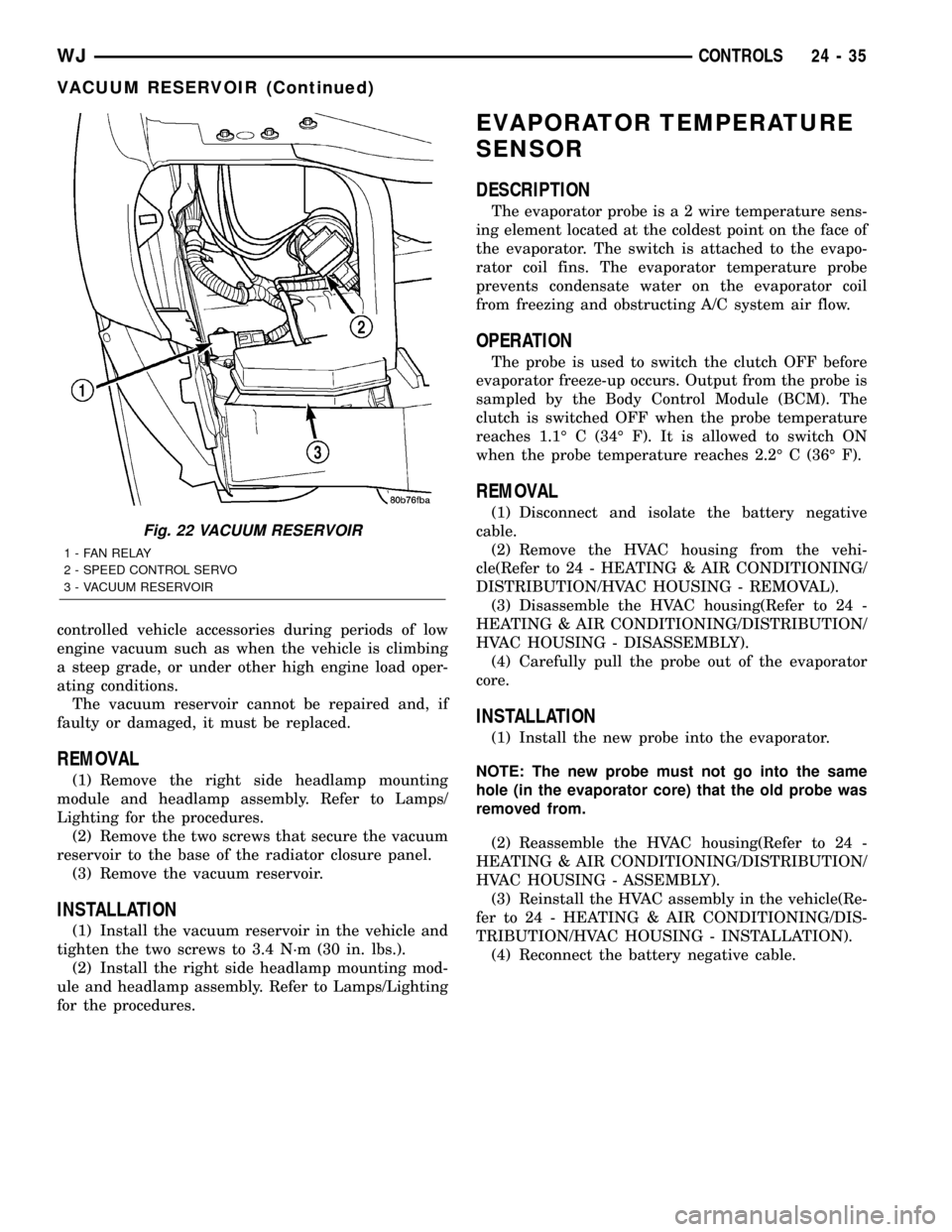

controlled vehicle accessories during periods of low

engine vacuum such as when the vehicle is climbing

a steep grade, or under other high engine load oper-

ating conditions.

The vacuum reservoir cannot be repaired and, if

faulty or damaged, it must be replaced.

REMOVAL

(1) Remove the right side headlamp mounting

module and headlamp assembly. Refer to Lamps/

Lighting for the procedures.

(2) Remove the two screws that secure the vacuum

reservoir to the base of the radiator closure panel.

(3) Remove the vacuum reservoir.

INSTALLATION

(1) Install the vacuum reservoir in the vehicle and

tighten the two screws to 3.4 N´m (30 in. lbs.).

(2) Install the right side headlamp mounting mod-

ule and headlamp assembly. Refer to Lamps/Lighting

for the procedures.

EVAPORATOR TEMPERATURE

SENSOR

DESCRIPTION

The evaporator probe is a 2 wire temperature sens-

ing element located at the coldest point on the face of

the evaporator. The switch is attached to the evapo-

rator coil fins. The evaporator temperature probe

prevents condensate water on the evaporator coil

from freezing and obstructing A/C system air flow.

OPERATION

The probe is used to switch the clutch OFF before

evaporator freeze-up occurs. Output from the probe is

sampled by the Body Control Module (BCM). The

clutch is switched OFF when the probe temperature

reaches 1.1É C (34É F). It is allowed to switch ON

when the probe temperature reaches 2.2É C (36É F).

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the HVAC housing from the vehi-

cle(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL).

(3) Disassemble the HVAC housing(Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - DISASSEMBLY).

(4) Carefully pull the probe out of the evaporator

core.

INSTALLATION

(1) Install the new probe into the evaporator.

NOTE: The new probe must not go into the same

hole (in the evaporator core) that the old probe was

removed from.

(2) Reassemble the HVAC housing(Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - ASSEMBLY).

(3) Reinstall the HVAC assembly in the vehicle(Re-

fer to 24 - HEATING & AIR CONDITIONING/DIS-

TRIBUTION/HVAC HOUSING - INSTALLATION).

(4) Reconnect the battery negative cable.

Fig. 22 VACUUM RESERVOIR

1 - FAN RELAY

2 - SPEED CONTROL SERVO

3 - VACUUM RESERVOIR

WJCONTROLS 24 - 35

VACUUM RESERVOIR (Continued)