wire ground JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 2108 of 2199

REMOVAL

REMOVAL - HEAT/DEFROST - PANEL/DEFROST

DOOR ELECTRIC ACTUATOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

These actuators are used only on models equipped

with the optional Automatic Zone Control (AZC) sys-

tem.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the two bolts that secure the center

instrument panel support bracket to the left side of

the floor panel transmission tunnel.

(3) Remove the two bolts that secure the center

instrument panel support bracket to the instrument

panel.

(4) Remove the center instrument panel support

bracket from the vehicle.

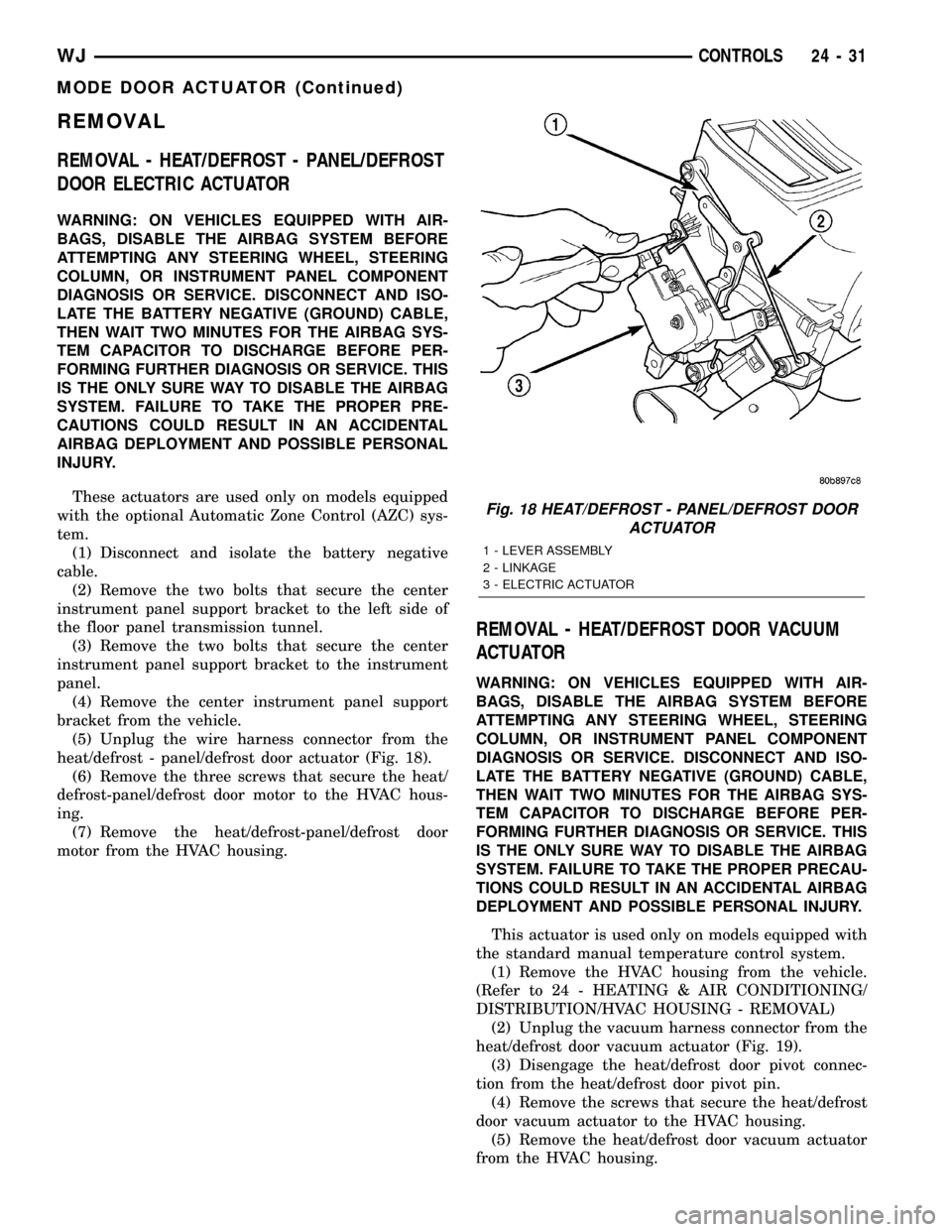

(5) Unplug the wire harness connector from the

heat/defrost - panel/defrost door actuator (Fig. 18).

(6) Remove the three screws that secure the heat/

defrost-panel/defrost door motor to the HVAC hous-

ing.

(7) Remove the heat/defrost-panel/defrost door

motor from the HVAC housing.

REMOVAL - HEAT/DEFROST DOOR VACUUM

ACTUATOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRECAU-

TIONS COULD RESULT IN AN ACCIDENTAL AIRBAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY.

This actuator is used only on models equipped with

the standard manual temperature control system.

(1) Remove the HVAC housing from the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

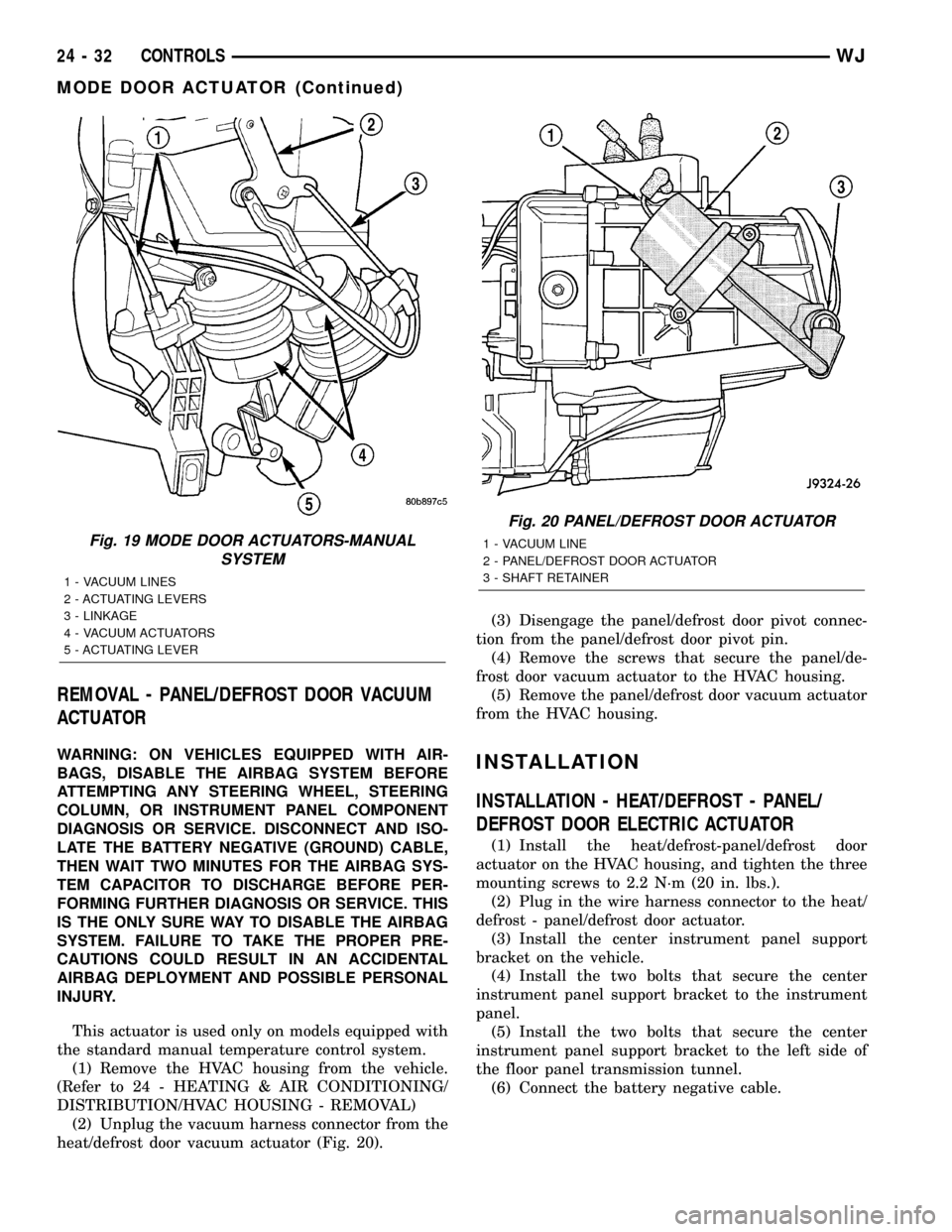

(2) Unplug the vacuum harness connector from the

heat/defrost door vacuum actuator (Fig. 19).

(3) Disengage the heat/defrost door pivot connec-

tion from the heat/defrost door pivot pin.

(4) Remove the screws that secure the heat/defrost

door vacuum actuator to the HVAC housing.

(5) Remove the heat/defrost door vacuum actuator

from the HVAC housing.

Fig. 18 HEAT/DEFROST - PANEL/DEFROST DOOR

ACTUATOR

1 - LEVER ASSEMBLY

2 - LINKAGE

3 - ELECTRIC ACTUATOR

WJCONTROLS 24 - 31

MODE DOOR ACTUATOR (Continued)

Page 2109 of 2199

REMOVAL - PANEL/DEFROST DOOR VACUUM

ACTUATOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

This actuator is used only on models equipped with

the standard manual temperature control system.

(1) Remove the HVAC housing from the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(2) Unplug the vacuum harness connector from the

heat/defrost door vacuum actuator (Fig. 20).(3) Disengage the panel/defrost door pivot connec-

tion from the panel/defrost door pivot pin.

(4) Remove the screws that secure the panel/de-

frost door vacuum actuator to the HVAC housing.

(5) Remove the panel/defrost door vacuum actuator

from the HVAC housing.INSTALLATION

INSTALLATION - HEAT/DEFROST - PANEL/

DEFROST DOOR ELECTRIC ACTUATOR

(1) Install the heat/defrost-panel/defrost door

actuator on the HVAC housing, and tighten the three

mounting screws to 2.2 N´m (20 in. lbs.).

(2) Plug in the wire harness connector to the heat/

defrost - panel/defrost door actuator.

(3) Install the center instrument panel support

bracket on the vehicle.

(4) Install the two bolts that secure the center

instrument panel support bracket to the instrument

panel.

(5) Install the two bolts that secure the center

instrument panel support bracket to the left side of

the floor panel transmission tunnel.

(6) Connect the battery negative cable.

Fig. 19 MODE DOOR ACTUATORS-MANUAL

SYSTEM

1 - VACUUM LINES

2 - ACTUATING LEVERS

3 - LINKAGE

4 - VACUUM ACTUATORS

5 - ACTUATING LEVER

Fig. 20 PANEL/DEFROST DOOR ACTUATOR

1 - VACUUM LINE

2 - PANEL/DEFROST DOOR ACTUATOR

3 - SHAFT RETAINER

24 - 32 CONTROLSWJ

MODE DOOR ACTUATOR (Continued)

Page 2110 of 2199

INSTALLATION - HEAT/DEFROST DOOR

VACUUM ACTUATOR

(1) Install the heat/defrost door vacuum actuator

on the HVAC housing and tighten the mounting

screws to 2.2 N´m (20 in. lbs.).

(2) Engage the heat/defrost door pivot connection

with the heat/defrost door pivot pin.

(3) Plug in the vacuum harness connector to the

heat/defrost door vacuum actuator.

(4) Install the HVAC housing in the vehicle. (Refer

to 24 - HEATING & AIR CONDITIONING/DISTRI-

BUTION/HVAC HOUSING - INSTALLATION)

INSTALLATION - PANEL/DEFROST DOOR

VACUUM ACTUATOR

(1) Install the panel/defrost door vacuum actuator

on the HVAC housing and tighten the mounting

screws to 2.2 N´m (20 in. lbs.).

(2) Engage the panel/defrost door pivot connection

with the panel/defrost door pivot pin.

(3) Plug in the vacuum harness connector to the

heat/defrost door vacuum actuator.

(4) Install the HVAC housing in the vehicle. (Refer

to 24 - HEATING & AIR CONDITIONING/DISTRI-

BUTION/HVAC HOUSING - INSTALLATION)

RECIRCULATION DOOR

ACTUATOR

DESCRIPTION

The recirculation door actuator for vehicles

equipped with the standard equipment manual tem-

perature control system is vacuum controlled. The

optional Automatic Zone Control (AZC) system uses

an electric recirculation door actuator. In the follow-

ing procedures, service for both types of actuators is

covered.

REMOVAL

REMOVAL - RECIRCULATION DOOR VACUUM

ACTUATOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAGSYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

This actuator is used only on models equipped with

the standard manual temperature control system.

(1) Remove the instrument panel from the vehicle.

Refer to Instrument Panel System for the procedures.

(2) Unplug the vacuum harness connector from the

recirculation door vacuum actuator.

(3) Disengage the recirculation door pivot connec-

tion from the door pivot pin.

(4) Disengage the recirculation door actuating rod

from the recirculation door lever.

(5) Remove the screws that secure the recircula-

tion door vacuum actuator to the HVAC housing.

(6) Remove the recirculation door vacuum actuator

from the HVAC housing.

REMOVAL - RECIRCULATION DOOR ELECTRIC

ACTUATOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

This actuator is used only on models equipped with

the optional Automatic Zone Control (AZC) system.

(1) Remove the instrument panel from the vehicle.

Refer to Instrument Panel System for the procedures.

(2) Unplug the wire harness connector from the

recirculation door actuator.

(3) Remove the 2 screws securing the recirculation

door housing to the HVAC unit (Fig. 21). Tilt the

front of the housing up while reaching around the

back releasing 2 tangs holding the rear of the hous-

ing down.

(4) Remove the recirculation door housing from the

HVAC unit.

(5) Remove the screws that secure the recircula-

tion door actuator to the HVAC housing.

(6) Remove the recirculation door actuator from

the HVAC housing.

WJCONTROLS 24 - 33

MODE DOOR ACTUATOR (Continued)

Page 2114 of 2199

BLOWER MOTOR

DESCRIPTION

The blower motor and blower wheel are located in

the passenger side end of the HVAC housing, below

the glove box module. The blower motor controls the

velocity of the air flowing through the HVAC housing

by spinning a squirrel cage-type blower wheel within

the housing at the selected speed. The blower motor

and blower wheel can be serviced from the passenger

compartment side of the housing.

OPERATION

The blower motor will only operate when the igni-

tion switch is in the On position, and the a/c heater

mode control switch is in any position, except off. The

blower motor circuit is protected by a fuse in the

junction block. On models with the standard manual

temperature control system, the blower motor speed

is controlled by regulating the battery feed through

the blower motor switch and the blower motor resis-

tor. On models with the optional Automatic Zone

Control (AZC) system, the blower motor speed is con-

trolled by using Pulse Width Modulation (PWM). The

blower motor controller adjusts the battery feed volt-

age to the blower motor, based upon an input from

the blower motor switch, through the AZC control

module. Pulse width modulation of blower power

allows the blower to operate at any speed from sta-

tionary, to full speed.

The blower motor and blower motor wheel cannot

be repaired, and if faulty or damaged, they must be

replaced. The blower motor and blower wheel are

each serviced separately.

DIAGNOSIS AND TESTING - BLOWER MOTOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. Possible causes of an

inoperative blower motor include:

²Faulty fuse²Faulty blower motor circuit wiring or wire har-

ness connections

²Faulty blower motor resistor (if the vehicle is so

equipped)

²Faulty blower motor controller (if the vehicle is

so equipped)

²Faulty blower motor switch

²Faulty a/c heater mode control switch

²Faulty blower motor.

Possible causes of the blower motor not operating

in all speeds include:

²Faulty fuse

²Faulty blower motor switch

²Faulty blower motor resistor (if the vehicle is so

equipped)

²Faulty blower motor controller (if the vehicle is

so equipped)

²Faulty AZC module (if the vehicle is so

equipped)

²Faulty blower motor circuit wiring or wire har-

ness connections.

VIBRATION

Possible causes of blower motor vibration include:

²Improper blower motor mounting

²Improper blower wheel mounting

²Blower wheel out of balance or bent

²Blower motor faulty.

NOISE

To verify that the blower is the source of the noise,

unplug the blower motor wire harness connector and

operate the HVAC system. If the noise goes away,

possible causes include:

²Foreign material in the HVAC housing

²Improper blower motor mounting

²Improper blower wheel mounting

²Blower motor faulty.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WJDISTRIBUTION 24 - 37

Page 2115 of 2199

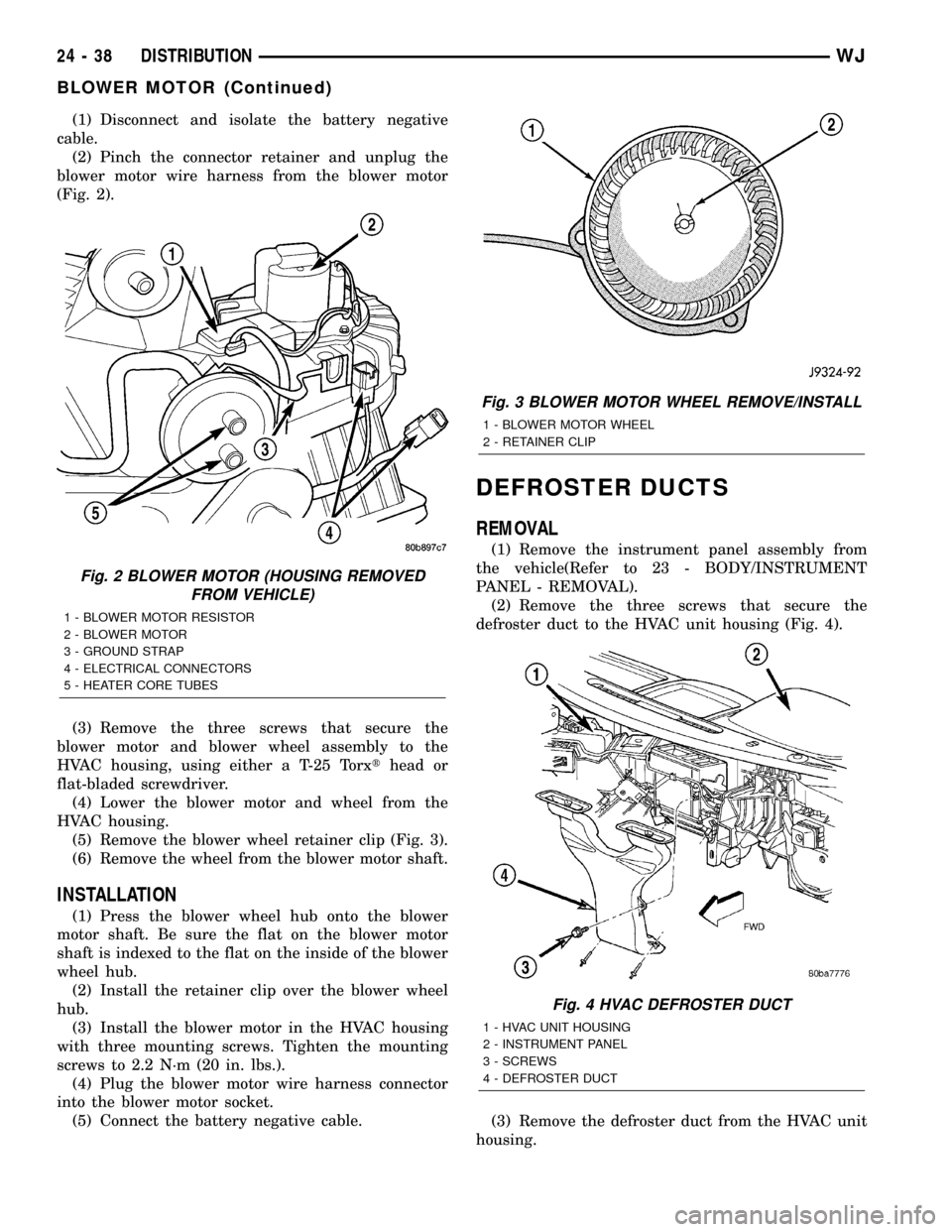

(1) Disconnect and isolate the battery negative

cable.

(2) Pinch the connector retainer and unplug the

blower motor wire harness from the blower motor

(Fig. 2).

(3) Remove the three screws that secure the

blower motor and blower wheel assembly to the

HVAC housing, using either a T-25 Torxthead or

flat-bladed screwdriver.

(4) Lower the blower motor and wheel from the

HVAC housing.

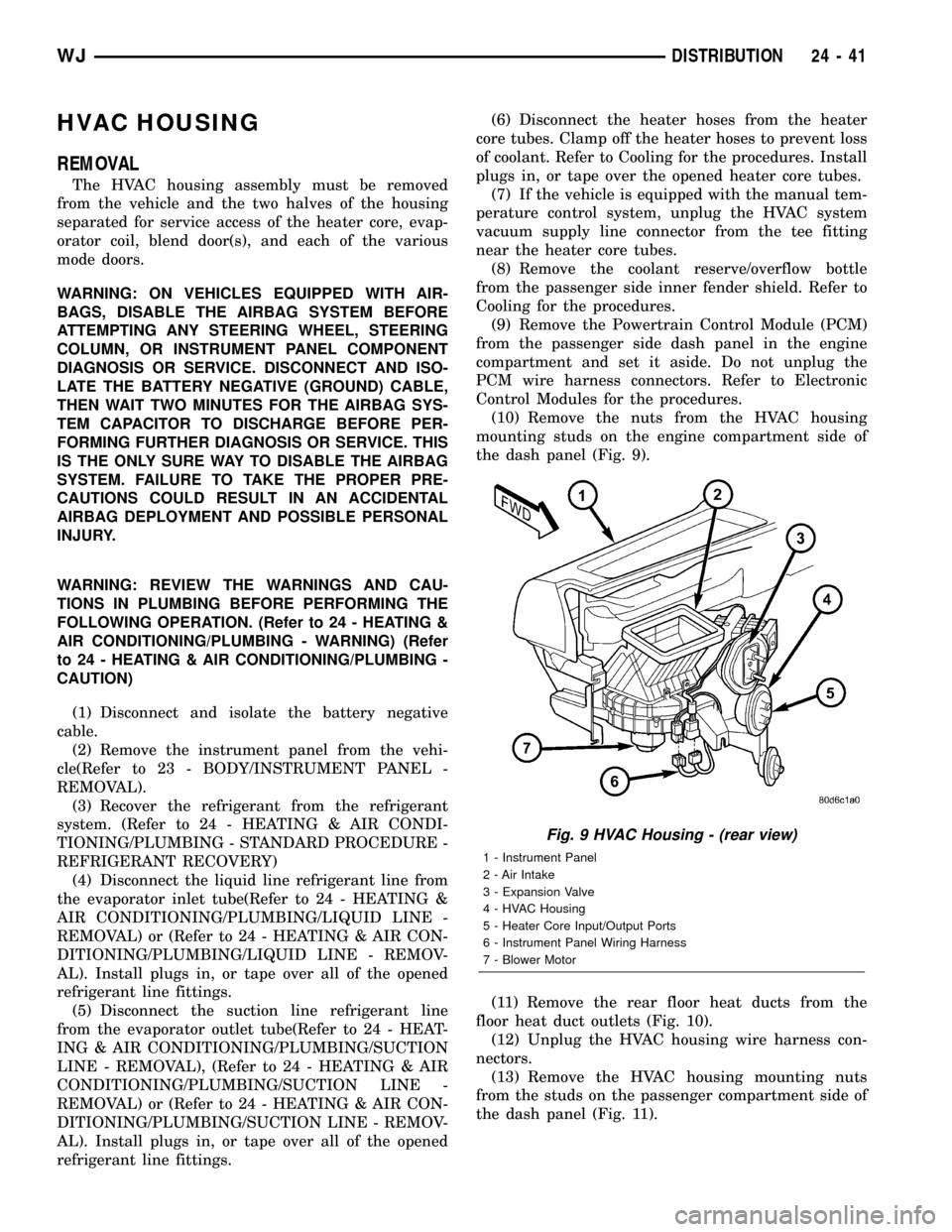

(5) Remove the blower wheel retainer clip (Fig. 3).

(6) Remove the wheel from the blower motor shaft.

INSTALLATION

(1) Press the blower wheel hub onto the blower

motor shaft. Be sure the flat on the blower motor

shaft is indexed to the flat on the inside of the blower

wheel hub.

(2) Install the retainer clip over the blower wheel

hub.

(3) Install the blower motor in the HVAC housing

with three mounting screws. Tighten the mounting

screws to 2.2 N´m (20 in. lbs.).

(4) Plug the blower motor wire harness connector

into the blower motor socket.

(5) Connect the battery negative cable.

DEFROSTER DUCTS

REMOVAL

(1) Remove the instrument panel assembly from

the vehicle(Refer to 23 - BODY/INSTRUMENT

PANEL - REMOVAL).

(2) Remove the three screws that secure the

defroster duct to the HVAC unit housing (Fig. 4).

(3) Remove the defroster duct from the HVAC unit

housing.

Fig. 2 BLOWER MOTOR (HOUSING REMOVED

FROM VEHICLE)

1 - BLOWER MOTOR RESISTOR

2 - BLOWER MOTOR

3 - GROUND STRAP

4 - ELECTRICAL CONNECTORS

5 - HEATER CORE TUBES

Fig. 3 BLOWER MOTOR WHEEL REMOVE/INSTALL

1 - BLOWER MOTOR WHEEL

2 - RETAINER CLIP

Fig. 4 HVAC DEFROSTER DUCT

1 - HVAC UNIT HOUSING

2 - INSTRUMENT PANEL

3 - SCREWS

4 - DEFROSTER DUCT

24 - 38 DISTRIBUTIONWJ

BLOWER MOTOR (Continued)

Page 2118 of 2199

HVAC HOUSING

REMOVAL

The HVAC housing assembly must be removed

from the vehicle and the two halves of the housing

separated for service access of the heater core, evap-

orator coil, blend door(s), and each of the various

mode doors.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN PLUMBING BEFORE PERFORMING THE

FOLLOWING OPERATION. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - WARNING) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel from the vehi-

cle(Refer to 23 - BODY/INSTRUMENT PANEL -

REMOVAL).

(3) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(4) Disconnect the liquid line refrigerant line from

the evaporator inlet tube(Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING/LIQUID LINE -

REMOVAL) or (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING/LIQUID LINE - REMOV-

AL). Install plugs in, or tape over all of the opened

refrigerant line fittings.

(5) Disconnect the suction line refrigerant line

from the evaporator outlet tube(Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/SUCTION

LINE - REMOVAL), (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING/SUCTION LINE -

REMOVAL) or (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING/SUCTION LINE - REMOV-

AL). Install plugs in, or tape over all of the opened

refrigerant line fittings.(6) Disconnect the heater hoses from the heater

core tubes. Clamp off the heater hoses to prevent loss

of coolant. Refer to Cooling for the procedures. Install

plugs in, or tape over the opened heater core tubes.

(7) If the vehicle is equipped with the manual tem-

perature control system, unplug the HVAC system

vacuum supply line connector from the tee fitting

near the heater core tubes.

(8) Remove the coolant reserve/overflow bottle

from the passenger side inner fender shield. Refer to

Cooling for the procedures.

(9) Remove the Powertrain Control Module (PCM)

from the passenger side dash panel in the engine

compartment and set it aside. Do not unplug the

PCM wire harness connectors. Refer to Electronic

Control Modules for the procedures.

(10) Remove the nuts from the HVAC housing

mounting studs on the engine compartment side of

the dash panel (Fig. 9).

(11) Remove the rear floor heat ducts from the

floor heat duct outlets (Fig. 10).

(12) Unplug the HVAC housing wire harness con-

nectors.

(13) Remove the HVAC housing mounting nuts

from the studs on the passenger compartment side of

the dash panel (Fig. 11).

Fig. 9 HVAC Housing - (rear view)

1 - Instrument Panel

2 - Air Intake

3 - Expansion Valve

4 - HVAC Housing

5 - Heater Core Input/Output Ports

6 - Instrument Panel Wiring Harness

7 - Blower Motor

WJDISTRIBUTION 24 - 41

Page 2121 of 2199

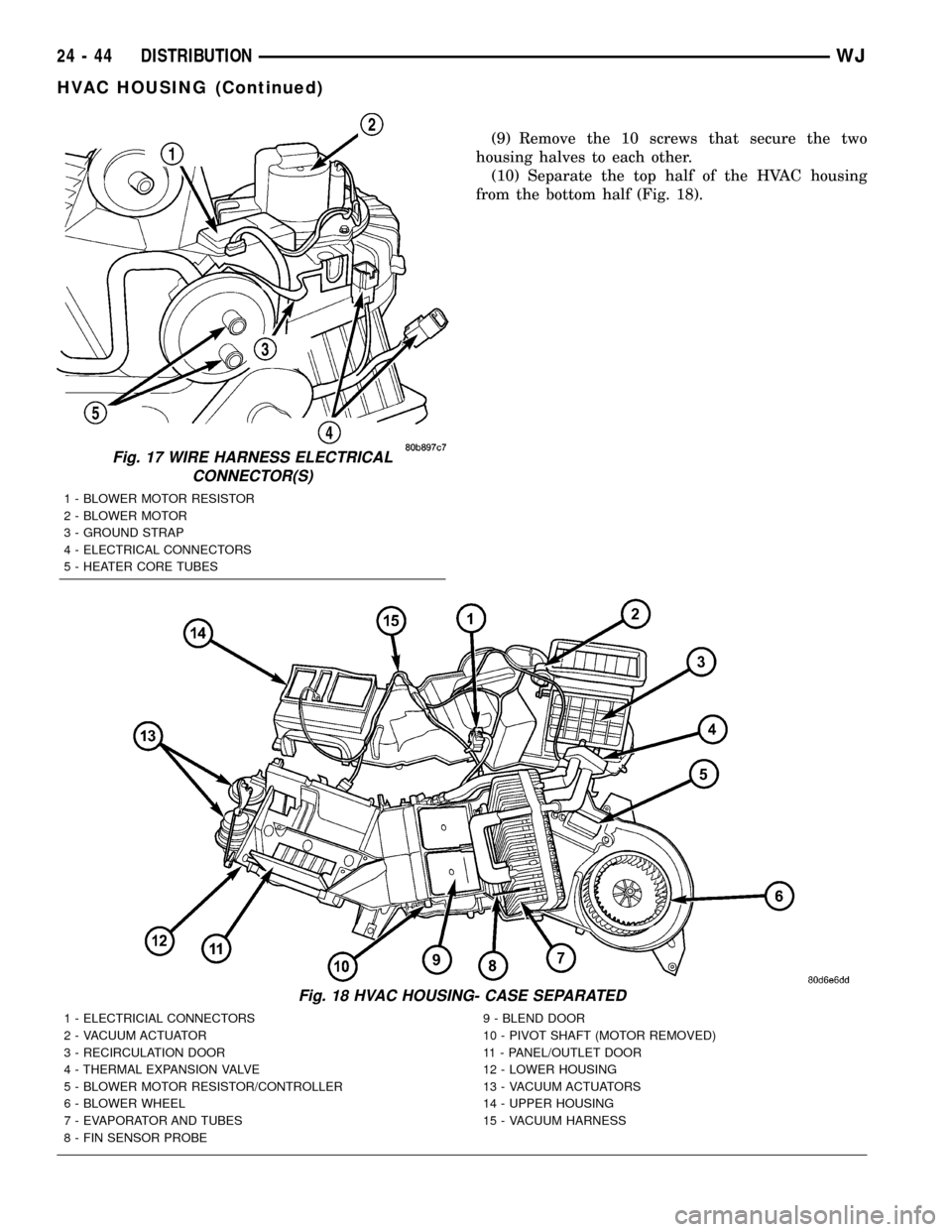

(9) Remove the 10 screws that secure the two

housing halves to each other.

(10) Separate the top half of the HVAC housing

from the bottom half (Fig. 18).

Fig. 17 WIRE HARNESS ELECTRICAL

CONNECTOR(S)

1 - BLOWER MOTOR RESISTOR

2 - BLOWER MOTOR

3 - GROUND STRAP

4 - ELECTRICAL CONNECTORS

5 - HEATER CORE TUBES

Fig. 18 HVAC HOUSING- CASE SEPARATED

1 - ELECTRICIAL CONNECTORS

2 - VACUUM ACTUATOR

3 - RECIRCULATION DOOR

4 - THERMAL EXPANSION VALVE

5 - BLOWER MOTOR RESISTOR/CONTROLLER

6 - BLOWER WHEEL

7 - EVAPORATOR AND TUBES

8 - FIN SENSOR PROBE9 - BLEND DOOR

10 - PIVOT SHAFT (MOTOR REMOVED)

11 - PANEL/OUTLET DOOR

12 - LOWER HOUSING

13 - VACUUM ACTUATORS

14 - UPPER HOUSING

15 - VACUUM HARNESS

24 - 44 DISTRIBUTIONWJ

HVAC HOUSING (Continued)

Page 2126 of 2199

INSTALLATION

INSTALLATION - PANEL OUTLET DOOR

(1) Snap the panel outlet door pivot shaft retainer

on the pivot shaft.

(2) Attach the panel outlet door pivot shaft to the

HVAC case.

(3) Reassemble the HVAC housing and install in

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HVAC HOUSING -

ASSEMBLY) (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/HVAC HOUSING -

INSTALLATION)

INSTALLATION - HEAT/DEFROST DOOR

(1) Install the heat/defrost door by snapping the

heat/defrost door pivot shaft into the HVAC case.

(2) Install the heat/defrost door sub-assembly and

tighten the mounting screws to 2.2 N´m (20 in. lbs.).

(3) Attach the metal linkage to the heat/defrost

door lever.

(4) Snap the duct adapter to the bottom of the

heat/defrost door sub-assembly.

(5) Install the 2 floor heat ducts and tighten the

mounting screws to 2.2 N´m (20 in. lbs.)..

(6) Install the evaporator, and styrofoam tray in

the lower case.

(7) Reassemble the HVAC housing and install in

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HVAC HOUSING -

ASSEMBLY) (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/HVAC HOUSING -

INSTALLATION)

INSTALLATION - PANEL/DEFROST DOOR

(1) Snap the panel/defrost door pivot shaft retainer

on the pivot shaft.

(2) Attach the panel/defrost door pivot shaft to the

HVAC case.

(3) Reassemble the HVAC housing and install in

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HVAC HOUSING -

ASSEMBLY) (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/HVAC HOUSING -

INSTALLATION)

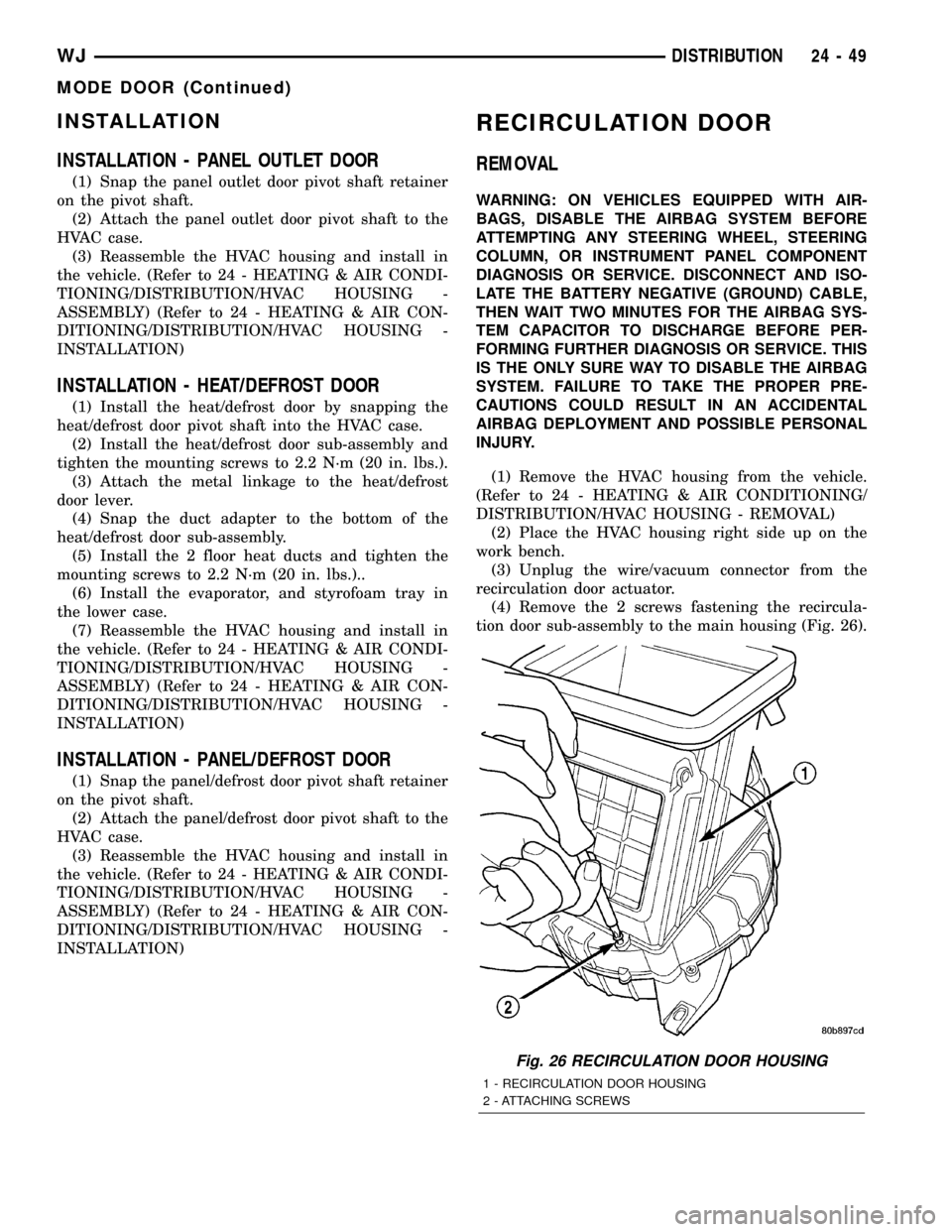

RECIRCULATION DOOR

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Remove the HVAC housing from the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(2) Place the HVAC housing right side up on the

work bench.

(3) Unplug the wire/vacuum connector from the

recirculation door actuator.

(4) Remove the 2 screws fastening the recircula-

tion door sub-assembly to the main housing (Fig. 26).

Fig. 26 RECIRCULATION DOOR HOUSING

1 - RECIRCULATION DOOR HOUSING

2 - ATTACHING SCREWS

WJDISTRIBUTION 24 - 49

MODE DOOR (Continued)

Page 2146 of 2199

INSTALLATION - 2.7L TURBO DIESEL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

Any kinks or sharp bends in the refrigerant plumb-

ing will reduce the capacity of the entire air condi-

tioning system. Kinks and sharp bends reduce the

flow of refrigerant in the system. A good rule for the

flexible hose refrigerant lines is to keep the radius of

all bends at least ten times the diameter of the hose.

In addition, the flexible hose refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) from the exhaust manifold.

High pressures are produced in the refrigerant sys-

tem when the air conditioning compressor is operat-

ing. Extreme care must be exercised to make sure

that each of the refrigerant system connections is

pressure-tight and leak free. It is a good practice to

inspect all flexible hose refrigerant lines at least once

a year to make sure they are in good condition and

properly routed.

(1) Carefully position the suction line in the vehi-

cle.

(2) Remove the cap or tape and install the suction

line on the compressor. Be certain the sealing o-ring

is well lubricated with PAG oil and free of tears.

Torque the retaining fastener to 22 N´m (200 in. lbs.).

(3) Position and install the refrigerant line support

bracket bolt on the cylinder head cap. Torque the bolt

to 20 N´m (177 in. lbs.).

(4) Remove the cap or tape and install the suction

line on the H-Valve Block. Be certain the sealing

O-ring is well lubricated with PAG oil and free of

tears. Torque the retaining fastener to 28 N´m (21 ft.

lbs.).

(5) Install the tie-straps retaining the wire har-

ness on the suction line.

(6) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(7) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

(8) Connect the negative battery cable.

A/C EVAPORATOR

DESCRIPTION

The evaporator coil is located in the HVAC hous-

ing, under the instrument panel. The evaporator coil

is positioned in the HVAC housing so that all air that

enters the housing must pass over the fins of the

evaporator before it is distributed through the sys-

tem ducts and outlets. However, air passing over the

evaporator coil fins will only be conditioned when the

compressor is engaged and circulating refrigerant

through the evaporator coil tubes.

OPERATION

Refrigerant enters the evaporator from the orifice

tube as a low-temperature, low-pressure liquid. As

air flows over the fins of the evaporator, the humidity

in the air condenses on the fins, and the heat from

the air is absorbed by the refrigerant. Heat absorp-

tion causes the refrigerant to boil and vaporize. The

refrigerant becomes a low-pressure gas before it

leaves the evaporator.

The evaporator coil cannot be repaired and, if

faulty or damaged, it must be replaced.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Remove and disassemble the HVAC housing.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - DISASSEMBLY)

(2) Lift the evaporator coil unit out of the lower

half of the HVAC housing (Fig. 11).

WJPLUMBING 24 - 69

SUCTION LINE (Continued)

Page 2156 of 2199

EMISSIONS CONTROL

TABLE OF CONTENTS

page page

EMISSIONS CONTROL

DESCRIPTION

DESCRIPTION - EMISSION CONTROL

SYSTEM.............................1

DESCRIPTION - STATE DISPLAY TEST

MODE...............................2

DESCRIPTION - CIRCUIT ACTUATION TEST

MODE...............................2

DESCRIPTION - DIAGNOSTIC TROUBLE

CODES..............................2DESCRIPTION - TASK MANAGER.........17

DESCRIPTION - MONITORED SYSTEMS . . . 17

DESCRIPTION - TRIP DEFINITION........19

DESCRIPTION - COMPONENT MONITORS . . 19

DESCRIPTION - NON-MONITORED

CIRCUITS...........................20

DESCRIPTION - HIGH AND LOW LIMITS . . . 20

DESCRIPTION - LOAD VALUE...........20

OPERATION - TASK MANAGER............21

EVAPORATIVE EMISSIONS................24

EMISSIONS CONTROL

DESCRIPTION

DESCRIPTION - EMISSION CONTROL SYSTEM

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a prob-

lem with a monitored circuit often enough to indicate an

actual problem, it stores a Diagnostic Trouble Code

(DTC) in the PCM's memory. If the code applies to a

non-emissions related component or system, and the

problem is repaired or ceases to exist, the PCM cancels

the code after 40 warm-up cycles. Diagnostic trouble

codes that affect vehicle emissions illuminate the Mal-

function Indicator (check engine) Lamp. Refer to Mal-

function Indicator Lamp in this section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored cir-

cuit even though a malfunction has occurred. This may

happen because one of the DTC criteria for the circuit

has not been met.For example

,assume the diagnostic

trouble code criteria requires the PCM to monitor the

circuit only when the engine operates between 750 and

2000 RPM. Suppose the sensor's output circuit shorts to

ground when engine operates above 2400 RPM (result-

ing in 0 volt input to the PCM). Because the condition

happens at an engine speed above the maximum thresh-

old (2000 rpm), the PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

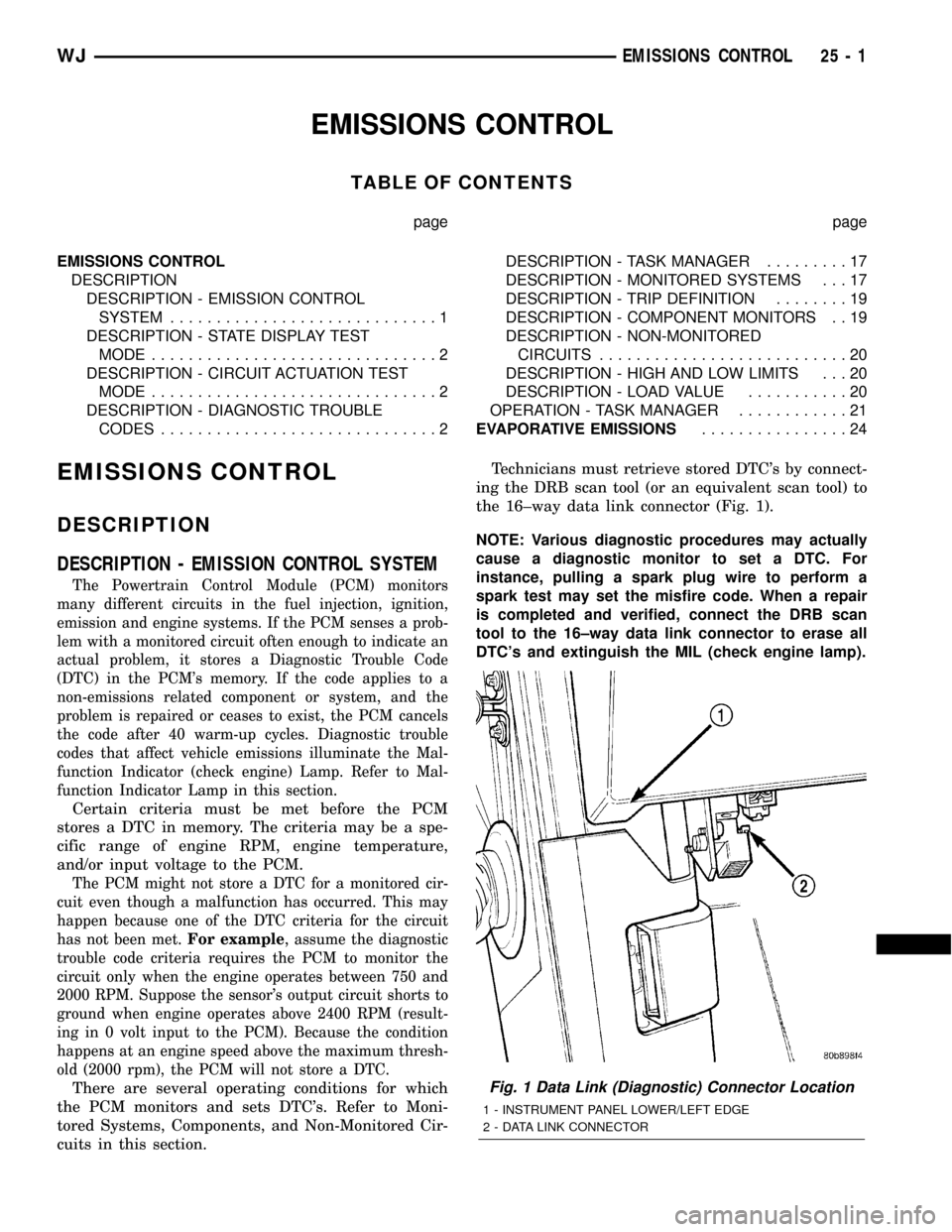

cuits in this section.Technicians must retrieve stored DTC's by connect-

ing the DRB scan tool (or an equivalent scan tool) to

the 16±way data link connector (Fig. 1).

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, connect the DRB scan

tool to the 16±way data link connector to erase all

DTC's and extinguish the MIL (check engine lamp).Fig. 1 Data Link (Diagnostic) Connector Location

1 - INSTRUMENT PANEL LOWER/LEFT EDGE

2 - DATA LINK CONNECTOR

WJEMISSIONS CONTROL 25 - 1