engine control JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1533 of 2199

Test Four - Transmission In Reverse

NOTE: This test checks pump output, pressure reg-

ulation and the front clutch and rear servo circuits.

Use 300 psi Test Gauge C-3293-SP for this test.

(1) Leave vehicle on hoist and leave gauge C-3292

in place at accumulator port.

(2) Move 300 psi Gauge C-3293-SP back to rear

servo port.

(3) Have helper start and run engine at 1600 rpm

for test.

(4) Move transmission shift lever four detents

rearward from full forward position. This is Reverse

range.

(5) Move transmission throttle lever fully forward

then fully rearward and note reading at Gauge

C-3293-SP.

(6) Pressure should be 145 - 175 psi (1000-1207

kPa) with throttle lever forward and increase to 230 -

280 psi (1586-1931 kPa) as lever is gradually moved

rearward.

Test Five - Governor Pressure

NOTE: This test checks governor operation by mea-

suring governor pressure response to changes in

vehicle speed. It is usually not necessary to check

governor operation unless shift speeds are incor-

rect or if the transmission will not downshift. The

test should be performed on the road or on a hoist

that will allow the rear wheels to rotate freely.

(1) Move 100 psi Test Gauge C-3292 to governor

pressure port.

(2) Move transmission shift lever two detents rear-

ward from full forward position. This is D range.

(3) Have helper start and run engine at curb idle

speed. Then firmly apply service brakes so wheels

will not rotate.

(4) Note governor pressure:

²Governor pressure should be no more than 20.6

kPa (3 psi) at curb idle speed and wheels not rotat-

ing.

²If pressure exceeds 20.6 kPa (3 psi), a fault

exists in governor pressure control system.

(5) Release brakes, slowly increase engine speed,

and observe speedometer and pressure test gauge (do

not exceed 30 mph on speedometer). Governor pres-

sure should increase in proportion to vehicle speed.

Or approximately 6.89 kPa (1 psi) for every 1 mph.

(6) Governor pressure rise should be smooth and

drop back to no more than 20.6 kPa (3 psi), after

engine returns to curb idle and brakes are applied to

prevent wheels from rotating.

(7) Compare results of pressure test with analysis

chart.Test Six - Transmission In Overdrive Fourth Gear

NOTE: This test checks line pressure at the over-

drive clutch in fourth gear range. Use 300 psi Test

Gauge C-3293-SP for this test. The test should be

performed on the road or on a chassis dyno.

(1) Remove tachometer; it is not needed for this

test.

(2) Move 300 psi Gauge to overdrive clutch pres-

sure test port. Then remove other gauge and reinstall

test port plug.

(3) Lower vehicle.

(4) Turn OD switch on.

(5) Secure test gauge so it can be viewed from

drivers seat.

(6) Start engine and shift into D range.

(7) Increase vehicle speed gradually until 3-4 shift

occurs and note gauge pressure.

(8) Pressure should be 469-496 kPa (68-72 psi)

with closed throttle and increase to 620-827 kPa (90-

120 psi) at 1/2 to 3/4 throttle. Note that pressure can

increase to around 896 kPa (130 psi) at full throttle.

(9) Return to shop or move vehicle off chassis

dyno.

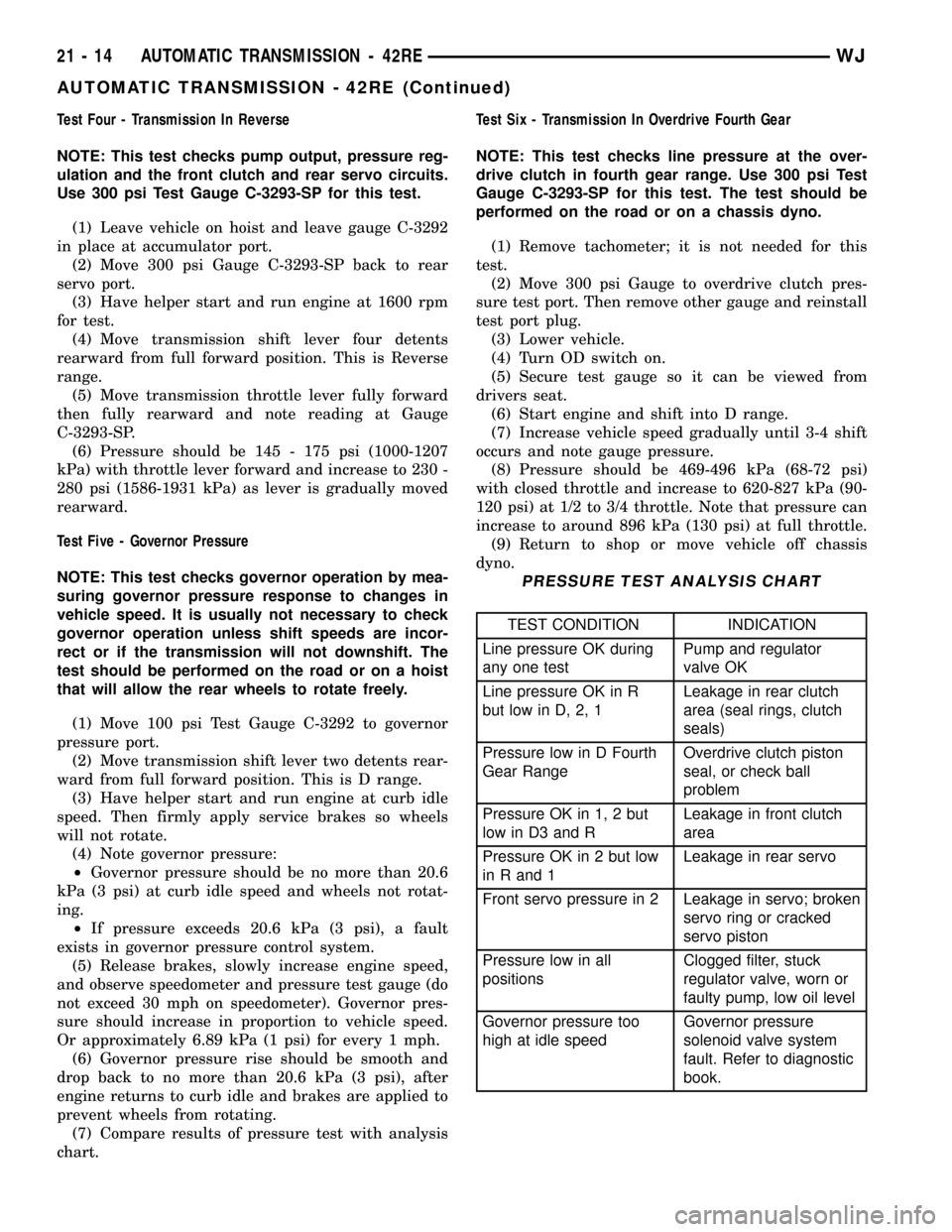

PRESSURE TEST ANALYSIS CHART

TEST CONDITION INDICATION

Line pressure OK during

any one testPump and regulator

valve OK

Line pressure OK in R

but low in D, 2, 1Leakage in rear clutch

area (seal rings, clutch

seals)

Pressure low in D Fourth

Gear RangeOverdrive clutch piston

seal, or check ball

problem

Pressure OK in 1, 2 but

low in D3 and RLeakage in front clutch

area

Pressure OK in 2 but low

in R and 1Leakage in rear servo

Front servo pressure in 2 Leakage in servo; broken

servo ring or cracked

servo piston

Pressure low in all

positionsClogged filter, stuck

regulator valve, worn or

faulty pump, low oil level

Governor pressure too

high at idle speedGovernor pressure

solenoid valve system

fault. Refer to diagnostic

book.

21 - 14 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1536 of 2199

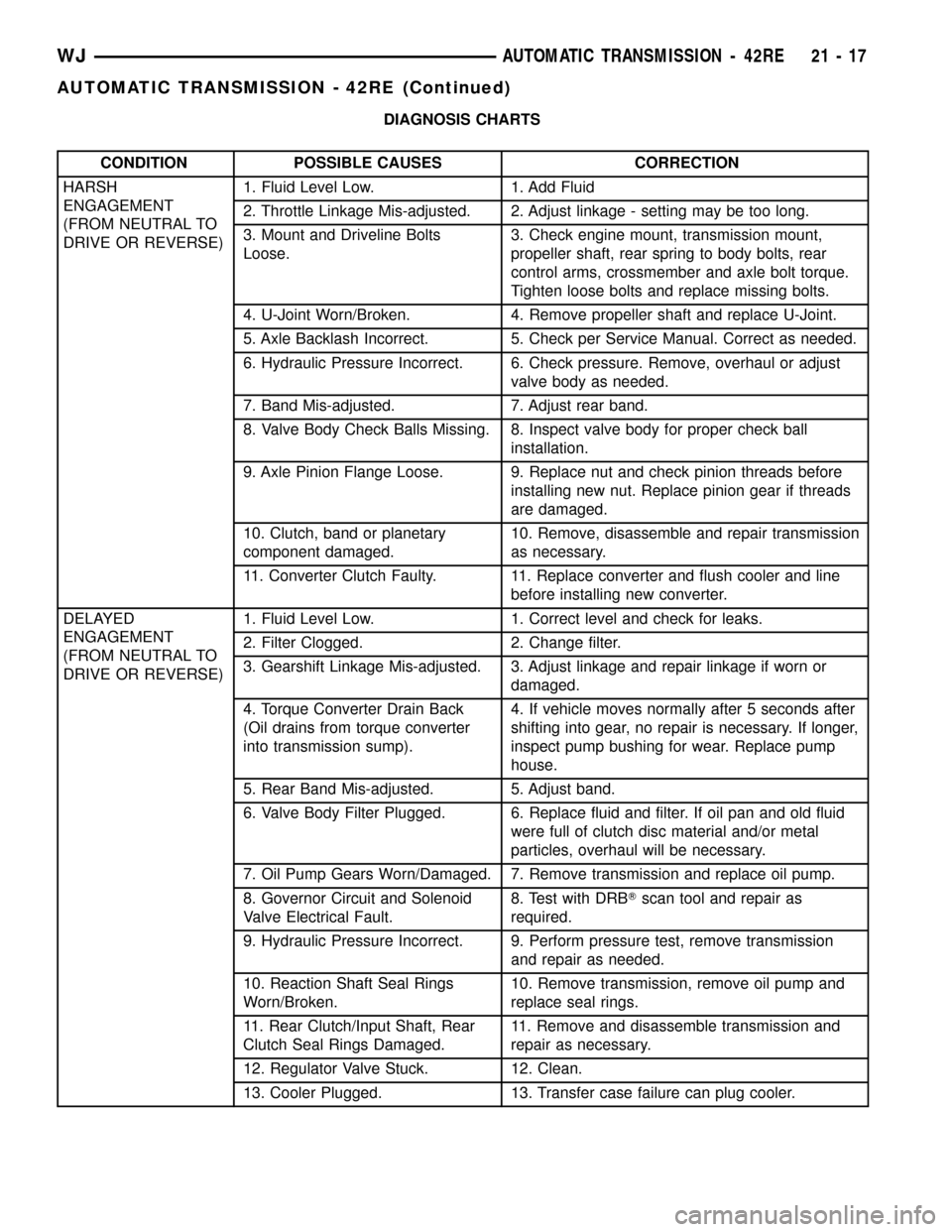

DIAGNOSIS CHARTS

CONDITION POSSIBLE CAUSES CORRECTION

HARSH

ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low. 1. Add Fluid

2. Throttle Linkage Mis-adjusted. 2. Adjust linkage - setting may be too long.

3. Mount and Driveline Bolts

Loose.3. Check engine mount, transmission mount,

propeller shaft, rear spring to body bolts, rear

control arms, crossmember and axle bolt torque.

Tighten loose bolts and replace missing bolts.

4. U-Joint Worn/Broken. 4. Remove propeller shaft and replace U-Joint.

5. Axle Backlash Incorrect. 5. Check per Service Manual. Correct as needed.

6. Hydraulic Pressure Incorrect. 6. Check pressure. Remove, overhaul or adjust

valve body as needed.

7. Band Mis-adjusted. 7. Adjust rear band.

8. Valve Body Check Balls Missing. 8. Inspect valve body for proper check ball

installation.

9. Axle Pinion Flange Loose. 9. Replace nut and check pinion threads before

installing new nut. Replace pinion gear if threads

are damaged.

10. Clutch, band or planetary

component damaged.10. Remove, disassemble and repair transmission

as necessary.

11. Converter Clutch Faulty. 11. Replace converter and flush cooler and line

before installing new converter.

DELAYED

ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low. 1. Correct level and check for leaks.

2. Filter Clogged. 2. Change filter.

3. Gearshift Linkage Mis-adjusted. 3. Adjust linkage and repair linkage if worn or

damaged.

4. Torque Converter Drain Back

(Oil drains from torque converter

into transmission sump).4. If vehicle moves normally after 5 seconds after

shifting into gear, no repair is necessary. If longer,

inspect pump bushing for wear. Replace pump

house.

5. Rear Band Mis-adjusted. 5. Adjust band.

6. Valve Body Filter Plugged. 6. Replace fluid and filter. If oil pan and old fluid

were full of clutch disc material and/or metal

particles, overhaul will be necessary.

7. Oil Pump Gears Worn/Damaged. 7. Remove transmission and replace oil pump.

8. Governor Circuit and Solenoid

Valve Electrical Fault.8. Test with DRBTscan tool and repair as

required.

9. Hydraulic Pressure Incorrect. 9. Perform pressure test, remove transmission

and repair as needed.

10. Reaction Shaft Seal Rings

Worn/Broken.10. Remove transmission, remove oil pump and

replace seal rings.

11. Rear Clutch/Input Shaft, Rear

Clutch Seal Rings Damaged.11. Remove and disassemble transmission and

repair as necessary.

12. Regulator Valve Stuck. 12. Clean.

13. Cooler Plugged. 13. Transfer case failure can plug cooler.

WJAUTOMATIC TRANSMISSION - 42RE 21 - 17

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1540 of 2199

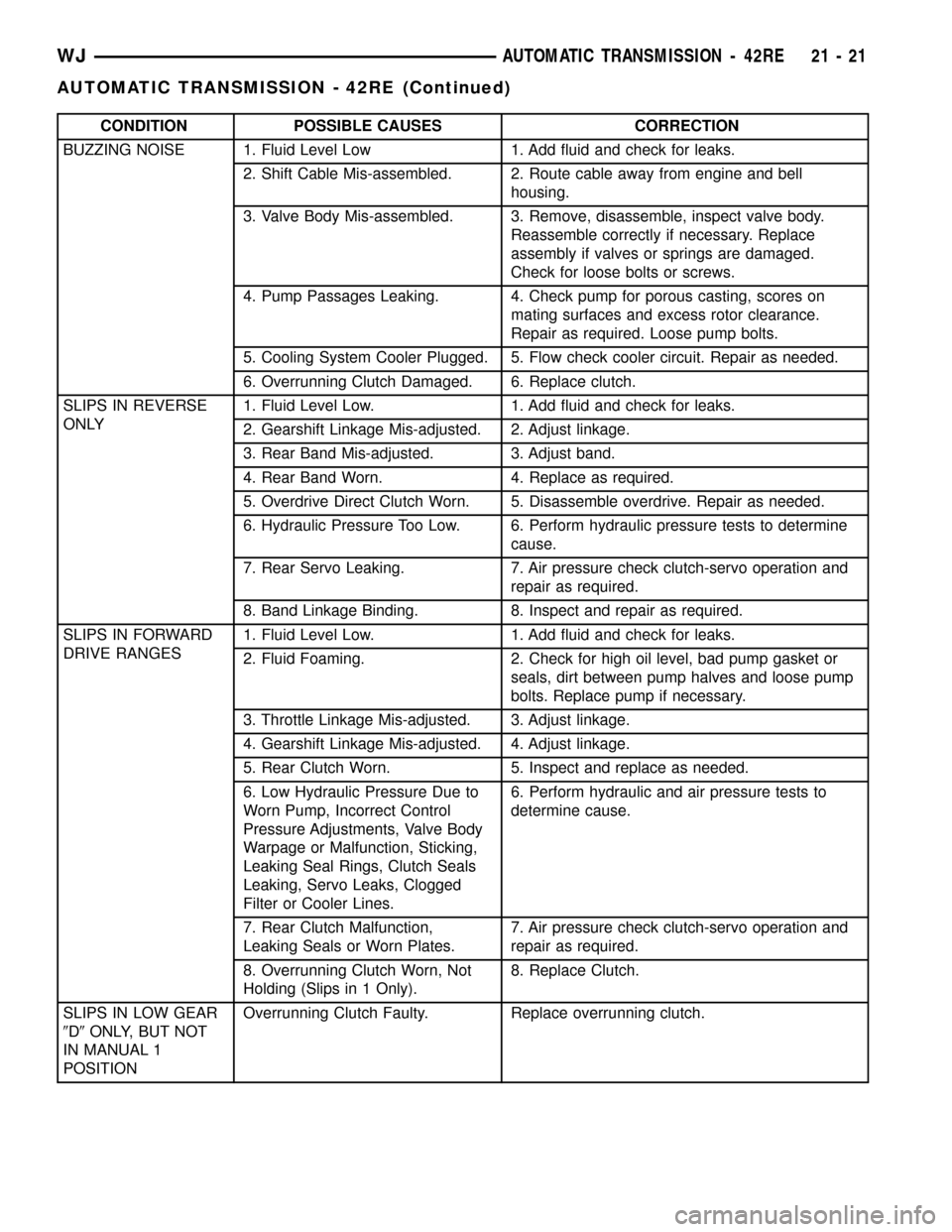

CONDITION POSSIBLE CAUSES CORRECTION

BUZZING NOISE 1. Fluid Level Low 1. Add fluid and check for leaks.

2. Shift Cable Mis-assembled. 2. Route cable away from engine and bell

housing.

3. Valve Body Mis-assembled. 3. Remove, disassemble, inspect valve body.

Reassemble correctly if necessary. Replace

assembly if valves or springs are damaged.

Check for loose bolts or screws.

4. Pump Passages Leaking. 4. Check pump for porous casting, scores on

mating surfaces and excess rotor clearance.

Repair as required. Loose pump bolts.

5. Cooling System Cooler Plugged. 5. Flow check cooler circuit. Repair as needed.

6. Overrunning Clutch Damaged. 6. Replace clutch.

SLIPS IN REVERSE

ONLY1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Gearshift Linkage Mis-adjusted. 2. Adjust linkage.

3. Rear Band Mis-adjusted. 3. Adjust band.

4. Rear Band Worn. 4. Replace as required.

5. Overdrive Direct Clutch Worn. 5. Disassemble overdrive. Repair as needed.

6. Hydraulic Pressure Too Low. 6. Perform hydraulic pressure tests to determine

cause.

7. Rear Servo Leaking. 7. Air pressure check clutch-servo operation and

repair as required.

8. Band Linkage Binding. 8. Inspect and repair as required.

SLIPS IN FORWARD

DRIVE RANGES1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Fluid Foaming. 2. Check for high oil level, bad pump gasket or

seals, dirt between pump halves and loose pump

bolts. Replace pump if necessary.

3. Throttle Linkage Mis-adjusted. 3. Adjust linkage.

4. Gearshift Linkage Mis-adjusted. 4. Adjust linkage.

5. Rear Clutch Worn. 5. Inspect and replace as needed.

6. Low Hydraulic Pressure Due to

Worn Pump, Incorrect Control

Pressure Adjustments, Valve Body

Warpage or Malfunction, Sticking,

Leaking Seal Rings, Clutch Seals

Leaking, Servo Leaks, Clogged

Filter or Cooler Lines.6. Perform hydraulic and air pressure tests to

determine cause.

7. Rear Clutch Malfunction,

Leaking Seals or Worn Plates.7. Air pressure check clutch-servo operation and

repair as required.

8. Overrunning Clutch Worn, Not

Holding (Slips in 1 Only).8. Replace Clutch.

SLIPS IN LOW GEAR

9D9ONLY, BUT NOT

IN MANUAL 1

POSITIONOverrunning Clutch Faulty. Replace overrunning clutch.

WJAUTOMATIC TRANSMISSION - 42RE 21 - 21

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1542 of 2199

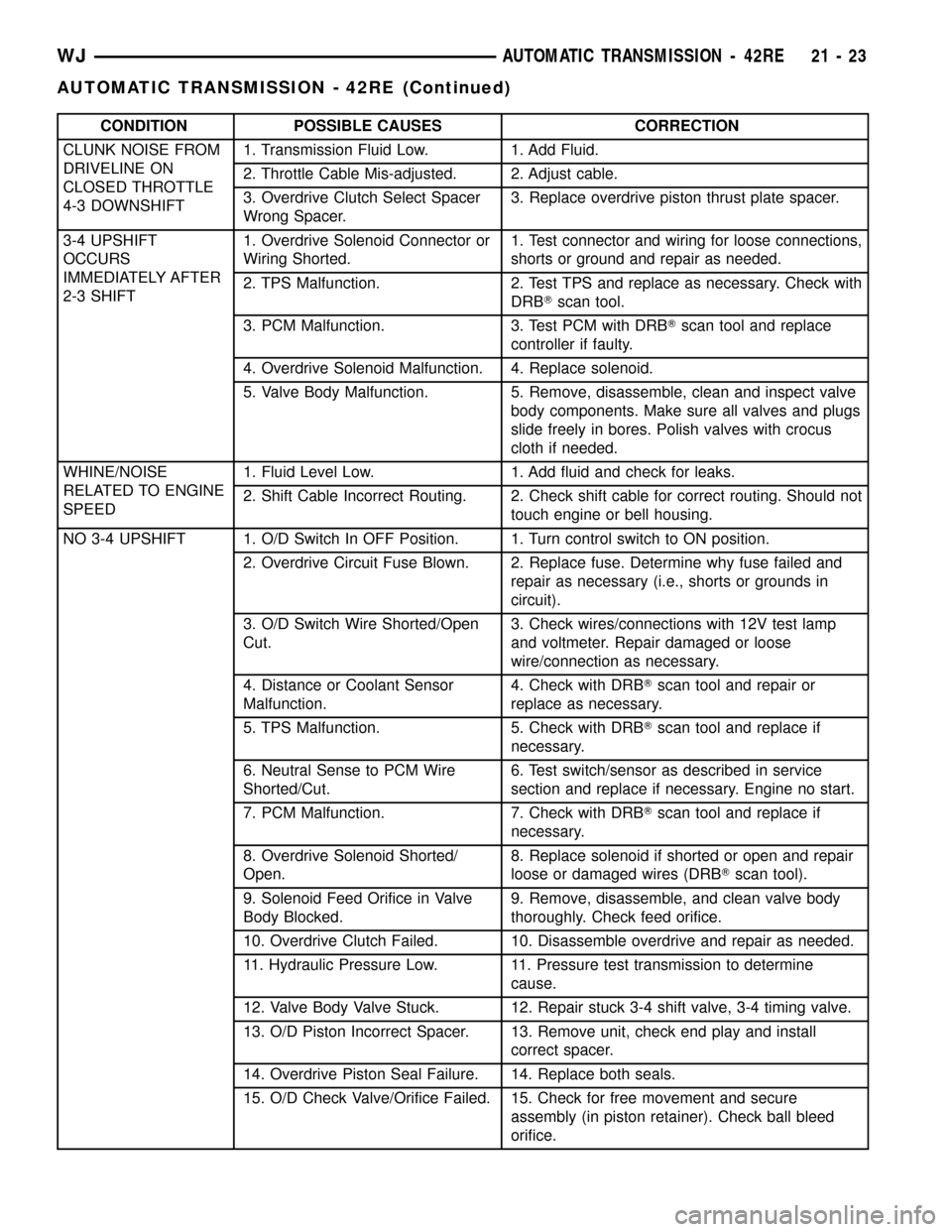

CONDITION POSSIBLE CAUSES CORRECTION

CLUNK NOISE FROM

DRIVELINE ON

CLOSED THROTTLE

4-3 DOWNSHIFT1. Transmission Fluid Low. 1. Add Fluid.

2. Throttle Cable Mis-adjusted. 2. Adjust cable.

3. Overdrive Clutch Select Spacer

Wrong Spacer.3. Replace overdrive piston thrust plate spacer.

3-4 UPSHIFT

OCCURS

IMMEDIATELY AFTER

2-3 SHIFT1. Overdrive Solenoid Connector or

Wiring Shorted.1.

Test connector and wiring for loose connections,

shorts or ground and repair as needed.

2. TPS Malfunction. 2. Test TPS and replace as necessary. Check with

DRBTscan tool.

3. PCM Malfunction. 3. Test PCM with DRBTscan tool and replace

controller if faulty.

4. Overdrive Solenoid Malfunction. 4. Replace solenoid.

5. Valve Body Malfunction. 5. Remove, disassemble, clean and inspect valve

body components. Make sure all valves and plugs

slide freely in bores. Polish valves with crocus

cloth if needed.

WHINE/NOISE

RELATED TO ENGINE

SPEED1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Shift Cable Incorrect Routing. 2. Check shift cable for correct routing. Should not

touch engine or bell housing.

NO 3-4 UPSHIFT 1. O/D Switch In OFF Position. 1. Turn control switch to ON position.

2. Overdrive Circuit Fuse Blown. 2. Replace fuse. Determine why fuse failed and

repair as necessary (i.e., shorts or grounds in

circuit).

3. O/D Switch Wire Shorted/Open

Cut.3. Check wires/connections with 12V test lamp

and voltmeter. Repair damaged or loose

wire/connection as necessary.

4. Distance or Coolant Sensor

Malfunction.4. Check with DRBTscan tool and repair or

replace as necessary.

5. TPS Malfunction. 5. Check with DRBTscan tool and replace if

necessary.

6. Neutral Sense to PCM Wire

Shorted/Cut.6. Test switch/sensor as described in service

section and replace if necessary. Engine no start.

7. PCM Malfunction. 7. Check with DRBTscan tool and replace if

necessary.

8. Overdrive Solenoid Shorted/

Open.8. Replace solenoid if shorted or open and repair

loose or damaged wires (DRBTscan tool).

9. Solenoid Feed Orifice in Valve

Body Blocked.9. Remove, disassemble, and clean valve body

thoroughly. Check feed orifice.

10. Overdrive Clutch Failed. 10. Disassemble overdrive and repair as needed.

11. Hydraulic Pressure Low. 11. Pressure test transmission to determine

cause.

12. Valve Body Valve Stuck. 12. Repair stuck 3-4 shift valve, 3-4 timing valve.

13. O/D Piston Incorrect Spacer. 13. Remove unit, check end play and install

correct spacer.

14. Overdrive Piston Seal Failure. 14. Replace both seals.

15. O/D Check Valve/Orifice Failed. 15. Check for free movement and secure

assembly (in piston retainer). Check ball bleed

orifice.

WJAUTOMATIC TRANSMISSION - 42RE 21 - 23

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1584 of 2199

(8) Engine starts must be possible with shifter

lever in PARK or NEUTRAL gate positions only.

Engine starts must not be possible in any other gate

positions other than PARK or NEUTRAL.

(9) With shifter lever handle push-button not

depressed and lever detent in:

²PARK position- apply forward force on center of

handle and remove pressure. Engine start must be

possible.

²PARK position- apply rearward force on center

of handle and remove pressure. Engine start must be

possible.

²NEUTRAL position- engine start must be possi-

ble.

²NEUTRAL position, engine running and brakes

applied- Apply forward force on center of shift han-

dle. Transmission should not be able to shift into

REVERSE detent.

ELECTRONIC GOVERNOR

DESCRIPTION

Governor pressure is controlled electronically. Com-

ponents used for governor pressure control include:

²Governor body

²Valve body transfer plate

²Governor pressure solenoid valve

²Governor pressure sensor

²Fluid temperature thermistor

²Throttle position sensor (TPS)

²Transmission speed sensor

²Powertrain control module (PCM)

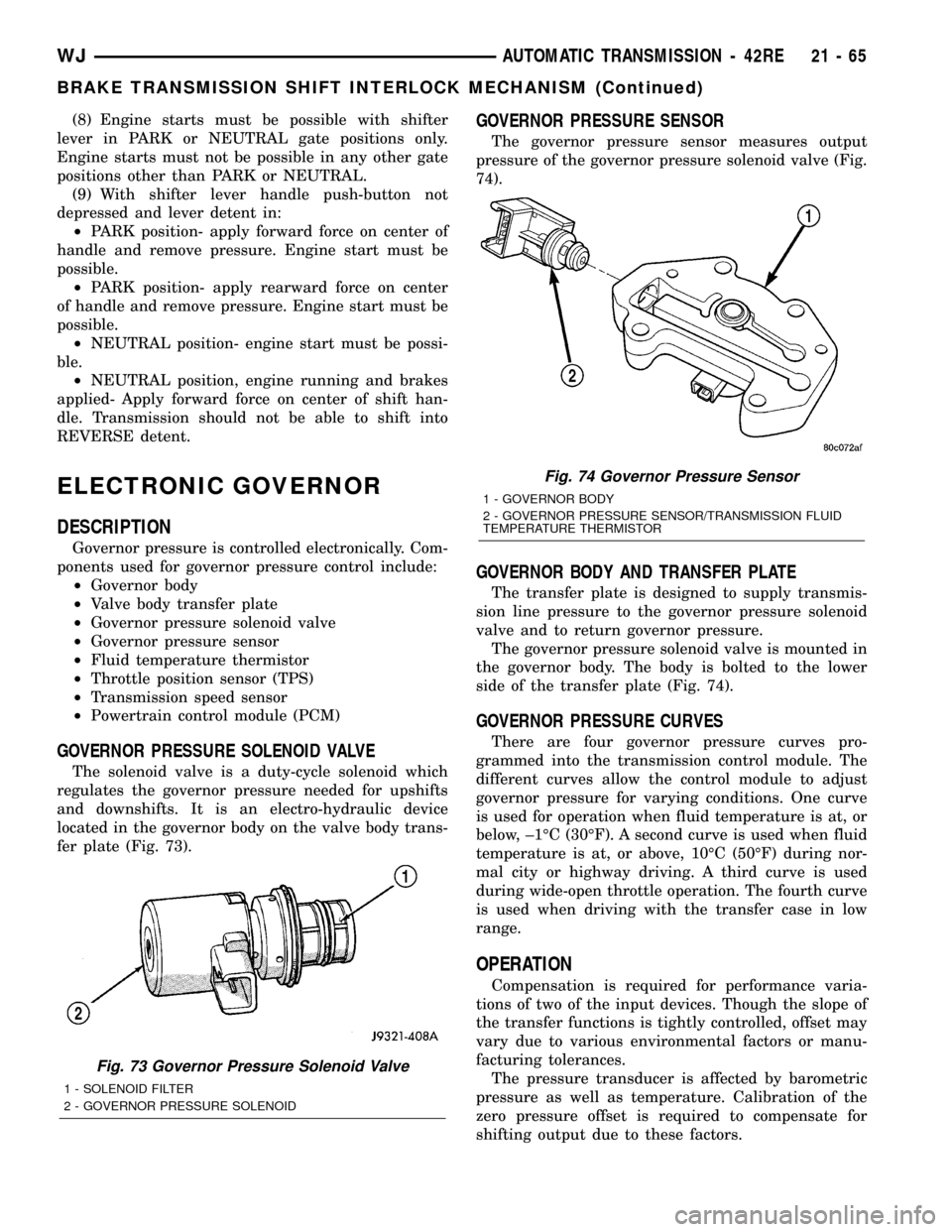

GOVERNOR PRESSURE SOLENOID VALVE

The solenoid valve is a duty-cycle solenoid which

regulates the governor pressure needed for upshifts

and downshifts. It is an electro-hydraulic device

located in the governor body on the valve body trans-

fer plate (Fig. 73).

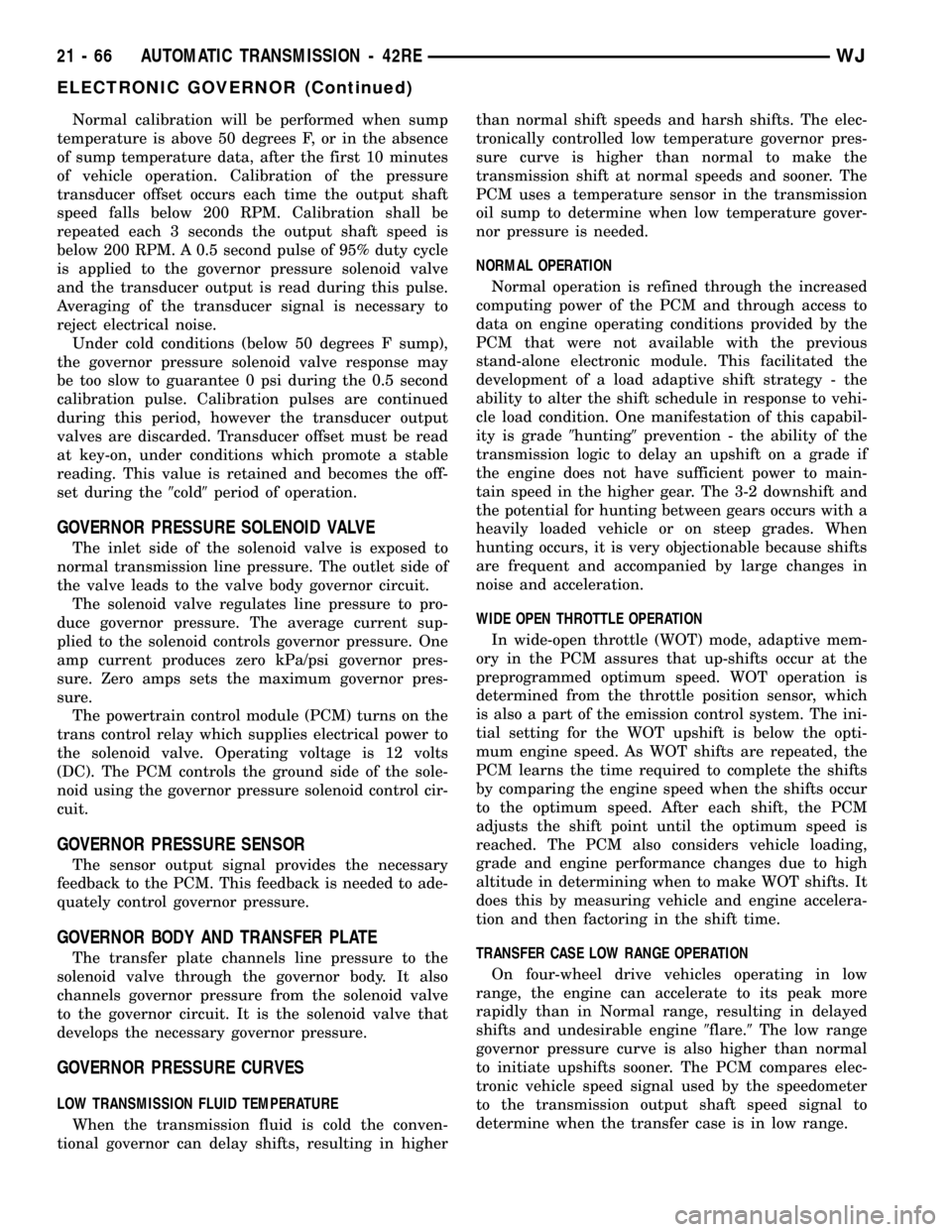

GOVERNOR PRESSURE SENSOR

The governor pressure sensor measures output

pressure of the governor pressure solenoid valve (Fig.

74).

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate is designed to supply transmis-

sion line pressure to the governor pressure solenoid

valve and to return governor pressure.

The governor pressure solenoid valve is mounted in

the governor body. The body is bolted to the lower

side of the transfer plate (Fig. 74).

GOVERNOR PRESSURE CURVES

There are four governor pressure curves pro-

grammed into the transmission control module. The

different curves allow the control module to adjust

governor pressure for varying conditions. One curve

is used for operation when fluid temperature is at, or

below, ±1ÉC (30ÉF). A second curve is used when fluid

temperature is at, or above, 10ÉC (50ÉF) during nor-

mal city or highway driving. A third curve is used

during wide-open throttle operation. The fourth curve

is used when driving with the transfer case in low

range.

OPERATION

Compensation is required for performance varia-

tions of two of the input devices. Though the slope of

the transfer functions is tightly controlled, offset may

vary due to various environmental factors or manu-

facturing tolerances.

The pressure transducer is affected by barometric

pressure as well as temperature. Calibration of the

zero pressure offset is required to compensate for

shifting output due to these factors.

Fig. 73 Governor Pressure Solenoid Valve

1 - SOLENOID FILTER

2 - GOVERNOR PRESSURE SOLENOID

Fig. 74 Governor Pressure Sensor

1 - GOVERNOR BODY

2 - GOVERNOR PRESSURE SENSOR/TRANSMISSION FLUID

TEMPERATURE THERMISTOR

WJAUTOMATIC TRANSMISSION - 42RE 21 - 65

BRAKE TRANSMISSION SHIFT INTERLOCK MECHANISM (Continued)

Page 1585 of 2199

Normal calibration will be performed when sump

temperature is above 50 degrees F, or in the absence

of sump temperature data, after the first 10 minutes

of vehicle operation. Calibration of the pressure

transducer offset occurs each time the output shaft

speed falls below 200 RPM. Calibration shall be

repeated each 3 seconds the output shaft speed is

below 200 RPM. A 0.5 second pulse of 95% duty cycle

is applied to the governor pressure solenoid valve

and the transducer output is read during this pulse.

Averaging of the transducer signal is necessary to

reject electrical noise.

Under cold conditions (below 50 degrees F sump),

the governor pressure solenoid valve response may

be too slow to guarantee 0 psi during the 0.5 second

calibration pulse. Calibration pulses are continued

during this period, however the transducer output

valves are discarded. Transducer offset must be read

at key-on, under conditions which promote a stable

reading. This value is retained and becomes the off-

set during the9cold9period of operation.

GOVERNOR PRESSURE SOLENOID VALVE

The inlet side of the solenoid valve is exposed to

normal transmission line pressure. The outlet side of

the valve leads to the valve body governor circuit.

The solenoid valve regulates line pressure to pro-

duce governor pressure. The average current sup-

plied to the solenoid controls governor pressure. One

amp current produces zero kPa/psi governor pres-

sure. Zero amps sets the maximum governor pres-

sure.

The powertrain control module (PCM) turns on the

trans control relay which supplies electrical power to

the solenoid valve. Operating voltage is 12 volts

(DC). The PCM controls the ground side of the sole-

noid using the governor pressure solenoid control cir-

cuit.

GOVERNOR PRESSURE SENSOR

The sensor output signal provides the necessary

feedback to the PCM. This feedback is needed to ade-

quately control governor pressure.

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate channels line pressure to the

solenoid valve through the governor body. It also

channels governor pressure from the solenoid valve

to the governor circuit. It is the solenoid valve that

develops the necessary governor pressure.

GOVERNOR PRESSURE CURVES

LOW TRANSMISSION FLUID TEMPERATURE

When the transmission fluid is cold the conven-

tional governor can delay shifts, resulting in higherthan normal shift speeds and harsh shifts. The elec-

tronically controlled low temperature governor pres-

sure curve is higher than normal to make the

transmission shift at normal speeds and sooner. The

PCM uses a temperature sensor in the transmission

oil sump to determine when low temperature gover-

nor pressure is needed.

NORMAL OPERATION

Normal operation is refined through the increased

computing power of the PCM and through access to

data on engine operating conditions provided by the

PCM that were not available with the previous

stand-alone electronic module. This facilitated the

development of a load adaptive shift strategy - the

ability to alter the shift schedule in response to vehi-

cle load condition. One manifestation of this capabil-

ity is grade9hunting9prevention - the ability of the

transmission logic to delay an upshift on a grade if

the engine does not have sufficient power to main-

tain speed in the higher gear. The 3-2 downshift and

the potential for hunting between gears occurs with a

heavily loaded vehicle or on steep grades. When

hunting occurs, it is very objectionable because shifts

are frequent and accompanied by large changes in

noise and acceleration.

WIDE OPEN THROTTLE OPERATION

In wide-open throttle (WOT) mode, adaptive mem-

ory in the PCM assures that up-shifts occur at the

preprogrammed optimum speed. WOT operation is

determined from the throttle position sensor, which

is also a part of the emission control system. The ini-

tial setting for the WOT upshift is below the opti-

mum engine speed. As WOT shifts are repeated, the

PCM learns the time required to complete the shifts

by comparing the engine speed when the shifts occur

to the optimum speed. After each shift, the PCM

adjusts the shift point until the optimum speed is

reached. The PCM also considers vehicle loading,

grade and engine performance changes due to high

altitude in determining when to make WOT shifts. It

does this by measuring vehicle and engine accelera-

tion and then factoring in the shift time.

TRANSFER CASE LOW RANGE OPERATION

On four-wheel drive vehicles operating in low

range, the engine can accelerate to its peak more

rapidly than in Normal range, resulting in delayed

shifts and undesirable engine9flare.9The low range

governor pressure curve is also higher than normal

to initiate upshifts sooner. The PCM compares elec-

tronic vehicle speed signal used by the speedometer

to the transmission output shaft speed signal to

determine when the transfer case is in low range.

21 - 66 AUTOMATIC TRANSMISSION - 42REWJ

ELECTRONIC GOVERNOR (Continued)

Page 1605 of 2199

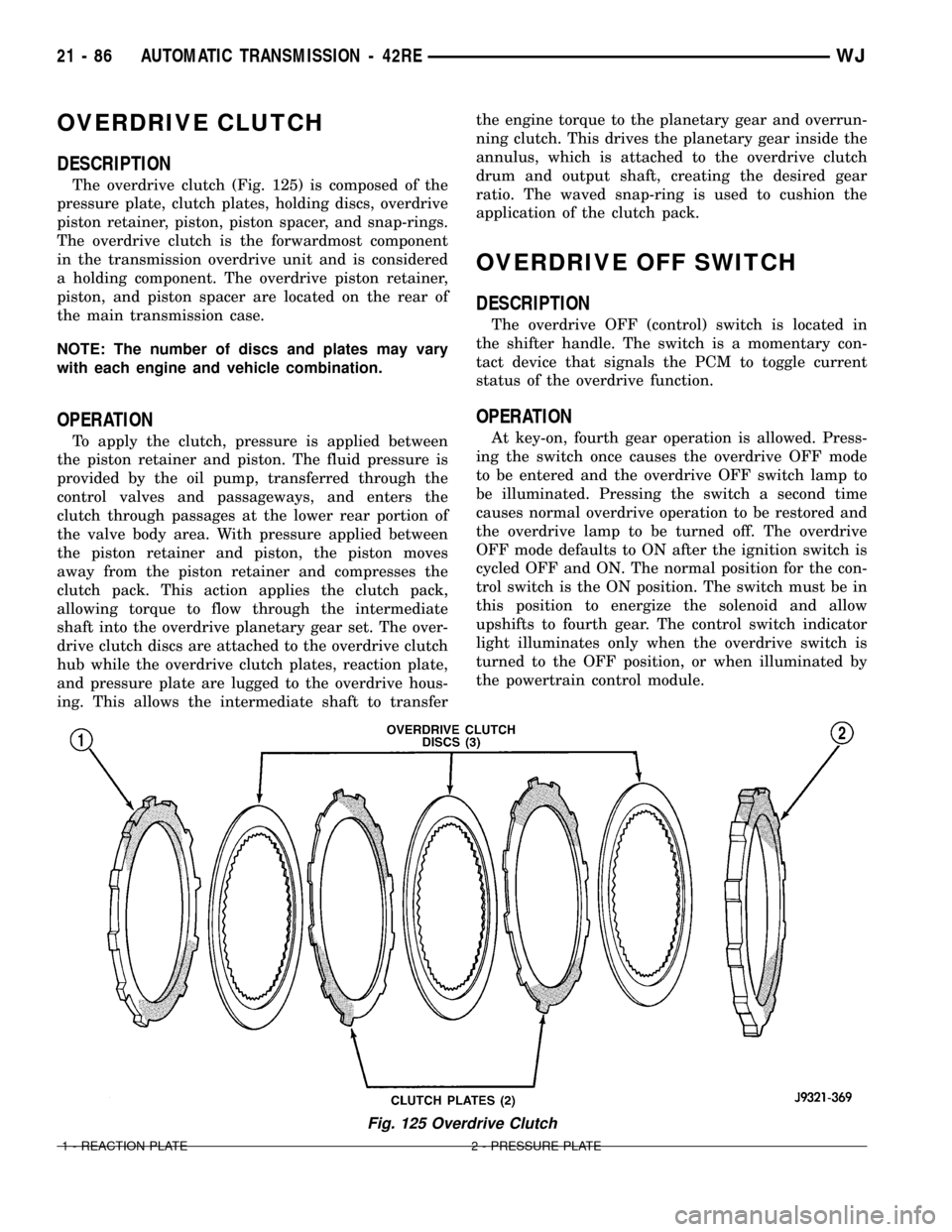

OVERDRIVE CLUTCH

DESCRIPTION

The overdrive clutch (Fig. 125) is composed of the

pressure plate, clutch plates, holding discs, overdrive

piston retainer, piston, piston spacer, and snap-rings.

The overdrive clutch is the forwardmost component

in the transmission overdrive unit and is considered

a holding component. The overdrive piston retainer,

piston, and piston spacer are located on the rear of

the main transmission case.

NOTE: The number of discs and plates may vary

with each engine and vehicle combination.

OPERATION

To apply the clutch, pressure is applied between

the piston retainer and piston. The fluid pressure is

provided by the oil pump, transferred through the

control valves and passageways, and enters the

clutch through passages at the lower rear portion of

the valve body area. With pressure applied between

the piston retainer and piston, the piston moves

away from the piston retainer and compresses the

clutch pack. This action applies the clutch pack,

allowing torque to flow through the intermediate

shaft into the overdrive planetary gear set. The over-

drive clutch discs are attached to the overdrive clutch

hub while the overdrive clutch plates, reaction plate,

and pressure plate are lugged to the overdrive hous-

ing. This allows the intermediate shaft to transferthe engine torque to the planetary gear and overrun-

ning clutch. This drives the planetary gear inside the

annulus, which is attached to the overdrive clutch

drum and output shaft, creating the desired gear

ratio. The waved snap-ring is used to cushion the

application of the clutch pack.

OVERDRIVE OFF SWITCH

DESCRIPTION

The overdrive OFF (control) switch is located in

the shifter handle. The switch is a momentary con-

tact device that signals the PCM to toggle current

status of the overdrive function.

OPERATION

At key-on, fourth gear operation is allowed. Press-

ing the switch once causes the overdrive OFF mode

to be entered and the overdrive OFF switch lamp to

be illuminated. Pressing the switch a second time

causes normal overdrive operation to be restored and

the overdrive lamp to be turned off. The overdrive

OFF mode defaults to ON after the ignition switch is

cycled OFF and ON. The normal position for the con-

trol switch is the ON position. The switch must be in

this position to energize the solenoid and allow

upshifts to fourth gear. The control switch indicator

light illuminates only when the overdrive switch is

turned to the OFF position, or when illuminated by

the powertrain control module.

Fig. 125 Overdrive Clutch

1 - REACTION PLATE 2 - PRESSURE PLATE

21 - 86 AUTOMATIC TRANSMISSION - 42REWJ

Page 1637 of 2199

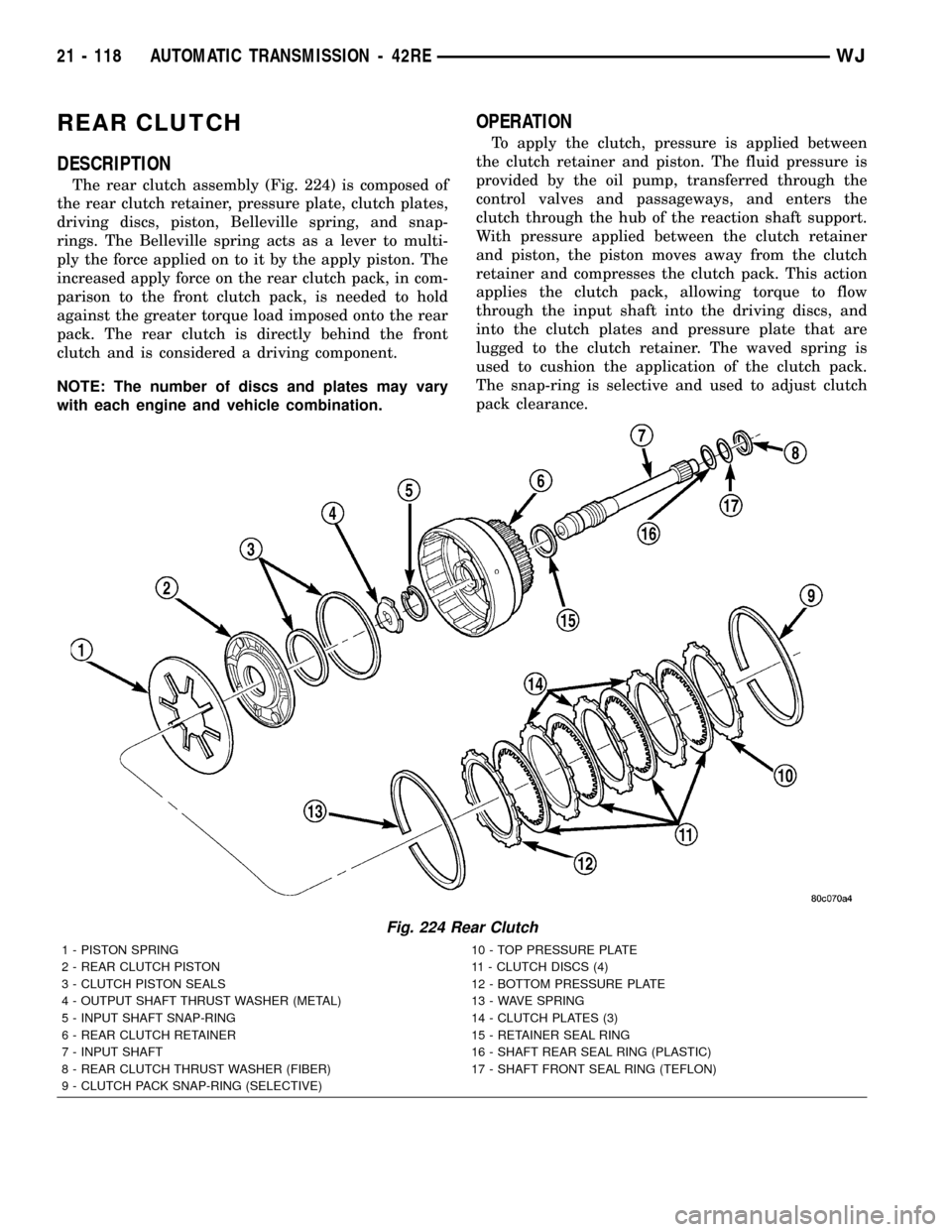

REAR CLUTCH

DESCRIPTION

The rear clutch assembly (Fig. 224) is composed of

the rear clutch retainer, pressure plate, clutch plates,

driving discs, piston, Belleville spring, and snap-

rings. The Belleville spring acts as a lever to multi-

ply the force applied on to it by the apply piston. The

increased apply force on the rear clutch pack, in com-

parison to the front clutch pack, is needed to hold

against the greater torque load imposed onto the rear

pack. The rear clutch is directly behind the front

clutch and is considered a driving component.

NOTE: The number of discs and plates may vary

with each engine and vehicle combination.

OPERATION

To apply the clutch, pressure is applied between

the clutch retainer and piston. The fluid pressure is

provided by the oil pump, transferred through the

control valves and passageways, and enters the

clutch through the hub of the reaction shaft support.

With pressure applied between the clutch retainer

and piston, the piston moves away from the clutch

retainer and compresses the clutch pack. This action

applies the clutch pack, allowing torque to flow

through the input shaft into the driving discs, and

into the clutch plates and pressure plate that are

lugged to the clutch retainer. The waved spring is

used to cushion the application of the clutch pack.

The snap-ring is selective and used to adjust clutch

pack clearance.

Fig. 224 Rear Clutch

1 - PISTON SPRING 10 - TOP PRESSURE PLATE

2 - REAR CLUTCH PISTON 11 - CLUTCH DISCS (4)

3 - CLUTCH PISTON SEALS 12 - BOTTOM PRESSURE PLATE

4 - OUTPUT SHAFT THRUST WASHER (METAL) 13 - WAVE SPRING

5 - INPUT SHAFT SNAP-RING 14 - CLUTCH PLATES (3)

6 - REAR CLUTCH RETAINER 15 - RETAINER SEAL RING

7 - INPUT SHAFT 16 - SHAFT REAR SEAL RING (PLASTIC)

8 - REAR CLUTCH THRUST WASHER (FIBER) 17 - SHAFT FRONT SEAL RING (TEFLON)

9 - CLUTCH PACK SNAP-RING (SELECTIVE)

21 - 118 AUTOMATIC TRANSMISSION - 42REWJ

Page 1645 of 2199

A solenoid can also be described by the method by

which it is controlled. Some of the possibilities

include variable force, pulse-width modulated, con-

stant ON, or duty cycle. The variable force and pulse-

width modulated versions utilize similar methods to

control the current flow through the solenoid to posi-

tion the solenoid plunger at a desired position some-

where between full ON and full OFF. The constant

ON and duty cycled versions control the voltage

across the solenoid to allow either full flow or no flow

through the solenoid's valve.

OPERATION

When an electrical current is applied to the sole-

noid coil, a magnetic field is created which produces

an attraction to the plunger, causing the plunger to

move and work against the spring pressure and the

load applied by the fluid the valve is controlling. The

plunger is normally directly attached to the valve

which it is to operate. When the current is removed

from the coil, the attraction is removed and the

plunger will return to its original position due to

spring pressure.

The plunger is made of a conductive material and

accomplishes this movement by providing a path for

the magnetic field to flow. By keeping the air gap

between the plunger and the coil to the minimum

necessary to allow free movement of the plunger, the

magnetic field is maximized.

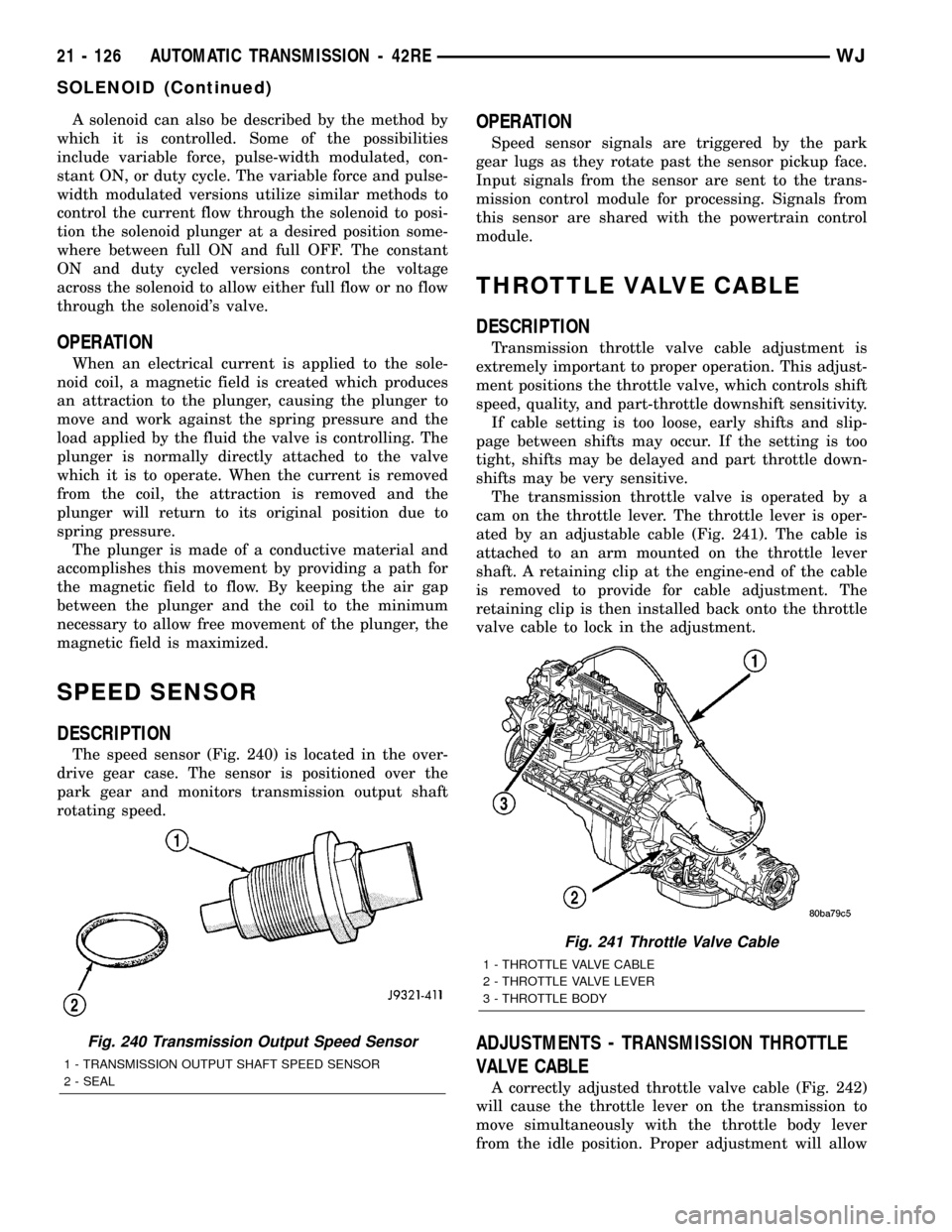

SPEED SENSOR

DESCRIPTION

The speed sensor (Fig. 240) is located in the over-

drive gear case. The sensor is positioned over the

park gear and monitors transmission output shaft

rotating speed.

OPERATION

Speed sensor signals are triggered by the park

gear lugs as they rotate past the sensor pickup face.

Input signals from the sensor are sent to the trans-

mission control module for processing. Signals from

this sensor are shared with the powertrain control

module.

THROTTLE VALVE CABLE

DESCRIPTION

Transmission throttle valve cable adjustment is

extremely important to proper operation. This adjust-

ment positions the throttle valve, which controls shift

speed, quality, and part-throttle downshift sensitivity.

If cable setting is too loose, early shifts and slip-

page between shifts may occur. If the setting is too

tight, shifts may be delayed and part throttle down-

shifts may be very sensitive.

The transmission throttle valve is operated by a

cam on the throttle lever. The throttle lever is oper-

ated by an adjustable cable (Fig. 241). The cable is

attached to an arm mounted on the throttle lever

shaft. A retaining clip at the engine-end of the cable

is removed to provide for cable adjustment. The

retaining clip is then installed back onto the throttle

valve cable to lock in the adjustment.

ADJUSTMENTS - TRANSMISSION THROTTLE

VALVE CABLE

A correctly adjusted throttle valve cable (Fig. 242)

will cause the throttle lever on the transmission to

move simultaneously with the throttle body lever

from the idle position. Proper adjustment will allow

Fig. 240 Transmission Output Speed Sensor

1 - TRANSMISSION OUTPUT SHAFT SPEED SENSOR

2 - SEAL

Fig. 241 Throttle Valve Cable

1 - THROTTLE VALVE CABLE

2 - THROTTLE VALVE LEVER

3 - THROTTLE BODY

21 - 126 AUTOMATIC TRANSMISSION - 42REWJ

SOLENOID (Continued)

Page 1652 of 2199

TORQUE CONVERTER CLUTCH (TCC)

The torque converter clutch is hydraulically

applied and is released when fluid is vented from the

hydraulic circuit by the torque converter control

(TCC) solenoid on the valve body. The torque con-

verter clutch is controlled by the Powertrain Control

Module (PCM). The torque converter clutch engages

in fourth gear, and in third gear under various con-

ditions, such as when the O/D switch is OFF, when

the vehicle is cruising on a level surface after the

vehicle has warmed up. The torque converter clutch

will disengage momentarily when an increase in

engine load is sensed by the PCM, such as when the

vehicle begins to go uphill or the throttle pressure is

increased.

REMOVAL

(1) Remove transmission and torque converter

from vehicle.

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive notches for sharp

edges, burrs, scratches, or nicks. Polish the hub and

notches with 320/400 grit paper or crocus cloth if nec-

essary. The hub must be smooth to avoid damaging

the pump seal at installation.

(1) Lubricate oil pump seal lip with transmission

fluid.

(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or bushing

while inserting torque converter into the front of the

transmission.

(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

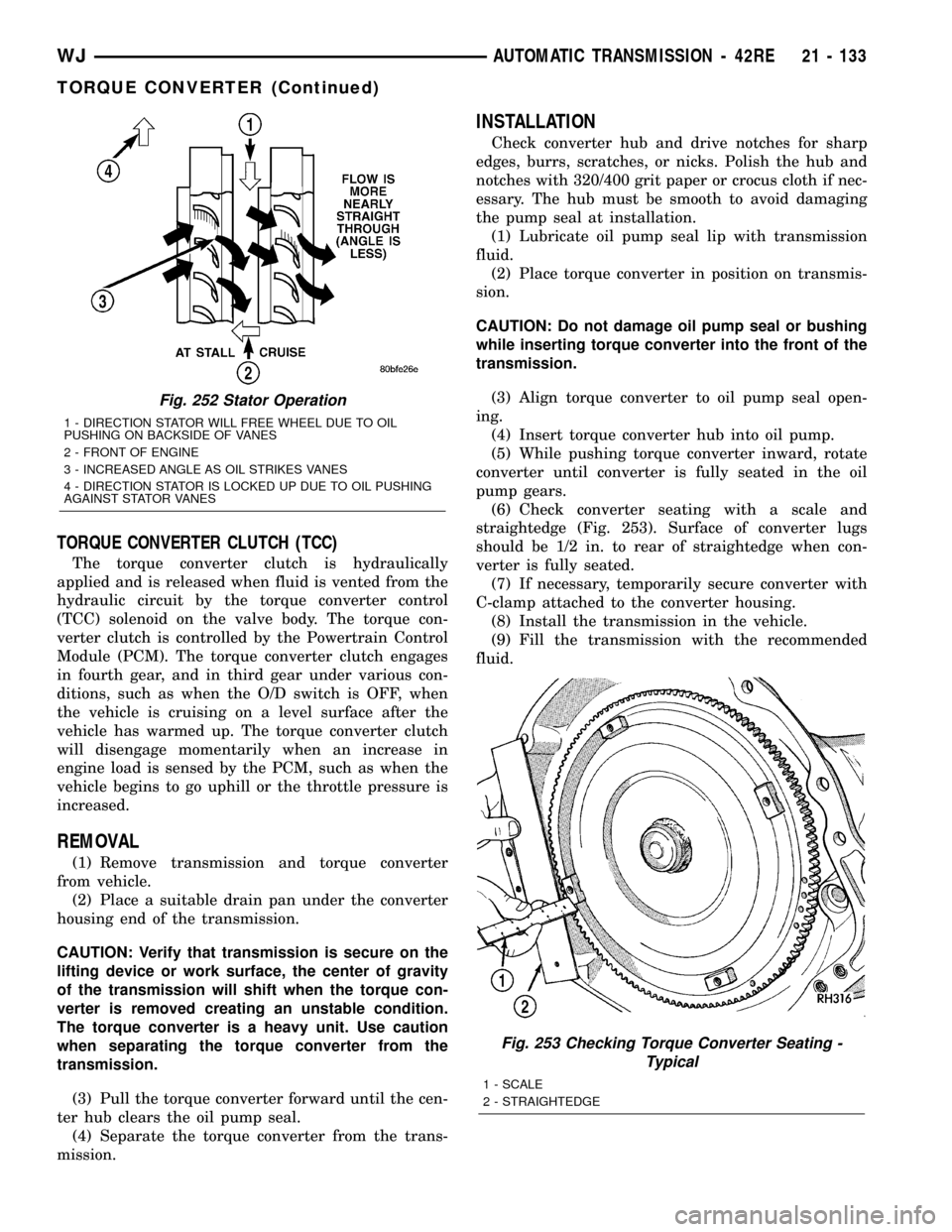

(6) Check converter seating with a scale and

straightedge (Fig. 253). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle.

(9) Fill the transmission with the recommended

fluid.

Fig. 252 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

Fig. 253 Checking Torque Converter Seating -

Typical

1 - SCALE

2 - STRAIGHTEDGE

WJAUTOMATIC TRANSMISSION - 42RE 21 - 133

TORQUE CONVERTER (Continued)