electrical JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1380 of 2199

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Disconnect generator electrical connections.

(8) Unbolt the generator and move it away from

the intake manifold for clearance.

(9) Disconnect air conditioning compressor electri-

cal connections.

(10) Unbolt the air conditioning compressor and

move it away from the intake manifold for clearance.

(11) Disconnect left and right radio suppressor

straps.

(12) Disconnect and remove ignition coil towers

(Refer to 8 - ELECTRICAL/IGNITION CONTROL/

IGNITION COIL - REMOVAL).

(13) Remove top oil dipstick tube retaining bolt

and ground strap.

(14) Bleed pressure from fuel system (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY - STANDARD

PROCEDURE).

(15) Remove fuel rail (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL RAIL - REMOVAL).

(16) Remove throttle body assembly and mounting

bracket.

(17) Drain cooling system below coolant tempera-

ture level (Refer to 7 - COOLING - STANDARD

PROCEDURE).

(18) Remove coolant temperature sensor (Refer to

7 - COOLING/ENGINE/ENGINE COOLANT TEMP

SENSOR - REMOVAL).

(19) Remove cowl to hood seal. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/COWL WEATHER-

STRIP - REMOVAL).

(20) Remove right side engine lifting stud.

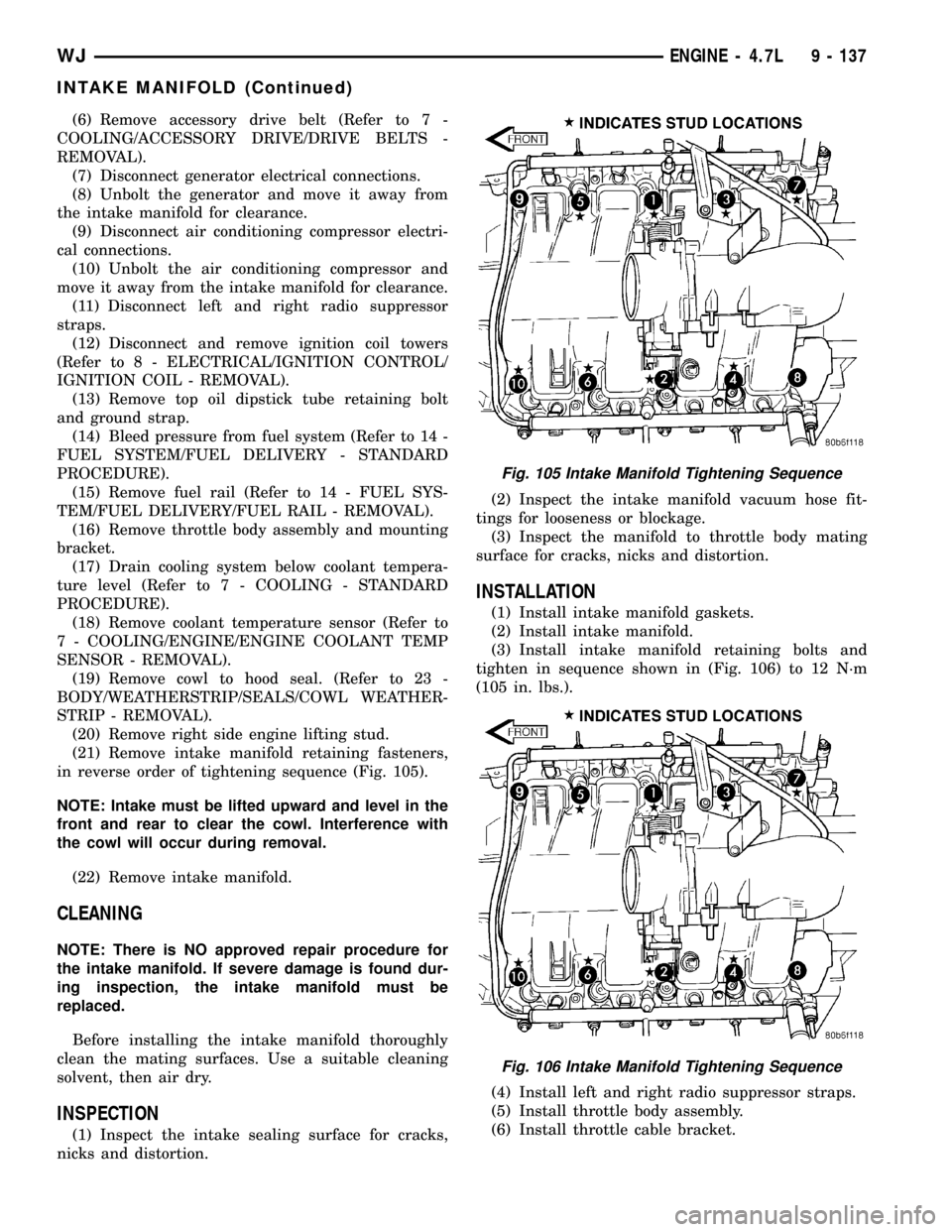

(21) Remove intake manifold retaining fasteners,

in reverse order of tightening sequence (Fig. 105).

NOTE: Intake must be lifted upward and level in the

front and rear to clear the cowl. Interference with

the cowl will occur during removal.

(22) Remove intake manifold.

CLEANING

NOTE: There is NO approved repair procedure for

the intake manifold. If severe damage is found dur-

ing inspection, the intake manifold must be

replaced.

Before installing the intake manifold thoroughly

clean the mating surfaces. Use a suitable cleaning

solvent, then air dry.

INSPECTION

(1) Inspect the intake sealing surface for cracks,

nicks and distortion.(2) Inspect the intake manifold vacuum hose fit-

tings for looseness or blockage.

(3) Inspect the manifold to throttle body mating

surface for cracks, nicks and distortion.

INSTALLATION

(1) Install intake manifold gaskets.

(2) Install intake manifold.

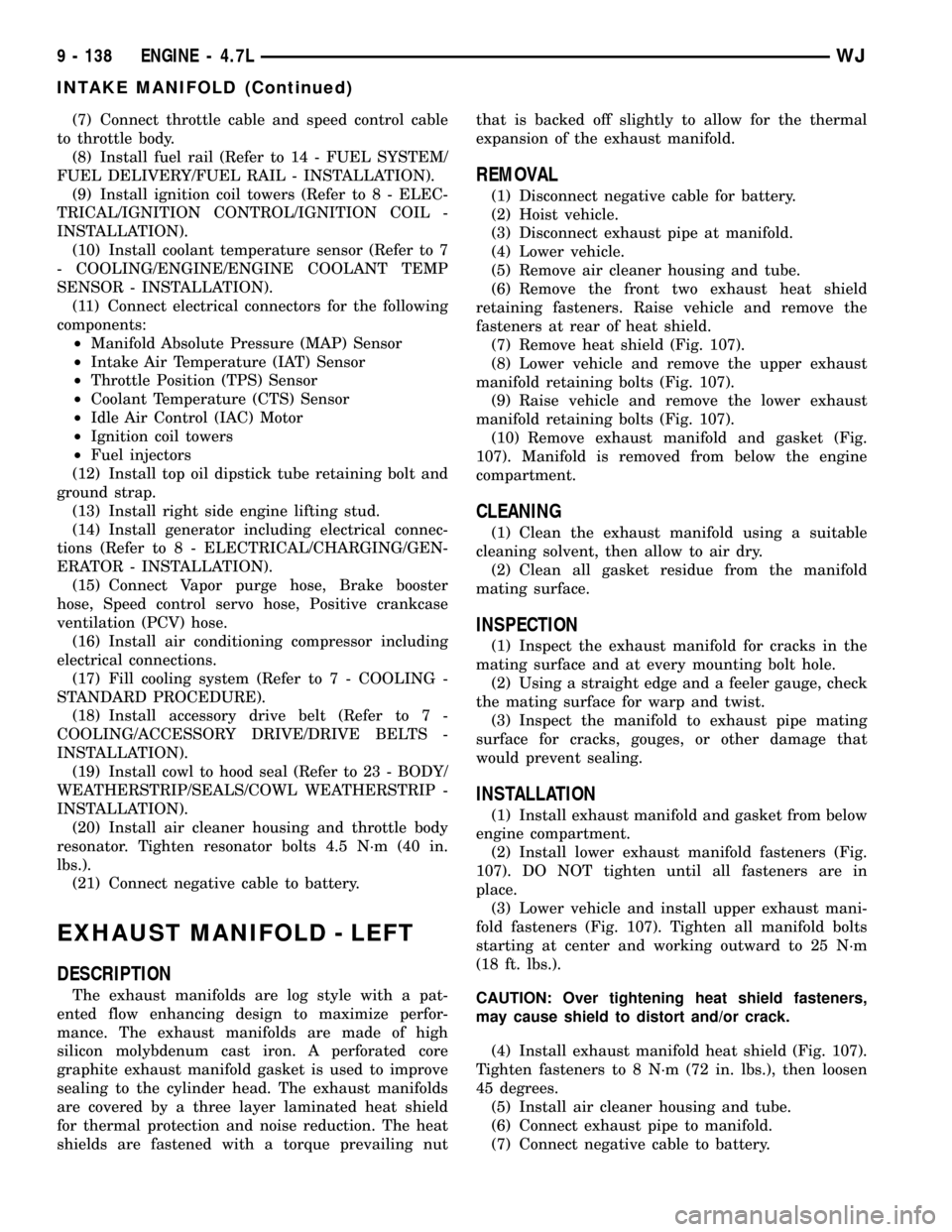

(3) Install intake manifold retaining bolts and

tighten in sequence shown in (Fig. 106) to 12 N´m

(105 in. lbs.).

(4) Install left and right radio suppressor straps.

(5) Install throttle body assembly.

(6) Install throttle cable bracket.

Fig. 105 Intake Manifold Tightening Sequence

Fig. 106 Intake Manifold Tightening Sequence

WJENGINE - 4.7L 9 - 137

INTAKE MANIFOLD (Continued)

Page 1381 of 2199

(7) Connect throttle cable and speed control cable

to throttle body.

(8) Install fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL RAIL - INSTALLATION).

(9) Install ignition coil towers (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/IGNITION COIL -

INSTALLATION).

(10) Install coolant temperature sensor (Refer to 7

- COOLING/ENGINE/ENGINE COOLANT TEMP

SENSOR - INSTALLATION).

(11) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

²Ignition coil towers

²Fuel injectors

(12) Install top oil dipstick tube retaining bolt and

ground strap.

(13) Install right side engine lifting stud.

(14) Install generator including electrical connec-

tions (Refer to 8 - ELECTRICAL/CHARGING/GEN-

ERATOR - INSTALLATION).

(15) Connect Vapor purge hose, Brake booster

hose, Speed control servo hose, Positive crankcase

ventilation (PCV) hose.

(16) Install air conditioning compressor including

electrical connections.

(17) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(18) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(19) Install cowl to hood seal (Refer to 23 - BODY/

WEATHERSTRIP/SEALS/COWL WEATHERSTRIP -

INSTALLATION).

(20) Install air cleaner housing and throttle body

resonator. Tighten resonator bolts 4.5 N´m (40 in.

lbs.).

(21) Connect negative cable to battery.

EXHAUST MANIFOLD - LEFT

DESCRIPTION

The exhaust manifolds are log style with a pat-

ented flow enhancing design to maximize perfor-

mance. The exhaust manifolds are made of high

silicon molybdenum cast iron. A perforated core

graphite exhaust manifold gasket is used to improve

sealing to the cylinder head. The exhaust manifolds

are covered by a three layer laminated heat shield

for thermal protection and noise reduction. The heat

shields are fastened with a torque prevailing nutthat is backed off slightly to allow for the thermal

expansion of the exhaust manifold.

REMOVAL

(1) Disconnect negative cable for battery.

(2) Hoist vehicle.

(3) Disconnect exhaust pipe at manifold.

(4) Lower vehicle.

(5) Remove air cleaner housing and tube.

(6) Remove the front two exhaust heat shield

retaining fasteners. Raise vehicle and remove the

fasteners at rear of heat shield.

(7) Remove heat shield (Fig. 107).

(8) Lower vehicle and remove the upper exhaust

manifold retaining bolts (Fig. 107).

(9) Raise vehicle and remove the lower exhaust

manifold retaining bolts (Fig. 107).

(10) Remove exhaust manifold and gasket (Fig.

107). Manifold is removed from below the engine

compartment.

CLEANING

(1) Clean the exhaust manifold using a suitable

cleaning solvent, then allow to air dry.

(2) Clean all gasket residue from the manifold

mating surface.

INSPECTION

(1) Inspect the exhaust manifold for cracks in the

mating surface and at every mounting bolt hole.

(2) Using a straight edge and a feeler gauge, check

the mating surface for warp and twist.

(3) Inspect the manifold to exhaust pipe mating

surface for cracks, gouges, or other damage that

would prevent sealing.

INSTALLATION

(1) Install exhaust manifold and gasket from below

engine compartment.

(2) Install lower exhaust manifold fasteners (Fig.

107). DO NOT tighten until all fasteners are in

place.

(3) Lower vehicle and install upper exhaust mani-

fold fasteners (Fig. 107). Tighten all manifold bolts

starting at center and working outward to 25 N´m

(18 ft. lbs.).

CAUTION: Over tightening heat shield fasteners,

may cause shield to distort and/or crack.

(4) Install exhaust manifold heat shield (Fig. 107).

Tighten fasteners to 8 N´m (72 in. lbs.), then loosen

45 degrees.

(5) Install air cleaner housing and tube.

(6) Connect exhaust pipe to manifold.

(7) Connect negative cable to battery.

9 - 138 ENGINE - 4.7LWJ

INTAKE MANIFOLD (Continued)

Page 1426 of 2199

(3) Apply a small amount of clean engine oil to

o-rings.

(4) Position filter/regulator to body and install 2

bolts. Tighten bolts to 3 N´m (30 in. lbs.) torque.

(5) Connect 3 fittings. Refer to Quick-Connect Fit-

tings.

(6) Connect negative battery cable to battery.

(7) Start engine and check for leaks.

FUEL LEVEL SENDING UNIT /

SENSOR

DESCRIPTION

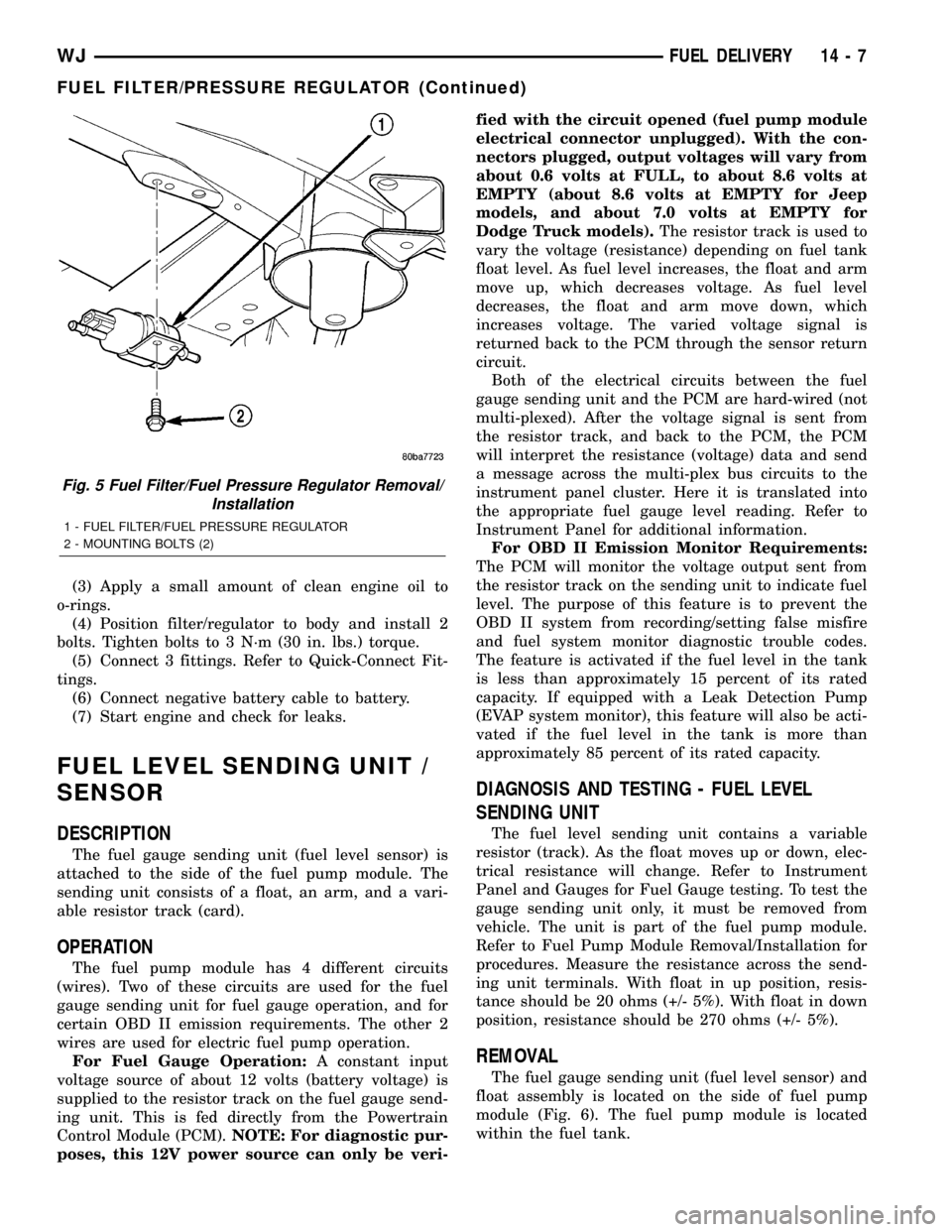

The fuel gauge sending unit (fuel level sensor) is

attached to the side of the fuel pump module. The

sending unit consists of a float, an arm, and a vari-

able resistor track (card).

OPERATION

The fuel pump module has 4 different circuits

(wires). Two of these circuits are used for the fuel

gauge sending unit for fuel gauge operation, and for

certain OBD II emission requirements. The other 2

wires are used for electric fuel pump operation.

For Fuel Gauge Operation:A constant input

voltage source of about 12 volts (battery voltage) is

supplied to the resistor track on the fuel gauge send-

ing unit. This is fed directly from the Powertrain

Control Module (PCM).NOTE: For diagnostic pur-

poses, this 12V power source can only be veri-fied with the circuit opened (fuel pump module

electrical connector unplugged). With the con-

nectors plugged, output voltages will vary from

about 0.6 volts at FULL, to about 8.6 volts at

EMPTY (about 8.6 volts at EMPTY for Jeep

models, and about 7.0 volts at EMPTY for

Dodge Truck models).The resistor track is used to

vary the voltage (resistance) depending on fuel tank

float level. As fuel level increases, the float and arm

move up, which decreases voltage. As fuel level

decreases, the float and arm move down, which

increases voltage. The varied voltage signal is

returned back to the PCM through the sensor return

circuit.

Both of the electrical circuits between the fuel

gauge sending unit and the PCM are hard-wired (not

multi-plexed). After the voltage signal is sent from

the resistor track, and back to the PCM, the PCM

will interpret the resistance (voltage) data and send

a message across the multi-plex bus circuits to the

instrument panel cluster. Here it is translated into

the appropriate fuel gauge level reading. Refer to

Instrument Panel for additional information.

For OBD II Emission Monitor Requirements:

The PCM will monitor the voltage output sent from

the resistor track on the sending unit to indicate fuel

level. The purpose of this feature is to prevent the

OBD II system from recording/setting false misfire

and fuel system monitor diagnostic trouble codes.

The feature is activated if the fuel level in the tank

is less than approximately 15 percent of its rated

capacity. If equipped with a Leak Detection Pump

(EVAP system monitor), this feature will also be acti-

vated if the fuel level in the tank is more than

approximately 85 percent of its rated capacity.

DIAGNOSIS AND TESTING - FUEL LEVEL

SENDING UNIT

The fuel level sending unit contains a variable

resistor (track). As the float moves up or down, elec-

trical resistance will change. Refer to Instrument

Panel and Gauges for Fuel Gauge testing. To test the

gauge sending unit only, it must be removed from

vehicle. The unit is part of the fuel pump module.

Refer to Fuel Pump Module Removal/Installation for

procedures. Measure the resistance across the send-

ing unit terminals. With float in up position, resis-

tance should be 20 ohms (+/- 5%). With float in down

position, resistance should be 270 ohms (+/- 5%).

REMOVAL

The fuel gauge sending unit (fuel level sensor) and

float assembly is located on the side of fuel pump

module (Fig. 6). The fuel pump module is located

within the fuel tank.

Fig. 5 Fuel Filter/Fuel Pressure Regulator Removal/

Installation

1 - FUEL FILTER/FUEL PRESSURE REGULATOR

2 - MOUNTING BOLTS (2)

WJFUEL DELIVERY 14 - 7

FUEL FILTER/PRESSURE REGULATOR (Continued)

Page 1427 of 2199

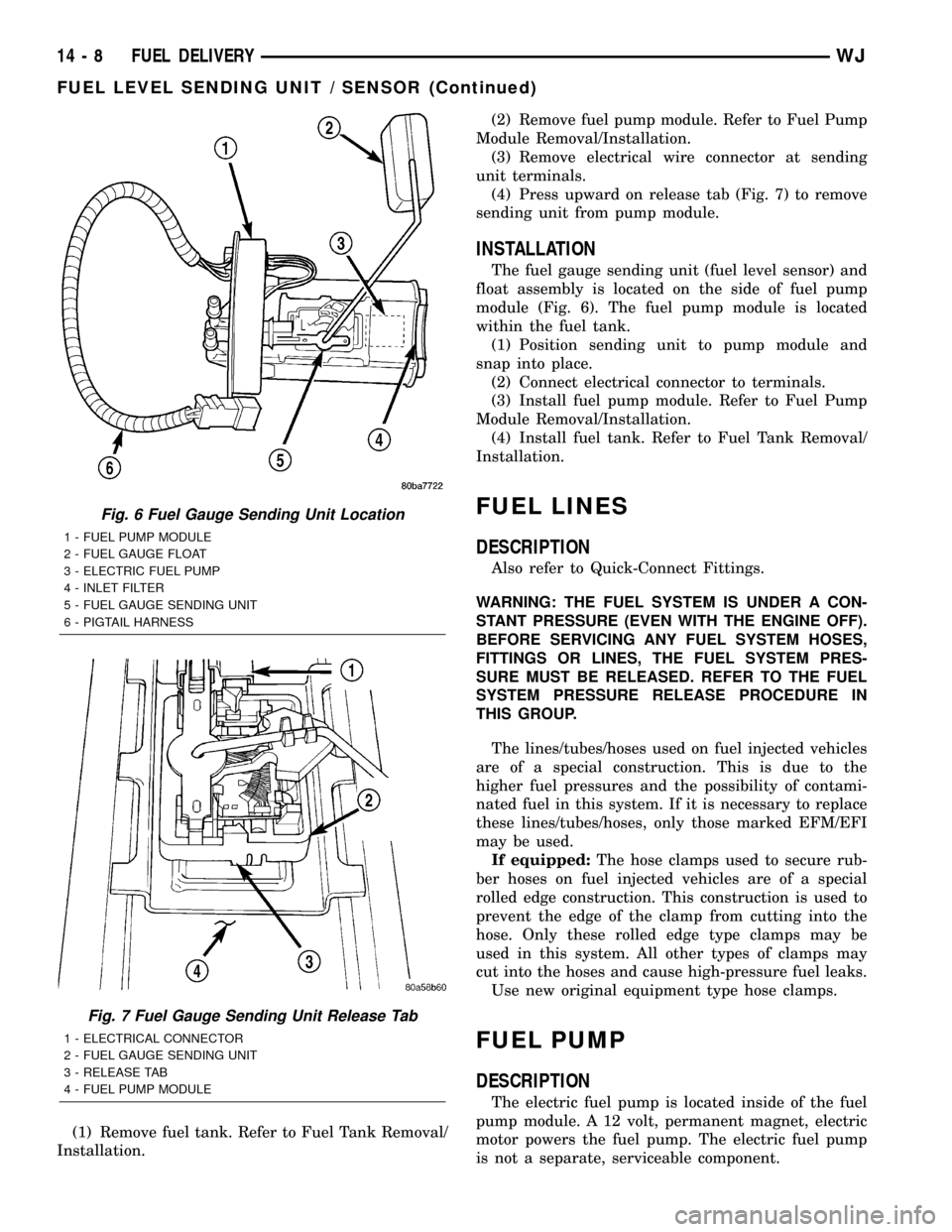

(1) Remove fuel tank. Refer to Fuel Tank Removal/

Installation.(2) Remove fuel pump module. Refer to Fuel Pump

Module Removal/Installation.

(3) Remove electrical wire connector at sending

unit terminals.

(4) Press upward on release tab (Fig. 7) to remove

sending unit from pump module.

INSTALLATION

The fuel gauge sending unit (fuel level sensor) and

float assembly is located on the side of fuel pump

module (Fig. 6). The fuel pump module is located

within the fuel tank.

(1) Position sending unit to pump module and

snap into place.

(2) Connect electrical connector to terminals.

(3) Install fuel pump module. Refer to Fuel Pump

Module Removal/Installation.

(4) Install fuel tank. Refer to Fuel Tank Removal/

Installation.

FUEL LINES

DESCRIPTION

Also refer to Quick-Connect Fittings.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP.

The lines/tubes/hoses used on fuel injected vehicles

are of a special construction. This is due to the

higher fuel pressures and the possibility of contami-

nated fuel in this system. If it is necessary to replace

these lines/tubes/hoses, only those marked EFM/EFI

may be used.

If equipped:The hose clamps used to secure rub-

ber hoses on fuel injected vehicles are of a special

rolled edge construction. This construction is used to

prevent the edge of the clamp from cutting into the

hose. Only these rolled edge type clamps may be

used in this system. All other types of clamps may

cut into the hoses and cause high-pressure fuel leaks.

Use new original equipment type hose clamps.

FUEL PUMP

DESCRIPTION

The electric fuel pump is located inside of the fuel

pump module. A 12 volt, permanent magnet, electric

motor powers the fuel pump. The electric fuel pump

is not a separate, serviceable component.

Fig. 6 Fuel Gauge Sending Unit Location

1 - FUEL PUMP MODULE

2 - FUEL GAUGE FLOAT

3 - ELECTRIC FUEL PUMP

4 - INLET FILTER

5 - FUEL GAUGE SENDING UNIT

6 - PIGTAIL HARNESS

Fig. 7 Fuel Gauge Sending Unit Release Tab

1 - ELECTRICAL CONNECTOR

2 - FUEL GAUGE SENDING UNIT

3 - RELEASE TAB

4 - FUEL PUMP MODULE

14 - 8 FUEL DELIVERYWJ

FUEL LEVEL SENDING UNIT / SENSOR (Continued)

Page 1429 of 2199

(5) Connect (-) and (+) test cable leads into LCS

adapter receptacles. Use10 amp (10A +)receptacle

and common (-) receptacles.

(6) Gain access to MAIN MENU on DRB screen.

(7) Press DVOM button on DRB.

(8) Using left/right arrow keys, highlight CHAN-

NEL 1 function on DRB screen.

(9) Press ENTER three times.

(10) Using up/down arrow keys, highlight RANGE

on DRB screen (screen will default to 2 amp scale).

(11) Press ENTER to change 2 amp scale to 10

amp scale.This step must be done to prevent

damage to DRB scan tool or LCS adapter

(blown fuse).

(12) Remove cover from Power Distribution Center

(PDC).

(13) Remove fuel pump relay from PDC. Refer to

label on PDC cover for relay location.

WARNING: BEFORE PROCEEDING TO NEXT STEP,

NOTE THE FUEL PUMP WILL BE ACTIVATED AND

SYSTEM PRESSURE WILL BE PRESENT. THIS WILL

OCCUR AFTER CONNECTING TEST LEADS FROM

LCS ADAPTER INTO FUEL PUMP RELAY CAVITIES.

THE FUEL PUMP WILL OPERATE EVEN WITH IGNI-

TION KEY IN OFF POSITION. BEFORE ATTACHING

TEST LEADS, BE SURE ALL FUEL LINES AND

FUEL SYSTEM COMPONENTS ARE CONNECTED.

CAUTION: To prevent possible damage to the vehi-

cle electrical system and LCS adapter, the test

leads must be connected into relay cavities exactly

as shown in following steps.

Depending upon vehicle model, year or engine con-

figuration, three different types of relays may be

used: Type-1, type-2 and type±3.

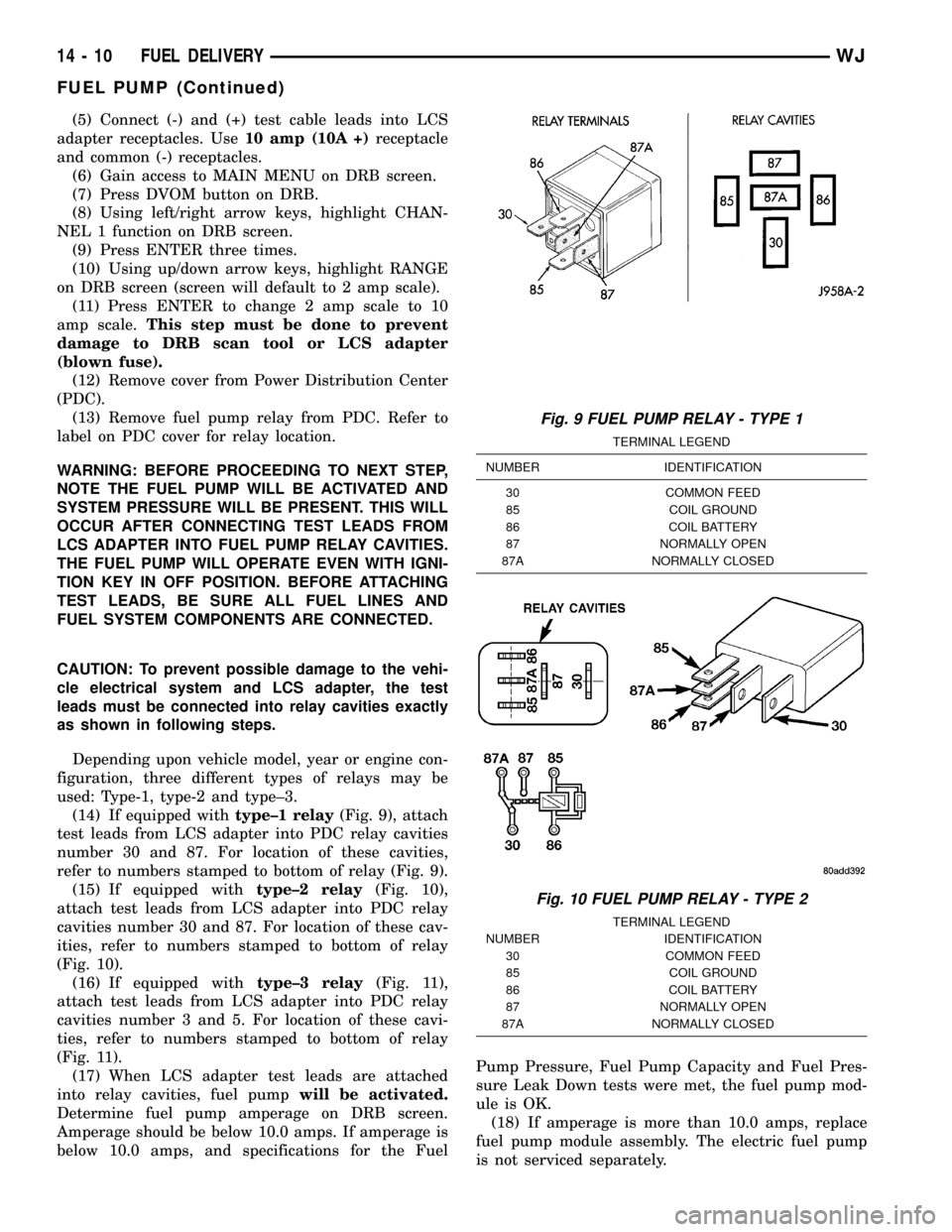

(14) If equipped withtype±1 relay(Fig. 9), attach

test leads from LCS adapter into PDC relay cavities

number 30 and 87. For location of these cavities,

refer to numbers stamped to bottom of relay (Fig. 9).

(15) If equipped withtype±2 relay(Fig. 10),

attach test leads from LCS adapter into PDC relay

cavities number 30 and 87. For location of these cav-

ities, refer to numbers stamped to bottom of relay

(Fig. 10).

(16) If equipped withtype±3 relay(Fig. 11),

attach test leads from LCS adapter into PDC relay

cavities number 3 and 5. For location of these cavi-

ties, refer to numbers stamped to bottom of relay

(Fig. 11).

(17) When LCS adapter test leads are attached

into relay cavities, fuel pumpwill be activated.

Determine fuel pump amperage on DRB screen.

Amperage should be below 10.0 amps. If amperage is

below 10.0 amps, and specifications for the FuelPump Pressure, Fuel Pump Capacity and Fuel Pres-

sure Leak Down tests were met, the fuel pump mod-

ule is OK.

(18) If amperage is more than 10.0 amps, replace

fuel pump module assembly. The electric fuel pump

is not serviced separately.

Fig. 9 FUEL PUMP RELAY - TYPE 1

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

Fig. 10 FUEL PUMP RELAY - TYPE 2

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

14 - 10 FUEL DELIVERYWJ

FUEL PUMP (Continued)

Page 1432 of 2199

(e) Use DRB scan tool to power fuel pump. If

pressure is now within specifications, replace fuel

filter/fuel pressure regulator.

(f) If pressure is still low, replace fuel pump

module.

(4) If operating pressure is above 54.2 psi, electric

fuel pump is OK, but fuel pressure regulator is defec-

tive. Replace fuel filter/fuel pressure regulator.

(5) Install test port cap to fuel rail test port.

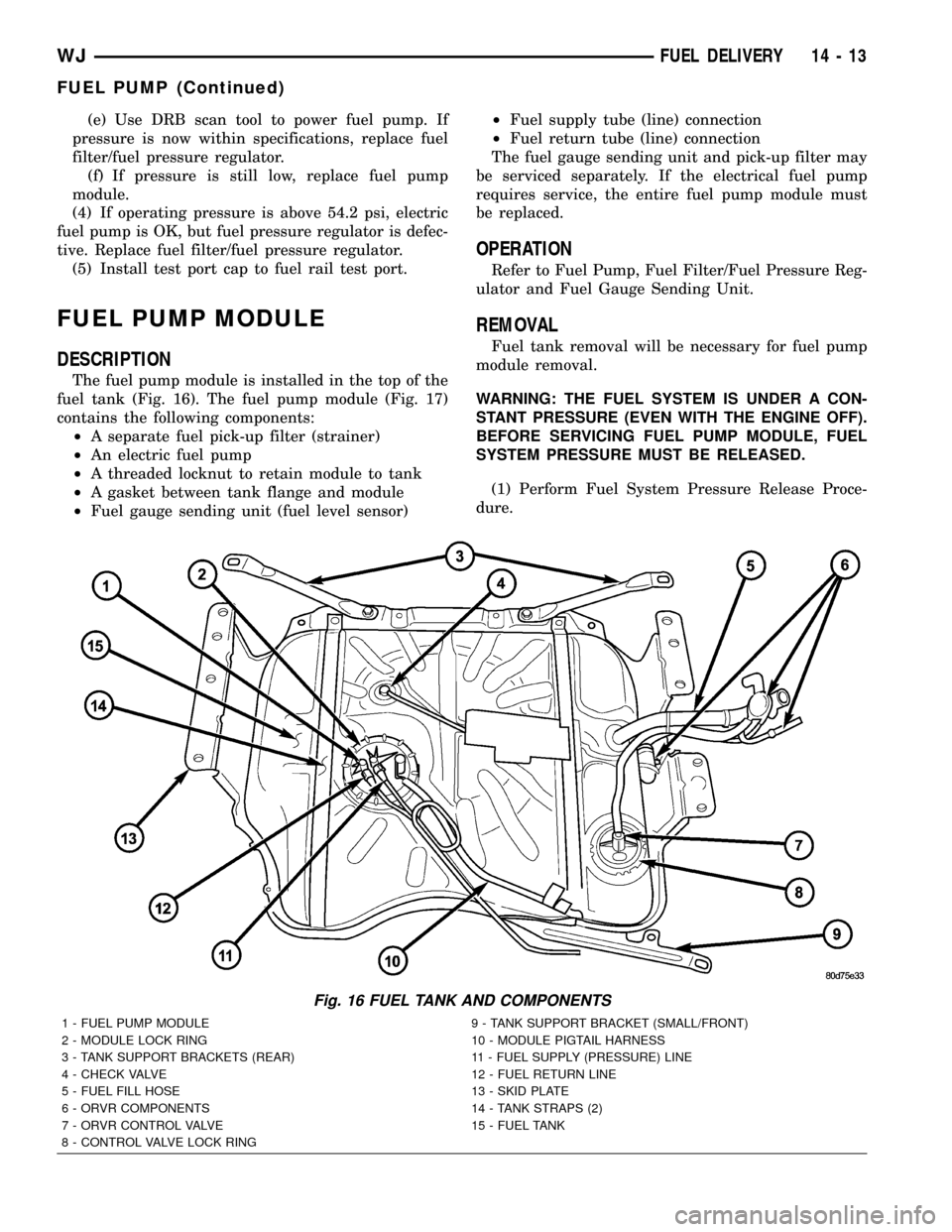

FUEL PUMP MODULE

DESCRIPTION

The fuel pump module is installed in the top of the

fuel tank (Fig. 16). The fuel pump module (Fig. 17)

contains the following components:

²A separate fuel pick-up filter (strainer)

²An electric fuel pump

²A threaded locknut to retain module to tank

²A gasket between tank flange and module

²Fuel gauge sending unit (fuel level sensor)²Fuel supply tube (line) connection

²Fuel return tube (line) connection

The fuel gauge sending unit and pick-up filter may

be serviced separately. If the electrical fuel pump

requires service, the entire fuel pump module must

be replaced.

OPERATION

Refer to Fuel Pump, Fuel Filter/Fuel Pressure Reg-

ulator and Fuel Gauge Sending Unit.

REMOVAL

Fuel tank removal will be necessary for fuel pump

module removal.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING FUEL PUMP MODULE, FUEL

SYSTEM PRESSURE MUST BE RELEASED.

(1) Perform Fuel System Pressure Release Proce-

dure.

Fig. 16 FUEL TANK AND COMPONENTS

1 - FUEL PUMP MODULE 9 - TANK SUPPORT BRACKET (SMALL/FRONT)

2 - MODULE LOCK RING 10 - MODULE PIGTAIL HARNESS

3 - TANK SUPPORT BRACKETS (REAR) 11 - FUEL SUPPLY (PRESSURE) LINE

4 - CHECK VALVE 12 - FUEL RETURN LINE

5 - FUEL FILL HOSE 13 - SKID PLATE

6 - ORVR COMPONENTS 14 - TANK STRAPS (2)

7 - ORVR CONTROL VALVE 15 - FUEL TANK

8 - CONTROL VALVE LOCK RING

WJFUEL DELIVERY 14 - 13

FUEL PUMP (Continued)

Page 1435 of 2199

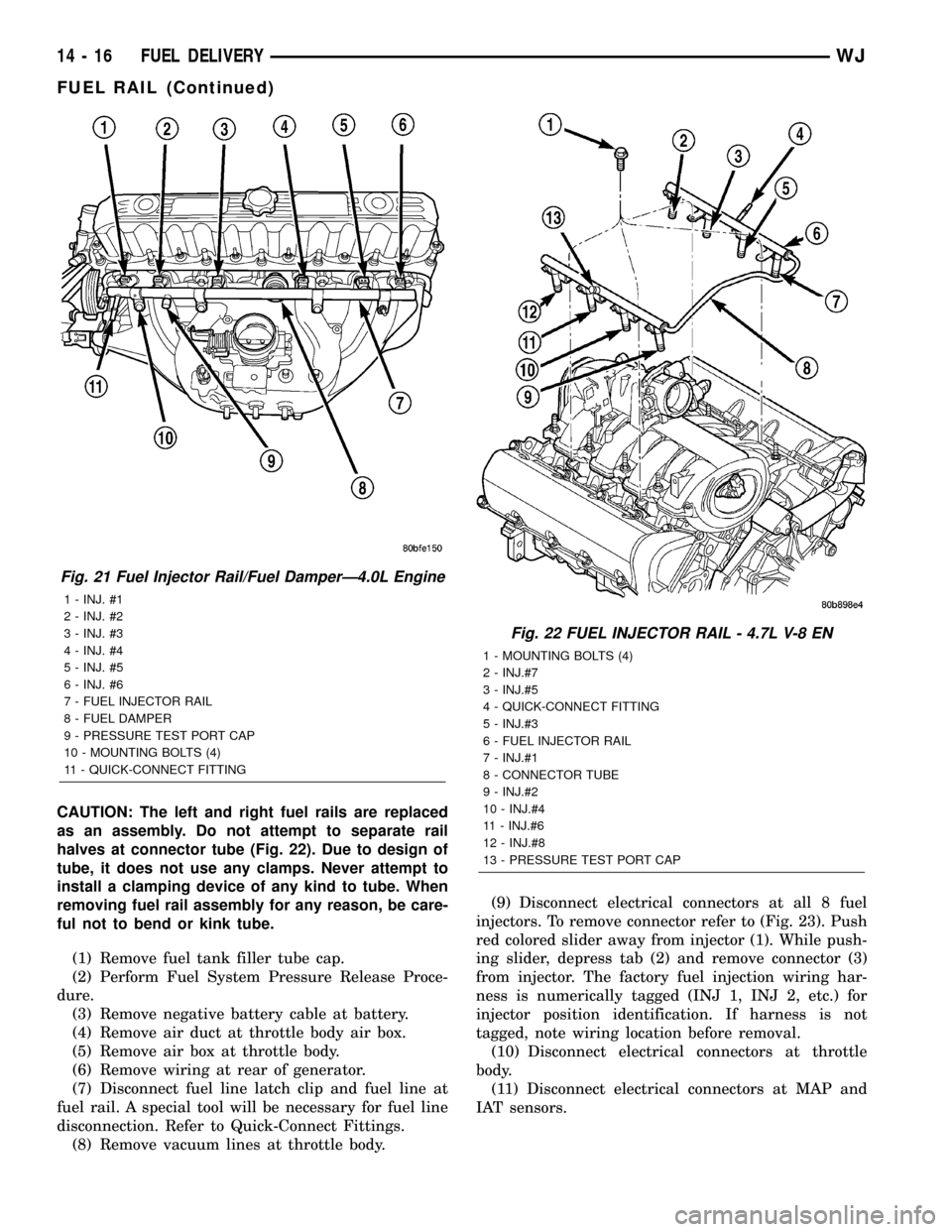

CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate rail

halves at connector tube (Fig. 22). Due to design of

tube, it does not use any clamps. Never attempt to

install a clamping device of any kind to tube. When

removing fuel rail assembly for any reason, be care-

ful not to bend or kink tube.

(1) Remove fuel tank filler tube cap.

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Remove negative battery cable at battery.

(4) Remove air duct at throttle body air box.

(5) Remove air box at throttle body.

(6) Remove wiring at rear of generator.

(7) Disconnect fuel line latch clip and fuel line at

fuel rail. A special tool will be necessary for fuel line

disconnection. Refer to Quick-Connect Fittings.

(8) Remove vacuum lines at throttle body.(9) Disconnect electrical connectors at all 8 fuel

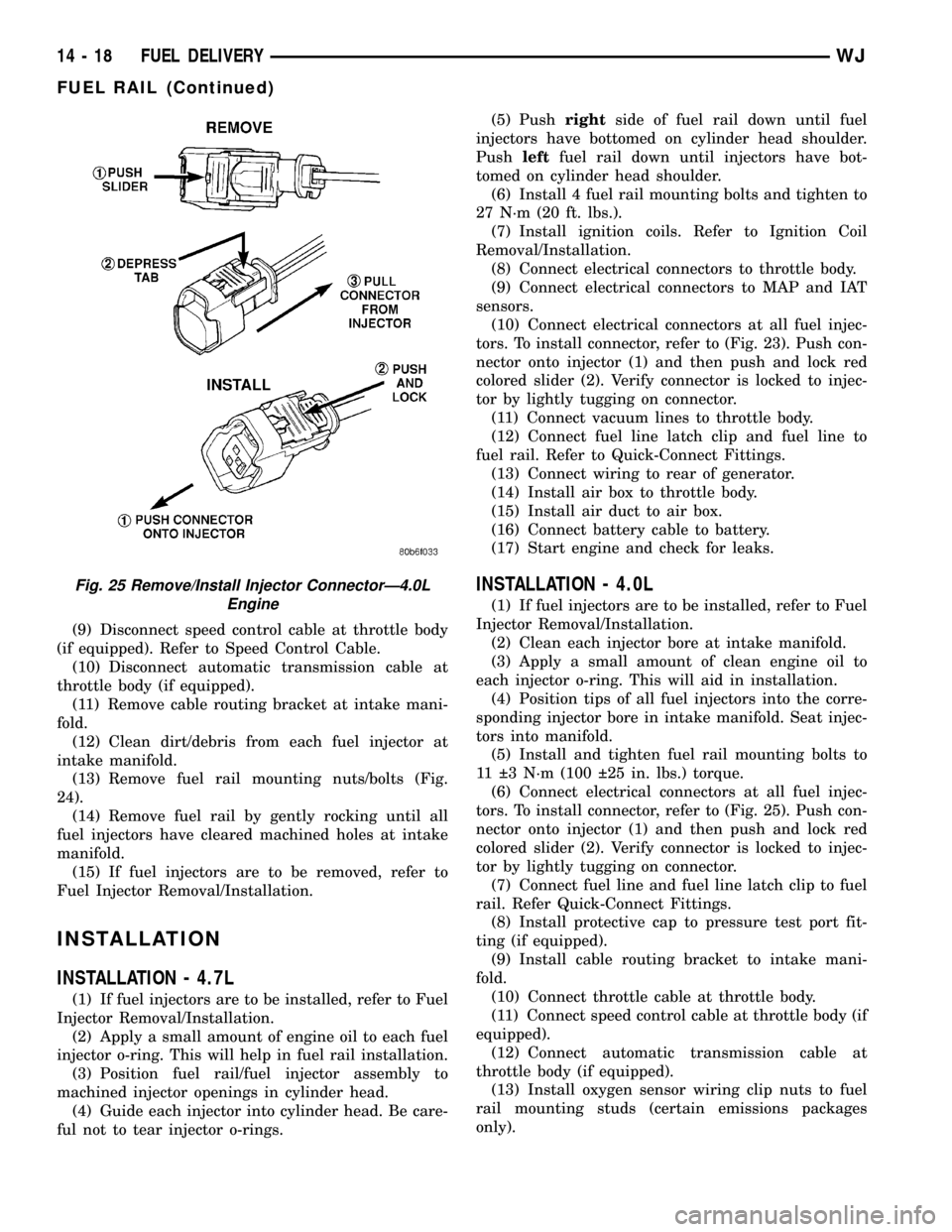

injectors. To remove connector refer to (Fig. 23). Push

red colored slider away from injector (1). While push-

ing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring har-

ness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(10) Disconnect electrical connectors at throttle

body.

(11) Disconnect electrical connectors at MAP and

IAT sensors.

Fig. 21 Fuel Injector Rail/Fuel DamperÐ4.0L Engine

1 - INJ. #1

2 - INJ. #2

3 - INJ. #3

4 - INJ. #4

5 - INJ. #5

6 - INJ. #6

7 - FUEL INJECTOR RAIL

8 - FUEL DAMPER

9 - PRESSURE TEST PORT CAP

10 - MOUNTING BOLTS (4)

11 - QUICK-CONNECT FITTING

Fig. 22 FUEL INJECTOR RAIL - 4.7L V-8 EN

1 - MOUNTING BOLTS (4)

2 - INJ.#7

3 - INJ.#5

4 - QUICK-CONNECT FITTING

5 - INJ.#3

6 - FUEL INJECTOR RAIL

7 - INJ.#1

8 - CONNECTOR TUBE

9 - INJ.#2

10 - INJ.#4

11 - INJ.#6

12 - INJ.#8

13 - PRESSURE TEST PORT CAP

14 - 16 FUEL DELIVERYWJ

FUEL RAIL (Continued)

Page 1436 of 2199

(12) Remove first three ignition coils on each bank

(cylinders #1, 3, 5, 2, 4 and 6). Refer to Ignition Coil

Removal/Installation.

(13) Remove 4 fuel rail mounting bolts (Fig. 22).

(14) Gently rock and pullleftside of fuel rail until

fuel injectors just start to clear machined holes in

cylinder head. Gently rock and pullrightside of rail

until injectors just start to clear cylinder head holes.

Repeat this procedure (left/right) until all injectors

have cleared cylinder head holes.

(15) Remove fuel rail (with injectors attached)

from engine.

(16) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

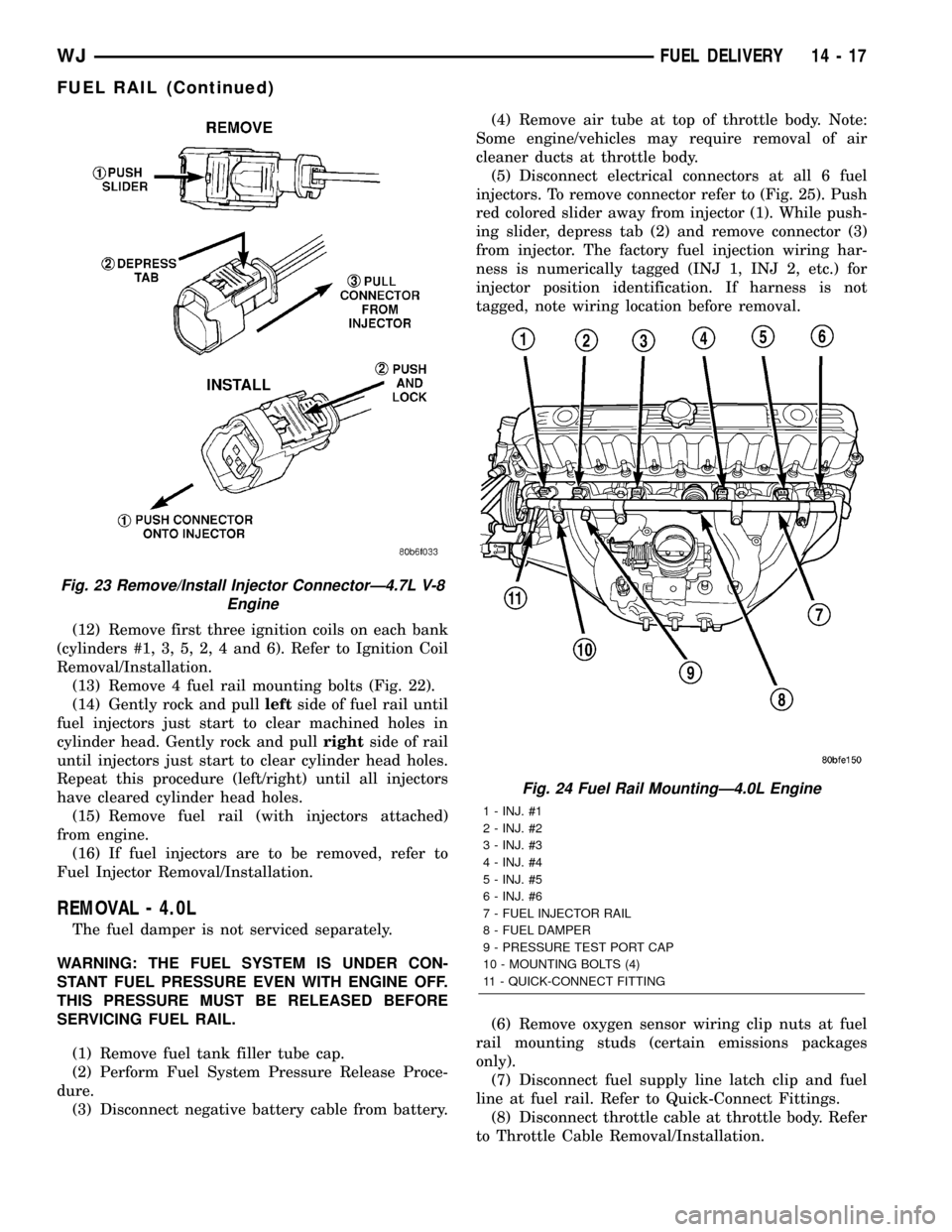

REMOVAL - 4.0L

The fuel damper is not serviced separately.

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT FUEL PRESSURE EVEN WITH ENGINE OFF.

THIS PRESSURE MUST BE RELEASED BEFORE

SERVICING FUEL RAIL.

(1) Remove fuel tank filler tube cap.

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Disconnect negative battery cable from battery.(4) Remove air tube at top of throttle body. Note:

Some engine/vehicles may require removal of air

cleaner ducts at throttle body.

(5) Disconnect electrical connectors at all 6 fuel

injectors. To remove connector refer to (Fig. 25). Push

red colored slider away from injector (1). While push-

ing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring har-

ness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(6) Remove oxygen sensor wiring clip nuts at fuel

rail mounting studs (certain emissions packages

only).

(7) Disconnect fuel supply line latch clip and fuel

line at fuel rail. Refer to Quick-Connect Fittings.

(8) Disconnect throttle cable at throttle body. Refer

to Throttle Cable Removal/Installation.

Fig. 23 Remove/Install Injector ConnectorÐ4.7L V-8

Engine

Fig. 24 Fuel Rail MountingÐ4.0L Engine

1 - INJ. #1

2 - INJ. #2

3 - INJ. #3

4 - INJ. #4

5 - INJ. #5

6 - INJ. #6

7 - FUEL INJECTOR RAIL

8 - FUEL DAMPER

9 - PRESSURE TEST PORT CAP

10 - MOUNTING BOLTS (4)

11 - QUICK-CONNECT FITTING

WJFUEL DELIVERY 14 - 17

FUEL RAIL (Continued)

Page 1437 of 2199

(9) Disconnect speed control cable at throttle body

(if equipped). Refer to Speed Control Cable.

(10) Disconnect automatic transmission cable at

throttle body (if equipped).

(11) Remove cable routing bracket at intake mani-

fold.

(12) Clean dirt/debris from each fuel injector at

intake manifold.

(13) Remove fuel rail mounting nuts/bolts (Fig.

24).

(14) Remove fuel rail by gently rocking until all

fuel injectors have cleared machined holes at intake

manifold.

(15) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

INSTALLATION

INSTALLATION - 4.7L

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(3) Position fuel rail/fuel injector assembly to

machined injector openings in cylinder head.

(4) Guide each injector into cylinder head. Be care-

ful not to tear injector o-rings.(5) Pushrightside of fuel rail down until fuel

injectors have bottomed on cylinder head shoulder.

Pushleftfuel rail down until injectors have bot-

tomed on cylinder head shoulder.

(6) Install 4 fuel rail mounting bolts and tighten to

27 N´m (20 ft. lbs.).

(7) Install ignition coils. Refer to Ignition Coil

Removal/Installation.

(8) Connect electrical connectors to throttle body.

(9) Connect electrical connectors to MAP and IAT

sensors.

(10) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 23). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(11) Connect vacuum lines to throttle body.

(12) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(13) Connect wiring to rear of generator.

(14) Install air box to throttle body.

(15) Install air duct to air box.

(16) Connect battery cable to battery.

(17) Start engine and check for leaks.

INSTALLATION - 4.0L

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean each injector bore at intake manifold.

(3) Apply a small amount of clean engine oil to

each injector o-ring. This will aid in installation.

(4) Position tips of all fuel injectors into the corre-

sponding injector bore in intake manifold. Seat injec-

tors into manifold.

(5) Install and tighten fuel rail mounting bolts to

11 3 N´m (100 25 in. lbs.) torque.

(6) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 25). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(7) Connect fuel line and fuel line latch clip to fuel

rail. Refer Quick-Connect Fittings.

(8) Install protective cap to pressure test port fit-

ting (if equipped).

(9) Install cable routing bracket to intake mani-

fold.

(10) Connect throttle cable at throttle body.

(11) Connect speed control cable at throttle body (if

equipped).

(12) Connect automatic transmission cable at

throttle body (if equipped).

(13) Install oxygen sensor wiring clip nuts to fuel

rail mounting studs (certain emissions packages

only).

Fig. 25 Remove/Install Injector ConnectorÐ4.0L

Engine

14 - 18 FUEL DELIVERYWJ

FUEL RAIL (Continued)

Page 1439 of 2199

(19) Disconnect fuel return line at fuel filter/fuel

pressure regulator (Fig. 36). Refer to Quick-Connect

Fittings for procedures.

(20) Disconnect fuel pressure line at fuel filter/fuel

pressure regulator (Fig. 36). Refer to Quick-Connect

Fittings for procedures.

(21) Disconnect EVAP canister vent line near front

of tank (Fig. 36).

(22) Disconnect fuel pump module electrical con-

nector (pigtail harness) near front of tank (Fig. 36).

Harness connector is clipped to body.

(23) Remove left / front tank support bracket bolt

at frame (Fig. 37).

(24)WITHOUT TRAILER HITCH:Remove tank-

to-frame mounting bolts (Fig. 39). Remove rear tank

support bracket bolts at frame (Fig. 38). Carefully

lower tank until clear of vehicle. Place tank on floor.

(25)WITH TRAILER HITCH:Remove tank /

hitch mounting bolts (Fig. 40). Carefully lower tank

until clear of vehicle. Place tank on floor.

(26) If necessary, separate skid plate from fuel

tank by removing 2 fuel tank strap nuts (Fig. 39) and

remove 2 tank straps.

(27) If fuel pump module removal is necessary,

refer to Fuel Pump Module Removal/Installation.

(28) If hoses are to be removed at fuel tank end,

note painted alignment (indexing) markings on

hoses, and molded indexing tangs on tank before

removal. Remove hoses.

(29) If necessary, remove 3 fuel filler tube assem-

bly mounting bolts (Fig. 41) and remove fuel filler

tube.

INSTALLATION

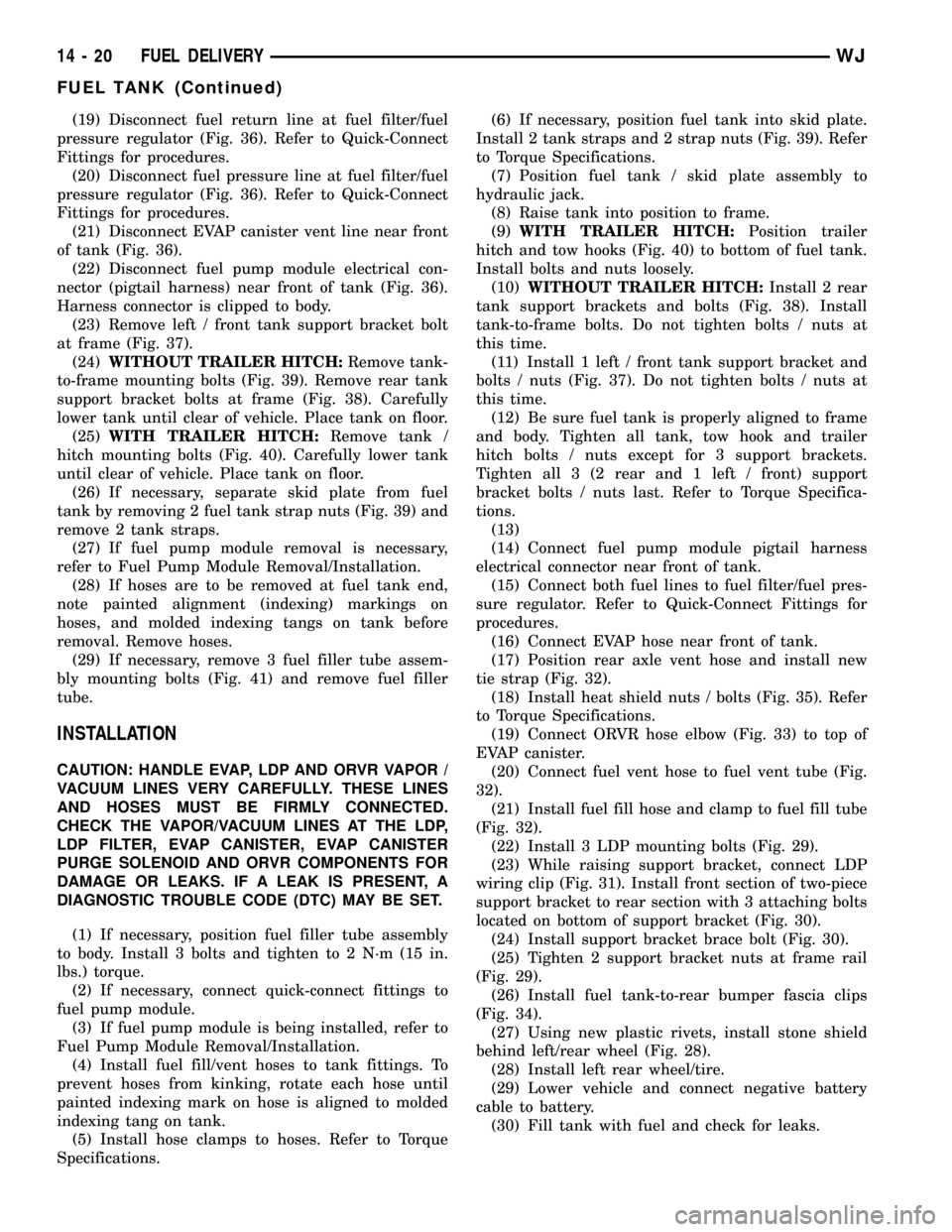

CAUTION: HANDLE EVAP, LDP AND ORVR VAPOR /

VACUUM LINES VERY CAREFULLY. THESE LINES

AND HOSES MUST BE FIRMLY CONNECTED.

CHECK THE VAPOR/VACUUM LINES AT THE LDP,

LDP FILTER, EVAP CANISTER, EVAP CANISTER

PURGE SOLENOID AND ORVR COMPONENTS FOR

DAMAGE OR LEAKS. IF A LEAK IS PRESENT, A

DIAGNOSTIC TROUBLE CODE (DTC) MAY BE SET.

(1) If necessary, position fuel filler tube assembly

to body. Install 3 bolts and tighten to 2 N´m (15 in.

lbs.) torque.

(2) If necessary, connect quick-connect fittings to

fuel pump module.

(3) If fuel pump module is being installed, refer to

Fuel Pump Module Removal/Installation.

(4) Install fuel fill/vent hoses to tank fittings. To

prevent hoses from kinking, rotate each hose until

painted indexing mark on hose is aligned to molded

indexing tang on tank.

(5) Install hose clamps to hoses. Refer to Torque

Specifications.(6) If necessary, position fuel tank into skid plate.

Install 2 tank straps and 2 strap nuts (Fig. 39). Refer

to Torque Specifications.

(7) Position fuel tank / skid plate assembly to

hydraulic jack.

(8) Raise tank into position to frame.

(9)WITH TRAILER HITCH:Position trailer

hitch and tow hooks (Fig. 40) to bottom of fuel tank.

Install bolts and nuts loosely.

(10)WITHOUT TRAILER HITCH:Install 2 rear

tank support brackets and bolts (Fig. 38). Install

tank-to-frame bolts. Do not tighten bolts / nuts at

this time.

(11) Install 1 left / front tank support bracket and

bolts / nuts (Fig. 37). Do not tighten bolts / nuts at

this time.

(12) Be sure fuel tank is properly aligned to frame

and body. Tighten all tank, tow hook and trailer

hitch bolts / nuts except for 3 support brackets.

Tighten all 3 (2 rear and 1 left / front) support

bracket bolts / nuts last. Refer to Torque Specifica-

tions.

(13)

(14) Connect fuel pump module pigtail harness

electrical connector near front of tank.

(15) Connect both fuel lines to fuel filter/fuel pres-

sure regulator. Refer to Quick-Connect Fittings for

procedures.

(16) Connect EVAP hose near front of tank.

(17) Position rear axle vent hose and install new

tie strap (Fig. 32).

(18) Install heat shield nuts / bolts (Fig. 35). Refer

to Torque Specifications.

(19) Connect ORVR hose elbow (Fig. 33) to top of

EVAP canister.

(20) Connect fuel vent hose to fuel vent tube (Fig.

32).

(21) Install fuel fill hose and clamp to fuel fill tube

(Fig. 32).

(22) Install 3 LDP mounting bolts (Fig. 29).

(23) While raising support bracket, connect LDP

wiring clip (Fig. 31). Install front section of two-piece

support bracket to rear section with 3 attaching bolts

located on bottom of support bracket (Fig. 30).

(24) Install support bracket brace bolt (Fig. 30).

(25) Tighten 2 support bracket nuts at frame rail

(Fig. 29).

(26) Install fuel tank-to-rear bumper fascia clips

(Fig. 34).

(27) Using new plastic rivets, install stone shield

behind left/rear wheel (Fig. 28).

(28) Install left rear wheel/tire.

(29) Lower vehicle and connect negative battery

cable to battery.

(30) Fill tank with fuel and check for leaks.

14 - 20 FUEL DELIVERYWJ

FUEL TANK (Continued)