Horn JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 555 of 2199

(3) Align and seat the one pin and the two mount-

ing ears on the clockspring case to their respective

holes in the multi-function switch mounting housing.

(4) Install and tighten the two clockspring mount-

ing screws. Tighten the screws to 2.5 N´m (22 in.

lbs.).

(5) Reconnect the two instrument panel wire har-

ness connectors for the clockspring to the two connec-

tor receptacles below the steering column on the back

of the clockspring case.

(6) Position the lower tilting steering column

shroud onto the steering column (Fig. 16).

(7) Install and tighten the screw that secures the

lower tilting steering column shroud to the multi-

function switch mounting housing. Tighten the screw

to 2 N´m (17 in. lbs.).

(8) Position the upper tilting column shroud onto

the steering column with the hazard warning switch

button inserted through the hole in the upper surface

of the shroud. Align the upper tilting steering column

shroud to the lower shroud and snap the two shroud

halves together.

(9) Align the snap features on the upper and lower

shrouds and apply hand pressure to snap them

together.

(10) Reinstall the steering wheel onto the steering

column. (Refer to 19 - STEERING/COLUMN/STEER-

ING WHEEL - INSTALLATION).

(11)

Reconnect the steering wheel wire harness con-

nectors to the upper clockspring connector receptacles.

(12) Reinstall the driver airbag onto the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

DRIVER AIRBAG

DESCRIPTION

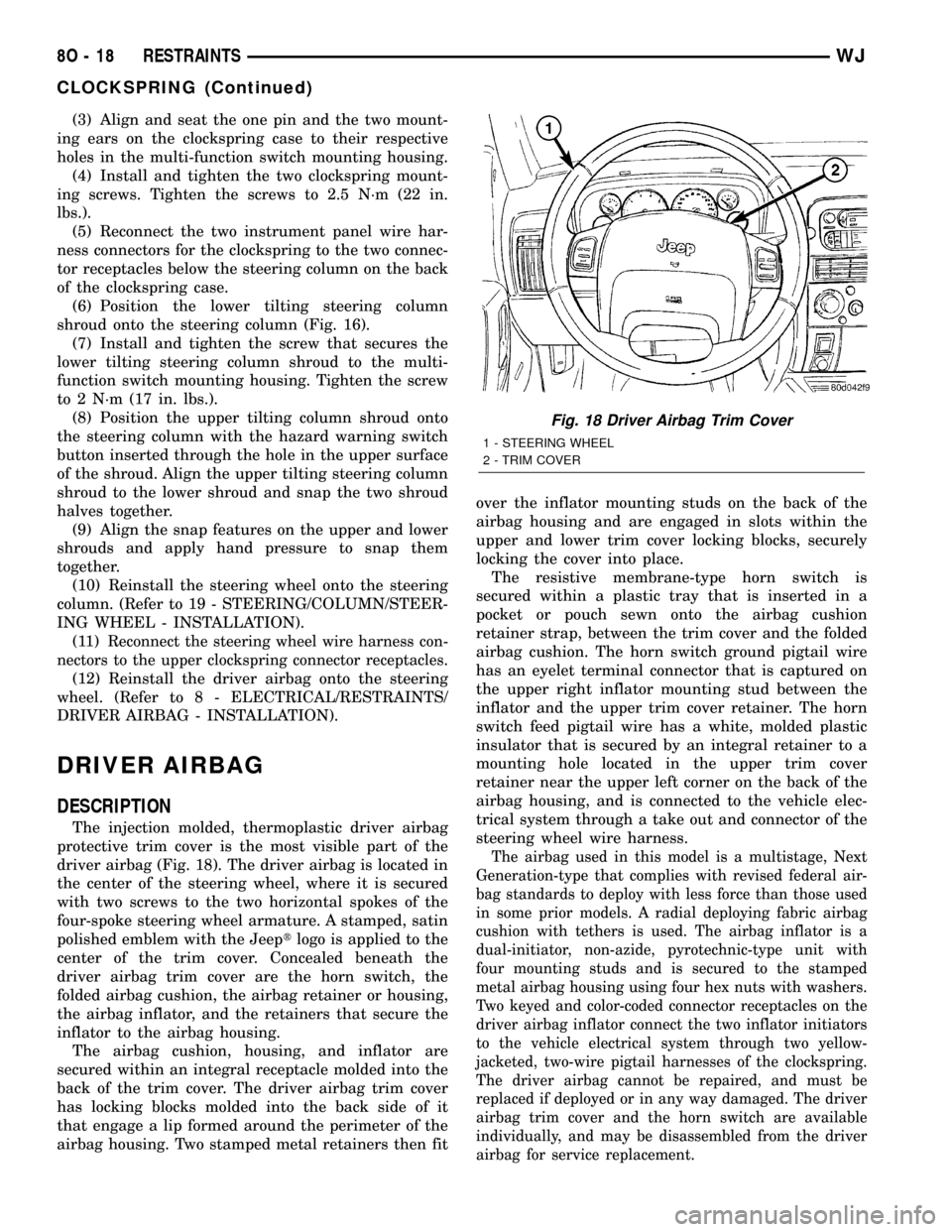

The injection molded, thermoplastic driver airbag

protective trim cover is the most visible part of the

driver airbag (Fig. 18). The driver airbag is located in

the center of the steering wheel, where it is secured

with two screws to the two horizontal spokes of the

four-spoke steering wheel armature. A stamped, satin

polished emblem with the Jeeptlogo is applied to the

center of the trim cover. Concealed beneath the

driver airbag trim cover are the horn switch, the

folded airbag cushion, the airbag retainer or housing,

the airbag inflator, and the retainers that secure the

inflator to the airbag housing.

The airbag cushion, housing, and inflator are

secured within an integral receptacle molded into the

back of the trim cover. The driver airbag trim cover

has locking blocks molded into the back side of it

that engage a lip formed around the perimeter of the

airbag housing. Two stamped metal retainers then fitover the inflator mounting studs on the back of the

airbag housing and are engaged in slots within the

upper and lower trim cover locking blocks, securely

locking the cover into place.

The resistive membrane-type horn switch is

secured within a plastic tray that is inserted in a

pocket or pouch sewn onto the airbag cushion

retainer strap, between the trim cover and the folded

airbag cushion. The horn switch ground pigtail wire

has an eyelet terminal connector that is captured on

the upper right inflator mounting stud between the

inflator and the upper trim cover retainer. The horn

switch feed pigtail wire has a white, molded plastic

insulator that is secured by an integral retainer to a

mounting hole located in the upper trim cover

retainer near the upper left corner on the back of the

airbag housing, and is connected to the vehicle elec-

trical system through a take out and connector of the

steering wheel wire harness.

The airbag used in this model is a multistage, Next

Generation-type that complies with revised federal air-

bag standards to deploy with less force than those used

in some prior models. A radial deploying fabric airbag

cushion with tethers is used. The airbag inflator is a

dual-initiator, non-azide, pyrotechnic-type unit with

four mounting studs and is secured to the stamped

metal airbag housing using four hex nuts with washers.

Two keyed and color-coded connector receptacles on the

driver airbag inflator connect the two inflator initiators

to the vehicle electrical system through two yellow-

jacketed, two-wire pigtail harnesses of the clockspring.

The driver airbag cannot be repaired, and must be

replaced if deployed or in any way damaged. The driver

airbag trim cover and the horn switch are available

individually, and may be disassembled from the driver

airbag for service replacement.

Fig. 18 Driver Airbag Trim Cover

1 - STEERING WHEEL

2 - TRIM COVER

8O - 18 RESTRAINTSWJ

CLOCKSPRING (Continued)

Page 556 of 2199

OPERATION

The multistage driver airbag is deployed by electri-

cal signals generated by the Airbag Control Module

(ACM) through the driver airbag squib 1 and squib 2

circuits to the two initiators in the airbag inflator. By

using two initiators, the airbag can be deployed at

multiple levels of force. The force level is controlled

by the ACM to suit the monitored impact conditions

by providing one of four delay intervals between the

electrical signals provided to the two initiators. The

longer the delay between these signals, the less force-

fully the airbag will deploy. When the ACM sends the

proper electrical signals to each initiator, the electri-

cal energy generates enough heat to initiate a small

pyrotechnic charge which, in turn ignites chemical

pellets within the inflator. Once ignited, these chem-

ical pellets burn rapidly and produce a large quantity

of nitrogen gas. The inflator is sealed to the back of

the airbag housing and a diffuser in the inflator

directs all of the nitrogen gas into the airbag cush-

ion, causing the cushion to inflate. As the cushion

inflates, the driver airbag trim cover will split at pre-

determined breakout lines, then fold back out of the

way along with the horn switch and tray unit. Fol-

lowing an airbag deployment, the airbag cushion

quickly deflates by venting the nitrogen gas towards

the instrument panel through vent holes within the

fabric used to construct the back (steering wheel

side) panel of the airbag cushion.

Some of the chemicals used to create the nitrogen

gas may be considered hazardous while in their solid

state before they are burned, but they are securely

sealed within the airbag inflator. Typically, both ini-

tiators are used and all potentially hazardous chem-

icals are burned during an airbag deployment event.

However, it is possible for only one initiator to be

used during a deployment due to an airbag system

fault; therefore, it is necessary to always confirm

that both initiators have been used in order to avoid

the improper disposal of potentially live pyrotechnic

or hazardous materials. (Refer to 8 - ELECTRICAL/

RESTRAINTS - STANDARD PROCEDURE - SER-

VICE AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT). The nitrogen gas that is produced

when the chemicals are burned is harmless. How-

ever, a small amount of residue from the burned

chemicals may cause some temporary discomfort if it

contacts the skin, eyes, or breathing passages. If skin

or eye irritation is noted, rinse the affected area with

plenty of cool, clean water. If breathing passages are

irritated, move to another area where there is plenty

of clean, fresh air to breath. If the irritation is not

alleviated by these actions, contact a physician.

REMOVAL

The following procedure is for replacement of a

faulty or damaged driver airbag. If the airbag is

faulty or damaged, but not deployed, review the rec-

ommended procedures for handling non-deployed

supplemental restraints. (Refer to 8 - ELECTRICAL/

RESTRAINTS - STANDARD PROCEDURE - HAN-

DLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the driver airbag has been

deployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the airbag from the vehicle. (Refer to

8 - ELECTRICAL/RESTRAINTS - STANDARD PRO-

CEDURE - SERVICE AFTER A SUPPLEMENTAL

RESTRAINT DEPLOYMENT).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: WHEN REMOVING A DEPLOYED AIR-

BAG, RUBBER GLOVES, EYE PROTECTION, AND A

LONG-SLEEVED SHIRT SHOULD BE WORN. THERE

MAY BE DEPOSITS ON THE AIRBAG CUSHION AND

OTHER INTERIOR SURFACES. IN LARGE DOSES,

THESE DEPOSITS MAY CAUSE IRRITATION TO THE

SKIN AND EYES.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

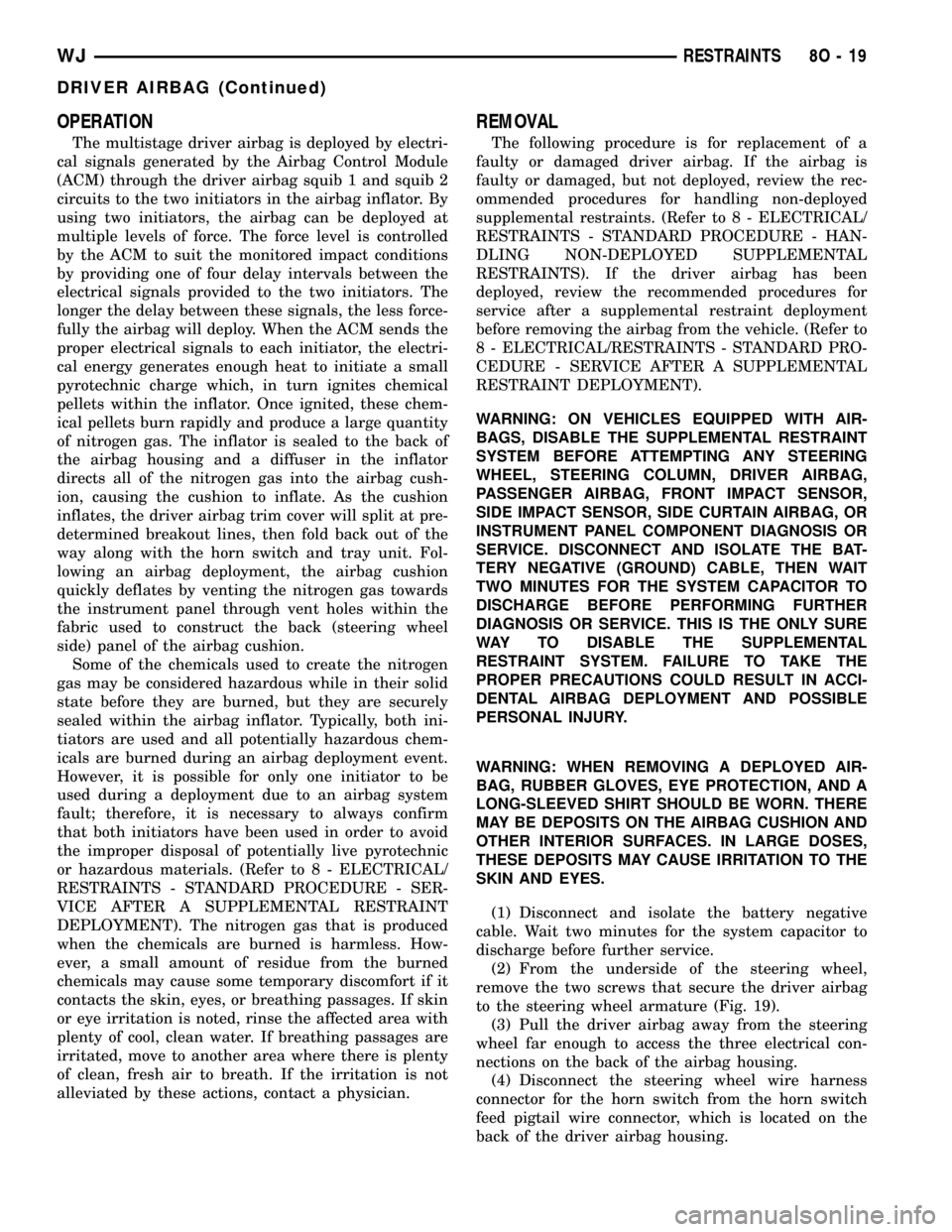

(2) From the underside of the steering wheel,

remove the two screws that secure the driver airbag

to the steering wheel armature (Fig. 19).

(3) Pull the driver airbag away from the steering

wheel far enough to access the three electrical con-

nections on the back of the airbag housing.

(4) Disconnect the steering wheel wire harness

connector for the horn switch from the horn switch

feed pigtail wire connector, which is located on the

back of the driver airbag housing.

WJRESTRAINTS 8O - 19

DRIVER AIRBAG (Continued)

Page 557 of 2199

CAUTION: Do not pull on the clockspring pigtail

wires or pry on the connector insulator to disen-

gage the connector from the driver airbag inflator

connector receptacle. Improper removal of these

pigtail wires and their connector insulators can

result in damage to the airbag circuits or connector

insulators.

(5) The clockspring driver airbag pigtail wire con-

nectors are secured by an integral lock to the airbag

inflator connector receptacles, which are located at

the back of the driver airbag housing. Firmly grasp

and pull the lock straight out from the connector

insulator, then pull the insulators straight out from

the airbag inflator to disconnect them from the con-

nector receptacles.

(6) Remove the driver airbag from the steering

wheel.

(7) If the driver airbag has been deployed, the

clockspring must be replaced. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/CLOCKSPRING - REMOVAL).

DISASSEMBLY

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAITTWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: THE HORN SWITCH IS INTEGRAL TO

THE DRIVER AIRBAG UNIT. SERVICE OF THIS UNIT

SHOULD BE PERFORMED ONLY BY

DAIMLERCHRYSLER-TRAINED AND AUTHORIZED

DEALER SERVICE TECHNICIANS. FAILURE TO

TAKE THE PROPER PRECAUTIONS OR TO FOL-

LOW THE PROPER PROCEDURES COULD RESULT

IN ACCIDENTAL, INCOMPLETE, OR IMPROPER AIR-

BAG DEPLOYMENT AND POSSIBLE OCCUPANT

INJURIES.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(2) Remove the driver airbag from the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

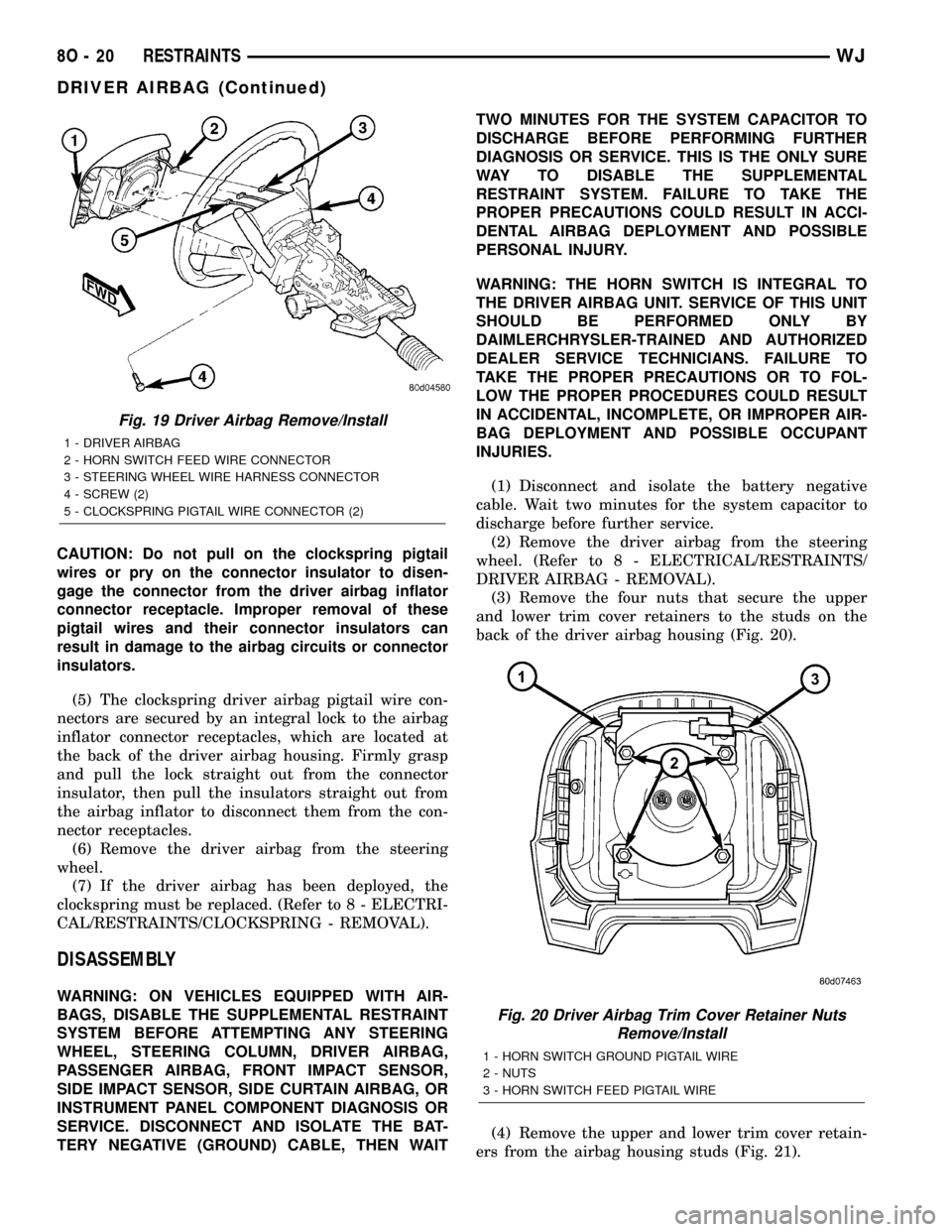

(3) Remove the four nuts that secure the upper

and lower trim cover retainers to the studs on the

back of the driver airbag housing (Fig. 20).

(4) Remove the upper and lower trim cover retain-

ers from the airbag housing studs (Fig. 21).

Fig. 19 Driver Airbag Remove/Install

1 - DRIVER AIRBAG

2 - HORN SWITCH FEED WIRE CONNECTOR

3 - STEERING WHEEL WIRE HARNESS CONNECTOR

4 - SCREW (2)

5 - CLOCKSPRING PIGTAIL WIRE CONNECTOR (2)

Fig. 20 Driver Airbag Trim Cover Retainer Nuts

Remove/Install

1 - HORN SWITCH GROUND PIGTAIL WIRE

2 - NUTS

3 - HORN SWITCH FEED PIGTAIL WIRE

8O - 20 RESTRAINTSWJ

DRIVER AIRBAG (Continued)

Page 558 of 2199

(5) Disengage the horn switch feed pigtail wire

connector retainer from the mounting hole in the

upper trim cover retainer.

(6) Remove the horn switch ground pigtail wire

eyelet terminal from the upper right airbag housing

stud.

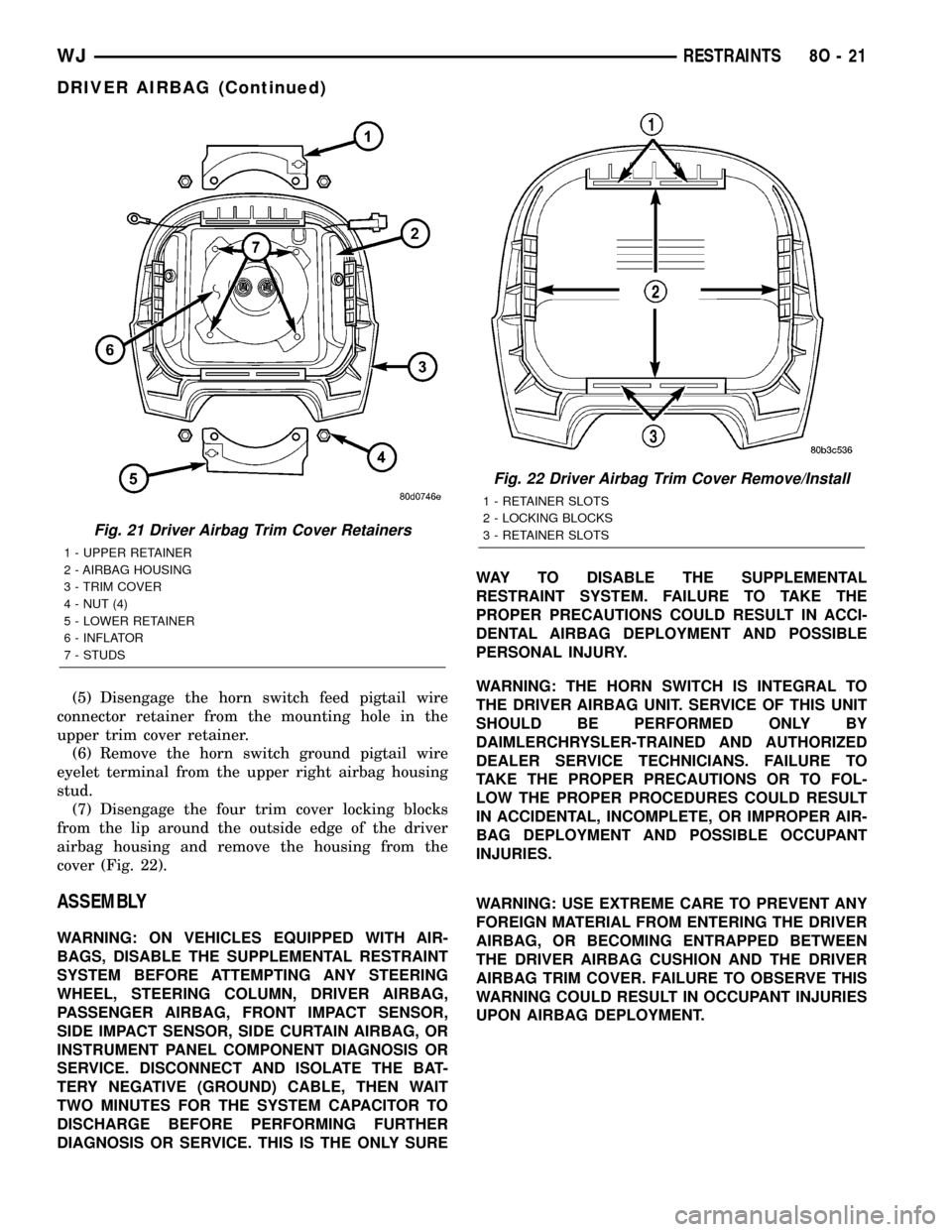

(7) Disengage the four trim cover locking blocks

from the lip around the outside edge of the driver

airbag housing and remove the housing from the

cover (Fig. 22).

ASSEMBLY

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SUREWAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: THE HORN SWITCH IS INTEGRAL TO

THE DRIVER AIRBAG UNIT. SERVICE OF THIS UNIT

SHOULD BE PERFORMED ONLY BY

DAIMLERCHRYSLER-TRAINED AND AUTHORIZED

DEALER SERVICE TECHNICIANS. FAILURE TO

TAKE THE PROPER PRECAUTIONS OR TO FOL-

LOW THE PROPER PROCEDURES COULD RESULT

IN ACCIDENTAL, INCOMPLETE, OR IMPROPER AIR-

BAG DEPLOYMENT AND POSSIBLE OCCUPANT

INJURIES.

WARNING: USE EXTREME CARE TO PREVENT ANY

FOREIGN MATERIAL FROM ENTERING THE DRIVER

AIRBAG, OR BECOMING ENTRAPPED BETWEEN

THE DRIVER AIRBAG CUSHION AND THE DRIVER

AIRBAG TRIM COVER. FAILURE TO OBSERVE THIS

WARNING COULD RESULT IN OCCUPANT INJURIES

UPON AIRBAG DEPLOYMENT.

Fig. 21 Driver Airbag Trim Cover Retainers

1 - UPPER RETAINER

2 - AIRBAG HOUSING

3 - TRIM COVER

4 - NUT (4)

5 - LOWER RETAINER

6 - INFLATOR

7 - STUDS

Fig. 22 Driver Airbag Trim Cover Remove/Install

1 - RETAINER SLOTS

2 - LOCKING BLOCKS

3 - RETAINER SLOTS

WJRESTRAINTS 8O - 21

DRIVER AIRBAG (Continued)

Page 559 of 2199

WARNING: THE DRIVER AIRBAG TRIM COVER

MUST NEVER BE PAINTED. REPLACEMENT TRIM

COVERS ARE SERVICED IN THE ORIGINAL COL-

ORS. PAINT MAY CHANGE THE WAY IN WHICH THE

MATERIAL OF THE TRIM COVER RESPONDS TO AN

AIRBAG DEPLOYMENT. FAILURE TO OBSERVE

THIS WARNING COULD RESULT IN OCCUPANT

INJURIES UPON AIRBAG DEPLOYMENT.

NOTE: If the horn switch and tray have been

removed from the sewn pouch in the airbag cush-

ion retaining strap, be certain that they are properly

reinstalled with the horn switch feed and ground

pigtail wires properly oriented before assembling

the trim cover onto the airbag housing. (Refer to 8 -

ELECTRICAL/HORN/HORN SWITCH - INSTALLA-

TION).

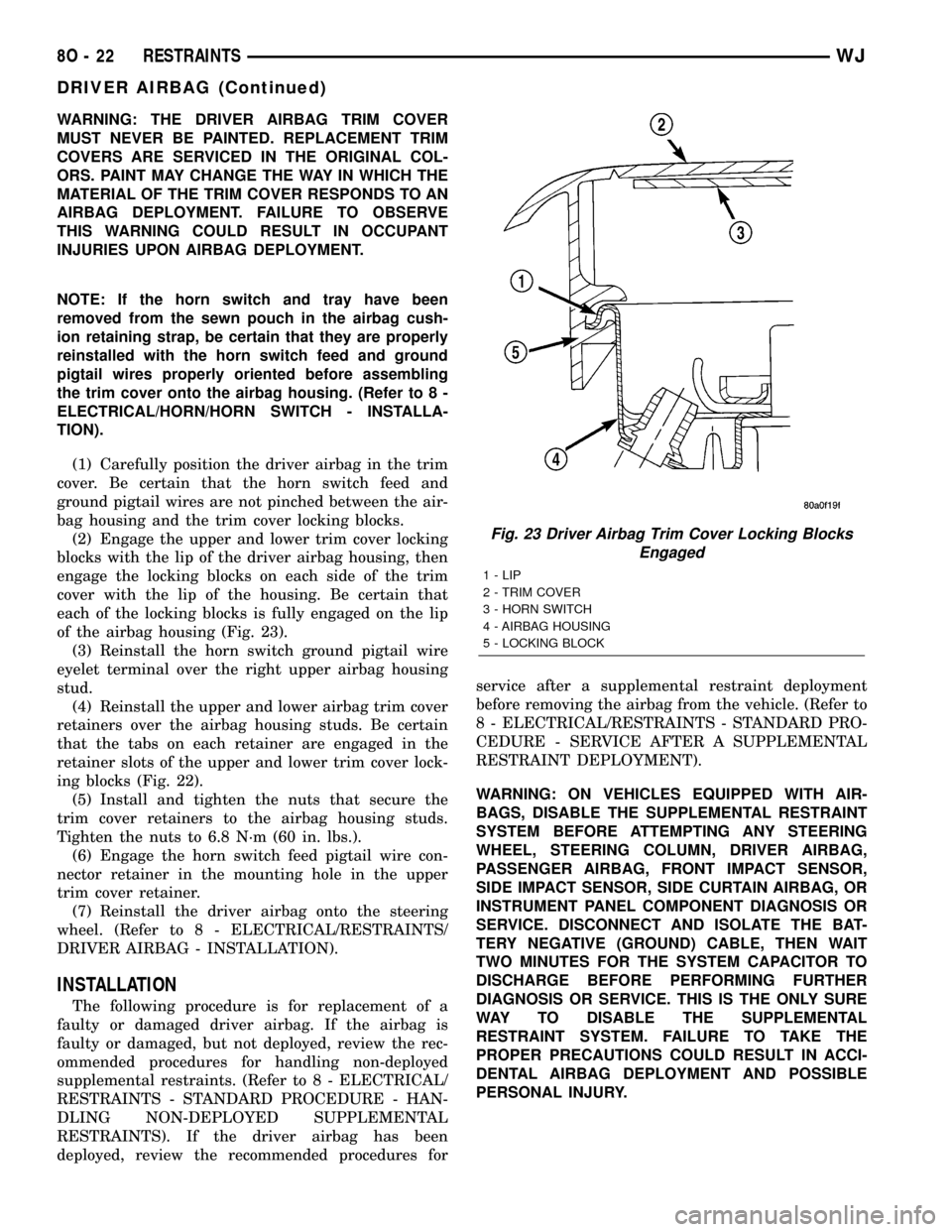

(1) Carefully position the driver airbag in the trim

cover. Be certain that the horn switch feed and

ground pigtail wires are not pinched between the air-

bag housing and the trim cover locking blocks.

(2) Engage the upper and lower trim cover locking

blocks with the lip of the driver airbag housing, then

engage the locking blocks on each side of the trim

cover with the lip of the housing. Be certain that

each of the locking blocks is fully engaged on the lip

of the airbag housing (Fig. 23).

(3) Reinstall the horn switch ground pigtail wire

eyelet terminal over the right upper airbag housing

stud.

(4) Reinstall the upper and lower airbag trim cover

retainers over the airbag housing studs. Be certain

that the tabs on each retainer are engaged in the

retainer slots of the upper and lower trim cover lock-

ing blocks (Fig. 22).

(5) Install and tighten the nuts that secure the

trim cover retainers to the airbag housing studs.

Tighten the nuts to 6.8 N´m (60 in. lbs.).

(6) Engage the horn switch feed pigtail wire con-

nector retainer in the mounting hole in the upper

trim cover retainer.

(7) Reinstall the driver airbag onto the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

INSTALLATION

The following procedure is for replacement of a

faulty or damaged driver airbag. If the airbag is

faulty or damaged, but not deployed, review the rec-

ommended procedures for handling non-deployed

supplemental restraints. (Refer to 8 - ELECTRICAL/

RESTRAINTS - STANDARD PROCEDURE - HAN-

DLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the driver airbag has been

deployed, review the recommended procedures forservice after a supplemental restraint deployment

before removing the airbag from the vehicle. (Refer to

8 - ELECTRICAL/RESTRAINTS - STANDARD PRO-

CEDURE - SERVICE AFTER A SUPPLEMENTAL

RESTRAINT DEPLOYMENT).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

Fig. 23 Driver Airbag Trim Cover Locking Blocks

Engaged

1 - LIP

2 - TRIM COVER

3 - HORN SWITCH

4 - AIRBAG HOUSING

5 - LOCKING BLOCK

8O - 22 RESTRAINTSWJ

DRIVER AIRBAG (Continued)

Page 560 of 2199

WARNING: USE EXTREME CARE TO PREVENT ANY

FOREIGN MATERIAL FROM ENTERING THE DRIVER

AIRBAG, OR BECOMING ENTRAPPED BETWEEN

THE DRIVER AIRBAG CUSHION AND THE DRIVER

AIRBAG TRIM COVER. FAILURE TO OBSERVE THIS

WARNING COULD RESULT IN OCCUPANT INJURIES

UPON AIRBAG DEPLOYMENT.

WARNING: THE DRIVER AIRBAG TRIM COVER

MUST NEVER BE PAINTED. REPLACEMENT AIR-

BAGS AND TRIM COVERS ARE SERVICED IN THE

ORIGINAL COLORS. PAINT MAY CHANGE THE WAY

IN WHICH THE MATERIAL OF THE TRIM COVER

RESPONDS TO AN AIRBAG DEPLOYMENT. FAIL-

URE TO OBSERVE THIS WARNING COULD RESULT

IN OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

(1) Assemble the driver airbag trim cover onto the

airbag housing. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/DRIVER AIRBAG - ASSEMBLY).

(2) Position the driver airbag close enough to the

steering wheel to reconnect all three electrical con-

nections on the back of the airbag housing.

(3) When installing the driver airbag, reconnect

the two clockspring driver airbag pigtail wire connec-

tors to the airbag inflator connector receptacles by

pressing straight in on the connectors (Fig. 19), then

pushing the locks straight into the connectors. You

can be certain that the connector is fully engaged by

listening carefully for a distinct, audible click as the

connector latches snap into place.

(4) Reconnect the steering wheel wire harness con-

nector for the horn switch to the horn switch feed

pigtail wire connector, which is located at the back of

the driver airbag housing.

(5) Carefully position the driver airbag in the

steering wheel. Be certain that the clockspring pig-

tail wires and steering wheel wire harness in the

steering wheel hub area are not pinched between the

driver airbag and the steering wheel armature.

(6) From the underside of the steering wheel,

install and tighten the two screws that secure the

driver airbag to the steering wheel armature.

Tighten the screws to 10 N´m (90 in. lbs.).

(7) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).FRONT IMPACT SENSOR

DESCRIPTION

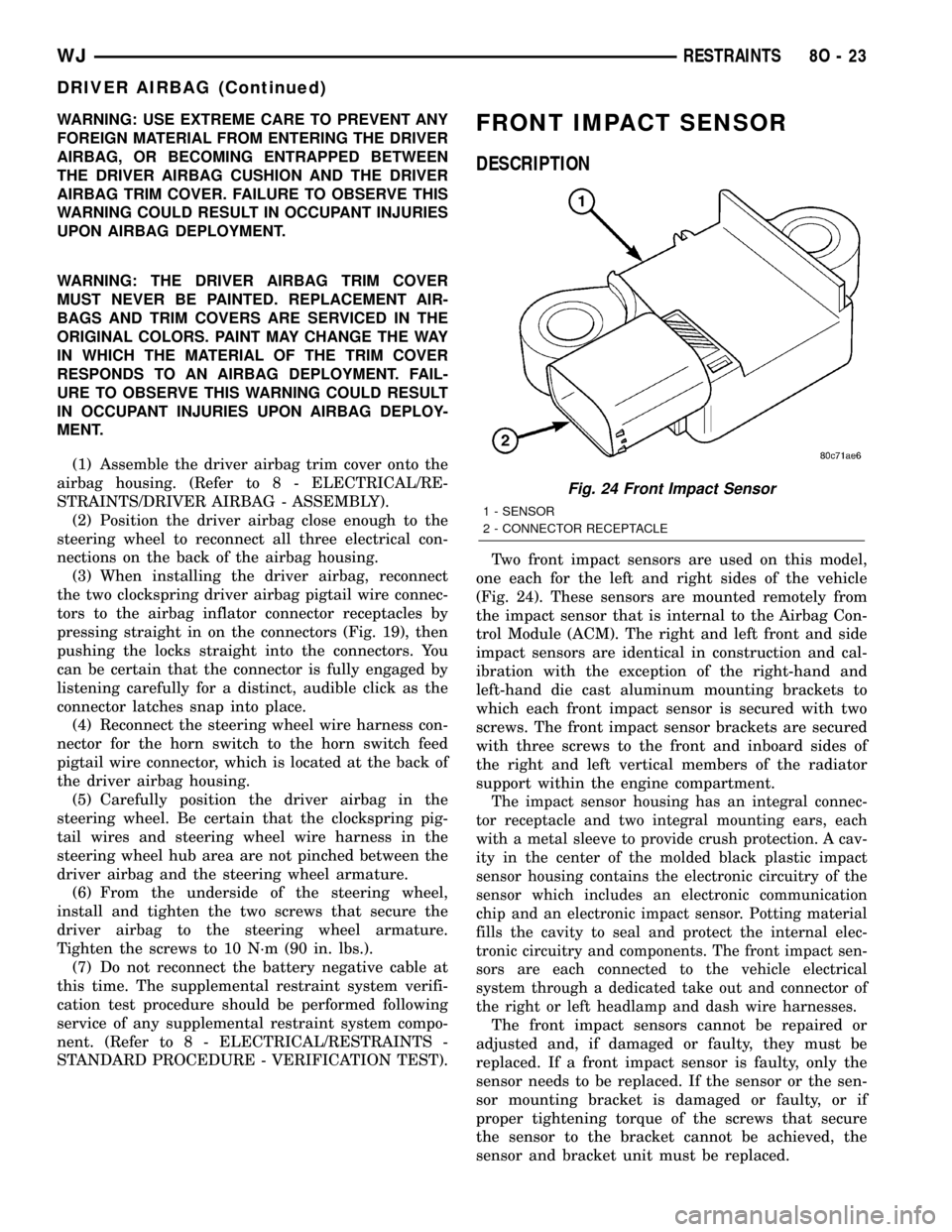

Two front impact sensors are used on this model,

one each for the left and right sides of the vehicle

(Fig. 24). These sensors are mounted remotely from

the impact sensor that is internal to the Airbag Con-

trol Module (ACM). The right and left front and side

impact sensors are identical in construction and cal-

ibration with the exception of the right-hand and

left-hand die cast aluminum mounting brackets to

which each front impact sensor is secured with two

screws. The front impact sensor brackets are secured

with three screws to the front and inboard sides of

the right and left vertical members of the radiator

support within the engine compartment.

The impact sensor housing has an integral connec-

tor receptacle and two integral mounting ears, each

with a metal sleeve to provide crush protection. A cav-

ity in the center of the molded black plastic impact

sensor housing contains the electronic circuitry of the

sensor which includes an electronic communication

chip and an electronic impact sensor. Potting material

fills the cavity to seal and protect the internal elec-

tronic circuitry and components. The front impact sen-

sors are each connected to the vehicle electrical

system through a dedicated take out and connector of

the right or left headlamp and dash wire harnesses.

The front impact sensors cannot be repaired or

adjusted and, if damaged or faulty, they must be

replaced. If a front impact sensor is faulty, only the

sensor needs to be replaced. If the sensor or the sen-

sor mounting bracket is damaged or faulty, or if

proper tightening torque of the screws that secure

the sensor to the bracket cannot be achieved, the

sensor and bracket unit must be replaced.

Fig. 24 Front Impact Sensor

1 - SENSOR

2 - CONNECTOR RECEPTACLE

WJRESTRAINTS 8O - 23

DRIVER AIRBAG (Continued)

Page 592 of 2199

VEHICLE THEFT SECURITY

TABLE OF CONTENTS

page page

VEHICLE THEFT SECURITY

DESCRIPTION

DESCRIPTION - VEHICLE THEFT

SECURITY SYSTEM....................1

DESCRIPTION - SENTRY KEY

IMMOBILIZER SYSTEM..................2

OPERATION

OPERATION - VEHICLE THEFT SECURITY

SYSTEM.............................2

OPERATION - SENTRY KEY IMMOBILIZER

SYSTEM.............................4

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - VEHICLE

THEFT SECURITY SYSTEM..............4

DIAGNOSIS AND TESTING - SENTRY KEY

IMMOBILIZER SYSTEM..................5

STANDARD PROCEDURE

STANDARD PROCEDURE - SKIS

INITIALIZATION........................6

STANDARD PROCEDURE - SENTRY KEY

TRANSPONDER PROGRAMMING..........6

DOOR CYLINDER LOCK SWITCH

DESCRIPTION..........................7

OPERATION............................8

DIAGNOSIS AND TESTING - DOOR

CYLINDER LOCK SWITCH...............8

REMOVAL.............................8

INSTALLATION..........................9

HOOD AJAR SWITCH

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - HOOD AJAR

SWITCH.............................9REMOVAL

REMOVAL - HOOD AJAR SWITCH........10

REMOVAL - HOOD AJAR SWITCH

BRACKET...........................10

REMOVAL - HOOD AJAR SWITCH STRIKER . 10

INSTALLATION

INSTALLATION - HOOD AJAR SWITCH.....10

INSTALLATION - HOOD AJAR SWITCH

BRACKET...........................10

INSTALLATION - HOOD AJAR SWITCH

STRIKER............................11

INTRUSION TRANSCEIVER MODULE

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................12

INSTALLATION.........................12

SIREN

DESCRIPTION.........................13

OPERATION...........................13

REMOVAL.............................14

INSTALLATION.........................14

SKIS INDICATOR LAMP

DESCRIPTION.........................14

OPERATION...........................14

TRANSPONDER KEY

DESCRIPTION.........................15

OPERATION...........................15

VTSS INDICATOR

DESCRIPTION.........................15

OPERATION...........................16

DIAGNOSIS AND TESTING - VTSS

INDICATOR..........................16

VEHICLE THEFT SECURITY

DESCRIPTION

DESCRIPTION - VEHICLE THEFT SECURITY

SYSTEM

The Vehicle Theft Security System (VTSS) is

designed to provide perimeter protection against

unauthorized vehicle use or tampering by monitoring

the vehicle doors, the liftgate, the liftgate flip-up

glass, the ignition system and, only on vehicles built

for sale in certain international markets where it is

required equipment, the hood. If unauthorized vehi-cle use or tampering is detected, the system responds

by pulsing the horn and flashing the exterior lamps.

In many markets the VTSS also includes the Sentry

Key Immobilizer System (SKIS), which provides pas-

sive vehicle protection by preventing the engine from

operating unless a valid electronically encoded key is

detected in the ignition lock cylinder. (Refer to 8 -

ELECTRICAL/VEHICLE THEFT SECURITY -

DESCRIPTION - SENTRY KEY IMMOBILIZER

SYSTEM).

The VTSS includes the following major compo-

nents, which are described in further detail else-

where in this service manual:

²Body Control Module (Refer to 8 - ELECTRI-

CAL/ELECTRONIC CONTROL MODULES/BODY

WJVEHICLE THEFT SECURITY 8Q - 1

Page 593 of 2199

CONTROL/CENTRAL TIMER MODULE -

DESCRIPTION).

²Combination Flasher (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - EXTERIOR/COMBINA-

TION FLASHER - DESCRIPTION).

²Door Ajar Switch (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - INTERIOR/DOOR AJAR

SWITCH - DESCRIPTION - DOOR AJAR SWITCH).

²Driver Cylinder Lock Switch (Refer to 8 - ELEC-

TRICAL/POWER LOCKS/DOOR CYLINDER LOCK/

UNLOCK SWITCH - DESCRIPTION).

²Hood Ajar Switch(Refer to 8 - ELECTRICAL/VE-

HICLE THEFT SECURITY/HOOD AJAR SWITCH -

DESCRIPTION).

²Horn Relay (Refer to 8 - ELECTRICAL/HORN/

HORN RELAY - DESCRIPTION).

²Liftgate Ajar Switch (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - INTERIOR/DOOR AJAR

SWITCH - DESCRIPTION - LIFTGATE AJAR

SWITCH).

²Liftgate Flip-Up Glass Ajar Switch(Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - INTERIOR/

DOOR AJAR SWITCH - DESCRIPTION - LIFTGATE

FLIP-UP GLASS AJAR SWITCH).

²Low Beam Headlamp Relay

²VTSS Indicator (Refer to 8 - ELECTRICAL/VE-

HICLE THEFT SECURITY/VTSS INDICATOR -

DESCRIPTION).

Certain functions and features of the VTSS rely

upon resources shared with or controlled by other

modules in the vehicle over the Programmable Com-

munications Interface (PCI) data bus network. The

other modules that may affect VTSS operation are:

²Driver Door Module (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/DOOR MOD-

ULE - DESCRIPTION).

²Passenger Door Module (Refer to 8 - ELECTRI-

CAL/ELECTRONIC CONTROL MODULES/DOOR

MODULE - DESCRIPTION).

DESCRIPTION - SENTRY KEY IMMOBILIZER

SYSTEM

Vehicles equipped with the Sentry Key Immobilizer

System (SKIS) can be identified by the presence of

an amber SKIS indicator in the instrument cluster

that will illuminate for about three seconds each

time the ignition switch is turned to the On position,

or by a gray molded rubber cap on the head of the

ignition key. Models not equipped with SKIS still

have a SKIS indicator in the cluster, but it will not

illuminate. Also, models not equipped with the SKIS

have a black molded rubber cap on the head of the

ignition key.

The SKIS includes the following major components,

which are described in further detail elsewhere in

this service manual:²Powertrain Control Module

²Sentry Key Immobilizer Module

²Sentry Key Transponder

²SKIS Indicator

Except for the Sentry Key transponders, which rely

upon Radio Frequency (RF) communication, hard

wired circuitry connects the SKIS components to the

electrical system of the vehicle.Refer to the appropri-

ate wiring information.

OPERATION

OPERATION - VEHICLE THEFT SECURITY

SYSTEM

The Vehicle Theft Security System (VTSS) is

divided into two basic subsystems: Vehicle Theft

Alarm (VTA) and Sentry Key Immobilizer System

(SKIS). The following are paragraphs that briefly

describe the operation of each of those two sub-

systems.

A Body Control Module (BCM) is used to control

and integrate many of the functions and features

included in the Vehicle Theft Security System

(VTSS). In the VTSS, the BCM receives inputs indi-

cating the status of the door ajar switches, the driver

cylinder lock switch, the ignition switch, the liftgate

ajar switches, the liftgate flip-up glass ajar switch,

the power lock switches and, in vehicles so equipped,

the hood ajar switch. The programming in the BCM

allows it to process the information from all of these

inputs and send control outputs to energize or de-en-

ergize the combination flasher, the horn relay (except

vehicles with the premium version of the VTA), and

the VTSS indicator. In addition, in vehicles built for

certain markets where premium versions of the VTA

is required, the BCM also exchanges messages with

the Intrusion Transceiver Module (ITM) over the Pro-

grammable Communications Interface (PCI) data

buss network to provide the features found in this

version of the VTA. The control of these inputs and

outputs are what constitute all of the features of the

VTSS. Following is information on the operation of

each of the VTSS features.

ENABLING

The BCM must have the VTSS function enabled in

order for the VTSS to perform as designed. The logic

in the BCM keeps its VTSS function dormant until it

is enabled using a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

PRE-ARMING

The VTA has a pre-arming sequence. Pre-arming

occurs when a door, the tailgate, or the flip-up glass

is open when the vehicle is locked using a power lock

8Q - 2 VEHICLE THEFT SECURITYWJ

VEHICLE THEFT SECURITY (Continued)

Page 594 of 2199

switch, or when the ªLockº button on the Remote

Keyless Entry (RKE) transmitter is depressed. The

powerlock switch will not initiate the pre-arming

sequence if the key is in the ignition switch. When

the VTA is pre-armed, the arming sequence is

delayed until all of the doors, the tailgate and the

flip-up glass are closed.

ARMING

Passive arming of the VTSS occurs when the vehi-

cle is exited with the key removed from the ignition

switch, the headlamps are turned off, and the doors

are locked while they are open using the power lock

switch. The power lock switch will not function if the

key is in the ignition switch or the headlamps are

turned on with the driver side front door open. The

VTSS will not arm if the driver side front door is

locked using the key in the lock cylinder or using the

mechanical lock button. Active arming of the VTSS

occurs when the ªLockº button on the Remote Key-

less Entry (RKE) transmitter is depressed to lock the

vehicle, even if the doors and/or the liftgate are open

when the RKE transmitter Lock button is depressed.

However, the VTSS arming will not be complete until

all of the doors, the liftgate and the liftgate flip-up

glass are closed. On vehicles equipped with the hood

ajar switch, VTSS arming will complete if the hood is

open, but the underhood area will not be protected

unless the hood is closed when the VTSS is armed.

Following successful passive or active VTSS arm-

ing, the VTSS indicator on the top of the instrument

panel will flash rapidly for about sixteen seconds

after the illuminated entry system times out. This

indicates that VTSS arming is in progress. Once the

sixteen second arming function is successfully com-

pleted, the indicator will flash at a slower rate, indi-

cating that the VTSS is armed.

DISARMING

Passive disarming of the VTSS occurs when the

vehicle is unlocked using the key to unlock the driver

side front door. Active disarming of the VTSS occurs

when the vehicle is unlocked by depressing the

ªUnlockº button of the Remote Keyless Entry (RKE)

transmitter. Once the alarm has been activated,

either disarming method will also deactivate the

alarm. Depressing the ªPanicº button on the RKE

transmitter will also disarm the VTSS, but the horn

will continue to pulse and the exterior lamps will

continue to flash for about three minutes as part of

the Panic feature function. The Panic feature is over-

ridden if the ªPanicº button is depressed a second

time, or if a vehicle speed of about 24 kilometers-per-

hour (15 miles-per-hour) is attained.POWER-UP MODE

When the armed VTSS senses that the battery has

been disconnected and reconnected, it enters its pow-

er-up mode. In the power-up mode the alarm system

remains armed following a battery failure or discon-

nect. If the VTSS was armed prior to a battery dis-

connect or failure, the technician or vehicle operator

will have to actively or passively disarm the alarm

system after the battery is reconnected. The pow-

er-up mode will also apply if the battery goes dead

while the system is armed, and battery jump-starting

is then attempted. The VTSS will be armed until it is

actively or passively disarmed. If the VTSS is in the

disarmed mode prior to a battery disconnect or fail-

ure, it will remain disarmed after the battery is

reconnected or replaced, or if jump-starting is

attempted.

ALARM

The VTA alarm output varies by the version of the

VTA with which the vehicle is equipped. In all cases,

the alarm provides both visual and audible outputs;

however, the time intervals of these outputs vary by

the requirements of the market for which the vehicle

is manufactured. In all cases, the visual output will

be a flashing of the exterior lamps. For vehicles

equipped with North American or the base version of

the VTA, the audible output will be the pulsing of the

horn. For vehicles with the premium version of the

VTA, the audible output will be the cycling of the

siren. The inputs that will trigger the alarm include

the door ajar switch, the flip-up glass ajar switch,

and in vehicles built for certain markets where they

are required, the hood ajar switch and the Intrusion

Transceiver Module (ITM).

TAMPER ALERT

The VTSS tamper alert feature will sound the horn

(or the alarm siren for the premium version) three

times upon VTA disarming, if the alarm was trig-

gered and has since timed-out (about eighteen min-

utes). This feature alerts the vehicle operator that

the VTA alarm was activated while the vehicle was

unattended.

INTRUSION ALARM

The Intrusion Alarm is an exclusive feature of the

premium version of the VTA, which is only available

in certain markets, where it is required. When the

VTA is armed, a motion sensor in the Intrusion

Transceiver Module (ITM) monitors the interior of

the vehicle for movement. If motion is detected, the

ITM sends a message to the BCM over the PCI bus

to invoke the visual alarm feature, and sends a mes-

sage to the alarm siren over a dedicated serial bus to

invoke the audible alarm feature. The motion detec-

WJVEHICLE THEFT SECURITY 8Q - 3

VEHICLE THEFT SECURITY (Continued)

Page 654 of 2199

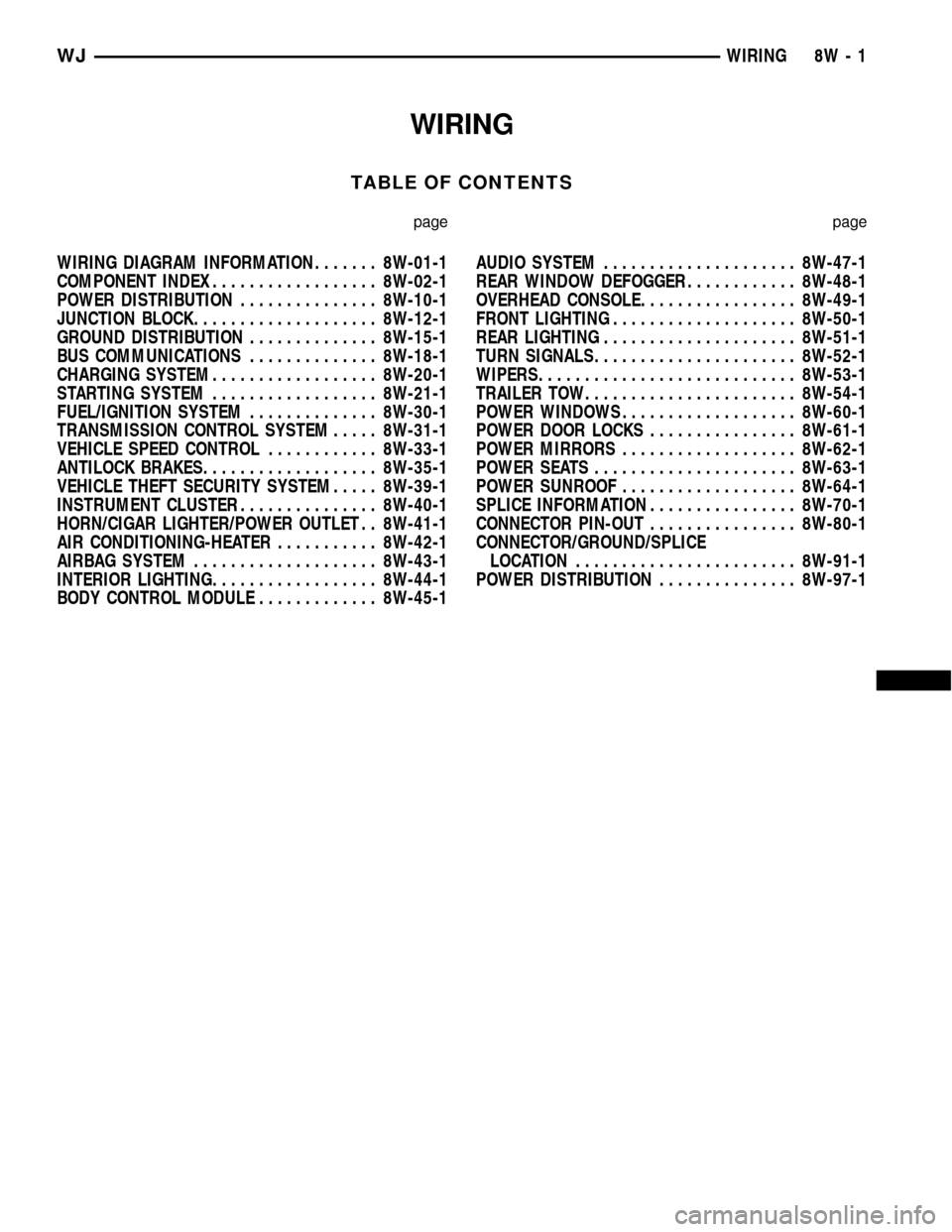

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

JUNCTION BLOCK.................... 8W-12-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

ANTILOCK BRAKES................... 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING-HEATER........... 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1

BODY CONTROL MODULE............. 8W-45-1AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

POWER SUNROOF................... 8W-64-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUT................ 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION............... 8W-97-1 WJWIRING 8W - 1