Lamps JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 267 of 2199

the radiator to flush the radiator and/or A/C con-

denser of debris.

INSPECTION

The radiator cooling fins should be checked for

damage or deterioration. Inspect cooling fins to make

sure they are not bent or crushed, these areas result

in reduced heat exchange causing the cooling system

to operate at higher temperatures. Inspect the plastic

end tanks for cracks, damage or leaks.

Inspect the radiator neck for damage or distortion.

INSTALLATION

CAUTION: Before installing the radiator or A/C con-

denser, be sure the radiator-to-body and radiator-to-

A/C condenser rubber air seals (Fig. 39) are

properly fastened to their original positions. These

are used at the top, bottom and sides of the radia-

tor and A/C condenser. To prevent overheating,

these seals must be installed to their original posi-

tions.

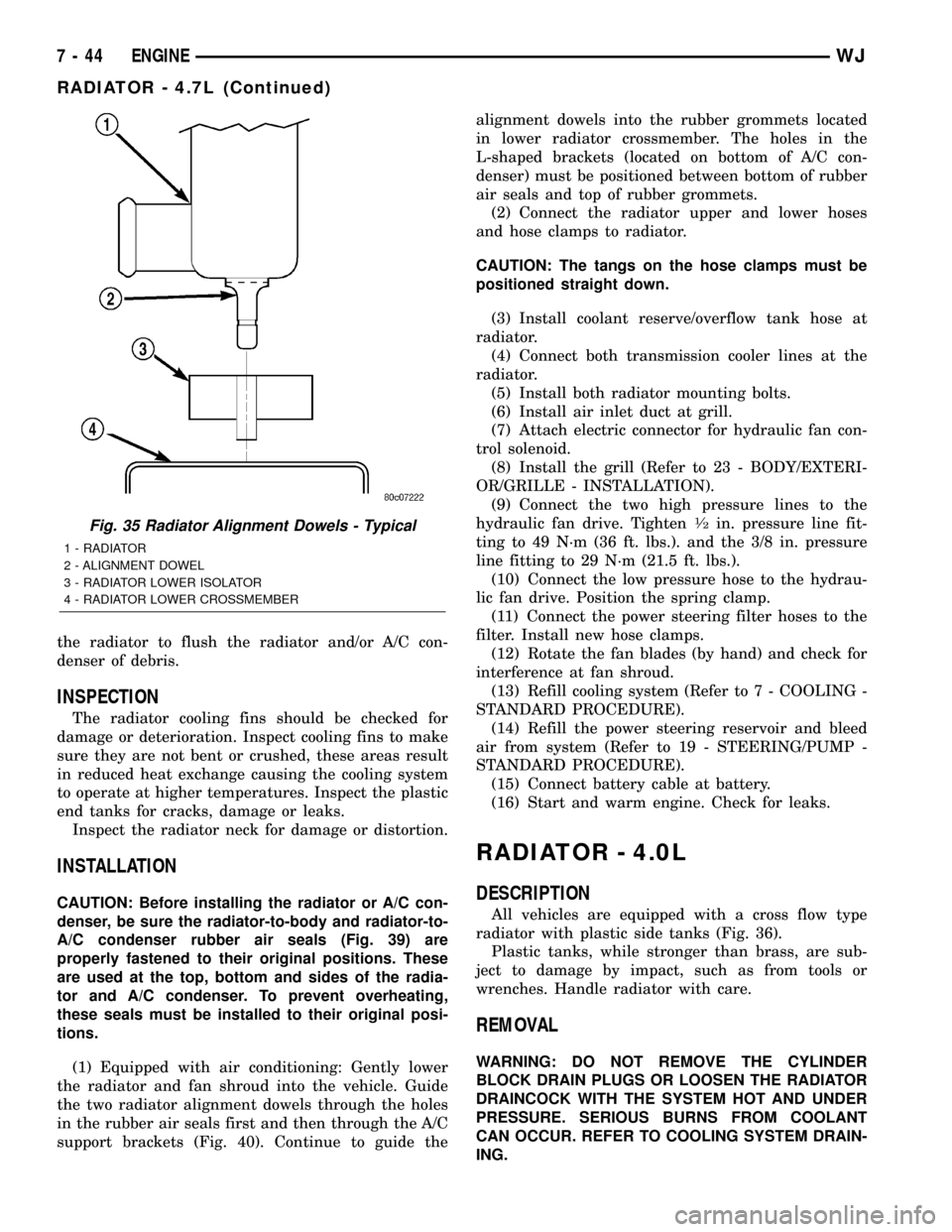

(1) Equipped with air conditioning: Gently lower

the radiator and fan shroud into the vehicle. Guide

the two radiator alignment dowels through the holes

in the rubber air seals first and then through the A/C

support brackets (Fig. 40). Continue to guide thealignment dowels into the rubber grommets located

in lower radiator crossmember. The holes in the

L-shaped brackets (located on bottom of A/C con-

denser) must be positioned between bottom of rubber

air seals and top of rubber grommets.

(2) Connect the radiator upper and lower hoses

and hose clamps to radiator.

CAUTION: The tangs on the hose clamps must be

positioned straight down.

(3) Install coolant reserve/overflow tank hose at

radiator.

(4) Connect both transmission cooler lines at the

radiator.

(5) Install both radiator mounting bolts.

(6) Install air inlet duct at grill.

(7) Attach electric connector for hydraulic fan con-

trol solenoid.

(8) Install the grill (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION).

(9) Connect the two high pressure lines to the

hydraulic fan drive. Tighten

1¤2in. pressure line fit-

ting to 49 N´m (36 ft. lbs.). and the 3/8 in. pressure

line fitting to 29 N´m (21.5 ft. lbs.).

(10) Connect the low pressure hose to the hydrau-

lic fan drive. Position the spring clamp.

(11) Connect the power steering filter hoses to the

filter. Install new hose clamps.

(12) Rotate the fan blades (by hand) and check for

interference at fan shroud.

(13) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(14) Refill the power steering reservoir and bleed

air from system (Refer to 19 - STEERING/PUMP -

STANDARD PROCEDURE).

(15) Connect battery cable at battery.

(16) Start and warm engine. Check for leaks.

RADIATOR - 4.0L

DESCRIPTION

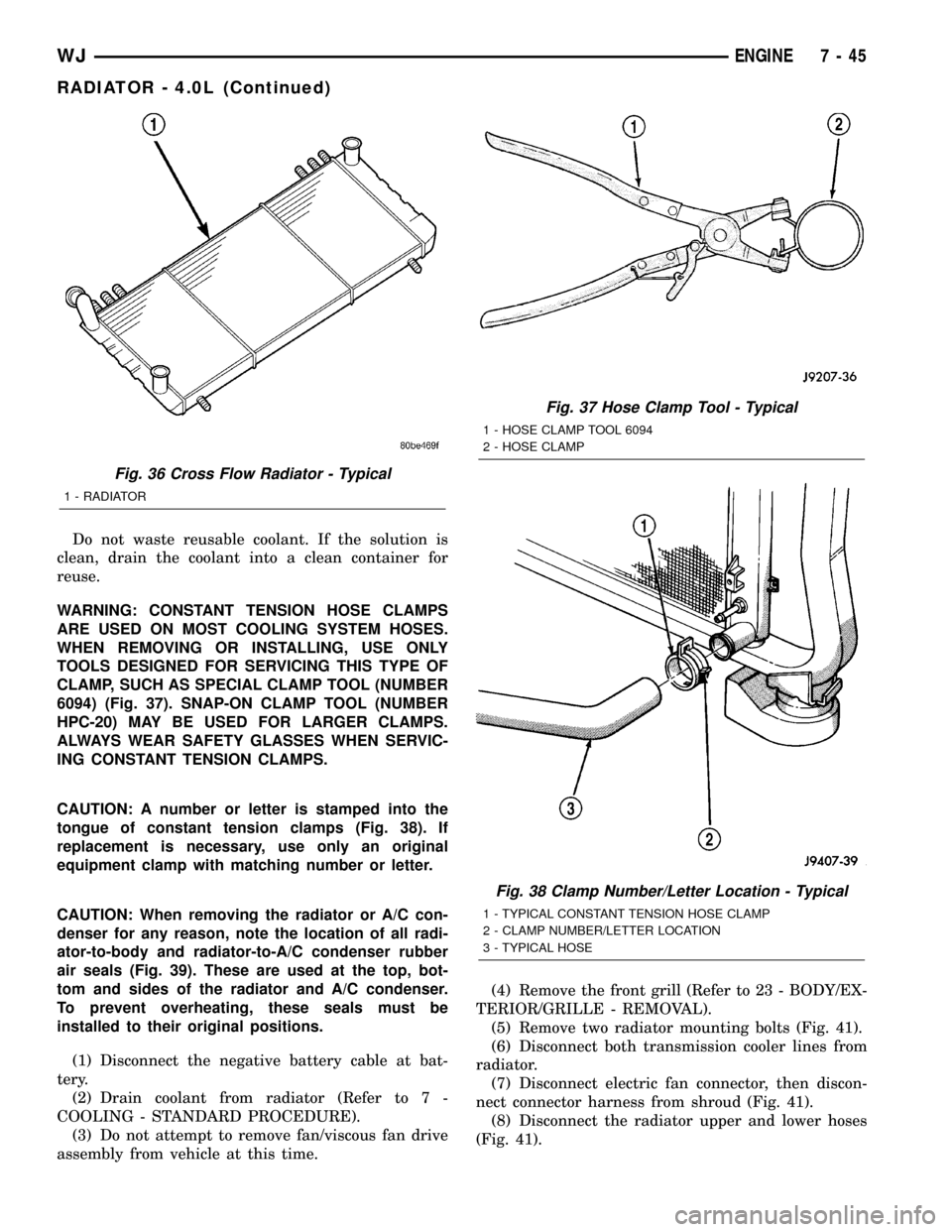

All vehicles are equipped with a cross flow type

radiator with plastic side tanks (Fig. 36).

Plastic tanks, while stronger than brass, are sub-

ject to damage by impact, such as from tools or

wrenches. Handle radiator with care.

REMOVAL

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR. REFER TO COOLING SYSTEM DRAIN-

ING.

Fig. 35 Radiator Alignment Dowels - Typical

1 - RADIATOR

2 - ALIGNMENT DOWEL

3 - RADIATOR LOWER ISOLATOR

4 - RADIATOR LOWER CROSSMEMBER

7 - 44 ENGINEWJ

RADIATOR - 4.7L (Continued)

Page 268 of 2199

Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for

reuse.

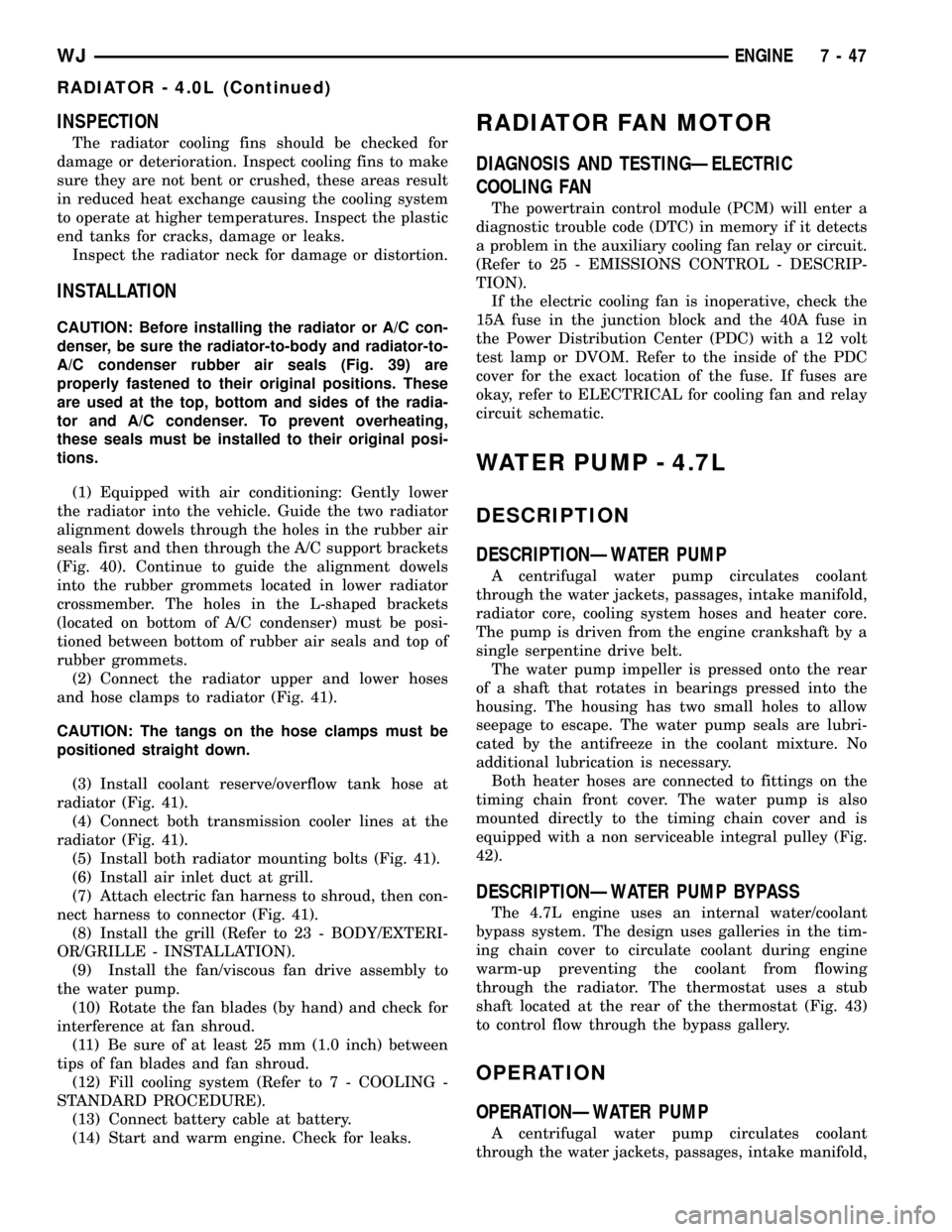

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094) (Fig. 37). SNAP-ON CLAMP TOOL (NUMBER

HPC-20) MAY BE USED FOR LARGER CLAMPS.

ALWAYS WEAR SAFETY GLASSES WHEN SERVIC-

ING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps (Fig. 38). If

replacement is necessary, use only an original

equipment clamp with matching number or letter.

CAUTION: When removing the radiator or A/C con-

denser for any reason, note the location of all radi-

ator-to-body and radiator-to-A/C condenser rubber

air seals (Fig. 39). These are used at the top, bot-

tom and sides of the radiator and A/C condenser.

To prevent overheating, these seals must be

installed to their original positions.

(1) Disconnect the negative battery cable at bat-

tery.

(2) Drain coolant from radiator (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(3) Do not attempt to remove fan/viscous fan drive

assembly from vehicle at this time.(4) Remove the front grill (Refer to 23 - BODY/EX-

TERIOR/GRILLE - REMOVAL).

(5) Remove two radiator mounting bolts (Fig. 41).

(6) Disconnect both transmission cooler lines from

radiator.

(7) Disconnect electric fan connector, then discon-

nect connector harness from shroud (Fig. 41).

(8) Disconnect the radiator upper and lower hoses

(Fig. 41).

Fig. 36 Cross Flow Radiator - Typical

1 - RADIATOR

Fig. 37 Hose Clamp Tool - Typical

1 - HOSE CLAMP TOOL 6094

2 - HOSE CLAMP

Fig. 38 Clamp Number/Letter Location - Typical

1 - TYPICAL CONSTANT TENSION HOSE CLAMP

2 - CLAMP NUMBER/LETTER LOCATION

3 - TYPICAL HOSE

WJENGINE 7 - 45

RADIATOR - 4.0L (Continued)

Page 270 of 2199

INSPECTION

The radiator cooling fins should be checked for

damage or deterioration. Inspect cooling fins to make

sure they are not bent or crushed, these areas result

in reduced heat exchange causing the cooling system

to operate at higher temperatures. Inspect the plastic

end tanks for cracks, damage or leaks.

Inspect the radiator neck for damage or distortion.

INSTALLATION

CAUTION: Before installing the radiator or A/C con-

denser, be sure the radiator-to-body and radiator-to-

A/C condenser rubber air seals (Fig. 39) are

properly fastened to their original positions. These

are used at the top, bottom and sides of the radia-

tor and A/C condenser. To prevent overheating,

these seals must be installed to their original posi-

tions.

(1) Equipped with air conditioning: Gently lower

the radiator into the vehicle. Guide the two radiator

alignment dowels through the holes in the rubber air

seals first and then through the A/C support brackets

(Fig. 40). Continue to guide the alignment dowels

into the rubber grommets located in lower radiator

crossmember. The holes in the L-shaped brackets

(located on bottom of A/C condenser) must be posi-

tioned between bottom of rubber air seals and top of

rubber grommets.

(2) Connect the radiator upper and lower hoses

and hose clamps to radiator (Fig. 41).

CAUTION: The tangs on the hose clamps must be

positioned straight down.

(3) Install coolant reserve/overflow tank hose at

radiator (Fig. 41).

(4) Connect both transmission cooler lines at the

radiator (Fig. 41).

(5) Install both radiator mounting bolts (Fig. 41).

(6) Install air inlet duct at grill.

(7) Attach electric fan harness to shroud, then con-

nect harness to connector (Fig. 41).

(8) Install the grill (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION).

(9) Install the fan/viscous fan drive assembly to

the water pump.

(10) Rotate the fan blades (by hand) and check for

interference at fan shroud.

(11) Be sure of at least 25 mm (1.0 inch) between

tips of fan blades and fan shroud.

(12) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(13) Connect battery cable at battery.

(14) Start and warm engine. Check for leaks.

RADIATOR FAN MOTOR

DIAGNOSIS AND TESTINGÐELECTRIC

COOLING FAN

The powertrain control module (PCM) will enter a

diagnostic trouble code (DTC) in memory if it detects

a problem in the auxiliary cooling fan relay or circuit.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

If the electric cooling fan is inoperative, check the

15A fuse in the junction block and the 40A fuse in

the Power Distribution Center (PDC) with a 12 volt

test lamp or DVOM. Refer to the inside of the PDC

cover for the exact location of the fuse. If fuses are

okay, refer to ELECTRICAL for cooling fan and relay

circuit schematic.

WATER PUMP - 4.7L

DESCRIPTION

DESCRIPTIONÐWATER PUMP

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core.

The pump is driven from the engine crankshaft by a

single serpentine drive belt.

The water pump impeller is pressed onto the rear

of a shaft that rotates in bearings pressed into the

housing. The housing has two small holes to allow

seepage to escape. The water pump seals are lubri-

cated by the antifreeze in the coolant mixture. No

additional lubrication is necessary.

Both heater hoses are connected to fittings on the

timing chain front cover. The water pump is also

mounted directly to the timing chain cover and is

equipped with a non serviceable integral pulley (Fig.

42).

DESCRIPTIONÐWATER PUMP BYPASS

The 4.7L engine uses an internal water/coolant

bypass system. The design uses galleries in the tim-

ing chain cover to circulate coolant during engine

warm-up preventing the coolant from flowing

through the radiator. The thermostat uses a stub

shaft located at the rear of the thermostat (Fig. 43)

to control flow through the bypass gallery.

OPERATION

OPERATIONÐWATER PUMP

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

WJENGINE 7 - 47

RADIATOR - 4.0L (Continued)

Page 272 of 2199

WARNING: DO NOT LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM THE COOL-

ANT CAN OCCUR.

(1) Drain sufficient coolant from the radiator to

decrease the level below the heater hose inlet. On

4.7L engines this requires complete draining.

(2) Remove the heater hose.

(3) Inspect the inlet for metal casting flash or

other restrictions.

NOTE: On 4.0L engines remove the pump from the

engine before removing restriction to prevent con-

tamination of the coolant with debris. . On 4.7L

engine remove the fitting from the timing chain

cover, If the restriction is in the timing chain cover,

remove the timing chain cover.

REMOVAL

The water pump on 4.7L engines is bolted directly

to the engine timing chain case/cover.

A gasket is used as a seal between the water pump

and timing chain case/cover.

The water pump can be removed without discharg-

ing the air conditioning system (if equipped).

(1) Disconnect negative battery cable from battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE). Do not waste reusable

coolant. If solution is clean, drain coolant into a clean

container for reuse.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094). SNAP-ON CLAMP TOOL (NUMBER HPC-20)

MAY BE USED FOR LARGER CLAMPS. ALWAYS

WEAR SAFETY GLASSES WHEN SERVICING CON-

STANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with matching number or letter.

(3) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove lower radiator hose clamp and remove

lower hose at water pump.

(5) Remove seven water pump mounting bolts and

one stud bolt.CAUTION: Do not pry water pump at timing chain

case/cover. The machined surfaces may be dam-

aged resulting in leaks.

(6) Remove water pump and gasket. Discard gas-

ket.

CLEANING

Clean the gasket mating surface. Use caution not

to damage the gasket sealing surface.

INSPECTION

Inspect the water pump assembly for cracks in the

housing, Water leaks from shaft seal, Loose or rough

turning bearing or Impeller rubbing either the pump

body or timing chain case/cover.

INSTALLATION

(1) Clean gasket mating surfaces.

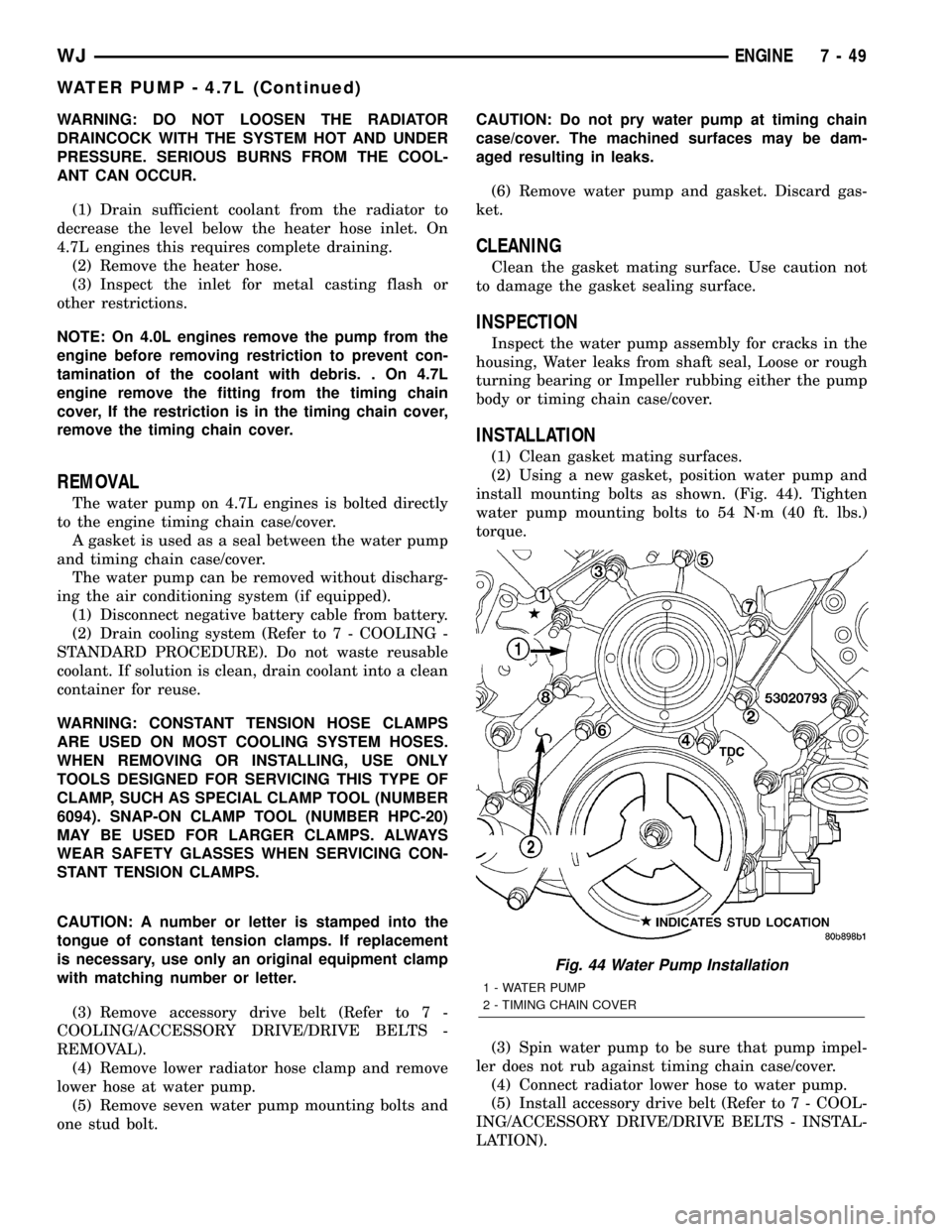

(2) Using a new gasket, position water pump and

install mounting bolts as shown. (Fig. 44). Tighten

water pump mounting bolts to 54 N´m (40 ft. lbs.)

torque.

(3) Spin water pump to be sure that pump impel-

ler does not rub against timing chain case/cover.

(4) Connect radiator lower hose to water pump.

(5) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

Fig. 44 Water Pump Installation

1 - WATER PUMP

2 - TIMING CHAIN COVER

WJENGINE 7 - 49

WATER PUMP - 4.7L (Continued)

Page 274 of 2199

NOTE: On 4.0L engines remove the pump from the

engine before removing restriction to prevent con-

tamination of the coolant with debris. . On 4.7L

engine remove the fitting from the timing chain

cover, If the restriction is in the timing chain cover,

remove the timing chain cover.

REMOVAL

CAUTION: If the water pump is replaced because of

mechanical damage, the fan blades and viscous fan

drive should also be inspected. These components

could have been damaged due to excessive vibra-

tion.

The water pump impeller is pressed on the rear of

the pump shaft and bearing assembly. The water

pump is serviced only as a complete assembly.

NOTE: The water pump can be replaced without

discharging the A/C system.

WARNING: DO NOT REMOVE THE BLOCK DRAIN

PLUG(S) OR LOOSEN RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

DO NOT WASTE reusable coolant. If the solution

is clean, drain coolant into a clean container for

reuse.

(1) Disconnect negative battery cable at battery.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(3) The thermal viscous fan drive is attached

(threaded) to the water pump hub shaft. Remove fan/

viscous fan drive assembly from water pump by turn-

ing mounting nut counterclockwise as viewed from

front. Threads on viscous fan drive areRIGHT

HANDDo not attempt to remove fan/viscous fan

drive assembly from vehicle at this time.

(4) If water pump is being replaced, do not unbolt

fan blade assembly from thermal viscous fan drive.

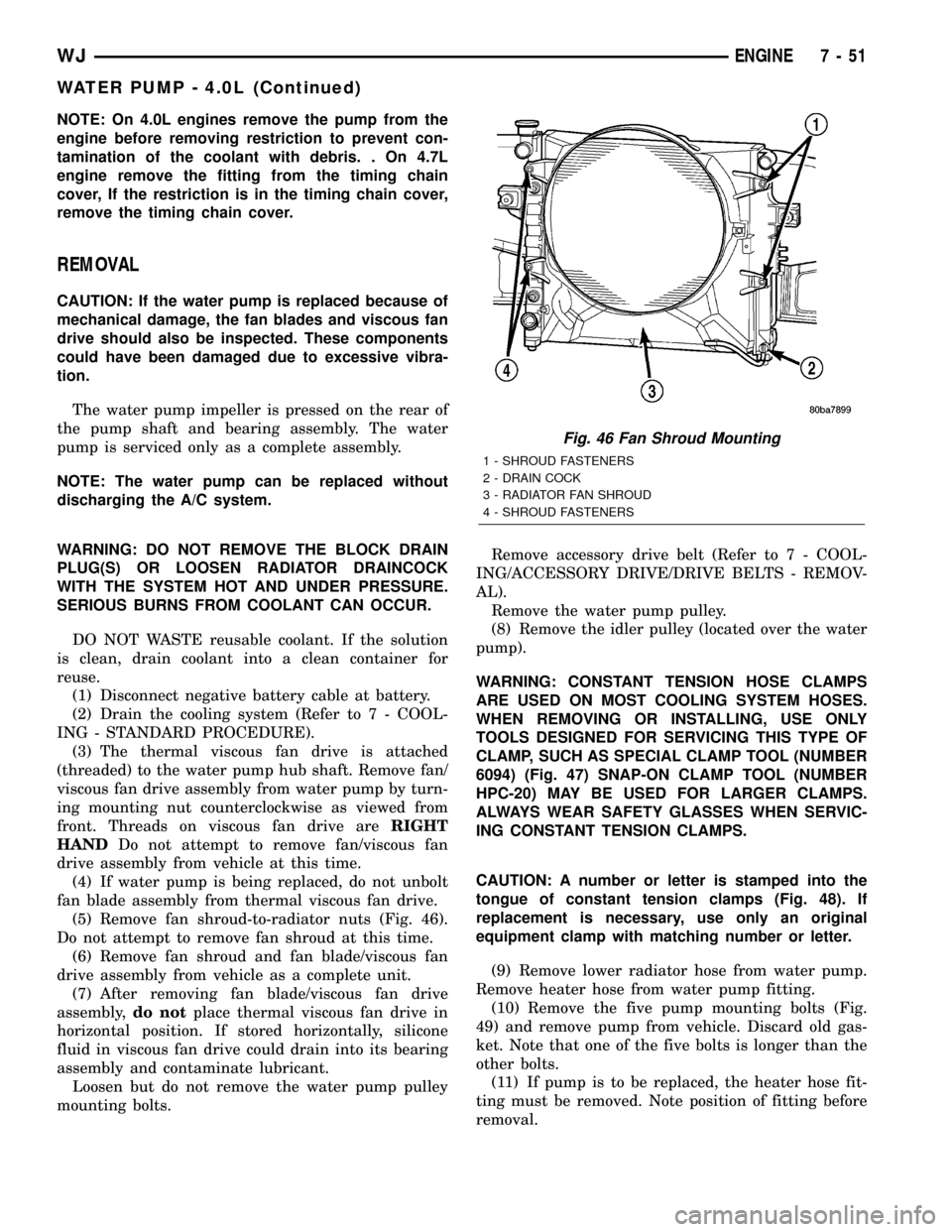

(5) Remove fan shroud-to-radiator nuts (Fig. 46).

Do not attempt to remove fan shroud at this time.

(6) Remove fan shroud and fan blade/viscous fan

drive assembly from vehicle as a complete unit.

(7) After removing fan blade/viscous fan drive

assembly,do notplace thermal viscous fan drive in

horizontal position. If stored horizontally, silicone

fluid in viscous fan drive could drain into its bearing

assembly and contaminate lubricant.

Loosen but do not remove the water pump pulley

mounting bolts.Remove accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOV-

AL).

Remove the water pump pulley.

(8) Remove the idler pulley (located over the water

pump).

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094) (Fig. 47) SNAP-ON CLAMP TOOL (NUMBER

HPC-20) MAY BE USED FOR LARGER CLAMPS.

ALWAYS WEAR SAFETY GLASSES WHEN SERVIC-

ING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps (Fig. 48). If

replacement is necessary, use only an original

equipment clamp with matching number or letter.

(9) Remove lower radiator hose from water pump.

Remove heater hose from water pump fitting.

(10) Remove the five pump mounting bolts (Fig.

49) and remove pump from vehicle. Discard old gas-

ket. Note that one of the five bolts is longer than the

other bolts.

(11) If pump is to be replaced, the heater hose fit-

ting must be removed. Note position of fitting before

removal.

Fig. 46 Fan Shroud Mounting

1 - SHROUD FASTENERS

2 - DRAIN COCK

3 - RADIATOR FAN SHROUD

4 - SHROUD FASTENERS

WJENGINE 7 - 51

WATER PUMP - 4.0L (Continued)

Page 277 of 2199

INSPECTION

Visually inspect the pressure valve gasket on the

cap. Replace cap if the gasket is swollen, torn or

worn. Inspect the area around radiator filler neck for

white deposits that indicate a leaking cap.

WATER PUMP INLET TUBE

REMOVAL

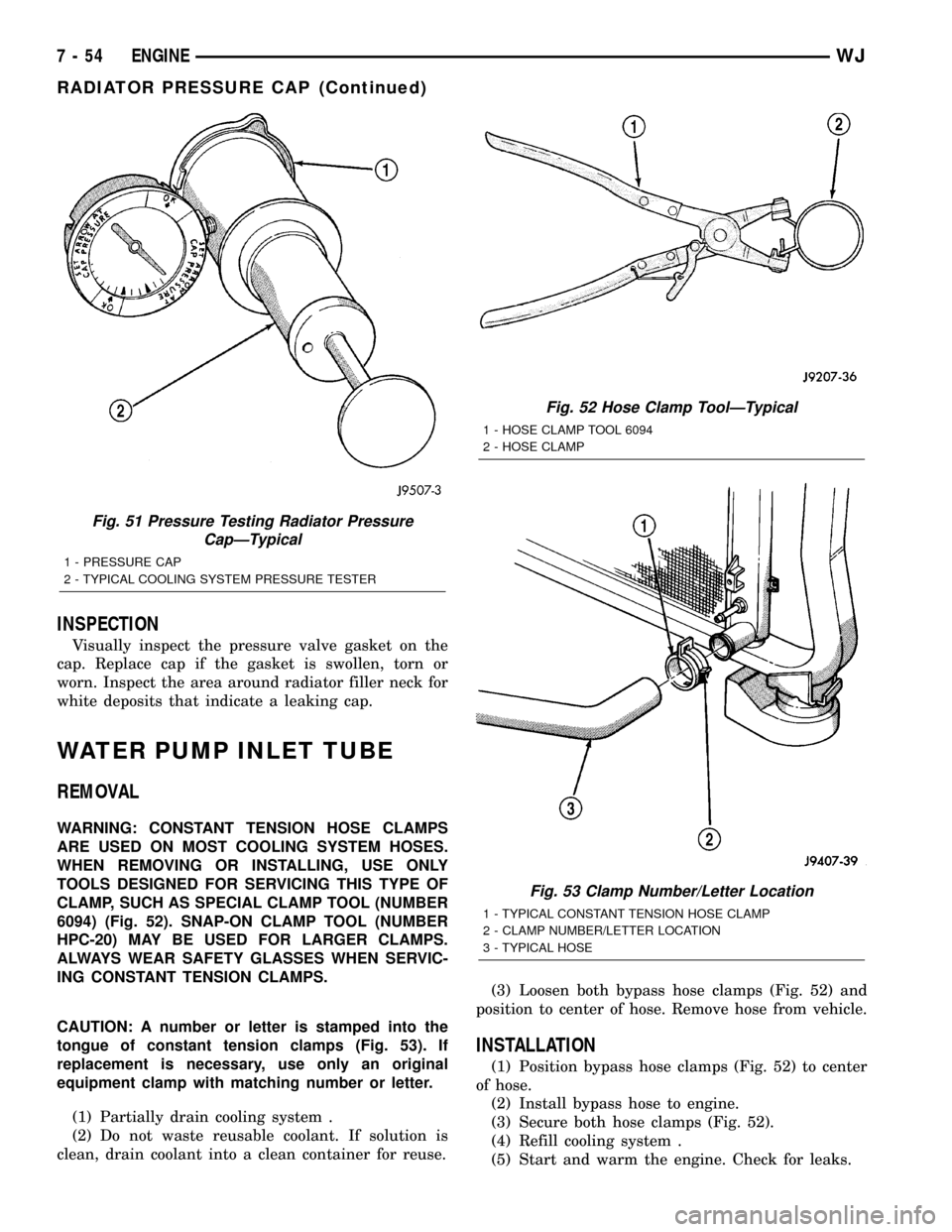

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094) (Fig. 52). SNAP-ON CLAMP TOOL (NUMBER

HPC-20) MAY BE USED FOR LARGER CLAMPS.

ALWAYS WEAR SAFETY GLASSES WHEN SERVIC-

ING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps (Fig. 53). If

replacement is necessary, use only an original

equipment clamp with matching number or letter.

(1) Partially drain cooling system .

(2) Do not waste reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.(3) Loosen both bypass hose clamps (Fig. 52) and

position to center of hose. Remove hose from vehicle.

INSTALLATION

(1) Position bypass hose clamps (Fig. 52) to center

of hose.

(2) Install bypass hose to engine.

(3) Secure both hose clamps (Fig. 52).

(4) Refill cooling system .

(5) Start and warm the engine. Check for leaks.

Fig. 51 Pressure Testing Radiator Pressure

CapÐTypical

1 - PRESSURE CAP

2 - TYPICAL COOLING SYSTEM PRESSURE TESTER

Fig. 52 Hose Clamp ToolÐTypical

1 - HOSE CLAMP TOOL 6094

2 - HOSE CLAMP

Fig. 53 Clamp Number/Letter Location

1 - TYPICAL CONSTANT TENSION HOSE CLAMP

2 - CLAMP NUMBER/LETTER LOCATION

3 - TYPICAL HOSE

7 - 54 ENGINEWJ

RADIATOR PRESSURE CAP (Continued)

Page 307 of 2199

The chime warning system provides an audible

indication to the vehicle operator under the following

conditions:

²Fasten Seat Belt Warning- The Body Control

Module (BCM) chime tone generator will generate

repetitive chimes to announce that an input from the

seat belt switch indicates the driver side front seat

belt is not fastened. Unless the driver side front seat

belt is fastened, the chimes will continue to sound for

a duration of about six seconds each time the ignition

switch is turned to the On position or until the driver

side front seat belt is fastened.

²Head/Park Lights-On Warning- The BCM

chime tone generator will generate repetitive chimes

at a fast rate to announce that a Programmable

Communications Interface (PCI) data bus driver door

ajar message, along with hard wired inputs from the

headlamp switch indicate that the exterior lamps are

turned On with the driver side front door opened.

The chime will continue to sound until the exterior

lamps are turned Off, the driver side front door is

closed, or the ignition switch is turned to the On

position.

²Key-In-Ignition Warning- The BCM chime

tone generator will generate repetitive chimes at a

fast rate to announce that a PCI data bus driver door

ajar message received from the Driver Door Module

(DDM), along with hard wired inputs from the key-

in-ignition warning switch indicate that the key is in

the ignition cylinder with the driver side front door

opened and the ignition switch in the Off position.

The chime will continue to sound until the key is

removed from the ignition lock cylinder, the driver

side front door is closed, or the ignition switch is

turned to the On position.

²Overspeed Warning- The BCM chime tone

generator will generate repetitive chimes at a slowrate to announce that a PCI data bus vehicle speed

message received from the Powertrain Control Mod-

ule (PCM) indicates that the vehicle speed is above

120 kilometers-per-hour (75 miles-per-hour). The

chimes will continue to sound until the vehicle speed

is below 120 kilometers-per-hour (75 miles-per-hour).

This feature is only enabled on a BCM that has been

programmed with a Middle East Gulf Coast Country

(GCC) country code.

²Tactile Beep Support- The BCM chime tone

generator will generate a single beep each time a

PCI data bus tactile beep request message is received

from the Electronic Vehicle Information Center

(EVIC) or the Sentry Key Immobilizer Module

(SKIM). This beep provides an audible confirmation

that an EVIC button was completely depressed, or

that the optional Sentry Key Immobilizer System

(SKIS) is in the ªCustomer Learnº mode.

²Warning Beep Support- The BCM chime tone

generator will generate a short series of beeps each

time a PCI data bus warning beep request message

is received from the EVIC or the Electro-Mechanical

Instrument Cluster (EMIC). These beeps provide an

audible alert to the vehicle operator, of certain visual

warning indications displayed by the EVIC and/or

the EMIC.

The BCM provides chime service for all available

features in the chime warning system. The BCM

relies upon message inputs received from other mod-

ules over the PCI data bus network to provide chime

service for all of the remaining chime warning sys-

tem features.

The internal programming of the BCM determines

the priority of each chime tone request input that is

received, as well as the rate and duration of each

chime tone that is to be generated.

8B - 2 CHIME/BUZZERWJ

CHIME WARNING SYSTEM (Continued)

Page 309 of 2199

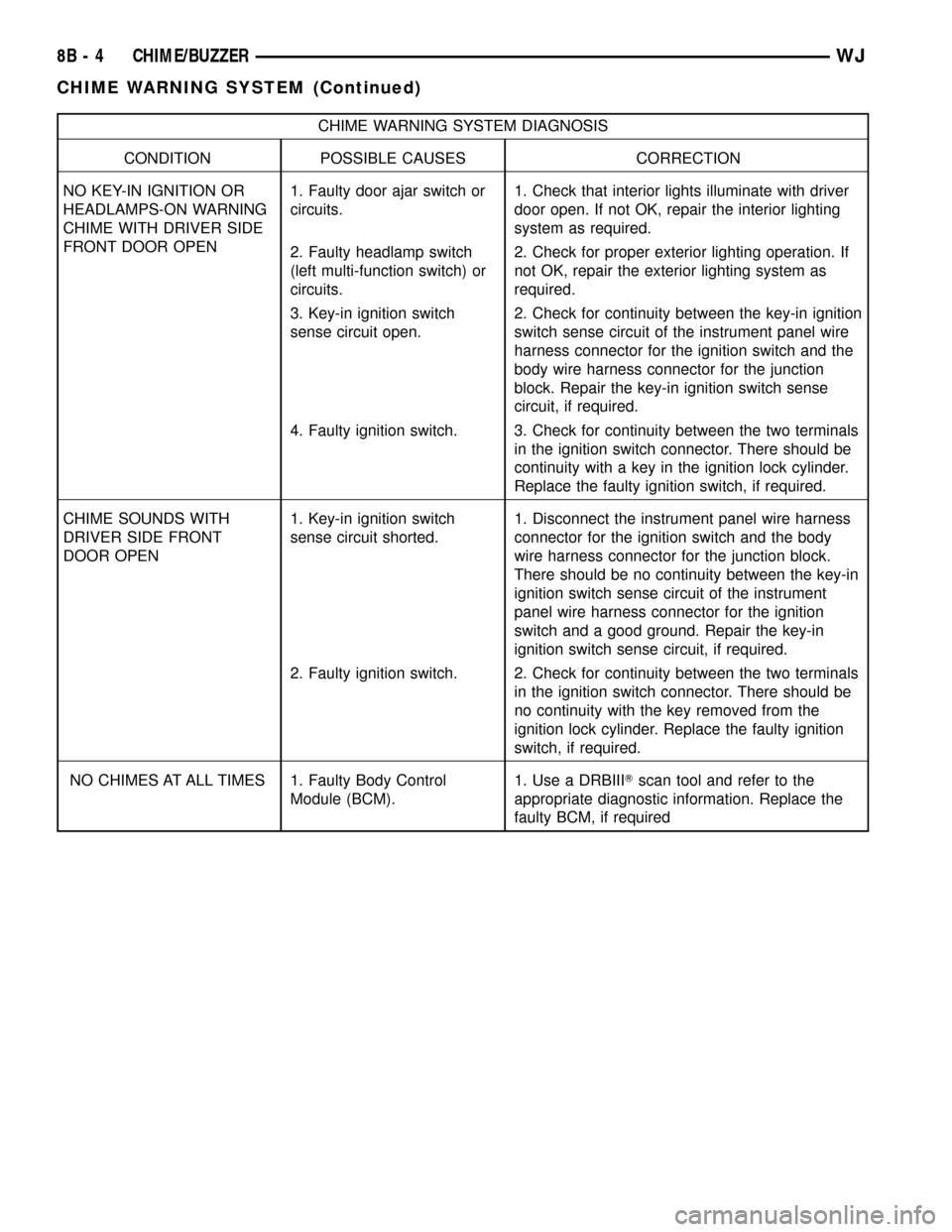

CHIME WARNING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO KEY-IN IGNITION OR

HEADLAMPS-ON WARNING

CHIME WITH DRIVER SIDE

FRONT DOOR OPEN1. Faulty door ajar switch or

circuits.1. Check that interior lights illuminate with driver

door open. If not OK, repair the interior lighting

system as required.

2. Faulty headlamp switch

(left multi-function switch) or

circuits.2. Check for proper exterior lighting operation. If

not OK, repair the exterior lighting system as

required.

3. Key-in ignition switch

sense circuit open.2. Check for continuity between the key-in ignition

switch sense circuit of the instrument panel wire

harness connector for the ignition switch and the

body wire harness connector for the junction

block. Repair the key-in ignition switch sense

circuit, if required.

4. Faulty ignition switch. 3. Check for continuity between the two terminals

in the ignition switch connector. There should be

continuity with a key in the ignition lock cylinder.

Replace the faulty ignition switch, if required.

CHIME SOUNDS WITH

DRIVER SIDE FRONT

DOOR OPEN1. Key-in ignition switch

sense circuit shorted.1. Disconnect the instrument panel wire harness

connector for the ignition switch and the body

wire harness connector for the junction block.

There should be no continuity between the key-in

ignition switch sense circuit of the instrument

panel wire harness connector for the ignition

switch and a good ground. Repair the key-in

ignition switch sense circuit, if required.

2. Faulty ignition switch. 2. Check for continuity between the two terminals

in the ignition switch connector. There should be

no continuity with the key removed from the

ignition lock cylinder. Replace the faulty ignition

switch, if required.

NO CHIMES AT ALL TIMES 1. Faulty Body Control

Module (BCM).1. Use a DRBIIITscan tool and refer to the

appropriate diagnostic information. Replace the

faulty BCM, if required

8B - 4 CHIME/BUZZERWJ

CHIME WARNING SYSTEM (Continued)

Page 313 of 2199

BCM programming then performs those tasks and

provides features through both PCI data bus commu-

nication with other electronic modules and hard

wired outputs to a number of relays. These relays

provide the BCM with the ability to control numer-

ous high current accessory systems in the vehicle.

The BCM circuitry operates on battery current

received through fuses in the Junction Block (JB) on a

non-switched fused B(+) circuit, a fused ignition switch

output (start-run) circuit, and a fused ignition switch

output (run-accessory) circuit. This arrangement allows

the BCM to provide some features regardless of the

ignition switch position. The BCM circuitry is grounded

through the chassis beneath the center console.

The BCM monitors its own internal circuitry as

well as many of its input and output circuits, and

will store a Diagnostic Trouble Code (DTC) in elec-

tronic memory for any failure it detects. These DTCs

can be retrieved and diagnosed using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

HARD WIRED INPUTS

The hard wired inputs to the BCM include the fol-

lowing:

²A/C switch signal

²Ambient temperature sensor signal

²Body control module flash enable

²Coolant level switch sense

²Door ajar switch sense (two circuits - one left

rear, and one right rear)

²Driver seat heater switch mux

²Fog lamp switch sense

²Fused B(+)

²Fused ignition switch output (run-acc)

²Fused ignition switch output (st-run)

²Ground (five circuits - two Z1, and three Z2)

²Hazard switch sense

²Headlamp switch mux

²High beam switch sense

²Hood ajar switch sense (export)

²Key-in ignition switch sense

²Liftgate ajar switch sense

²Liftgate courtesy disable

²Liftgate flip-up ajar switch sense

²Panel lamps dimmer signal

²Park lamp relay output

²Passenger seat heater switch mux

²PCI bus

²Radio control mux

²Rear window defogger switch sense

²Seat belt switch sense

²Ultralight sensor signal

²Washer fluid switch sense

²Washer pump switch sense

²Windshield wiper switch mux

²Wiper park switch sense

MESSAGING

The BCM uses the following messages received

from other electronic modules over the PCI data bus:

²Accessory Delay Control (DDM/PDM)

²Battery Temperature (PCM)

²Chime Request (EMIC, EVIC, SKIM)

²Cylinder Lock Switch Status (DDM)

²Door Ajar Status/Front Doors (DDM/PDM)

²Door Lock Status (DDM/PDM)

²Engine Model (PCM)

²Engine RPM (PCM)

²Engine Temperature (PCM)

²English/Metric Default (EMIC)

²Fuel Tank Level (PCM)

²Fuel Used/Injector Pulses (PCM)

²Panic Control (PDM)

²Programmable Features Preferences/Audible &

Optical Chirps/Headlamp Delay (EVIC)

²RKE Status (PDM)

²Vehicle Identification Number (PCM)

²Vehicle Speed (PCM)

The BCM provides the following messages to other

electronic modules over the PCI data bus:

²A/C Switch Status (PCM)

²Ambient Temperature Data (AZC/EVIC/PCM)

²Average/Instantaneous Fuel Economy (EVIC)

²Country Code (EMIC)

²Courtesy Lamp Status (DDM/PDM)

²Distance To Empty (EVIC)

²Elapsed Ignition On Timer (EVIC)

²English/Metric Status (EMIC)

²Front & Rear Door Ajar Status (EVIC)

²Front & Rear Fog Lamp Status (EMIC)

²Heated Seat Switch Status (HSM/MHSM)

²High Beam Status (EMIC)

²Ignition Off Timer (EVIC)

²Ignition Switch Position (DDM/PDM)

²Key-In Ignition Status (DDM/PDM)

²Low Beam Status (EMIC)

²Panel Lamp Status (AZC/EMIC/Radio)

²Rear Window Defogger Relay Status (DDM/

PDM)

²Remote Radio Switch Status (Radio)

²Seatbelt Status (EMIC/MHSM/MSM)

DIAGNOSIS AND TESTING - BODY CONTROL

MODULE

The hard wired inputs to and outputs from the

Body Control Module (BCM) may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. Refer to the appropriate wiring information.

Conventional diagnostic methods may not prove

conclusive in the diagnosis of the BCM. In order to

obtain conclusive testing of the BCM, the Program-

mable Communications Interface (PCI) data bus net-

work and all of the electronic modules that provide

8E - 4 ELECTRONIC CONTROL MODULESWJ

BODY CONTROL MODULE (Continued)

Page 317 of 2199

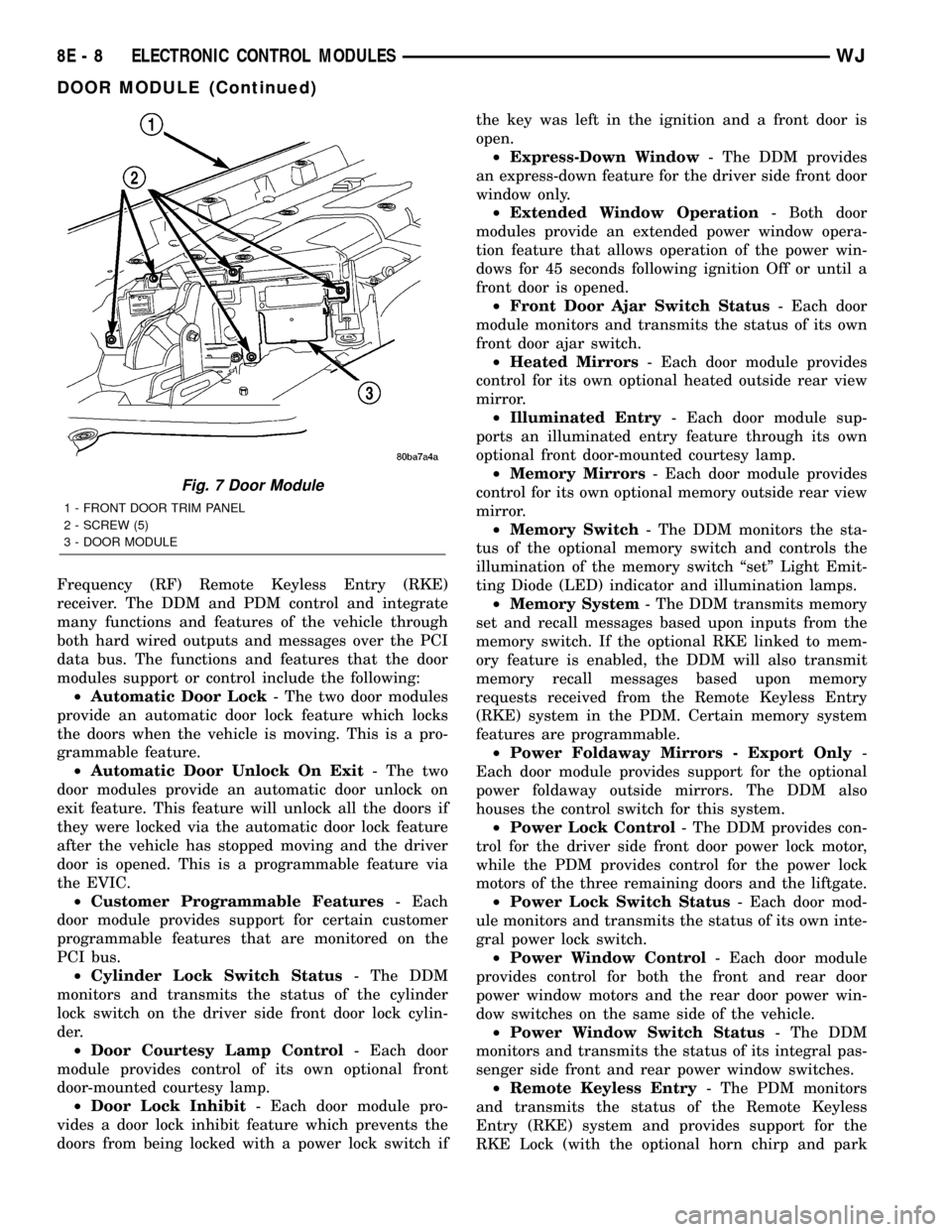

Frequency (RF) Remote Keyless Entry (RKE)

receiver. The DDM and PDM control and integrate

many functions and features of the vehicle through

both hard wired outputs and messages over the PCI

data bus. The functions and features that the door

modules support or control include the following:

²Automatic Door Lock- The two door modules

provide an automatic door lock feature which locks

the doors when the vehicle is moving. This is a pro-

grammable feature.

²Automatic Door Unlock On Exit- The two

door modules provide an automatic door unlock on

exit feature. This feature will unlock all the doors if

they were locked via the automatic door lock feature

after the vehicle has stopped moving and the driver

door is opened. This is a programmable feature via

the EVIC.

²Customer Programmable Features- Each

door module provides support for certain customer

programmable features that are monitored on the

PCI bus.

²Cylinder Lock Switch Status- The DDM

monitors and transmits the status of the cylinder

lock switch on the driver side front door lock cylin-

der.

²Door Courtesy Lamp Control- Each door

module provides control of its own optional front

door-mounted courtesy lamp.

²Door Lock Inhibit- Each door module pro-

vides a door lock inhibit feature which prevents the

doors from being locked with a power lock switch ifthe key was left in the ignition and a front door is

open.

²Express-Down Window- The DDM provides

an express-down feature for the driver side front door

window only.

²Extended Window Operation- Both door

modules provide an extended power window opera-

tion feature that allows operation of the power win-

dows for 45 seconds following ignition Off or until a

front door is opened.

²Front Door Ajar Switch Status- Each door

module monitors and transmits the status of its own

front door ajar switch.

²Heated Mirrors- Each door module provides

control for its own optional heated outside rear view

mirror.

²Illuminated Entry- Each door module sup-

ports an illuminated entry feature through its own

optional front door-mounted courtesy lamp.

²Memory Mirrors- Each door module provides

control for its own optional memory outside rear view

mirror.

²Memory Switch- The DDM monitors the sta-

tus of the optional memory switch and controls the

illumination of the memory switch ªsetº Light Emit-

ting Diode (LED) indicator and illumination lamps.

²Memory System- The DDM transmits memory

set and recall messages based upon inputs from the

memory switch. If the optional RKE linked to mem-

ory feature is enabled, the DDM will also transmit

memory recall messages based upon memory

requests received from the Remote Keyless Entry

(RKE) system in the PDM. Certain memory system

features are programmable.

²Power Foldaway Mirrors - Export Only-

Each door module provides support for the optional

power foldaway outside mirrors. The DDM also

houses the control switch for this system.

²Power Lock Control- The DDM provides con-

trol for the driver side front door power lock motor,

while the PDM provides control for the power lock

motors of the three remaining doors and the liftgate.

²Power Lock Switch Status- Each door mod-

ule monitors and transmits the status of its own inte-

gral power lock switch.

²Power Window Control- Each door module

provides control for both the front and rear door

power window motors and the rear door power win-

dow switches on the same side of the vehicle.

²Power Window Switch Status- The DDM

monitors and transmits the status of its integral pas-

senger side front and rear power window switches.

²Remote Keyless Entry- The PDM monitors

and transmits the status of the Remote Keyless

Entry (RKE) system and provides support for the

RKE Lock (with the optional horn chirp and park

Fig. 7 Door Module

1 - FRONT DOOR TRIM PANEL

2 - SCREW (5)

3 - DOOR MODULE

8E - 8 ELECTRONIC CONTROL MODULESWJ

DOOR MODULE (Continued)